Numerical Simulation of Fluid Flow and Solidification in Round Bloom Continuous Casting with Alternate Final Electromagnetic Stirring

Abstract

1. Introduction

2. Mathematical Model

2.1. Basic Assumption

- The time-averaged electromagnetic force is used instead of the instantaneous value as a body force term in the momentum equation.

- The Joule heat generated by the induced current is negligible and thus neglected in the strand temperature calculation [1].

- Since M-EMS is located far upstream from the F-EMS installation position (12 m from the meniscus), its influence is ignored to reduce computational cost.

- The curvature of the strand is assumed to be negligible.

2.2. Governing Equations

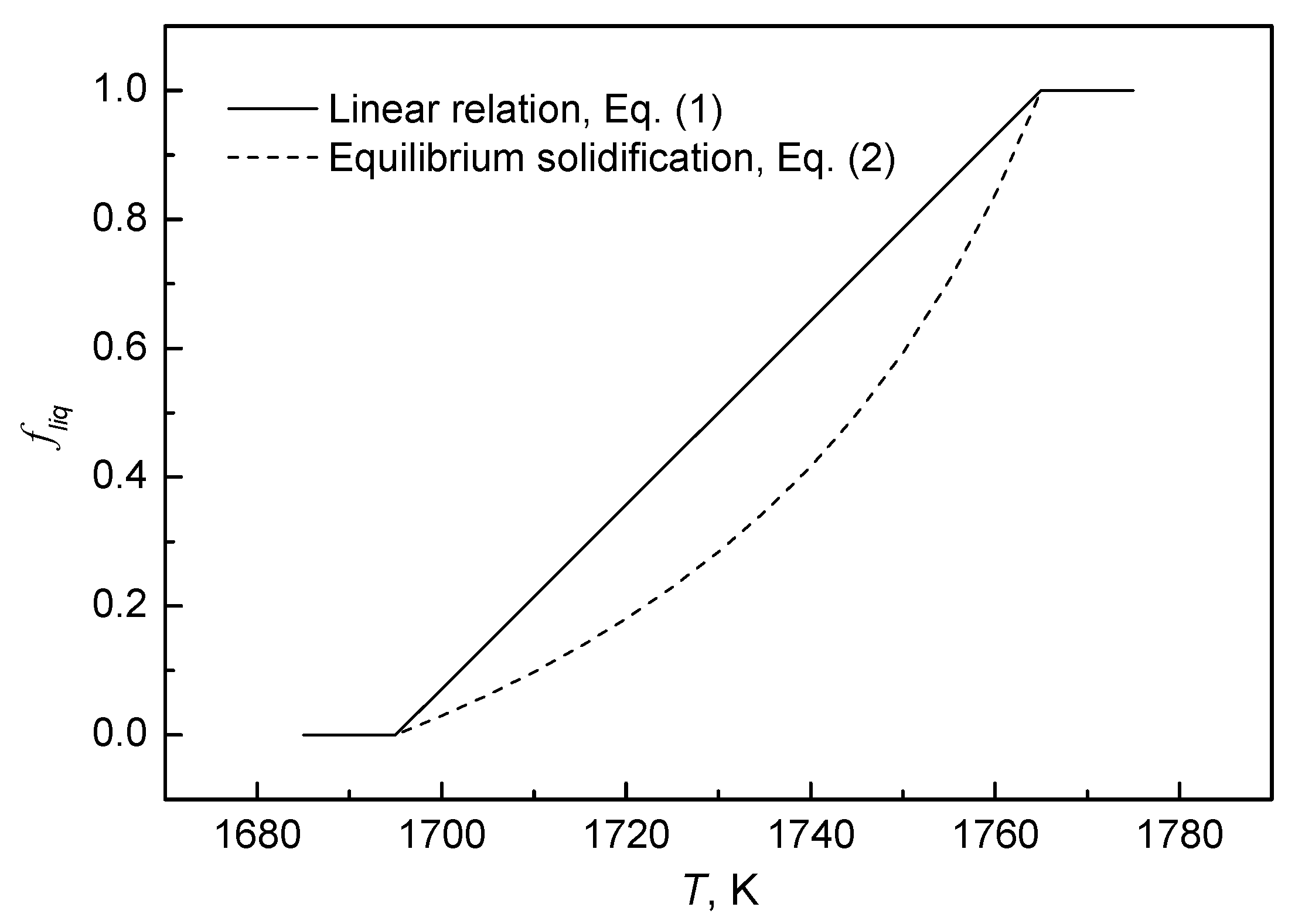

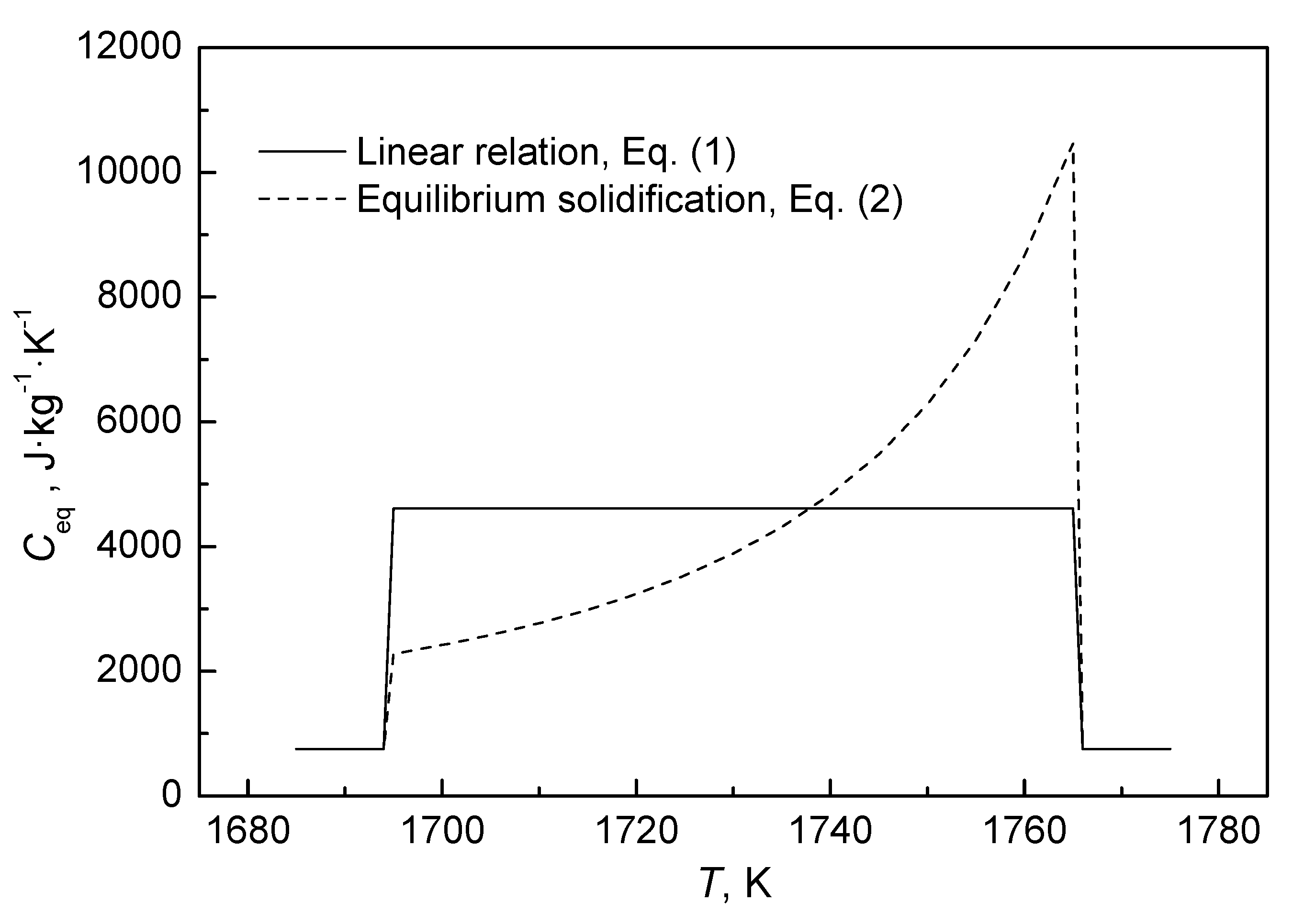

2.2.1. Linear Relationship

2.2.2. Equilibrium Expression

2.3. Boundary Conditions

2.4. Thermophysical Properties

2.5. Numerical Solution

3. Results and Discussion

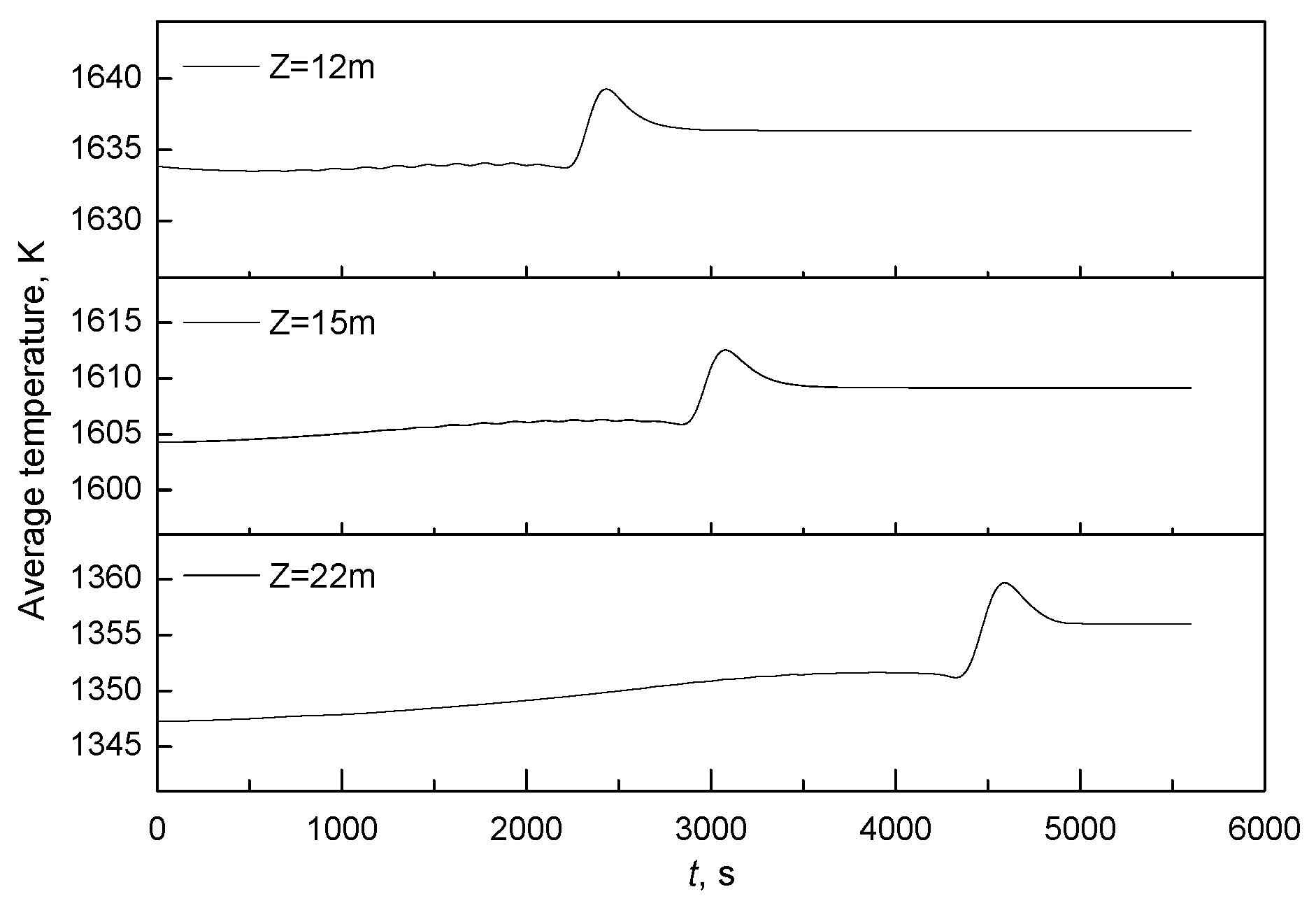

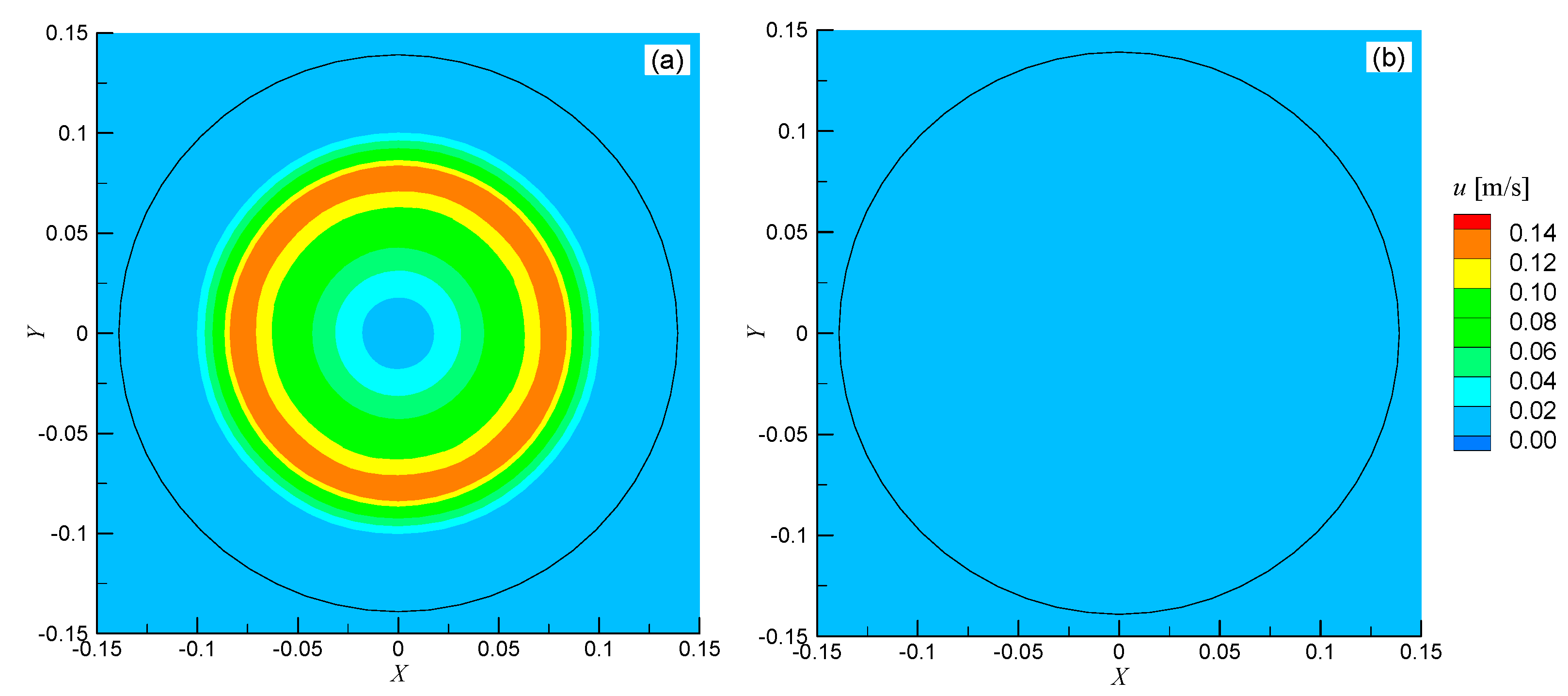

3.1. Model Validation

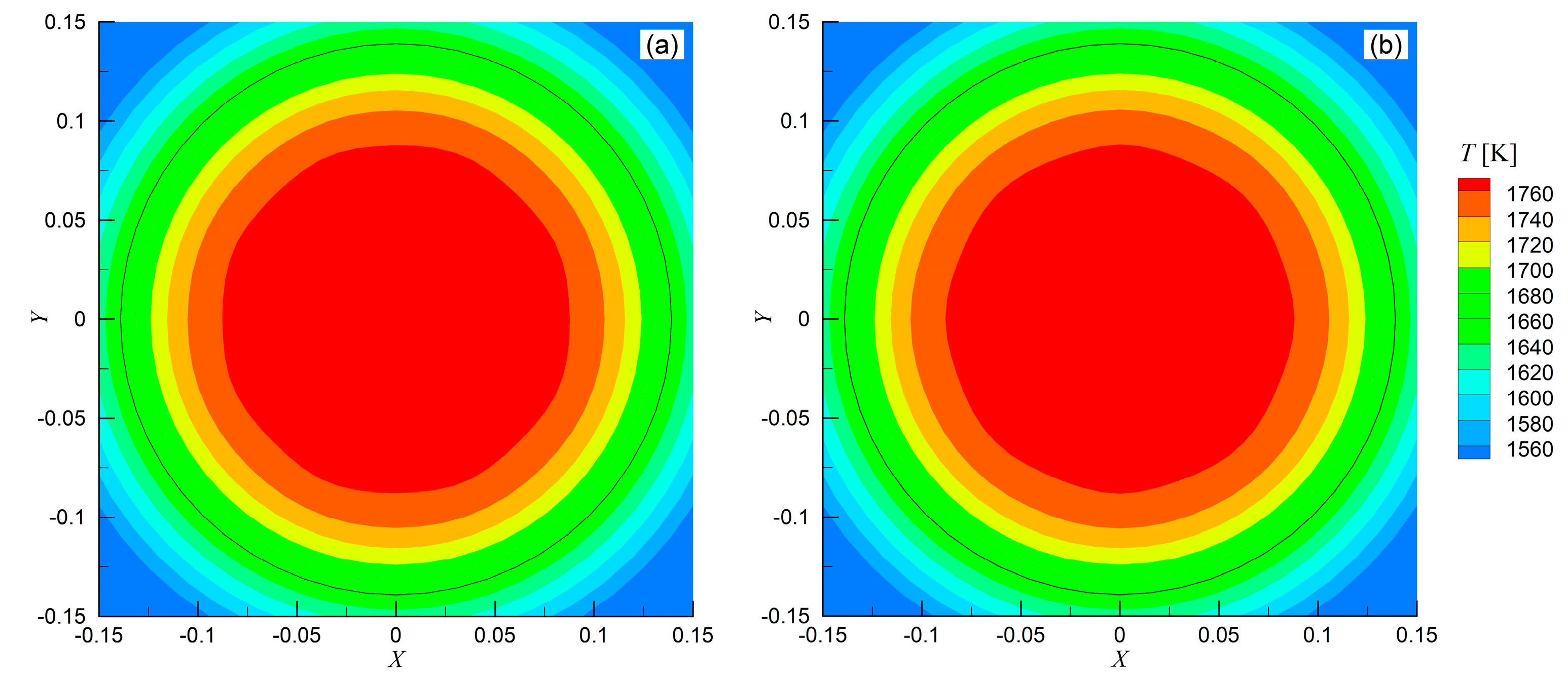

3.2. Effect of Latent Heat Release Model

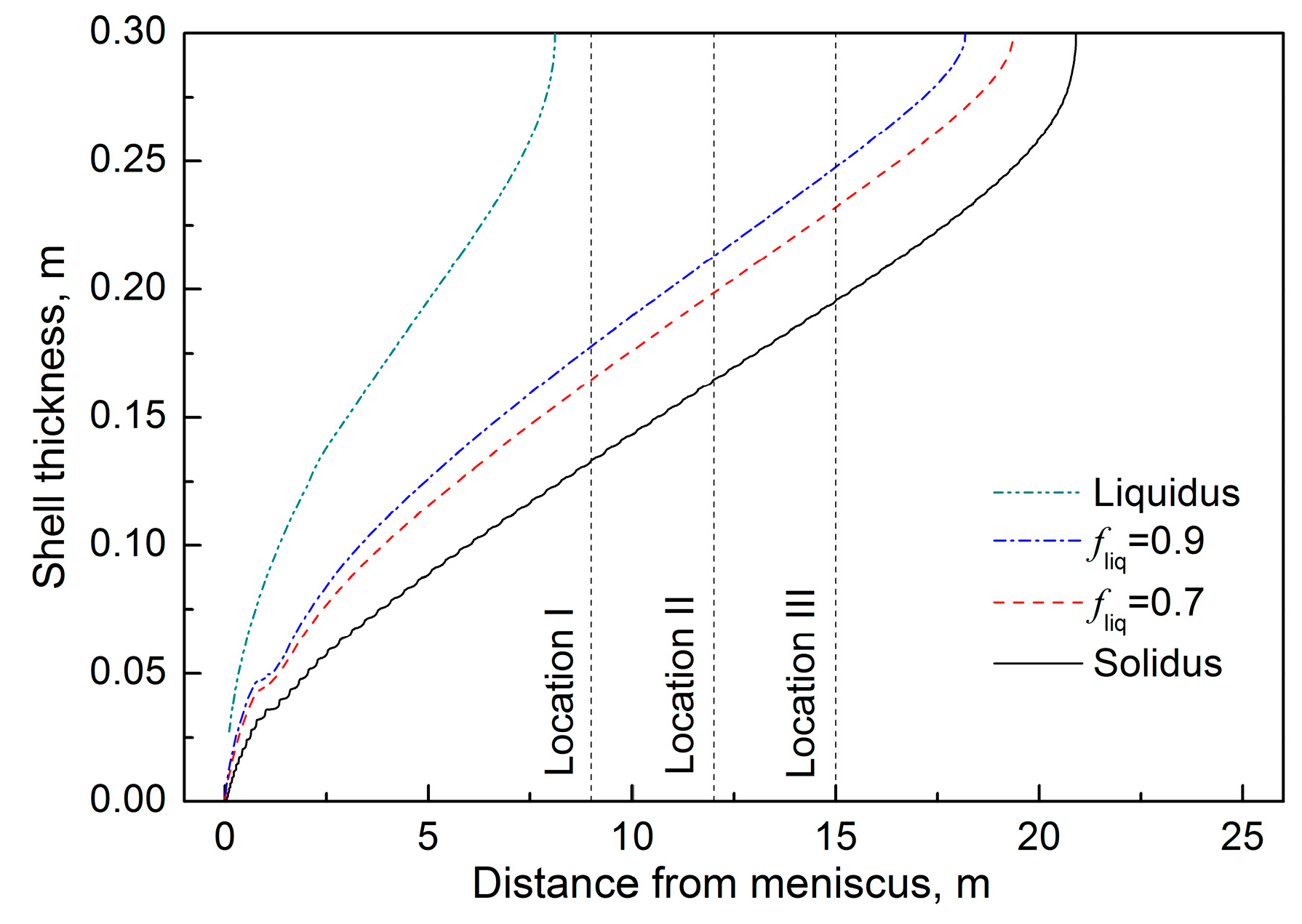

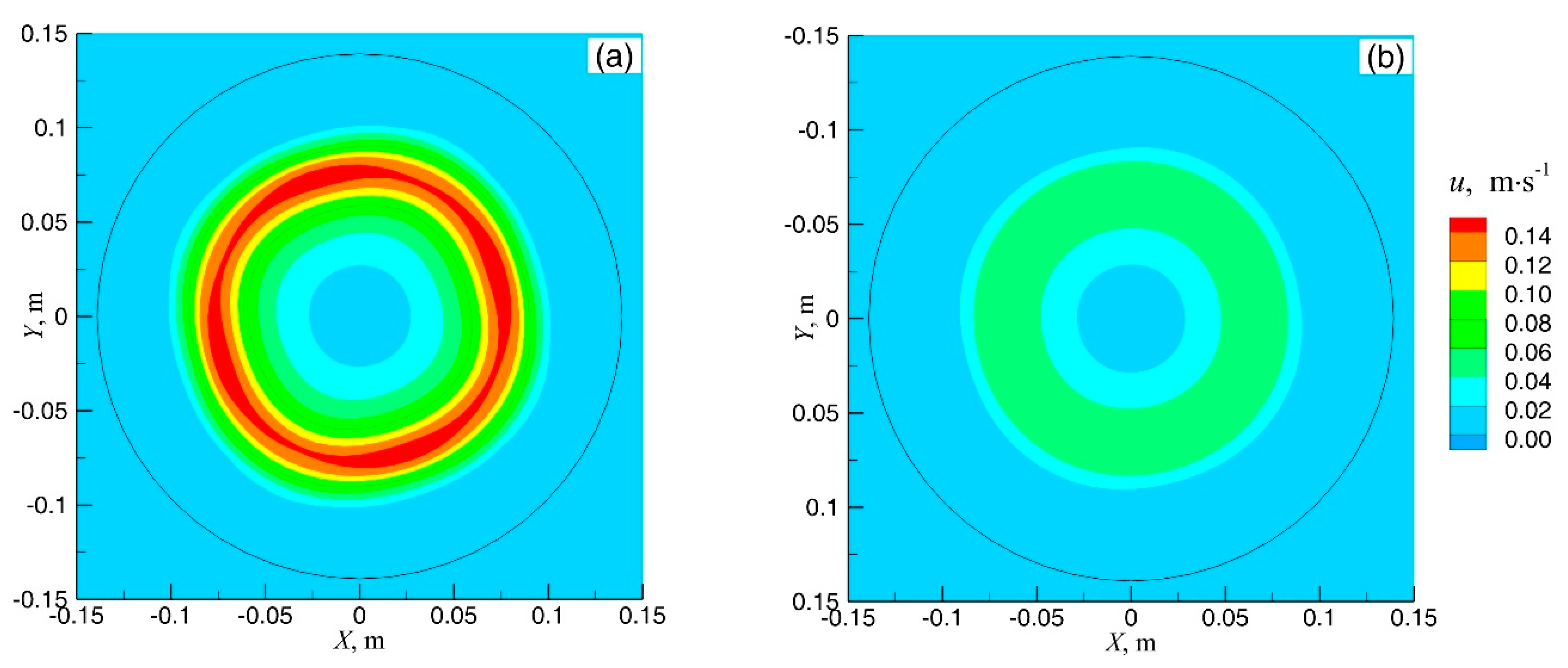

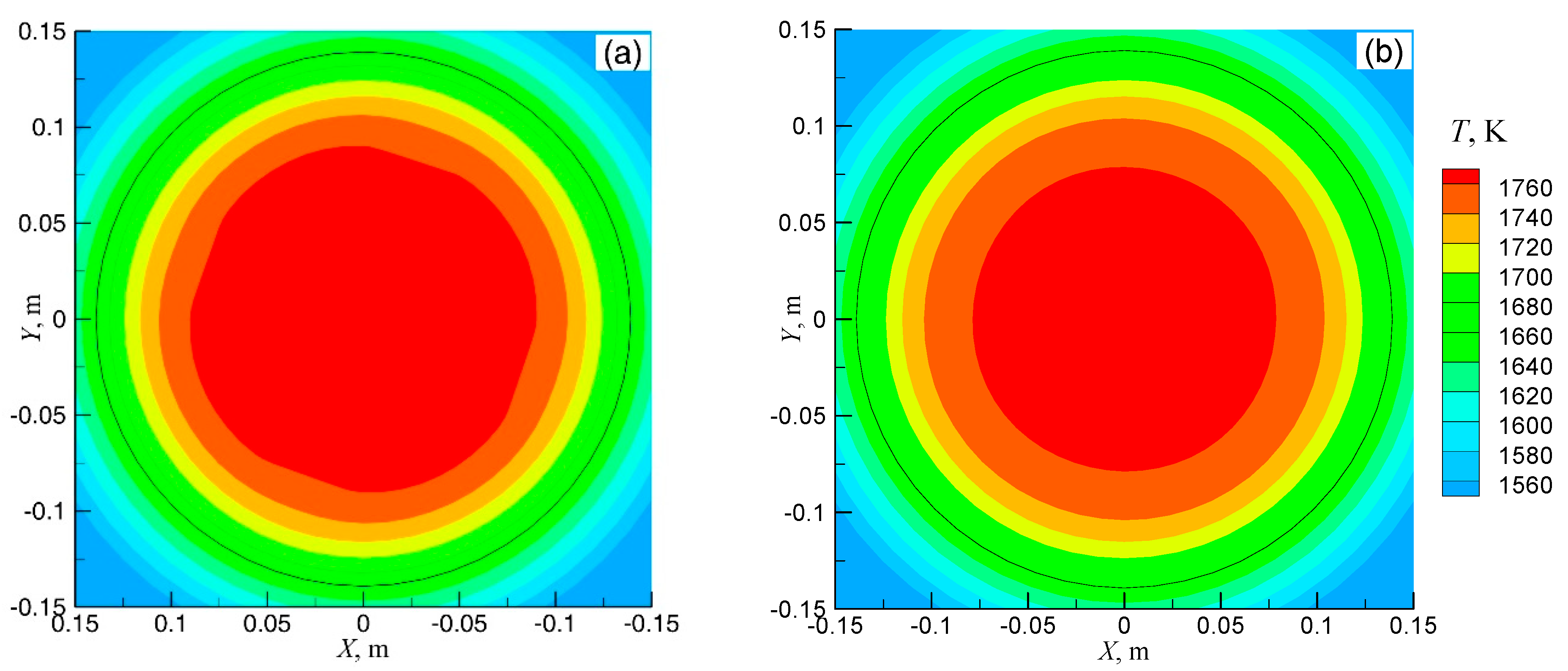

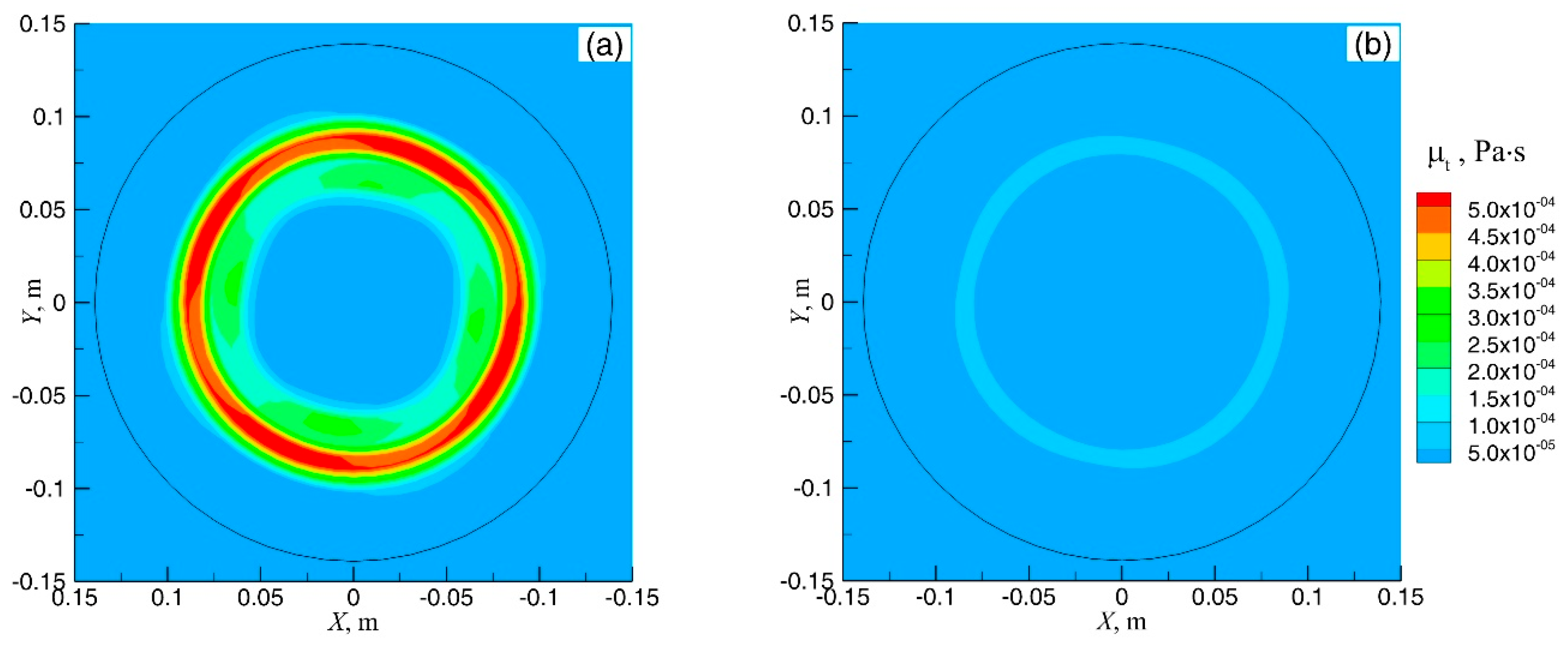

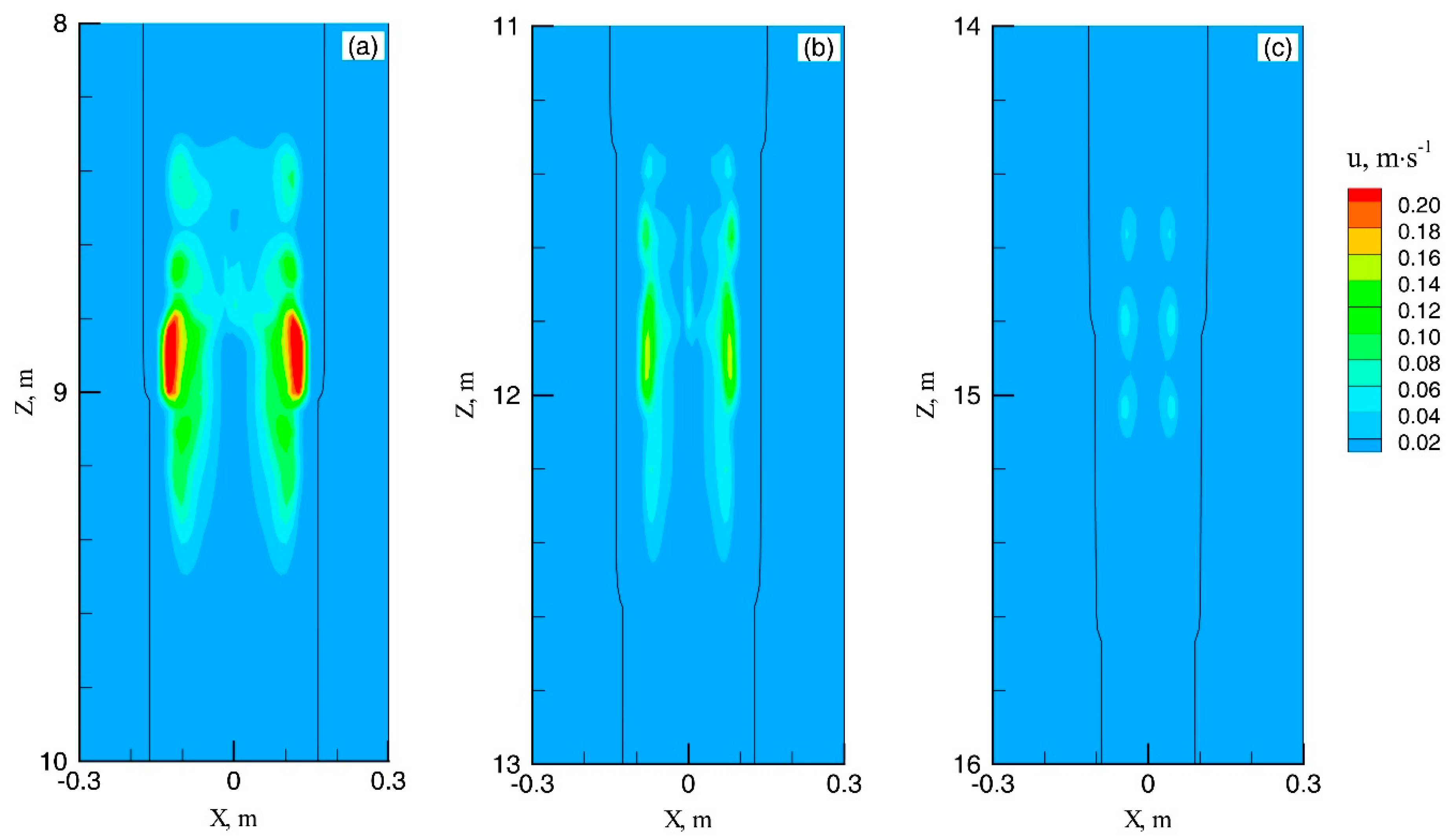

3.3. Flow and Solidification in the Continuous Stirring Mode

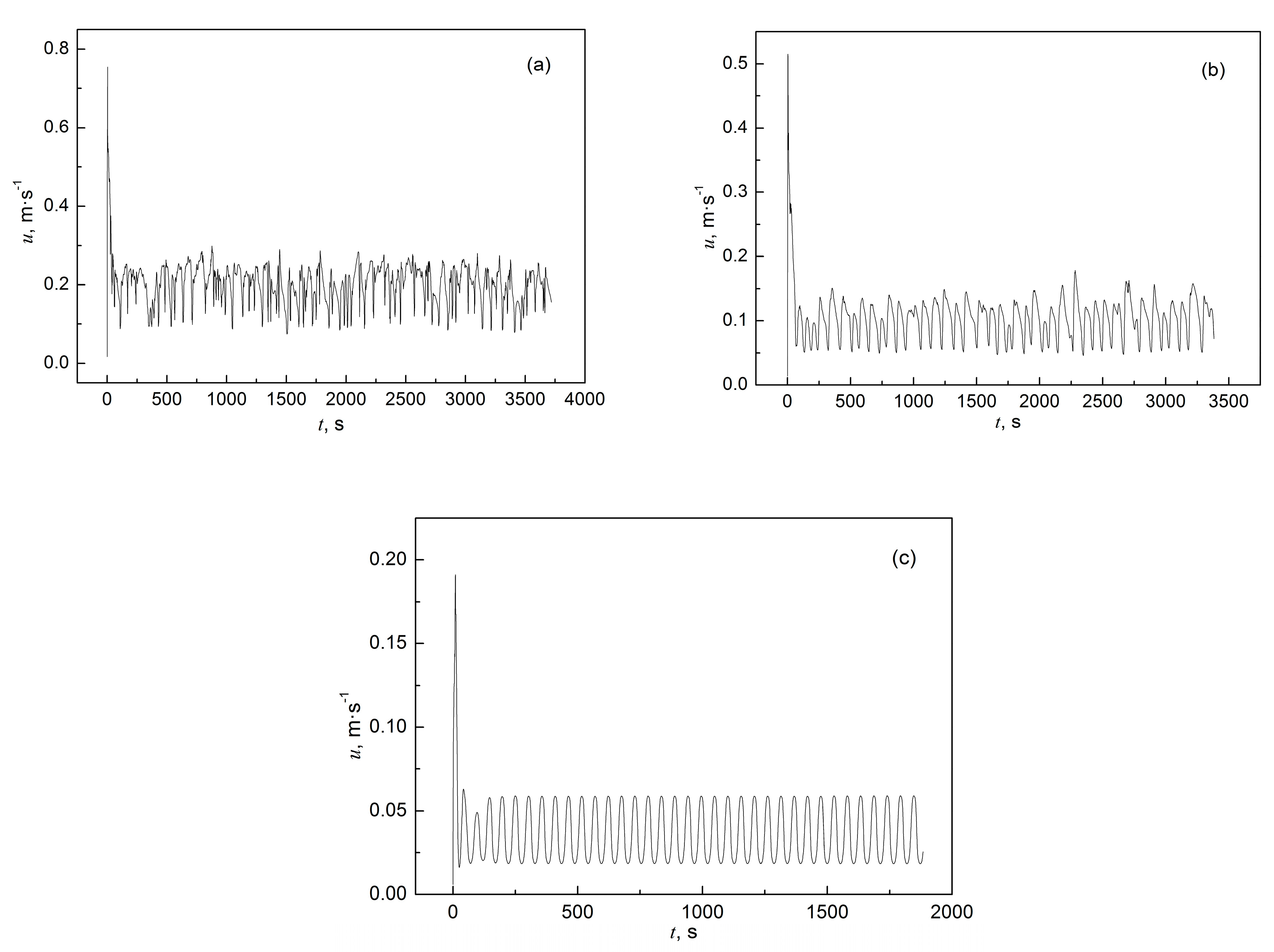

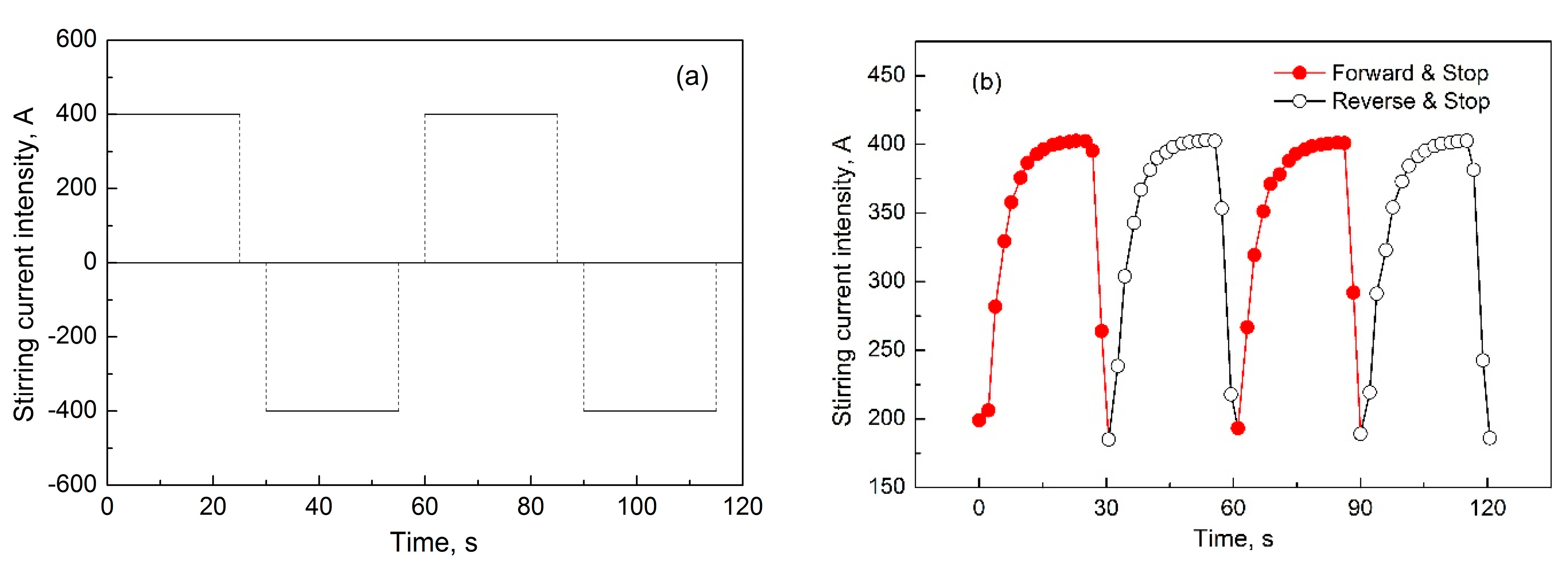

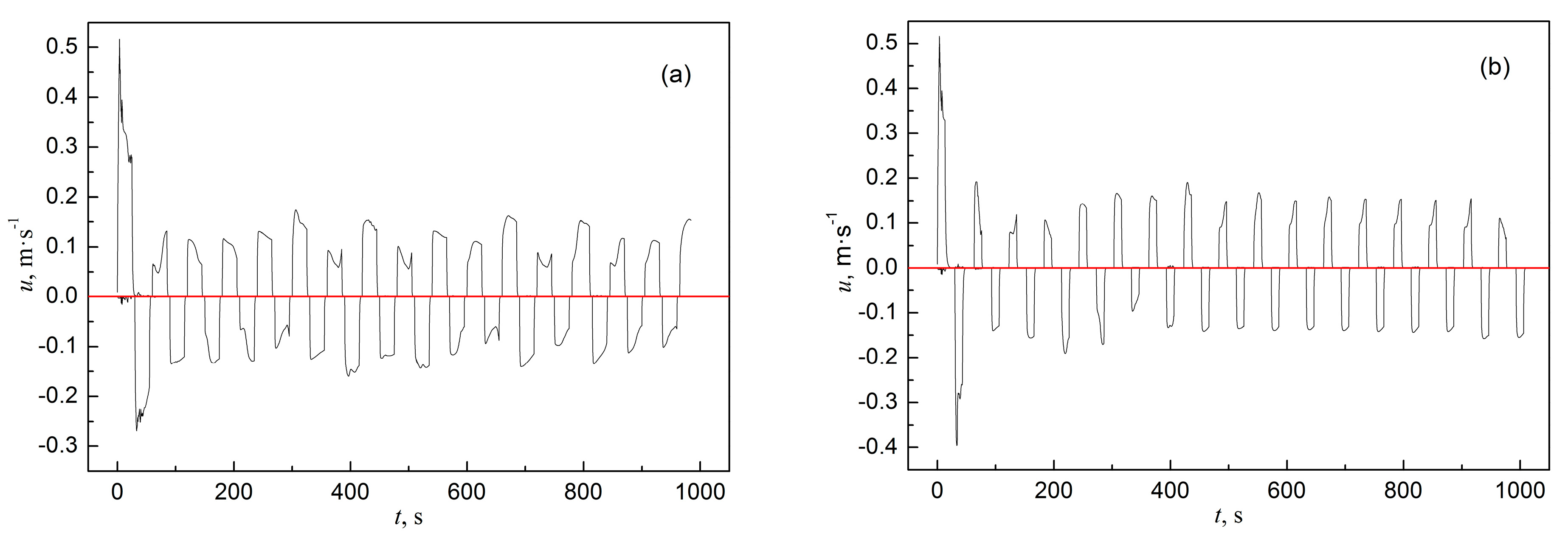

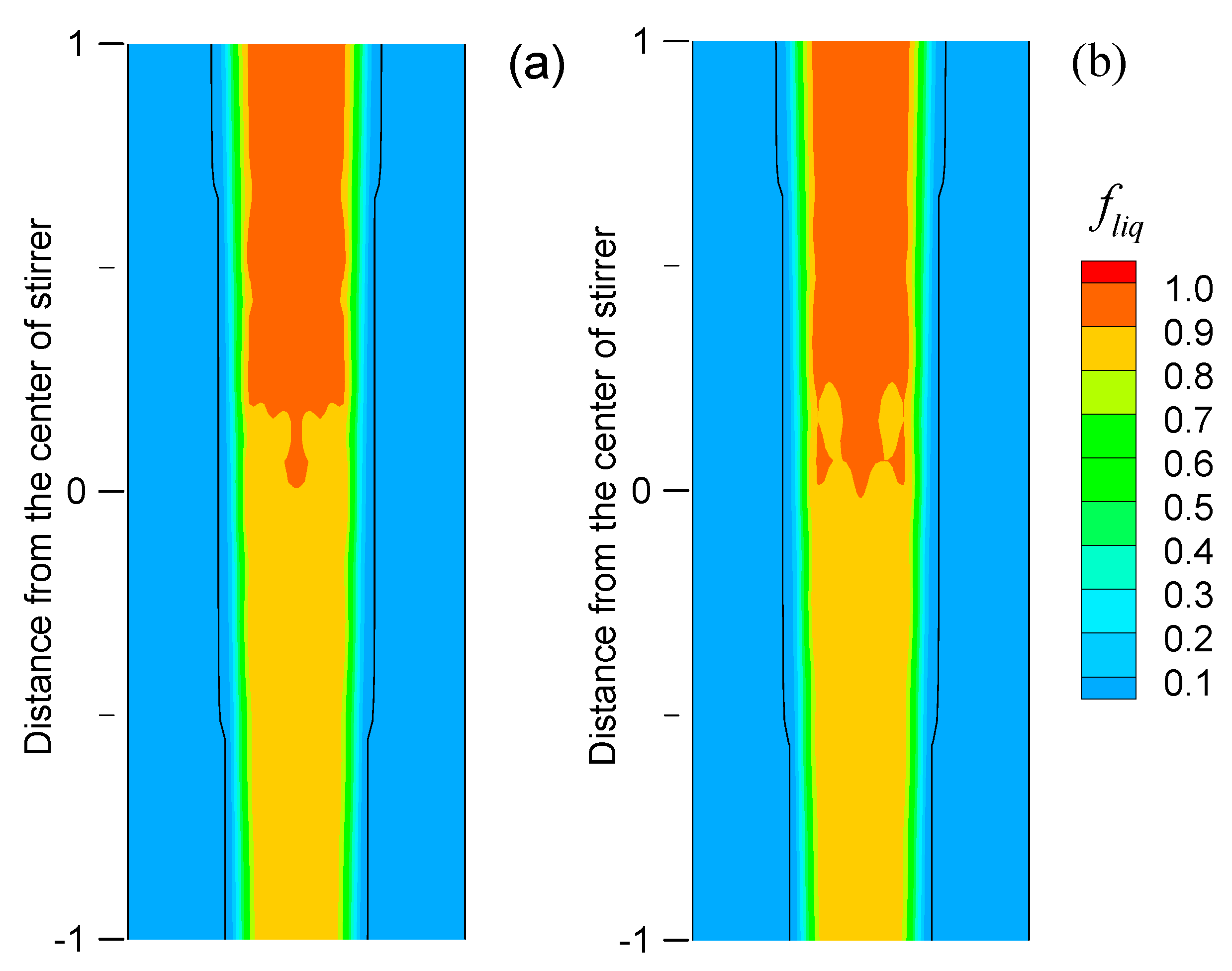

3.4. Flow and Solidification in the Alternate Stirring Mode

4. Conclusions

- In the simulation, the expression of liquid fraction significantly influences the mushy zone, and the equilibrium solidification mode is recommended, as it better reflects actual molten steel behavior.

- The closer the F-EMS installation is to the meniscus, the greater the stirring velocity of molten steel, owing to the wider mushy zone.

- In the alternate stirring mode, the actual current rise time exceeds 10 s, making short stirring cycles insufficient for large-section blooms. Based on simulation results and practical considerations, a 25 s forward and reverse stirring duration is recommended for Φ600 mm round bloom casting with F-EMS. This cycle allows sufficient development of stirring intensity, enhances flow stability, improves heat transfer and liquid fraction uniformity in the mushy zone, and helps mitigate negative segregation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ren, B.; Chen, D.; Xia, W.; Wang, H.; Han, Z. Numerical Simulation of Electromagnetic Field in Round Bloom Continuous Casting with Final Electromagnetic Stirring. Metals 2018, 8, 903. [Google Scholar] [CrossRef]

- Xu, G.; Tan, R.; Song, B.; Liu, W.; Yang, S.; Zuo, X.; Huang, Y. Numerical Simulation of the Effect of Solidified Shell Conductivity and Billet Sizes on the Magnetic Field with Final Electromagnetic Stirring in Continuous Casting. Materials 2023, 16, 4765. [Google Scholar] [CrossRef]

- Guo, Q.; Sha, M.; Jia, J.; Zhu, X.; Zou, H.; Cai, L. Effect of Final EMS on Shrinkage Cavity of Bloom. J. Iron Steel Res. Int. 2015, 22, 93–97. [Google Scholar] [CrossRef]

- Jiang, D.; Zhu, M. Flow and Solidification in Billet Continuous Casting Machine with Dual Electromagnetic Stirrings of Mold and the Final Solidification. Steel Res. Int. 2015, 86, 993–1003. [Google Scholar] [CrossRef]

- Jiang, W.; Long, M.; Liu, T.; Chen, D.; Chen, H.; Cao, J.; Fan, H.; Yu, S.; Duan, H. Fluid Flow and Solidified Shell Remelting in F-EMS During Billet Continuous Casting. JOM 2018, 70, 2059–2064. [Google Scholar] [CrossRef]

- Wu, H.; Lei, C.; Xu, C.; Wang, T.; Liu, N.; Ma, G. Effect of Final Electromagnetic Stirring on Internal Thermal Stress, Strain and Cracking of Continuous Casting Bloom. ISIJ Int. 2023, 63, 1373–1382. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, E.; Fautrelle, Y.; Zhai, Z. Numerical Simulation of Melt Flow, Heat Transfer and Solidification in Final Solidification Zone of Bloom Continuous Casting with Vertical Linear Electromagnetic Stirring. Metall. Mater. Trans. B 2024, 55, 1482–1496. [Google Scholar] [CrossRef]

- Wu, H.J.; Xu, C.J.; Jin, H.Y.; Gao, Y.L.; Zhang, X.B.; Jin, Y.K. Effect of Different Positions of Final Electromagnetic Stirring for Φ800mm Vertical Round Billet on Fluid Flow and Heat Transfer. Appl. Phys. A 2022, 128, 108. [Google Scholar] [CrossRef]

- Sun, H.; Li, L.; Ye, D.; Wu, X. On the Alternate Stirring Mode of F-EMS for Bloom Continuous Castings. Metall. Mater. Trans. B 2018, 49, 1909–1918. [Google Scholar] [CrossRef]

- Feng, Z.; Zhang, G.; Li, P.; Yan, P. Numerical Simulation of Fluid Flow, Solidification, and Solute Distribution in Billets under Combined Mold and Final Electromagnetic Stirring. Materials 2024, 17, 530. [Google Scholar] [CrossRef]

- Sun, H.; Li, L.; Cheng, X.; Qiu, W.; Liu, Z.; Zeng, L. Reduction in Macrosegregation on 380 Mm×490 Mm Bloom Caster Equipped Combination M+F-EMS by Optimising Casting Speed. Ironmak. Steelmak. 2015, 42, 439–449. [Google Scholar] [CrossRef]

- Feng, Z.; Zhang, G.; Li, P.; Yan, P.; McLean, A. Improvement of Carbon Segregation in Billet by Final-EMS, Based on Segmented Continuous Casting Model. Ironmak. Steelmak. Process. Prod. Appl. 2024, 51, 112–121. [Google Scholar] [CrossRef]

- Jiang, D.; Zhu, M. Center Segregation with Final Electromagnetic Stirring in Billet Continuous Casting Process. Metall. Mater. Trans. B 2017, 48, 444–455. [Google Scholar] [CrossRef]

- Li, S.; Han, Z.; Zhang, J. Numerical Modeling of the Macrosegregation Improvement in Continuous Casting Blooms by Using F-EMS. JOM 2020, 72, 4117–4126. [Google Scholar] [CrossRef]

- Fang, Q.; Zhang, H.; Wang, J.; Zhao, P.; Wu, G.; Ni, H. Effect of Final Electromagnetic Stirring on Flow, Solidification, and Solute Transport in Continuous Casting Bloom. JOM 2021, 73, 2698–2708. [Google Scholar] [CrossRef]

- Yin, S.; Luo, S.; Zhang, W.; Wang, W.; Zhu, M. Numerical Simulation of Macrosegregation in Continuously Cast Gear Steel 20CrMnTi with Final Electromagnetic Stirring. J. Iron Steel Res. Int. 2021, 28, 424–436. [Google Scholar] [CrossRef]

- Luo, S.; Piao, F.; Jiang, D.; Wang, W.; Zhu, M. Numerical Simulation and Experimental Study of F-EMS for Continuously Cast Billet of High Carbon Steel. J. Iron Steel Res. Int. 2014, 21, 51–55. [Google Scholar] [CrossRef]

- Wang, P.; Chen, L.; Ma, Z.; Shao, J.; Jiang, C.; Zhang, B.; Zhang, J. Improving Compositional Homogeneity of CF53 Steel Products by Modifying Their Solidification Structure and F-EMS Intensity. Ironmak. Steelmak. Process. Prod. Appl. 2024, 51, 228–237. [Google Scholar] [CrossRef]

- Jiang, M.; Xu, D.; Ya, B.; Meng, L.; Zhu, M.; Shan, C.; Zhang, X. Effect of Electromagnetic Power on the Microstructure and Properties of 2219 Aluminum Alloy in Electromagnetic Continuous Casting Technology. Metals 2024, 14, 393. [Google Scholar] [CrossRef]

- Xie, Q.; Ni, P.; Ersson, M.; Liu, Q.; Li, Y. Effect of Swirling Flow Submerged Entry Nozzle on Solidification and Macrosegregation Behavior of a Round Bloom with Mold and Final Electromagnetic Stirring. Metall. Mater. Trans. B 2025, 56, 154–169. [Google Scholar] [CrossRef]

- Ren, B.-Z.; Chen, D.-F.; Wang, H.-D.; Long, M.-J.; Han, Z.-W. Numerical Simulation of Fluid Flow and Solidification in Bloom Continuous Casting Mould with Electromagnetic Stirring. Ironmak. Steelmak. 2015, 42, 401–408. [Google Scholar] [CrossRef]

- Ren, B.; Chen, D.; Wang, H.; Long, M. Numerical Analysis of Coupled Turbulent Flow and Macroscopic Solidification in a Round Bloom Continuous Casting Mold with Electromagnetic Stirring. Steel Res. Int. 2015, 86, 1104–1115. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, J. Study on the Macrosegregation Behavior for the Bloom Continuous Casting: Model Development and Validation. Metall. Mater. Trans. B 2014, 45, 1133–1149. [Google Scholar] [CrossRef]

- Wang, X.; Shu-guo, Z.; Zhu, M. Fluid Flow, Solidification and Solute Transport in Billet Continuous Casting with Different Stirrer Positions. Ironmak. Steelmak. 2022, 49, 343–353. [Google Scholar] [CrossRef]

- Flemings, M.C. Behavior of Metal Alloys in the Semisolid State. Metall. Trans. B 1991, 22, 269–293. [Google Scholar] [CrossRef]

- Mizukami, H.; Komatsu, M.; Kitagawa, T.; Kawakami, K. Effect of Electromagnetic Stirring at the Final Stage of Solidification of Continuously Cast Strand. Trans. Iron Steel Inst. Jpn. 1984, 24, 923–930. [Google Scholar] [CrossRef]

- Xu, Y.; Xu, R.; Fan, Z.; Li, C.; Deng, A.; Wang, E. Analysis of cracking phenomena in continuous casting of 1Cr13 stainless steel billets with final electromagnetic stirring. Int. J. Miner. Metall. Mater. 2016, 23, 534–541. [Google Scholar] [CrossRef]

- Jiang, D.; Wang, R.; Zhang, Q.; Zhang, Z.; Tu, T.; Wang, J.; Ren, Z. Effect of Final Electromagnetic Stirring on Solidification Microstructure of GCr15 Bearing Steel in Simulated Continuous Casting. J. Iron Steel Res. Int. 2020, 27, 141–147. [Google Scholar] [CrossRef]

- Kovačič, M.; Župerl, U. Continuous Caster Final Electromagnetic Stirrers Position Optimization Using Genetic Programming. Mater. Manuf. Process. 2023, 38, 2009–2017. [Google Scholar] [CrossRef]

- Mao, B.; Li, A. Theory and Technology of Electromagnetic Stirring for Continuous Casting; Metallurgical Industry Press: Beijing, China, 2012. [Google Scholar]

| Cooling Zone | Length, m |

|---|---|

| Mold zone | 0.7 |

| Water spray zone | 0.2 |

| Air mist cooling zone 1 | 1.0 |

| Air mist cooling zone 2 | 1.0 |

| Air cooling zone | 7.9 |

| Heat insulation zone | 11.0 |

| Element | Content, % |

|---|---|

| C | 0.45 |

| Si | 0.25 |

| Mn | 0.65 |

| Item | Value |

|---|---|

| Density/(kg·m−3) | 7000 |

| Dynamic viscosity/(Pa·s) | 0.006 |

| Specific heat/(J·kg−1·K−1) | 750 |

| Thermal conductivity/(W·m−1·K−1) | 35 |

| Thermal expansion coefficient/K−1 | 1 × 10−4 |

| Latent heat/(J·kg−1) | 2.5 × 105 |

| Melting temperature of pure iron/K | 1811 |

| Liquidus temperature/K | 1765 |

| Solidus temperature/K | 1695 |

| Partition coefficient | 0.40 |

| Mushy zone parameter/(kg·m−3·s−1) | 1 × 108 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, B.; Zhu, L.; Wang, H.; Chen, D. Numerical Simulation of Fluid Flow and Solidification in Round Bloom Continuous Casting with Alternate Final Electromagnetic Stirring. Metals 2025, 15, 605. https://doi.org/10.3390/met15060605

Ren B, Zhu L, Wang H, Chen D. Numerical Simulation of Fluid Flow and Solidification in Round Bloom Continuous Casting with Alternate Final Electromagnetic Stirring. Metals. 2025; 15(6):605. https://doi.org/10.3390/met15060605

Chicago/Turabian StyleRen, Bingzhi, Lilong Zhu, Hongdan Wang, and Dengfu Chen. 2025. "Numerical Simulation of Fluid Flow and Solidification in Round Bloom Continuous Casting with Alternate Final Electromagnetic Stirring" Metals 15, no. 6: 605. https://doi.org/10.3390/met15060605

APA StyleRen, B., Zhu, L., Wang, H., & Chen, D. (2025). Numerical Simulation of Fluid Flow and Solidification in Round Bloom Continuous Casting with Alternate Final Electromagnetic Stirring. Metals, 15(6), 605. https://doi.org/10.3390/met15060605