Current-Carrying Wear Behavior of Cu–TiC Coatings Obtained Through High-Speed Laser Cladding on Conductive Slip Rings of 7075 Aluminum Alloy

Abstract

1. Introduction

2. Experimental Procedures

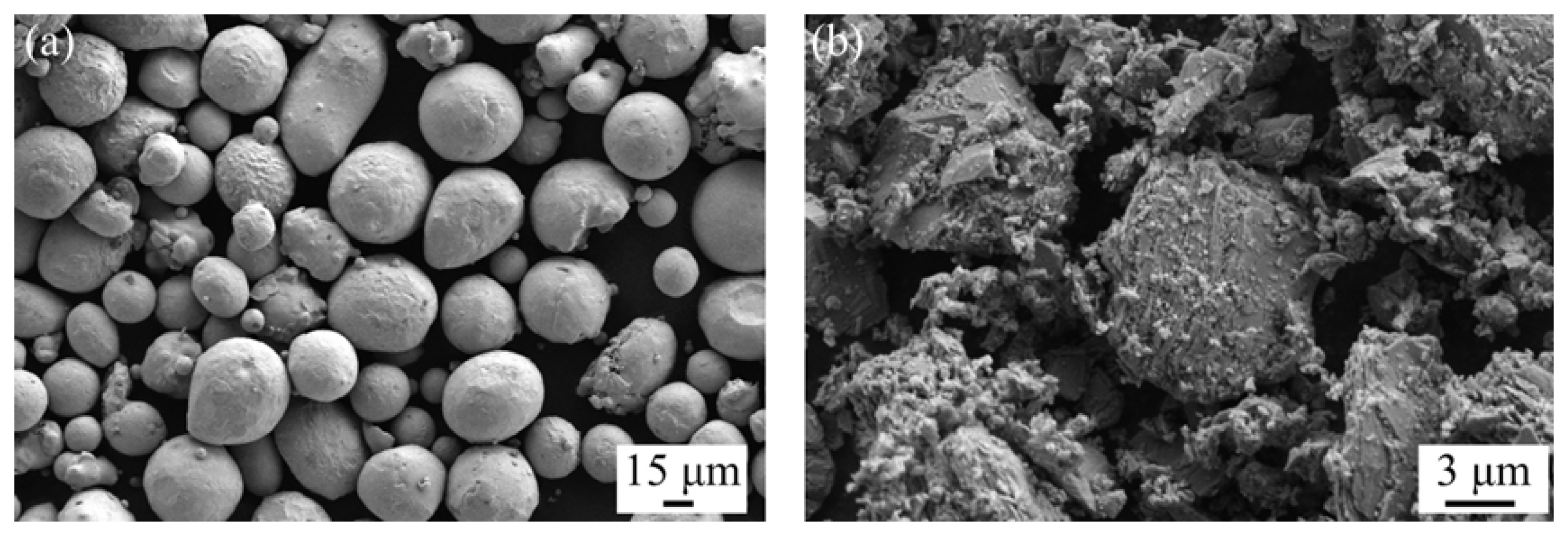

2.1. Materials and Cladding Coatings Preparations

2.2. Characterization Methods

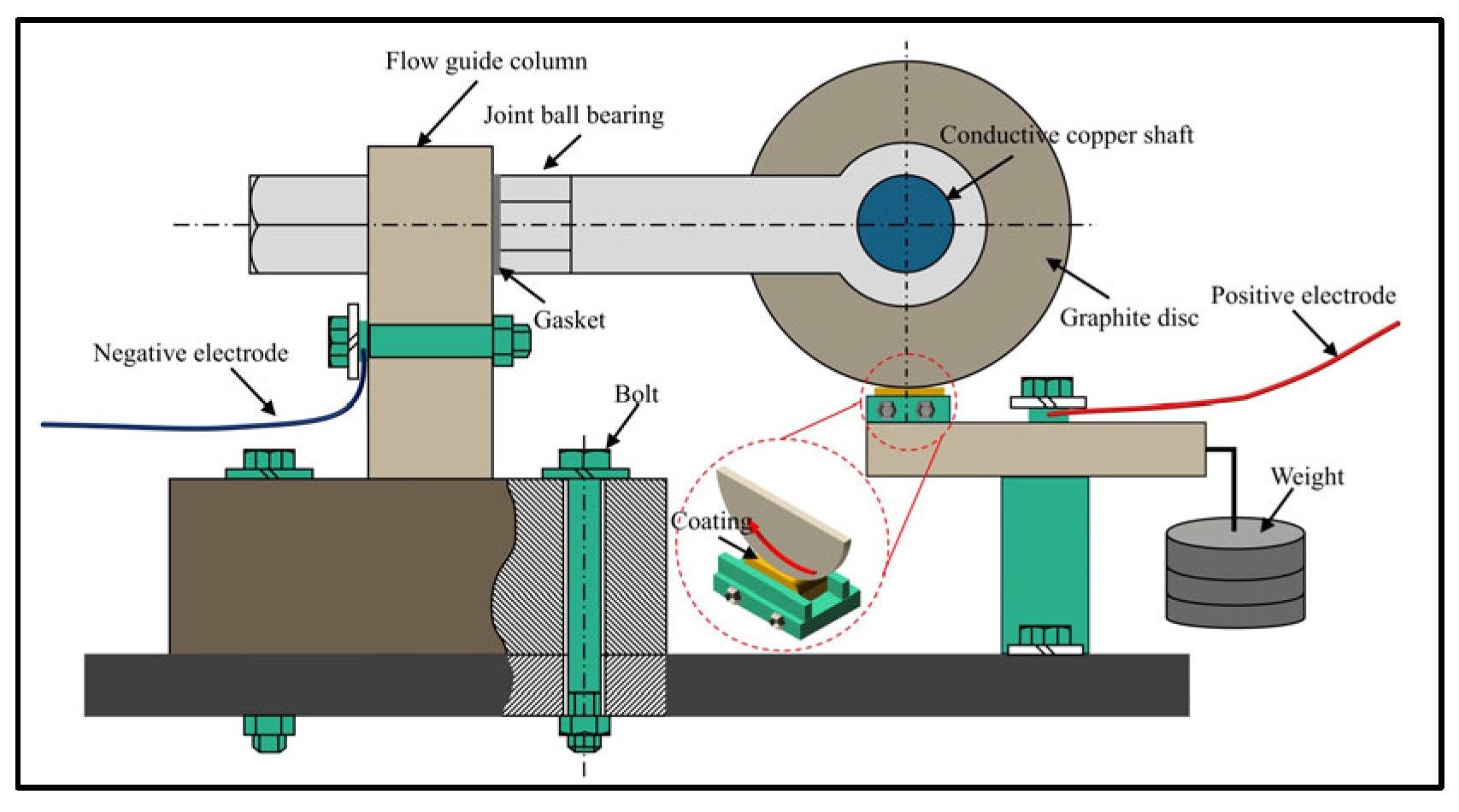

2.3. Current-Carrying Friction-Wear Test

3. Results and Discussion

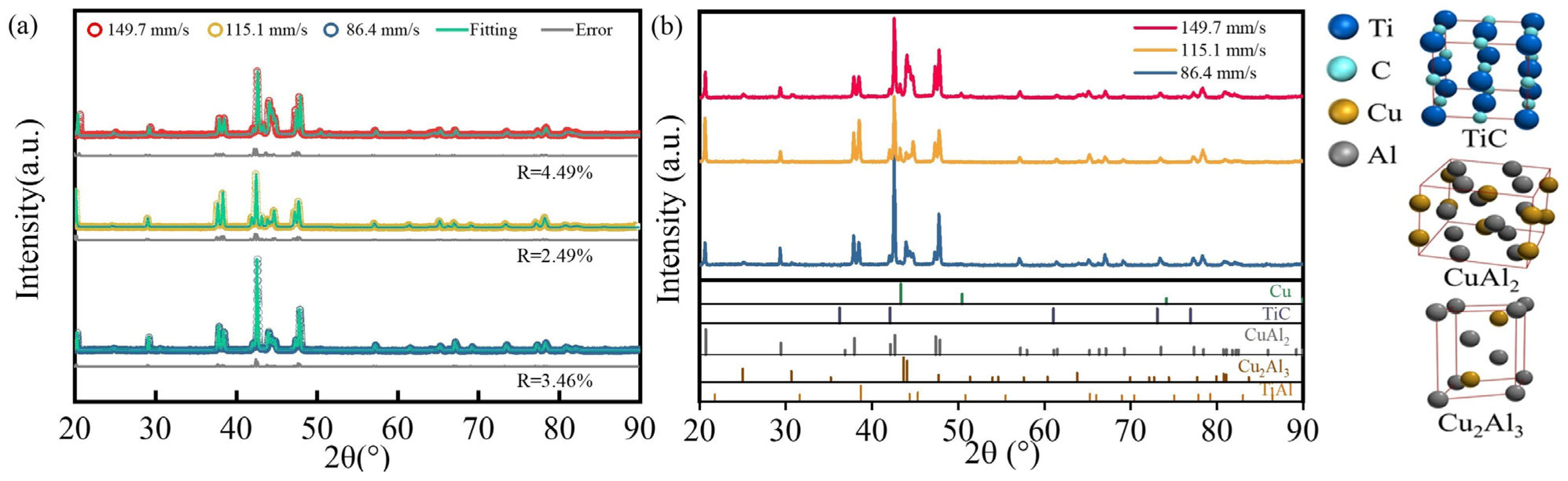

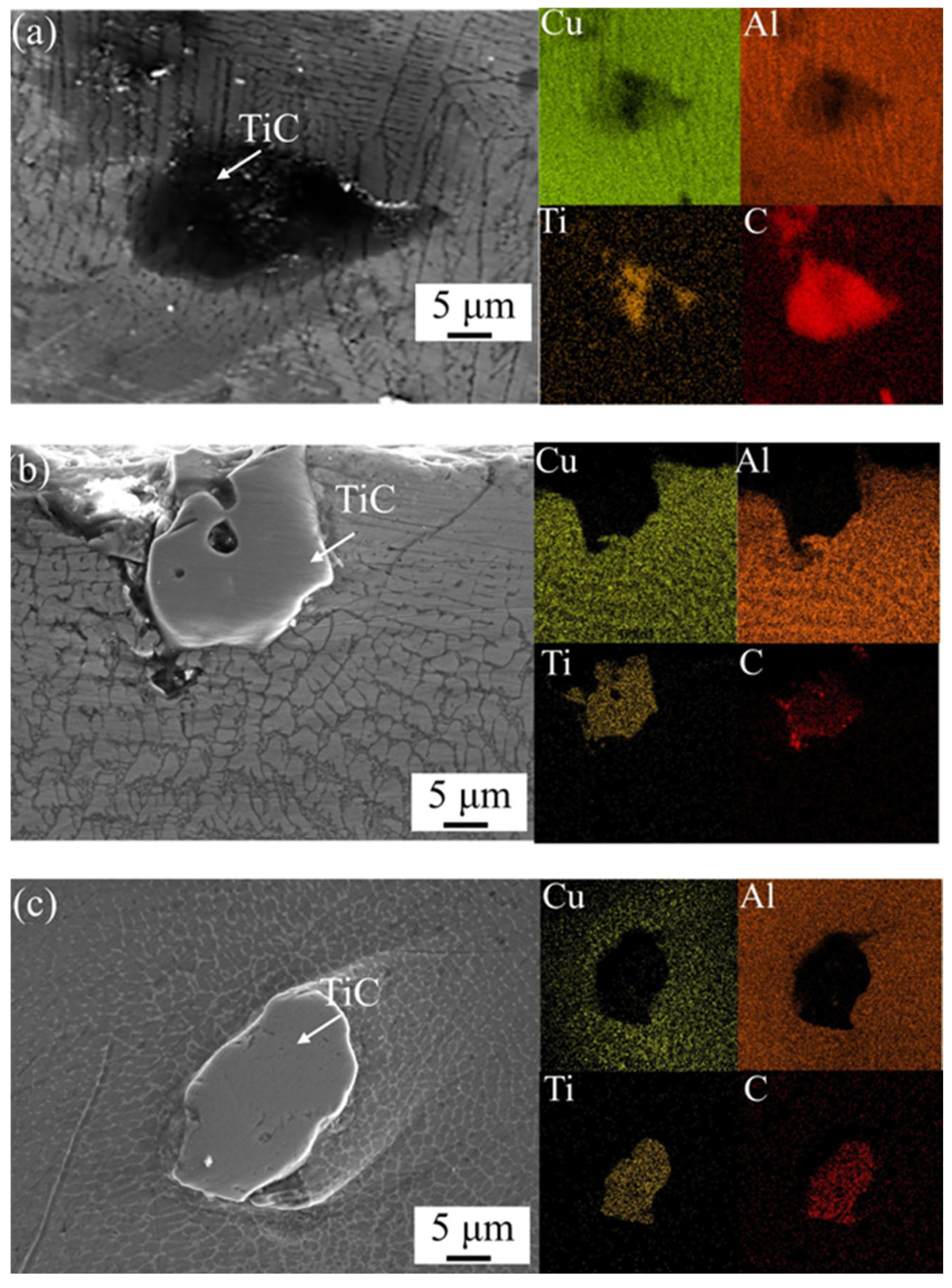

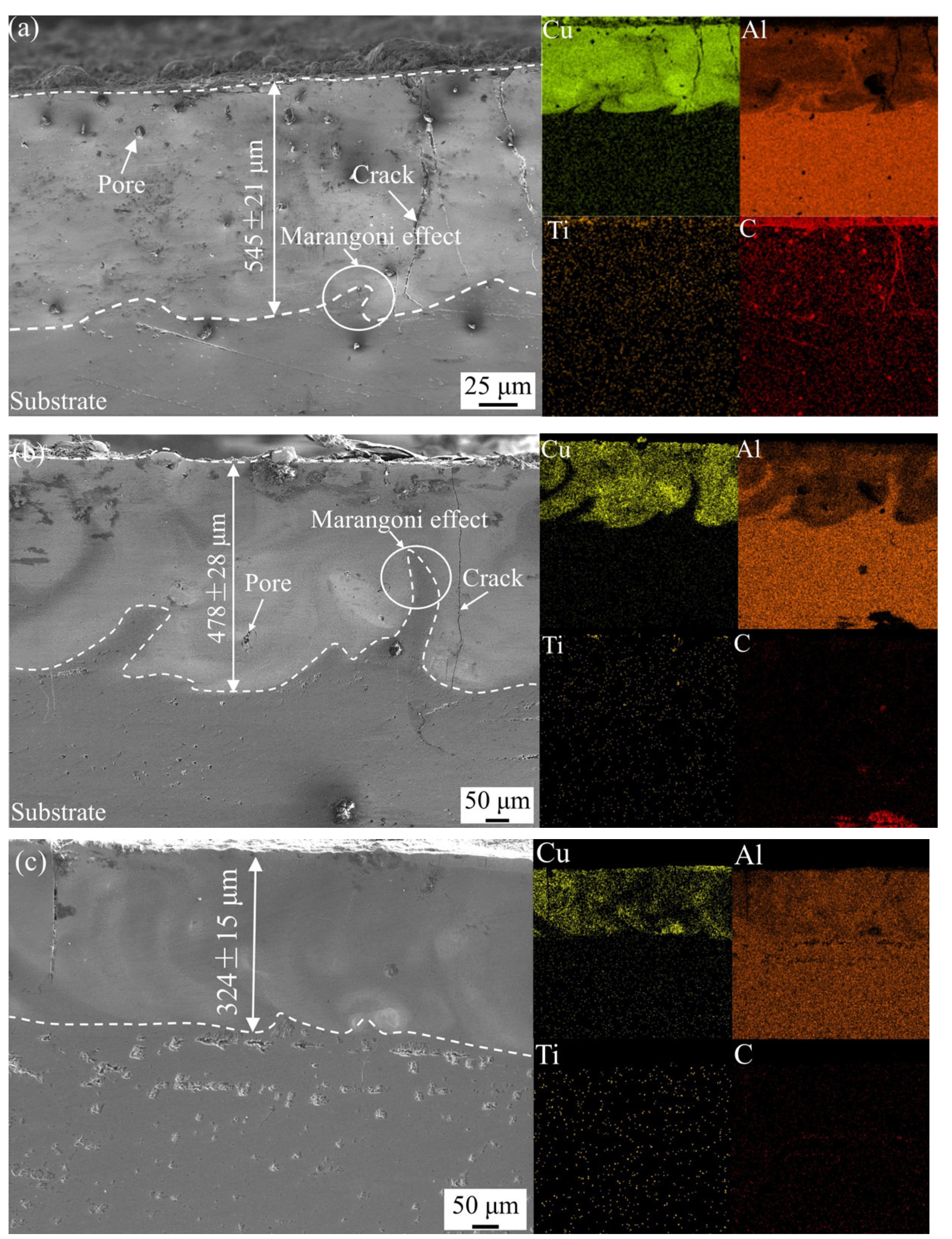

3.1. Microstructure of Coating

3.2. Hardness Analysis

3.3. Current-Carrying Wear Behavior

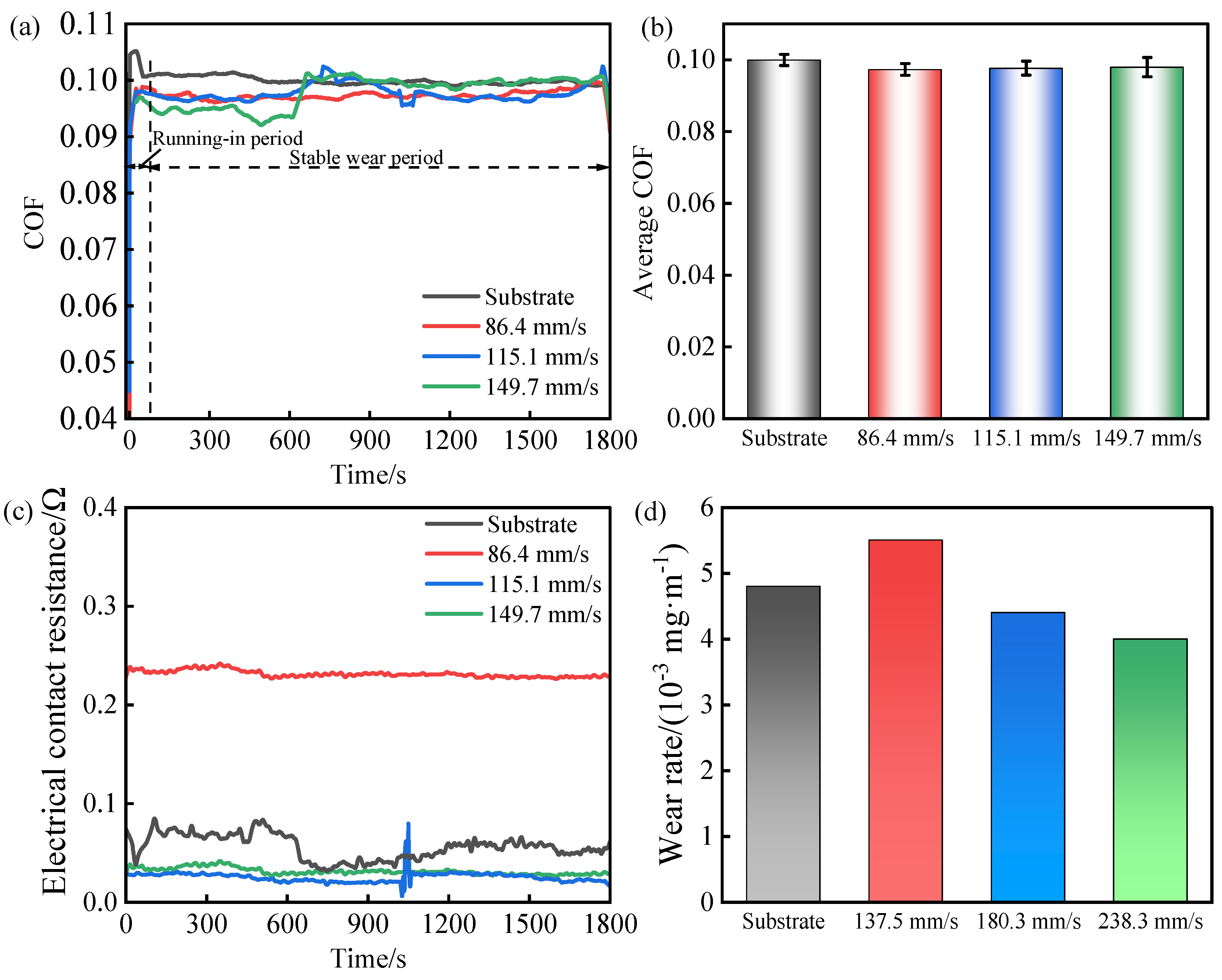

3.3.1. Coefficient of Friction (COF) and Wear Rate

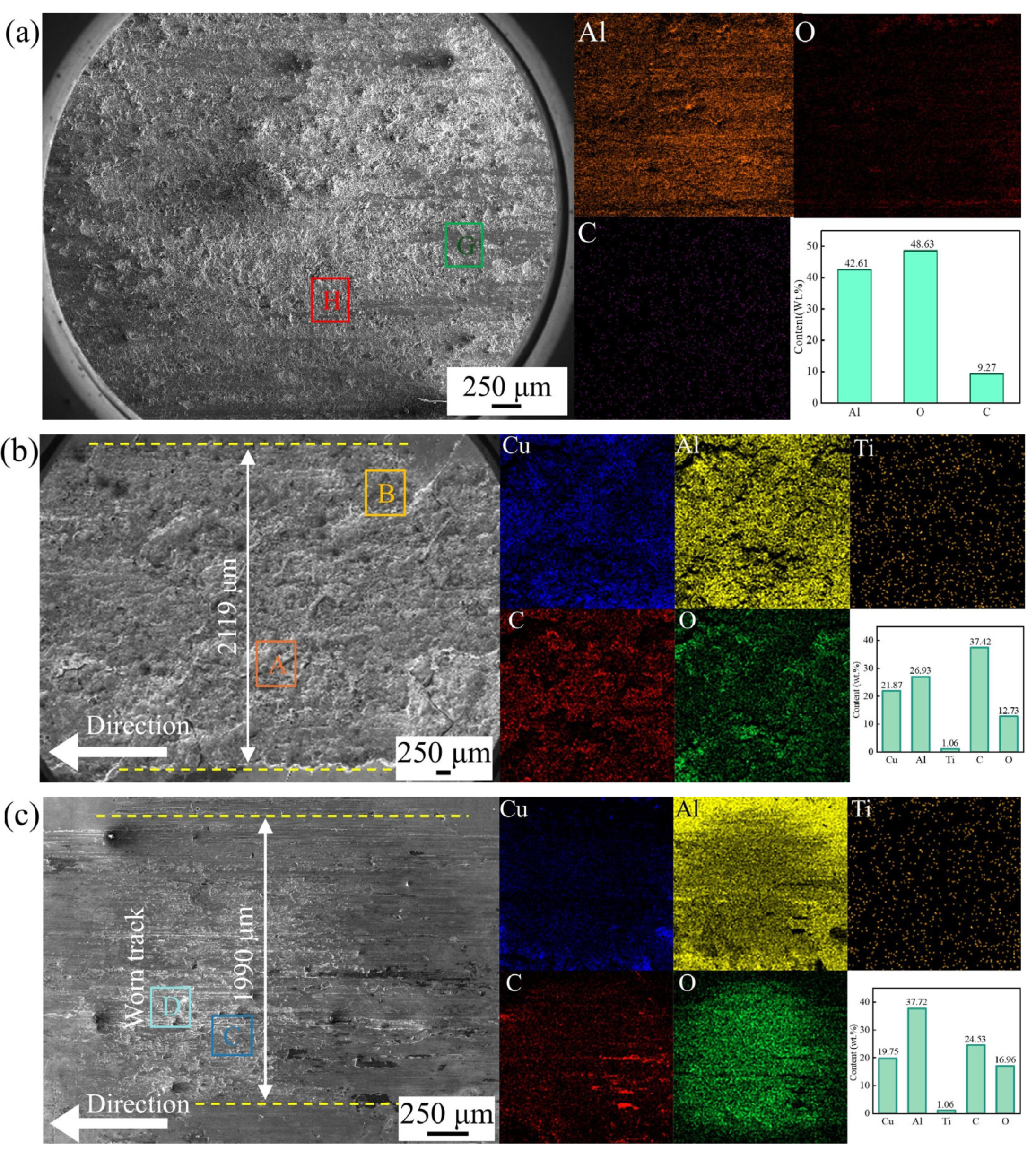

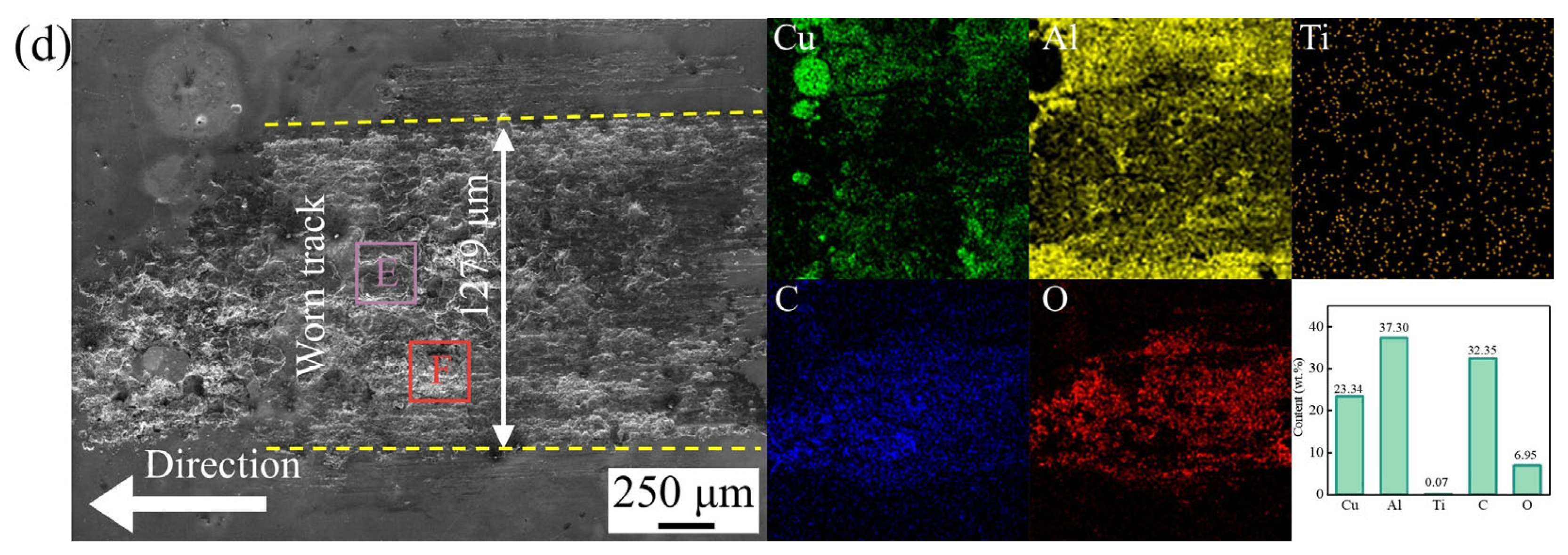

3.3.2. Current-Carrying Tribological Properties

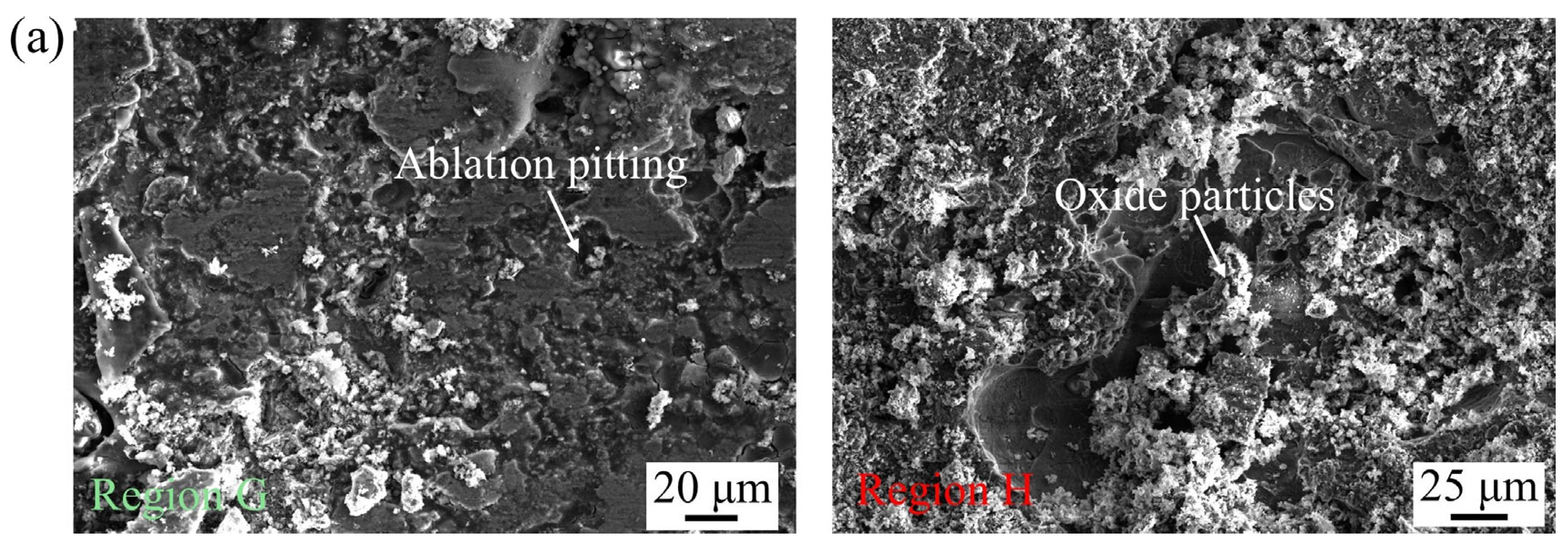

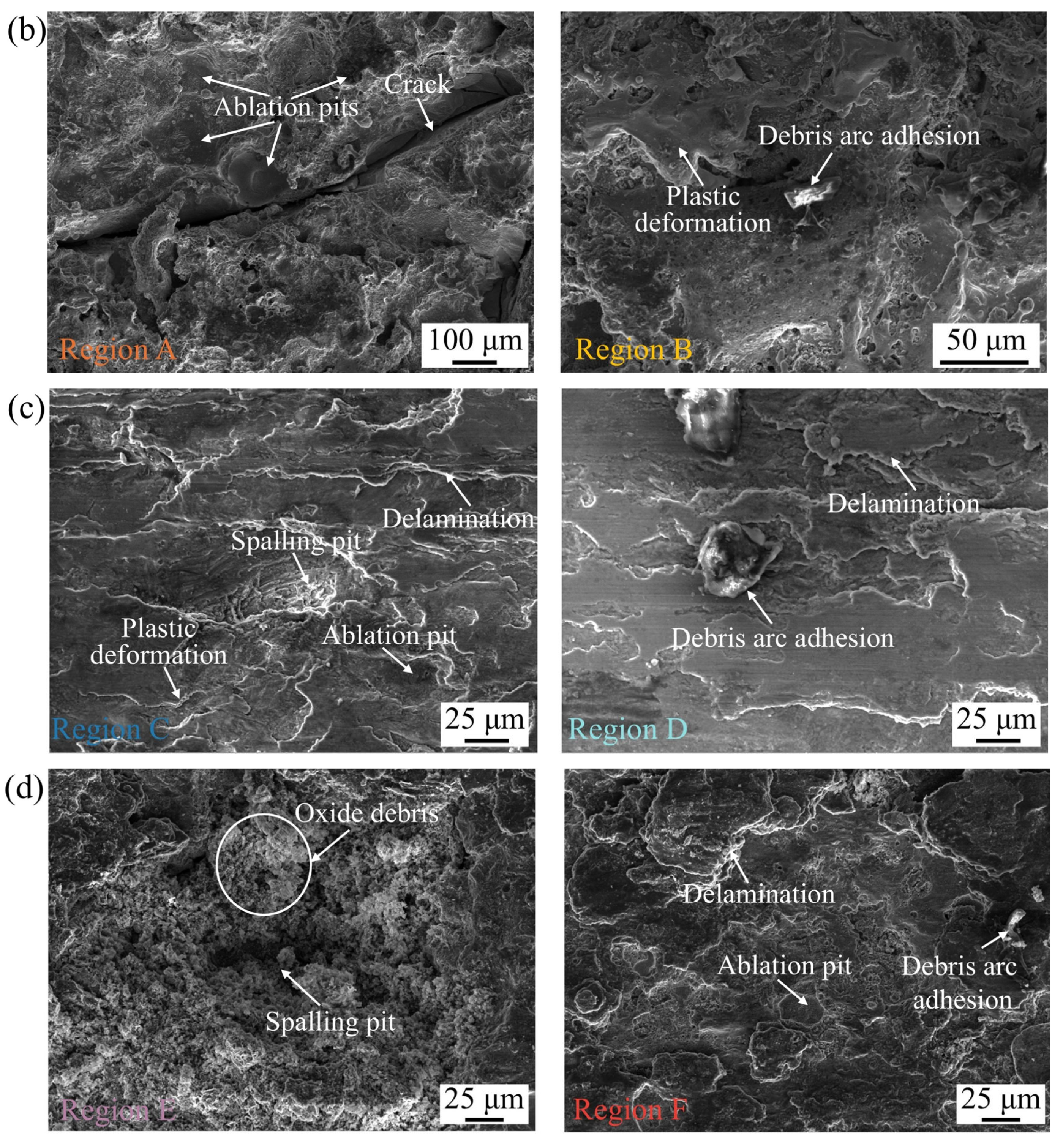

3.4. Failure Mechanism Analysis

4. Conclusions

- 1.

- Elevated scanning speeds effectively inhibit the formation of the CuAl2 phase on the Cu–TiC coating, while the content of the Cu2Al3 phase exhibits a corresponding increase, and the microstructure of the coating undergoes a progressive evolution from cellular and columnar crystals → columnar and equiaxed crystals → ultimately, fully equiaxed crystals with scanning speeds increasing from 86.4 mm/s to 149.7 mm/s. The highest coating quality is achieved at a scanning speed of 149.7 mm/s, but the rapid solidification due to the high scanning speed led to elemental segregation of the coating.

- 2.

- The Cu–TiC coating presents the best antifriction property and electrical conductivity when the scanning speed reaches 149.7 mm/s, showing the best wear resistance of all the tested coatings. The wear rates of the Cu–TiC coating at 149.7 mm/s are 4 × 10−3 mg·m−1, which are reduced by 16.7% compared to those of the substrate.

- 3.

- The plastic deformation of the Cu–TiC coatings is intensified by the randomly emerging arc erosion produced by the current, causing the wear mechanism of the coatings at different scanning speeds to comprise adhesive wear, oxidative wear, and electrical damage.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, P.; Yue, X.; Sun, Y.; Zhou, H.; Zhang, J.; Wang, Y. Research on the mechanism of microbial corrosion in the subsurface layer of 7075 aluminum alloy under different corrosion environments with ultra low temperature double increase effect. Vacuum 2024, 227, 113348. [Google Scholar] [CrossRef]

- Zhao, Q.; Guo, C.; Niu, K.; Zhao, J.; Huang, Y.; Li, X. Long–term corrosion behavior of the 7A85 aluminum alloy in an industrial-marine atmospheric environment. J. Mater. Res. Technol. 2021, 12, 1350–1359. [Google Scholar] [CrossRef]

- Wang, Z.-Z.; Min, S.-S.; Peng, F.; Shen, X.-R. Comparison of self–propulsion performance between vessels with single-screw propulsion and hybrid contra–rotating podded propulsion. Ocean Eng. 2021, 232, 109095. [Google Scholar] [CrossRef]

- Zuo, X.; Xie, W.; Zhou, Y. Influence of Electric Current on the Wear Topography of Electrical Contact Surfaces. J. Tribol. 2022, 144, 071702. [Google Scholar] [CrossRef]

- Zhao, H.; Feng, Y.; Zhou, Z.; Qian, G.; Zhang, J.; Huang, X.; Zhang, X. Effect of electrical current density, apparent contact pressure, and sliding velocity on the electrical sliding wear behavior of Cu–Ti3AlC2 composites. Wear 2020, 444–445, 203156. [Google Scholar] [CrossRef]

- Qian, G.; Feng, Y.; Chen, Y.-M.; Mo, F.; Wang, Y.-Q.; Liu, W.-H. Effect of WS2 addition on electrical sliding wear behaviors of Cu–graphite–WS2 composites. Trans. Nonferrous Met. Soc. China 2015, 25, 1986–1994. [Google Scholar] [CrossRef]

- Zhou, T.; Wang, X.; Qin, L.-X.; Qiu, W.-T.; Li, S.-F.; Jiang, Y.-B.; Jia, Y.-L.; Li, Z. Electrical sliding friction wear behaviors and mechanisms of Cu–Sn matrix composites containing MoS2/graphite. Wear 2024, 548–549, 205388. [Google Scholar] [CrossRef]

- Feng, J.; Liang, S.; Song, K.; Guo, X.; Zhou, Y. Micro–Nano Dual–Scale Particle–Reinforced TiB2/Cu–0.5Cr Composites Prepared by Vacuum Arc Melting. J. Mater. Eng. Perform. 2020, 29, 3353–3360. [Google Scholar] [CrossRef]

- Sankar, B.; Vinay, C.; Vishnu, J.; Shankar, K.V.; Gokul, G.P.K.; Govind, V.; Jayakrishna, A.J. Focused Review on Cu–Ni–Sn Spinodal Alloys: From Casting to Additive Manufacturing. Met. Mater. Int. 2023, 29, 1203–1228. [Google Scholar] [CrossRef]

- Pang, Y.; Miao, X.; Zhang, Q.; Chen, Z.; Hao, L.; Zhong, J.; Liang, S. Effect of graphene on the high–energy arc erosion performance of the W–Cu composite. Vacuum 2023, 210, 111827. [Google Scholar] [CrossRef]

- Cui, J.; Zhou, R.; Yang, W.; Zhang, C.; Gao, W.; He, J. Effect of Mg on microstructure and properties of Cu–Ni–Fe–P alloy with high strength and high conductivity. Mater. Today Commun. 2024, 41, 110513. [Google Scholar] [CrossRef]

- Gryguc, A.; Behravesh, S.B.; Jahed, H.; Wells, M.; Williams, B.; Gruber, R.; Duquett, A.; Sparrow, T.; Lambrou, M.; Su, X. Effect of Thermomechanical Processing Defects on Fatigue and Fracture Behaviour of Forged Magnesium. Frat. Integrità Strutturale 2020, 15, 213–227. [Google Scholar] [CrossRef]

- Zhu, Z.; Ren, X.; Jin, K.; Tan, H.; Zhu, S.; Cheng, J.; Guo, J.; Yang, J. Current–carrying tribological properties and wear mechanisms of Mo–containing Cu alloy coatings produced by laser cladding. Tribol. Int. 2024, 200, 110107. [Google Scholar] [CrossRef]

- Cao, Z.; Li, R.; Shou, M.; Luo, R.; Wei, B.; Wang, T. Mechanical properties and tribological behaviors of Ag/graphene composite coating under sliding friction and current–carrying fretting. Tribol. Int. 2024, 197, 109811. [Google Scholar] [CrossRef]

- Li, J.; Guo, Q.; Tang, Q.; Zhao, G.; Li, H.; Ma, L. Effect of electron beam remelting on microstructure and wear properties of HVOF Ni/WC coatings. Wear 2024, 558–559, 205560. [Google Scholar] [CrossRef]

- Chafjiri, Z.S.; Amir, A.-Z.; Seraj, R.-A.; Azarniya, A. Effect of cold spray processing parameters on the microstructure, wear, and corrosion behavior of Cu and Cu–Al2O3 coatings deposited on AZ31 alloy substrate. Results Eng. 2023, 20, 101594. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Y.; Tan, N.; Ma, G.; Li, G.; Cai, Y.; Wang, H. Electrical and current-carrying tribological properties of CoCrFeNi–(Mo, Ti, W) high-entropy alloy coatings on copper alloys by infrared-blue composite laser cladding. Surf. Coat. Technol. 2024, 494, 131357. [Google Scholar] [CrossRef]

- Grechanyuk, N.I.; Konoval, V.P.; Grechanyuk, V.G.; Bagliuk, G.A.; Myroniuk, D.V. Properties of Cu–Mo Materials Produced by Physical Vapor Deposition for Electrical Contacts. Powder Metall. Met. Ceram. 2021, 60, 183–190. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, Y.; Wu, Y.; Zhang, Z.; Liu, J.; Xie, S.; Deng, L.; Ge, C.; Chen, C.; Chen, H. Steel-based brake disc laser cladding coating preparation method and brake performance study. Eng. Failure Anal. 2025, 167, 108962. [Google Scholar] [CrossRef]

- Xiao, D.; Jiang, F.; Song, T.; Wei, C.; Zhang, Y.; Liang, P.; Yang, F. Impact of dilution on the microstructural evolution and corrosion Behavior in High-Entropy alloy coatings applied via laser cladding on marine engineering equipment. Eng. Failure Anal. 2025, 171, 109337. [Google Scholar] [CrossRef]

- Jiang, T.-H.; Zhou, S.; Pan, A.-X.; Che, Y.-H.; Li, G.-Q.; Xu, H.-J.; Gong, Y.; Yang, Z.-G. Failure analysis of the abnormal wear of rolling bearing in the centrifugal fan for nuclear power plant. Eng. Failure Anal. 2025, 171, 109353. [Google Scholar] [CrossRef]

- Yuan, J.; Yao, Y.; Zhuang, M.; Du, Y.; Wang, L.; Yu, Z. Effects of Cu and WS2 addition on microstructural evolution and tribological properties of self–lubricating anti–wear coatings prepared by laser cladding. Tribol. Int. 2021, 157, 106872. [Google Scholar] [CrossRef]

- Liang, Q.; Xu, Y.; Xu, B.; Du, Y. Parameter optimization for in-situ synthesized TiB2/TiC particle composite coatings by laser cladding based on OOA–RFR and U–NSGA–III. Opt. Laser Technol. 2025, 181, 111755. [Google Scholar] [CrossRef]

- Chen, G.-D.; Liu, X.-B.; Yang, C.-M.; Zhang, F.-Z.; Li, X.-G.; Zheng, J.; Liu, J. Strengthening mechanisms of laser cladding TiC/FeCoCrNiCu high–entropy composite coatings: Microstructure evolution and wear behaviors. Tribol. Int. 2024, 199, 109979. [Google Scholar] [CrossRef]

- Li, Y.; Yuan, X.; Chen, Y.; Yang, G.; Ou, W.; Li, T. Improved microstructure and wear resistance of (CoCrNi)82Al9Ti9 cladding layers via extreme high-speed laser cladding. Surf. Coat. Technol. 2024, 49, 131298. [Google Scholar] [CrossRef]

- Liang, Y.; Liao, Z.Y.; Zhang, L.L.; Cai, M.W.; Wei, X.S.; Shen, J. A review on coatings deposited by extreme high–speed laser cladding: Processes, materials, and properties. Opt. Laser Technol. 2023, 164, 109472. [Google Scholar] [CrossRef]

- Yuan, W.; Zhu, L.; Luo, C.; Liu, H.; Chen, Z.; He, Y.; Han, E. Enhanced CO2 separation properties by incorporating acid-functionalized graphene oxide into polyimide membrane. High Perform. Polym. 2021, 33, 405–416. [Google Scholar] [CrossRef]

- Fu, J.; Gui, W.; Qin, J.; Lin, J.; Ren, X.; Luan, B. High–speed laser–clad 3533-00 Fe–based cemented carbide coatings on nuclear power valve sealing surface to enhanced wear and corrosion resistance. Surf. Coat. Technol. 2024, 480, 130594. [Google Scholar] [CrossRef]

- Jian, Y.; Liu, Y.; Qi, H.; He, P.; Huang, G.; Huang, Z. Effects of scanning speed on the microstructure, hardness and corrosion properties of high–speed laser cladding Fe–based stainless coatings. J. Mater. Res. Technol. 2024, 29, 3380–3392. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, C.; Qu, F.; Liu, L.; Liu, X. Fe–based metallic glass coatings with suppressed cracks and enhanced wear resistance prepared by extreme high–speed laser cladding. Intermetallics 2024, 175, 108517. [Google Scholar] [CrossRef]

- Cheng, S.; Zhou, Y.; Zuo, X. Effect of scanning speed on wear and corrosion behaviors of high-speed laser-cladded Cu-TiC coating. Metals. 2025, 15, 641. [Google Scholar] [CrossRef]

- Wang, X.; Song, K.; Duan, J.; Feng, J.; Huang, T.; Xing, J. Current-carrying tribological behavior and wear mechanism of CuW composites with different W content. Tribol. Int. 2024, 200, 110125. [Google Scholar] [CrossRef]

- Cui, C.; Wu, M.P.; Miao, X.J.; Gong, Y.L.; Zhao, Z.S. The effect of laser energy density on the geometric characteristics, microstructure and corrosion resistance of Co–based coatings by laser cladding. J. Mater. Res. Technol. 2021, 15, 2405–2418. [Google Scholar] [CrossRef]

- Limmaneevichitr, C.; Kou, S. Experiments to simulate effect of Marangoni convection on weld pool shape. Weld. J. 2000, 79, 8. [Google Scholar]

- Cui, N.; Zhao, T.; Wang, Z.; Zhao, Y.; Chao, Y.; Lin, H.; Li, D. Strengthening Effect on Microstructures and Properties with CuAl2 and Mg2Si in Forged 2A50 Alloy Under Different T6 Heat Treatment. J. Alloys Compd. 2025, 1010, 178310. [Google Scholar] [CrossRef]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1987. [Google Scholar]

- Da, H.H.; Manory, R.; Sinkis, H. A sliding wear tester for overhead wires and current collectors in light rail systems. Wear 2000, 239, 10–20. [Google Scholar] [CrossRef]

- Wang, Y.; Li, J.; Yan, Y.; Qiao, L. Effect of electrical current on tribological behavior of copper-impregnated metallized carbon against a Cu–Cr–Zr alloy. Tribol. Int. 2012, 50, 26–34. [Google Scholar] [CrossRef]

- Fu, Y.; Qin, H.; Xu, X.; Zhang, X.; Guo, Z. What are the Progresses and Challenges, from the Electrical Properties of Current-Carrying Friction System to Tribological Performance, for a Stable Current-Carrying Interface. J. Bio- Tribo-Corros. 2022, 8, 4. [Google Scholar] [CrossRef]

- Nagasawa, H.; Kato, K. Wear mechanism of copper alloy wire sliding against iron-base strip under electric current. Wear 1998, 216, 179–183. [Google Scholar] [CrossRef]

- Guo, F.; Wang, Z.; Zheng, Z.; Zhang, J.; Wang, H. Electromagnetic noise of pantograph arc under low current conditions. Int. J. Appl. Electrom. 2016, 53, 397–408. [Google Scholar] [CrossRef]

- Dow, T.A.; Kannel, J.W. Thermomechanical effects in high current density electrical slip rings. Wear 1982, 79, 93–105. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, Z.; Song, K.; Pang, X. Shangguan, Triboelectric behaviors of materials under high speeds and large currents. Friction 2013, 1, 259–270. [Google Scholar] [CrossRef]

| Element | Al | Zn | Cr | Mg | Mn | Cu | Fe | Si |

|---|---|---|---|---|---|---|---|---|

| Content | Bal. | 5.10–6.10 | 0.18–0.28 | 2.10–2.90 | 0.30 | 1.20–2.00 | 0.50 | 0.40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, S.; Zhou, Y.; Zuo, X. Current-Carrying Wear Behavior of Cu–TiC Coatings Obtained Through High-Speed Laser Cladding on Conductive Slip Rings of 7075 Aluminum Alloy. Metals 2025, 15, 688. https://doi.org/10.3390/met15070688

Cheng S, Zhou Y, Zuo X. Current-Carrying Wear Behavior of Cu–TiC Coatings Obtained Through High-Speed Laser Cladding on Conductive Slip Rings of 7075 Aluminum Alloy. Metals. 2025; 15(7):688. https://doi.org/10.3390/met15070688

Chicago/Turabian StyleCheng, Shiya, Yuankai Zhou, and Xue Zuo. 2025. "Current-Carrying Wear Behavior of Cu–TiC Coatings Obtained Through High-Speed Laser Cladding on Conductive Slip Rings of 7075 Aluminum Alloy" Metals 15, no. 7: 688. https://doi.org/10.3390/met15070688

APA StyleCheng, S., Zhou, Y., & Zuo, X. (2025). Current-Carrying Wear Behavior of Cu–TiC Coatings Obtained Through High-Speed Laser Cladding on Conductive Slip Rings of 7075 Aluminum Alloy. Metals, 15(7), 688. https://doi.org/10.3390/met15070688