Study on Hydrogen Embrittlement Behavior of X65 Pipeline Steel in Gaseous Hydrogen Environment

Abstract

1. Introduction

2. Materials and Methods

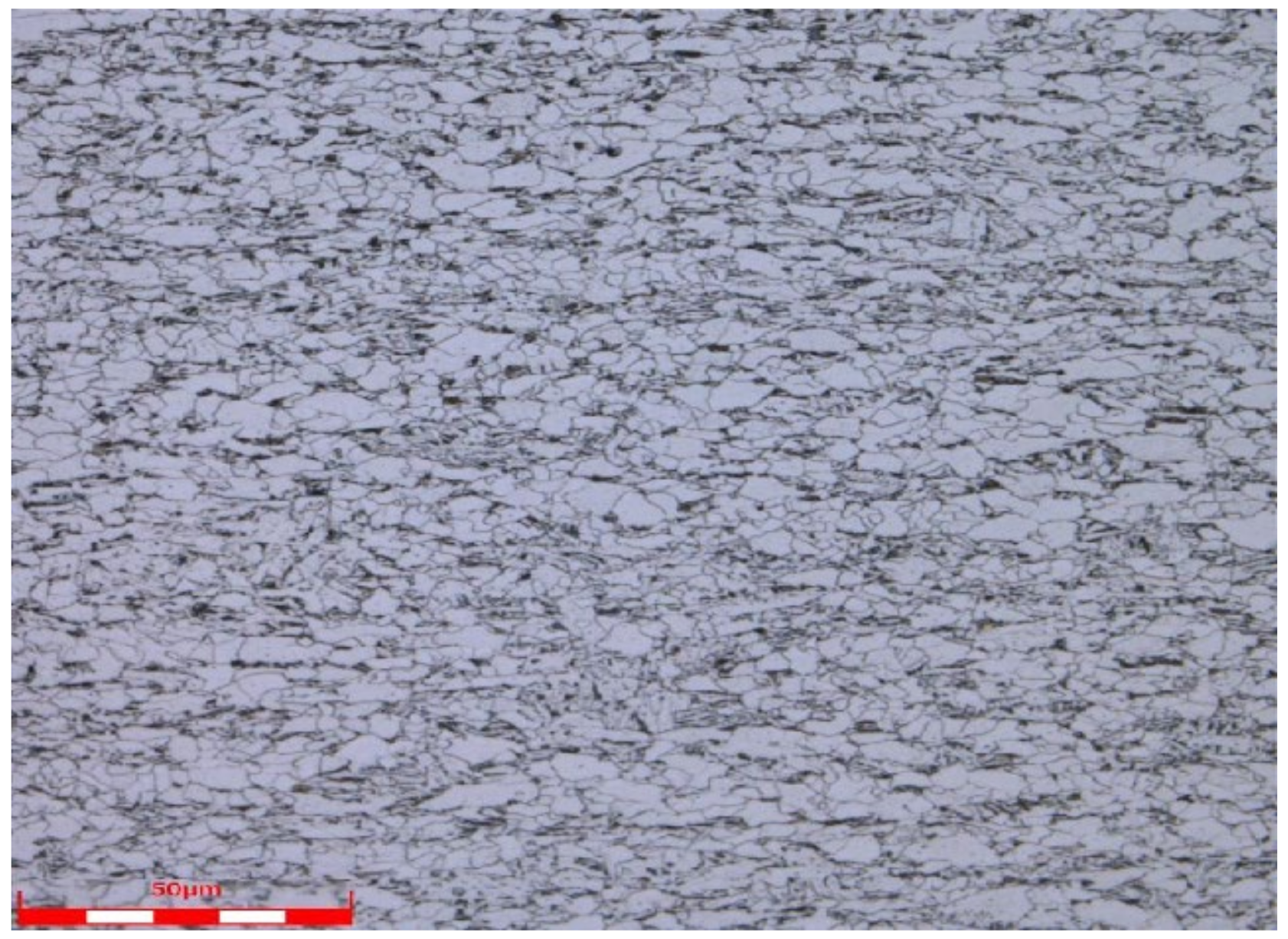

2.1. Materials

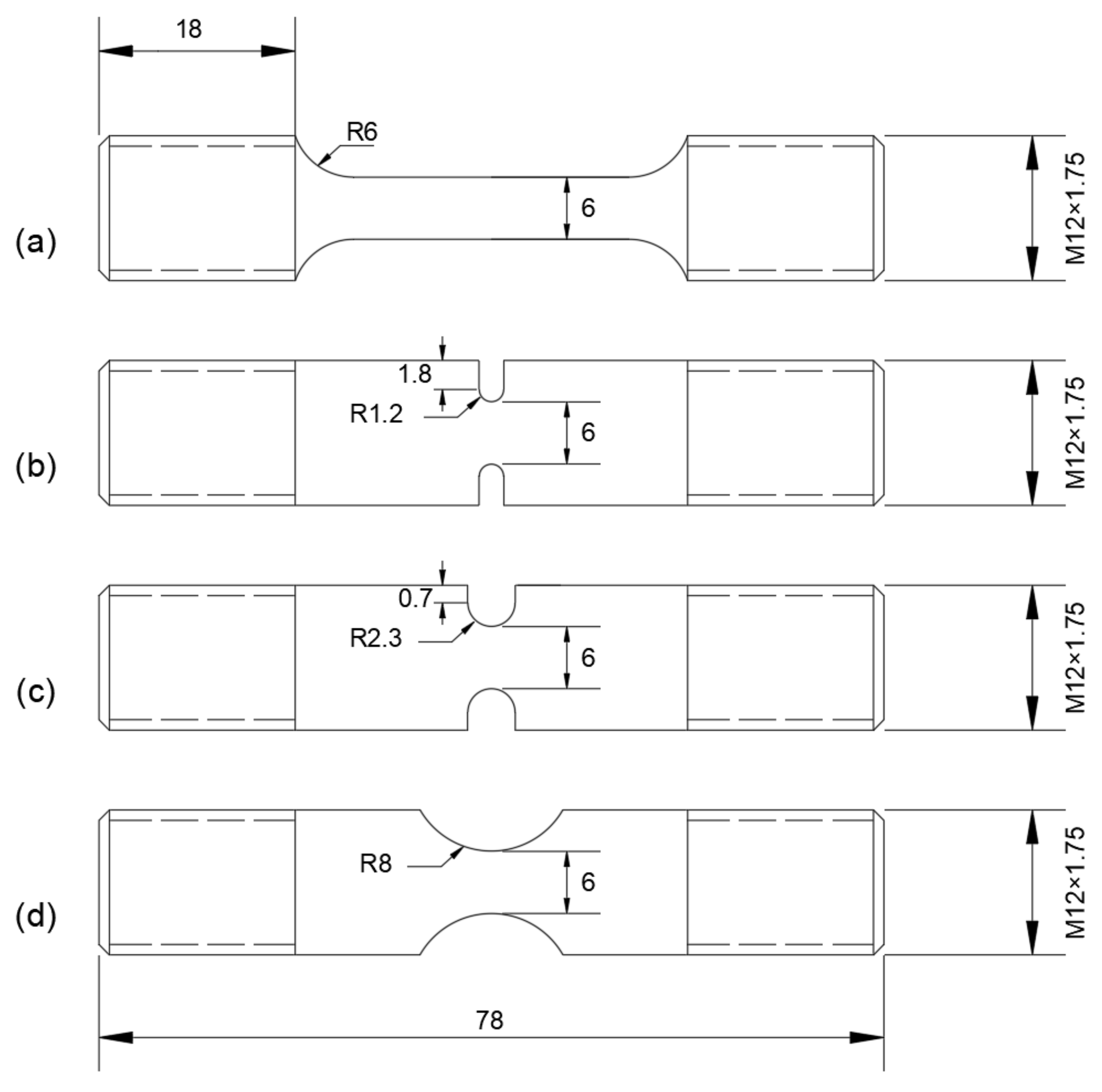

2.2. Experimental Methods

- Hydrogen Pre-Charging

- 2.

- Hydrogen Quantification

- 3.

- In Situ Tensile Testing

3. Results and Discussion

3.1. Hydrogen Pre-Charge

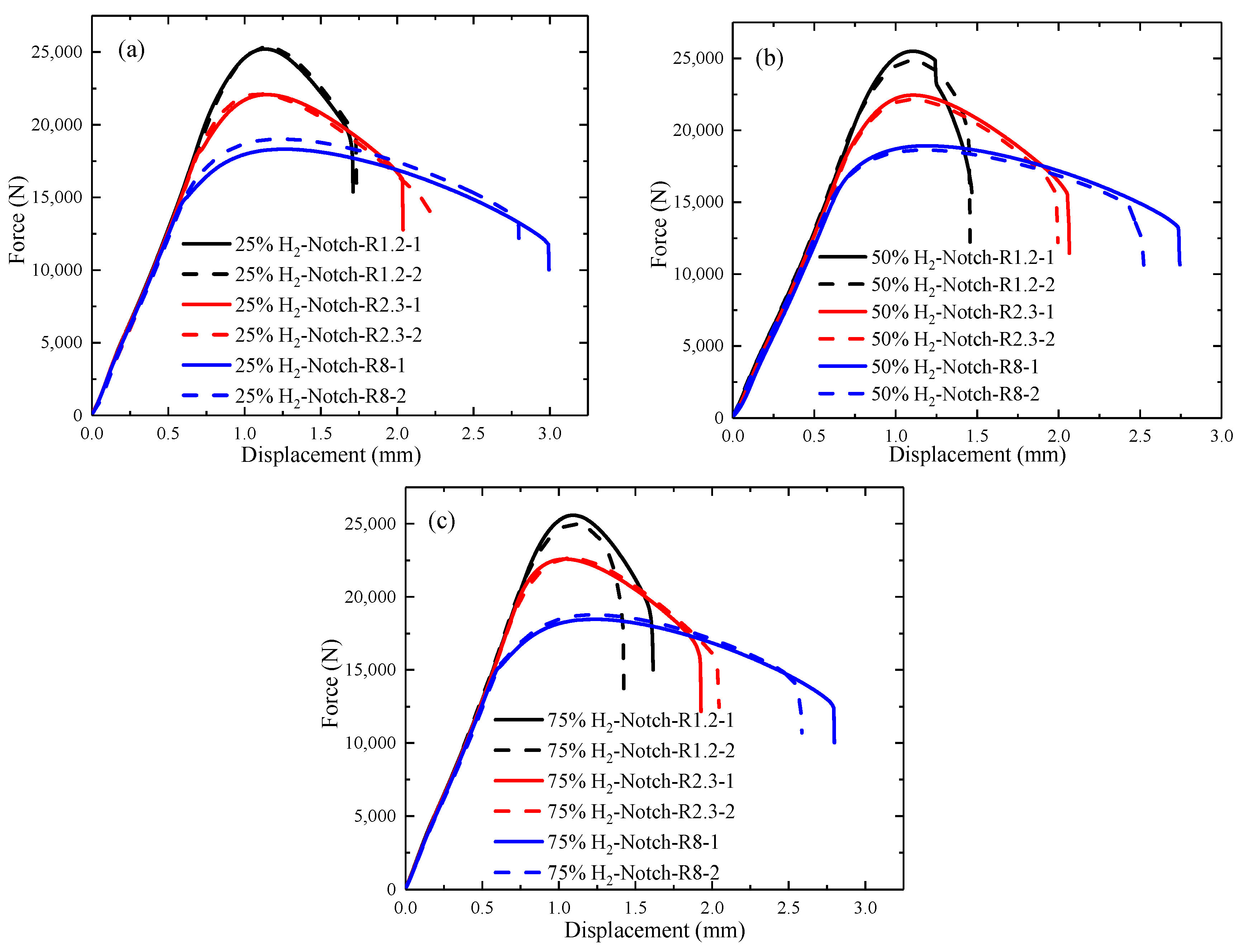

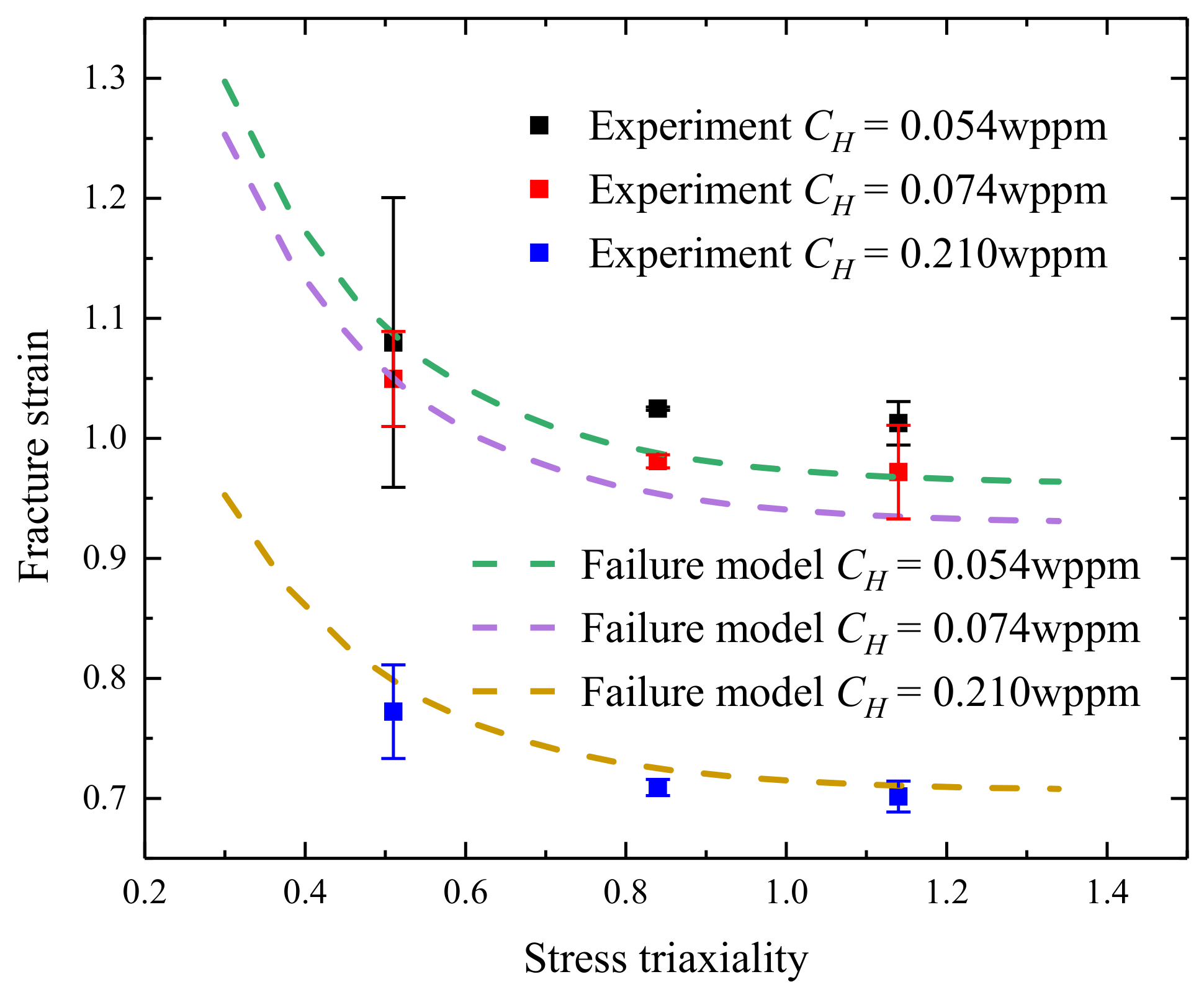

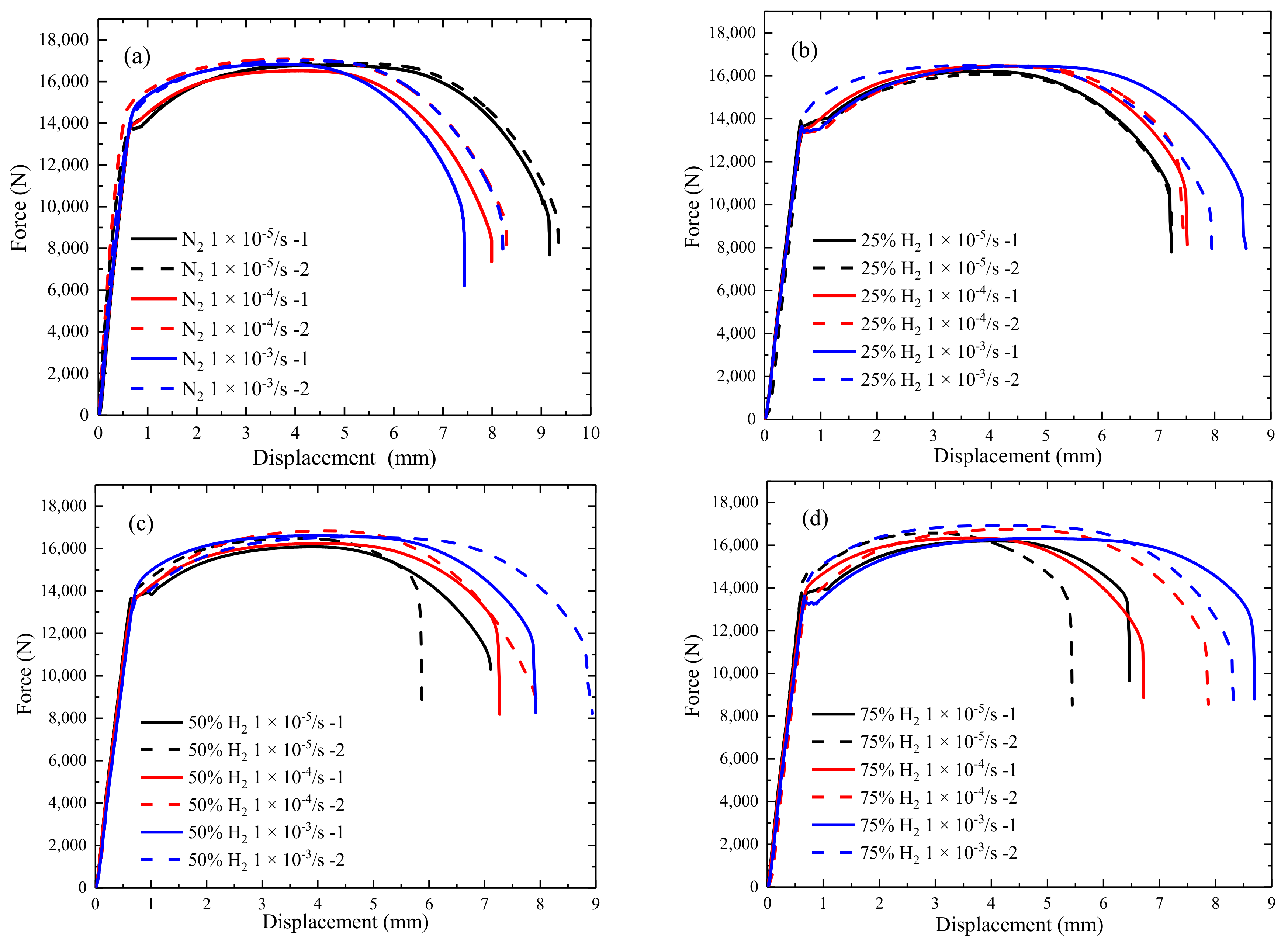

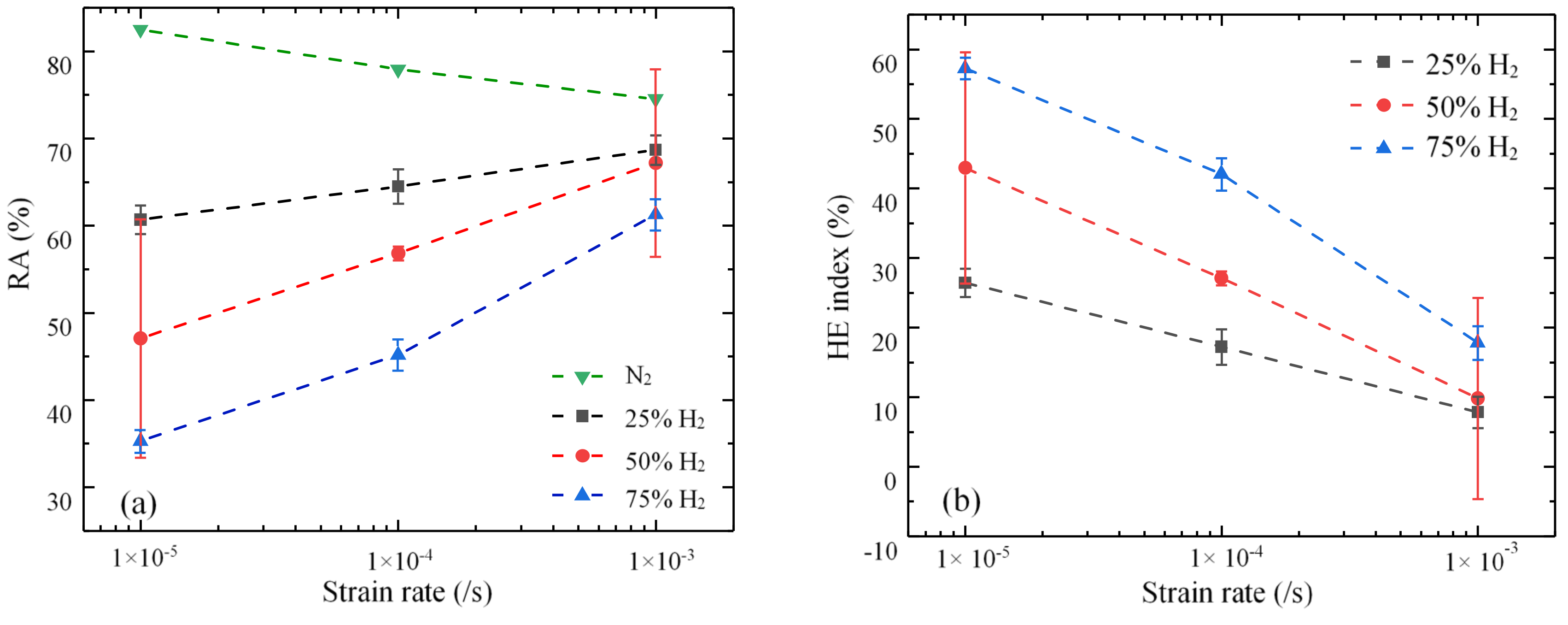

3.2. Notch Tensile with Hydrogen

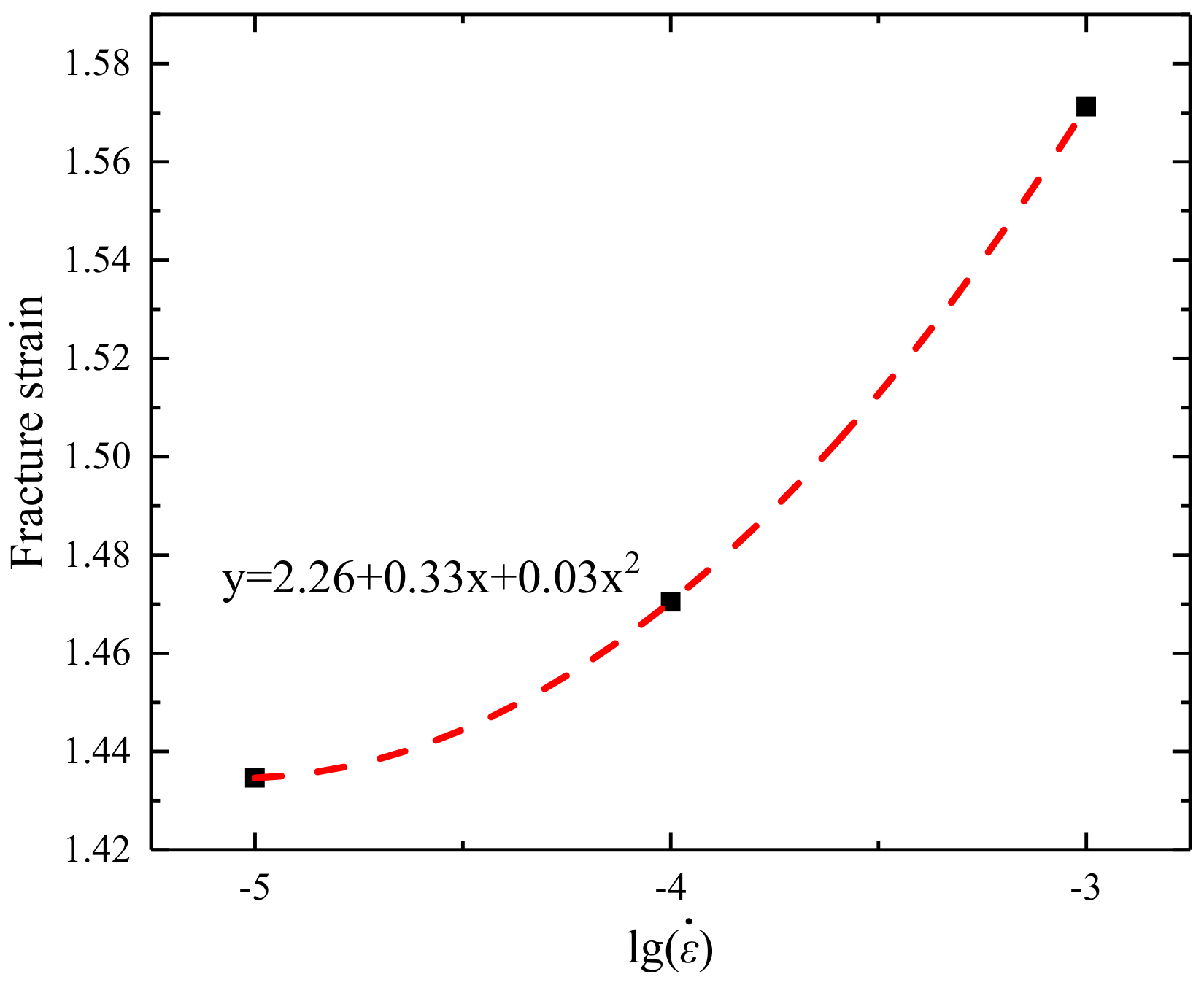

3.3. Strain Rate

4. Conclusions

- (1)

- The presence of hydrogen weakens the plastic deformation capacity of the material, resulting in a significant decrease in elongation and a failure mode from ductile fracture to brittle fracture. The increase of hydrogen pre-charge duration will weaken the plastic deformation ability of X65 pipeline steel;

- (2)

- The synergistic effect of hydrogen and stress triaxiality affect the failure process of the material, and the high stress triaxiality will aggravate the influence of HE effect on the fracture behavior of X65 pipeline steel;

- (3)

- Under the coupling effect of strain rate and hydrogen concentration, the slower the strain rate and the higher the hydrogen concentration, the higher the hydrogen enrichment under the action of the stress field, which leads to the more serious HE of X65 pipeline steel;

- (4)

- Through the analysis of the experimental results in the hydrogen environment, the failure model under the coupling effect of stress triaxiality and hydrogen concentration is . The failure model under the coupling of strain rate and hydrogen concentration is .

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Witkowski, A.; Rusin, A.; Majkut, M.; Stolecka, K. Analysis of compression and transport of the methane/hydrogen mixture in existing natural gas pipelines. Int. J. Press. Vessel. Pip. 2018, 166, 24–34. [Google Scholar] [CrossRef]

- Budny, C.; Madlener, R.; Hilgers, C. Economic feasibility of pipe storage and underground reservoir storage options for power-to-gas load balancing. Energy Procedia 2014, 61, 2201–2205. [Google Scholar] [CrossRef]

- Hanley, E.S.; Deane, J.; Gallachóir, B.Ó.J.R.; Reviews, S.E. The role of hydrogen in low carbon energy futures–A review of existing perspectives. Renew. Sustain. Energy Rev. 2018, 82, 3027–3045. [Google Scholar] [CrossRef]

- Edwards, R.L.; Font-Palma, C.; Howe, J. The status of hydrogen technologies in the UK: A multi-disciplinary review. Sustain. Energy Technol. Assess. 2021, 43, 100901. [Google Scholar] [CrossRef]

- Ball, M.; Wietschel, M. The future of hydrogen–opportunities and challenges. Int. J. Hydrogen Energy 2009, 34, 615–627. [Google Scholar] [CrossRef]

- Ohaeri, E.; Eduok, U.; Szpunar, J. Hydrogen related degradation in pipeline steel: A review. Int. J. Hydrogen Energy 2018, 43, 14584–14617. [Google Scholar] [CrossRef]

- Koren, E.; Hagen, C.M.; Wang, D.; Lu, X.; Johnsen, R.; Yamabe, J. Experimental comparison of gaseous and electrochemical hydrogen charging in x65 pipeline steel using the permeation technique. Corros. Sci. 2023, 215, 111025. [Google Scholar] [CrossRef]

- Liu, Q.; Gray, E.; Venezuela, J.; Zhou, Q.; Tapia-Bastidas, C.; Zhang, M.; Atrens, A. Equivalent hydrogen fugacity during electrochemical charging of 980dp steel determined by thermal desorption spectroscopy. Adv. Eng. Mater. 2017, 20, 1700469. [Google Scholar] [CrossRef]

- Venezuela, J.; Gray, E.; Liu, Q.; Zhou, Q.; Tapia-Bastidas, C.; Zhang, M.; Atrens, A. Equivalent hydrogen fugacity during electrochemical charging of some martensitic advanced high-strength steels. Corros. Sci. 2017, 127, 45–58. [Google Scholar] [CrossRef]

- Venezuela, J.; Tapia-Bastidas, C.; Zhou, Q.; Depover, T.; Verbeken, K.; Gray, E.; Liu, Q.; Liu, Q.; Zhang, M.; Atrens, A. Determination of the equivalent hydrogen fugacity during electrochemical charging of 3.5NiCrMoV steel. Corros. Sci. 2018, 132, 90–106. [Google Scholar] [CrossRef]

- Zhang, P.; Laleh, M.; Hughes, A.E.; Marceau, R.K.W.; Hilditch, T.; Tan, M.Y. A systematic study on the influence of electrochemical charging conditions on the hydrogen embrittlement behaviour of a pipeline steel. Int. J. Hydrogen Energy 2023, 48, 16501–16516. [Google Scholar] [CrossRef]

- Asadipoor, M.; Pourkamali Anaraki, A.; Kadkhodapour, J.; Sharifi, S.M.H.; Barnoush, A. Macro- and microscale investigations of hydrogen embrittlement in x70 pipeline steel by in-situ and ex-situ hydrogen charging tensile tests and in-situ electrochemical micro-cantilever bending test. Mater. Sci. Eng. A 2020, 772, 138762. [Google Scholar] [CrossRef]

- Song, E.J.; Baek, S.-W.; Nahm, S.H.; Baek, U.B. Notched-tensile properties under high-pressure gaseous hydrogen: Comparison of pipeline steel x70 and austenitic stainless type 304l, 316l steels. Int. J. Hydrogen Energy 2017, 42, 8075–8082. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, H.; Liu, C.; Wang, C.; Fan, X.; Cheng, Y.F.; Li, Y. Effects of defect on the hydrogen embrittlement behavior of x80 pipeline steel in hydrogen-blended natural gas environments. Int. J. Hydrogen Energy 2024, 58, 158–173. [Google Scholar] [CrossRef]

- Nanninga, N.E.; Levy, Y.S.; Drexler, E.S.; Condon, R.T.; Stevenson, A.E.; Slifka, A.J. Comparison of hydrogen embrittlement in three pipeline steels in high pressure gaseous hydrogen environments. Corros. Sci. 2012, 59, 1–9. [Google Scholar] [CrossRef]

- Zhou, D.; Li, T.; Huang, D.; Wu, Y.; Huang, Z.; Xiao, W.; Wang, Q.; Wang, X. The experiment study to assess the impact of hydrogen blended natural gas on the tensile properties and damage mechanism of X80 pipeline steel. Int. J. Hydrogen Energy 2021, 46, 7402–7414. [Google Scholar] [CrossRef]

- Lin, M.; Yu, H.; Wang, D.; Díaz, A.; Alvaro, A.; Olden, V.; Koren, E.; Ding, Y.; He, J.; Zhang, Z. Experimental and numerical study on hydrogen-induced failure of x65 pipeline steel. Mater. Sci. Eng. A 2024, 894, 146175. [Google Scholar] [CrossRef]

- Mendibide, C.; Vucko, F.; Martinez, M.; Joshi, G.R.; Kittel, J. Effect of degraded environmental conditions on the service behavior of a x65 pipeline steel not designed for hydrogen transport. Int. J. Hydrogen Energy 2024, 52, 1019–1032. [Google Scholar] [CrossRef]

- Yu, H.; Diaz, A.; Lu, X.; Sun, B.; Ding, Y.; Koyama, M.; He, J.; Zhou, X.; Oudriss, A.; Feaugas, X.; et al. Hydrogen embrittlement as a conspicuous material challenge horizontal line comprehensive review and future directions. Chem. Rev. 2024, 124, 6271–6392. [Google Scholar] [CrossRef]

- Lee, Y.-H.; Lee, H.M.; Kim, Y.-i.; Nahm, S.-H. Mechanical degradation of API x65 pipeline steel by exposure to hydrogen gas. Met. Mater. Int. 2011, 17, 389–395. [Google Scholar] [CrossRef]

- Singh, V.; Singh, R.; Arora, K.S.; Mahajan, D.K. Hydrogen induced blister cracking and mechanical failure in x65 pipeline steels. Int. J. Hydrogen Energy 2019, 44, 22039–22049. [Google Scholar] [CrossRef]

- Kryzhanivs’kyi, E.I.; Nykyforchyn, H.M. Specific features of hydrogen-induced corrosion degradation of steels of gas and oil pipelines and oil storage reservoirs. Mater. Sci. 2011, 47, 127–136. [Google Scholar] [CrossRef]

- Nykyforchyn, H.; Zvirko, O.; Dzioba, I.; Krechkovska, H.; Hredil, M.; Tsyrulnyk, O.; Student, O.; Lipiec, S.; Pala, R. Assessment of operational degradation of pipeline steels. Materials 2021, 14, 3274. [Google Scholar] [CrossRef]

- Depraetere, R.; De Waele, W.; Cauwels, M.; Depover, T.; Verbeken, K.; Hertele, S. Modeling of hydrogen-charged notched tensile tests of an x70 pipeline steel with a hydrogen-informed gurson model. Materials 2023, 16. [Google Scholar] [CrossRef]

- Tu, S.; Ren, X.; Nyhus, B.; Akselsen, O.M.; He, J.; Zhang, Z. A special notched tensile specimen to determine the flow stress-strain curve of hardening materials without applying the Bridgman correction. Eng. Fract. Mech. 2017, 179, 225–239. [Google Scholar] [CrossRef]

- Wang, M.; Akiyama, E.; Tsuzaki, K. Effect of hydrogen and stress concentration on the notch tensile strength of AISI 4135 steel. Mater. Sci. Eng. A 2005, 398, 37–46. [Google Scholar] [CrossRef]

- Cui, T.C.; Liu, P.F.; Zheng, J.Y.; Gu, C.H. Finite element analysis of hydrogen transport in steel pressure vessel at room temperature. J. Fail. Anal. Prev. 2016, 16, 449–456. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, J.; Liu, C.; Hu, Q.; Zhang, R.; Xu, X.; Yang, H.; Ning, Y.; Li, Y. Study on hydrogen embrittlement susceptibility of X80 steel through in-situ gaseous hydrogen permeation and slow strain rate tensile tests. Int. J. Hydrogen Energy 2023, 48, 243–256. [Google Scholar] [CrossRef]

- Rice, J.R.; Tracey, D.M. On the ductile enlargement of voids in triaxial stress fields. J. Mech. Phys. Solids 1969, 17, 201–217. [Google Scholar] [CrossRef]

- Kanvinde, A.M. Micromechanical Simulation of Earthquake-Induced Fracture in Steel Structures; Stanford University: Stanford, CA, USA, 2004. [Google Scholar]

- Yao, D.; Cai, L.; Bao, C. A new fracture criterion for ductile materials based on a finite element aided testing method. Mater. Sci. Eng. A 2016, 673, 633–647. [Google Scholar] [CrossRef]

- Huang, X.; Chen, Y.; Zhu, J. The method to determine the failure functions of notched specimens from tensile tests. Chin. J. Solid Mech. 2008, 29, 385–388. [Google Scholar] [CrossRef]

- Bridgman, P.W. Studies in Large Plastic Flow and Fracture: With Special Emphasis on the Effects of Hydrostatic Pressure; Harvard University Press: Cambridge, MA, USA, 1964. [Google Scholar]

- ASTM E1820-20; Standard Test Method for Measurement of Fracture Toughness. ASTM International: West Conshohocken, PE, USA, 2020.

- ISO 12135:2002; Metallic Materials—Unified Method of Test for the Determination of Quasi-Static Fracture Toughness. International Organization for Standardization: Geneva, Switzerland, 2002.

- Ogawa, Y.; Hino, M.; Nakamura, M.; Matsunaga, H. Pearlite-driven surface-cracking and associated loss of tensile ductility in plain-carbon steels under exposure to high-pressure gaseous hydrogen. Int. J. Hydrogen Energy 2021, 46, 6945–6959. [Google Scholar] [CrossRef]

- Djukic, M.B.; Zeravcic, V.S.; Bakic, G.M.; Sedmak, A.; Rajicic, B. Hydrogen damage of steels: A case study and hydrogen embrittlement model. Eng. Fail. Anal. 2015, 58, 485–498. [Google Scholar] [CrossRef]

- Depraetere, R.; De Waele, W.; Cauwels, M.; Depover, T.; Verbeken, K.; Boone, M.; Hertelé, S. Influence of stress triaxiality on hydrogen assisted ductile damage in an x70 pipeline steel. Mater. Sci. Eng. A 2023, 864. [Google Scholar] [CrossRef]

- Bal, B.; Çetin, B.; Bayram, F.C.; Billur, E. Effect of hydrogen on fracture locus of Fe–16Mn–0.6 C–2.15 Al TWIP steel. Int. J. Hydrogen Energy 2020, 45, 34227–34240. [Google Scholar] [CrossRef]

- Bai, Y.; Wierzbicki, T. A new model of metal plasticity and fracture with pressure and Lode dependence. Int. J. Plast. 2008, 24, 1071–1096. [Google Scholar] [CrossRef]

- Münstermann, S.; Schruff, C.; Lian, J.; Döbereiner, B.; Brinnel, V.; Wu, B. Predicting lower bound damage curves for high-strength low-alloy steels. Fatigue Fract. Eng. Mater. Struct. 2013, 36, 779–794. [Google Scholar] [CrossRef]

- Bergo, S.; Morin, D.; Børvik, T.; Hopperstad, O.S. Micromechanics-based identification of a ductile fracture model for three structural steels. Eng. Fract. Mech. 2020, 224, 106803. [Google Scholar] [CrossRef]

- Sofronis, P.; Dadfarnia, M.; Novak, P.; Yuan, R.; Somerday, B.; Robertson, I.; Ritchie, R.; Kanezaki, T.; Murakami, Y. A combined applied mechanics/materials science approach toward quantifying the role of hydrogen on material degradation. In Proceedings of the 12th International Conference on Fracture (ICF-12), Ottawa, ON, Canada, 12–17 July 2009; pp. 1–10. [Google Scholar]

- Fan, H.; Wang, Q.; El-Awady, J.A.; Raabe, D.; Zaiser, M. Strain rate dependency of dislocation plasticity. Nat. Commun. 2021, 12, 1845. [Google Scholar] [CrossRef]

- Guzmán, A.A.; Jeon, J.; Hartmaier, A.; Janisch, R. Hydrogen embrittlement at cleavage planes and grain boundaries in bcc iron—Revisiting the first-principles cohesive zone model. Materials 2020, 13, 5785. [Google Scholar] [CrossRef]

| Materials | C | Si | Mn | P | S | Cr | Nb | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| API 5L X65 | 0.076 | 0.22 | 1.52 | 0.015 | 0.0034 | 0.18 | 0.044 | 0.011 | 0.022 |

| Pre-Charge Duration | Fracture Displacement (mm) | Fracture Load (N) |

|---|---|---|

| N2 | 9.15 | 9322 |

| 0 h (No charge) | 8.23 | 9375 |

| 1 h | 8.07 | 10,286 |

| 4 h | 7.30 | 11,007 |

| 7 h | 6.86 | 10,321 |

| 24 h | 5.83 | 13,971 |

| Type | Function | MSE |

|---|---|---|

| Type 1 | 0.0228 | |

| Type 2 | 0.0088 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, L.; Feng, H.; Li, S.; Guo, Z.; Chi, Q. Study on Hydrogen Embrittlement Behavior of X65 Pipeline Steel in Gaseous Hydrogen Environment. Metals 2025, 15, 596. https://doi.org/10.3390/met15060596

Yu L, Feng H, Li S, Guo Z, Chi Q. Study on Hydrogen Embrittlement Behavior of X65 Pipeline Steel in Gaseous Hydrogen Environment. Metals. 2025; 15(6):596. https://doi.org/10.3390/met15060596

Chicago/Turabian StyleYu, Linlin, Hui Feng, Shengnan Li, Zhicheng Guo, and Qiang Chi. 2025. "Study on Hydrogen Embrittlement Behavior of X65 Pipeline Steel in Gaseous Hydrogen Environment" Metals 15, no. 6: 596. https://doi.org/10.3390/met15060596

APA StyleYu, L., Feng, H., Li, S., Guo, Z., & Chi, Q. (2025). Study on Hydrogen Embrittlement Behavior of X65 Pipeline Steel in Gaseous Hydrogen Environment. Metals, 15(6), 596. https://doi.org/10.3390/met15060596