Effects of Warm Rolling Temperature on Microstructure and Texture Evolution in Cu–10Fe Alloy Sheets

Abstract

1. Introduction

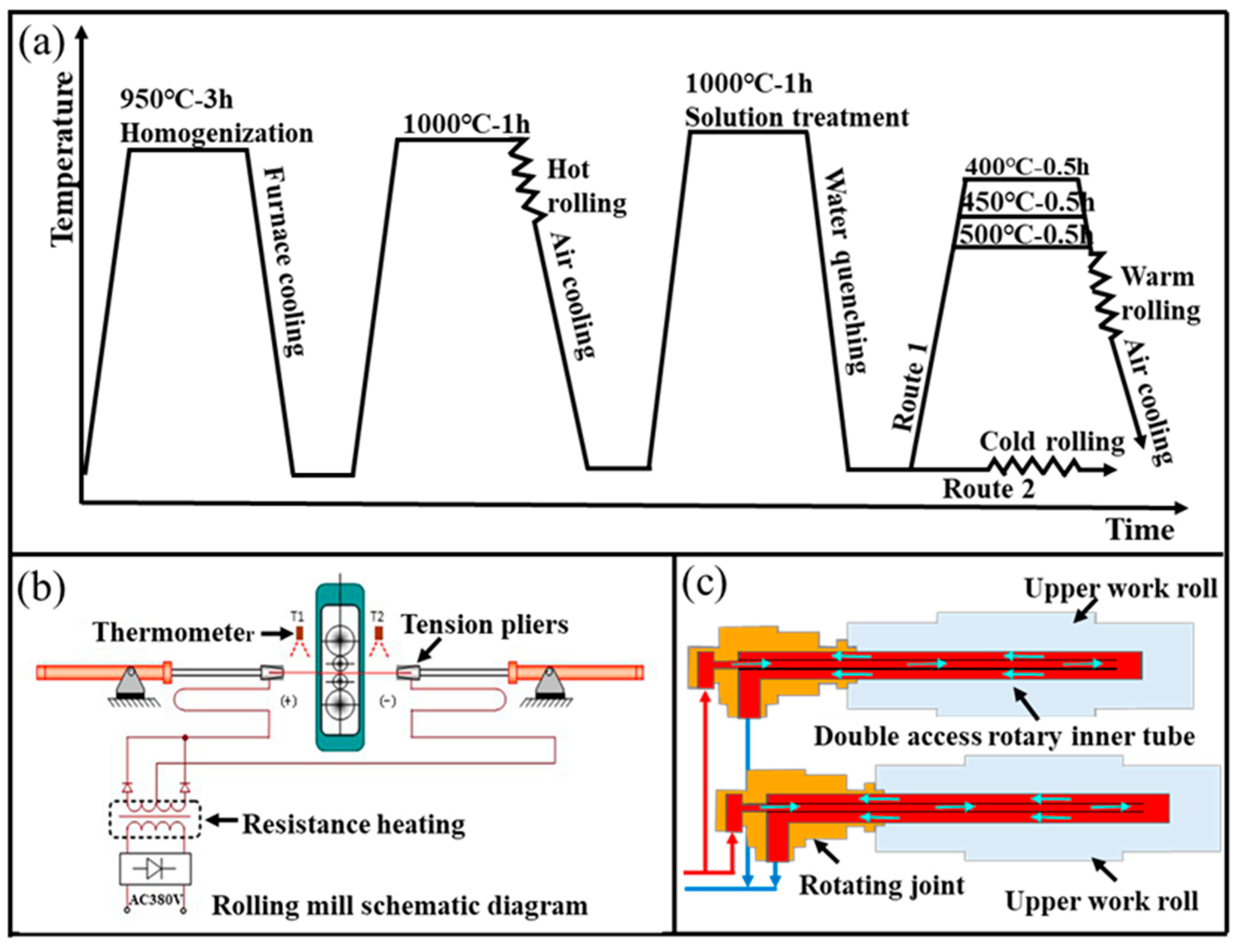

2. Experimental Process and Method

3. Results

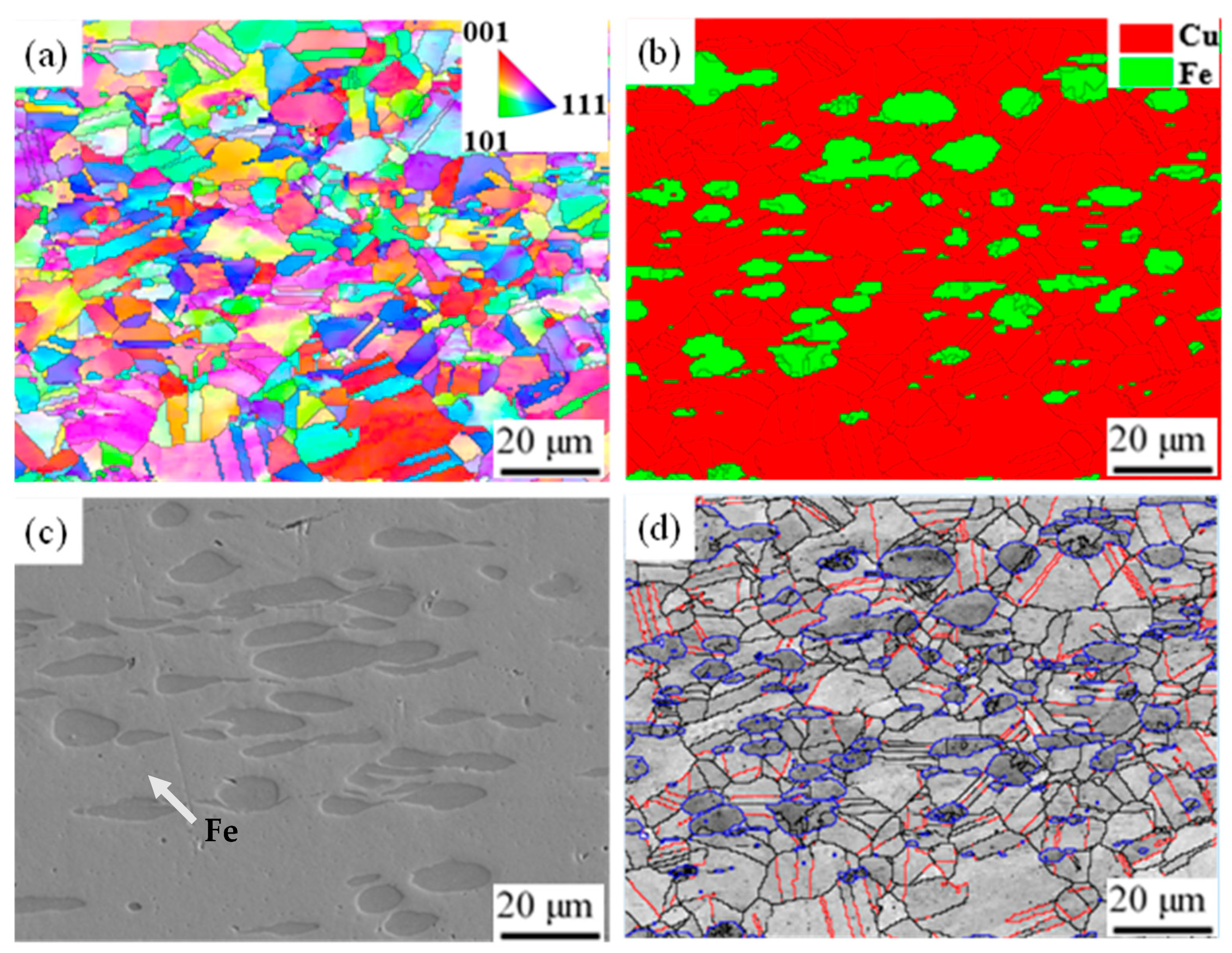

3.1. Pre-Rolling Microstructure of Cu–10Fe Alloy

3.2. Microstructure and Properties of Rolled Cu–10Fe Alloy

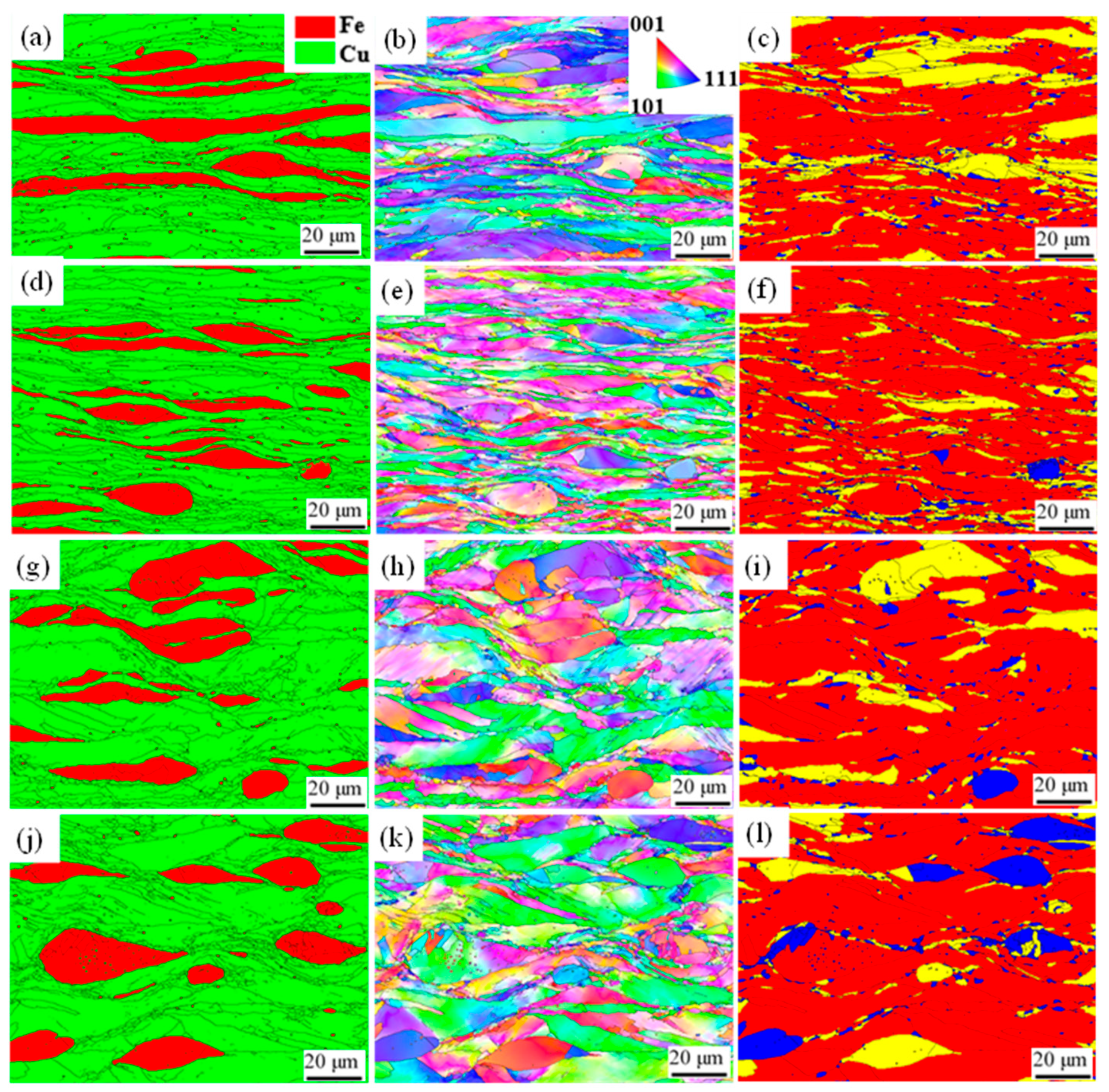

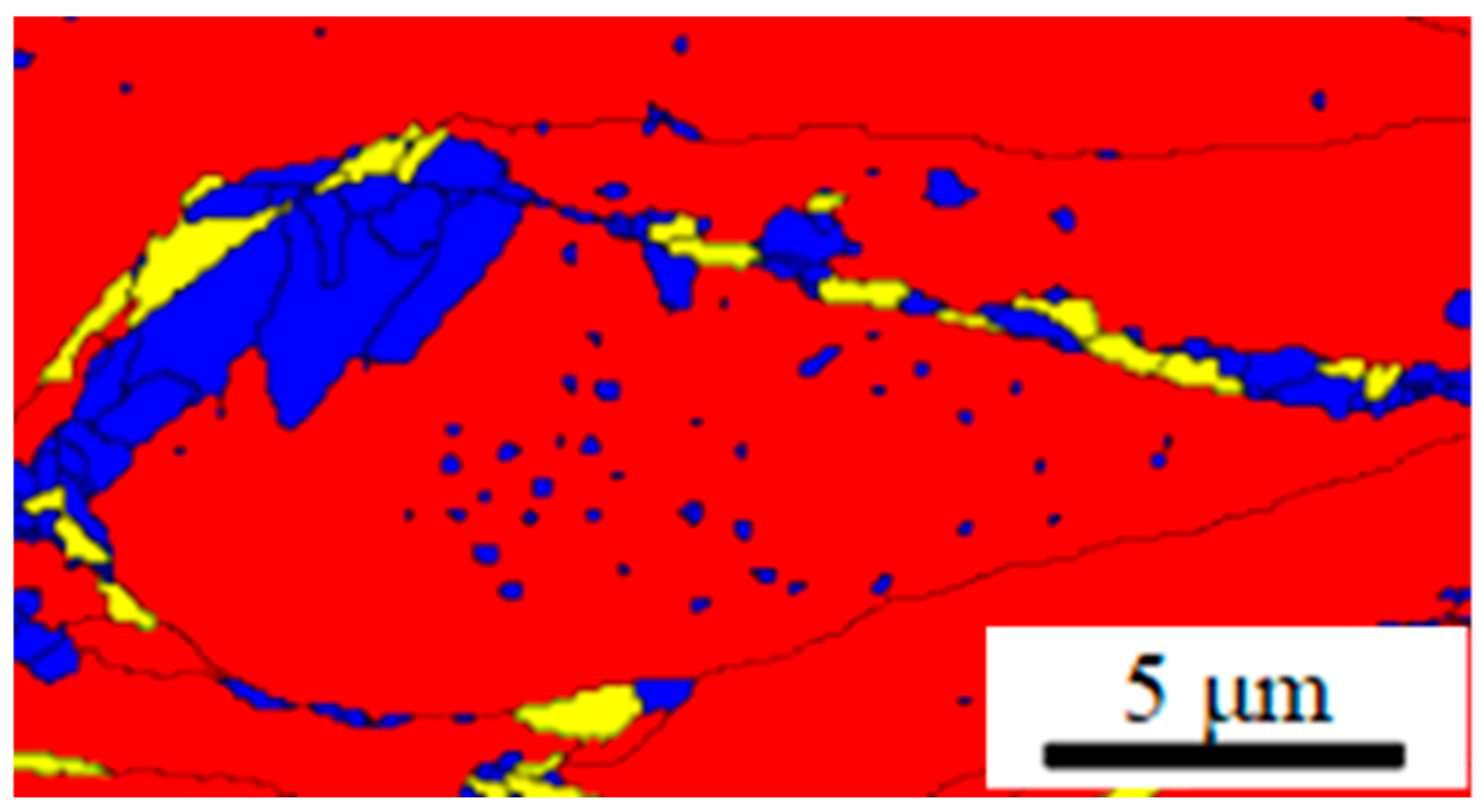

3.2.1. Microstructural Morphology of Rolled Cu–10Fe Alloy

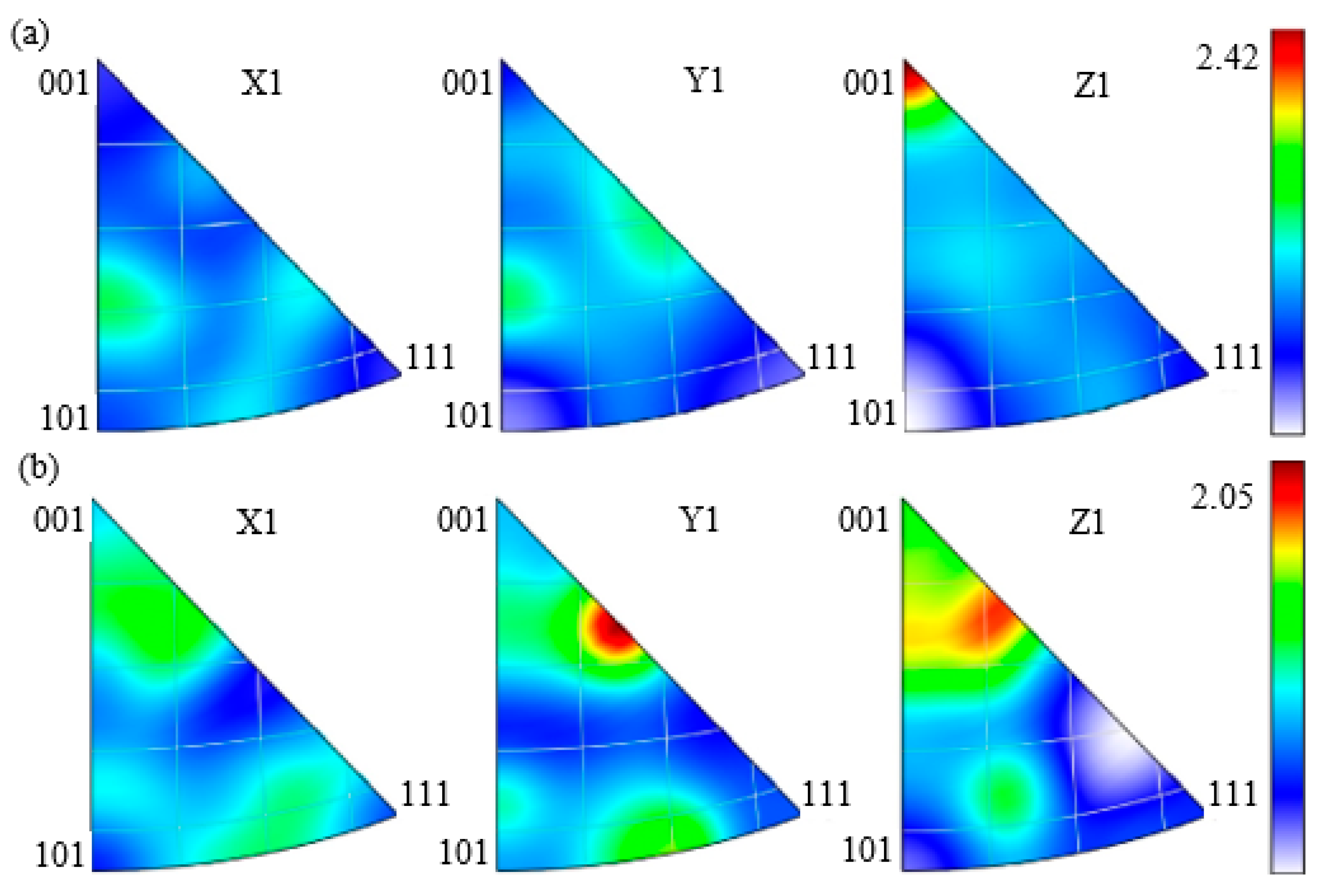

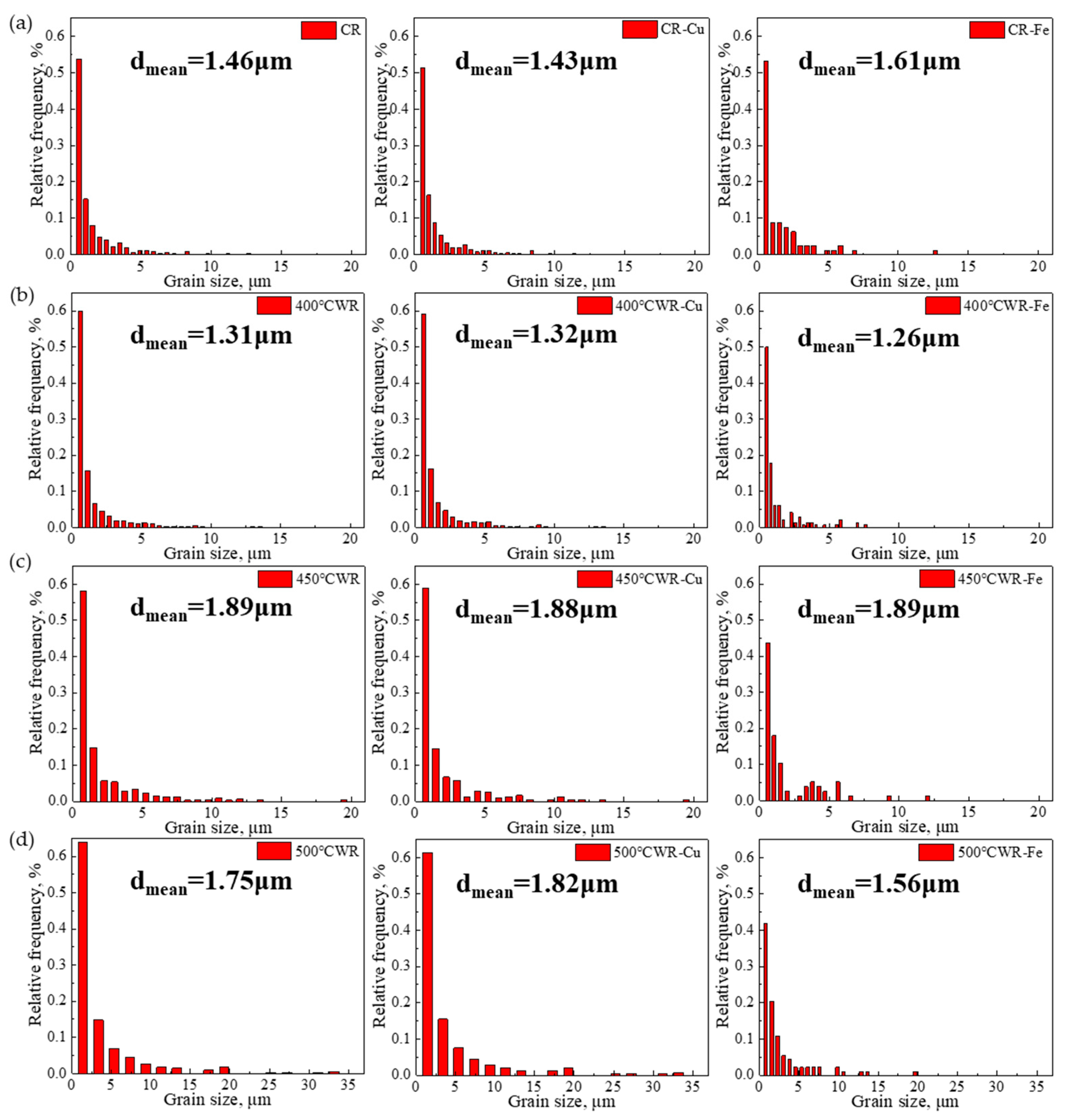

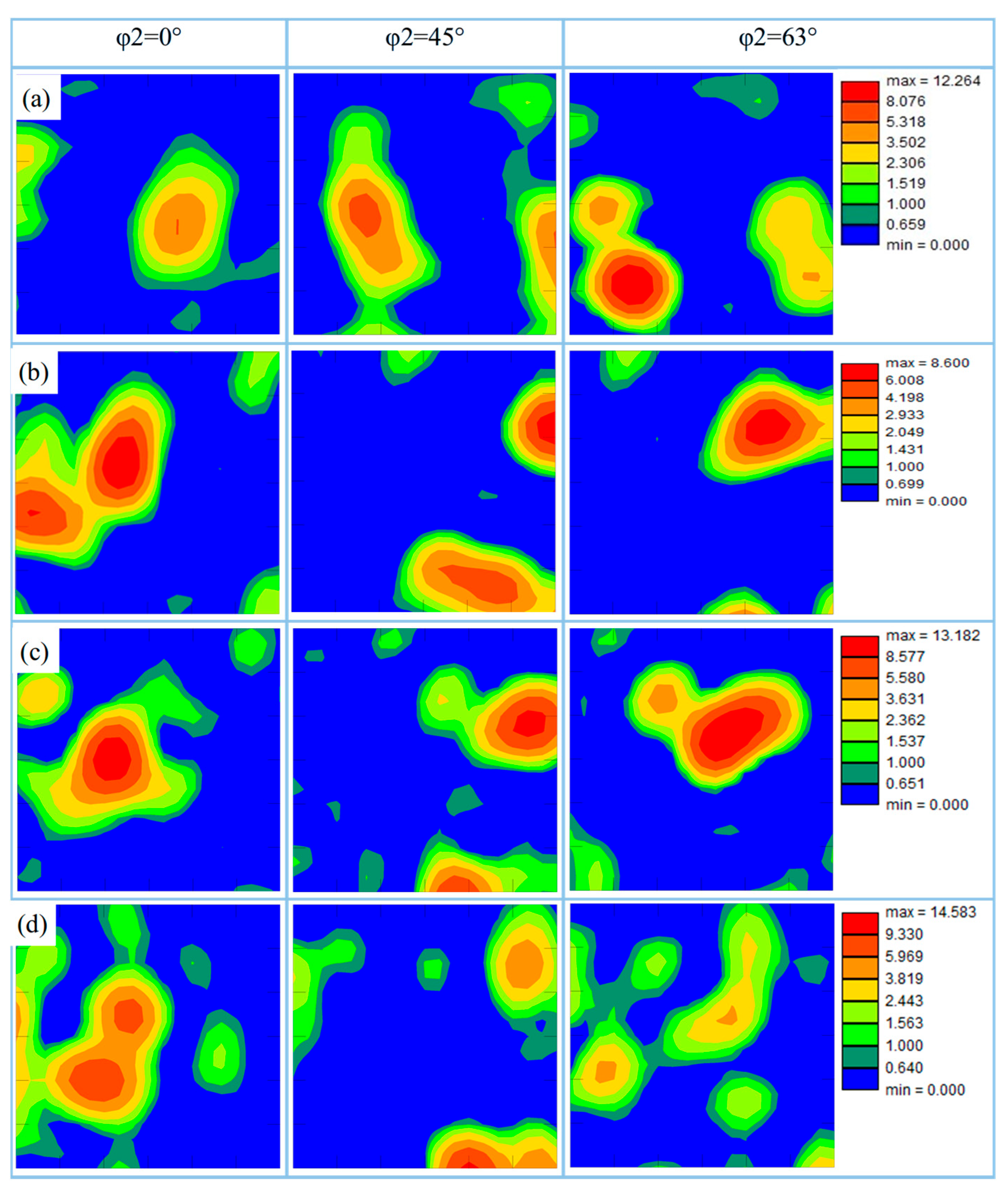

3.2.2. Texture Changes of Rolled Cu–10Fe Alloy

3.2.3. Properties Changes of Rolled Cu–10Fe Alloy

4. Discussion

4.1. Influence of Microstructure on Mechanical and Electrical Properties

4.2. The Influence of Texture on Mechanical and Electrical Properties

5. Conclusions

- With increasing rolling temperature (cold rolling → 500 °C), the Fe phase transitions from a fibrous to spherical/ellipsoidal morphology, while the Cu grain size initially decreases and then increases. At 500 °C, recrystallized Cu grains appear within Fe grains, with a recrystallization rate of only 11.9%, but dynamic recovery significantly reduces the dislocation density, forming a bimodal grain structure (fine recrystallized grains coordinate deformation, while larger grains strengthen the material).

- In the cold-rolled state, Brass-R texture (intensity 2.45) dominates, resulting in a high dislocation density and low plasticity (elongation 1.96%). At 400–450 °C, synergistic effects of Goss and Copper textures (intensity 6.9–13.82) result in elongation increasing to 7.03%. At 500 °C, Brass texture becomes dominant (intensity 14.58), and increased recrystallized grains further enhance elongation to 9.21%, while tensile strength progressively rises to 472 MPa.

- In the cold-rolled state, the lowest electrical conductivity (10.09% IACS) is caused by high dislocation density and lattice distortion. As the temperature increases, dynamic recovery and recrystallization reduce the dislocation density, while Fe precipitation alleviates lattice distortion. At 500 °C, the electrical conductivity significantly improves to 19.43% IACS, though magnetic scattering from the Fe phase still partially suppresses electrical conductivity.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huang, S.; Lin, B.; Niu, W.; Wang, G.; Li, J. Study on the microstructure evolution and mechanical properties of spray-forming Cu-Fe alloys with varying Fe compositions. J. Alloys Compd. 2025, 1013, 178452. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, C.; Liu, X.; Yan, M.; Qi, M.; Li, X.; Li, Y.; Zhang, H.; Yang, F.; Wang, W.; et al. High strength and high electrical conductivity in Cu–Fe alloys with nano and micro Fe particles. Mater. Sci. Eng. A 2022, 855, 143948. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, C.; Li, P.; Yan, M.; Qin, Q.; Yang, F.; Wang, W.; Guo, Z.; Volinsky, A.A. Microstructure and properties evolution of rolled powder metallurgy Cu-30Fe alloy. J. Alloys Compd. 2022, 909, 164761. [Google Scholar] [CrossRef]

- Tang, S.; Xiao, Z.; Ding, Y.; Li, Y.; Wang, R.; Jia, Y.; Gong, S.; Li, Z. Precipitation behavior and mechanical properties of a novel Cu–2Fe-0.5Ti alloy produced by thermos-mechanical treatment. Mater. Sci. Eng. A 2023, 882, 145453. [Google Scholar] [CrossRef]

- Peng, S.Y.; Tian, Y.Z.; Yang, Y.; Jiang, M.; Li, H.X.; Wang, J.W.; Li, S.; Qin, G. Achieving homogeneous Fe distribution and high strength in Cu-Fe composite consolidated by powder rolling. Mater. Sci. Eng. A 2023, 884, 145563. [Google Scholar] [CrossRef]

- Zhang, P.; Yuan, X.; Li, Y.; Zhou, Y.; Lai, R.; Li, Y.; Lei, Q.; Chiba, A. Influence of minor Ag addition on the microstructure and properties of powder metallurgy Cu-10 wt% Fe alloy. J. Alloys Compd. 2022, 904, 163983. [Google Scholar] [CrossRef]

- Abbas, S.F.; Park, K.-T.; Kim, T.-S. Effect of composition and powder size on magnetic properties of rapidly solidified copper-iron alloys. J. Alloys Compd. 2018, 741, 1188–1195. [Google Scholar] [CrossRef]

- Liu, S.; Jie, J.; Guo, Z.; Yue, S.; Li, T. A comprehensive investigation on microstructure and magnetic properties of immiscible Cu-Fe alloys with variation of Fe content. Mater. Chem. Phys. 2019, 238, 121909. [Google Scholar] [CrossRef]

- Liu, S.; Xu, S.; Jie, J.; Zhang, J.; Dong, Y.; Li, X.; Li, T. Microstructure evolution and magnetic properties of metastable immiscible Cu-Fe alloy with micro-alloying B element. J. Alloys Compd. 2021, 888, 161627. [Google Scholar] [CrossRef]

- Guo, K.; Meng, K.; Miao, D.; Wang, Q.; Zhang, C.; Wang, T. Effect of annealing on microstructure and tensile properties of skew hot rolled Ti–6Al–3Nb–2Zr–1Mo alloy tube. Mater. Sci. Eng. A 2019, 766, 138346. [Google Scholar] [CrossRef]

- Quelennec, X.; Menand, A.; Le Breton, J.M.; Pippan, R.; Sauvage, X. Homogeneous Cu–Fe supersaturated solid solutions prepared by severe plastic deformation. Philos. Mag. 2010, 90, 1179–1195. [Google Scholar] [CrossRef]

- Stepanov, N.D.; Kuznetsov, A.V.; Salishchev, G.A.; Khlebova, N.E.; Pantsyrny, V.I. Evolution of microstructure and mechanical properties in Cu–14%Fe alloy during severe cold rolling. Mater. Sci. Eng. A 2013, 564, 264–272. [Google Scholar] [CrossRef]

- Wang, M.; Jiang, Y.; Li, Z.; Xiao, Z.; Gong, S.; Qiu, W.; Lei, Q. Microstructure evolution and deformation behaviour of Cu-10wt%Fe alloy during cold rolling. Mater. Sci. Eng. A 2021, 801, 140379. [Google Scholar] [CrossRef]

- Ding, Y.; Deng, Z.; Xiao, Z.; Fang, M.; Gong, S.; Qiu, W.; Wang, X. Effect of Nb content on mechanical reinforcement of the Cu-10Fe composites. J. Alloys Compd. 2023, 966, 171540. [Google Scholar] [CrossRef]

- Verhoeven, J.D.; Chueh, S.C.; Gibson, E.D. Strength and conductivity ofin situ Cu-Fe alloys. J. Mater. Sci. 1989, 24, 1748–1752. [Google Scholar] [CrossRef]

- Yang, J.; Bu, K.; Zhou, Y.; Song, K.; Huang, T.; Peng, X.; Peng, X.; Liu, H.; Du, Y. Microstructure, residual stress, and mechanical properties evolution of a Cu–Fe–P alloy under different conditions. J. Mater. Res. Technol. 2023, 24, 7896–7909. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, R.; Xiao, Z.; Gong, S.; Jiang, Y.; Li, Z. Microstructure and properties of Cu-10 wt%Fe alloy produced by double melt mixed casting and multi-stage thermomechanical treatment. J. Alloys Compd. 2020, 820, 153323. [Google Scholar] [CrossRef]

- Weng, K.; Wang, Y.; Song, Y.; Fan, Y.; Zhao, H.; Hong, Z.; Song, K.; Dong, X.; Guo, C. Optimizing strength and electrical conductivity of Cu–Fe–Ti alloy by pre-aging treatment. J. Mater. Res. Technol. 2023, 26, 2009–2016. [Google Scholar] [CrossRef]

- Yuan, D.; Xiao, X.; Luo, X.; Wang, H.; Han, B.; Liu, B.; Yang, B. Effect of multi-stage thermomechanical treatment on Fe phase evolution and properties of Cu-6.5Fe-0.3Mg alloy. Mater. Charact. 2022, 185, 111707. [Google Scholar] [CrossRef]

- Xia, Y.; Zhang, Y.; Wu, T.; Wang, N.; Ran, R.; Wang, Y.; Fang, F.; Wang, G. Deformation twinning caused by warm rolling and secondary recrystallization in twin-roll strip casting Fe81Ga19 alloy. J. Alloys Compd. 2022, 922, 166039. [Google Scholar] [CrossRef]

- Guo, W.; Yi, Y.; Huang, S.; Ruan, J.; Guo, Y. Effect of warm-rolling temperature on the microstructural evolution and mechanical properties of large 2219 Al-Cu alloy rings. Mater. Today Commun. 2023, 36, 106702. [Google Scholar] [CrossRef]

- Xu, J.; Guan, B.; Fu, R.; Wu, Y.; Hu, Q.; Zou, J.; Huang, G.; Yan, C. Tailoring the microstructure and mechanical properties of Cu–Fe alloy by varying the rolling path and rolling temperature. J. Mater. Res. Technol. 2023, 27, 182–193. [Google Scholar] [CrossRef]

- Shi, R.P.; Wang, C.P.; Wheeler, D.; Liu, X.J.; Wang, Y. Formation mechanisms of self-organized core/shell and core/shell/corona microstructures in liquid droplets of immiscible alloys. Acta Mater. 2013, 61, 1229–1243. [Google Scholar] [CrossRef]

- Lu, K. Stabilizing nanostructures in metals using grain and twin boundary architectures. Nat. Rev. Mater. 2016, 1, 16019. [Google Scholar] [CrossRef]

- Zhao, P.-C.; Chen, B.; Zheng, Z.-G.; Guan, B.; Zhang, X.-C.; Tu, S.-T. Microstructure and Texture Evolution in a Post-dynamic Recrystallized Titanium During Annealing, Monotonic and Cyclic Loading. Metall. Mater. Trans. A 2021, 52, 394–412. [Google Scholar] [CrossRef]

- Allain, S.; Chateau, J.-P.; Bouaziz, O.; Migot, S.; Guelton, N. Correlations between the calculated stacking fault energy and the plasticity mechanisms in Fe–Mn–C alloys. Mater. Sci. Eng. A 2004, 387–389, 158–162. [Google Scholar] [CrossRef]

- Niu, R.; An, X.; Li, L.; Zhang, Z.; Mai, Y.-W.; Liao, X. Mechanical properties and deformation behaviours of submicron-sized Cu–Al single crystals. Acta Mater. 2022, 223, 117460. [Google Scholar] [CrossRef]

- Yan, Z.; Wang, D.; He, X.; Wang, W.; Zhang, H.; Dong, P.; Li, C.; Li, Y.; Zhou, J.; Liu, Z.; et al. Deformation behaviors and cyclic strength assessment of AZ31B magnesium alloy based on steady ratcheting effect. Mater. Sci. Eng. A 2018, 723, 212–220. [Google Scholar] [CrossRef]

- Cheng, Z.; Bu, L.; Zhang, Y.; Wu, H.; Zhu, T.; Lu, L. Characterization of gradient plastic deformation in gradient nanotwinned Cu. Acta Mater. 2023, 246, 118673. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, J.; Wang, W.; Liu, S.; Sun, B.; Xie, J.; Xiao, T. Unveiling the deformation mechanism of highly deformable magnesium alloy with heterogeneous grains. Scr. Mater. 2022, 221, 114963. [Google Scholar] [CrossRef]

- Yang, Y.; Gong, Y.; Li, X.; Liu, H.; Li, C.; Yang, J.; Pan, H.; Shu, B.; Deng, C.; Fang, J.; et al. Effect of bimodal grain size and gradient structure on heterogeneous deformation induced (HDI) stress and mechanical properties of Cu. Mater. Res. Express 2022, 9, 035004. [Google Scholar] [CrossRef]

- Dai, X.; Jia, S.; Zhou, Y.; Ma, Y.; Xiao, Z.; Guo, H.; Cao, X.; Fu, Y.; Song, K.; Ding, Z. Microstructural evolution and properties of the Cu-Cr-Ti alloys after cold deformation and subsequent aging treatment. Prog. Nat. Sci. Mater. Int. 2024, 34, 1258–1266. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, C.; Huang, L.; Lu, T.; Li, P.; Wang, W.; Yang, F.; Volinsky, A.A.; Guo, Z. Microstructure and properties of Cu-Fe alloys fabricated via powder metallurgy and rolling. Powder Metall. 2021, 64, 308–320. [Google Scholar] [CrossRef]

- Cheng, Z.; Zhou, H.; Lu, Q.; Gao, H.; Lu, L. Extra strengthening and work hardening in gradient nanotwinned metals. Science 2018, 362, eaau1925. [Google Scholar] [CrossRef]

- Wu, H.; Fan, G. An overview of tailoring strain delocalization for strength-ductility synergy. Prog. Mater. Sci. 2020, 113, 100675. [Google Scholar] [CrossRef]

- Huang, X.; Xin, Y.; Cao, Y.; Li, W.; Huang, G.; Zhao, X.; Liu, Q.; Wu, P. Understanding the mechanisms of texture evolution in an Mg-2Zn-1Ca alloy during cold rolling and annealing. Int. J. Plast. 2022, 158, 103412. [Google Scholar] [CrossRef]

- Liu, Z.; Li, P.; Xiong, L.; Liu, T.; He, L. High-temperature tensile deformation behavior and microstructure evolution of Ti55 titanium alloy. Mater. Sci. Eng. A 2017, 680, 259–269. [Google Scholar] [CrossRef]

- Cheng, Z.; Wan, T.; Bu, L.; Lu, L. Effect of volume fractions of gradient transition layer on mechanical behaviors of nanotwinned Cu. Acta Mater. 2023, 242, 118456. [Google Scholar] [CrossRef]

- Baik, S.-I.; Gupta, R.K.; Kumar, K.S.; Seidman, D.N. Temperature increases and thermoplastic microstructural evolution in adiabatic shear bands in a high-strength and high-toughness 10 wt.% Ni steel. Acta Mater. 2021, 205, 116568. [Google Scholar] [CrossRef]

- Li, W.; Chen, Z.; Liu, J.; Wang, Q.; Sui, G. Effect of texture on anisotropy at 600 °C in a near-α titanium alloy Ti60 plate. Mater. Sci. Eng. A 2017, 688, 322–329. [Google Scholar] [CrossRef]

- Geng, Y.; Ban, Y.; Li, X.; Zhang, Y.; Jia, Y.; Tian, B.; Zhou, M.; Liu, Y.; Volinsky, A.A.; Song, K.; et al. Excellent mechanical properties and high electrical conductivity of Cu-Co-Si-Ti alloy due to multiple strengthening. Mater. Sci. Eng. A 2021, 821, 141639. [Google Scholar] [CrossRef]

- Li, C.; Jin, J.; Yan, H.; Shan, Z.; Mao, Y.; Chen, R. Investigation of hot deformation behavior of Mg-14Gd-0.5Zr (wt%) through constitutive analysis and processing maps. J. Alloys Compd. 2023, 953, 170112. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, B.; Wang, D.; Tang, S.; Huang, S.; Li, J. Effects of Warm Rolling Temperature on Microstructure and Texture Evolution in Cu–10Fe Alloy Sheets. Metals 2025, 15, 606. https://doi.org/10.3390/met15060606

Lin B, Wang D, Tang S, Huang S, Li J. Effects of Warm Rolling Temperature on Microstructure and Texture Evolution in Cu–10Fe Alloy Sheets. Metals. 2025; 15(6):606. https://doi.org/10.3390/met15060606

Chicago/Turabian StyleLin, Baosen, Dongxiao Wang, Shuai Tang, Su Huang, and Jianping Li. 2025. "Effects of Warm Rolling Temperature on Microstructure and Texture Evolution in Cu–10Fe Alloy Sheets" Metals 15, no. 6: 606. https://doi.org/10.3390/met15060606

APA StyleLin, B., Wang, D., Tang, S., Huang, S., & Li, J. (2025). Effects of Warm Rolling Temperature on Microstructure and Texture Evolution in Cu–10Fe Alloy Sheets. Metals, 15(6), 606. https://doi.org/10.3390/met15060606