Abstract

High-chromium cast irons (HCCIs) have emerged as preferred materials for critical wear-resistant components operating under extreme conditions, owing to their excellent wear resistance, low cost, and good castability. They are widely used in metallurgy, energy, and mechanical engineering industries. The evolution of solidification microstructure directly governs the final properties of HCCIs, making the in-depth investigation of their solidification behavior of great significance. This paper provides a comprehensive review of recent experimental and simulation-based advances in understanding the solidification microstructure evolution of HCCIs. The effects of alloy composition, cooling rate, and inoculation treatments on microstructure development and phase distribution during solidification are critically analyzed. Furthermore, the application of simulation techniques—including thermodynamic modeling, phase-field method, cellular automata, and finite element analysis—is discussed in detail, highlighting their roles in revealing the mechanisms of microstructural evolution. Finally, the current challenges and potential future research directions in the study of the solidification behavior of high-chromium cast irons are outlined.

1. Introduction

Compared to traditional wear-resistant materials such as high-manganese steel, Ni-hard alloys, and low-alloy steels, high chromium cast irons (HCCIs) exhibit superior overall performance in environments dominated by abrasive and corrosive wear. Their excellent wear resistance, combined with low production costs and good castability, makes HCCIs ideal for critical components operating under extreme service conditions—such as slurry pump flow parts, mill liners, and crusher components [1,2]. Since the 1960s, HCCIs have been increasingly adopted in industries including mining, building materials, thermal power generation, and mineral processing.

In this study, HCCIs are defined as cast irons containing 12 wt.% or more chromium, which is the generally accepted threshold for classifying a cast iron as high chromium. Based on their carbon content and the resulting solidification characteristics, HCCIs are further categorized into hypoeutectic, eutectic, and hypereutectic types. The solidification microstructure is a critical factor that determines their performance. In hypoeutectic HCCIs, primary austenite dendrites precipitate first during solidification, followed by the formation of an austenite + M7C3 carbide eutectic structure through a eutectic reaction in the remaining liquid. In contrast, hypereutectic HCCIs initially precipitate a large amount of primary M7C3 carbides, which are followed by the eutectic solidification of the remaining liquid, resulting in a characteristic coarse carbide network [3]. The volume fraction, size, morphology, and distribution of carbides in the solidified microstructure directly affect the material’s wear resistance, toughness, and overall service performance. Extensive experimental studies have shown that by adjusting alloying elements—such as the C/Cr ratio [4], Si addition [5], and Cu alloying [6]—and optimizing cooling rates [7], the proportion and morphology of primary phases and eutectic structures can be effectively controlled. Moreover, inoculation or modification treatments can promote heterogeneous nucleation, refine carbides, and improve microstructural uniformity [3,8].

Meanwhile, numerical simulation techniques have played an increasingly vital role in elucidating the mechanisms of solidification microstructure evolution [9]. Thermodynamic simulations can accurately predict solidification pathways, phase compositions, and the evolution of phase fractions. The phase-field method enables intuitive modeling of dendritic growth, eutectic reactions, and the precipitation kinetics of carbides. Cellular automaton (CA) methods, when integrated with finite element modeling (FEM), can simultaneously predict microstructural evolution, temperature field distribution, and the formation of shrinkage defects. These simulation approaches provide critical insights into the mechanisms underlying solidification and the coupled effects of multiple factors. The integration of experimental investigations with simulation studies has significantly advanced the theoretical framework for controlling the solidification microstructure of HCCIs and offers strong support for the design of novel high-performance wear-resistant materials [10].

Significant progress has been made in the study of solidification microstructure evolution in high-chromium alloys. Several researchers have reviewed this topic from different perspectives. For instance, Jain et al. [3] focused primarily on the refinement methods and mechanisms of carbides; Fashu [1] and Gong [8] emphasized the corrosion-wear behavior of HCCIs; and Liu et al. [11] concentrated on the alloying effects of austenite-stabilizing and modifying elements. However, there is still a lack of comprehensive reviews on the solidification microstructure evolution of HCCIs in complex multi-element systems, particularly with regard to simulation-based studies. To illustrate the research activity in this area, a bibliometric analysis was conducted covering the subject areas of Engineering and Materials Science over the past decade. The search yielded about 200 relevant papers, highlighting that, although HCCIs are widely applied in industrial contexts, studies specifically addressing their solidification microstructures are relatively limited. These findings underscore the necessity and timeliness of the present review. This paper provides a systematic overview of the solidification microstructure evolution in HCCIs. It first discusses experimental investigations concerning the effects of alloying elements, cooling rates, and inoculation/modification treatments. Subsequently, it summarizes the applications of thermodynamic simulations, phase-field modeling, cellular automata, and finite element methods in simulating solidification microstructures. Finally, based on the current challenges, future research directions are proposed to support the further development and application of high-performance HCCIs.

2. Experimental Investigations on the Solidification Microstructure Evolution of HCCIs

The matrix microstructure of HCCIs can generally be tailored through appropriate heat treatment processes, thereby affecting the final properties of high chromium cast iron [12,13,14,15]. However, once eutectic carbides are formed, conventional heat treatments have a limited effect on their morphology. The only effective method for modifying eutectic carbides is remelting, combined with alloying and/or adjustments to processing parameters. Therefore, experimental studies on the solidification microstructure evolution of high-chromium alloys primarily focus on controlling the morphology, size, and distribution of eutectic carbides through alloying, cooling rate regulation, modification treatments, and other approaches. This section provides a comprehensive summary of recent experimental advancements concerning the effects of alloy composition, cooling rate control, and modification treatments on the solidification microstructure of HCCIs, offering a scientific basis for optimizing alloying strategies in the development of high-performance HCCIs.

2.1. The Role of Alloy Composition in Microstructure Evolution Control

In HCCIs, alloying is routinely employed to refine the matrix microstructure and tailor carbide morphology, thereby markedly improving wear resistance, corrosion performance, and overall mechanical properties. In addition, the addition of alloying elements can also affect the phase transformation process of the matrix [16]. Alloying elements may be categorized by their affinity for carbon into non-carbide-forming and carbide-forming groups. Non-carbide-formers—such as Si, B, Ni, N, Cu, and Mn—primarily influence the matrix chemistry and solidification behavior without directly generating new carbides. In contrast, carbide-formers—including Cr, Mo, Ti, V, Nb, and W—actively participate in carbide nucleation and growth, exerting a profound and varied impact on the type, size, and distribution of carbides in HCCIs [17]. The distinct roles and mechanisms of each category will be discussed in detail in the sections that follow.

2.1.1. Influence of Non-Carbide-Forming Elements

Non-carbide-forming elements are alloying additions that remain primarily in the matrix rather than forming carbonitrides or carbides. Through mechanisms such as solid-solution strengthening, phase-transformation control, and the modification of electrochemical behavior, these elements exert a significant influence on the microstructure and overall properties of HCCIs. Their impact on the solidification microstructure is predominantly through the regulation of matrix phases, allowing precise tuning of hardness, toughness, and corrosion resistance.

- (1)

- Si

Si, although not forming carbides in high-chromium cast irons [5], strongly influences phase fractions and carbide morphology. Lai et al. [18,19] observed that increasing Si content produced a finer, more uniform distribution of eutectic M7C3 carbides and transformed the matrix from austenite to pearlite. They attributed this to a Si-induced depression of the eutectic reaction temperature and a destabilization of austenite, but did not elucidate the refining mechanism.

Subsequent first-principles calculations by Chen et al. [20] revealed that Si atoms preferentially adsorb onto the (0001) growth planes of primary M7C3 carbides, inhibiting their growth—a finding consistent with Zhi et al.’s experimental observations [21]. Gong et al. [22] proposed that Si in solid solution promotes the rejection of carbon from the matrix, thereby increasing the nucleation rate and overall number of carbides. Others have suggested that by lowering the eutectic transformation temperature, Si increases the required undercooling for solidification, which further refines the eutectic carbide network. Collectively, these studies establish that Si additions—while remaining in the matrix—play a critical role in refining carbide structures and tailoring the matrix phase balance in HCCIs [23,24].

- (2)

- B

B exhibits unique solubility and phase-transformation effects in HCCIs. Because B has very low solubility in iron, it tends to segregate at grain boundaries or incorporate into carbide phases rather than remain in solid solution. Notably, B dissolves more readily in carbides than in the matrix, forming M2B borides and substituting for carbon in the lattices of primary carbides such as M7C3 and M23C6 [25]. This substitution raises the effective carbon concentration in the matrix, promoting an increased volume fraction of primary carbides and generating additional heterogeneous nucleation sites [26,27,28,29].

Moreover, B atoms can replace carbon in austenite, destabilizing the austenitic phase and facilitating its transformation to martensite or bainite during cooling [30]. Bedolla-Jacuinde et al. [31] demonstrated that B additions can double the carbide volume fraction and drive the conversion of chromium-rich M7C3 eutectic carbides into lower-carbon, B-stabilized M23(C,B)6 carbides. Li et al. [32] further identified core–shell structures in which M7C3 cores are encapsulated by M23C6 shells. While B refines the interdendritic spacing, it also tends to enlarge the size of primary carbides. Trace boron additions offer a powerful means to tailor both the volume fraction and morphology of carbides in HCCIs [33,34].

- (3)

- Ni

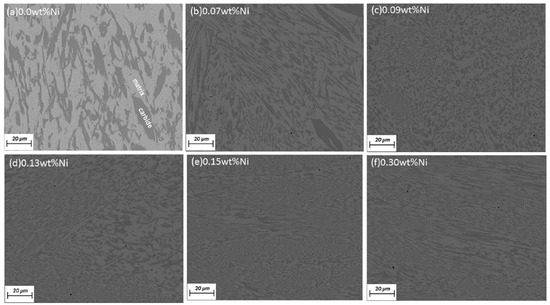

Ni remains virtually insoluble in carbides and is instead fully retained in the iron matrix, where it acts as a strong austenite stabilizer and significantly enhances toughness in HCCIs [8,11]. Although Ni’s effects on microstructure have been extensively studied in ductile iron [35,36]—owing to its propensity to promote graphite formation—its role in HCCIs has received scant attention. Inthidech et al. [37] observed that Ni additions transform the as-cast matrix from pearlite to austenite, with little change in carbide morphology. In contrast, Li et al. [38] demonstrated that trace Ni does not alter phase fractions but markedly refines carbide size (Figure 1). First-principles calculations of the work of adhesion indicate that Ni at the carbide–matrix interface lowers the local interfacial energy, reducing the nucleation energy barrier and thereby accelerating carbide nucleation. These findings suggest that Ni can be leveraged to tailor carbide refinement in HCCIs, but further systematic investigations are required to fully elucidate its mechanisms and optimize its effects.

Figure 1.

Microstructures of HCCIs containing different amounts of trace Ni. The base alloy is Fe-35Cr-3C. The trace Ni has its concentration in the range of 0–0.30. Reprinted with permission from ref. [38].

- (4)

- N

N dissolves predominantly in the matrix of HCCIs [39,40], where it exerts a powerful influence on microstructure and properties. Similarly to nickel, nitrogen significantly expands the austenite phase field—by up to twenty times more effectively than Ni [41]—thereby increasing both the volume fraction and stability of austenite [42]. During solidification, nitrogen reacts with chromium to form Cr2N nitrides [43], which act as heterogeneous nucleation sites for carbide precipitation, leading to a finer, more uniform microstructure and carbide distribution [42]. Furthermore, Li et al. [44] have shown that nitrogen raises the equilibrium partition coefficients of N, C, and V, effectively suppressing the microsegregation of these alloying elements and promoting a more homogeneous chemical profile.

- (5)

- Cu

Cu is another non-carbide-forming element that dissolves readily in the iron matrix, imparting pronounced solid solution strengthening [11]. As an austenite stabilizer, increasing Cu content expands the austenite phase field and elevates the retained austenite fraction [37]. Moreover, Cu has been shown to refine carbide dimensions in HCCIs, as shown in Figure 2; first-principles studies indicate that Cu atoms preferentially adsorb onto the M7C3 (0001) growth planes, impeding carbide coarsening [45]. During subsequent heat treatment, Cu also promotes the precipitation of fine secondary carbides [46], further enhancing the alloy’s hardness and wear resistance.

Figure 2.

Microstructure of as-cast HHCCI with different Cu contents: (a) 0Cu; (b) 0.5Cu; (c) 1.0Cu; (d) 1.5Cu. Reprinted with permission from ref. [45].

- (6)

- Mn

Mn in HCCIs exhibits weak carbide-forming tendencies alongside multiple phase-transformation effects. Its enthalpy of carbide formation is markedly lower than that of strong carbide formers such as Cr, Ti, or V. In HCCIs, Mn remains in solid solution within the matrix, where it contributes to solid solution strengthening through lattice distortion and short-range ordering. Moreover, increasing Mn content significantly stabilizes austenite and enhances hardenability, while simultaneously depressing the martensite start (Ms) temperature [11,47]. During subsequent heat treatments, Mn also promotes the precipitation of secondary carbides [48,49], further refining the microstructure and enhancing wear resistance.

2.1.2. Influence of Carbide-Forming Elements

Carbide-forming elements are alloying additions that directly influence the solidification process by precipitating carbides or by promoting their nucleation. Elements such as Cr, Mo, and W actively participate in carbide formation during solidification, controlling the type and volume fraction of primary and eutectic carbides. Others—like Nb, V, and Ti—enhance carbide precipitation by providing additional heterogeneous nucleation sites. Through these mechanisms, carbide-forming elements not only dictate the morphology, size, and distribution of carbide phases but also indirectly refine the matrix microstructure and tailor the mechanical and tribological performance of high-chromium cast irons.

- (1)

- Cr

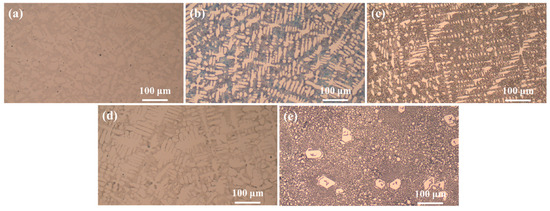

Cr is the principal alloying element in high-chromium cast irons, partitioning into both the matrix and carbide phases [8]. Its concentration dictates the type, morphology, and distribution of carbides as well as the matrix phase balance, thereby exerting a profound influence on solidification microstructure [1]. Below approximately 12 wt.% Cr, the metastable M3C carbide forms first, typically as a continuous network. As Cr content increases, these carbides transform into predominantly M7C3 eutectic carbides, which adopt discontinuous rod-like or “flower” morphologies and exhibit a markedly higher volume fraction [50]. However, in irons with very high carbon (e.g., 5 wt.% C), the total carbide volume may remain nearly constant with increasing Cr, the primary effect being an elevated Cr/Fe ratio within the carbides rather than an increase in overall carbide fraction [51]. When Cr is in great excess relative to carbon, the carbides are refined and the austenite fraction rises [50]. Ultimately, the Cr/C ratio is the key parameter governing these transitions [4,52], as shown in Figure 3.

Figure 3.

Optical micrographs of HCCIs at various Cr/C ratios: (a) 16.9 (1.6C), (b) 13.5 (2.0C), (c) 11.3 (2.4C), (d) 9.6 (2.8C), (e) 8.4 (3.2C). Reprinted with permission from ref. [4].

Increasing Cr content also raises the eutectic reaction temperature and delays the precipitation of primary austenite [8], extending the time available for carbide nucleation and growth. Consequently, carbides tend to coarsen, even as the dendrite arm spacing of austenite decreases and the proportion of eutectic structure increases [53]. This dual effect—coarser carbides within a finer austenitic framework—must be carefully balanced to optimize wear resistance and toughness.

- (2)

- Mo

Mo exerts a profound influence on the solidification microstructure of high-chromium cast irons by altering the solidification pathway, regulating carbide nucleation, and modifying the matrix phase balance. Unlike other carbide-formers, Mo preferentially precipitates as high-hardness MC, M2C, and M6C carbides, significantly boosting overall hardness [54,55]. These high-melting-point carbides can also serve as heterogeneous nucleation sites for primary carbides, leading to a refined carbide size and a more uniform morphology and distribution [56]. Furthermore, due to its higher mixing entropy, Mo competes with Cr for carbon, reducing the available C for M7C3 formation and thereby lowering its volume fraction [57]. When Mo exceeds approximately 3 wt.%, an M2C eutectic carbide forms during solidification [58,59]. For example, the addition of 6 wt.% Mo has been shown to transform a single-phase M7C3 network into a multiphase mixture of M2C and M3C carbides [60]. Beyond its carbide-forming role, Mo also dissolves into the matrix, providing solid solution strengthening and enhanced austenite stability [37].

- (3)

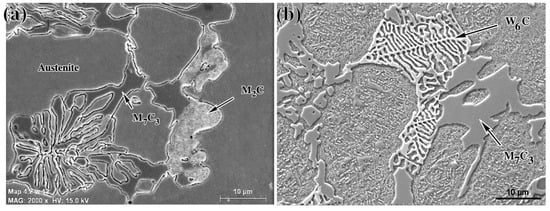

- W

W, a potent carbide-forming element, profoundly alters the solidification microstructure and phase transformations in HCCIs. W preferentially precipitates as hard carbides such as WC, W6C, and W3C, with their volume fraction rising in proportion to W content [61]. This additional carbide formation consumes carbon in the melt, which can lower the volume fraction of primary M7C3 carbides and shift the alloy toward a eutectic or hypoeutectic solidification regime [62]. At higher W levels, local carbon depletion raises the martensite start temperature—promoting austenite-to-martensite transformation—and yields a more irregular carbide distribution, although this effect is mitigated in alloys with high Cr content [63].

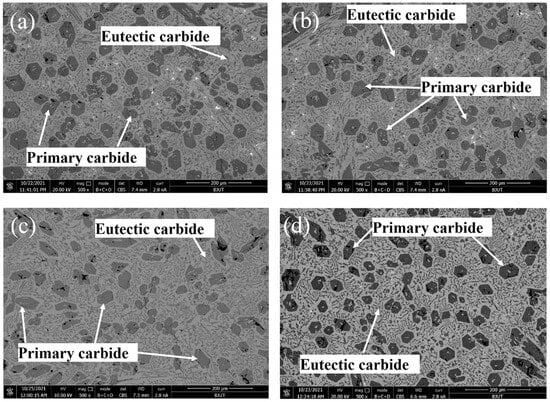

Cortés-Carrillo et al. [64] demonstrated that at 4 wt.% W, W dissolves into both the matrix and M7C3 carbides, reinforcing both phases and enhancing overall hardness. Beyond 4 wt.% W, harder M2C and M6C carbides become prevalent, as shown in Figure 4. Yamamoto’s investigation into the co-addition of W and Mo revealed that increasing the W equivalent delays pearlite and bainite transformations during continuous cooling while raising the martensite start temperature [65]. Additionally, W in solid solution within the matrix provides effective solid solution strengthening, further boosting the alloy’s mechanical performance [66].

Figure 4.

Morphologies of different carbides in HCCIs: (a) M7C3 + M2C, (b) M7C3 + M6C. Reprinted with permission from ref. [64].

- (4)

- Nb, V, and Ti

Nb, V, and Ti each exhibit a strong affinity for carbon, reacting early in solidification to form MC-type carbides [67,68,69,70]. These MC particles serve as heterogeneous nucleation sites for primary carbides and refine both primary and eutectic carbide distributions [71], yielding a fine and uniform microstructure (Figure 5) [72,73]. Their effects on the solidification microstructure of high-chromium cast irons can be summarized as follows:

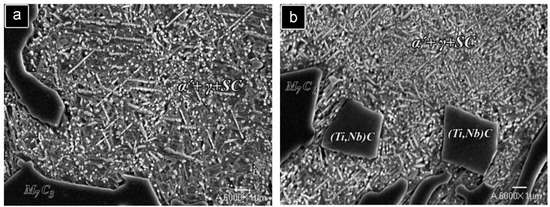

Figure 5.

SEM micrographs showing the heat-treated structure of (a) base white iron and (b) V–Nb–Ti alloyed white iron. The matrix is composed of martensite (α′), retained austenite (γ), and secondary carbides (SC). Reprinted with permission from ref. [73].

Nb preferentially precipitates as nanoscale NbC, which “pins” austenite dendrite growth and refines the dendritic structure. The uniformly dispersed NbC also promotes an even distribution of subsequent eutectic carbides [74,75,76,77]. V substitutes for Cr in M7C3 carbides to form (Cr,V)7C3 mixed carbides. By reducing the activity coefficient of carbon in the melt, V narrows the eutectic reaction range and suppresses carbide coarsening, thereby mitigating elemental segregation [78,79,80,81,82]. Ti exhibits a bimodal distribution of TiC; micron-sized TiC particles act as primary austenite nucleation sites, while nanoscale TiC particles provide Zener pinning, inhibiting carbide agglomeration and further refining the overall carbide network [83,84,85,86]. Because each of these elements consumes carbon to form stable MC carbides, high levels of Nb, V, or Ti can reduce the effective carbon content in the matrix, which in turn influences the solidification pathway and final phase balance.

2.1.3. Synergistic Effects of Multiple Alloying Elements

Alloy composition profoundly influences the solidification microstructure and performance of HCCIs through three primary mechanisms: modification of the solidification path, control of carbide nucleation and growth, and stabilization of the matrix phase. Single-element additions—while effective in certain respects—often suffer from drawbacks such as carbide coarsening or limited control over phase transformations. Consequently, recent research has turned to multi-element synergistic design to leverage coupled effects on thermodynamic stability, nucleation kinetics, and interfacial properties.

For example, Inthidech et al. [37] introduced a Mo–Ni–Cu system into a 26 wt.% Cr hypoeutectic HCCI. Here, Mo substitutes for Fe in M7C3 carbides—raising their hardness and thermal stability—while Ni and Cu lower the martensite start temperature and increase the austenite fraction by 12%, boosting impact toughness to 18 J/cm2. Bedolla-Jacuinde et al. [73] demonstrated that V–Nb–Ti co-alloying transforms the microstructure into a composite of eutectic M7C3, an austenitic matrix, and in situ MC primary carbides—distinct from conventional eutectic ferritic matrices. Liu et al. [11] reported that a Ni–Mn–Ce–B alloying regime delays phase transformation (via Ni), refines grains (via Mn), and purifies grain boundaries (via Ce and B), reducing primary grain size from 50 to 30 μm, increasing casting density by 15%, and raising fracture toughness by 20%. Tabrett’s “carbide–matrix compatibility” model [87] further shows that Mo–V co-addition optimizes precipitation sequence and lowers interfacial energy, achieving both high hardness and impact toughness.

In high-temperature applications, Li et al. [61] developed a W–Mo–Mn system: W promotes M6C carbide formation to strengthen high-temperature hardness, Mo refines M7C3 distribution and mitigates segregation, and Mn enhances austenite thermal stability, resulting in a refined austenitic matrix with uniform M7C3 and particulate M6C. More recently, Liu et al. [88] investigated a V–Fe–Ti–Nb–C–Zr–B multi-element alloy, finding that V, Ti, Nb, and B dissolve into M7C3 to form (Cr,Fe,V,Ti,Nb)7(C,B)3 composite carbides, while Zr in solution suppresses retained austenite formation—raising hardenability by 30%, hardness by 8%, and impact toughness by 16.9%, and reducing friction coefficient and wear volume by 2.3% and 7.0%, respectively.

These studies underscore that multi-element synergistic design—through coupled nucleation kinetics, phase stability, and interfacial engineering—can markedly enhance the combined hardness, toughness, and wear resistance of HCCIs. However, given the vast compositional space and interaction complexity, research has largely concentrated on individual alloy systems. A systematic, generalized framework for multi-element interactions remains to be established, necessitating further comprehensive investigations to guide the development of next-generation, high-performance HCCIs.

2.2. Influence of Cooling Rate on Microstructure and Phase Distribution

Cooling rate, a critical processing parameter during solidification, profoundly influences the dendritic morphology, carbide precipitation behavior, and matrix phase distribution in HCCIs by modulating the temperature gradient at the solid–liquid interface, the degree of undercooling, and solute-diffusion kinetics. These microstructural effects, in turn, dictate the alloy’s strength, toughness, wear resistance, and corrosion performance.

Increasing the cooling rate markedly refines carbides and optimizes their spatial distribution [89]. For instance, Yang et al. [90] demonstrated that elevating the cooling rate from 3 °C/s to 10 °C/s reduced the average size of M7C3 carbides from 3.8 μm to 1.5 μm, decreased inter-carbide spacing by 40%, raised microhardness to 680 HV, and significantly improved wear resistance. The cooling rate further optimizes the matrix by suppressing dendrite coarsening and steering phase-transformation pathways. Wang et al. [91] reported that increasing solidification rates from 3 °C/s to 15 °C/s in GCr15 steel reduced dendrite arm spacing by 35% and replaced coarse plate M7C3 carbides with finely dispersed M23C6 and VC, thereby enhancing wear resistance. Bleckmann et al. [92] showed that the rapid quenching of Fe–Cr–V–C alloys induces a transition from a ferrite–pearlite matrix to a metastable martensite structure, achieving hardness values up to 720 HV. Cryogenic treatment in liquid nitrogen has been used to lower retained austenite from 18.99% to 9.93% and to promote secondary M23C6 precipitation, resulting in markedly improved overall properties [93].

Synergistic interactions between alloying elements and the cooling rate further amplify microstructural control. Liu et al. [94] demonstrated that Ti microalloying combined with high cooling rates increased TiC nucleation rates by 25% and improved impact toughness by 30%. Siekaniec et al. [95] used inoculation plus controlled cooling to convert continuous cementite networks into banded distributions, increasing the carbide volume fraction by 15% and reducing fatigue-crack initiation by 40%. Under rapid cooling, additions of W and Mo have been shown to induce M6C carbide formation, boosting wear resistance by a factor of 1.5 [61].

Advanced in situ characterization techniques—such as high-temperature confocal scanning laser microscopy (HT-CSLM) [96,97] and X-ray computed tomography (X-CT) [98]—have directly visualized the dynamic solidification process, confirming the grain-refining effect of rapid cooling. Complementary simulations using Thermo-Calc 2019a and MAGMA V5.3 software predict solidification pathways, phase stability, and shrinkage-void formation, guiding the optimization of process parameters [99]. Collectively, these insights underscore that precise control of the cooling rate, in concert with tailored alloy chemistry, is essential for engineering the microstructure and enhancing the performance of high-chromium cast irons.

Despite these advances, several challenges remain. The complexity of multivariable interactions, such as those between cooling rate, alloy composition, and mold geometry, has not been systematically addressed. Rapid cooling may induce microcracks in complex castings due to thermal stress concentration. Additionally, traditional metallographic techniques lack the resolution to capture transient solidification behavior. Therefore, future research should focus on constructing multi-field coupled experimental platforms, developing real-time imaging techniques based on synchrotron radiation, and establishing multiscale models to enable precise control of the microstructure and performance under complex service conditions.

2.3. Effect of Inoculation Treatment on Microstructural Evolution of HCCIs

Inoculation treatment is an effective method for modifying the solidification microstructure by introducing inoculants into the melt. These inoculants act as heterogeneous nucleation sites and provide sufficient undercooling for the formation of nucleation particles, thereby significantly increasing the nucleation rate of carbides while suppressing their growth. This results in the refinement and uniform distribution of carbides [68]. Although techniques such as semi-solid processing and pulsed current treatment can also achieve microstructural refinement and control in HCCIs, their practical application in industrial settings remains limited [3,8]. In contrast, inoculation treatment is simple, efficient, and possesses broad industrial applicability.

Common inoculating elements include Mg, Al, Zn, Cu, V, Ti, Nb, B, Ba, Ca, K, Na, and rare earth elements (RE), among which rare earth inoculation has proven to be particularly effective in enhancing the wear resistance of HCCI. Panichkin et al. [100] investigated the effects of RE such as Sm, La, Ce, Nd, and Y on the microstructure of hypereutectic HCCIs. Their results indicated that RE addition alone did not markedly alter the morphology of primary and eutectic carbides. However, there was a strong interaction between cooling rate and RE addition. At low cooling rates, elements such as Sm, La, and Ce + La increased the size of primary carbides, whereas at high cooling rates, Nd and Ce + La reduced their size by 70% and 45%, respectively. In contrast, Sm, La, and Y caused anomalous coarsening under the same conditions. Furthermore, elements such as Sm, La, and Ce were found to dissolve into the M7C3 carbides, while La and Ce also dissolved into the austenitic matrix. Nd and Y did not dissolve into the iron-based phases but instead precipitated as high-concentration inclusions.

Guo [85] compared the effects of different inoculants on carbide refinement in hypereutectic HCCI and found that adding 0.6 wt.% of rare-earth magnesium inoculant reduced the average carbide size by approximately 50%, significantly improving toughness without compromising hardness. Dojka’s work revealed that the combination of Ti with rare earth elements provided abundant heterogeneous nucleation sites for carbides, promoting their refinement and spheroidization while reducing interfacial energy and improving impact toughness. However, excessive Ti content could lead to TiC agglomeration and microstructural inhomogeneity [101]. Jain [102] used TiB₂ as an inoculant and found that even a 0.03 wt.% addition significantly decreased the volume fraction and average length of needle-like carbides, while further refining equiaxed carbides by 32%. Nonetheless, excessive TiB2, though reducing needle-like carbides further, also increased material brittleness.

Siekaniec [103] observed that Fe-Ti inoculants significantly increased carbide number density, with the grain volume density of primary austenite exhibiting an exponential increase with inoculant addition. Teker et al. [104] studied the effects of FeTi–FeB inoculants on the morphology of reinforcing carbides in hypereutectic HCCIs. Their findings highlighted two primary mechanisms of refinement and nucleation control: (1) heterogeneous nucleation promoted primary carbide formation, refining their size and altering their shape; and (2) distribution optimization led to isolated blocky carbides and reduced interdendritic segregation. From the perspective of the solidification path and microstructural uniformity, the inoculation treatment reduced the eutectic reaction interval by modifying the thermal gradient during solidification, suppressed coarse dendritic growth of primary austenite, and minimized Cr and C segregation in the interdendritic regions, thereby promoting uniform carbide distribution. Gong et al. [105] employed a composite inoculation approach using N + Ti + V + RE − Mg for refining carbides in hypereutectic HCCI. As illustrated in Figure 6, the refinement mechanisms were attributed primarily to two factors: (1) heterogeneous nucleation of TiC and VC particles, and (2) an adsorption-induced refinement mechanism, whereby N, Ti, and V preferentially adsorbed on the (0001) growth planes of M7C3 carbides to hinder their growth.

Figure 6.

SEM images of different modification as-cast hypereutectic HCCIs: (a) without modification, (b) N, (c) N + RE − Mg, (d) N + RE − Mg + Ti + V. Reprinted with permission from ref. [105].

3. Simulation of Solidification Microstructure Evolution in HCCIs

With the rapid advancement of computational materials science, the traditional paradigm of relying solely on experimental methods to study the solidification microstructure evolution of HCCIs is undergoing a fundamental transformation. As a typical multi-phase, multi-scale alloy system, the solidification of HCCIs involves complex thermodynamic reactions, phase boundary migration, solute redistribution, and microstructural morphology evolution. Experimental techniques face notable limitations in capturing transient microstructural dynamics and in shortening the alloy design cycle. Therefore, developing accurate and scalable solidification simulation models has become an essential approach for understanding microstructure formation mechanisms and guiding the optimization of alloy compositions and processing parameters.

This section provides a systematic overview of thermodynamic modeling and phase diagram calculations, solidification kinetics simulations, and three representative numerical methods—phase-field modeling, CA, and FEM—with a focus on their application in the solidification microstructure evolution of HCCIs. Their suitability and advantages in predicting grain growth, carbide precipitation, dendritic evolution, and solidification defects are critically analyzed. Furthermore, the representative literature examples are discussed to illustrate the current application status and emerging trends of these approaches, laying a theoretical foundation for the design of high-performance HCCIs.

3.1. Thermodynamics and Phase Diagram Calculation

The CALPHAD (Calculation of Phase Diagrams) method, by integrating thermodynamic databases with phase diagram calculations, provides a robust theoretical framework for predicting carbide precipitation, eutectic reaction pathways, and phase stability during the solidification of HCCIs. It has become a core tool for thermodynamic analysis in multicomponent alloy systems. In terms of carbide precipitation and phase diagram prediction, CALPHAD enables accurate forecasting of the precipitation sequence and stability ranges of carbides in HCCIs.

Jain [17] employed a thermodynamic model to evaluate the growth-limiting factors of primary carbides under the influence of various solute elements. By calculating the liquidus temperatures associated with different solutes, he assessed their effects on primary carbide formation, concluding that solute additions below 1 wt.% have negligible impact. Elements such as Ti, Nb, Mo, Mn, and W tend to form other carbides or intermetallic compounds prior to primary carbide formation, thus exerting minimal influence on their nucleation. In contrast, non-reactive solutes including Al, Ca, Co, Cu, Mg, N, Ni, and Si are unable to establish sufficient constitutional undercooling before the growth of primary carbides, and therefore do not facilitate additional nucleation.

Kundrat [106], through phase diagram studies of the Fe–Cr–C ternary system, demonstrated that when the Cr content exceeds 12 wt.%, M7C3 carbides preferentially precipitate via eutectic reactions, followed by the formation of refined M23C6 carbides during cooling. Yamamoto [107] further investigated the effects of the C/Cr ratio on phase constitution and found that when C > 2.5 wt.% and Cr > 25 wt.%, the volume fraction of M7C3 exceeds 60%, significantly enhancing wear resistance.

Li et al. [108] utilized the Thermo-Calc software to calculate the phase transformation paths during the solidification of HCCIs with varying Cr content. The predictions were consistent with differential scanning calorimetry (DSC) results, confirming the reliability of thermodynamic calculations for guiding microstructural design in HCCI. Wieczerzak [109] designed a hypoeutectic Fe–Cr–C alloy via thermodynamic modeling to obtain a high-volume fraction of thermodynamically stable eutectic M23C6 carbides. It was found that at 25 wt.% Cr, M23C6 remains stable at elevated temperatures (~1100 °C), and the matrix phase transition from BCC to FCC occurs above this temperature, thereby avoiding interference from intermediate transformations during diffusion processes.

Studies on non-equilibrium solidification have revealed that cooling rate and solute interactions play a critical role in microstructural evolution. Son observed discrepancies between Thermo-Calc and JMatPro in predicting the initial solidification phases and eutectic compositions [7]. In heat treatment optimization, Akyildiz [110] employed a thermodynamic–kinetic coupling model to predict the sequential precipitation of M7C3 and M23C6 carbides during destabilization and tempering. Guitar [111,112] constructed CCT and TTT diagrams for 26% Cr HCCI based on dilatometric experiments, validated them with isothermal heat treatment, and used MatCal to simulate thermodynamic and kinetic behavior of carbide transformations during destabilization. The results agreed with experimental observations, demonstrating that thermodynamic modeling can effectively narrow the heat treatment window and reduce experimental workload while enabling accurate microstructure control.

Due to the complexity of HCCIs systems, several researchers have also focused on the development and validation of thermodynamic databases. For example, Liu [113] developed a Fe–Cr–Ni–C database capable of predicting carbide stability ranges under different C/Cr ratios and cooling rates. Bonny [114] refined the Gibbs free energy expression for Fe–Cr alloys to improve the accuracy of M7C6 stability prediction in the intermediate temperature range—a model now adopted in databases such as TCFE8.

Through the integration of thermodynamic modeling and experimental validation, the CALPHAD method has systematically elucidated the mechanisms governing carbide precipitation, phase stability, and non-equilibrium solidification behavior in HCCIs. Nevertheless, challenges remain, particularly in accurately simulating rapid solidification behavior and in expanding thermodynamic database coverage for complex multicomponent systems.

3.2. Solidification Dynamics Simulation

The solidification kinetics model offers a micro-mechanistic theoretical foundation for understanding the microstructural evolution of HCCIs by analyzing the coupling behavior of solid–liquid interface migration, dendrite growth rate, solute redistribution, and thermal gradients. Guo et al. [115], integrating numerical simulation with EDS analysis, found that the addition of 0.5 wt.% Cu reduces dendrite arm spacing by 18%, increases interface migration rate by 12%, and promotes the dense and uniform distribution of M7C3 carbides along the advancing solid–liquid interface, thereby significantly enhancing microstructural continuity. To address the challenge of macrosegregation during continuous casting, Meng [116] developed a multi-segment non-equilibrium coupled model. By optimizing withdrawal speed and thermal gradient, the width of the central segregation zone was controlled within 5 mm. The model also accurately predicted the aggregation behavior of M7C3 carbides in the final stages of solidification, providing a quantitative basis for process optimization. In terms of the interaction between fluid dynamics and dendritic growth, Wang et al. [117] demonstrated that increasing the melt shear rate to 10 s−1 reduced the secondary dendrite arm spacing from 45 μm to 30 μm and led to a more dispersed carbide distribution. This study was the first to incorporate fluid dynamic parameters into solidification modeling of HCCI, offering a new strategy for suppressing coarse dendritic channel structures.

The columnar-to-equiaxed transition (CET) plays a critical role in achieving microstructural uniformity. Wang et al. [118] used the CA method to investigate the CET mechanism in Fe–C alloys. Their results showed that the CET conditions (temperature gradient and cooling rate) in Fe–0.82C alloy agreed well with the predictions of the Hunt model. Two types of CET were identified—tip-induced and interdendritic—attributed to the coupled effects of melt undercooling and solute segregation. A reduction in thermal gradient, an increase in cooling rate, or higher carbon content all facilitated CET, promoting a transition from mixed dendritic structures to fully equiaxed grains. CET location and dendrite size were found to fluctuate significantly under high thermal gradients, low cooling rates, and low carbon contents, but stabilized upon parameter optimization, resulting in finer and more homogeneous dendrites. The thermal gradient directly influences undercooling, while carbon content indirectly affects solidification via its impact on dendrite growth velocity, providing theoretical guidance for improving solidification quality. Azizi et al. [119] further pointed out that under large temperature gradients (>20 °C/cm), local liquid enrichment between dendrites leads to the formation of segregation islands, which promote the intergranular bridging of M7C3 carbides. This defect can be effectively mitigated by optimizing the cooling rate and compositional ratio. Kinetic studies on the effect of carbon content on microstructure evolution revealed that high-carbon conditions promote dendrite coalescence, advance carbide precipitation fronts by 15 μm, increase the width of segregation zones by 30%, refine grain size, and weaken crystallographic texture. A dual-carbon control strategy was proposed to balance the trade-off between refinement and segregation [120]. In a systematic analysis of the nonlinear relationship between dendritic evolution and interface behavior, Domeij [121] summarized relevant studies on HCCIs, with a particular focus on the interplay between solute transport rate, interface stability, and cooling rate, and advocated for a coordinated approach involving chill casting and C/Cr ratio control to optimize microstructure.

The following sections will introduce the application of the phase-field method, cellular automaton method, and finite element method in modeling the solidification process of high-chromium cast iron.

3.2.1. Phase-Field Method

The phase-field method enables high-fidelity simulation of solid–liquid interface migration, grain growth, and carbide precipitation during the solidification of HCCIs without explicitly tracking the interface morphology, by employing free energy functionals and the Allen–Cahn/Cahn–Hilliard governing equations. In simulations of as-cast microstructural evolution, Siekaniec et al. [95] captured the dynamic transition from coarse columnar to equiaxed grains in hypoeutectic HCCIs using a two-dimensional phase-field model. The simulation results exhibited strong agreement with EBSD micrographs, confirming the synergistic effect of optimized cooling paths and alloy composition on grain boundary bending, coalescence, and interwoven carbide growth. Li et al. [122] focused on the isothermal coarsening behavior of M7C3 eutectic carbides, revealing that the gradient of Cr concentration and interface curvature jointly govern the nonlinear growth kinetics of carbides. Under a diffusion-controlled mechanism, the discrepancy between simulation and experimental results was less than 10%. Gong et al. [123] further coupled the CALPHAD database with a phase-field model to elucidate the strong correlation between dendrite growth and solute segregation. A chemical gradient zone was formed between dendrites in Cr-rich regions, with simulated results deviating less than 10% from EDS analyses.

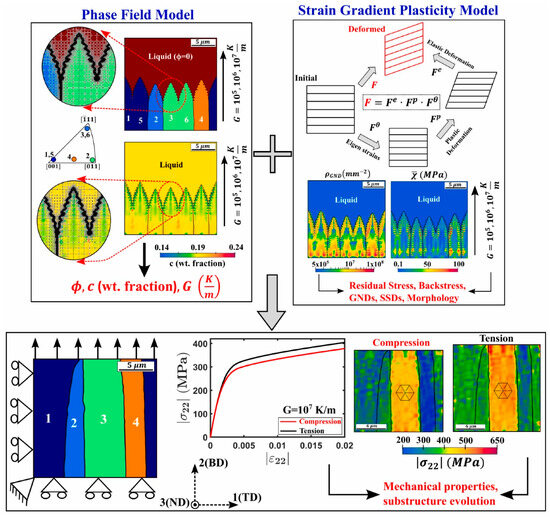

To investigate the stress–microstructure coupling effects in rapid solidification, Pai et al. [124] developed an enhanced phase-field model integrated with strain-gradient plasticity (as shown in Figure 7), incorporating anisotropy and polycrystalline interactions. The strain-gradient framework included dislocation/solute strengthening and back stress from geometrically necessary dislocations (GNDs). Their findings showed that high cooling rates intensified solute segregation, GND density, and back stress in Fe–Cr alloys, resulting in more pronounced thermal contraction asymmetry and mechanical anisotropy in the rapidly solidified microstructure.

Figure 7.

Schematic of the coupled phase field-strain gradient plasticity framework and its application in simulating solidification as well as post-solidification Tension–Compression asymmetry in rapidly solidified microstructures. Reprinted with permission from ref. [124].

To address the simulation demands of complex systems, Gao et al. [125] established a multiphase phase-field framework for the Fe–Cr–C ternary system based on the Kim–Kim–Suzuki (KKS) model. Their results revealed that interfacial anisotropy and differences in growth velocity lead to the formation of directionally distributed M7C3 carbides and grain orientation differentiation. Guzik et al. [126] incorporated the ProCAST phase-field module to simulate castings with complex geometries and found that thin-walled regions exhibited finer and denser grains, whereas thick-walled regions showed pronounced columnar grains and macrosegregation. The simulation error remained below 10%. Barnes et al. [127] developed a three-phase model to investigate the growth direction selectivity of M7C3 carbides in hardfacing coatings, demonstrating that differences in interfacial energy dominate the preferred crystallographic orientation. Liu et al. [113] simulated the effect of interphase boundary competition on M7C3 nucleation in the Fe–Cr–Ni–C system, achieving carbide volume fraction prediction errors within ±5%.

Current research has validated the versatility of the phase-field method in modeling interfacial dynamics, microstructural evolution, and engineering-scale predictions. However, studies specifically focusing on complex multi-component systems remain relatively limited.

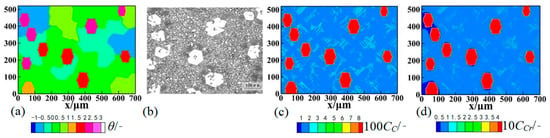

3.2.2. Cellular Automaton

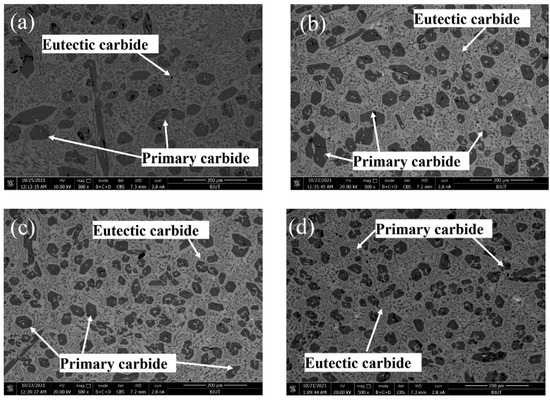

The CA method, known for its simple rules and high computational efficiency, has become a valuable tool for simulating grain nucleation, growth, and carbide evolution during the solidification of high-chromium cast iron. Gandin et al. [128] pioneered the development of a multiscale “FE–CA” coupled model, which dynamically integrates macroscopic temperature fields with microscopic grain evolution. This model successfully predicted the effects of grain boundary propagation rate and nucleation density on the final grain size distribution under isothermal solidification conditions. The simulation results showed strong agreement with experimental data, laying the foundation for multiscale microstructure mapping. At the engineering scale, Guzik et al. [126] incorporated a CA module into the ProCAST 2022.0 software to simulate grain distribution in high-chromium castings with varying wall thicknesses. They found that the density of primary austenite grains at the thin-wall edge was 2–3 times higher than in the central region, consistent with EBSD analyses. Rashid [129] further applied the CA model to optimize the casting process of grinding balls. By adjusting the pouring temperature (1450–1520 °C) and cooling rate (1–5 °C/s), the shrinkage porosity was reduced by 40%, demonstrating the practical utility of CA in defect control. In terms of simulating carbide-level behavior, Zhang et al. [130] developed a solute-driven CA model to quantify the nucleation and aggregation mechanisms of M7C3 carbides. The simulations revealed that the redistribution of C and Cr elements at the solid–liquid interface promotes preferential nucleation of M7C3 along grain boundaries. During the final stage of solidification, solute segregation facilitates the formation of chain-like or blocky carbide aggregates, as shown in Figure 8. The results closely matched experimental observations of Fe–4C–17Cr alloys, with XRD phase fraction prediction errors within 5%.

Figure 8.

Final solidification microstructure (a) simulated and (b) experimental and simulated solute concentration of (c) C and (d) Cr for Fe-4C-17Cr alloy. Copyright 2020, IOP Publishing Ltd. Reprinted from ref. [130].

To address complex operating conditions such as continuous casting, Luo et al. [131] developed a coupled CA–FD (finite difference) model, revealing the regulatory effect of thermal gradients on grain morphology. High temperature gradients (10–15 °C/cm) promoted the directional growth of columnar grains, while low gradients (<5 °C/cm) increased the proportion of equiaxed grains to 70%. Furthermore, a doubling of nucleation density resulted in a 20% reduction in average grain size. Building upon this, Wang et al. [132] introduced a dynamic grain nucleation redistribution mechanism into the model. Their results showed that strong directional heat flow led to dendrite deflection and coarsening in edge regions (with grain size increasing by 30%), whereas the uniform temperature gradient in the central region ensured a fine and dense structure (grain size < 50 μm). This provides a theoretical basis for controlling central porosity defects in large castings. Zhi et al. [133] conducted a comprehensive review of the development of CA methodologies, highlighting advances in single-phase and dual-phase CA models as well as CA–FE/CALPHAD coupled approaches. They emphasized the need for future models to integrate thermodynamic databases more thoroughly—such as interface mobility and latent heat parameters—to enable accurate prediction under multi-physics driving forces.

3.2.3. Finite Element Method

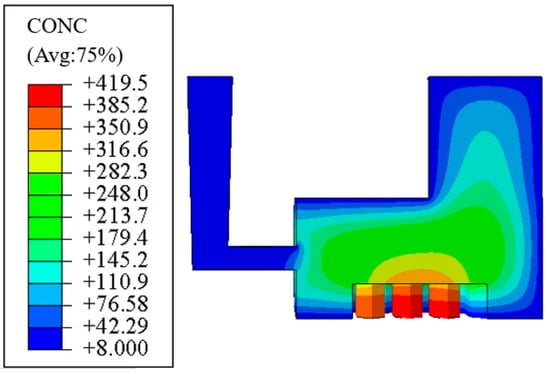

The FEM, owing to its capability for multi-physics field coupling, has become a core tool for modeling the evolution of temperature and stress fields and predicting casting defects during the solidification of high-chromium cast iron. In complex casting defect prediction, Ma [134] performed three-dimensional simulations of the entire lost foam casting process using ProCAST software. The results showed that shrinkage cavities mainly occurred in the terminal solidification zones far from the riser. By optimizing riser placement, adding insulation covers, and adjusting pouring temperature, the predicted defect rate was reduced by 60%. Yang et al. [135] conducted a systematic study on WC-reinforced high-chromium cast iron, analyzing the influence of different pouring temperatures on melt flow, temperature, and stress field distributions during solidification. They further investigated the diffusion behavior of WC ceramics and its coupling effect on stress and temperature fields. It was found that pouring at 1575 °C minimized the interfacial effective stress, promoted uniform diffusion of WC particles into the matrix, and increased the interface layer width, as shown in Figure 9. The simulation results agreed well with experimental observations. In terms of coupling mechanisms between solidification microstructure and stress evolution, Svensson et al. [136] developed a customized FEM model using FORTRAN, achieving bidirectional coupling between volumetric shrinkage and thermal field evolution for the first time. They discovered that thermal stress in regions with a temperature gradient exceeding 20 °C/cm surpassed the hot ductility limit of the material, closely correlating with actual hot cracking locations in large-section castings. Bellet et al. [137] proposed the “thermal strain rate index” as a quantitative criterion to identify crack-prone regions. They also introduced the ratio of relative strain rate to thermal conductivity as an indicator for determining the presence of a “hot ductility brittleness window.” In regions where the temperature gradient was ≥30 °C/cm, more than 50% of potential hot-cracking zones were accurately identified. This approach provides a high-precision prediction method for thermal stress fields in alloys with high hot-cracking susceptibility, such as high-chromium cast iron.

Figure 9.

Diffusion distribution of ceramic particles of WC/iron matrix composites at 1575 °C. Reprinted with permission from ref. [135].

In terms of microstructural refinement and macrosegregation control, Zhong et al. [138] utilized COMSOL(Version was not annotated in the original literature) simulations and found that when the superheat was reduced to 15 °C, the secondary dendrite arm spacing (SDAS) in 6Cr3Mo steel billets decreased, and central segregation was significantly mitigated. Lower superheat combined with higher cooling intensity also promoted microstructural refinement. Similar simulation results were reported by Tian et al. [139]. Cui et al. [140] employed a micro-kinetic model to investigate the impact of the core–shell structure of carbides on the corrosion resistance of high-chromium cast iron, revealing that interfacial strain-concentrated regions were directly correlated with corrosion initiation sites, thereby providing theoretical support for optimizing carbide morphology. Xu et al. [141] conducted thermo-mechanical coupling simulations and revealed that latent heat release during the liquid-to-solid phase transition induced transient temperature spikes in ZTAp/high-chromium cast iron composites, triggering local stress peaks. Based on this, an optimized pore diameter-to-wall thickness ratio of 1.5 for the prefabricated ceramic preform was proposed. Du [142] further optimized the pouring temperature and velocity and found that defect-free castings were achieved at 1843 K and 0.2 m/s, respectively—offering important insights for practical production.

Although FEM has made significant progress in the field of alloy steel casting, its application in high-chromium cast iron remains limited. Firstly, most existing thermophysical parameters are based on alloy steel systems, while the precipitation behavior of M7C3 carbides and latent heat of phase transformations in high-chromium cast iron require further investigation and refinement. Secondly, a comprehensive model integrating thermal, mechanical, chemical, and fluid field interactions is still lacking, making it difficult to capture the dynamic coupling between carbide nucleation and evolving stress fields. Thirdly, many simulations are constrained to laboratory-scale geometries, lacking verification and scalability for large industrial castings such as mill liners and rolling work rolls.

In summary, numerical simulation has played an increasingly vital role in uncovering the solidification mechanisms of high-chromium cast iron. The CALPHAD method accurately predicts carbide precipitation pathways, eutectic reaction intervals, and stability boundaries, providing essential thermodynamic input for both macro- and micro-scale simulations. Solidification kinetics models enable the coupling of dendrite morphology and solute redistribution. Phase-field methods offer high-fidelity simulations of interface migration and phase boundary evolution, elucidating grain competition and carbide growth mechanisms. Cellular automata (CA) and finite element methods (FEM) have, respectively, demonstrated strong capabilities in grain-scale evolution and thermo-mechanical field prediction, supporting defect control and structure optimization under complex conditions. Despite substantial achievements, several critical challenges remain. First, there is a lack of a universal parameterization bridge between experiments and simulations, leading to poor model transferability and strong dependence on experimentally fitted parameters. Second, the modeling of real casting boundary conditions is often oversimplified. In advanced processes such as hardfacing, rapid quenching, and high-pressure casting, dynamic interactions between temperature and composition fields are difficult to fully capture. Third, a unified framework bridging macro and microstructure evolution is still underdeveloped, limiting full-process simulation from alloy design to property prediction. To advance the application of numerical simulation in high-chromium cast iron, it is essential to establish a dedicated property database and develop a multiscale collaborative modeling platform. This would enable coupled prediction of microstructural evolution and service performance, facilitating the integration of process–structure–property relationships into digital alloy design.

3.3. Coupling of Experimental and Simulation Studies

Experimental techniques such as OM, SEM, TEM, and EBSD allow for the direct characterization of microstructures and phase distributions. However, simulation methods can visualize and predict complex phenomena that are difficult to observe in real time, such as thermal field evolution, solute redistribution, stress accumulation, and carbide precipitation. The integration of experiments and simulations provides a cross-scale research paradigm for understanding solidification behavior and optimizing processing strategies in HCCIs. This synergy is reflected in the following aspects:

First, experimental data provide essential input parameters for simulations, while simulation results, in turn, guide experimental design—forming a closed-loop optimization process. For example, Li et al. [122] used CALPHAD calculations to obtain the actual Gibbs free energy of austenite and M7C3 carbides in Fe-Cr alloys, driving a phase-field model to simulate the coarsening path of carbides. By using FESEM (JEOL-6340)-EDS to observe Cr and C concentration gradients, the interfacial diffusion coefficients were refined, establishing a feedback cycle of “thermodynamic database–phase-field equations–experimental validation”. Similarly, Du et al. [143] applied the volume of fluid (VOF) method and a porous media model to simulate the mold filling behavior during the infiltration casting of ZTAp/HCCI composites. The simulated results showed excellent agreement with experimental observations, and through further verification, optimal parameters and gating system configurations were determined, resulting in defect-free castings.

Second, microstructural evolution observed experimentally is validated and interpreted through simulation, revealing intrinsic mechanisms. Li et al. employed a 3D phase-field model to dynamically simulate the separation of Cr-rich α phases from metastable to unstable states in Fe-(25–45)at.%Cr alloys. The simulated morphologies matched well with TEM observations, and the evolution of particle size, number density, and microhardness was quantitatively consistent with experimental data. By analyzing the composition evolution at the α/α′ interface, the transition mechanism from “nucleation and growth” to “spinodal decomposition” in 30at.%Cr alloys was clarified. This study confirmed the reliability of phase-field models in quantitatively describing phase separation dynamics and provided an effective tool for high-throughput prediction of alloy transformation behavior. In another example, Li et al. [122] combined phase-field simulations with isothermal aging experiments to capture the coarsening sequence of M7C3 carbides from isolated nuclei to rod-like and lamellar eutectics. EDS elemental mapping confirmed a “Cr-rich core/C-rich shell” architecture, uncovering the role of concentration gradients in driving morphological transitions.

Lastly, cross-scale models supported by experimental data enable holistic validation of mechanisms from the microscale to the macroscale. Gao et al. [125], using the KKS phase-field model, demonstrated that increasing Cr content led to greater variability in dendritic morphology and reduced tip growth velocity in ternary dendrites. These findings were confirmed by high-temperature in situ confocal observations, which showed that secondary dendrite arm growth accelerated with increasing undercooling, while the arm spacing decreased—providing a theoretical basis for dendrite refinement and bridging micro to mesoscale structures. Bai [144] reproduced the continuous casting solidification of ferritic stainless steel using an isothermal solidification simulator and analyzed the effects of cooling rate and superheat on grain growth and columnar-to-equiaxed transition (CET) using the CAFE model. Experiments showed that reducing superheat (from 40 °C to 30 °C) increased equiaxed grain fraction from 26% to 42%, while reducing the cooling rate led to a significant rise in equiaxed fraction (from 14% to 42%). Simulated results for temperature profiles, grain morphology, and chill zone thickness qualitatively matched the experiments, validating the predictive capability of the CAFE model under various process conditions. Furthermore, Chen et al. [145] used ProCAST to simulate the temperature and stress fields in high-vanadium elbow castings and predicted shrinkage porosity, which was later confirmed via industrial CT scans. Optimizing the gating system based on these insights significantly reduced defect rates, highlighting the closed-loop value of “simulation prediction→experimental validation→industrial application”.

In conclusion, coupling simulation and experimental methods enables a more comprehensive and efficient understanding of the solidification behavior of HCCIs. This integrated approach lays a solid foundation for the development and performance enhancement of next-generation wear-resistant cast irons.

4. Conclusions and Outlook

As a key wear-resistant material for extreme-service environments, HCCIs will continue to evolve toward more precise, intelligent, and sustainable solidification control strategies, providing essential material support for high-end equipment manufacturing. This review systematically summarizes recent advances in both experimental investigations and numerical simulations of solidification microstructure evolution in HCCIs, critically analyzes current limitations, and outlines future research directions, aiming to promote theoretical breakthroughs and industrial applications of HCCIs.

4.1. Conclusions

- (1)

- The solidification microstructure of HCCIs—comprising primary austenite and eutectic carbides—is strongly influenced by the synergistic effects of alloy composition, cooling rate, and inoculation treatment. Non-carbide-forming elements enhance the matrix strength via solid solution strengthening and phase transformation control, while carbide-forming elements refine carbides and modify the interface, thereby improving wear resistance. Multicomponent alloy design enables simultaneous optimization of carbide toughening and matrix phase stabilization. An increased cooling rate significantly refines carbides and promotes the transformation of austenite to martensite, although it must be balanced against microcrack risks. Inoculation improves carbide refinement and uniformity through heterogeneous nucleation and adsorption mechanisms.

- (2)

- Numerical simulations have played a pivotal role in elucidating the mechanisms of solidification microstructure evolution. Thermodynamic calculations can accurately predict carbide precipitation pathways and phase stability. Phase-field and cellular automaton (CA) methods have successfully simulated dendritic growth, eutectic reactions, and carbide evolution. The combined phase-field and strain-gradient plasticity model provides insights into mechanical anisotropy under rapid solidification. Finite element methods (FEM) show excellent performance in predicting macro-defects and thermal–mechanical field distributions.

- (3)

- Despite remarkable progress at both experimental and simulation levels, several key challenges remain. These include the disconnect between experimental and simulation parameters, limited model generalizability (due to strong dependence on fitted data and poor cross-system predictability), oversimplified multiphysics coupling in complex processes (with insufficient capture of temperature–composition interactions), fragmented linkage between macro and microstructure (lacking end-to-end multiscale modeling), and underutilized high-throughput data techniques (with insufficient quantitative mapping of composition–property relationships). To address these challenges, future efforts could focus on developing a more universal parameterization framework, integrating dynamic multiscale correlation models, and utilizing high-throughput data platforms. These approaches may facilitate a deeper understanding of solidification mechanisms and support intelligent optimization of HCCI processing.

4.2. Outlook

- (1)

- Develop dedicated thermodynamic databases for HCCIs (e.g., interfacial energy, latent heat of transformation), and integrate machine learning algorithms to optimize nonequilibrium solidification path predictions. Construct a multiscale simulation platform combining CALPHAD, phase-field, CA, and FEM, enabling full-process modeling from atomic-level mechanisms to macroscopic properties.

- (2)

- Explore novel composite inoculants to break the carbide refinement limit. Design gradient-composition and multiphase composite microstructures tailored for extreme environments such as high temperature and corrosion.

- (3)

- Leverage advanced in situ techniques such as synchrotron radiation and high-temperature confocal scanning laser microscopy (HT-CSLM) to dynamically capture solidification processes and calibrate simulation parameters. Establish quantitative “composition–process–microstructure–property” maps to support inverse design of high-performance HCCIs.

- (4)

- Develop cross-scale defect prediction models for large castings (e.g., mill liners and work rolls), optimize gating and cooling system design, and integrate multiphysics simulations to improve service life under complex conditions.

Author Contributions

Conceptualization, methodology, software, investigation, visualization, and writing—original draft preparation, L.H.; methodology, validation, formal analysis, investigation, and data curation, Y.L.; conceptualization, writing—review and editing, supervision, project administration, and funding acquisition, H.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Key Research and Development Program of China, grant number 2024YFC3908402.

Data Availability Statement

No new data were created or analyzed in this study.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Fashu, S.; Trabadelo, V. Development and performance of high chromium white cast irons (HCWCIs) for wear–corrosive environments: A critical review. Metals 2023, 13, 1831. [Google Scholar] [CrossRef]

- Ngqase, M.; Pan, X. An overview on types of white cast irons and high chromium white cast irons. J. Phys. Conf. Ser. 2020, 1495, 012023. [Google Scholar] [CrossRef]

- Jain, A.S.; Chang, H.; Tang, X.; Hinckley, B.; Zhang, M.X. Refinement of primary carbides in hypereutectic high-chromium cast irons: A review. J. Mater. Sci. 2021, 56, 999–1038. [Google Scholar] [CrossRef]

- Liu, S.; Li, J.; Su, X.; Cui, S.; Zhang, H.; Ren, Z. Effect of Cr: C ratio on open three-body wear resistance of squeeze cast high chromium cast iron. Tribol. Int. 2025, 202, 110315. [Google Scholar] [CrossRef]

- Gundlach, R.B.; Tartaglia, J.M. Effects of silicon in High-Cr white cast irons. Int. J. Met. 2024, 18, 1843–1853. [Google Scholar] [CrossRef]

- Oguzie, E.E.; Li, J.; Liu, Y.; Chen, D.; Li, Y.; Yang, K.; Wang, F. The effect of Cu addition on the electrochemical corrosion and passivation behavior of stainless steels. Electrochim. Acta 2010, 55, 5028–5035. [Google Scholar] [CrossRef]

- Son, H.Y.; Jung, I.Y.; Choi, B.G.; Shin, J.H.; Jo, C.Y.; Lee, J.H. Effects of Chemical Composition and Solidification Rate on the Solidification Behavior of High-Cr White Irons. Metals 2024, 14, 276. [Google Scholar] [CrossRef]

- Gong, L.; Fu, H.; Zhi, X. Corrosion wear of hypereutectic high chromium cast iron: A review. Metals 2023, 13, 308. [Google Scholar] [CrossRef]

- Nastac, L. Modeling and Simulation of Microstructure Evolution in Solidifying Alloys; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Cusato, N.; Nabavizadeh, S.A.; Eshraghi, M. A review of large-scale simulations of microstructural evolution during alloy solidification. Metals 2023, 13, 1169. [Google Scholar] [CrossRef]

- Liu, S.; Liang, L. Research Progress on Alloying of High Chromium Cast Iron—Austenite Stabilizing Elements and Modifying Elements. Crystals 2025, 15, 210. [Google Scholar] [CrossRef]

- Wu, S.; Wang, D.; Tao, X.; Wang, X.; Zhang, R.; Zhou, Z.; Zhang, S.; Wu, C.; Sun, X.; Cui, C. Normalizing temperature influence on the microstructure characteristics, mechanical and wear performance of a novel high chromium cast iron. Tribol. Int. 2025, 202, 110327. [Google Scholar] [CrossRef]

- Li, S.; Cheng, X.; Fu, H. Effect of quenching temperature on microstructure and properties of multivariate high chromium cast iron. Metall. Res. Technol. 2024, 121, 608. [Google Scholar]

- Ngo, H.K.L.; Yamamoto, K.; Okuyama, T.; Nakayama, M.; Mizuno, K.; Koizumi, K. Influence of Heat Treatment on Erosive Wear Resistance of High Cr Cast Irons. Int. J. Met. 2024, 19, 1281–1294. [Google Scholar] [CrossRef]

- Escherová, J.; Krbata, M.; Kohutiar, M.; Barényi, I.; Chochlíková, H.; Eckert, M.; Jus, M.; Majerský, J.; Janík, R.; Dubcová, P. The Influence of Q&T Heat Treatment on the Change of Tribological Properties of Powder Tool Steels ASP2017, ASP2055 and Their Comparison with Steel X153CrMoV12. Materials 2024, 17, 974. [Google Scholar]

- Li, Y.; San Martín, D.; Wang, J.; Wang, C.; Xu, W. A review of the thermal stability of metastable austenite in steels: Martensite formation. J. Mater. Sci. Technol. 2021, 91, 200–214. [Google Scholar] [CrossRef]

- Jain, A.S.; Chang, H.; Ahmad, H.; Ma, X.; Zhang, M.X. Effect of solutes on the formation of primary carbides during solidification of hypereutectic high chromium cast irons through thermodynamic modeling. J. Mater. Sci. 2022, 57, 1429–1447. [Google Scholar] [CrossRef]

- Lai, J.P.; Pan, Q.L.; Sun, Y.W.; Xiao, C.A. Effect of Si content on the microstructure and wear resistance of high chromium cast iron. ISIJ Int. 2018, 58, 1532–1537. [Google Scholar] [CrossRef]

- Lai, J.P.; Pan, Q.L.; Peng, H.J.; Cui, H.R.; Xiao, C.A. Effects of Si on the microstructures and mechanical properties of high-chromium cast iron. J. Mater. Eng. Perform. 2016, 25, 4617–4623. [Google Scholar] [CrossRef]

- Chen, Z.; Fu, H.; Wang, F.; Yuan, N.; Lin, J. Effect of Si on microstructure and wear resistance of hypereutectic high-chromium cast iron. J. Mater. Eng. Perform. 2023, 32, 5450–5465. [Google Scholar] [CrossRef]

- Zhi, X.; Xing, J.; Fu, H.; Gao, Y. Effect of fluctuation and modification on microstructure and impact toughness of 20 wt.% Cr hypereutectic white cast iron. Mater. Werkst. Entwickl. Fert. Prüf. Eig. Anwendungen Tech. Werkst. 2008, 39, 391–393. [Google Scholar]

- Gong, L.; Chen, Z.; Xing, Z.; Fu, H. Microstructure evolution and corrosive wear of heat-treated silicon-bearing hypereutectic high-chromium cast iron. J. Mater. Sci. 2023, 58, 17623–17647. [Google Scholar] [CrossRef]

- Jacuinde, A.B.; Rainforth, W.M. The wear behaviour of high-chromium white cast irons as a function of silicon and Mischmetal content. Wear 2001, 250, 449–461. [Google Scholar] [CrossRef]

- Bedolla-Jacuinde, A.; Rainforth, M.W.; Mejia, I. The role of silicon in the solidification of high-Cr cast irons. Metall. Mater. Trans. A 2013, 44, 856–872. [Google Scholar] [CrossRef]

- Ma, S.; Zhang, J. Wear resistant high boron cast alloy-A review. Rev. Adv. Mater. Sci. 2016, 44, 54–62. [Google Scholar]

- Chung, R.J.; Tang, X.; Li, D.Y.; Hinckley, B.; Dolman, K. Microstructure refinement of hypereutectic high Cr cast irons using hard carbide-forming elements for improved wear resistance. Wear 2013, 301, 695–706. [Google Scholar] [CrossRef]

- Aso, S.; Goto, S.; Komatsu, Y.; Liu, W.; Liu, C. The effect of solidification conditions on phase transformation of iron matrix of Fe-25mass% Cr-CB alloys. Int. J. Cast Met. Res. 1999, 11, 285–290. [Google Scholar] [CrossRef]

- Purba, R.H.; Shimizu, K.; Kusumoto, K.; Gaqi, Y.; Todaka, T. Effect of boron addition on three-body abrasive wear characteristics of high chromium based multi-component white cast iron. Mater. Chem. Phys. 2022, 275, 125232. [Google Scholar] [CrossRef]

- Lu, H.; Li, T.; Cui, J.; Li, Q.; Li, D.Y. Improvement in erosion-corrosion resistance of high-chromium cast irons by trace boron. Wear 2017, 376, 578–586. [Google Scholar] [CrossRef]

- Chabak, Y.G.; Shimizu, K.; Efremenko, V.G.; Golinskyi, M.A.; Kusumoto, K.; Zurnadzhy, V.I.; Efremenko, A.V. Microstructure and phase elemental distribution in high-boron multi-component cast irons. Int. J. Miner. Metall. Mater. 2022, 29, 78–87. [Google Scholar] [CrossRef]

- Bedolla-Jacuinde, A.; Guerra, F.V.; Guerrero-Pastran, A.J.; Sierra-Cetina, M.A.; Valdez-Medina, S. Microstructural effect and wear performance of high chromium white cast iron modified with high boron contents. Wear 2021, 476, 203675. [Google Scholar] [CrossRef]

- Li, J.; Tang, Y.; Tang, X.; Li, D.Y. Promoting in situ formation of core-shell structured carbides in high-Cr cast irons by boron addition. J. Am. Ceram. Soc. 2021, 104, 4891–4901. [Google Scholar] [CrossRef]

- Çöl, M.; Koç, F.G.; Öktem, H.; Kır, D. The role of boron content in high alloy white cast iron (Ni-Hard 4) on microstructure, mechanical properties and wear resistance. Wear 2016, 348, 158–165. [Google Scholar] [CrossRef]

- Delijić, K.; Filipović, M. The Effect of Vanadium, Niobium and Boron on Microstructure, Mechanical and Corrosion Properties of High-Chromium White Cast Irons. Mach. Technol. Mater. 2022, 16, 286–289. [Google Scholar]

- Wang, X.; Du, Y.; Zhang, R.; Liu, C.; Mei, X.; Yang, X.; Jiang, B. Effects of nickel contents on phase constituent and mechanical properties of ductile iron. Int. J. Met. 2024, 18, 2721–2731. [Google Scholar] [CrossRef]

- Bork, M.; Chulist, R.; Górny, M.; Kowalczyk, M.; Marosz, J. The influence of nickel content on the structure parameters and magnetic properties of austenitic ductile iron castings. Arch. Civ. Mech. Eng. 2025, 25, 117. [Google Scholar] [CrossRef]

- Inthidech, S.; Sricharoenchai, P.; Matsubara, Y. Effect of alloying elements on heat treatment behavior of hypoeutectic high chromium cast iron. Mater. Trans. 2006, 47, 72–81. [Google Scholar] [CrossRef]

- Li, T.Z.; Li, L.; Lu, H.; Parent, L.; Tian, H.; Chung, R.J.; Li, D.Y. Effect of trace Ni on the resistance of high-Cr cast iron to slurry erosion. Wear 2019, 426, 605–611. [Google Scholar] [CrossRef]

- Lu, F.; Wei, S.; Xu, L.; Zhou, Y.; Wang, X.; Wang, F.; Yi, X. Erosion–wear behaviors of high-chromium cast iron with high nitrogen content in water–sand slurry and acid–sand slurry. Tribol. Trans. 2020, 63, 325–335. [Google Scholar] [CrossRef]

- Xu, L.; Wang, F.; Lu, F.; Zhou, Y.; Chen, C.; Wei, S. Microstructure and erosion wear properties of high chromium cast iron added nitrogen by high pressure in alkaline sand slurry. Wear 2021, 476, 203655. [Google Scholar] [CrossRef]

- Wang, J.; Liu, T.; Zhou, Y.; Xing, X.; Liu, S.; Yang, Y.; Yang, Q. Effect of nitrogen alloying on the microstructure and abrasive impact wear resistance of Fe-Cr-C-Ti-Nb hardfacing alloy. Surf. Coat. Technol. 2017, 309, 1072–1080. [Google Scholar] [CrossRef]

- Liu, Y.; Gong, L.; Dong, M.; Chen, Z.; Jin, T.; Yin, W.; Fu, H. Microstructure and properties of hypereutectic high chromium cast iron containing nitrogen. Mater. Sci. Technol. 2024, 40, 26–41. [Google Scholar] [CrossRef]

- Ibrahim, M.M.; Ibrahim, K.M. Effect of nitrogen addition on microstructure and mechanical properties of as-cast high-chromium cast iron containing niobium. Trans. Indian Inst. Met. 2020, 73, 2259–2267. [Google Scholar] [CrossRef]

- Li, S.; Li, J.; Shi, C.; Pan, J.; Sun, C.; Zhu, S.; Wei, H.; Li, Z. Effect of Nitrogen on Solidification Structure and Microsegregation of Electroslag Remelted 7Cr13 Steel. Metall. Mater. Trans. B 2024, 55, 1049–1068. [Google Scholar] [CrossRef]

- Gong, L.; Fu, H.; Zhi, X. Microstructure and properties of Cu-bearing hypereutectic high chromium cast iron. Mater. Charact. 2023, 195, 112546. [Google Scholar]

- Sarkar, T.; Mukherjee, M.; Pal, T.K. Effect of Cu addition on microstructure and hardness of As-Cast and heat-treated high-Cr cast iron. Trans. Indian Inst. Met. 2018, 71, 1455–1461. [Google Scholar] [CrossRef]

- Quintero-Ortiz, J.; Guerra, F.V.; Bedolla-Jacuinde, A.; Pacheco-Cedeño, J.S. Improving the sliding wear and strain behavior of a high-chromium white cast iron modified with Mn and Al. Wear 2025, 571, 205877. [Google Scholar] [CrossRef]

- Bouhamla, K.; Hadji, A.; Maouche, H.; Mentouri, Z.; Remili, S. Effect of manganese and molybdenum on the microstructure, the shape of secondary precipitation, and the wear behavior of a high chromium cast iron. Int. J. Met. 2024, 18, 1062–1074. [Google Scholar] [CrossRef]

- Hadji, A.; Bouhamla, K.; Maouche, H. Improving wear properties of high-chromium cast iron by manganese alloying. Int. J. Met. 2016, 10, 43–55. [Google Scholar] [CrossRef]

- Huq, M.J.; Shimizu Kand Kusumoto, K. Abrasive Wear Characteristics of High-Cr Multicomponent White Cast Irons at Elevated Temperatures. Crystals 2025, 15, 113. [Google Scholar] [CrossRef]

- Cui, J.; Guo, L.; Lu, H.; Li, D. Understanding effects of Cr content on the slurry erosion behavior of high-Cr cast irons through local property mapping and computational analysis. Wear 2017, 376, 587–594. [Google Scholar] [CrossRef]