Heat Treatment Analysis and Mechanical Characterization of a Recycled Gravity Die Cast EN 42000 Alloy

Abstract

1. Introduction

2. Materials and Methods

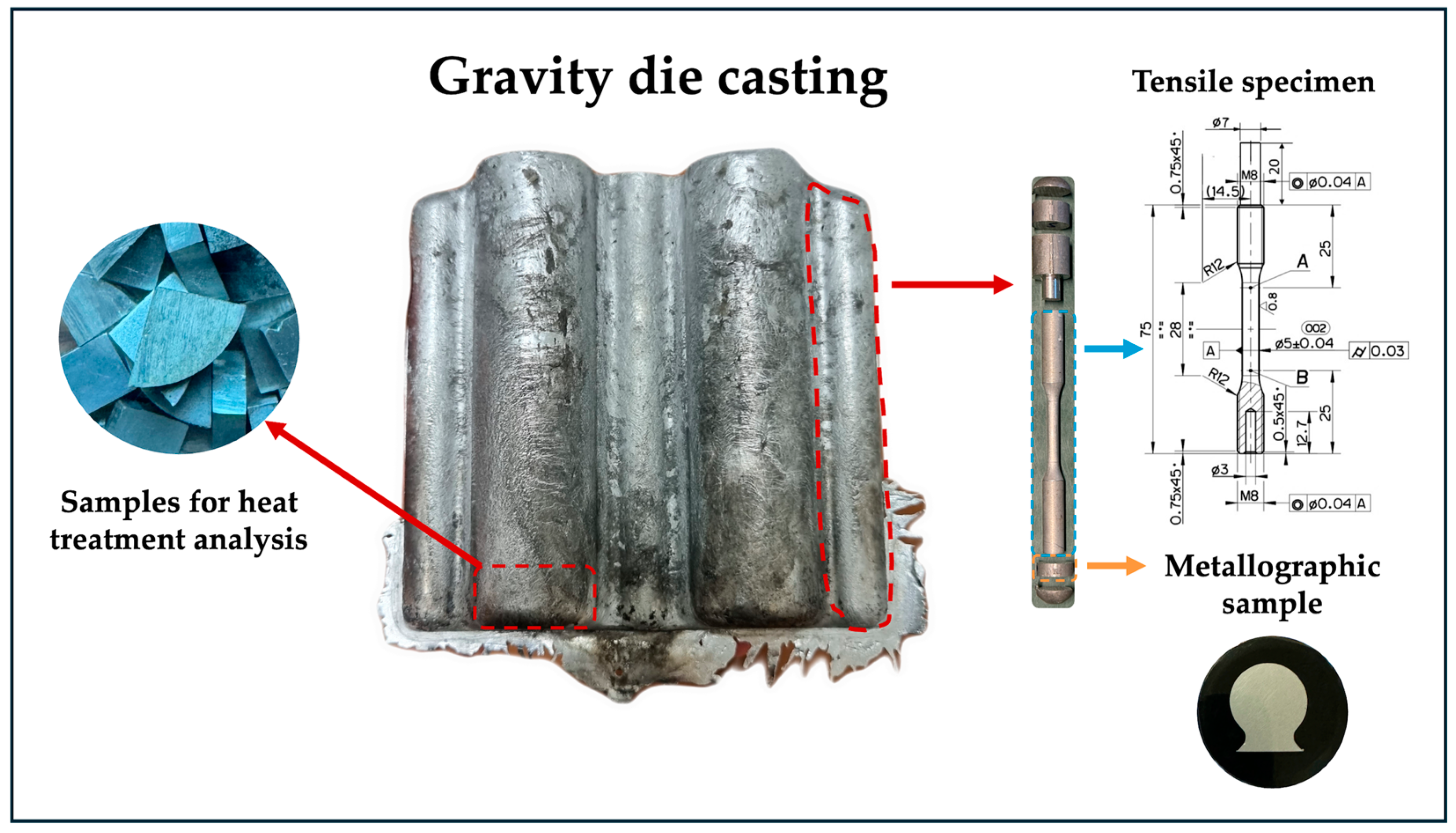

2.1. Materials and Casting Process

2.2. Microstructural Characterization

2.3. Heat Treatment Analysis

2.4. Mechanical Characterization

2.5. Fractographic Characterization

2.6. Correlations Between Microstructural Features and Mechanical Properties

3. Results and Discussion

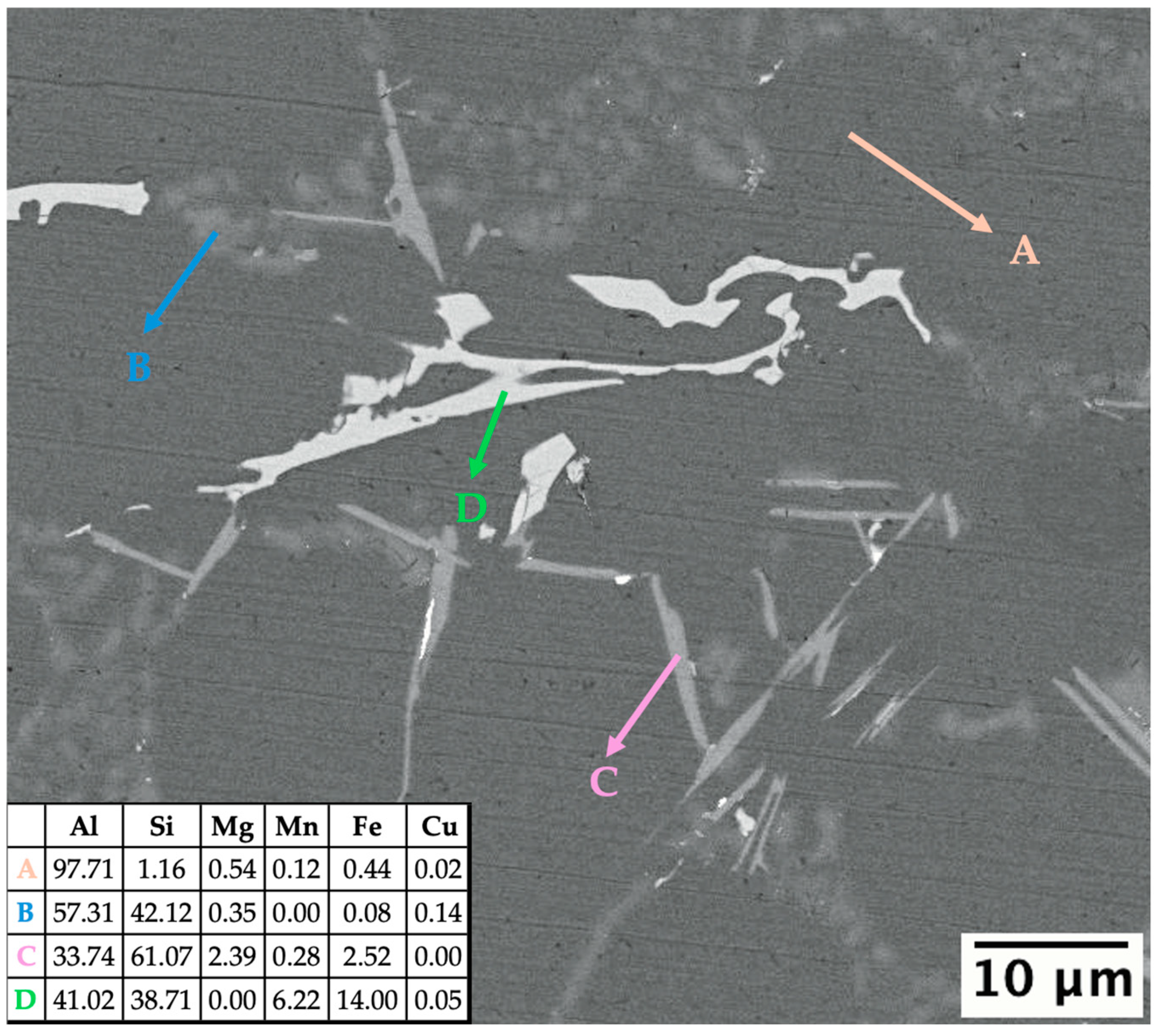

3.1. Microstructure

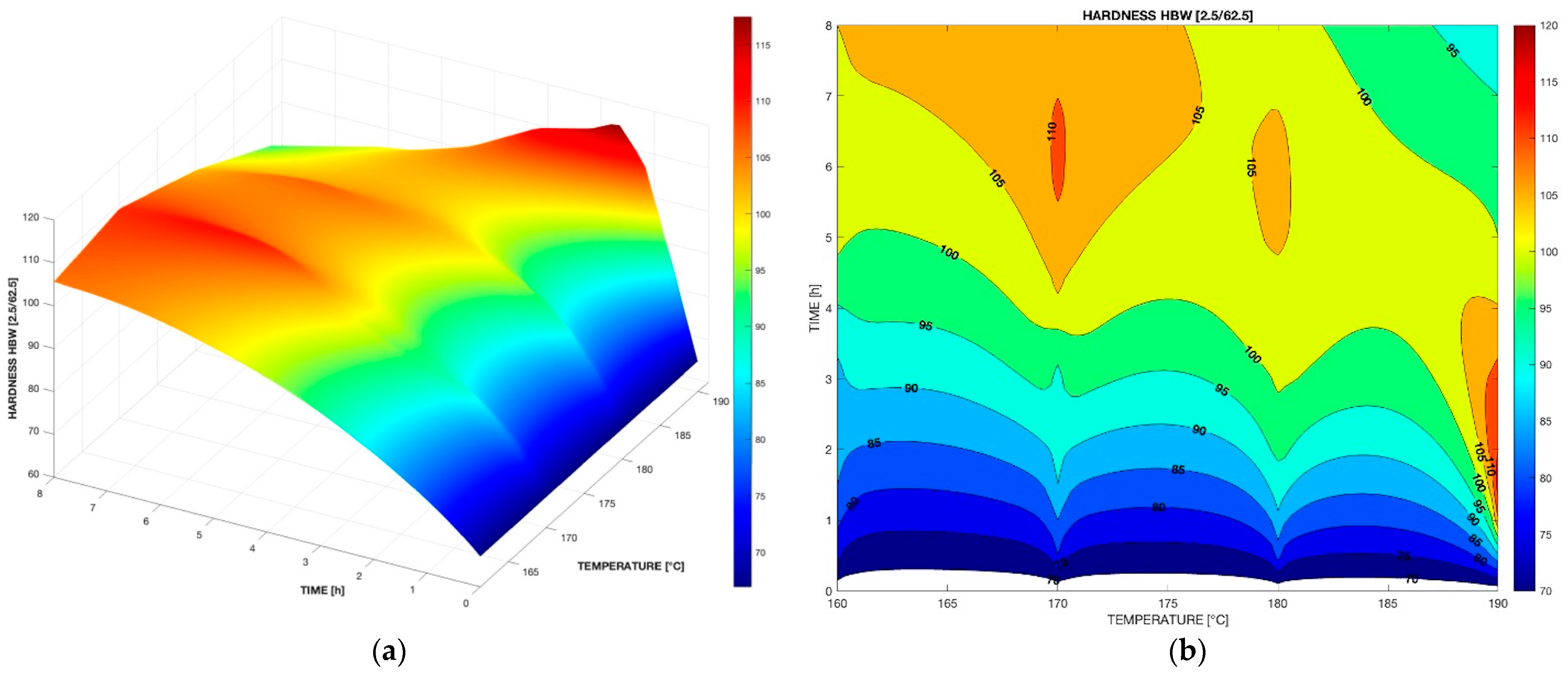

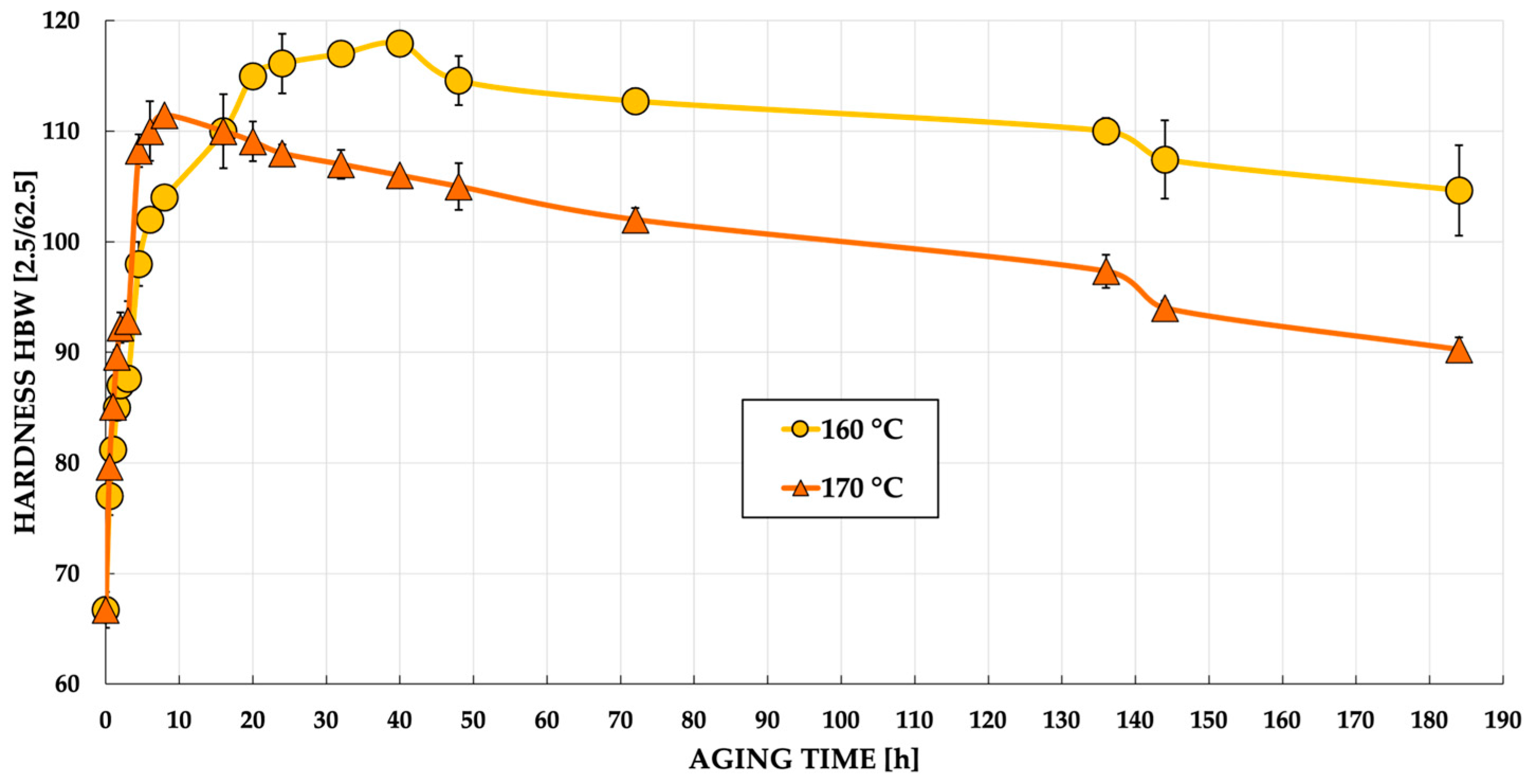

3.2. Heat Treatment and Aging Response

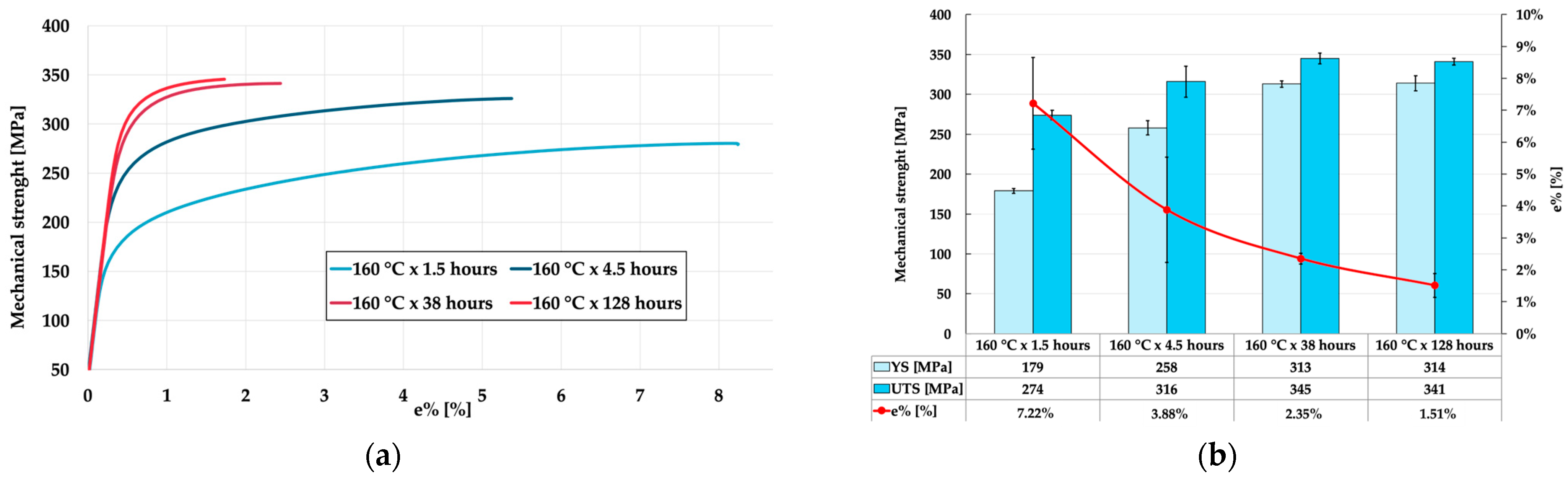

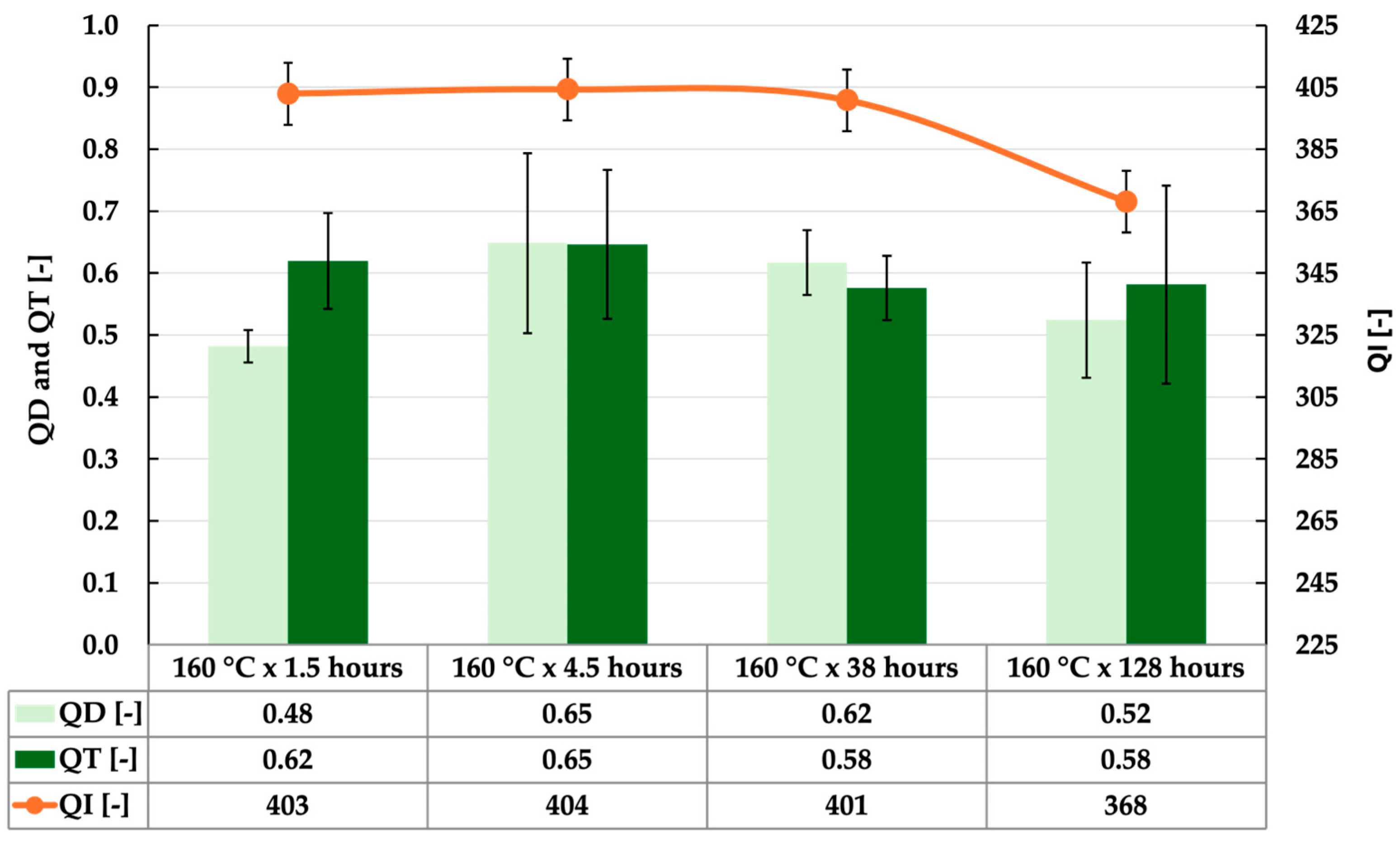

3.3. Mechanical Properties

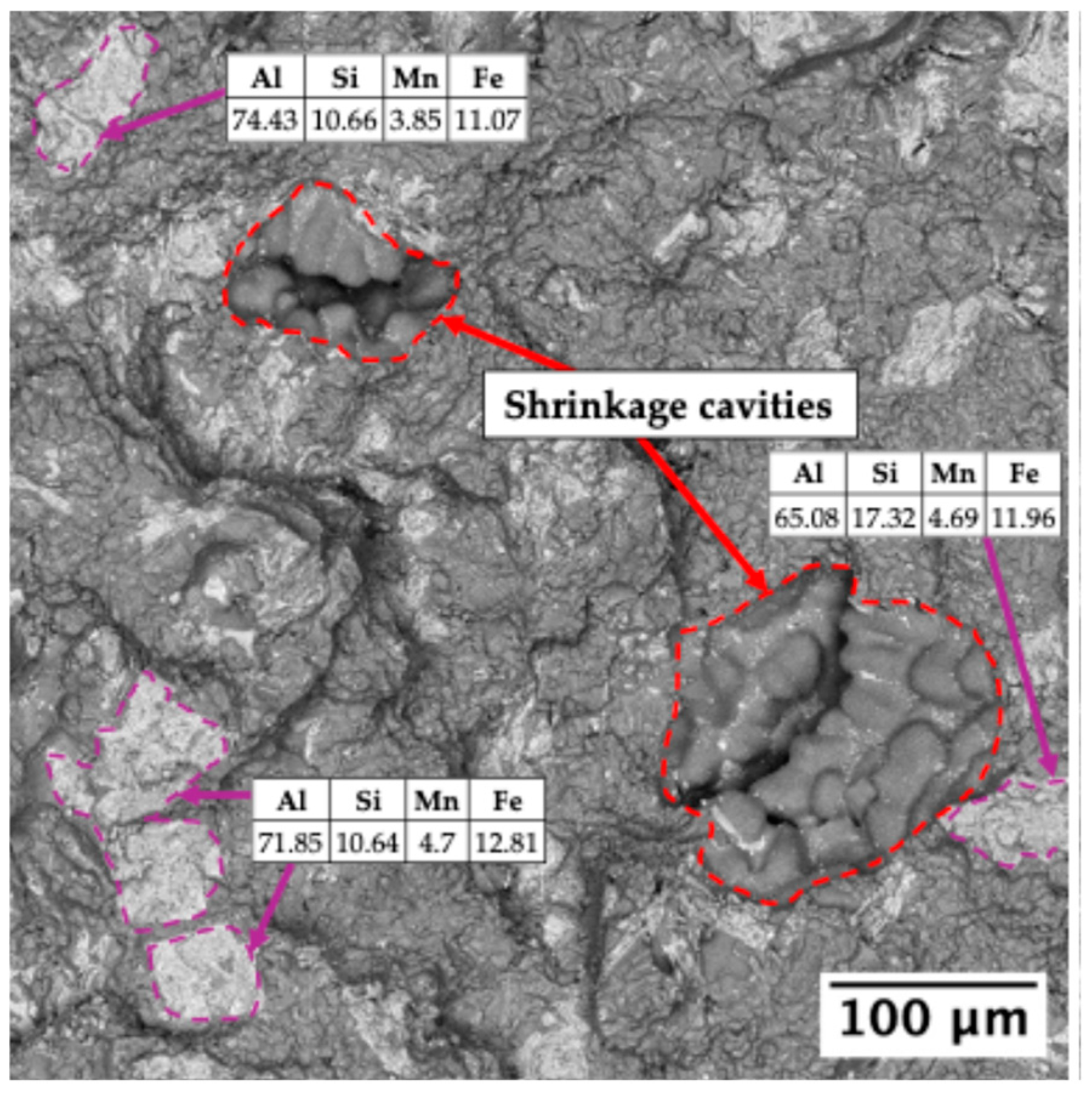

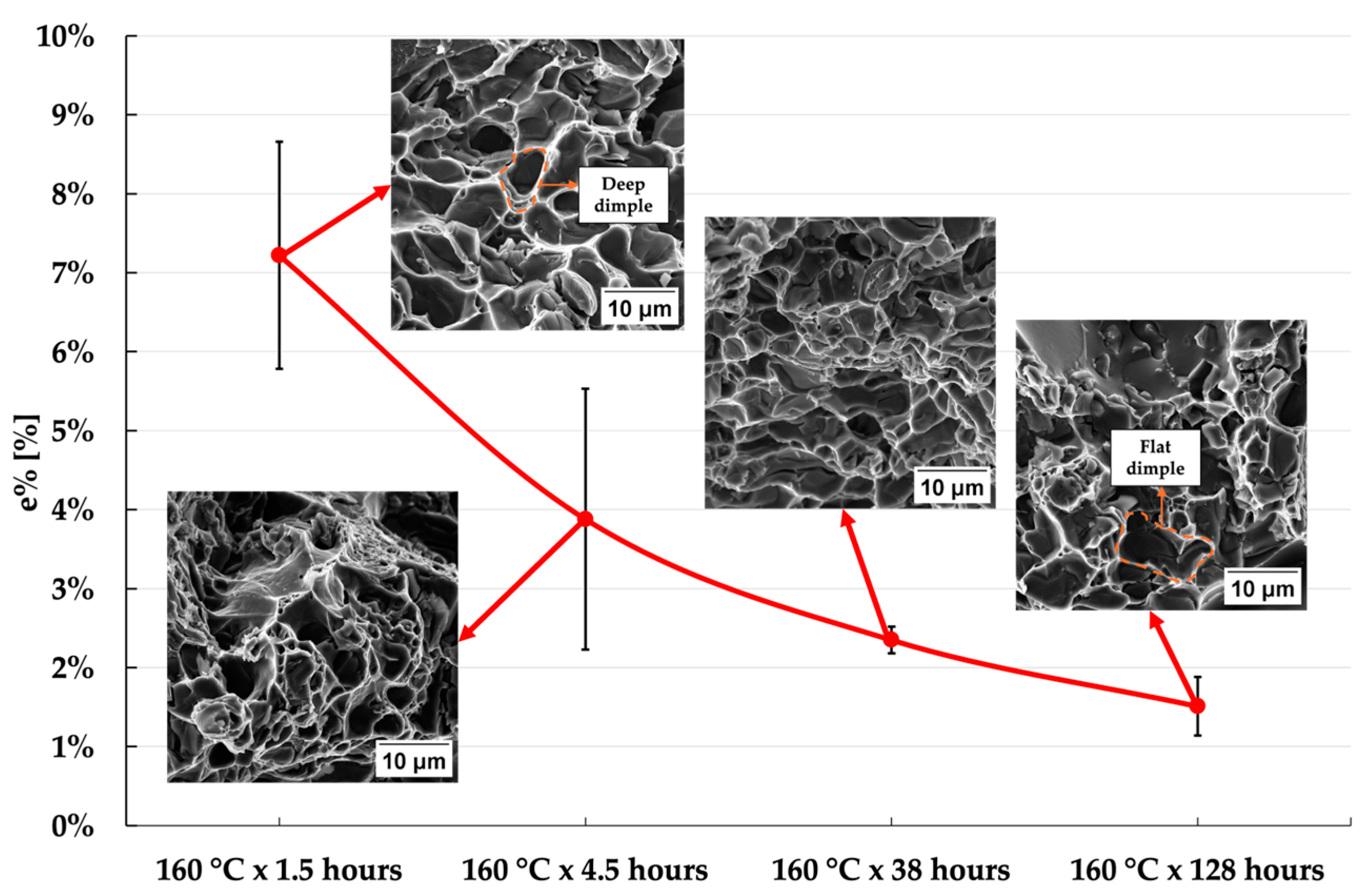

3.4. Fracture Behavior

3.5. Microstructure–Tensile Property Correlations

- %CS = True cross-sectional area (100%—percentage of area of defects on the fracture surface);

- %IM = Area percentage of intermetallic compounds on the fracture surface;

- A = Area fraction of eutectic silicon from metallographic specimens;

- HBW 2.5/62.5 = Brinell hardness.

4. Conclusions

- Microstructural analysis revealed a homogeneous structure with fine dendrites (SDAS ≈ 20 µm) and well-refined eutectic silicon, resulting from controlled processing under argon, which limited oxide inclusions. However, shrinkage cavities were still observed, mainly linked to script-like α-Al15(Fe,Mn)3Si2 intermetallics that hinder feeding during solidification and reduce castability.

- A T6 heat treatment consisting of a solution at 535 °C for 4.5 h, quenching in water at 60 °C, and aging at 160 °C provided improved thermal stability compared to aging at 170 °C. The aging curve at 160 °C revealed an initial hardness peak at 4.5 h and a peak-aged condition at 38 h.

- Aging at 160 °C for 4.5 h was identified as the optimal condition in terms of mechanical performance. Based on the evaluation of both ductility and toughness quality indices, this treatment provided a well-balanced combination of strength and ductility, with a yield strength of 258 MPa, an ultimate tensile strength of 313 MPa, and an elongation to fracture of 3.9%.

- A high Fe content promotes the formation of coarse intermetallic compounds, which act as stress concentrators and reduce ductility through the increased formation of shrinkage cavities. An inverse exponential correlation between Fe content and elongation to fracture was established through an innovative microstructure–mechanical property analysis, highlighting the combined influence of intermetallics and casting defects on fracture behavior.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| YS | Yield strength |

| UTS | Ultimate tensile strength |

| e% | Elongation to fracture |

| E | Elastic modulus |

| n | Strain hardening exponent |

| SDAS | Secondary Dendrite Arm Spacing |

| OM | Optical Microscopy |

| FEG-SEM | Field Emission Gun Scanning Electron Microscopy |

| SE | Secondary electrons |

| BSE | Backscattered electrons |

References

- Li, S.; Yue, X.; Li, Q.Y.; Peng, H.L.; Dong, B.X.; Liu, T.S.; Yang, H.Y.; Fan, J.; Shu, S.L.; Qiu, F.; et al. Development and applications of aluminum alloys for aerospace industry. J. Mater. Res. Technol. 2023, 27, 944–983. [Google Scholar] [CrossRef]

- Liu, W.; Peng, T.; Kishita, Y.; Umeda, Y.; Tang, R.; Tang, W.; Hu, L. Critical life cycle inventory for aluminum die casting: A lightweight-vehicle manufacturing enabling technology. Appl. Energy 2021, 304, 117814. [Google Scholar] [CrossRef]

- Ducker. Ducker Public Summary: Aluminum Content in Passenger Vehicles (Europe); Ducker: Troy, MI, USA, 2023. [Google Scholar]

- Rolseth, A.; Carlson, M.; Ghassemali, E.; Caro, L.P.; Jarfors, A.E.W. Impact of functional integration and electrification on aluminium scrap in the automotive sector: A review. Resour. Conserv. Recycl. 2024, 205, 107532. [Google Scholar] [CrossRef]

- BS EN 1706:2020; Aluminium and Aluminium Alloys. Castings. Chemical Composition and Mechanical Properties Table 1—Chemical Composition of Aluminium Castings. BSI Standards Publication: Bruxelles, Belgium, 2020.

- Raabe, D.; Ponge, D.; Uggowitzer, P.J.; Roscher, M.; Paolantonio, M.; Liu, C.; Antrekowitsch, H.; Kozeschnik, E.; Seidmann, D.; Gault, B.; et al. Making sustainable aluminum by recycling scrap: The science of “dirty” alloys. Prog. Mater. Sci. 2022, 128, 100947. [Google Scholar] [CrossRef]

- Kasińska, J.; Bolibruchová, D.; Matejka, M. The Influence of Remelting on the Properties of AlSi9Cu3 Alloy with Higher Iron Content. Materials 2020, 13, 575. [Google Scholar] [CrossRef] [PubMed]

- Capuzzi, S.; Timelli, G. Preparation and Melting of Scrap in Aluminum Recycling: A Review. Metals 2018, 8, 249. [Google Scholar] [CrossRef]

- Harazeen, A.; Lattanzi, L.; Matsushita, T.; Jarfors, A.E.W. Enhanced iron impurity removal in low iron Al-Si alloys by Mn addition. High Temp.-High Press. 2025, 54, 187–201. [Google Scholar] [CrossRef]

- Nunes, H.; Emadinia, O.; Soares, R.; Vieira, M.F.; Reis, A. Adding Value to Secondary Aluminum Casting Alloys: A Review on Trends and Achievements. Materials 2023, 16, 895. [Google Scholar] [CrossRef]

- Kuchariková, L.; Medvecká, D.; Tillová, E.; Belan, J.; Kritikos, M.; Chalupová, M.; Uhríčik, M. The Effect of the β-Al5FeSi Phases on Microstructure, Mechanical and Fatigue Properties in A356.0 Cast Alloys with Higher Fe Content without Additional Alloying of Mn. Materials 2021, 14, 1943. [Google Scholar] [CrossRef]

- Taylor, J.A. The Effect of Iron in Al-Si Casting Alloys; Australian Foundry Institute (AFI): Adelaide, Australia, 2004; pp. 148–157. [Google Scholar]

- Ji, S.; Yang, W.; Gao, F.; Watson, D. Fan. Effect of iron on the microstructure and mechanical property of Al–Mg–Si–Mn and Al–Mg–Si diecast alloys. Mater. Sci. Eng. A 2013, 564, 130–139. [Google Scholar] [CrossRef]

- Rometsch, P.A.; Schaffer, G.B. An age hardening model for Al–7Si–Mg casting alloys. Mater. Sci. Eng. A 2002, 325, 424–434. [Google Scholar] [CrossRef]

- Tonelli, L.; Liverani, E.; Morri, A.; Ceschini, L. Role of Direct Aging and Solution Treatment on Hardness, Microstructure and Residual Stress of the A357 (AlSi7Mg0.6) Alloy Produced by Powder Bed Fusion. Metall. Mater. Trans. B 2021, 52, 2484–2496. [Google Scholar] [CrossRef]

- Ibrahim, M.; Elgallad, E.; Valtierra, S.; Doty, H.; Samuel, F. Metallurgical Parameters Controlling the Eutectic Silicon Charateristics in Be-Treated Al-Si-Mg Alloys. Materials 2016, 9, 78. [Google Scholar] [CrossRef] [PubMed]

- ASM Handbook. Volume 4: Heat Treating ASM Handbook Committee; Heat Treating of Aluminum Alloys; ASM International: West Conshohocken, PA, USA, 1991; pp. 841–879.

- Mohamed, A.M.A.; Samuel, F.H. A Review on the Heat Treatment of Al-Si-Cu/Mg Casting Alloys. In Heat Treatment-Conventional and Novel Applications; Czerwinski, F., Ed.; InTech: Vienna, Austria, 2012. [Google Scholar] [CrossRef]

- Pezda, J. Optimization of Heat Treatment Parameters of AlSi7Mg Alloy. Materials 2022, 15, 1163. [Google Scholar] [CrossRef]

- Wang, Q.; Hao, Q.; Yu, W. Effect of Strontium Modification on Porosity Formation in A356 Alloy. Int. J. Met. 2019, 13, 944–952. [Google Scholar] [CrossRef]

- BS EN ISO 6892-1:2019; Metallic Materials-Tensile Testing, Method of Test at Room Temperature. BSI Standards Publication: Bruxelles, Belgium, 2019.

- E04 Committee. Guide for Preparation of Metallographic Specimens; ASTM: West Conshohocken, PA, USA, 2017. [Google Scholar] [CrossRef]

- E04 Committee. Practice for Microetching Metals and Alloys; ASTM: West Conshohocken, PA, USA, 2023. [Google Scholar] [CrossRef]

- Vandersluis, E.; Ravindran, C. Comparison of Measurement Methods for Secondary Dendrite Arm Spacing. Metallogr. Microstruct. Anal. 2017, 6, 89–94. [Google Scholar] [CrossRef]

- Djurdjevic, M.; Jiang, H.; Sokolowski, J. On-line prediction of aluminum–silicon eutectic modification level using thermal analysis. Mater. Charact. 2001, 46, 31–38. [Google Scholar] [CrossRef]

- Ceschini, L.; Morri, A.; Morri, A.; Pivetti, G. Predictive equations of the tensile properties based on alloy hardness and microstructure for an A356 gravity die cast cylinder head. Mater. Des. 2011, 32, 1367–1375. [Google Scholar] [CrossRef]

- Merlin, M.; Gramigna, D.; Baroni, E.; Fortini, A.; Feggi, F. Heat Treatment of the EN AC-42100 Alloy Within Industrial Furnaces: The Effect of Treatment Parameters on Mechanical Properties; Metallurgia Italiana: Milan, Italy, 2023; pp. 16–24. [Google Scholar]

- ISO 10275:2020; ISO, Metallic Materials—Sheet and Strip—Determination of Tensile Strain Hardening Exponent. BSI Standards Publication: Bruxelles, Belgium, 2020.

- Drouzy, M.; Jacob, S.; Richard, M. Interpretation of tensile results by means of quality index and probable yield strength. Int. Cast Met. J. 1980, 5, 43–50. [Google Scholar]

- Angella, G.; Zanardi, F. Validation of a New Quality Assessment Procedure for Ductile Irons Production Based on Strain Hardening Analysis. Metals 2019, 9, 837. [Google Scholar] [CrossRef]

- Tiryakioğlu, M.; Campbell, J.; Staley, J.T. Evaluating structural integrity of cast Al–7%Si–Mg alloys via work hardening characteristics: 1. Concept of target properties. Mater. Sci. Eng. A 2004, 368, 205–211. [Google Scholar] [CrossRef]

- Tiryakioğlu, M.; Staley, J.T.; Campbell, J. Evaluating structural integrity of cast Al–7%Si–Mg alloys via work hardening characteristics: 2. A new quality index. Mater. Sci. Eng. A 2004, 368, 231–238. [Google Scholar] [CrossRef]

- Caceres, C.H.; Djurdjevic, M.B.; Stockwell, T.J.; Sokolowski, J.H. The effect of cu content on the level of microporosity in Al-Si-Cu-Mg casting alloys. Scr. Mater. 1999, 40, 631–637. [Google Scholar] [CrossRef]

- Guo, J.; Guan, Z.P.; Yan, R.F.; Ma, P.K.; Wang, M.H.; Zhao, P.; Wang, J.G. Effect of Modification with Different Contents of Sb and Sr on the Thermal Conductivity of Hypoeutectic Al-Si Alloy. Metals 2020, 10, 1637. [Google Scholar] [CrossRef]

- Pezda, J. Effect of T6 heat treatment on mechanical properties and microstructure of EN AB-42000 alloy modified with strontium. Arch. Foundry Eng. 2011, 11, 169–174. [Google Scholar]

- Taylor, J.A. Iron-Containing Intermetallic Phases in Al-Si Based Casting Alloys. Procedia Mater. Sci. 2012, 1, 19–33. [Google Scholar] [CrossRef]

| Alloy | Recycling Rate | Si | Fe | Cu | Mn | Mg | Ni | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| EN 42000 | 95% | 7.018 | 0.447 | 0.108 | 0.255 | 0.508 | 0.013 | 0.054 | 0.12 | Bal. |

| ±0.101 | ±0.004 | ±0.002 | ±0.004 | ±0.009 | ±0.001 | ±0.010 | ±0.007 |

| Solution Temperature and Duration | Quenching Conditions | Aging Temperature [°C] | Aging Time [h] |

|---|---|---|---|

| 535 °C for 4.5 h | H2O at 60 °C | 160 | 0.5 1 1.5 2 3 4.5 5 6 8 |

| 170 | |||

| 180 | |||

| 190 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cascioli, C.; Arcaleni, R.; Morri, A.; Ceschini, L. Heat Treatment Analysis and Mechanical Characterization of a Recycled Gravity Die Cast EN 42000 Alloy. Metals 2025, 15, 726. https://doi.org/10.3390/met15070726

Cascioli C, Arcaleni R, Morri A, Ceschini L. Heat Treatment Analysis and Mechanical Characterization of a Recycled Gravity Die Cast EN 42000 Alloy. Metals. 2025; 15(7):726. https://doi.org/10.3390/met15070726

Chicago/Turabian StyleCascioli, Cristian, Riccardo Arcaleni, Alessandro Morri, and Lorella Ceschini. 2025. "Heat Treatment Analysis and Mechanical Characterization of a Recycled Gravity Die Cast EN 42000 Alloy" Metals 15, no. 7: 726. https://doi.org/10.3390/met15070726

APA StyleCascioli, C., Arcaleni, R., Morri, A., & Ceschini, L. (2025). Heat Treatment Analysis and Mechanical Characterization of a Recycled Gravity Die Cast EN 42000 Alloy. Metals, 15(7), 726. https://doi.org/10.3390/met15070726