Modeling of Tensile Tests Flow Curves Using an Explicit Piecewise Inverse Approach

Abstract

1. Introduction and State of the Art

Assessment of the Literature and the Problem Statement

2. Materials and Methods

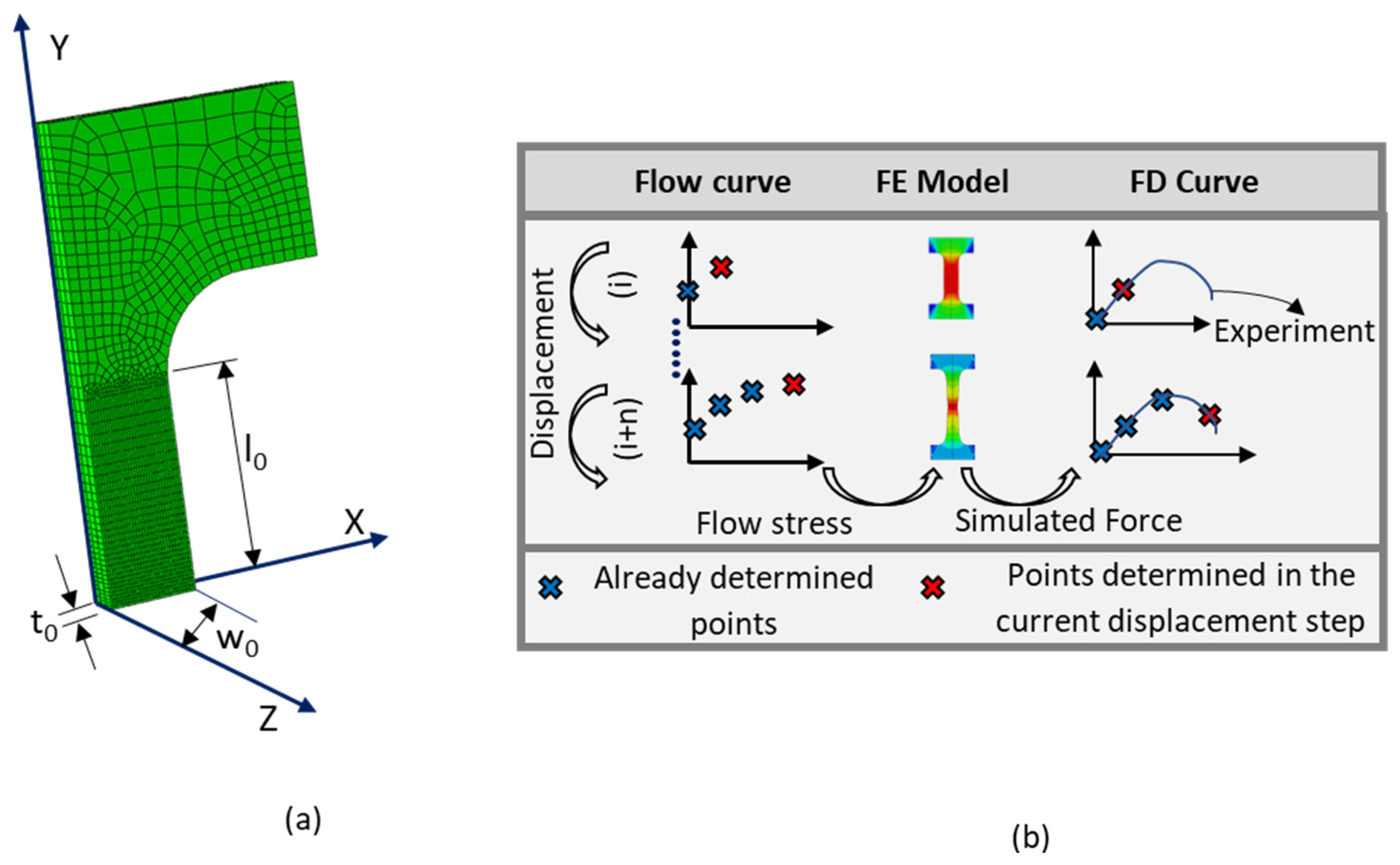

2.1. FE Model of the Tensile Specimen and Flow Curve Point Determination

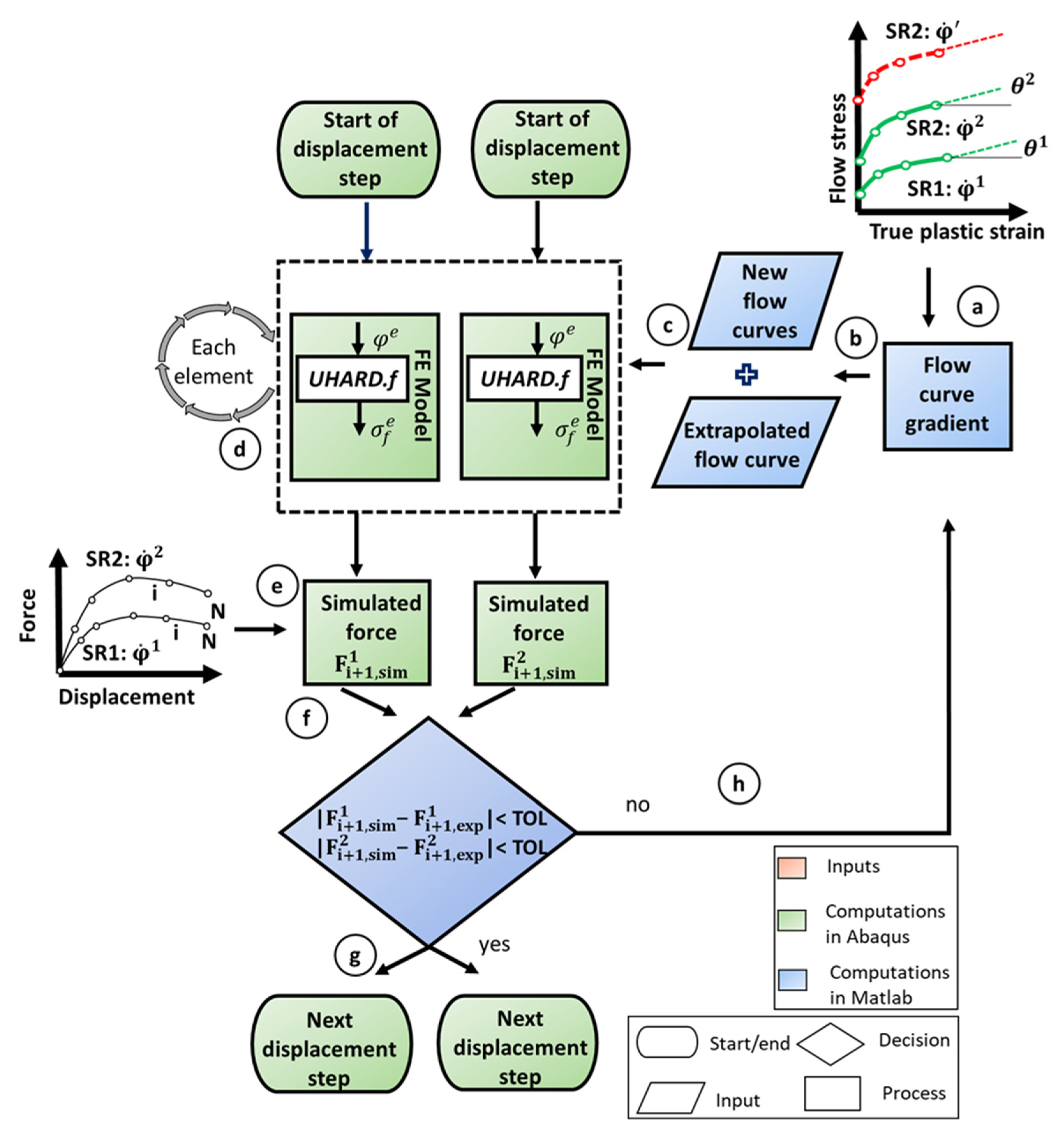

2.2. Constant Flow Curve Determination for Tensile Tests with FepiM

3. Results and Discussion

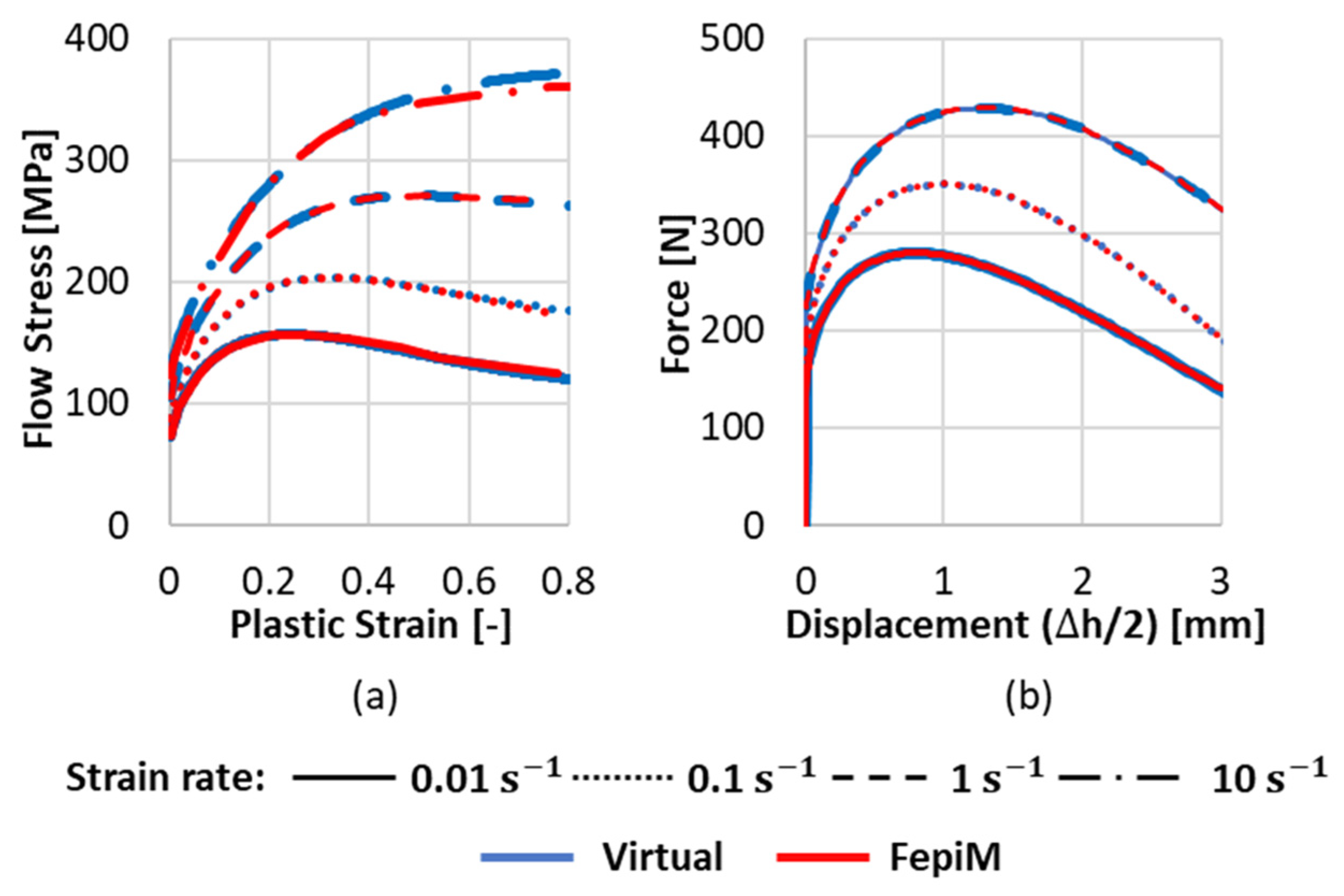

3.1. Results of FepiM Flow Curves Determined from Virtual Experiments

3.2. Discussion of FepiM Flow Curves Determined from Virtual Experiments

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kopp, R.; Wiegels, H. Einführung in die Umformtechnik; Verlag Mainz: Aachen, Germany, 2023; ISBN 3-86073-821-6. [Google Scholar]

- Sarafraz, Y.; Koch, A.; Felinks, N.; Biermann, D.; Walther, F. Influence of pre-drilling on hardness and tensile failure of formed internal threads in thin-walled AZ91 cast alloys. Eng. Fail. Anal. 2021, 130, 105783. [Google Scholar] [CrossRef]

- Tu, S.; Ren, X.; He, J.; Zhang, Z. Stress–strain curves of metallic materials and post-necking strain hardening characterization: A review. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 3–19. [Google Scholar] [CrossRef]

- Hollomon, J.H. Tensile Deformation. Trans. Metall. Soc. AIME 1945, 162, 268–290. [Google Scholar]

- Ramberg, W.; Osgood, W.R. Description of Stress-Strain Curves by Three Parameters; National Advisory Committee for Aeronautics: Hampton, VA, USA, 1943.

- Yin, Q. Verfestigungs-und Schâdigungsverhalten von Blechwerkstoffen im Ebenen Torsionsversuch. Ph.D. Thesis, Dortmund Technische Universität, Dortmund, Germany, 2014. [Google Scholar]

- Mecking, H.; Kocks, U.F. Kinetics of flow and strain-hardening. Acta Metall. 1981, 29, 1865–1875. [Google Scholar] [CrossRef]

- Kocks, U.F.; Mecking, H. Physics and phenomenology of strain hardening: The FCC case. Prog. Mater. Sci. 2003, 48, 171–273. [Google Scholar] [CrossRef]

- Roters, F.; Raabe, D.; Gottstein, G. Work hardening in heterogeneous alloys—A microstructural approach based on three internal state variables. Acta Mater. 2000, 48, 4181–4189. [Google Scholar] [CrossRef]

- Xiong, W. Adoption of New Strategies for Parameterization of a Microstructure-Based Flow Stress Model. Ph.D. Thesis, Rheinisch-Westfälische Technische Hochschule Aachen, Aachen, Germany, 2017. [Google Scholar]

- Bridgman, P.W. Studies in Large Plastic Flow and Fracture; Harvard University Press: Cambridge, MA, USA, 1952. [Google Scholar]

- Gromada, M.; Mishuris, G.; Öchsner, A. Correction Formulae for the Stress Distribution in Round Tensile Specimens at Neck Presence; Springer: Berlin/Heidelberg, Germany, 2011; ISBN 978-3-642-22133-0. [Google Scholar]

- Khoddam, S.; Solhjoo, S.; Hodgson, P.D. State of the art methods to post-process mechanical test data to characterize the hot deformation behavior of metals. Adv. Mech. Eng. 2021, 13, 168781402110610. [Google Scholar] [CrossRef]

- Zhang, C.; Chu, X.; Guines, D.; Leotoing, L.; Ding, J.; Zhao, G. Dedicated linear—Voce model and its application in investigating temperature and strain rate effects on sheet formability of aluminum alloys. Mater. Des. 2015, 67, 522–530. [Google Scholar] [CrossRef]

- Kamaya, M.; Kitsunai, Y.; Koshiishi, M. True stress–strain curve acquisition for irradiated stainless steel including the range exceeding necking strain. J. Nucl. Mater. 2015, 465, 316–325. [Google Scholar] [CrossRef]

- Vuppala, A.; Krämer, A.; Braun, A.; Lohmar, J.; Hirt, G. A New Inverse Explicit Flow Curve Determination Method for Compression Tests. Procedia Manuf. 2020, 47, 824–830. [Google Scholar] [CrossRef]

- Vuppala, A.; Krämer, A.; Lohmar, J.; Hirt, G.; Fepi, M. A Novel Inverse Piecewise Method to Determine Isothermal Flow Curves for Hot Working. Metals 2021, 11, 602. [Google Scholar] [CrossRef]

- Vuppala, A.; Brüggemann, H.; Bailly, D.; Scharifi, E. An Inverse Piecewise Flow Curve Determination Method for Torsion Tests at Elevated Temperature. Metals 2025, 15, 219. [Google Scholar] [CrossRef]

- Xu, Y.; Birnbaum, P.; Pilz, S.; Zhuang, X.; Zhao, Z.; Kräusel, V. Investigation of constitutive relationship and dynamic recrystallization behavior of 22MnB5 during hot deformation. Results Phys. 2019, 14, 102426. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vuppala, A.; Brüggemann, H.; Bailly, D.; Scharifi, E. Modeling of Tensile Tests Flow Curves Using an Explicit Piecewise Inverse Approach. Metals 2025, 15, 638. https://doi.org/10.3390/met15060638

Vuppala A, Brüggemann H, Bailly D, Scharifi E. Modeling of Tensile Tests Flow Curves Using an Explicit Piecewise Inverse Approach. Metals. 2025; 15(6):638. https://doi.org/10.3390/met15060638

Chicago/Turabian StyleVuppala, Aditya, Holger Brüggemann, David Bailly, and Emad Scharifi. 2025. "Modeling of Tensile Tests Flow Curves Using an Explicit Piecewise Inverse Approach" Metals 15, no. 6: 638. https://doi.org/10.3390/met15060638

APA StyleVuppala, A., Brüggemann, H., Bailly, D., & Scharifi, E. (2025). Modeling of Tensile Tests Flow Curves Using an Explicit Piecewise Inverse Approach. Metals, 15(6), 638. https://doi.org/10.3390/met15060638