Impact of High Contact Stress on the Wear Behavior of U75VH Heat-Treated Rail Steels Applied for Turnouts

Abstract

1. Introduction

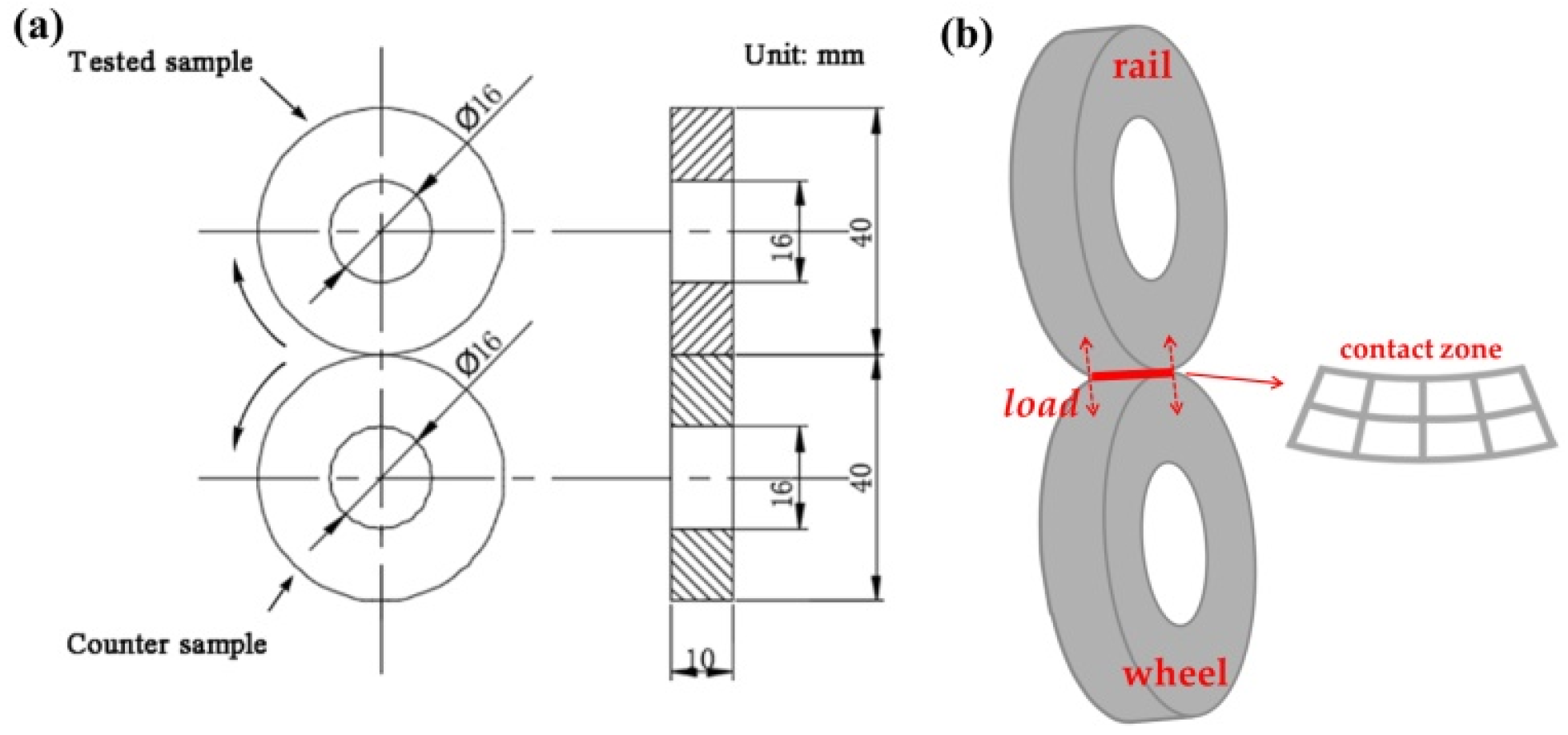

2. Materials and Methods

3. Results and Discussion

3.1. Wear Weight Loss

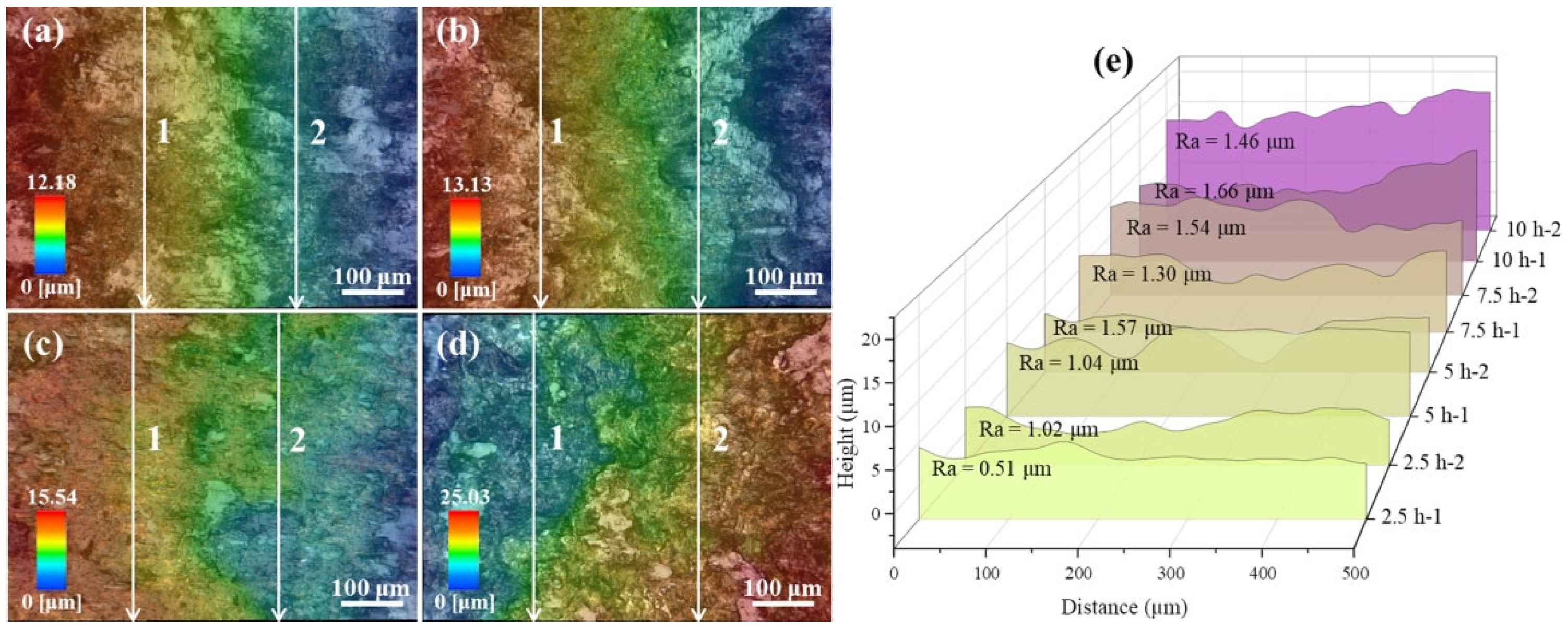

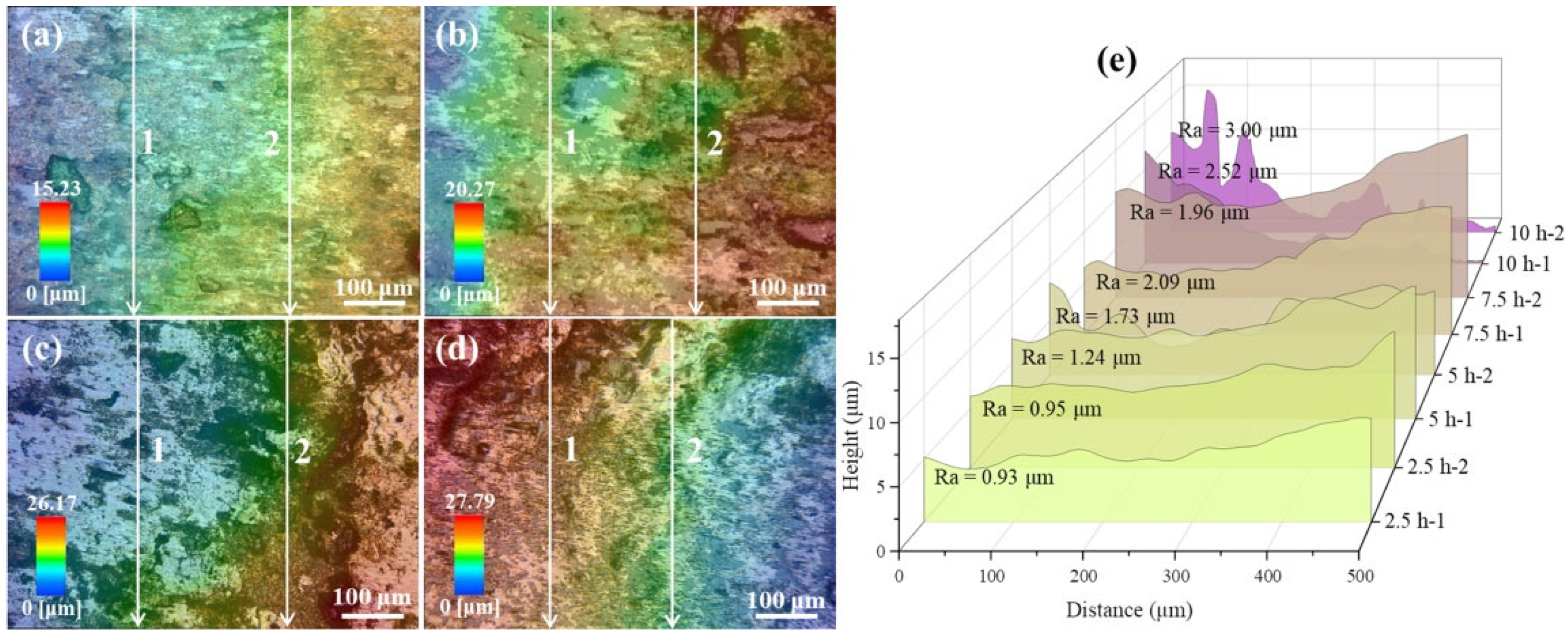

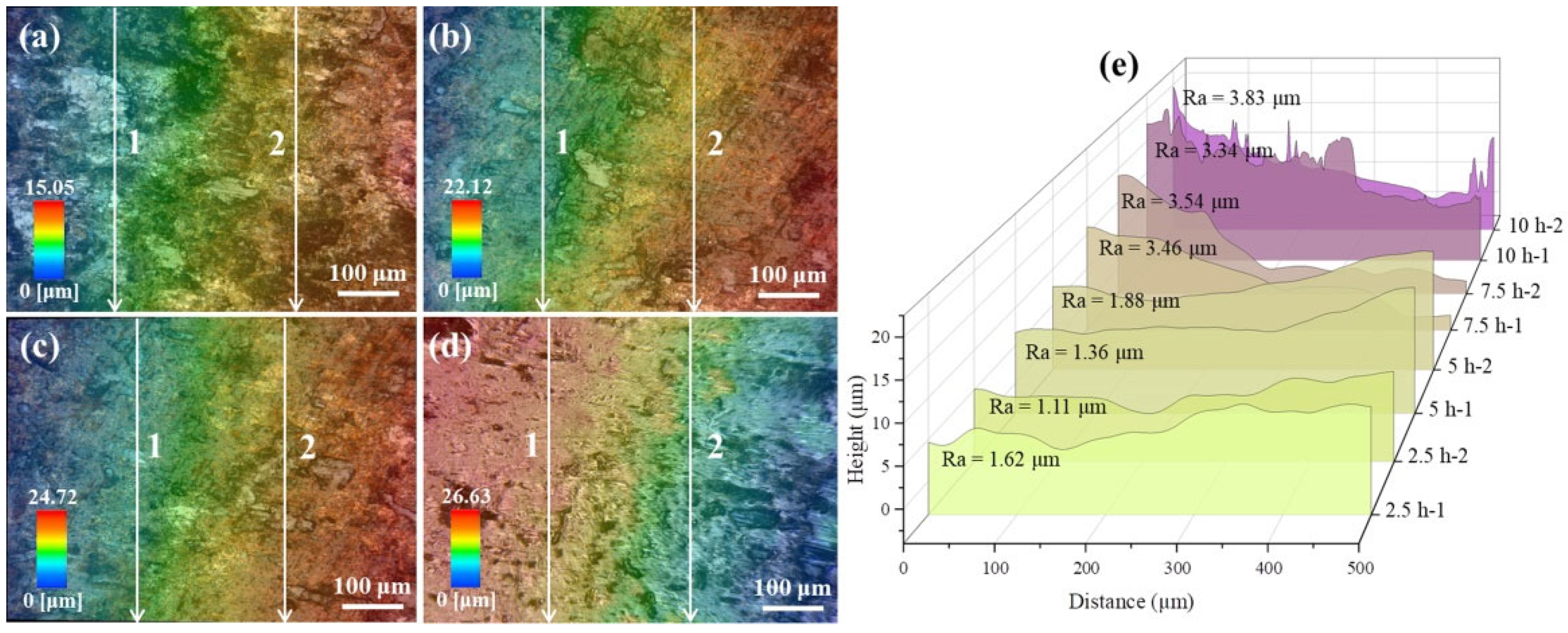

3.2. Worn Surface Morphology

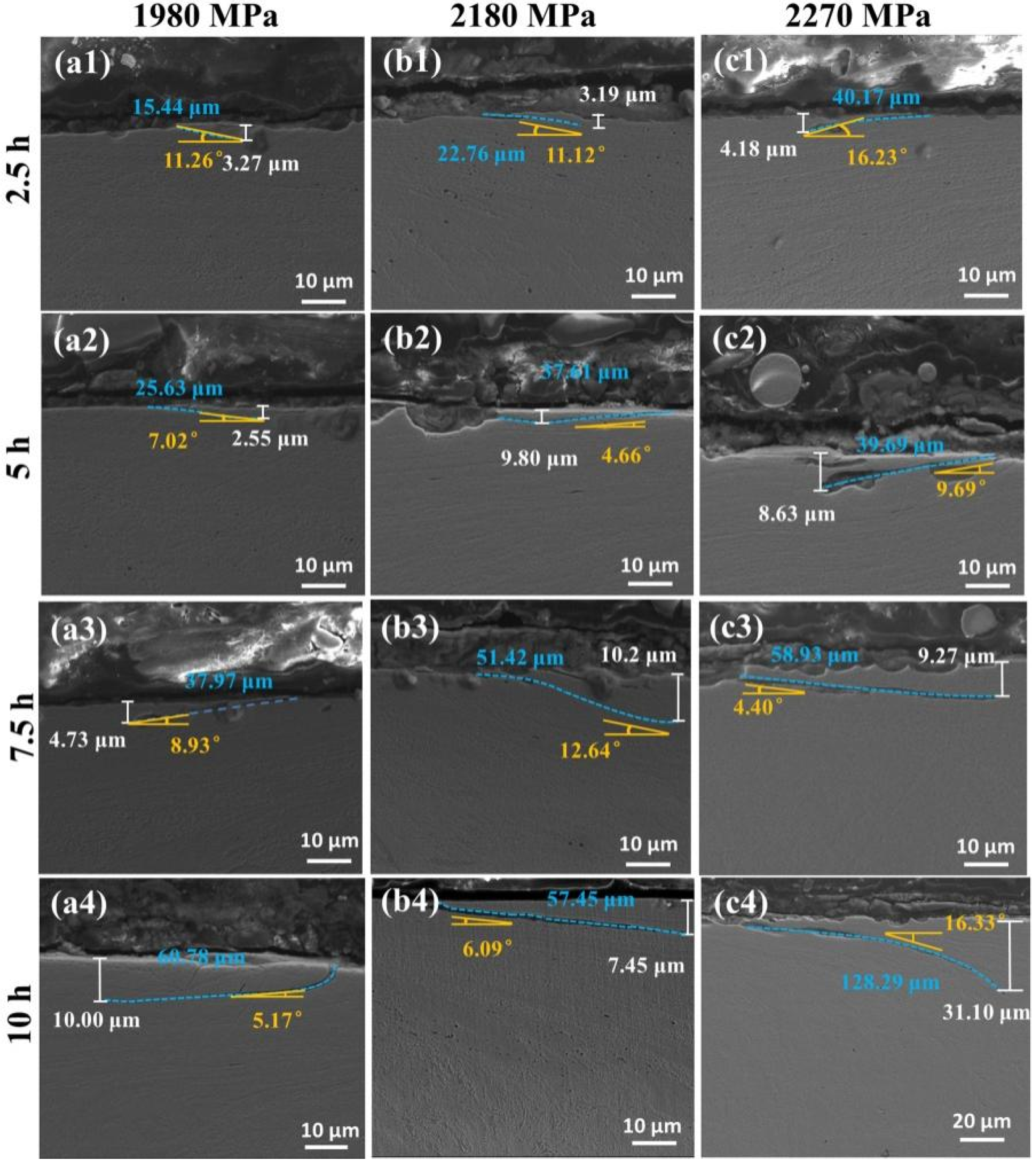

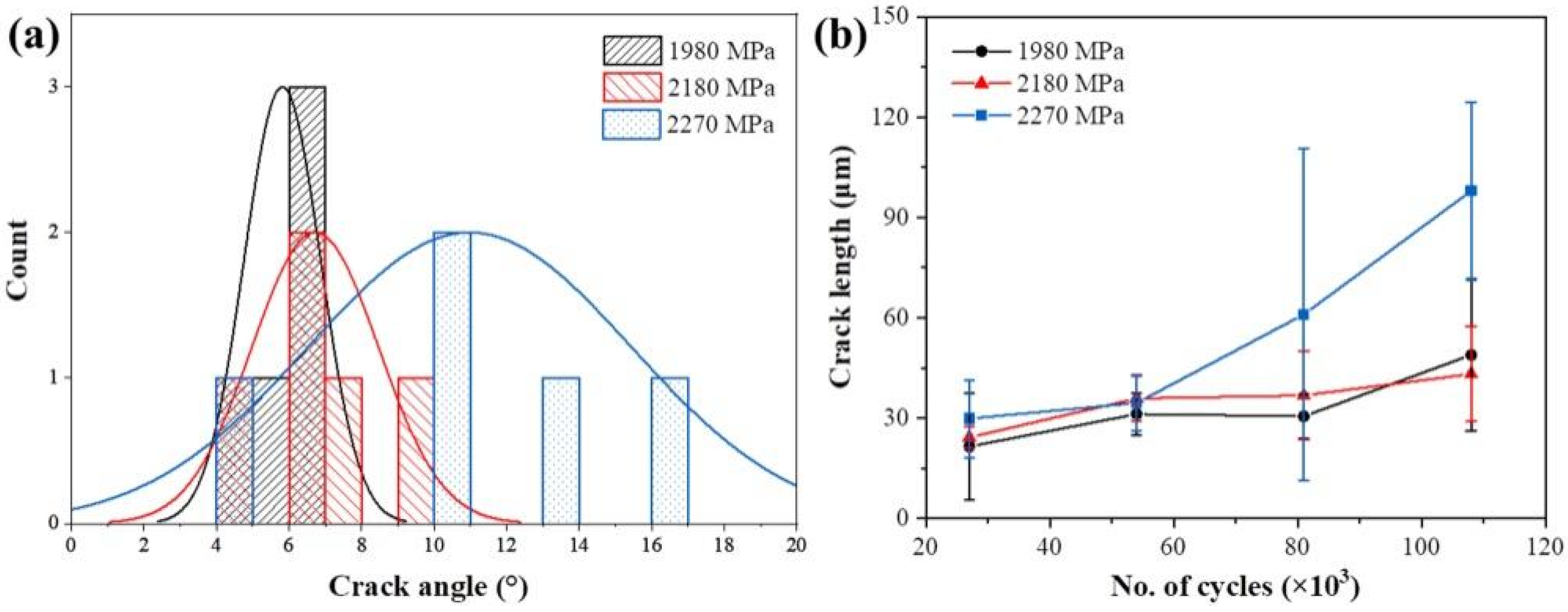

3.3. Fatigue Crack

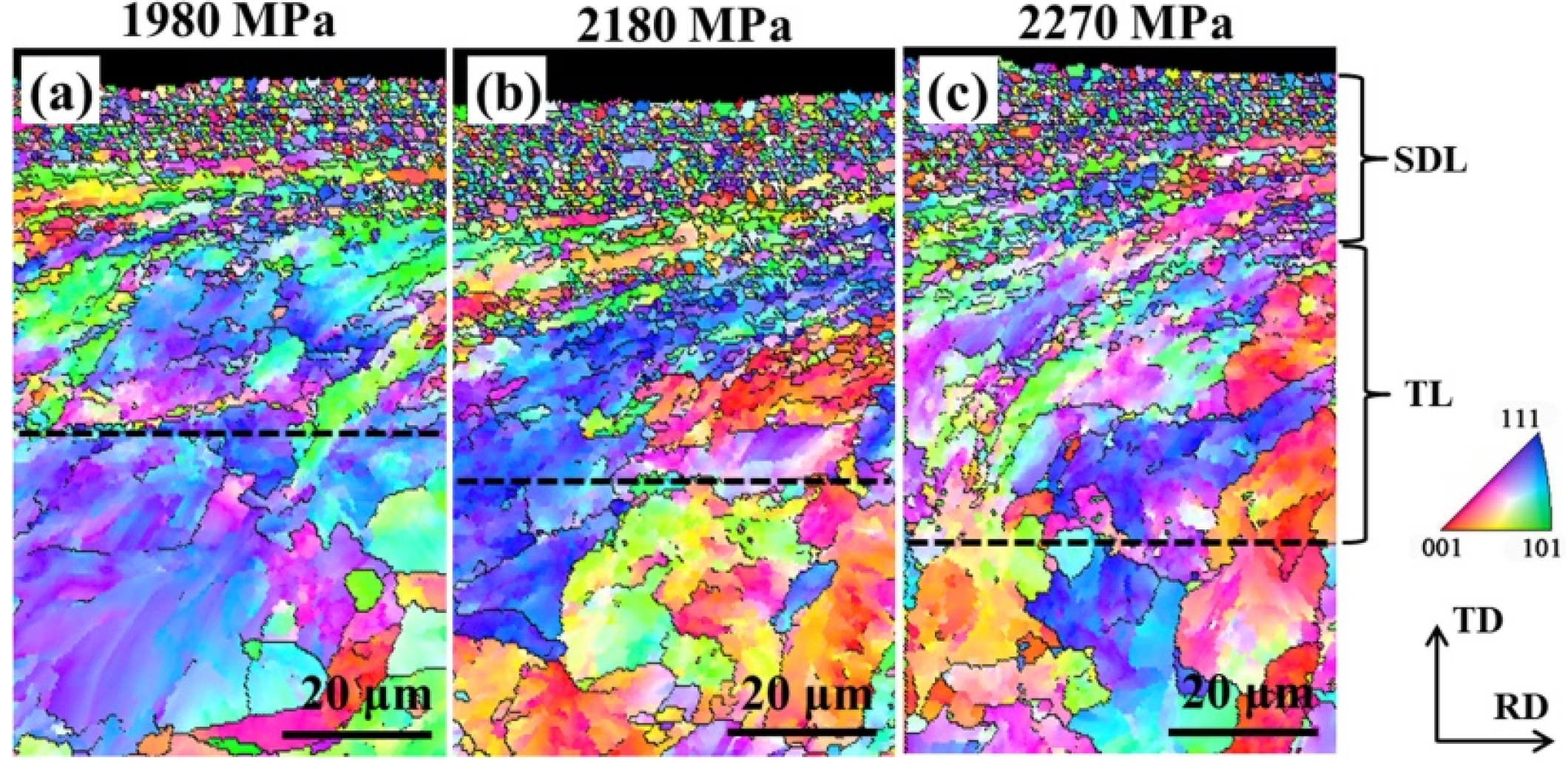

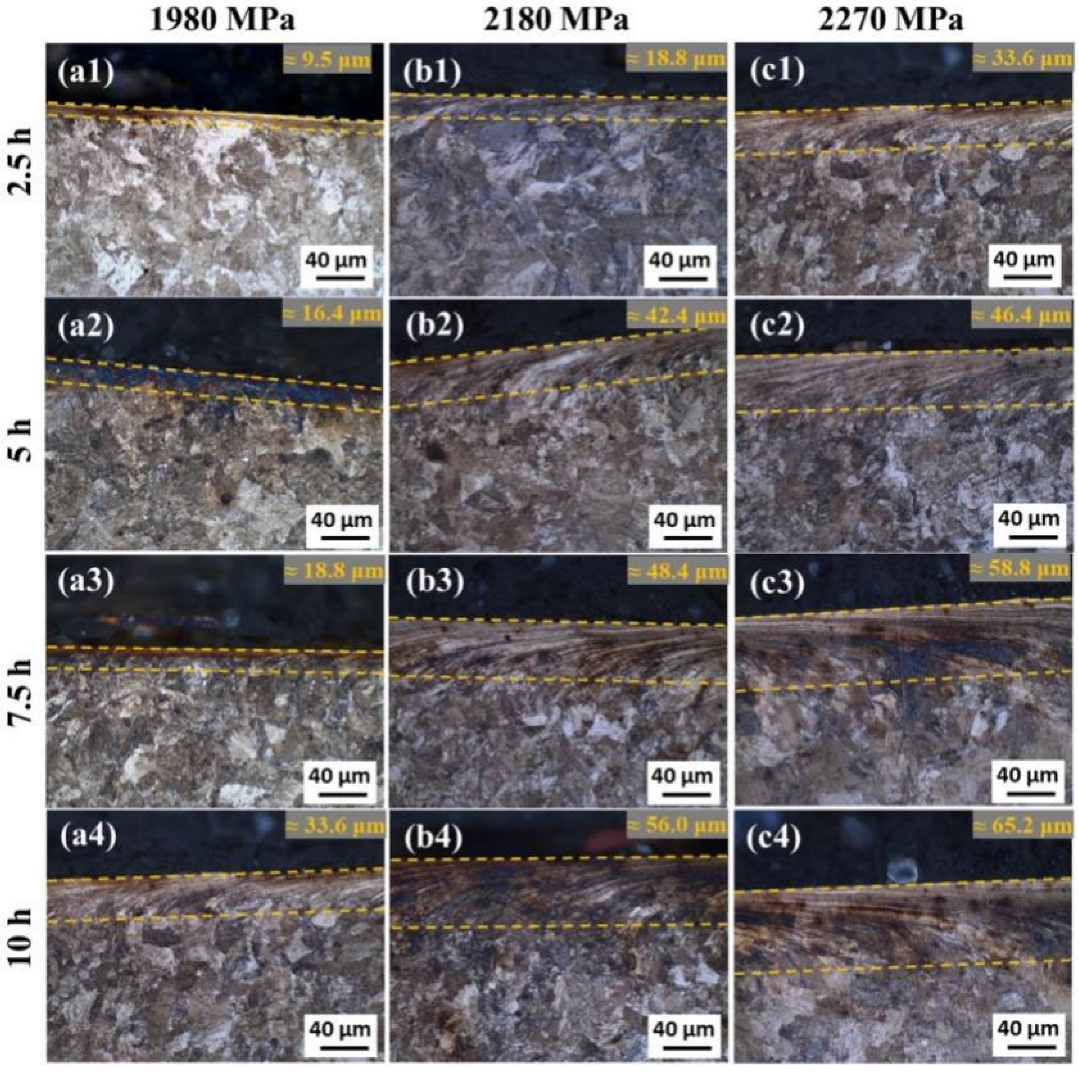

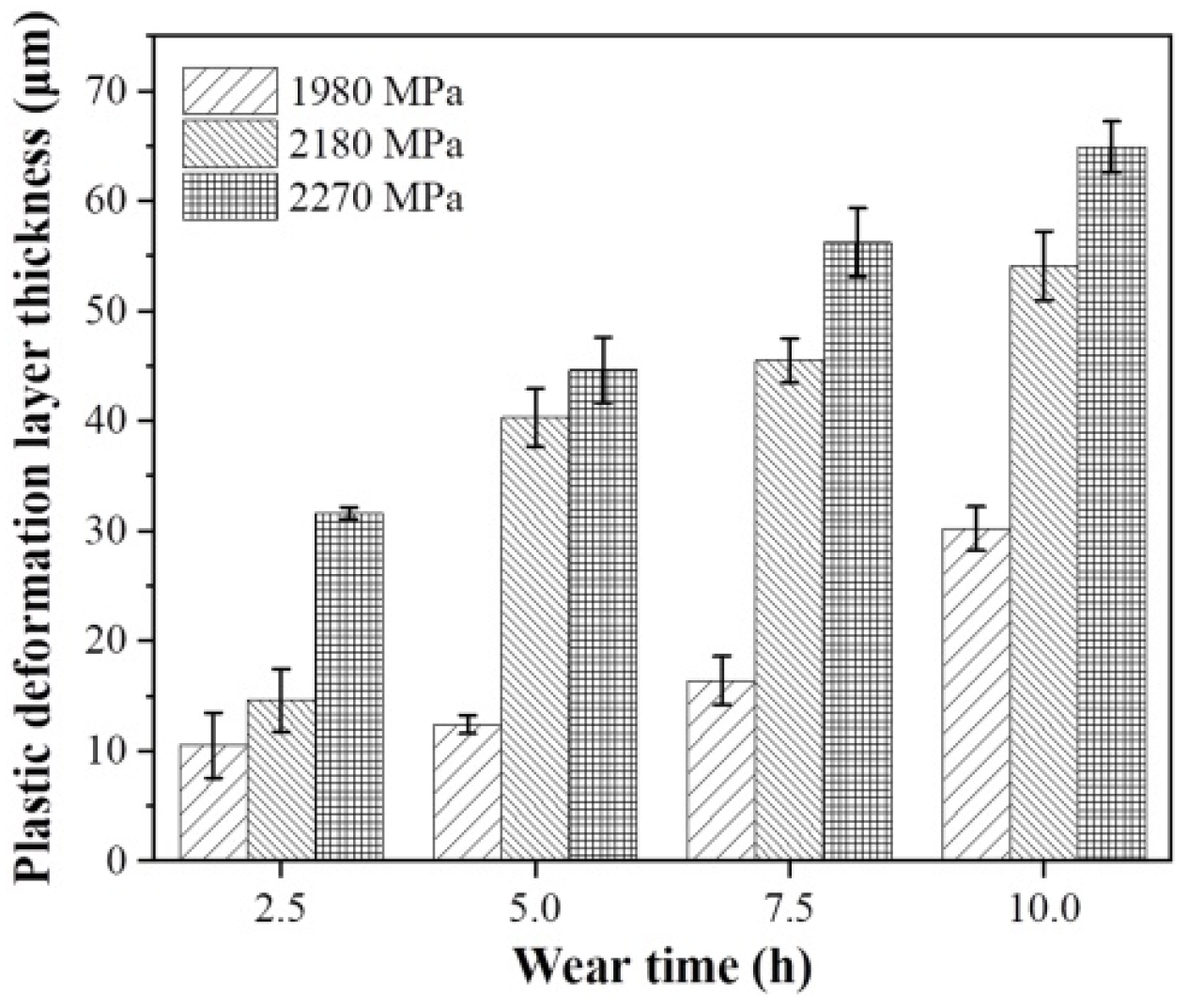

3.4. Plastic Deformation Layer

4. Conclusions

- (1)

- With increasing wear time, the crack length and depth increased significantly. Additionally, as contact stress increased, the energy available for crack propagation increased, making it easier for cracks to develop into the material at larger angles. This resulted in longer, deeper cracks with larger propagation angles and more severe fatigue wear, highlighting a significant stress concentration near the contact surface.

- (2)

- The wear weight loss increased with both wear time and contact stress. At a given contact stress, the wear rate increased with increasing wear time. The wear resistance increased with time and eventually tended to stabilize. Additionally, the wear rate of the rail samples showed a nearly linear increase as the contact stress increased.

- (3)

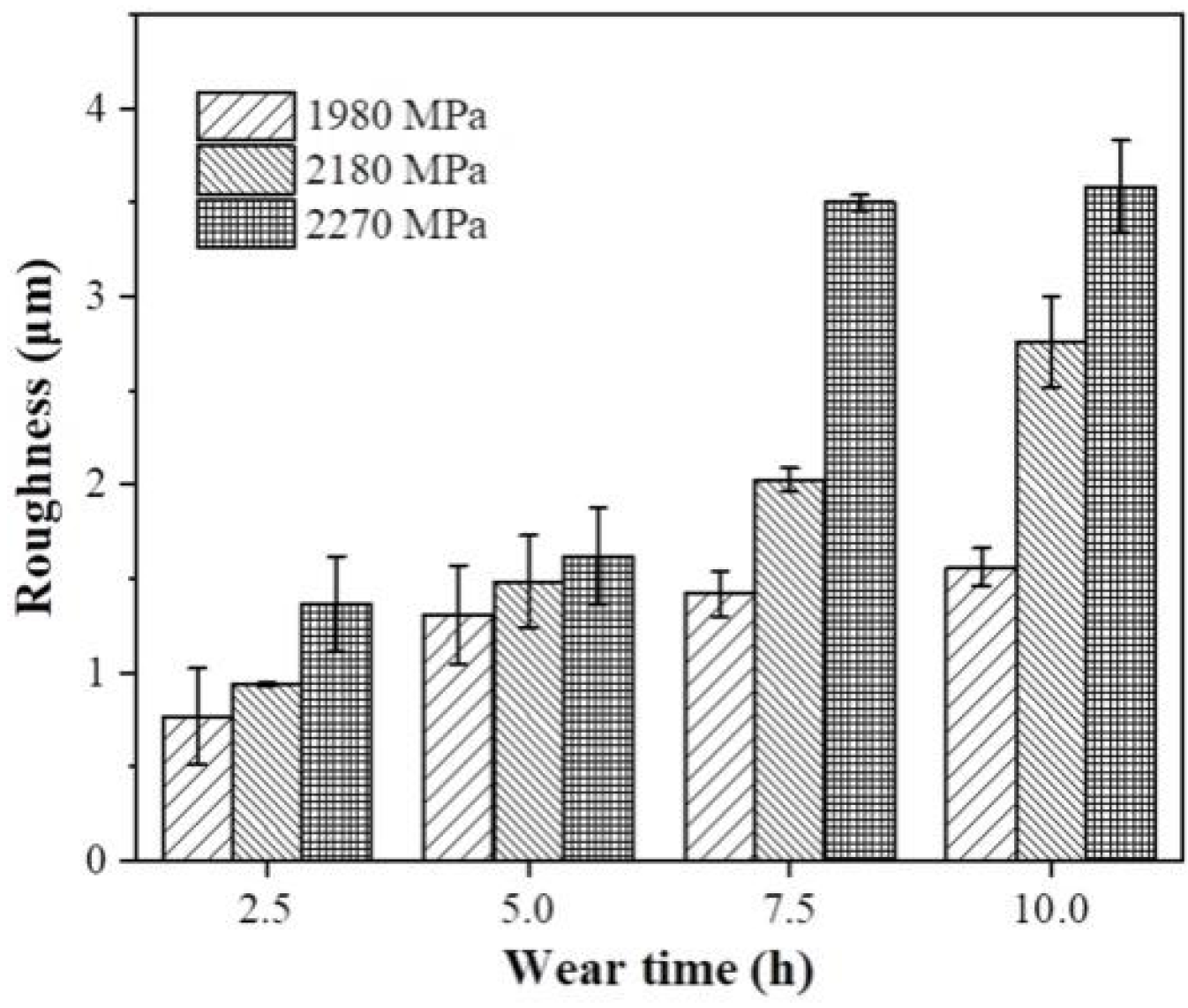

- As wear time and contact stress increased, the worn surface exhibited more pronounced spalling and extensive spalling pits. The wear degree of the rail sample surface increased significantly, leading to higher roughness. Moreover, the severity of adhesive and abrasive wear increased.

- (4)

- The thickness of the plastic deformation layer increased with increasing wear time. Moreover, at the same wear time, the thickness of the plastic deformation layer gradually increased with increasing contact stress. The surface hardness was dependent on the thickness of the plastic deformation layer.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| OM | Optical microscopy |

| SEM | Scanning electron microscope |

| EBSD | Electron backscatter diffraction |

| TRIP | Transformation induced plasticity |

| SDL | Severely deformed layer |

| TL | Transition layer |

| IPF | Inverse pole figure |

References

- Ramalho, A. Wear Modelling in Rail–Wheel Contact. Wear 2015, 330–331, 524–532. [Google Scholar] [CrossRef]

- Soleimani, H.; Moavenian, M. Tribological Aspects of Wheel–Rail Contact: A Review of Wear Mechanisms and Effective Factors on Rolling Contact Fatigue. Urban Rail Transit 2017, 3, 227–237. [Google Scholar] [CrossRef]

- Solano-Alvarez, W.; Bhadeshia, H.K.D.H. Steels for Rails. Prog. Mater. Sci. 2024, 146, 101313. [Google Scholar] [CrossRef]

- Chen, G.; Rahimi, R.; Xu, G.; Biermann, H.; Mola, J. Impact of Al Addition on Deformation Behavior of Fe–Cr–Ni–Mn–C Austenitic Stainless Steel. Mater. Sci. Eng. A 2020, 797, 140084. [Google Scholar] [CrossRef]

- Chen, G.; Xu, G.; Biermann, H.; Mola, J. Microstructure and Mechanical Properties of Co-Added and Al-Added Austenitic Stainless Steels. Mater. Sci. Eng. A 2022, 854, 143832. [Google Scholar] [CrossRef]

- Chen, G.; Hu, H.; Xu, G.; Tian, J.; Wan, X.; Wang, X. Optimizing Microstructure and Property by Ausforming in a Medium-Carbon Bainitic Steel. ISIJ Int. 2020, 60, 2007–2014. [Google Scholar] [CrossRef]

- Tian, J.; Wang, W.; Xu, G.; Wang, X.; Zhou, M.; Zurob, H. Microstructure and Properties of a Low Carbon Bainitic Steel Produced by Conventional and Inverted Two-Step Austempering Processes. Met. Mater. Int. 2023, 29, 1298–1310. [Google Scholar] [CrossRef]

- Adamczyk-Cieślak, B.; Koralnik, M.; Kuziak, R.; Majchrowicz, K.; Mizera, J. Studies of Bainitic Steel for Rail Applications Based on Carbide-Free, Low-Alloy Steel. Metall. Mater. Trans. A 2021, 52, 5429–5442. [Google Scholar] [CrossRef]

- Masoumi, M.; Tressia, G.; Centeno, D.M.A. Hélio Goldenstein Improving the Mechanical Properties and Wear Resistance of a Commercial Pearlitic Rail Steel Using a Two-Step Heat Treatment. Metall. Mater. Trans. A 2021, 52, 4888–4906. [Google Scholar] [CrossRef]

- Su, X.; Xu, G.; Zhu, M.; Zhang, Q.; Cai, F.; Liu, M. Investigation on the Interaction between Corrosion and Wear of U68CuCr Rail Steel with Different Corrosion Periods. Wear 2023, 516–517, 204598. [Google Scholar] [CrossRef]

- Fei, J.; Zhou, G.; Zhou, J.; Zhou, X.; Li, Z.; Zuo, D.; Wu, R. Research on the Effect of Pearlite Lamellar Spacing on Rolling Contact Wear Behavior of U75V Rail Steel. Metals 2023, 13, 237. [Google Scholar] [CrossRef]

- Xu, J.; Wang, P.; Wang, L.; Chen, R. Effects of Profile Wear on Wheel–Rail Contact Conditions and Dynamic Interaction of Vehicle and Turnout. Adv. Mech. Eng. 2016, 8, 1–14. [Google Scholar] [CrossRef]

- Wang, P.; Xu, J.; Xie, K.; Chen, R. Numerical Simulation of Rail Profiles Evolution in the Switch Panel of a Railway Turnout. Wear 2016, 366–367, 105–115. [Google Scholar] [CrossRef]

- Aquib Anis, M.; Srivastava, J.P.; Duhan, N.R.; Sarkar, P.K. Rolling Contact Fatigue and Wear in Rail Steels: An Overview. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Melbourne, Australia, 15–16 September 2018; Volume 377, p. 012098. [Google Scholar]

- Wang, R.; Chen, G.; Xu, N.; Chen, Z.; Zhu, M.; Xu, G. Synergistic Behavior of Salt Spray Corrosion and Fatigue Wear of U75VH Pearlite Heat-Treated Rail. Mater. Today Commun. 2025, 47, 113059. [Google Scholar] [CrossRef]

- Seo, J.-W.; Jun, H.-K.; Kwon, S.-J.; Lee, D.-H. Rolling Contact Fatigue and Wear of Two Different Rail Steels under Rolling–Sliding Contact. Int. J. Fatigue 2016, 83, 184–194. [Google Scholar] [CrossRef]

- Fletcher, D.I.; Beynon, J.H. The Effect of Contact Load Reduction on the Fatigue Life of Pearlitic Rail Steel in Lubricated Rolling–Sliding Contact. Fatigue Fract. Eng. Mater. Struct. 2000, 23, 639–650. [Google Scholar] [CrossRef]

- Hu, Y.; Guo, L.C.; Maiorino, M.; Liu, J.P.; Ding, H.H.; Lewis, R.; Meli, E.; Rindi, A.; Liu, Q.Y.; Wang, W.J. Comparison of Wear and Rolling Contact Fatigue Behaviours of Bainitic and Pearlitic Rails under Various Rolling-Sliding Conditions. Wear 2020, 460–461, 203455. [Google Scholar] [CrossRef]

- Zhang, S.; Spiryagin, M.; Lin, Q.; Ding, H.; Wu, Q.; Guo, J.; Liu, Q.; Wang, W. Study on Wear and Rolling Contact Fatigue Behaviours of Defective Rail under Different Slip Ratio and Contact Stress Conditions. Tribol. Int. 2022, 169, 107491. [Google Scholar] [CrossRef]

- Wang, H.; Ding, H.; Zhang, S.; Shi, Z.; Meli, E.; Wang, W.; Lewis, R.; Liu, Q.; Zhou, Z. Quantitative Characterization of the Relationship between Wear and Rolling Contact Fatigue of Rail Material. Wear 2025, 578–579, 206169. [Google Scholar] [CrossRef]

- Taleff, E.M.; Syn, C.K.; Lesuer, D.R.; Sherby, O.D. Pearlite in Ultrahigh Carbon Steels: Heat Treatments and Mechanical Properties. Metall. Mater. Trans. A 1996, 27, 111–118. [Google Scholar] [CrossRef]

- Zhang, G.-H.; Chae, J.-Y.; Kim, K.-H.; Suh, D.W. Effects of Mn, Si and Cr Addition on the Dissolution and Coarsening of Pearlitic Cementite during Intercritical Austenitization in Fe-1mass%C Alloy. Mater. Charact. 2013, 81, 56–67. [Google Scholar] [CrossRef]

- Min, N.; Zhu, Y.; Fan, S.; Xiao, Y.; Zhou, L.; Li, W.; Zhao, S. Synergistic Effect of Alloying on the Strength and Ductility of High Carbon Pearlitic Steel. Metals 2023, 13, 1535. [Google Scholar] [CrossRef]

- Liu, J.; Guo, K.; Ma, H.; He, J.; Wang, J.; Zhang, C.; Wang, T.; Wang, Q. Microstructural Evolution and Tensile Properties of Nb-V-Ti-N Microalloyed Steel with Varying Nitrogen Contents. Metals 2025, 15, 266. [Google Scholar] [CrossRef]

- Wen, H.; Wang, Q.; Dou, Y.; Wang, Q.; Xu, X.; Wang, Q. Comparison of Strengthening Mechanism of the Nb, V, and Nb-V Micro-Alloyed High-Strength Bolt Steels Investigated by Microstructural Evolution and Strength Modeling. Metals 2024, 14, 1309. [Google Scholar] [CrossRef]

- Gao, Y. Research on Transient Wheel-Rail Friction Contact Behavior and Non-Uniform Wear in Turnout Switch Panel. Ph.D. Thesis, Southwest Jiaotong University, Chengdu, China, 2021. (In Chinese). [Google Scholar]

- Wu, Y.; Zhao, J.; Miao, H.; Zhang, X.; Wen, Z.; Xu, J.; Wang, P.; Kan, Q. 3D Rolling Contact Finite Element Analysis of High-Speed Railway Turnout Considering Ratchetting Effect. Eng. Fail. Anal. 2024, 160, 108171. [Google Scholar] [CrossRef]

- Burgelman, N.; Li, Z.; Dollevoet, R. A New Rolling Contact Method Applied to Conformal Contact and the Train–Turnout Interaction. Wear 2014, 321, 94–105. [Google Scholar] [CrossRef]

- Wang, W.J.; Wang, H.; Wang, H.Y.; Guo, J.; Liu, Q.Y.; Zhu, M.H.; Jin, X.S. Sub-Scale Simulation and Measurement of Railroad Wheel/Rail Adhesion under Dry and Wet Conditions. Wear 2013, 302, 1461–1467. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and Rubbing of Flat Surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Andersson, J.; Almqvist, A.; Larsson, R. Numerical Simulation of a Wear Experiment. Wear 2011, 271, 2947–2952. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, W.J.; Watson, M.; Six, K.; Al-Maliki, H.; Meierhofer, A.; Lewis, R. Wear of Driving versus Driven Discs in a Twin Disc Rolling-Sliding Test. Wear 2023, 512–513, 204528. [Google Scholar] [CrossRef]

- Liu, J. Experimental Research on Rolling Wear and Contact Fatigue Damage Behaviors of Wheel/Rail Materials. Ph.D. Thesis, Southwest Jiaotong University, Chengdu, China, 2016. (In Chinese). [Google Scholar]

- Li, J.; Zhou, Y.; Cheng, Z.; Wang, C.; Weng, Z.-Y. Evolution of Microscopic Characteristics of Rolling Contact Fatigue Coexisting with Wear of U75V Rail. Tribol. Int. 2023, 190, 109041. [Google Scholar] [CrossRef]

- Paris, P.C. A Rational Analytic Theory of Fatigue. Trends Eng. 1961, 13, 9–14. [Google Scholar]

- Mazzù, A.; Petrogalli, C.; Lancini, M.; Ghidini, A.; Faccoli, M. Effect of Wear on Surface Crack Propagation in Rail–Wheel Wet Contact. J. Mater. Eng. Perform. 2018, 27, 630–639. [Google Scholar] [CrossRef]

- Kráčalík, M.; Trummer, G.; Daves, W. Application of 2D Finite Element Analysis to Compare Cracking Behaviour in Twin-Disc Tests and Full Scale Wheel/Rail Experiments. Wear 2016, 346–347, 140–147. [Google Scholar] [CrossRef]

- Tosangthum, N.; Krataitong, R.; Wila, P.; Koiprasert, H.; Buncham, K.; Kansuwan, P.; Manonukul, A.; Sheppard, P. Dry Rolling-Sliding Wear Behavior of ER9 Wheel and R260 Rail Couple under Different Operating Conditions. Wear 2023, 518–519, 204636. [Google Scholar] [CrossRef]

- Liang, X.; Wei, X.; Li, Y.; Wang, M.; Liu, F. Effects of Lubricating Conditions on Wear Performance of U77MnCrH Rail. Metals 2024, 14, 414. [Google Scholar] [CrossRef]

- Ding, H.H.; Fu, Z.K.; Wang, W.J.; Guo, J.; Liu, Q.Y.; Zhu, M.H. Investigation on the Effect of Rotational Speed on Rolling Wear and Damage Behaviors of Wheel/Rail Materials. Wear 2015, 330–331, 563–570. [Google Scholar] [CrossRef]

- Gren, D.; Ahlström, J. Fatigue Crack Propagation on Uniaxial Loading of Biaxially Predeformed Pearlitic Rail Steel. Metals 2023, 13, 1726. [Google Scholar] [CrossRef]

- Zhou, T.; Xu, H.; Ma, X.; Xu, Z.; Zhao, H.; He, Y. A Novel Carbide-Free Bainitic Heavy-Haul Wheel Steel with an Excellent Wear-Resistance under Rolling-Sliding Condition. Metals 2023, 13, 202. [Google Scholar] [CrossRef]

- Molyneux-Berry, P.; Davis, C.; Bevan, A. The Influence of Wheel/Rail Contact Conditions on the Microstructure and Hardness of Railway Wheels. Sci. World J. 2014, 2014, 209752. [Google Scholar] [CrossRef]

- Sun, P.; Yang, J.; Zhu, A.; Hu, Z.; Wang, J.; Liu, F.; Wang, X. Experimental Study on the Effect of Solid Lubricants on Wheel Rail Contact Wear and Surface Hardness Evolution. Ind. Lubr. Tribol. 2023, 75, 904–910. [Google Scholar] [CrossRef]

| Steels | C | Mn | Si | Cr | Ni | V | Ti | Fe |

|---|---|---|---|---|---|---|---|---|

| U75VH | 0.76 | 0.92 | 0.70 | 0.12 | / | 0.05 | / | Bal. |

| Wheel steel | 0.54 | 0.79 | 0.34 | 0.19 | 0.084 | 0.007 | 0.003 | Bal. |

| Contact Stress (MPa) | Wear Time (h) | Ave. Length (μm) | Max. Length (μm) | Ave. Depth (μm) | Max. Depth (μm) | Ave. Angle (°) | Max. Angle (°) |

|---|---|---|---|---|---|---|---|

| 1980 | 2.5 | 21.47 ± 16.08 | 39.69 | 2.76 ± 0.50 | 3.27 | 10.17 ± 4.58 | 14.11 |

| 5 | 31.20 ± 6.25 | 37.95 | 4.73 ± 2.38 | 7.27 | 11.87 ± 5.02 | 17.06 | |

| 7.5 | 30.52 ± 6.71 | 37.97 | 3.56 ± 1.17 | 4.73 | 7.47 ± 2.04 | 8.93 | |

| 10 | 48.85 ± 22.69 | 63.09 | 7.13 ± 2.49 | 10.00 | 6.02 ± 0.79 | 6.74 | |

| 2180 | 2.5 | 24.20 ± 3.27 | 27.85 | 4.24 ± 0.55 | 4.72 | 10.28 ± 2.60 | 13.17 |

| 5 | 35.87 ± 6.81 | 41.65 | 7.90 ± 1.78 | 9.80 | 13.44 ± 9.34 | 23.26 | |

| 7.5 | 36.77 ± 13.24 | 51.42 | 6.28 ± 3.83 | 10.20 | 11.09 ± 2.45 | 12.64 | |

| 10 | 43.18 ± 14.24 | 57.45 | 5.23 ± 2.02 | 7.45 | 6.55 ± 2.29 | 9.04 | |

| 2270 | 2.5 | 29.85 ± 11.59 | 40.17 | 4.09 ± 0.96 | 5.01 | 11.15 ± 5.32 | 16.23 |

| 5 | 34.51 ± 8.27 | 39.69 | 5.48 ± 2.74 | 8.63 | 10.35 ± 4.49 | 15.13 | |

| 7.5 | 60.96 ± 49.68 | 111.62 | 8.89 ± 5.76 | 14.45 | 8.19 ± 4.34 | 12.93 | |

| 10 | 97.92 ± 26.51 | 128.29 | 21.58 ± 9.29 | 31.10 | 11.20 ± 6.28 | 16.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, R.; Chen, G.; Xu, N.; Sun, L.; Wu, J.; Xu, G. Impact of High Contact Stress on the Wear Behavior of U75VH Heat-Treated Rail Steels Applied for Turnouts. Metals 2025, 15, 676. https://doi.org/10.3390/met15060676

Wang R, Chen G, Xu N, Sun L, Wu J, Xu G. Impact of High Contact Stress on the Wear Behavior of U75VH Heat-Treated Rail Steels Applied for Turnouts. Metals. 2025; 15(6):676. https://doi.org/10.3390/met15060676

Chicago/Turabian StyleWang, Ruimin, Guanghui Chen, Nuoteng Xu, Linyu Sun, Junhui Wu, and Guang Xu. 2025. "Impact of High Contact Stress on the Wear Behavior of U75VH Heat-Treated Rail Steels Applied for Turnouts" Metals 15, no. 6: 676. https://doi.org/10.3390/met15060676

APA StyleWang, R., Chen, G., Xu, N., Sun, L., Wu, J., & Xu, G. (2025). Impact of High Contact Stress on the Wear Behavior of U75VH Heat-Treated Rail Steels Applied for Turnouts. Metals, 15(6), 676. https://doi.org/10.3390/met15060676