Research Progress on Process Optimization of Metal Materials in Wire Electrical Discharge Machining

Abstract

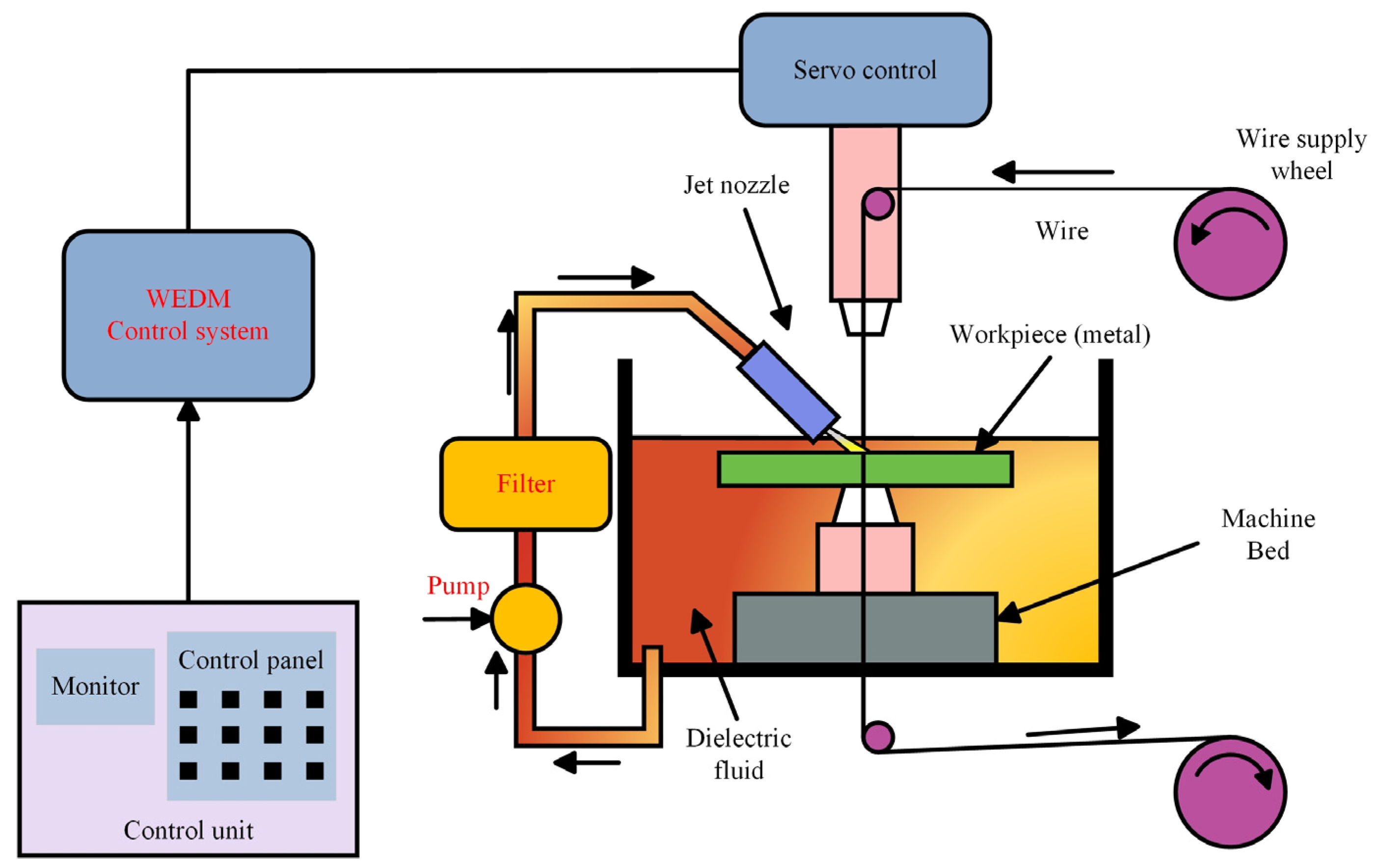

1. Introduction

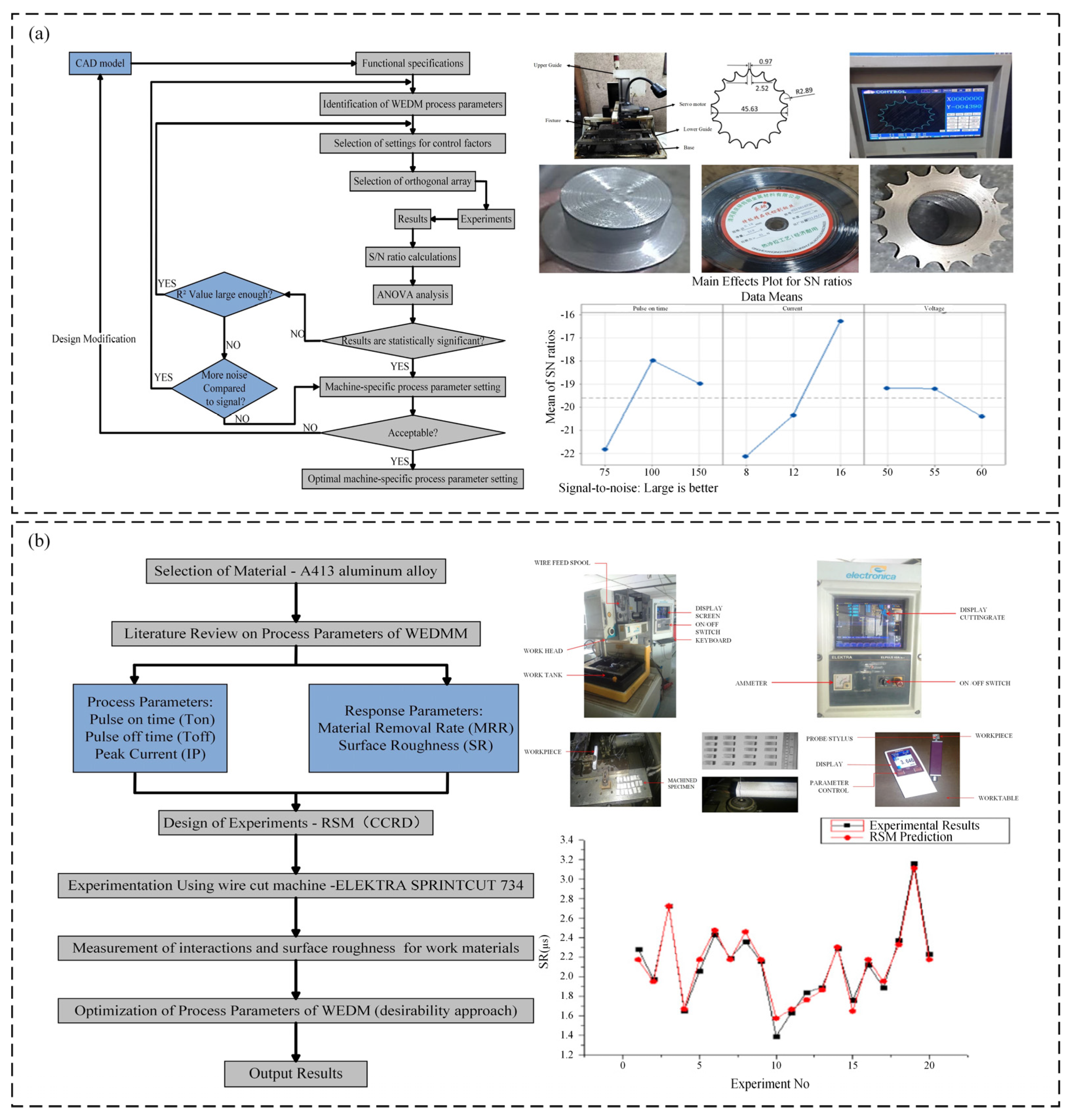

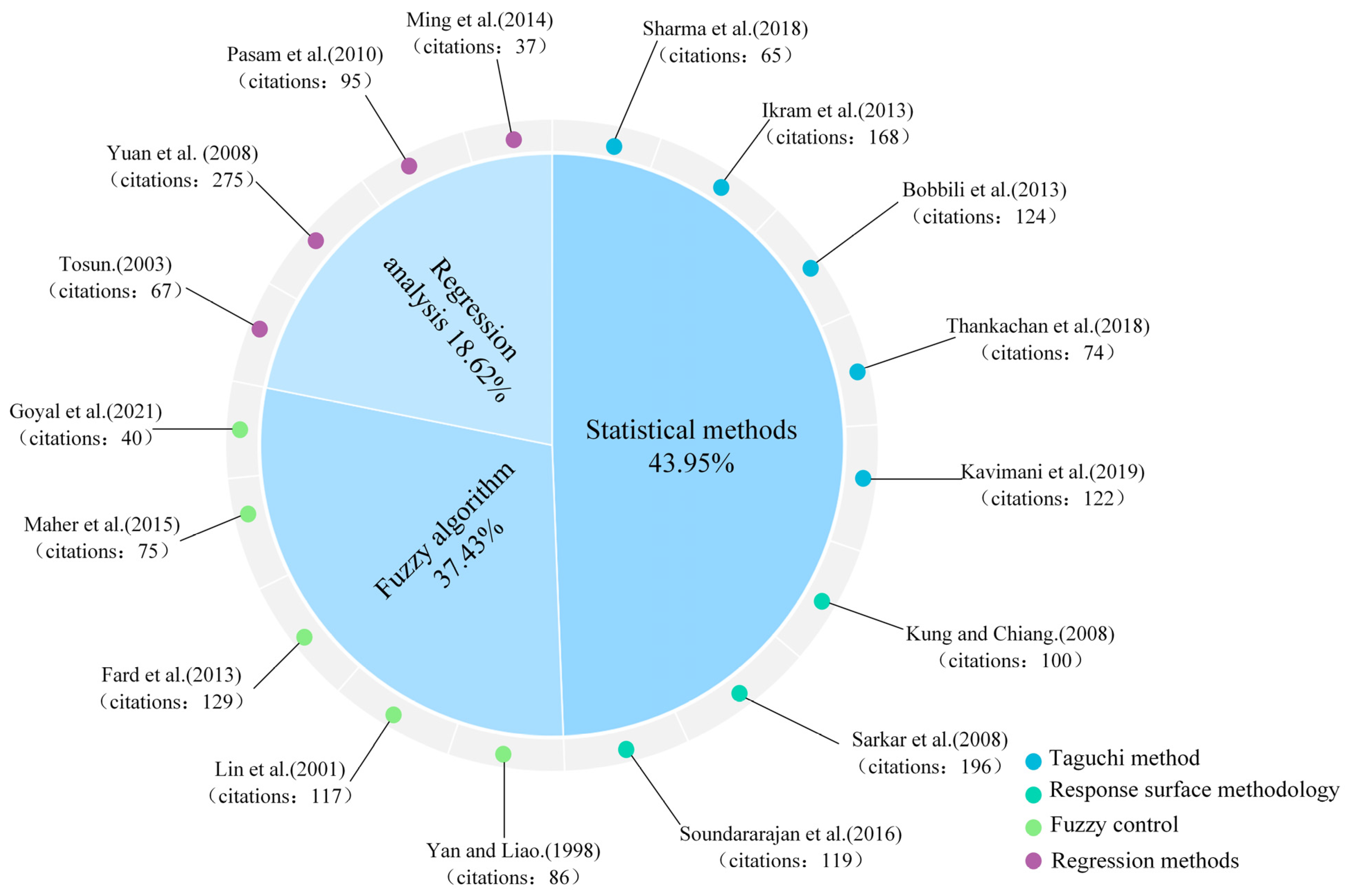

2. Traditional Methods

2.1. Statistical Methods

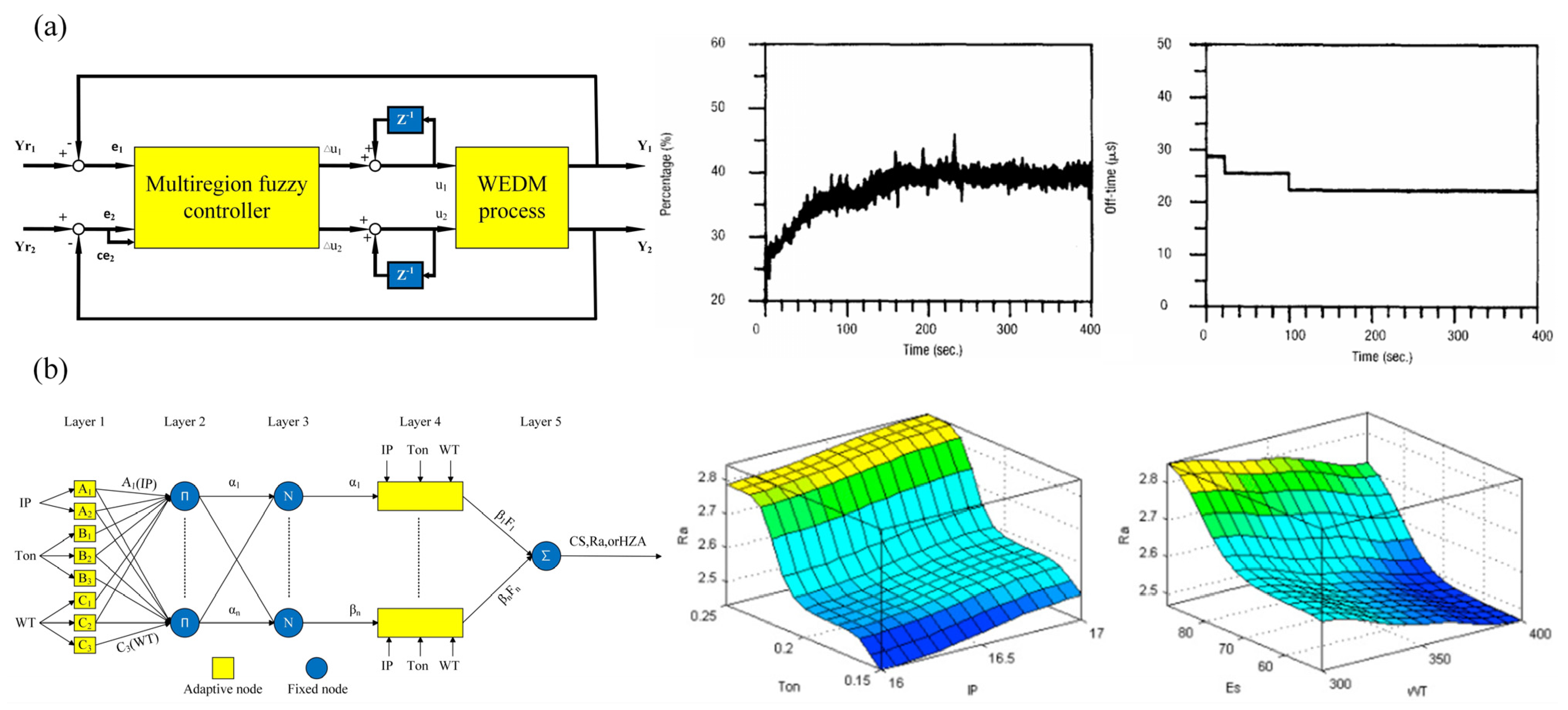

2.2. Fuzzy Algorithm

2.3. Other

2.4. Summary

| Metal (Material) | Author(s)/Year | Optimization Method | Comments | |

|---|---|---|---|---|

| High-temperature alloys | Inconel 706 | Sharma et al. (2018) [54] | Taguchi method, GRA, and Principal Component Analysis | By applying the Taguchi-GRA-PCA hybrid optimization method, simultaneous optimization of MRR and SR was achieved in wire-cutting processing of the novel aerospace high-temperature alloy Inconel 706, resulting in high productivity and excellent surface integrity. |

| γ-Titanium aluminide | Sarkar et al. (2008) [65] | RSM | The method improves the machining efficiency of γ-TiAl alloys while maintaining the required surface finish and geometric accuracy. | |

| Ti6Al4V alloys | Pasam et al. (2010) [78] | Linear regression analysis combined with GA | In the WEDM of Ti6Al4V alloy, a surface roughness of 1.85 µm can be achieved using optimized control parameters. | |

| Tool steels | Tool steel D2 | Ikram et al. (2013) [55] | Taguchi method with variance analysis and signal-to-noise ratio | The machining challenges of die materials are addressed in the WEDM of D2 tool steel, enabling effective processing of this high-hardness, high-performance material through parameter optimization. |

| SKD61 | Yan and Liao. (1998) [69] | Fuzzy logic-based WEDM monitoring and ACO system | Using SKD61 as a representative hard-to-machine material, the fuzzy control adaptive system is validated for its ability to enhance machining stability, reduce wire breakage, optimize material-removal rate, and improve surface finish in WEDM. | |

| SKD-11 | Lin et al. (2001) [70] | Fuzzy logic control strategy | Fuzzy logic control is validated using SKD-11, effectively addressing the critical issue of corner accuracy in machining high-hardness materials via WEDM. | |

| Chromium alloy (Cr12) | Yuan et al. (2008) [77] | GPR | This material validated the effectiveness of the GPR model and optimization methods for hard-to-machine materials, solving core issues related to efficiency, surface quality, and machining stability. | |

| Carbon steels and alloy steels | AISI 1045 medium carbon steel | Zaman et al. (2022) [60] | Taguchi method L9OA | The timing sprocket made of this material is selected to achieve maximum MRR through WEDM. |

| AISI 1050 carbon steel block | Maher et al. (2015) [72] | ANFIS combined with Taguchi method | Experiments on this material resolve the inherent trade-off between efficiency and surface quality in WEDM of high-hardness materials, while optimizing the heat-affected zone and energy consumption. | |

| AISI 4140 steel | Tosun (2003) [76] | Regression analysis | This study not only demonstrates the applicability of WEDM to hard-to-machine materials, but also resolves the efficiency–surface quality conflict through systematic experiments and statistical analysis. | |

| Non-ferrous metals and alloys | High-purity copper (99.98%) | Thankachan et al. (2018) [57] | Taguchi method with GRA | This material overcomes the decline in electrical conductivity of traditional composites caused by ceramic particle addition, while WEDM parameter optimization enables the development of a copper-based surface composite with high conductivity, wear resistance, and machinability. |

| AZ31 magnesium alloy | Kavimani et al. (2019) [58] | Taguchi method combined with GRA | AZ31 magnesium alloy is selected as the matrix, with graphene and SiC reinforcements introduced to address the limitations in mechanical properties and machining difficulties of magnesium alloys. | |

| A413 aluminum alloy | Soundararajan et al. (2016) [67] | RSM | The study on extrusion casting and WEDM parameters of A413 alloy demonstrates its favorable casting performance and machining quality, suggesting its suitability for industrial applications, particularly in the automotive and aerospace sectors. | |

| Aluminum matrix composite (A413-9% B4C) | Sivaprakasam et al. (2013) [66] | RSM | Research on A413–9% B4C composites not only addresses the challenges of machining hard materials, but also achieves high-efficiency and high-precision machining using Micro-WEDM and parameter optimization. | |

| 75%Al 6061–25%SiC | Fard et al. (2013) [71] | ANFIS combined with ABC | Using 75% Al 6061–25% SiC as the research subject, the study resolves issues such as tool wear, high cost, and environmental pollution in traditional machining of hard composites, while enhancing machining efficiency and surface quality through intelligent optimization methods. | |

| Special materials | α–β-Type titanium alloys | Goyal et al. (2021) [73] | ANFIS combined with NSGA-II | The use of Ti–6Al–4V titanium alloy not only confirms the efficiency of WEDM for hard-to-machine materials but also addresses the complexity of parameter optimization through intelligent algorithms. |

| Tungsten steel YG15 | Ming et al. (2014) [79] | GPR combined with NSGA-II | Using YG15, the advantages of WEDM in machining ultra-hard materials are validated, and the contradiction between high MRR and superior surface quality is effectively resolved through multi-objective optimization. | |

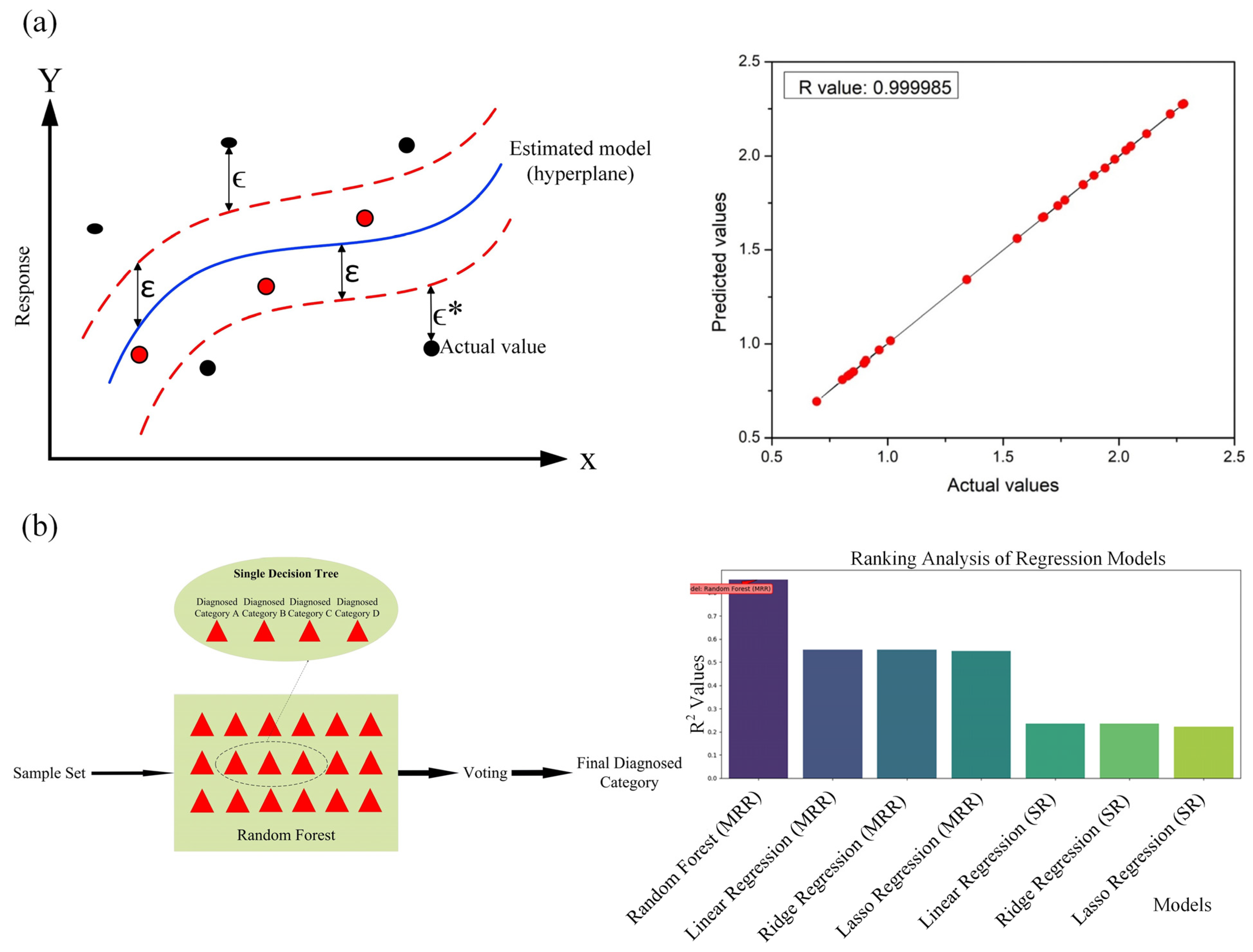

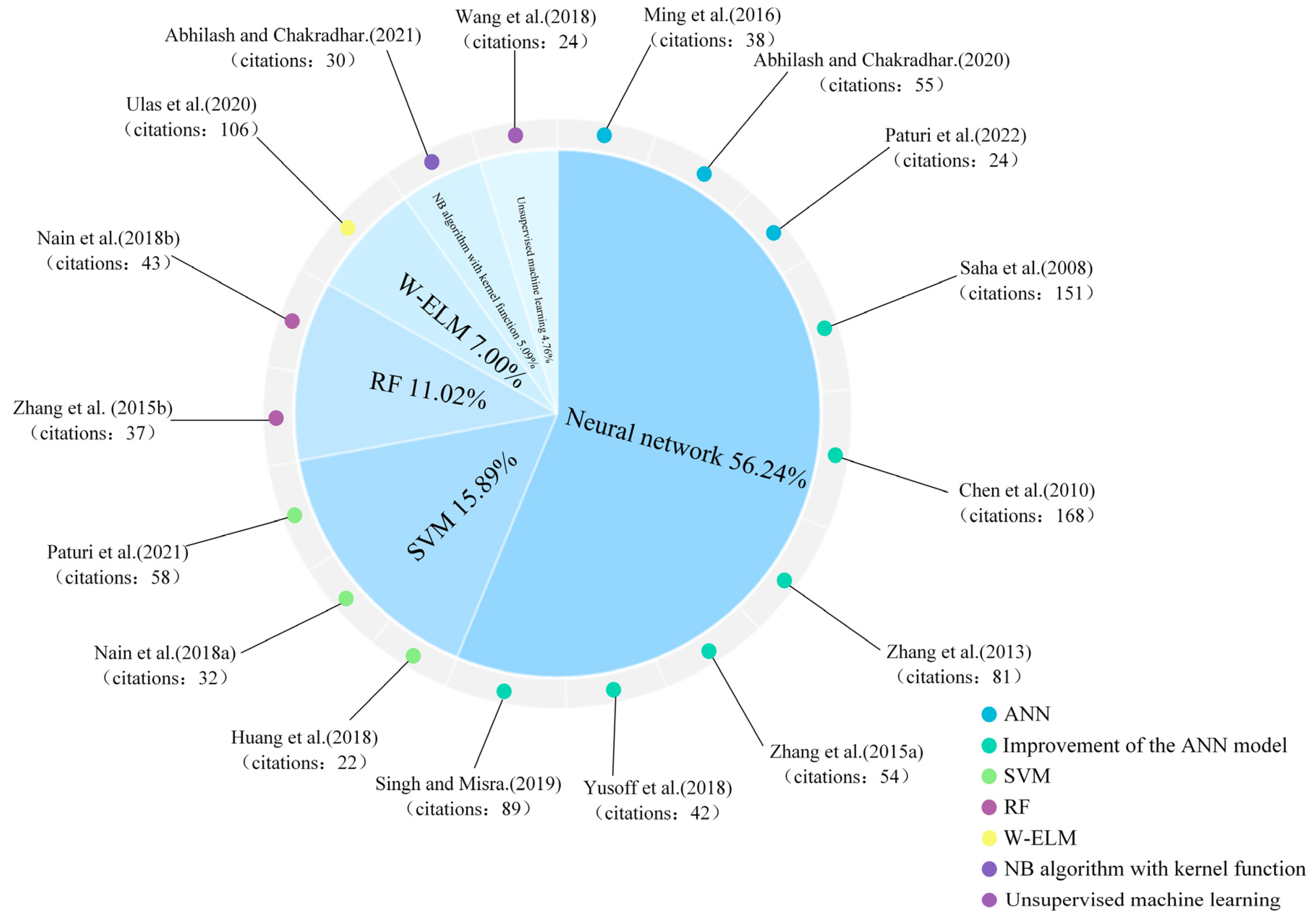

3. Machine Learning

3.1. Neural Network

3.2. Support Vector Machine and Random Forest

3.3. Other

3.4. Summary

| Metal (Material) | Author(s)/Year | Optimization Method | Comments | |

|---|---|---|---|---|

| High-temperature alloys | Inconel 718 | Abhilash and Chakradhar. (2020) [85] | ANN | Using Inconel 718 as the research subject not only highlights the unique advantages of WEDM in machining difficult-to-cut materials, but also addresses critical issues such as wire breakage and lack of spark during the process. |

| Yusoff et al. (2018) [93] | CFNN | By employing a CFNN-based approach, this study effectively tackles the multi-objective performance prediction challenges in WEDM of Inconel 718, significantly reducing experimental cost and time while enhancing prediction accuracy. | ||

| Paturi et al. (2021) [98] | SVM combined with GA | The selection of Inconel 718 as the workpiece material not only verifies the advantages of WEDM in processing difficult-to-machine alloys, but also achieves precise optimization of process parameters through machine learning, thereby resolving the core issue of surface-roughness control. | ||

| Wang et al. (2018) [106] | Unsupervised machine learning | This research overcomes the limitations of traditional broaching techniques for Inconel 718 by integrating intelligent monitoring, which substantially improves machining efficiency and surface quality, providing an innovative solution for the manufacturing of critical aerospace components. | ||

| Abhilash and Chakradhar. (2021) [109] | NB | Inconel 718 is chosen due to its high representativeness as a typical difficult-to-machine material. The study resolves the wire breakage issue during its WEDM processing, offering technical assurance for precision manufacturing of high-value components. | ||

| Nimonic 263 | Singh and Misra. (2019) [94] | Box–Behnken design combined with ANN | Through a systematic investigation into the WEDM characteristics of Nimonic 263, the study addresses the challenges of achieving high-efficiency and high-quality machining of difficult-to-cut materials, offering valuable process insights and technical support to relevant industrial sectors. | |

| Rectangular plate of Udimet-L605 | Nain et al. (2018) [96] | SVM combined with GRA | In the WEDM machining of Udimet-L605, this study solves the problems of low efficiency and severe tool wear encountered in conventional machining of high-temperature alloys. Machine learning-based parameter optimization is introduced to provide both theoretical and practical guidance for high-performance material processing in the aerospace industry. | |

| Udimet-L605 | Nain et al. (2018) [101] | RF and M5PTree combined with sensitivity analysis and PSO | This work aims to address the issues of efficiency, quality, and precision in the machining of Udimet-L605, thereby enhancing its application potential in the aviation industry. | |

| Tool steels | Tungsten carbide tool (YG15 grade) | Ming et al. (2016) [84] | ANN combined with LWPA method | The proposed method resolves challenges in traditional WEDM of YG15, including unstable surface quality, high machining cost, and low efficiency in parameter tuning. It validates the effectiveness of intelligent optimization algorithms in complex process-parameter matching. |

| Zhang et al. (2015) [92] | BPNN-GAand NSGA-II | YG15 tungsten carbide is selected as the workpiece to address its machining difficulties in the mold industry due to its high hardness and wear resistance. Parameter optimization enhances improvements in both surface quality and mechanical properties, and a reduction in rejection rates in industrial applications. | ||

| SKD11 | Zhang et al. (2013) [91] | BPNN-GA | Focusing on SKD11, the study aims to solve the process parameter-optimization problem in MS-WEDM. After optimization using BPNN-GA, the relative residuals of Ra and MRR were reduced to 1.2% and 5.24%, respectively. | |

| Zhang et al. (2015) [100] | SVM-RF | As a representative die steel, SKD11 demonstrates that pulse-off time plays a critical role in reducing harmful discharges, such as arcing and short circuits, achieving a balance between high material-removal rate and stable machining. | ||

| Tungsten carbide | Zhang et al. (2015) [100] | SVM-RF | Tungsten carbide, as a difficult-to-machine material, is adopted to reveal the discharge behavior under high energy and long pulse duration, offering guidance for selecting parameters in hard material machining. | |

| Tool steel | Huang et al. (2018) [95] | SVM | Using tool steel as the workpiece, this study addresses the key challenge of machining variable-height components in RT-WEDM. The proposed method achieved an estimation error of less than 2 mm and reduced machining time by more than 30%. | |

| Non-ferrous metals and alloys | Titanium alloy | Paturi et al. (2022) [88] | ANN | WEDM experiments on titanium alloy, combined with ANN for performance prediction, yields an R-value of 0.9995 between predicted and measured values, indicating high predictive accuracy. |

| Aluminum alloy 7075-T6 | Ulas et al. (2020) [107] | W-ELM | Using Al7075 T6 aluminum alloy as the workpiece, WEDM coupled with W-ELM prediction of Ra significantly reduced experimental cost and time, overcoming the limitations of conventional machining in achieving high-precision processing. | |

| Copper block | Zhang et al. (2015) [100] | SVM-RF | As a highly conductive material, copper is used to validate the influence of pulse-on time on spark discharge ratio, thereby optimizing machining stability. | |

| Special materials | Tungsten and tungsten alloys | Chen et al. (2010) [90] | BPNN and SAA | Pure tungsten and tungsten alloys were employed to solve the processing difficulties caused by their high hardness, melting point, and brittleness. High-efficiency machining of high-purity tungsten is successfully achieved using BPNN-SAA. |

| Tungsten carbide–cobalt (WC-Co) composite | Saha et al. (2008) [89] | Second-order multivariable regression model and BPNN | WC-Co composites are machined using WEDM, and the Cs and Ra values are predicted using BPNN and multiple regression models. The overall mean prediction error for Cs and Ra is 3.29%. This approach addresses the instability, poor surface quality, and parameter optimization difficulties arising from the hardness and compositional variability of such materials. | |

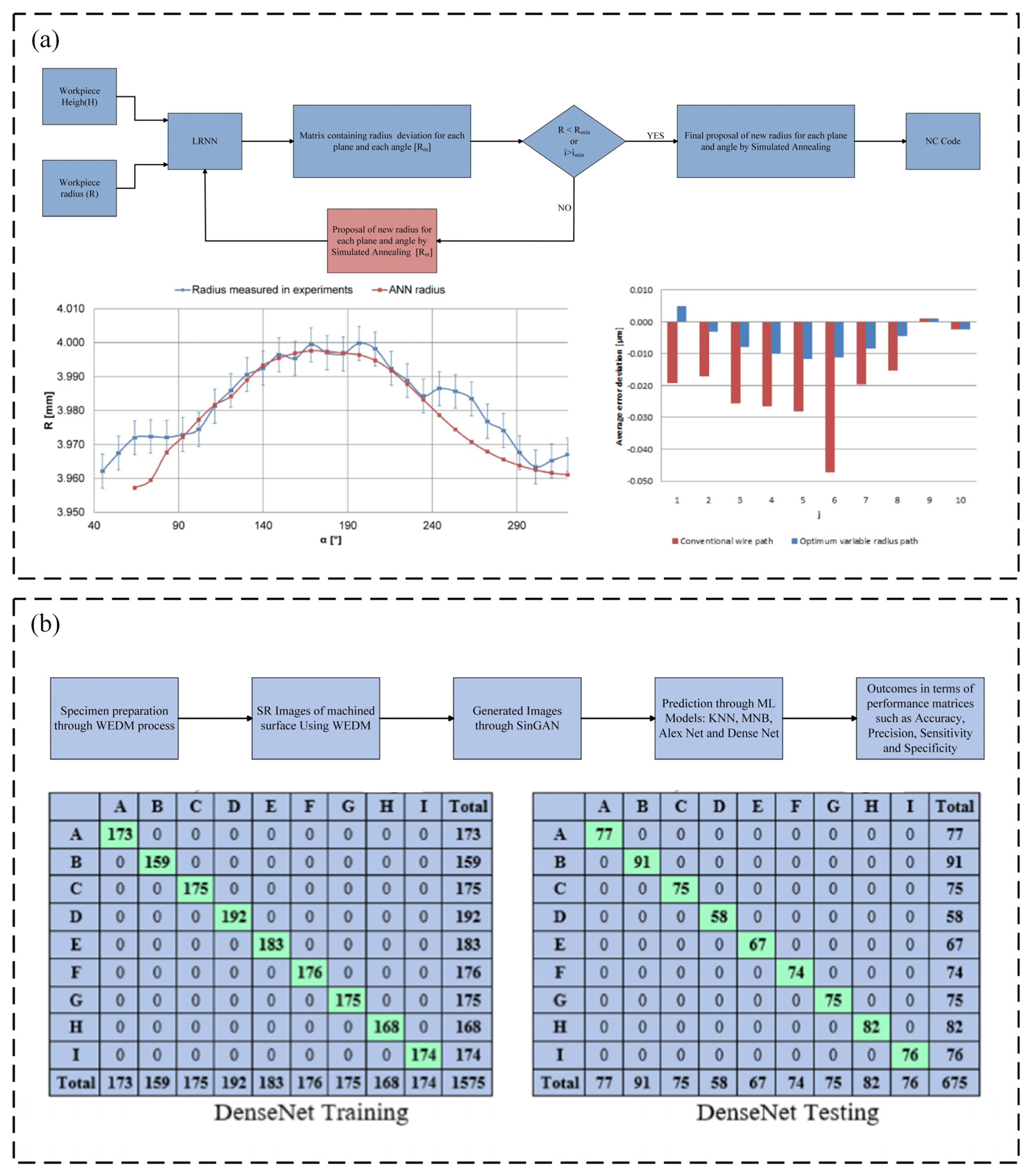

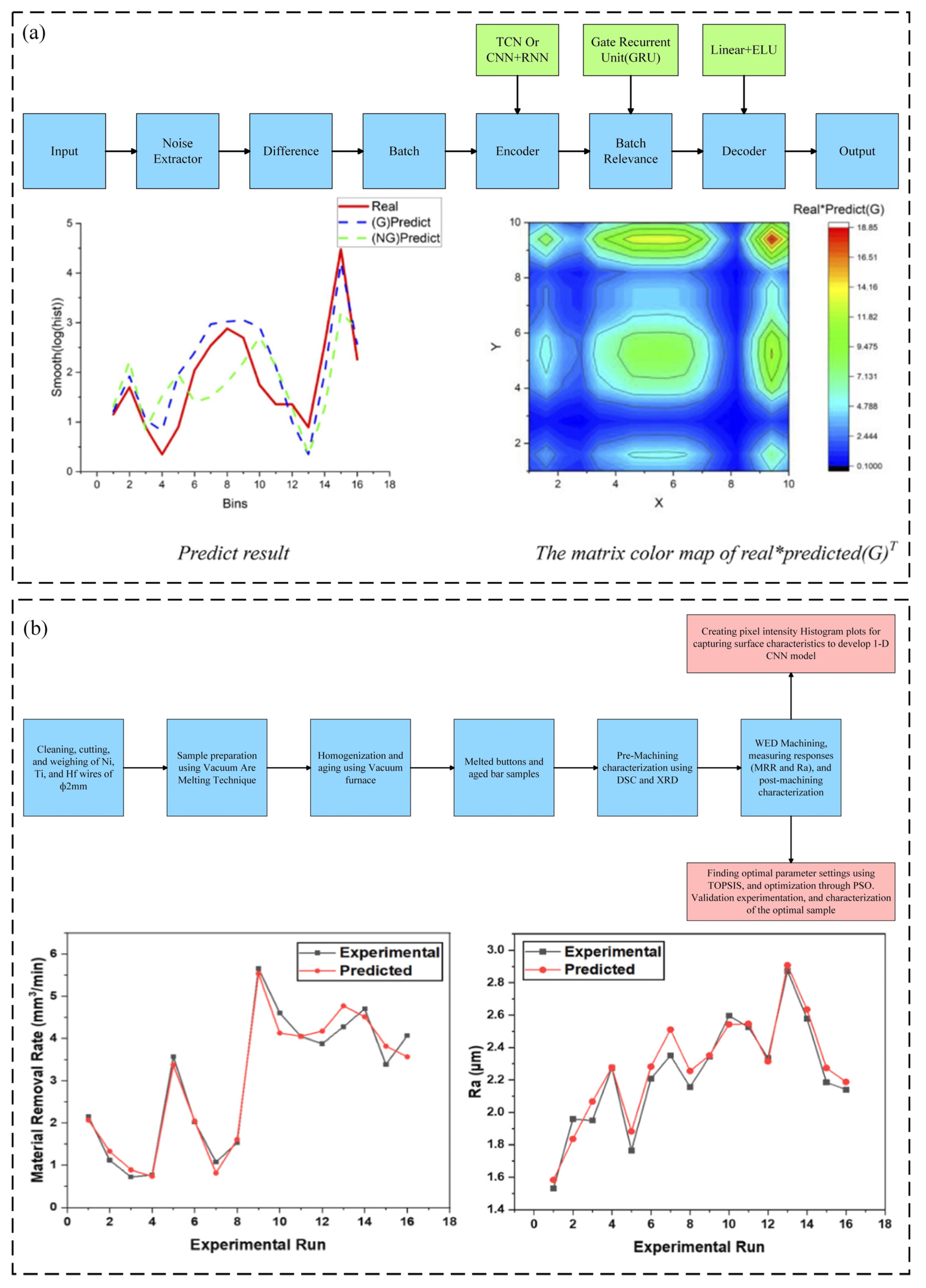

4. Deep Learning

4.1. Convolutional Neural Network

4.2. Deep Neural Network

4.3. Other

4.4. Summary

| Metal (Material) | Author(s)/Year | Optimization Method | Comments | |

|---|---|---|---|---|

| High-temperature alloys | Inconel 718 | Wang et al. (2019) [124] | Deep learning techniques | The integration of WEDM and deep learning techniques has successfully addressed the challenge of high-precision geometric defect detection in the fabrication of turbine disk fir-tree slots using Inconel 718 superalloy. |

| Tool steels | AISI P20+Ni | Kumar and Das (2023) [118] | DNN integrated with ANOVA and MRFO | AISI P20+Ni tool steel, known as one of the hardest steels for plastic-mold manufacturing, presents significant machining challenges. By employing zinc-coated brass wire electrodes and optimizing WEDM parameters, this study effectively achieves the synergistic optimization of MRR, recast layer thickness, and surface roughness. |

| Kumar and Das (2024) [119] | DNN combined with COOT | Using AISI P20+Ni tool steel as the workpiece material, UV-assisted WEDM can enhance a 45.88% improvement in MRR and a 69.81% reduction in SR, overcoming the issues of low efficiency and poor surface quality associated with conventional machining. | ||

| Kumar and Das (2023) [122] | RSM and DBN integrated with SAR | The machining behavior of AISI P20+Ni tool steel in WEDM has been thoroughly investigated, resolving key problems such as low efficiency, inferior surface quality, and excessive tool wear commonly encountered in high-hardness mold-steel processing. The advantages of low-temperature-treated zinc-coated wire electrodes in high-performance machining are confirmed, and advanced optimization algorithms are incorporated to achieve accurate process modeling and parameter tuning. | ||

| SKD61 | Jiang and Yen. (2021) [125] | Integration of MTF, CNN and LSTM | For SKD61 steel, the proposed MTF-CLSTM method effectively predicted surface roughness during WEDM. By transforming dynamic data into images and extracting spatiotemporal features, the model achieves a minimum MAPE of 2.94%, significantly improving prediction accuracy. | |

| SKD11 | Shen et al. (2019) [127] | Deep neural network learning | SKD11, a high-hardness and wear-resistant tool steel, exhibits complex discharge behavior during EDM. These variations pose greater demands on the sensitivity and accuracy of detection methods. | |

| Carbon steels and alloy steels | AISI 1045 | Liu et al. (2021) [111] | CNN combined with GRU | By analyzing spark image features and their relationship with discharge conditions during WEDM of AISI 1045 carbon steel, this study resolves the instability and latency issues inherent in conventional monitoring methods that rely solely on electrical parameters (e.g., voltage and current). |

| Carbon steel | Yang et al. (2022) [112] | BRTCN | The use of carbon steel as the workpiece material in WEDM enabled the investigation of discharge behavior, addressing limitations of traditional monitoring methods in terms of efficiency, stability, and real-time performance. Furthermore, AE signals are validated as effective in distinguishing different discharge states, such as short-circuiting, partial short-circuiting, and open-circuiting. | |

| AISI D2 | Sanchez et al. (2018) [120] | DNN | By integrating the material characteristics of AISI D2 tool steel with deep learning techniques, the study tackles quality degradation in industrial WEDM caused by sudden parameter changes (e.g., workpiece-thickness variation), offering a novel method for real-time monitoring and proactive intervention in intelligent manufacturing of high-precision, high-value components. | |

| Conde et al. (2018) [121] | LRNN combined with SA | When machining AISI D2 tool steel, dimensional accuracy loss caused by wire electrode deformation is effectively mitigated through the combination of an Elman-based LRNN and SA optimization. The proposed method reduces mean deviation by up to 80% and CV by 43%. | ||

| Non-ferrous metals and alloys | Al6061 | Shen et al. (2019) [127] | Deep neural network learning | Al6061, a lightweight aluminum alloy with excellent conductivity and machinability, differs significantly from steel in its discharge characteristics. Evaluating this material provides insight into the adaptability of algorithms to different electrical conductivities. |

| Brass | Shen et al. (2019) [127] | Deep neural network learning | Brass, favored for its good electrical conductivity and stability, is commonly used in precision-component machining. Analyzing its discharge waveforms further validates the reliability of detection methods under fine-machining conditions. | |

| Special materials | Ni-Ti-Hf SMA | Rahul et al. (2023) [115] | CNN integrated with PSO | The use of Ni-Ti-Hf SMAs in WEDM addressed the limitations of conventional NiTi alloys under high-temperature applications. By employing PSO and CNN-based image classification, machining parameters are optimized to enhance MRR and Ra while preserving high-temperature shape memory performance, overcoming processing challenges inherent to this alloy. |

| Ni55.8Ti SMA | Vakharia et al. (2022) [126] | Dense Net-based deep learning approach | The challenges of machining Ni55.8Ti SMAs, such as high hardness, rapid work hardening, pseudoelasticity, significant tool wear, and poor surface finish, were effectively addressed using DenseNet deep learning. This approach significantly improves machinability and surface quality where traditional methods fail. | |

5. Discussion

5.1. Model Analysis Comparison

5.2. Comparison and Analysis of Traditional Methods and Artificial Intelligence

5.3. Analysis of the Advantages and Disadvantages of Traditional Machine Learning and Deep Learning

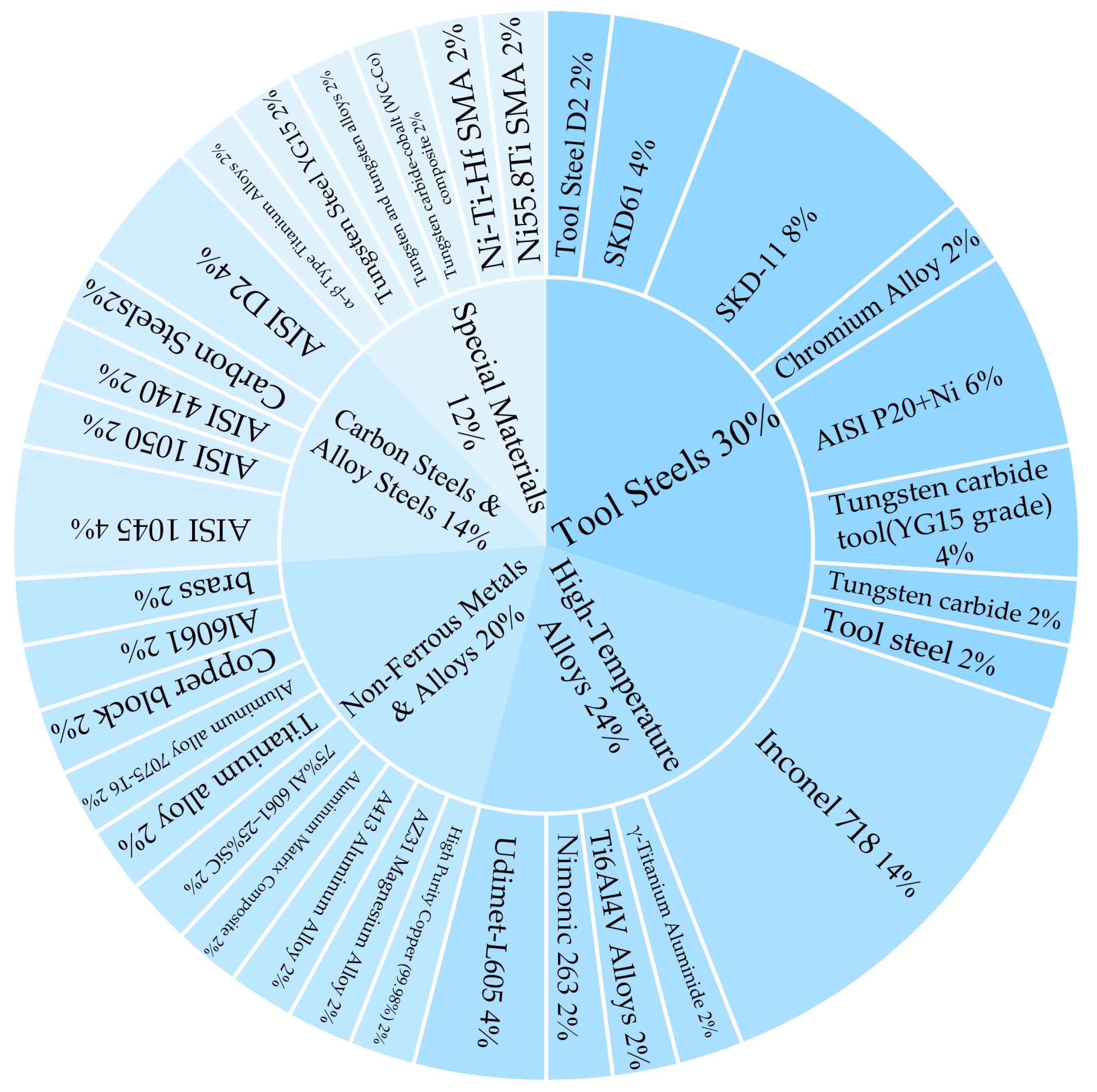

5.4. Application of Workpiece Materials During the Process of WEDM

6. Outlook

- Traditional optimization methods are expected to achieve breakthroughs in areas such as intelligent integration, real-time responsiveness, and adaptive modeling. By incorporating intelligent algorithms such as GA and PSO, multi-objective optimization capabilities can be significantly enhanced. Real-time performance can be improved through dynamic adjustment based on sensor feedback, while the integration of fuzzy logic and grey system theory can increase adaptability and robustness under complex machining conditions. Traditional methods are poised to gain renewed vitality through their integration with intelligent technologies.

- The development of machine learning will focus on enhancing generalization, enabling lightweight deployment, and establishing closed-loop data systems. Transfer learning and ensemble methods will improve model adaptability across different materials and equipment. Model compression and edge deployment will support on-site industrial applications. By integrating active learning and feedback mechanisms, a “prediction–optimization” closed-loop control system can be achieved, enhancing the practicality of models under small-sample conditions.

- Deep learning will continue to advance in the areas of cross-modal integration, edge intelligence, and enhanced interpretability. Multimodal models (such as Transformers) can fuse images, signals, and process data to achieve more refined state perception. Lightweight models (such as Mobile Net) will facilitate the implementation of real-time optimization. Explainable AI (XAI) techniques, including attention mechanisms and causal inference, will help improve model transparency, promoting a shift from “passive optimization” to “autonomous decision-making.”

- Collaborative innovation is a matter of concern, thus balancing the relationship between technological progress and the costs of industrialization. Looking ahead, there is a need to establish a seamless integration between process databases and design standards so as to develop a knowledge base of machining parameters suitable for specific operating conditions. In addition, the application of digital twin technology could facilitate the virtual validation of process results. This systematic optimization path will accelerate the transformation of WEDM machining from mere “machinability” to “optimized machining.” For example, in the field of hydraulic engineering, continuous support is provided for the reliable manufacturing of large hydraulic engineering equipment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Spedding, T.A.; Wang, Z.Q. Study on Modeling of Wire EDM Process. J. Mater. Process. Technol. 1997, 69, 18–28. [Google Scholar] [CrossRef]

- Ho, K.H.; Newman, S.T.; Rahimifard, S.; Allen, R.D. State of the Art in Wire Electrical Discharge Machining (WEDM). Int. J. Mach. Tools Manuf. 2004, 44, 1247–1259. [Google Scholar] [CrossRef]

- Slătineanu, L.; Dodun, O.; Coteaţă, M.; Nagîţ, G.; Băncescu, I.B.; Hriţuc, A. Wire Electrical Discharge Machining—A Review. Machines 2020, 8, 69. [Google Scholar] [CrossRef]

- Natarajan, K.; Ramakrishnan, H.; Gacem, A.; Vijayan, V.; Karthiga, K.; Ali, H.E.; Prakash, B.; Mekonnen, A. Study on Optimization of WEDM Process Parameters on Stainless Steel. J. Nanomater. 2022, 2022, 6765721. [Google Scholar] [CrossRef]

- Camposeco-Negrete, C. Analysis and Optimization of Sustainable Machining of AISI O1 Tool Steel by the Wire-EDM Process. Adv. Manuf. 2021, 9, 304–317. [Google Scholar] [CrossRef]

- Chakraborty, S.; Mitra, S.; Bose, D. Evaluation of Response Characteristics Using Sensitivity Analysis and TLBO Technique of Powder Mixed Wire EDM of Ti6Al4V Alloy. CIRP J. Manuf. Sci. Technol. 2023, 47, 260–272. [Google Scholar] [CrossRef]

- Zheng, J.; Ren, Y.; Qi, T.; Lin, F.; Shi, J.; Hu, X.; Pan, Q.; Yao, J.; Ling, W.; Guan, A.; et al. Modeling and Optimization of Energy Consumption in Wire Cut Electrical Discharge Machining. Comput. Ind. Eng. 2024, 191, 110167. [Google Scholar] [CrossRef]

- Liao, Y.S.; Woo, J.C. Design of a Fuzzy Controller for the Adaptive Control of WEDM Process. Int. J. Mach. Tools Manuf. 2000, 40, 2293–2307. [Google Scholar] [CrossRef]

- Takale, A.; Chougule, N. Optimization of Process Parameters of Wire Electro Discharge Machining for Ti49.4Ni50.6 Shape Memory Alloys Using the Taguchi Technique. Int. J. Struct. Integr. 2019, 10, 548–568. [Google Scholar] [CrossRef]

- Wang, S.-M.; Wu, J.-X.; Gunawan, H.; Tu, R.-Q. Optimization of Machining Parameters for Corner Accuracy Improvement for WEDM Processing. Appl. Sci. 2022, 12, 10324. [Google Scholar] [CrossRef]

- Abhilash, P.M.; Chakradhar, D. Wire EDM Failure Prediction and Process Control Based on Sensor Fusion and Pulse Train Analysis. Int. J. Adv. Manuf. Technol. 2022, 118, 1453–1467. [Google Scholar] [CrossRef]

- Abhilash, P.M.; Chakradhar, D. Performance Monitoring and Failure Prediction System for Wire Electric Discharge Machining Process through Multiple Sensor Signals. Mach. Sci. Technol. 2022, 26, 245–275. [Google Scholar] [CrossRef]

- Ozcanli, A.K.; Yaprakdal, F.; Baysal, M. Deep Learning Methods and Applications for Electrical Power Systems: A Comprehensive Review. Int. J. Energy Res. 2020, 44, 7136–7157. [Google Scholar] [CrossRef]

- Cen, J.; Yang, Z.; Liu, X.; Xiong, J.; Chen, H. A Review of Data-Driven Machinery Fault Diagnosis Using Machine Learning Algorithms. J. Vib. Eng. Technol. 2022, 10, 2481–2507. [Google Scholar] [CrossRef]

- Berus, L.; Hernavs, J.; Potocnik, D.; Sket, K.; Ficko, M. Enhancing Manufacturing Precision: Leveraging Motor Currents Data of Computer Numerical Control Machines for Geometrical Accuracy Prediction Through Machine Learning. Sensors 2025, 25, 169. [Google Scholar] [CrossRef]

- Zhang, L.; Du, J.; Zhuang, X.; Wang, Z.; Pei, J. Geometric Prediction of Conic Tool in Micro-EDM Milling with Fix-Length Compensation Using Simulation. Int. J. Mach. Tools Manuf. 2015, 89, 86–94. [Google Scholar] [CrossRef]

- Pramanik, A.; Basak, A.K.; Littlefair, G.; Debnath, S.; Prakash, C.; Singh, M.A.; Marla, D.; Singh, R.K. Methods and Variables in Electrical Discharge Machining of Titanium Alloy—A Review. Heliyon 2020, 6, e05554. [Google Scholar] [CrossRef]

- Zeng, K.; Wu, X.; Jiang, F.; Shen, J.; Zhu, L.; Li, L. A Comprehensive Review on the Cutting and Abrasive Machining of Cemented Carbide Materials. J. Manuf. Process. 2023, 108, 335–358. [Google Scholar] [CrossRef]

- Koshy, P.; Dumitrescu, P.; Ziada, Y. Novel Methods for Rapid Assessment of Tool Performance in Milling. Int. J. Mach. Tools Manuf. 2004, 44, 1599–1605. [Google Scholar] [CrossRef]

- Savas, V.; Ozay, C. The Optimization of the Surface Roughness in the Process of Tangential Turn-Milling Using Genetic Algorithm. Int. J. Adv. Manuf. Technol. 2008, 37, 335–340. [Google Scholar] [CrossRef]

- Sarıkaya, M.; Yılmaz, V.; Güllü, A. Analysis of Cutting Parameters and Cooling/Lubrication Methods for Sustainable Machining in Turning of Haynes 25 Superalloy. J. Clean. Prod. 2016, 133, 172–181. [Google Scholar] [CrossRef]

- Fuse, K.; Dalsaniya, A.; Modi, D.; Vora, J.; Pimenov, D.Y.; Giasin, K.; Prajapati, P.; Chaudhari, R.; Wojciechowski, S. Integration of Fuzzy AHP and Fuzzy TOPSIS Methods for Wire Electric Discharge Machining of Titanium (Ti6Al4V) Alloy Using RSM. Materials 2021, 14, 7408. [Google Scholar] [CrossRef] [PubMed]

- Mahapatra, S.S.; Patnaik, A. Parametric Optimization of Wire Electrical Discharge Machining (WEDM) Process Using Taguchi Method. J. Braz. Soc. Mech. Sci. Eng. 2006, 28, 422–429. [Google Scholar] [CrossRef]

- Mukherjee, R.; Chakraborty, S.; Samanta, S. Selection of Wire Electrical Discharge Machining Process Parameters Using Non-Traditional Optimization Algorithms. Appl. Soft Comput. 2012, 12, 2506–2516. [Google Scholar] [CrossRef]

- Çaydaş, U.; Hasçalık, A.; Ekici, S. An Adaptive Neuro-Fuzzy Inference System (ANFIS) Model for Wire-EDM. Expert Syst. Appl. 2009, 36, 6135–6139. [Google Scholar] [CrossRef]

- Ishfaq, K.; Sana, M.; Ashraf, W.M. Artificial Intelligence—Built Analysis Framework for the Manufacturing Sector: Performance Optimization of Wire Electric Discharge Machining System. Int. J. Adv. Manuf. Technol. 2023, 128, 5025–5039. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Pivkin, P.M.; Kozochkin, M.P.; Volosova, M.A.; Okunkova, A.A.; Porvatov, A.N.; Zelensky, A.A.; Nadykto, A.B. Physicomechanical Nature of Acoustic Emission Preceding Wire Breakage during Wire Electrical Discharge Machining (WEDM) of Advanced Cutting Tool Materials. Metals 2021, 11, 1865. [Google Scholar] [CrossRef]

- Zheng, J.; Zheng, W.; Chen, A.; Yao, J.; Ren, Y.; Zhou, C.; Wu, J.; Ling, W.; Bai, B.; Wang, W.; et al. Sustainability of Unconventional Machining Industry Considering Impact Factors and Reduction Methods of Energy Consumption: A Review and Analysis. Sci. Total Environ. 2020, 722, 137897. [Google Scholar] [CrossRef]

- Choudhary, K.; DeCost, B.; Chen, C.; Jain, A.; Tavazza, F.; Cohn, R.; Park, C.W.; Choudhary, A.; Agrawal, A.; Billinge, S.J.L.; et al. Recent Advances and Applications of Deep Learning Methods in Materials Science. npj Comput. Mater. 2022, 8, 59. [Google Scholar] [CrossRef]

- Song, J.; Wang, B.; Hao, X. Optimization Algorithms and Their Applications and Prospects in Manufacturing Engineering. Materials 2024, 17, 4093. [Google Scholar] [CrossRef]

- Sun, Y.; Zeng, W.; Ma, X.; Xu, B.; Liang, X.; Zhang, J. A Hybrid Approach for Processing Parameters Optimization of Ti-22Al-25Nb Alloy during Hot Deformation Using Artificial Neural Network and Genetic Algorithm. Intermetallics 2011, 19, 1014–1019. [Google Scholar] [CrossRef]

- Liu, S.; Yang, C. Machine Learning Design for High-Entropy Alloys: Models and Algorithms. Metals 2024, 14, 235. [Google Scholar] [CrossRef]

- Durodola, J.F. Machine Learning for Design, Phase Transformation and Mechanical Properties of Alloys. Prog. Mater. Sci. 2022, 123, 100797. [Google Scholar] [CrossRef]

- Gu, Z.; Sharma, S.; Riley, D.A.; Pantawane, M.V.; Joshi, S.S.; Fu, S.; Dahotre, N.B. A Universal Predictor-Based Machine Learning Model for Optimal Process Maps in Laser Powder Bed Fusion Process. J. Intell. Manuf. 2023, 34, 3341–3363. [Google Scholar] [CrossRef]

- Alzubaidi, L.; Zhang, J.; Humaidi, A.J.; Al-Dujaili, A.; Duan, Y.; Al-Shamma, O.; Santamaría, J.; Fadhel, M.A.; Al-Amidie, M.; Farhan, L. Review of Deep Learning: Concepts, CNN Architectures, Challenges, Applications, Future Directions. J. Big Data 2021, 8, 53. [Google Scholar] [CrossRef] [PubMed]

- Holm, E.A. In Defense of the Black Box. Science 2019, 364, 26–27. [Google Scholar] [CrossRef]

- Ma, W.; Cheng, F.; Xu, Y.; Wen, Q.; Liu, Y. Probabilistic Representation and Inverse Design of Metamaterials Based on a Deep Generative Model with Semi-Supervised Learning Strategy. Adv. Mater. 2019, 31, 1901111. [Google Scholar] [CrossRef]

- Pendokhare, D.; Chakraborty, S. A Review on Multi-Objective Optimization Techniques of Wire Electrical Discharge Machining. Arch. Comput. Methods Eng. 2024, 32, 1797–1839. [Google Scholar] [CrossRef]

- Liao, Y.S.; Yan, M.T.; Chang, C.C. A Neural Network Approach for the On-Line Estimation of Workpiece Height in WEDM. J. Mater. Process. Technol. 2002, 121, 252–258. [Google Scholar] [CrossRef]

- Yan, M.-T.; Chien, H.-T. Monitoring and Control of the Micro Wire-EDM Process. Int. J. Mach. Tools Manuf. 2007, 47, 148–157. [Google Scholar] [CrossRef]

- Modrak, V.; Pandian, R.S.; Kumar, S.S. Parametric Study of Wire-EDM Process in Al-Mg-MoS2 Composite Using NSGA-II and MOPSO Algorithms. Processes 2021, 9, 469. [Google Scholar] [CrossRef]

- Jadam, T.; Datta, S.; Masanta, M. Study of Surface Integrity and Machining Performance during Main/Rough Cut and Trim/Finish Cut Mode of WEDM on Ti–6Al–4V: Effects of Wire Material. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 151. [Google Scholar] [CrossRef]

- Hewidy, M.S.; El-Taweel, T.A.; El-Safty, M.F. Modelling the Machining Parameters of Wire Electrical Discharge Machining of Inconel 601 Using RSM. J. Mater. Process. Technol. 2005, 169, 328–336. [Google Scholar] [CrossRef]

- Kung, K.-Y.; Chiang, K.-T. Modeling and Analysis of Machinability Evaluation in the Wire Electrical Discharge Machining (WEDM) Process of Aluminum Oxide-Based Ceramic. Mater. Manuf. Process. 2008, 23, 241–250. [Google Scholar] [CrossRef]

- Li, Z.; Grandhi, R.V.; Srinivasan, R. Distortion Minimization during Gas Quenching Process. J. Mater. Process. Technol. 2006, 172, 249–257. [Google Scholar] [CrossRef]

- Kumar, K.; Agarwal, S. Multi-Objective Parametric Optimization on Machining with Wire Electric Discharge Machining. Int. J. Adv. Manuf. Technol. 2012, 62, 617–633. [Google Scholar] [CrossRef]

- Srivastava, V.; Basu, B.; Prabhu, N. Application of Machine Learning (ML)-Based Multi-Classifications to Identify Corrosion Fatigue Cracking Phenomena in Naval Steel Weldments. Mater. Today Commun. 2024, 39, 108591. [Google Scholar] [CrossRef]

- Bai, Y.; Sun, Z.; Zeng, B.; Long, J.; Li, L.; de Oliveira, J.V.; Li, C. A Comparison of Dimension Reduction Techniques for Support Vector Machine Modeling of Multi-Parameter Manufacturing Quality Prediction. J. Intell. Manuf. 2019, 30, 2245–2256. [Google Scholar] [CrossRef]

- Yang, N.; Yang, C.; Xing, C.; Ye, D.; Jia, J.; Chen, D.; Shen, X.; Huang, Y.; Zhang, L.; Zhu, B. Deep Learning-Based SCUC Decision-Making: An Intelligent Data-Driven Approach with Self-Learning Capabilities. IET Gener. Transm. Distrib. 2022, 16, 629–640. [Google Scholar] [CrossRef]

- Li, L.; Rong, S.; Wang, R.; Yu, S. Recent Advances in Artificial Intelligence and Machine Learning for Nonlinear Relationship Analysis and Process Control in Drinking Water Treatment: A Review. Chem. Eng. J. 2021, 405, 126673. [Google Scholar] [CrossRef]

- Cai, M.; Pipattanasomporn, M.; Rahman, S. Day-Ahead Building-Level Load Forecasts Using Deep Learning vs. Tradit. Time-Ser. Techniques. Appl. Energy 2019, 236, 1078–1088. [Google Scholar] [CrossRef]

- Mayer, R.; Jacobsen, H.-A. Scalable Deep Learning on Distributed Infrastructures: Challenges, Techniques, and Tools. ACM Comput. Surv. 2021, 53, 1–37. [Google Scholar] [CrossRef]

- Wang, J.; Ma, Y.; Zhang, L.; Gao, R.X.; Wu, D. Deep Learning for Smart Manufacturing: Methods and Applications. J. Manuf. Syst. 2018, 48, 144–156. [Google Scholar] [CrossRef]

- Sharma, P.; Chakradhar, D.; Narendranath, S. Analysis and Optimization of WEDM Performance Characteristics of Inconel 706 for Aerospace Application. Silicon 2018, 10, 921–930. [Google Scholar] [CrossRef]

- Ikram, A.; Mufti, N.A.; Saleem, M.Q.; Khan, A.R. Parametric Optimization for Surface Roughness, Kerf and MRR in Wire Electrical Discharge Machining (WEDM) Using Taguchi Design of Experiment. J. Mech. Sci. Technol. 2013, 27, 2133–2141. [Google Scholar] [CrossRef]

- Bobbili, R.; Madhu, V.; Gogia, A.K. Effect of Wire-EDM Machining Parameters on Surface Roughness and Material Removal Rate of High Strength Armor Steel. Mater. Manuf. Process. 2013, 28, 364–368. [Google Scholar] [CrossRef]

- Thankachan, T.; Soorya Prakash, K.; Loganathan, M. WEDM Process Parameter Optimization of FSPed Copper-BN Composites. Mater. Manuf. Process. 2018, 33, 350–358. [Google Scholar] [CrossRef]

- Kavimani, V.; Soorya Prakash, K.; Thankachan, T. Multi-Objective Optimization in WEDM Process of Graphene—SiC-Magnesium Composite through Hybrid Techniques. Measurement 2019, 145, 335–349. [Google Scholar] [CrossRef]

- Xiao, Y.; Ming, W.; Shen, D.; He, W.; Ma, J.; Jiao, J. Wolf Pack Algorithm for Optimisation of Cutting Parameters in WEDM Using Taguchi Method. Int. J. Internet Manuf. Serv. 2019, 6, 139–154. [Google Scholar] [CrossRef]

- Zaman, U.K.U.; Khan, U.A.; Aziz, S.; Baqai, A.A.; Butt, S.U.; Hussain, D.; Siadat, A.; Jung, D.W. Optimization of Wire Electric Discharge Machining (WEDM) Process Parameters for AISI 1045 Medium Carbon Steel Using Taguchi Design of Experiments. Materials 2022, 15, 7846. [Google Scholar] [CrossRef]

- Deshmukh, S.S.; Shaikh Zubair, A.; Jadhav, V.S.; Shrivastava, R. Optimization of Process Parameters of Wire Electric Discharge Machining on AISI 4140 Using Taguchi Method and Grey Relational Analysis. Mater. Today Proc. 2019, 18, 4261–4270. [Google Scholar] [CrossRef]

- Khan, Z.A.; Siddiquee, A.N.; Khan, N.Z.; Khan, U.; Quadir, G.A. Multi Response Optimization of Wire Electrical Discharge Machining Process Parameters Using Taguchi Based Grey Relational Analysis. Procedia Mater. Sci. 2014, 6, 1683–1695. [Google Scholar] [CrossRef]

- Lingadurai, K.; Nagasivamuni, B.; Muthu Kamatchi, M.; Palavesam, J. Selection of Wire Electrical Discharge Machining Process Parameters on Stainless Steel AISI Grade-304 Using Design of Experiments Approach. J. Inst. Eng. India Ser. C 2012, 93, 163–170. [Google Scholar] [CrossRef]

- Singh, V.; Bhandari, R.; Yadav, V.K. An Experimental Investigation on Machining Parameters of AISI D2 Steel Using WEDM. Int. J. Adv. Manuf. Technol. 2017, 93, 203–214. [Google Scholar] [CrossRef]

- Sarkar, S.; Sekh, M.; Mitra, S.; Bhattacharyya, B. Modeling and Optimization of Wire Electrical Discharge Machining of γ-TiAl in Trim Cutting Operation. J. Mater. Process. Technol. 2008, 205, 376–387. [Google Scholar] [CrossRef]

- Sivaprakasam, P.; Hariharan, P.; Gowri, S. Optimization of Micro-WEDM Process of Aluminum Matrix Composite (A413-B4C): A Response Surface Approach. Mater. Manuf. Process. 2013, 28, 1340–1347. [Google Scholar] [CrossRef]

- Soundararajan, R.; Ramesh, A.; Mohanraj, N.; Parthasarathi, N. An Investigation of Material Removal Rate and Surface Roughness of Squeeze Casted A413 Alloy on WEDM by Multi Response Optimization Using RSM. J. Alloys Compd. 2016, 685, 533–545. [Google Scholar] [CrossRef]

- Mohanraj, T.; Sakthivel, G.; Pramanik, A. Use of RSM Desirability Approach to Optimize WEDM of Mild Steel. Phys. Scr. 2024, 99, 105976. [Google Scholar] [CrossRef]

- Yan, M.T.; Liao, Y.S. Adaptive Control of the WEDM Process Using the Fuzzy Control Strategy. J. Manuf. Syst. 1998, 17, 263–274. [Google Scholar] [CrossRef]

- Lin, C.-T.; Chung, I.-F.; Huang, S.-Y. Improvement of Machining Accuracy by Fuzzy Logic at Corner Parts for Wire-EDM. Fuzzy Sets Syst. 2001, 122, 499–511. [Google Scholar] [CrossRef]

- Fard, R.K.; Afza, R.A.; Teimouri, R. Experimental Investigation, Intelligent Modeling and Multi-Characteristics Optimization of Dry WEDM Process of Al–SiC Metal Matrix Composite. J. Manuf. Process. 2013, 15, 483–494. [Google Scholar] [CrossRef]

- Maher, I.; Sarhan, A.A.D.; Barzani, M.M.; Hamdi, M. Increasing the Productivity of the Wire-Cut Electrical Discharge Machine Associated with Sustainable Production. J. Clean. Prod. 2015, 108, 247–255. [Google Scholar] [CrossRef]

- Goyal, A.; Gautam, N.; Pathak, V.K. An Adaptive Neuro-Fuzzy and NSGA-II-Based Hybrid Approach for Modelling and Multi-Objective Optimization of WEDM Quality Characteristics during Machining Titanium Alloy. Neural Comput. Appl. 2021, 33, 16659–16674. [Google Scholar] [CrossRef]

- Jithendra, T.; Basha, S.S.; Das, R.; Gajjela, R. Modeling and Optimization of WEDM of Monel 400 Alloy Using ANFIS and Snake Optimizer: A Comparative Study. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2024, 238, 1573–1589. [Google Scholar] [CrossRef]

- Naresh, C.; Bose, P.S.C.; Rao, C.S.P. Artificial Neural Networks and Adaptive Neuro-Fuzzy Models for Predicting WEDM Machining Responses of Nitinol Alloy: Comparative Study. SN Appl. Sci. 2020, 2, 314. [Google Scholar] [CrossRef]

- Tosun, N. The Effect of the Cutting Parameters on Performance of WEDM. KSME Int. J. 2003, 17, 816–824. [Google Scholar] [CrossRef]

- Yuan, J.; Wang, K.; Yu, T.; Fang, M. Reliable Multi-Objective Optimization of High-Speed WEDM Process Based on Gaussian Process Regression. Int. J. Mach. Tools Manuf. 2008, 48, 47–60. [Google Scholar] [CrossRef]

- Pasam, V.K.; Battula, S.B.; Madar Valli, P.; Swapna, M. Optimizing Surface Finish in WEDM Using the Taguchi Parameter Design Method. J. Braz. Soc. Mech. Sci. Eng. 2010, 32, 107–113. [Google Scholar] [CrossRef]

- Ming, W.; Zhang, Z.; Zhang, G.; Huang, Y.; Guo, J.; Chen, Y. Multi-Objective Optimization of 3D-Surface Topography of Machining YG15 in WEDM. Mater. Manuf. Process. 2014, 29, 514–525. [Google Scholar] [CrossRef]

- Nguyen, T.-T.; Duong, Q.-D. Optimization of WEDM Process of Mould Material Using Kriging Model to Improve Technological Performances. Sādhanā 2019, 44, 154. [Google Scholar] [CrossRef]

- Xu, J.; Li, M.; Zhong, J.; Hou, Y.; Xia, S.; Yu, P. Process Parameter Modeling and Multi-Response Optimization of Wire Electrical Discharge Machining NiTi Shape Memory Alloy. Mater. Today Commun. 2022, 33, 104252. [Google Scholar] [CrossRef]

- AbouHawa, M.; Eissa, A. Corner Cutting Accuracy for Thin-Walled CFRPC Parts Using HS-WEDM. Discov. Appl. Sci. 2024, 6, 130. [Google Scholar] [CrossRef]

- Singh, R.; Hussain, S.A.I.; Dash, A.; Rai, R.N. Modelling and Optimizing Performance Parameters in the Wire-Electro Discharge Machining of Al5083/B4C Composite by Multi-Objective Response Surface Methodology. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 344. [Google Scholar] [CrossRef]

- Ming, W.; Hou, J.; Zhang, Z.; Huang, H.; Xu, Z.; Zhang, G.; Huang, Y. Integrated ANN-LWPA for Cutting Parameter Optimization in WEDM. Int. J. Adv. Manuf. Technol. 2016, 84, 1277–1294. [Google Scholar] [CrossRef]

- Abhilash, P.M.; Chakradhar, D. Prediction and Analysis of Process Failures by ANN Classification during Wire-EDM of Inconel 718. Adv. Manuf. 2020, 8, 519–536. [Google Scholar] [CrossRef]

- Shandilya, P.; Jain, P.K.; Jain, N.K. Neural Network Based Modeling in Wire Electric Discharge Machining of SiCp/6061 Aluminum Metal Matrix Composite. Adv. Mater. Res. 2012, 383–390, 6679–6683. [Google Scholar] [CrossRef]

- Chou, P.-H.; Hwang, Y.-R.; Yan, B.-H. The Study of Machine Learning for Wire Rupture Prediction in WEDM. Int. J. Adv. Manuf. Technol. 2022, 119, 1301–1311. [Google Scholar] [CrossRef]

- Paturi, U.M.R.; Cheruku, S.; Salike, S.; Pasunuri, V.P.K.; Reddy, N.S. Estimation of Machinability Performance in Wire-EDM on Titanium Alloy Using Neural Networks. Mater. Manuf. Process. 2022, 37, 1073–1084. [Google Scholar] [CrossRef]

- Saha, P.; Singha, A.; Pal, S.K.; Saha, P. Soft Computing Models Based Prediction of Cutting Speed and Surface Roughness in Wire Electro-Discharge Machining of Tungsten Carbide Cobalt Composite. Int. J. Adv. Manuf. Technol. 2008, 39, 74–84. [Google Scholar] [CrossRef]

- Chen, H.-C.; Lin, J.-C.; Yang, Y.-K.; Tsai, C.-H. Optimization of Wire Electrical Discharge Machining for Pure Tungsten Using a Neural Network Integrated Simulated Annealing Approach. Expert Syst. Appl. 2010, 37, 7147–7153. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, Z.; Guo, J.; Ming, W.; Li, M.; Huang, Y. Modeling and Optimization of Medium-Speed WEDM Process Parameters for Machining SKD11. Mater. Manuf. Process. 2013, 28, 1124–1132. [Google Scholar] [CrossRef]

- Zhang, Z.; Ming, W.; Huang, H.; Chen, Z.; Xu, Z.; Huang, Y.; Zhang, G. Optimization of Process Parameters on Surface Integrity in Wire Electrical Discharge Machining of Tungsten Tool YG15. Int. J. Adv. Manuf. Technol. 2015, 81, 1303–1317. [Google Scholar] [CrossRef]

- Yusoff, Y.; Mohd Zain, A.; Sharif, S.; Sallehuddin, R.; Ngadiman, M.S. Potential ANN Prediction Model for Multiperformances WEDM on Inconel 718. Neural Comput. Appl. 2018, 30, 2113–2127. [Google Scholar] [CrossRef]

- Singh, B.; Misra, J.P. Surface Finish Analysis of Wire Electric Discharge Machined Specimens by RSM and ANN Modeling. Measurement 2019, 137, 225–237. [Google Scholar] [CrossRef]

- Huang, G.; Xia, W.; Qin, L.; Zhao, W. Online Workpiece Height Estimation for Reciprocated Traveling Wire EDM Based on Support Vector Machine. Procedia CIRP 2018, 68, 126–131. [Google Scholar] [CrossRef]

- Nain, S.S.; Garg, D.; Kumar, S. Evaluation and Analysis of Cutting Speed, Wire Wear Ratio, and Dimensional Deviation of Wire Electric Discharge Machining of Super Alloy Udimet-L605 Using Support Vector Machine and Grey Relational Analysis. Adv. Manuf. 2018, 6, 225–246. [Google Scholar] [CrossRef]

- Bijeta Nayak, B.; Sankar Mahapatra, S. An Intelligent Approach for Prediction of Angular Error in Taper Cutting Using Wire-EDM. Mater. Today Proc. 2018, 5, 6121–6127. [Google Scholar] [CrossRef]

- Paturi, U.M.R.; Cheruku, S.; Pasunuri, V.P.K.; Salike, S.; Reddy, N.S.; Cheruku, S. Machine Learning and Statistical Approach in Modeling and Optimization of Surface Roughness in Wire Electrical Discharge Machining. Mach. Learn. Appl. 2021, 6, 100099. [Google Scholar] [CrossRef]

- Sharma, V.; Misra, J.P.; Singhal, S. Surface Roughness Modeling Using Machine Learning Approaches for Wire Electro-Spark Machining of Titanium Alloy. Int. J. Struct. Integr. 2022, 13, 999–1012. [Google Scholar] [CrossRef]

- Zhang, Z.; Ming, W.; Zhang, G.; Huang, Y.; Wen, X.; Huang, H. A New Method for On-Line Monitoring Discharge Pulse in WEDM-MS Process. Int. J. Adv. Manuf. Technol. 2015, 81, 1403–1418. [Google Scholar] [CrossRef]

- Nain, S.S.; Garg, D.; Kumar, S. Performance Evaluation of the WEDM Process of Aeronautics Super Alloy. Mater. Manuf. Process. 2018, 33, 1793–1808. [Google Scholar] [CrossRef]

- Upadhyay, V.; Misra, J.P.; Singh, B. Wire-Breakage Prediction during WEDM of Ni-Based Superalloy Using Machine Learning-Based Classifier Approaches. Int. J. Interact. Des. Manuf. 2024, 18, 3739–3749. [Google Scholar] [CrossRef]

- Jai Rajesh, P.; Balambica, V.; Achudhan, M. Optimizing Ti6Al4V Alloy Wire Edm Parameters Using Regression Analysis and Metaheuristic Algorithm. J. Phys. Conf. Ser. 2024, 2837, 012045. [Google Scholar] [CrossRef]

- Saha, S.; Arunkumar, T.; Debnath, K.; Chaurasia, S. Optimization of Kerf Width in WEDM of Sandwich Woven CFRP-An Ensemble Machine Learning Based Approach. Arab. J. Sci. Eng. 2024, 1–12. [Google Scholar] [CrossRef]

- Konda, R. Predicting Machining Rate in Non-Traditional Machining Using Decision Tree Inductive Learning. Ph.D. Thesis, Nova Southeastern University, Fort Lauderdale, FL, USA, 2010. [Google Scholar]

- Wang, J.; Sanchez, J.A.; Ayesta, I.; Iturrioz, J.A. Unsupervised Machine Learning for Advanced Tolerance Monitoring of Wire Electrical Discharge Machining of Disc Turbine Fir-Tree Slots. Sensors 2018, 18, 3359. [Google Scholar] [CrossRef] [PubMed]

- Ulas, M.; Aydur, O.; Gurgenc, T.; Ozel, C. Surface Roughness Prediction of Machined Aluminum Alloy with Wire Electrical Discharge Machining by Different Machine Learning Algorithms. J. Mater. Res. Technol. 2020, 9, 12512–12524. [Google Scholar] [CrossRef]

- Trung-Thanh, N.; Khoa, D.N. Multi-Attribute Optimization of the WEDM Process for Surface Characteristics and Productivity. Teh. Vjesn. 2021, 28, 473–480. [Google Scholar] [CrossRef]

- Abhilash, P.M.; Chakradhar, D. Sustainability Improvement of WEDM Process by Analysing and Classifying Wire Rupture Using Kernel-Based Naive Bayes Classifier. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 64. [Google Scholar] [CrossRef]

- Vijayakumar, N.; Chandradass, J. Optimizing Wire Electrical Discharge Machining Parameters for Enhanced Gear Machining Performance: A Machine Learning Approach on 20MnCr5 Steel. J. Mater. Eng. Perform. 2024. [Google Scholar] [CrossRef]

- Liu, C.; Yang, X.; Peng, S.; Zhang, Y.; Peng, L.; Zhong, R.Y. Spark Analysis Based on the CNN-GRU Model for WEDM Process. Micromachines 2021, 12, 702. [Google Scholar] [CrossRef]

- Yang, X.; Liu, C.; Peng, L.; Peng, S.; Zhang, Y.; Xie, N.; Zhong, R.Y. A New BRTCN Model for Predicting Discharge Status of WEDM Based on Acoustic Emission. J. Manuf. Syst. 2022, 64, 409–423. [Google Scholar] [CrossRef]

- Ye, Z.Q.; Zhong, Z.P.; Deng, Y.C.; Zhang, Y.J.; Su, G.K. Discharge state recognition of WEDM based on CNN-GRU deep learning with Mixup data augmentation. Machinery 2023, 50, 8–15. [Google Scholar]

- Tang, Y.G.; Su, G.K.; Ye, Z.Q.; Chen, H.; Zhang, Y.J. Online pulse recognition of WEDM based on FPGA high-speed data acquisition. J. Xi’an Technol. Univ. 2024, 44, 273–282. [Google Scholar] [CrossRef]

- Rahul, V.M.; Balaji, V.; Narendranath, S. Optimization of Wire-EDM Process Parameters for Ni–Ti-Hf Shape Memory Alloy through Particle Swarm Optimization and CNN-Based SEM-Image Classification. Results Eng. 2023, 18, 101141. [Google Scholar] [CrossRef]

- Li, X.; Wang, Y.; Wang, Z. Convolutional Neural Network-Based Wire-Cut Image Recognition and Defect Detection Research. Eng. Res. Express 2025, 7, 015559. [Google Scholar] [CrossRef]

- Gonzalez-Sanchez, E.; Saccardo, D.; Esteves, P.B.; Kuffa, M.; Wegener, K. Automatic Characterization of WEDM Single Craters Through AI Based Object Detection. Int. J. Autom. Technol. 2024, 18, 265–275. [Google Scholar] [CrossRef]

- Kumar, B.K.; Das, V.C. Study and Optimisation of WEDM Parameters of AISI P20+Ni Using RSM and Hybrid Deep Neural Network. Adv. Mater. Process. Technol. 2023, 9, 1299–1327. [Google Scholar] [CrossRef]

- Kumar, B.K.; Das, V.C. Prediction and Optimization of Ultrasonic Vibration Assisted Wire EDM Process for AISI P20 + Ni Using COOT Optimization Algorithm Based Deep Neural Network. J. Vib. Eng. Technol. 2024, 12, 613–632. [Google Scholar] [CrossRef]

- Sanchez, J.A.; Conde, A.; Arriandiaga, A.; Wang, J.; Plaza, S. Unexpected Event Prediction in Wire Electrical Discharge Machining Using Deep Learning Techniques. Materials 2018, 11, 1100. [Google Scholar] [CrossRef]

- Conde, A.; Arriandiaga, A.; Sanchez, J.A.; Portillo, E.; Plaza, S.; Cabanes, I. High-Accuracy Wire Electrical Discharge Machining Using Artificial Neural Networks and Optimization Techniques. Robot. Comput.-Integr. Manuf. 2018, 49, 24–38. [Google Scholar] [CrossRef]

- Kumar, B.K.; Das, V.C. Study and Parameter Optimization with AISI P20 + Ni in Wire EDM Performance Using RSM and Hybrid DBN Based SAR. Int. J. Interact. Des. Manuf. 2023, 17, 679–701. [Google Scholar] [CrossRef]

- Kumar, S.; Jayswal, S.C. Deep Learning Approach for Optimizing Material Removal Rate in Wire Electrical Discharge Machining Using Neural Networks. Eng. Res. Express 2025, 7, 015519. [Google Scholar] [CrossRef]

- Wang, J.; Sanchez, J.A.; Iturrioz, J.A.; Ayesta, I. Geometrical Defect Detection in the Wire Electrical Discharge Machining of Fir-Tree Slots Using Deep Learning Techniques. Appl. Sci. 2019, 9, 90. [Google Scholar] [CrossRef]

- Jiang, J.-R.; Yen, C.-T. Product Quality Prediction for Wire Electrical Discharge Machining with Markov Transition Fields and Convolutional Long Short-Term Memory Neural Networks. Appl. Sci. 2021, 11, 5922. [Google Scholar] [CrossRef]

- Vakharia, V.; Vora, J.; Khanna, S.; Chaudhari, R.; Shah, M.; Pimenov, D.Y.; Giasin, K.; Prajapati, P.; Wojciechowski, S. Experimental Investigations and Prediction of WEDMed Surface of Nitinol SMA Using SinGAN and DenseNet Deep Learning Model. J. Mater. Res. Technol. 2022, 18, 325–337. [Google Scholar] [CrossRef]

- Shen, D.L.; Liu, D.M.; Du, J.G.; Ming, W.Y. Discharge state detection method for medium-speed WEDM based on deep neural network learning. Mech. Des. Manuf. 2019, 8, 146–149. [Google Scholar]

- Wang, F.; Li, J.W.; Zhang, Y.D.; Zhang, Y.J.; Huang, Z.G. Discharge state recognition of WEDM based on a dual-path deep learning network in time and frequency domains. Electro-Mach. Mould. 2022, 23–29, 40. [Google Scholar]

- Straka, Ľ.; Čorný, I. Simulation and Optimization of Surface Roughness and Process Performance during Machining of HSS by Micro-WEDM Technology. Micromachines 2024, 15, 372. [Google Scholar] [CrossRef]

- Pradhan, B.B.; Masanta, M.; Sarkar, B.R.; Bhattacharyya, B. Investigation of Electro-Discharge Micro-Machining of Titanium Super Alloy. Int. J. Adv. Manuf. Technol. 2009, 41, 1094–1106. [Google Scholar] [CrossRef]

- Singh Nain, S.; Garg, D.; Kumar, S. Prediction of the Performance Characteristics of WEDM on Udimet-L605 Using Different Modelling Techniques. Mater. Today Proc. 2017, 4, 546–556. [Google Scholar] [CrossRef]

- Phate, M.R.; Toney, S.B. Modeling and Prediction of WEDM Performance Parameters for Al/SiCp MMC Using Dimensional Analysis and Artificial Neural Network. Eng. Sci. Technol. Int. J. 2019, 22, 468–476. [Google Scholar] [CrossRef]

- Huang, H.; Zhang, Z.; Ming, W.; Xu, Z.; Zhang, Y. A Novel Numerical Predicting Method of Electric Discharge Machining Process Based on Specific Discharge Energy. Int. J. Adv. Manuf. Technol. 2017, 88, 409–424. [Google Scholar] [CrossRef]

- Lodhi, B.K.; Agarwal, S. Optimization of Machining Parameters in WEDM of AISI D3 Steel Using Taguchi Technique. Procedia CIRP 2014, 14, 194–199. [Google Scholar] [CrossRef]

- Nayak, B.B.; Mahapatra, S.S. An Intelligent Approach for Multi-Response Optimisation of WEDM Parameters. Int. J. Ind. Syst. Eng. 2017, 25, 197–227. [Google Scholar] [CrossRef]

- Sarkar, S.; Sekh, M.; Mitra, S.; Bhattacharyya, B. A Novel Method of Determination of Wire Lag for Enhanced Profile Accuracy in WEDM. Precis. Eng. 2011, 35, 339–347. [Google Scholar] [CrossRef]

- Meena, V.K.; Azad, M.S. Grey Relational Analysis of Micro-EDM Machining of Ti-6Al-4V Alloy. Mater. Manuf. Process. 2012, 27, 973–977. [Google Scholar] [CrossRef]

- Mahapatra, S.S.; Patnaik, A. Optimization of Wire Electrical Discharge Machining (WEDM) Process Parameters Using Taguchi Method. Int. J. Adv. Manuf. Technol. 2007, 34, 911–925. [Google Scholar] [CrossRef]

- Sharma, N.; Khanna, R.; Gupta, R.D.; Sharma, R. Modeling and Multiresponse Optimization on WEDM for HSLA by RSM. Int. J. Adv. Manuf. Technol. 2013, 67, 2269–2281. [Google Scholar] [CrossRef]

- Zhang, G.; Chen, Z.; Zhang, Z.; Huang, Y.; Ming, W.; Li, H. A Macroscopic Mechanical Model of Wire Electrode Deflection Considering Temperature Increment in MS-WEDM Process. Int. J. Mach. Tools Manuf. 2014, 78, 41–53. [Google Scholar] [CrossRef]

- Ming, W.; Ma, J.; Zhang, Z.; Huang, H.; Shen, D.; Zhang, G.; Huang, Y. Soft Computing Models and Intelligent Optimization System in Electro-Discharge Machining of SiC/Al Composites. Int. J. Adv. Manuf. Technol. 2016, 87, 201–217. [Google Scholar] [CrossRef]

- Ming, W.; Shen, F.; Zhang, G.; Liu, G.; Du, J.; Chen, Z. Green Machining: A Framework for Optimization of Cutting Parameters to Minimize Energy Consumption and Exhaust Emissions during Electrical Discharge Machining of Al 6061 and SKD 11. J. Clean. Prod. 2021, 285, 124889. [Google Scholar] [CrossRef]

- Chen, Y.; Hu, S.; Li, A.; Cao, Y.; Zhao, Y.; Ming, W. Parameters Optimization of Electrical Discharge Machining Process Using Swarm Intelligence: A Review. Metals 2023, 13, 839. [Google Scholar] [CrossRef]

- Elenchezhian, M.R.P.; Vadlamudi, V.; Raihan, R.; Reifsnider, K.; Reifsnider, E. Artificial Intelligence in Real-Time Diagnostics and Prognostics of Composite Materials and Its Uncertainties—A Review. Smart Mater. Struct. 2021, 30, 083001. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, Z.; Yu, Z.; Liu, Z.; Liu, D.; Lin, H.; Li, M.; Ma, S.; Avdeev, M.; Shi, S. Generative Artificial Intelligence and Its Applications in Materials Science: Current Situation and Future Perspectives. J. Mater. 2023, 9, 798–816. [Google Scholar] [CrossRef]

- Ayesta, I.; Izquierdo, B.; Flaño, O.; Sánchez, J.A.; Albizuri, J.; Avilés, R. Influence of the WEDM Process on the Fatigue Behavior of Inconel® 718. Int. J. Fatigue 2016, 92, 220–233. [Google Scholar] [CrossRef]

- Taylor, B.; Marco, V.S.; Wolff, W.; Elkhatib, Y.; Wang, Z. Adaptive Deep Learning Model Selection on Embedded Systems. ACM Sigplan Not. 2018, 53, 31–43. [Google Scholar] [CrossRef]

- Sze, V.; Chen, Y.-H.; Yang, T.-J.; Emer, J.S. Efficient Processing of Deep Neural Networks: A Tutorial and Survey. Proc. IEEE 2017, 105, 2295–2329. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, Z.; Wei, S.; Hao, B.; Chang, H.; Huang, Y.; Zhang, G. Study on Plasma Behaviour, Ablation Mechanism, and Surface Morphology of CFRP by Underwater Laser-Induced Plasma Micro-Machining. J. Mater. Process. Technol. 2025, 338, 118757. [Google Scholar] [CrossRef]

- Chang, H.; Zhang, Z.; Wang, P.; Zhang, G. A Novel Composite Film with Superhydrophobic Graphene for Anti-Icing/Deicing via Chemical-Assisted Magnetically Controllable Picosecond Laser Writing. Mater. Today Phys. 2025, 54, 101726. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Dong, B.; Dong, S.; Ming, W. Research Progress on Process Optimization of Metal Materials in Wire Electrical Discharge Machining. Metals 2025, 15, 706. https://doi.org/10.3390/met15070706

Zhao X, Dong B, Dong S, Ming W. Research Progress on Process Optimization of Metal Materials in Wire Electrical Discharge Machining. Metals. 2025; 15(7):706. https://doi.org/10.3390/met15070706

Chicago/Turabian StyleZhao, Xinfeng, Binghui Dong, Shengwen Dong, and Wuyi Ming. 2025. "Research Progress on Process Optimization of Metal Materials in Wire Electrical Discharge Machining" Metals 15, no. 7: 706. https://doi.org/10.3390/met15070706

APA StyleZhao, X., Dong, B., Dong, S., & Ming, W. (2025). Research Progress on Process Optimization of Metal Materials in Wire Electrical Discharge Machining. Metals, 15(7), 706. https://doi.org/10.3390/met15070706