Data Science in Order and Disorder of High-Entropy Materials

Abstract

1. Introduction

2. Order–Disorder Transitions in High-Entropy Materials

2.1. Ordering and Disordering of Materials

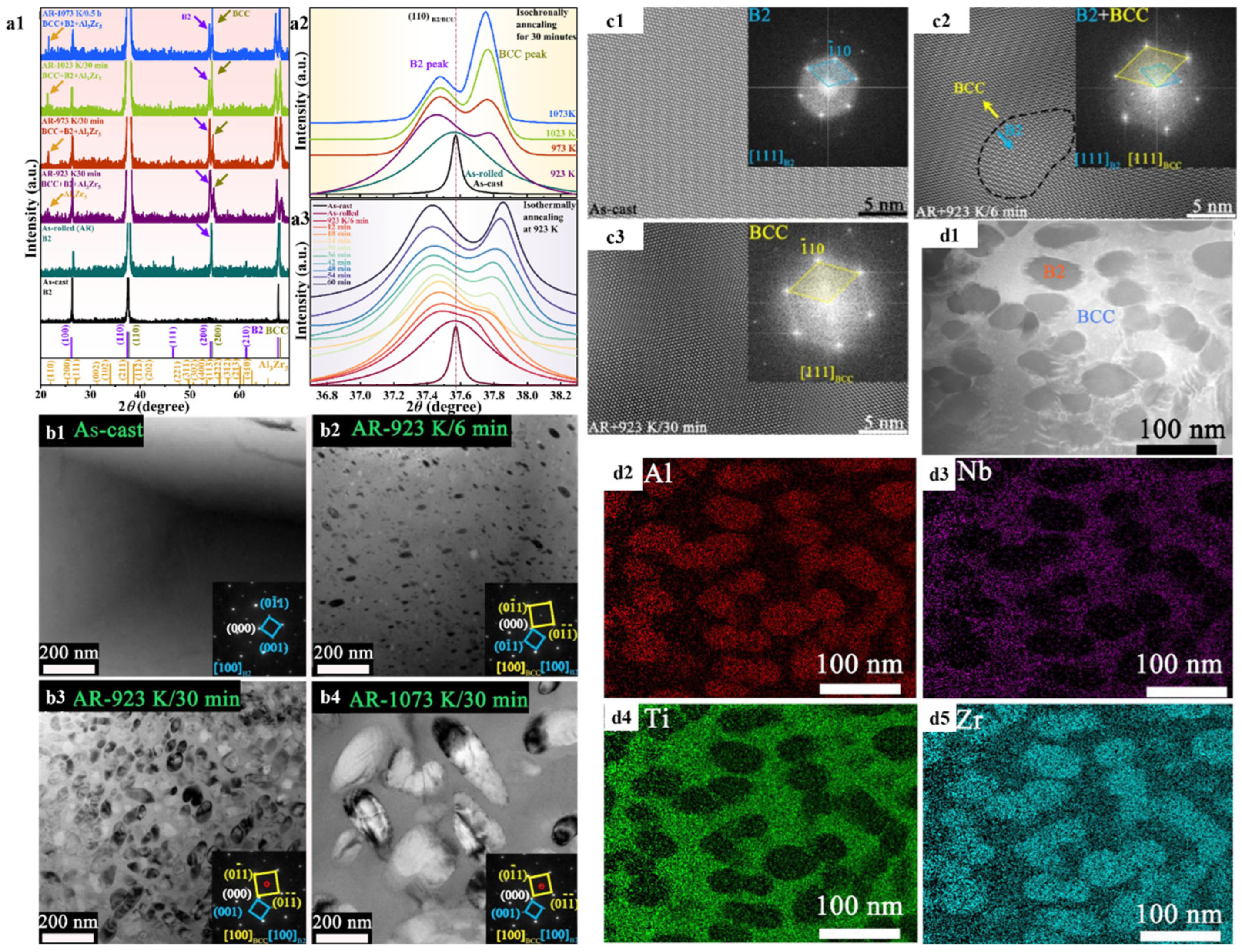

2.2. Order–Disorder Transitions in High-Entropy Alloys

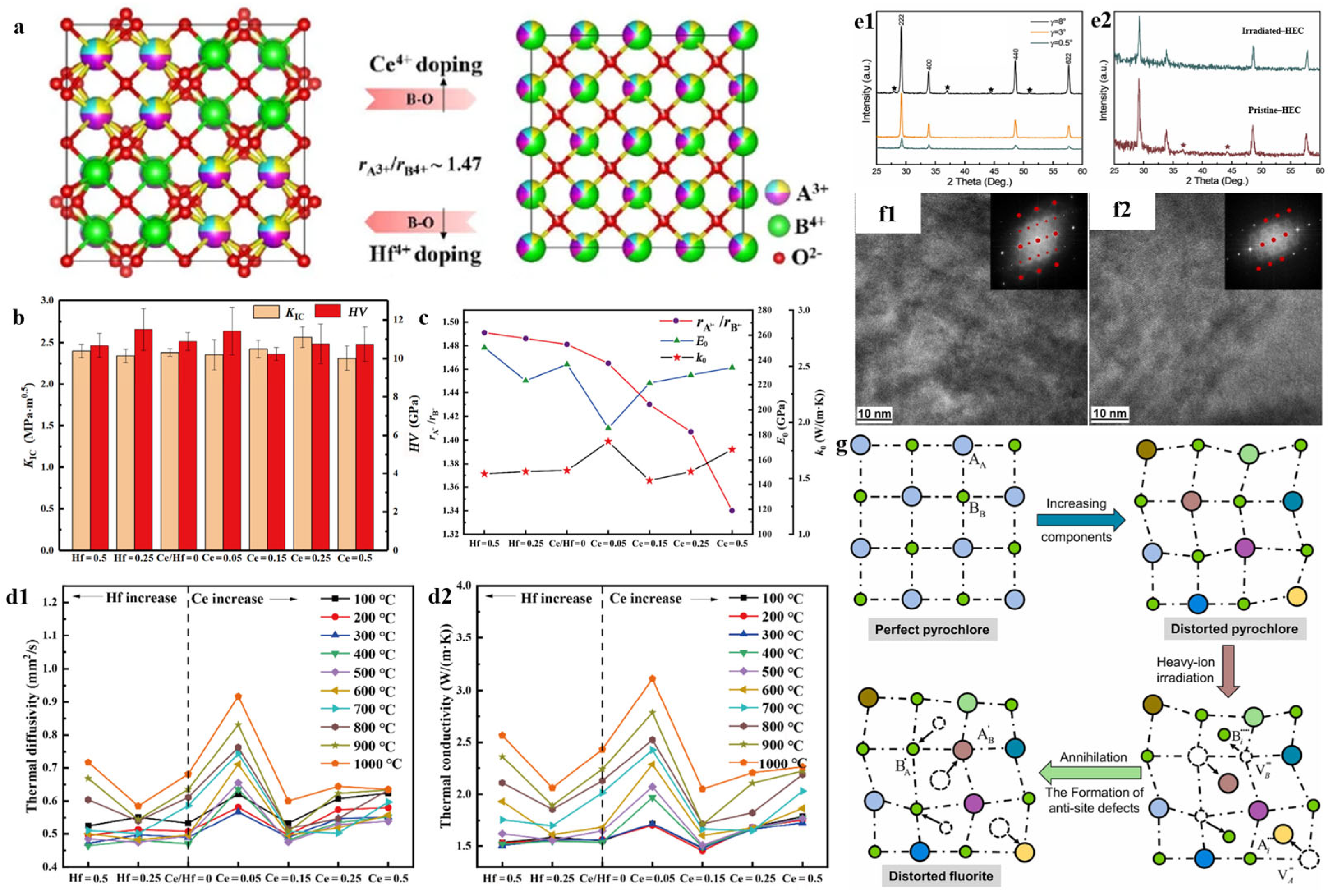

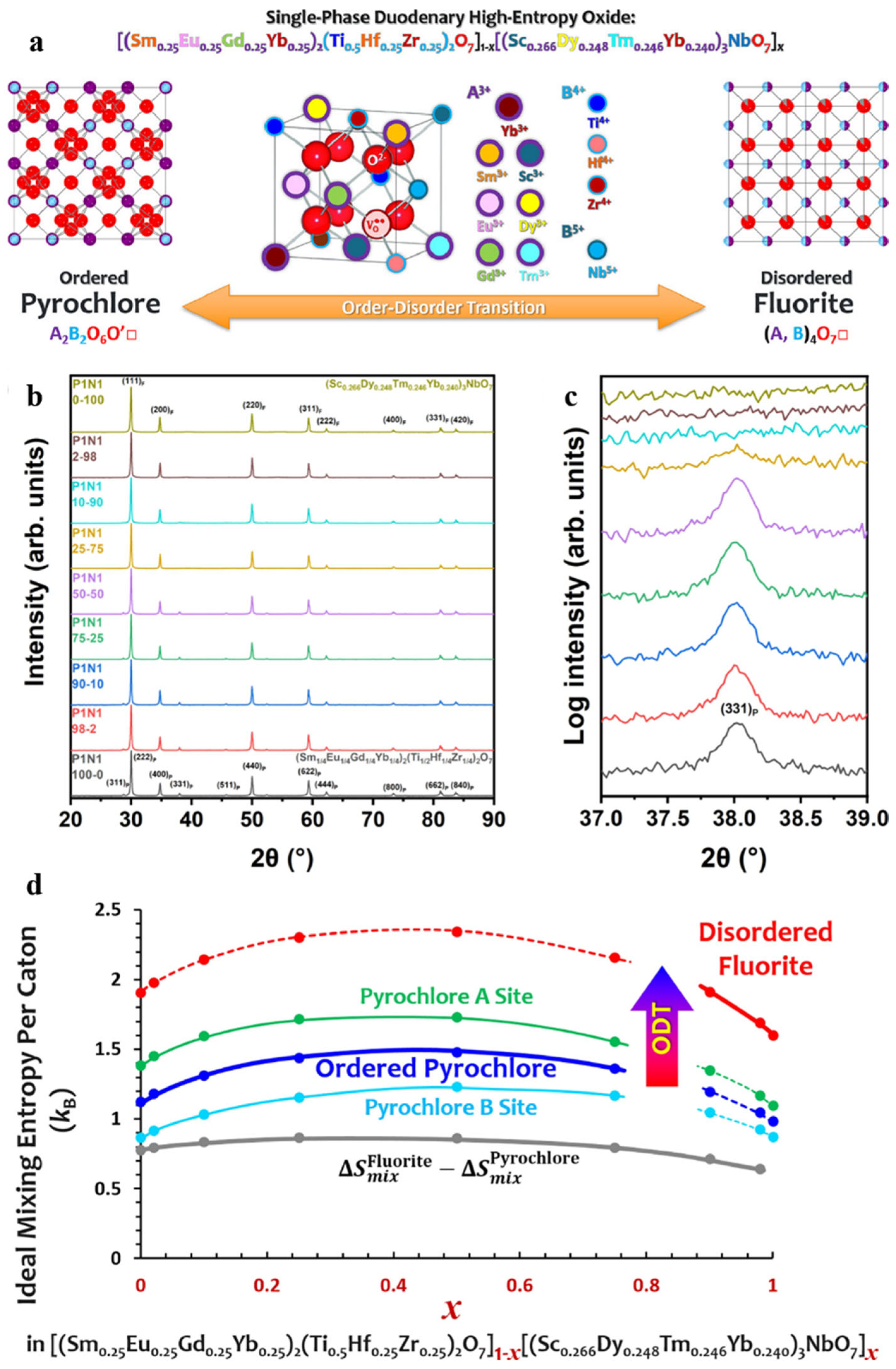

2.3. Order–Disorder Transitions in High-Entropy Ceramics

2.4. Nonlinear Law in High-Entropy Materials

3. The Rising Role of Data Science

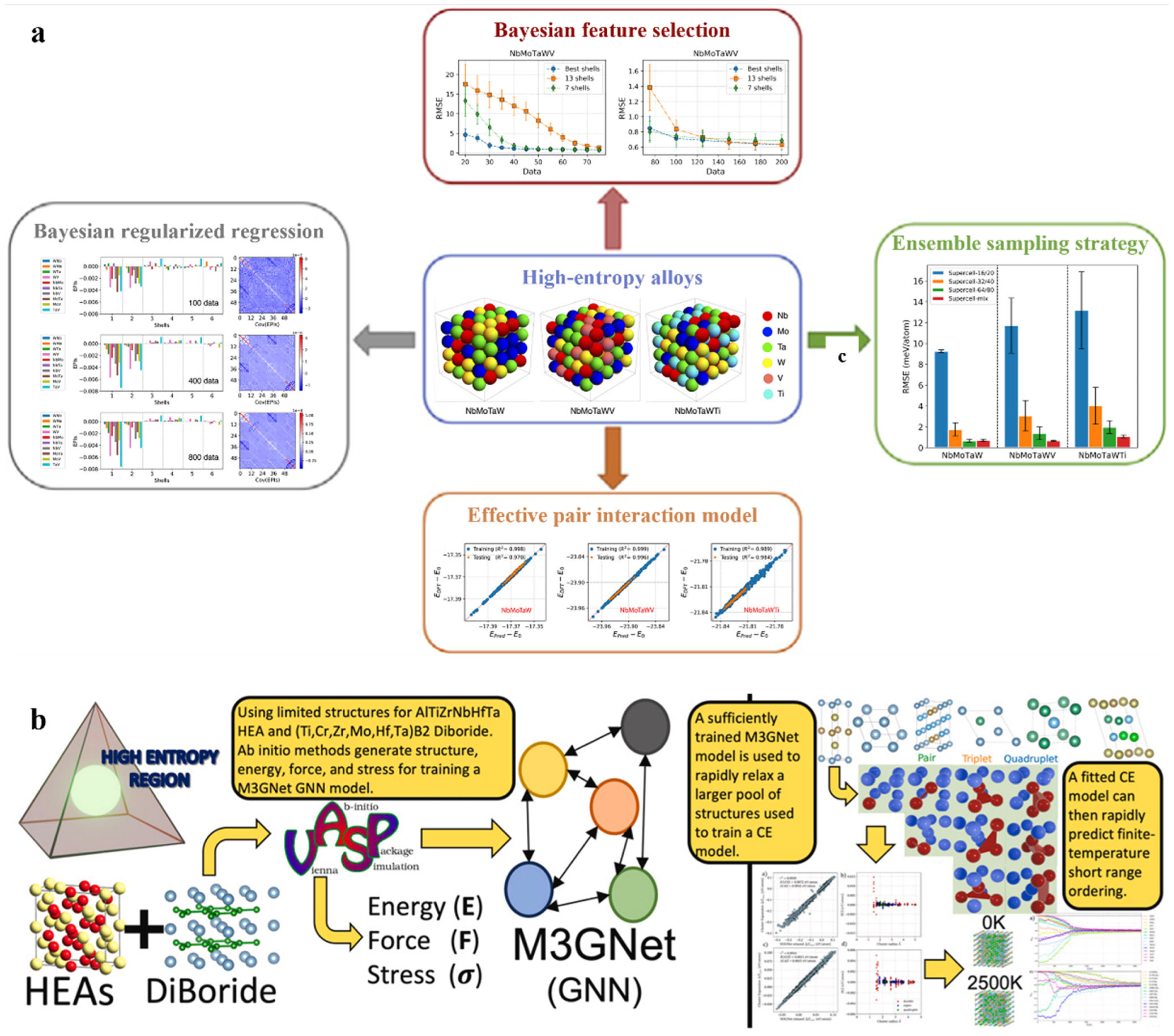

3.1. Machine Learning

3.2. Molecular Dynamics Simulations

3.3. Monte Carlo Simulations

4. Synergistic Insights and Future Perspectives

4.1. Current Understanding and Achievements

4.2. Challenges and Limitations

4.3. Future Directions

5. Summary

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2013, 61, 1–93. [Google Scholar] [CrossRef]

- Li, W.; Xie, D.; Li, D.; Zhang, Y.; Gao, Y.; Liaw, P.K. Mechanical behavior of high-entropy alloys. Prog. Mater. Sci. 2021, 118, 100777. [Google Scholar] [CrossRef]

- George, E.P.; Raabe, D.; Ritchie, R.O. High-entropy alloys. Nat. Rev. Mater. 2019, 4, 515–534. [Google Scholar] [CrossRef]

- Liu, C.; Li, S.; Zheng, Y.; Xu, M.; Su, H.; Miao, X.; Liu, Y.; Zhou, Z.; Qi, J.; Yang, B.; et al. Advances in high entropy oxides: Synthesis, structure, properties and beyond. Prog. Mater. Sci. 2024, 148, 101385. [Google Scholar] [CrossRef]

- Tsai, M.; Yeh, J. High-entropy alloys: A critical review. Mater. Res. Lett. 2014, 2, 107–123. [Google Scholar] [CrossRef]

- Miracle, D.; Senkov, O. A critical review of high entropy alloys and related concepts. Acta Mater. 2016, 122, 448–511. [Google Scholar] [CrossRef]

- Hsu, W.; Tsai, C.; Yeh, A.; Yeh, J. Clarifying the four core effects of high-entropy materials. Nat. Rev. Chem. 2024, 8, 471–485. [Google Scholar] [CrossRef]

- Han, L.; Zhu, S.; Rao, Z.; Scheu, C.; Ponge, D.; Ludwig, A.; Zhang, H.; Gutfleisch, O.; Hahn, H.; Li, Z.; et al. Multifunctional high-entropy materials. Nat. Rev. Mater. 2024, 9, 846–865. [Google Scholar] [CrossRef]

- Wyatt, B.C.; Nemani, S.K.; Hilmas, G.E.; Opila, E.J.; Anasori, B. Ultra-high temperature ceramics for extreme environments. Nat. Rev. Mater. 2023, 9, 773–789. [Google Scholar] [CrossRef]

- Xi, R.; Li, Y. Recent advances in the performance and mechanisms of high-entropy alloys under low- and high-temperature conditions. Coatings 2025, 15, 92. [Google Scholar] [CrossRef]

- Šíma, V. Order-disorder transformations in materials. J. Alloys Compd. 2004, 378, 44–51. [Google Scholar] [CrossRef]

- Pfeiler, W.; Sprušil, B. Atomic ordering in alloys: Stable states and kinetics. Mater. Sci. Eng. A 2002, 324, 34–42. [Google Scholar] [CrossRef]

- Luo, Q.; Guo, Y.; Liu, B.; Feng, Y.; Zhang, J.; Li, Q.; Chou, K. Thermodynamics and kinetics of phase transformation in rare earth-magnesium alloys: A critical review. J. Mater. Sci. Technol. 2020, 44, 171–190. [Google Scholar] [CrossRef]

- Yan, X.; Liaw, P.K.; Zhang, Y. Order and disorder in amorphous and high-entropy materials. Metall. Mater. Trans. A 2021, 52, 2111–2122. [Google Scholar] [CrossRef]

- Gao, K.; Chu, Y.; Zhou, W.; Tian, Y.; Zhang, Y.; Li, Y. Phase inversion in a lightweight high Al content refractory high-entropy alloy. J. Mater. Sci. Technol. 2023, 150, 124–137. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Y. Disorder-order transition in multiprincipal element alloy: A free energy perspective. Phys. Rev. Mater. 2023, 7, 033606. [Google Scholar] [CrossRef]

- Lokhande, V.; Malavekar, D.; Kim, C.; Vinu, A.; Ji, T. Order within disorder: Unveiling the potential of high entropy materials in energy storage and electrocatalysis. Energy Storage Mater. 2024, 72, 103718. [Google Scholar] [CrossRef]

- Lu, Z.; Ma, D.; Liu, X.; Lu, Z. High-throughput and data-driven machine learning techniques for discovering high-entropy alloys. Commun. Mater. 2024, 5, 76. [Google Scholar]

- Yao, Y.; Dong, Q.; Brozena, A.; Luo, J.; Miao, J.; Chi, M.; Wang, C.; Kevrekidis, I.G.; Ren, Z.J.; Greeley, J.; et al. High-entropy nanoparticles: Synthesis-structure-property relationships and data-driven discovery. Science 2022, 376, eabn3103. [Google Scholar] [CrossRef]

- Cui, K.; Qiao, J.; Liaw, P.K.; Zhang, Y. Data driving design of high-entropy alloys for lightweight and dynamic applications. Sci. China Phys. Mech. Astron. 2024, 67, 227101. [Google Scholar] [CrossRef]

- Meng, H.; Yu, H.; Zhuang, L.; Chu, Y. Data-driven acceleration of high-entropy ceramic discovery. Matter 2024, 7, 2646–2649. [Google Scholar] [CrossRef]

- Nix, F.C.; Shockley, W. Order-Disorder transformations in alloys. Rev. Mod. Phys. 1938, 10, 1–71. [Google Scholar] [CrossRef]

- Wu, X.; Wang, Z.; Yang, F.; Gao, R.; Liang, C.; Tey, M.K.; Li, X.; Pohl, T.; You, L. Dissipative time crystal in a strongly interacting Rydberg gas. Nat. Phys. 2024, 20, 1389–1394. [Google Scholar] [CrossRef]

- Çiftci, Y.; Çolakoğlu, K. Mechanical stability and elastic properties of some FCC metals: A many-body potential applications. Math. Comput. Appl. 2003, 8, 295–302. [Google Scholar] [CrossRef]

- Zhou, Z.Y.; Yang, Q.; Yu, H.B. Toward atomic-scale understanding of structure-dynamics-properties relations for metallic glasses. Prog. Mater. Sci. 2024, 145, 101311. [Google Scholar] [CrossRef]

- Deringer, V.L.; Bernstein, N.; Csányi, G.; Mahmoud, C.B.; Ceriotti, M.; Wilson, M.; Drabold, D.A.; Elliott, S.R. Origins of structural and electronic transitions in disordered silicon. Nature 2021, 589, 59–64. [Google Scholar] [CrossRef]

- Zhang, F.; Lou, H.; Cheng, B.; Zeng, Z.; Zeng, Q. High-pressure induced phase transitions in high-entropy alloys: A review. Entropy 2019, 21, 239. [Google Scholar] [CrossRef]

- Tian, L.; Levämäki, H.; Eriksson, O.; Kokko, K.; Nagy, Á.; Délczeg-Czirják, E.K.; Vitos, L. Density functional theory description of the order-disorder transformation in Fe-Ni. Sci. Rep. 2019, 9, 8172. [Google Scholar] [CrossRef]

- Bag, P.; Su, Y.; Kuo, Y.; Lai, Y.; Wu, S. Physical properties of face-centered cubic structured high-entropy alloys: Effects of NiCo, NiFe, and NiCoFe alloying with Mn, Cr, and Pd. Phys. Rev. Mater. 2021, 5, 085003. [Google Scholar] [CrossRef]

- Santos-Florez, P.A.; Dai, S.; Yao, Y.; Yanxon, H.; Li, L.; Wang, Y.; Zhu, Q.; Yu, X. Short-range order and its impacts on the BCC MoNbTaW multi-principal element alloy by the machine-learning potential. Acta Mater. 2023, 255, 119041. [Google Scholar] [CrossRef]

- Fernández-Caballero, A.; Fedorov, M.; Wróbel, J.; Mummery, P.; Nguyen-Manh, D. Configurational entropy in multicomponent alloys: Matrix formulation from ab initio based Hamiltonian and application to the FCC Cr-Fe-Mn-Ni system. Entropy 2019, 21, 68. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Miao, J.; Luo, A.A. Order-disorder transition and its mechanical effects in lightweight AlCrTiV high entropy alloys. Scr. Mater. 2021, 210, 114462. [Google Scholar] [CrossRef]

- Kumar, T.S.; Chauhan, L.; Chakravarthy, K.; Chelvane, A.; Shanmugasundaram, T. The improved galvanic corrosion resistance of a eutectic high entropy alloy through heat treatment. J. Mater. Res. 2022, 37, 4211–4221. [Google Scholar] [CrossRef]

- Chen, X.; Wang, Q.; Cheng, Z.; Zhu, J.; Jiang, L. Direct observation of chemical short-range order in a medium-entropy alloy. Nature 2021, 592, 712–716. [Google Scholar] [CrossRef]

- Zhang, R.; Zhao, S.; Ding, J.; Chong, Y.; Jia, T.; Ophus, C.; Asta, M.; Ritchie, R.O.; Minor, A.M. Short-range order and its impact on the CrCoNi medium-entropy alloy. Nature 2020, 581, 283–287. [Google Scholar] [CrossRef]

- Udayakumaran, G.; Gandhi, T.K.; Raju, R.; Bansal, R.; Kukade, J.; Barpha, V.; Saxena, K.K.; Panchal, S.M.; Bhavani, B. Study of phase equilibrium of refractory high-entropy alloys using the atomic size difference concept for turbine blade applications. High Temp. Mater. Proc. 2024, 43, 20240006. [Google Scholar] [CrossRef]

- Zhao, X.; Li, S.; Jiang, J.; Bai, J.; Xie, H.; Pan, H.; Tian, Y.; Ren, Y.; Teng, C.; Wu, L.; et al. Polytypic omega/omega-like transformation in a refractory high-entropy alloy. Acta Mater. 2022, 238, 118207. [Google Scholar] [CrossRef]

- Zhu, J.; Wei, M.; Xu, J.; Yang, R.; Meng, X.; Zhang, P.; Yang, J.; Li, G.; Gao, F. Influence of order-disorder transition on the mechanical and thermophysical properties of A2B2O7 high-entropy ceramics. J. Adv. Ceram. 2022, 11, 1222–1234. [Google Scholar] [CrossRef]

- Xu, L.; Niu, M.; Wang, H.; Su, L.; Gao, H.; Zhuang, L. Response of structure and mechanical properties of high entropy pyrochlore to heavy ion irradiation. J. Eur. Ceram. Soc. 2022, 42, 6624–6632. [Google Scholar] [CrossRef]

- Wright, A.J.; Wang, Q.; Hu, C.; Yeh, Y.; Chen, R.; Luo, J. Single-phase duodenary high-entropy fluorite/pyrochlore oxides with an order-disorder transition. Acta Mater. 2021, 211, 116858. [Google Scholar] [CrossRef]

- Pickering, E.J.; Jones, N.G. High-entropy alloys: A critical assessment of their founding principles and future prospects. Int. Mater. Rev. 2016, 61, 183–202. [Google Scholar] [CrossRef]

- Denton, A.R.; Ashcroft, N.W. Vegard’s law. Phys. Rev. A 1991, 43, 3161–3164. [Google Scholar] [CrossRef] [PubMed]

- Schwerer, F.; Conroy, J.; Arajs, S. Matthiessen’s rule and the electrical resistivity of iron-silicon solid solutions. J. Phys. Chem. Solids 1969, 30, 1513–1525. [Google Scholar] [CrossRef]

- Kumar, N.; Waghmare, U.V. Entropic stabilization and descriptors of structural transformation in high entropy alloys. Acta Mater. 2023, 255, 119077. [Google Scholar] [CrossRef]

- Yang, Y.; Jia, Z.; Zhang, X.; Liu, Y.; Wang, Q.; Li, Y.; Shao, L.; Di, S.; Kuang, J.; Sun, L.; et al. Chemical short-range order in multi-principal element alloy with ordering effects on water electrolysis performance. Mater. Today 2023, 72, 97–108. [Google Scholar] [CrossRef]

- Yu, P.Y.; Cardona, M.; Sham, L.J. Fundamentals of Semiconductors: Physics and materials properties. Phys. Today 1997, 50, 76–77. [Google Scholar] [CrossRef]

- Zhang, H.; Cai, D.; Sun, X.; Huang, H.; Lu, S.; Wang, Y.; Hu, Q.; Vitos, L.; Ding, X. Solid solution strengthening of high-entropy alloys from first-principles study. J. Mater. Sci. Technol. 2022, 121, 105–116. [Google Scholar] [CrossRef]

- Wang, Y.; Li, D.; Yang, J.; Jin, J.; Zhang, M.; Wang, X.; Li, B.; Hu, Z.; Gong, P. Effect of grain size on the tribological behavior of CoCrFeMnNi high entropy alloy. Materials 2023, 16, 1714. [Google Scholar] [CrossRef]

- Rossiter, P.L. The Electrical Resistivity of Metals and Alloys; Cambridge University Press: Cambridge, UK, 1987. [Google Scholar]

- Zhao, C.; Li, J.; He, Y.; Wang, J.; Wang, W.Y.; Kou, H.; Wang, J. Effect of strong magnetic field on the microstructure and mechanical-magnetic properties of AlCoCrFeNi high-entropy alloy. J. Alloys Compd. 2019, 820, 153407. [Google Scholar] [CrossRef]

- Yeh, J.; Chen, S.; Lin, S.; Gan, J.; Chin, T.; Shun, T.; Tsau, C.; Chang, S. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- John, S.; Rangarajan, R. Optimal structures for classical wave localization: An alternative to the Ioffe-Regel criterion. Phys. Rev. B 1988, 38, 10101–10104. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zuo, T.; Cheng, Y.; Liaw, P.K. High-entropy alloys with high saturation magnetization, electrical resistivity and malleability. Sci. Rep. 2013, 3, 1455. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Yang, C. Machine learning design for high-entropy alloys: Models and algorithms. Metals 2024, 14, 235. [Google Scholar] [CrossRef]

- Elkatatny, S.; Abd-Elaziem, W.; Sebaey, T.A.; Darwish, M.A.; Hamada, A. Machine-learning synergy in high-entropy alloys: A review. J. Mater. Res. Technol. 2024, 33, 3976–3997. [Google Scholar] [CrossRef]

- Pyzer-Knapp, E.O.; Pitera, J.W.; Staar, P.W.J.; Takeda, S.; Laino, T.; Sanders, D.P.; Sexton, J.; Smith, J.R.; Curioni, A. Accelerating materials discovery using artificial intelligence, high performance computing and robotics. Npj Comput. Mater. 2022, 8, 84. [Google Scholar] [CrossRef]

- Qi, J.; Fan, X.; Hoyos, D.I.; Widom, M.; Liaw, P.K.; Poon, J. Integrated design of aluminum-enriched high-entropy refractory B2 alloys with synergy of high strength and ductility. Sci. Adv. 2024, 10, eadq0083. [Google Scholar] [CrossRef]

- Ren, W.; Zhang, Y.; Wang, W.; Ding, S.; Li, N. Prediction and design of high hardness high entropy alloy through machine learning. Mater. Des. 2023, 235, 112454. [Google Scholar] [CrossRef]

- Gao, T.; Gao, J.; Yang, S.; Zhang, L. Data-driven design of novel lightweight refractory high-entropy alloys with superb hardness and corrosion resistance. npj Comput. Mater. 2024, 10, 256. [Google Scholar] [CrossRef]

- Wen, C.; Zhang, Y.; Wang, C.; Huang, H.; Wu, Y.; Lookman, T.; Su, Y. Machine-learning-assisted compositional design of refractory high-entropy alloys with optimal strength and ductility. Engineering 2024, 46, 214–223. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, J.; Pei, Z. Machine learning for high-entropy alloys: Progress, challenges and opportunities. Prog. Mater. Sci. 2022, 131, 101018. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, X.; Bi, S.; Yin, J.; Zhang, G.; Eisenbach, M. Robust data-driven approach for predicting the configurational energy of high entropy alloys. Mater. Des. 2019, 185, 108247. [Google Scholar] [CrossRef]

- Vazquez, G.; Sauceda, D.; Arróyave, R. Deciphering chemical ordering in high entropy materials: A machine learning-accelerated high-throughput cluster expansion approach. Acta Mater. 2024, 276, 120137. [Google Scholar] [CrossRef]

- Kadupitiya, J.C.S.; Fox, G.C.; Jadhao, V. Solving Newton’s equations of motion with large timesteps using recurrent neural networks based operators. Mach. Learn. Sci. Technol. 2022, 3, 025002. [Google Scholar] [CrossRef]

- Akter, R.; Khan, M.; Nobin, M.N.M.; Ali, M.S.; Hossain, M.M.; Rahaman, M.Z.; Ali, M.L. Effects of grain boundary and chemical short-range order on mechanical properties of NiCoCr multi-principal element alloys: A molecular dynamics simulations. Mater. Today Commun. 2023, 36, 106630. [Google Scholar] [CrossRef]

- Hasan, M.A.A.; Shin, S.; Liaw, P.K. Short-range order effects on the thermodynamic behavior of AlCoCrFeNi high-entropy alloys. Comput. Mater. Sci. 2024, 239, 112980. [Google Scholar] [CrossRef]

- Carreño, J.C.L.; Del Valle, E.; Laussy, F.P. Frequency-resolved Monte Carlo. Sci. Rep. 2018, 8, 6975. [Google Scholar]

- Alvarado, A.M.; Lee, C.; Wróbel, J.S.; Sobieraj, D.; Nguyen-Manh, D.; Poplawsky, J.D.; Fensin, S.J.; Martinez, E.; El-Atwani, O. Predicting short-range order evolution in WTaCrVHf refractory high-entropy alloys. Scr. Mater. 2023, 233, 115506. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, J.; Yin, J.; Bi, S.; Eisenbach, M.; Wang, Y. Monte Carlo simulation of order-disorder transition in refractory high entropy alloys: A data-driven approach. Comput. Mater. Sci. 2020, 187, 110135. [Google Scholar] [CrossRef]

- Yang, T.; Zhao, Y.L.; Tong, Y.; Jiao, Z.B.; Wei, J.; Cai, J.X.; Han, X.D.; Chen, D.; Hu, A.; Kai, J.J.; et al. Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys. Science 2018, 362, 933–937. [Google Scholar] [CrossRef]

- Lederer, Y.; Toher, C.; Vecchio, K.S.; Curtarolo, S. The search for high entropy alloys: A high-throughput ab-initio approach. Acta Mater. 2018, 159, 364–383. [Google Scholar] [CrossRef]

- Ren, F.; Pandolfi, R.; Van Campen, D.; Hexemer, A.; Mehta, A. On-the-fly data assessment for high-throughput X-ray diffraction measurements. ACS Comb. Sci. 2017, 19, 377–385. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Sheng, H.; Ma, E. Strengthening in multi-principal element alloys with local-chemical-order roughened dislocation pathways. Nat. Commun. 2019, 10, 3563. [Google Scholar] [CrossRef] [PubMed]

- Dai, F.; Wen, B.; Sun, Y.; Xiang, H.; Zhou, Y. Theoretical prediction on thermal and mechanical properties of high entropy (Zr0.2Hf0.2Ti0.2Nb0.2Ta0.2)C by deep learning potential. J. Mater. Sci. Technol. 2020, 43, 168–174. [Google Scholar] [CrossRef]

- Yao, Y.; Huang, Z.; Xie, P.; Lacey, S.D.; Jacob, R.J.; Xie, H.; Chen, F.; Nie, A.; Pu, T.; Rehwoldt, M.; et al. Carbothermal shock synthesis of high-entropy-alloy nanoparticles. Science 2018, 359, 1489–1494. [Google Scholar] [CrossRef]

- Soni, V.K.; Sinha, A.K. Effect of alloying elements, phases and heat treatments on properties of high-entropy alloys: A review. Trans. Indian Inst. Met. 2023, 76, 897–914. [Google Scholar] [CrossRef]

- Butler, K.T.; Davies, D.W.; Cartwright, H.; Isayev, O.; Walsh, A. Machine learning for molecular and materials science. Nature 2018, 559, 547–555. [Google Scholar] [CrossRef]

- Steingrimsson, B.; Fan, X.; Kulkarni, A.; Kulkarni, A.; Gao, M.C.; Liaw, P.K. Machine learning and data analytics for design and manufacturing of high-entropy materials exhibiting mechanical or fatigue properties of interest. In High-Entropy Materials: Theory, Experiments, and Applications; Springer International Publishing: Cham, Switzerland, 2022; pp. 115–238. [Google Scholar]

| Method | Accuracy | Scale | Cost | Scene |

|---|---|---|---|---|

| ML | High | Atom | Medium | Fast prediction, uncertainty quantification |

| MD | Medium | Atom | High | Dynamic evolution, micro-mechanism |

| MC | Medium | Atom | Medium | Balance property, phase transition |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Jiang, J.; Liaw, P.K.; Geng, G.; Zhang, Y. Data Science in Order and Disorder of High-Entropy Materials. Metals 2025, 15, 632. https://doi.org/10.3390/met15060632

Wang J, Jiang J, Liaw PK, Geng G, Zhang Y. Data Science in Order and Disorder of High-Entropy Materials. Metals. 2025; 15(6):632. https://doi.org/10.3390/met15060632

Chicago/Turabian StyleWang, Jiasheng, Jianzhong Jiang, Peter K. Liaw, Guihong Geng, and Yong Zhang. 2025. "Data Science in Order and Disorder of High-Entropy Materials" Metals 15, no. 6: 632. https://doi.org/10.3390/met15060632

APA StyleWang, J., Jiang, J., Liaw, P. K., Geng, G., & Zhang, Y. (2025). Data Science in Order and Disorder of High-Entropy Materials. Metals, 15(6), 632. https://doi.org/10.3390/met15060632