Effect of Elastic Strain Energy on Dynamic Recrystallization During Friction Stir Welding of Dissimilar Al/Mg Alloys

Abstract

1. Introduction

2. Model Formulation

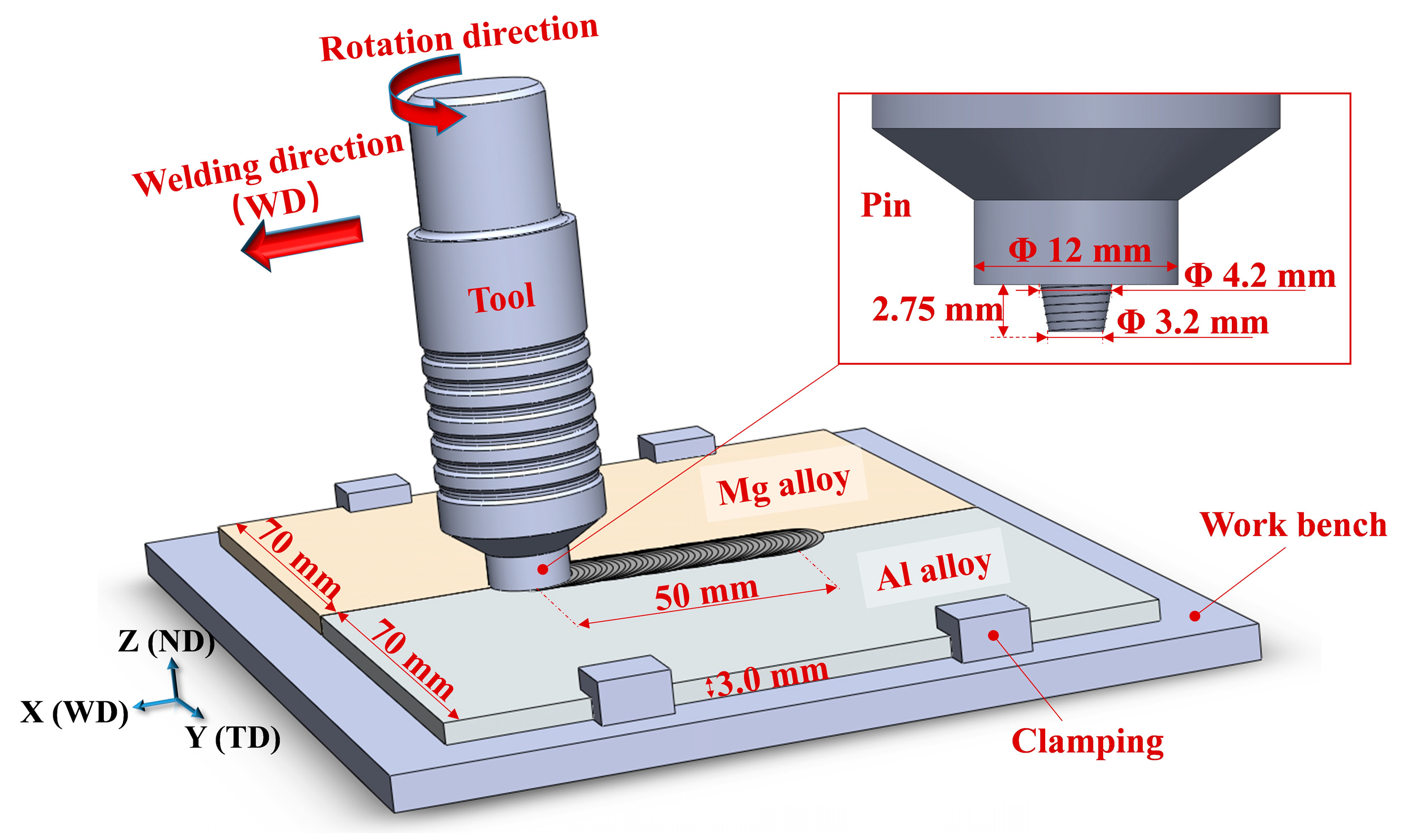

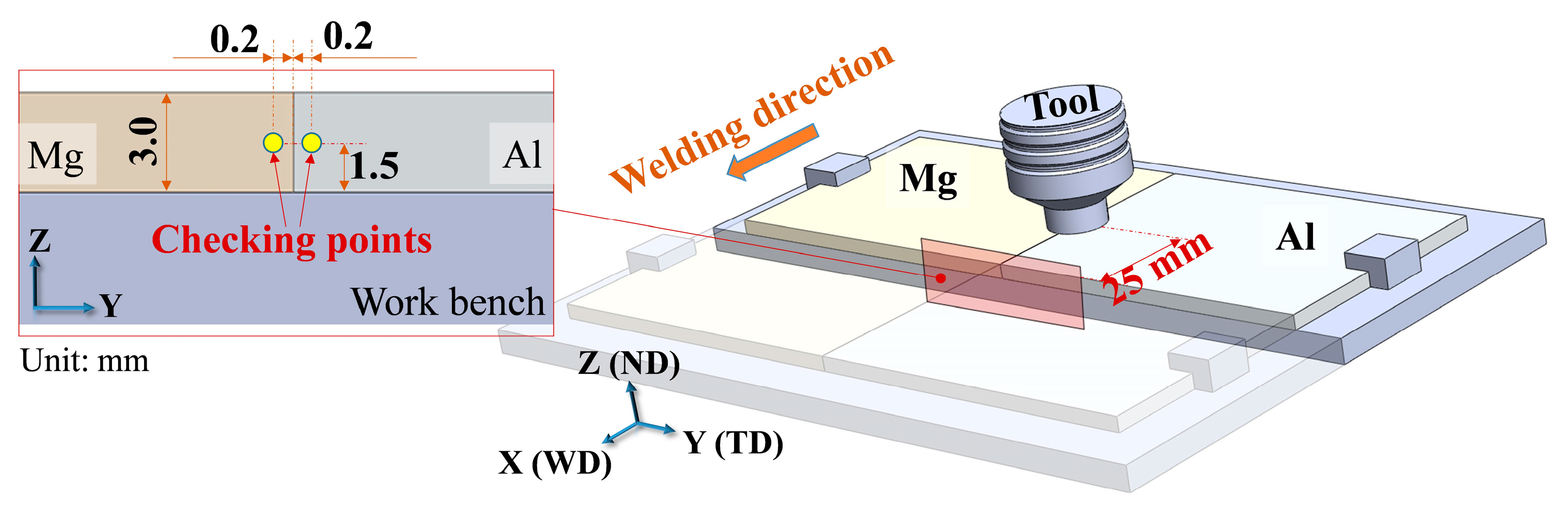

2.1. Thermo-Mechanical Model

2.2. DRX Model

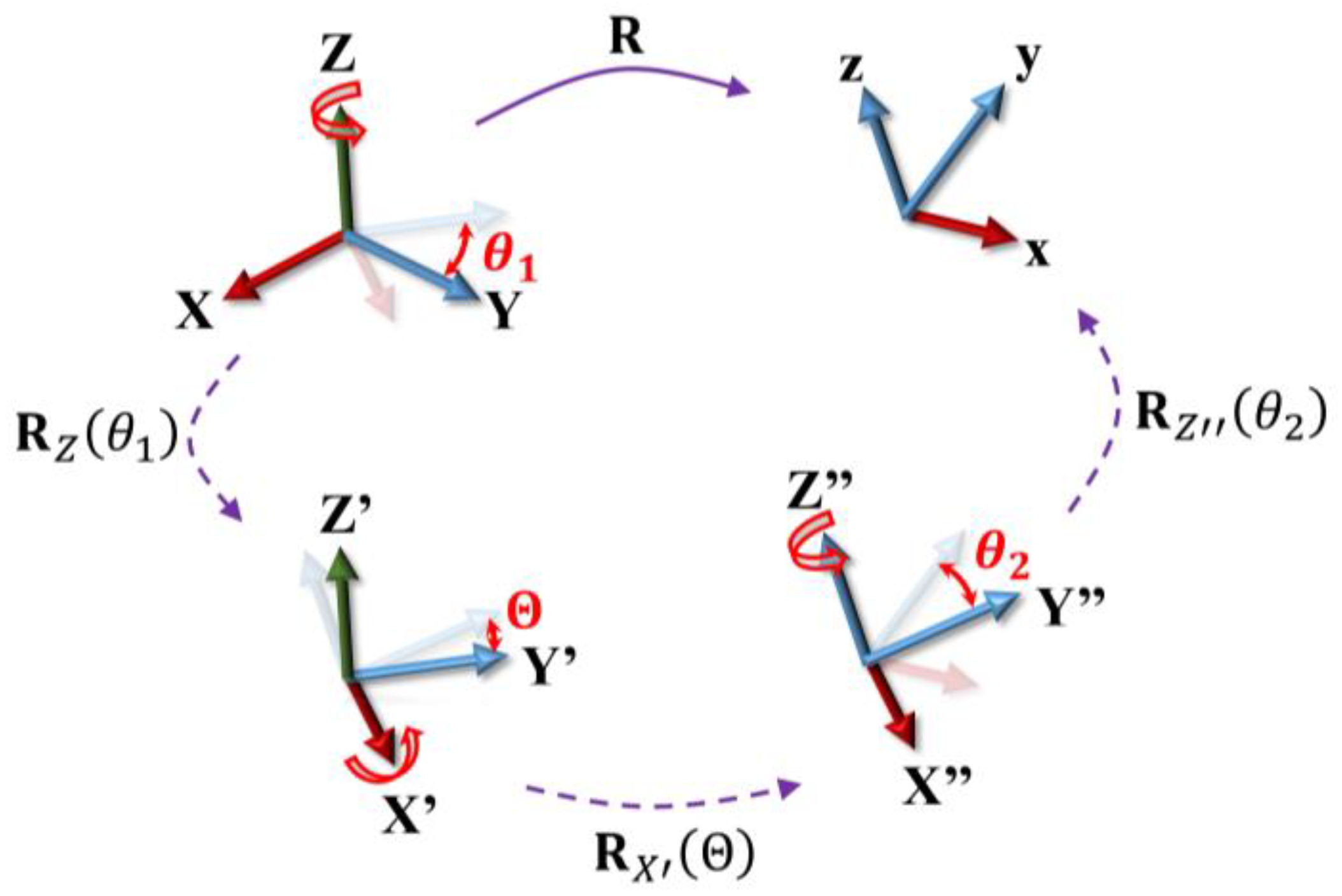

2.3. Elastic Strain Energy

2.4. Model Initialization

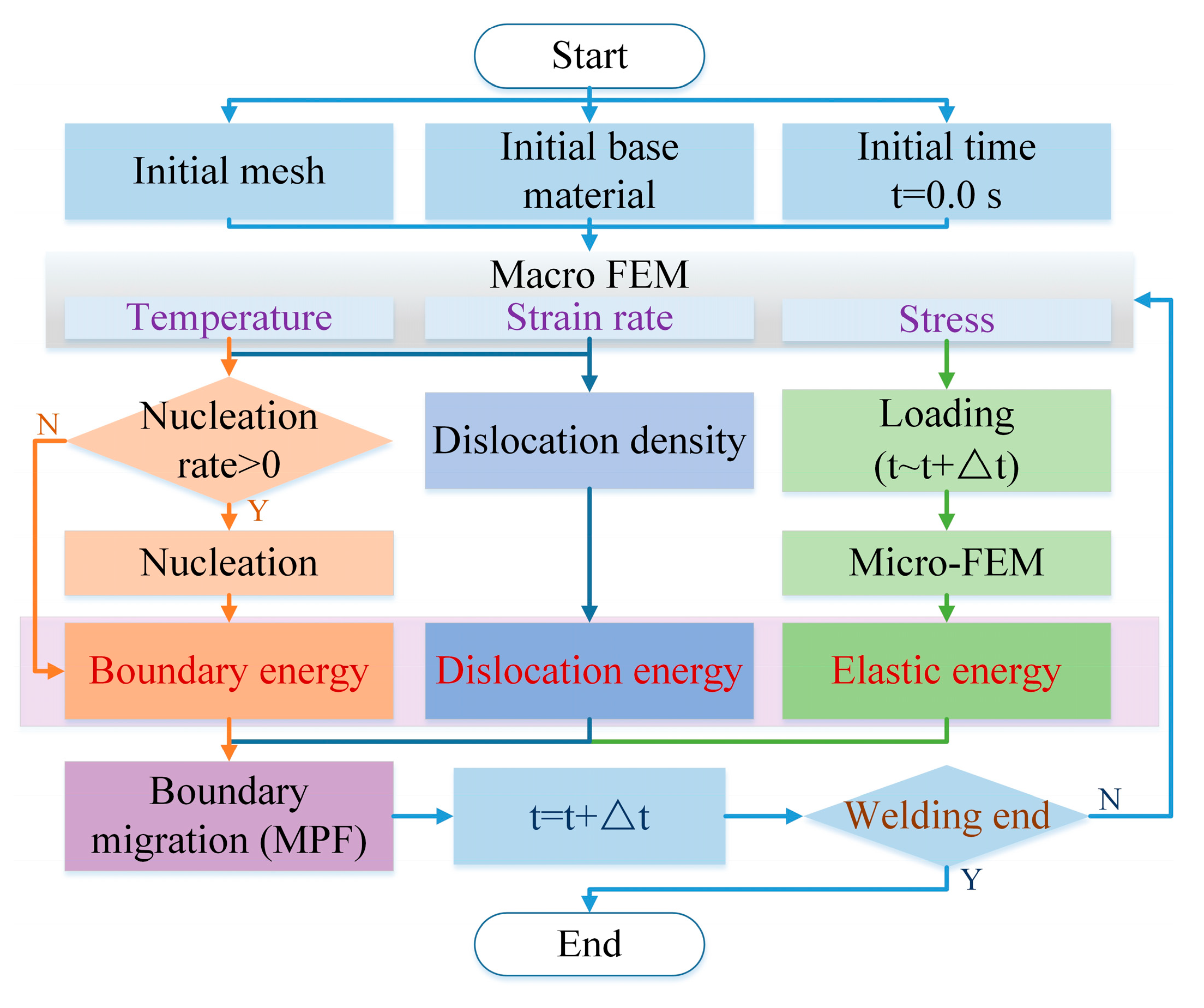

2.5. Simulation Process

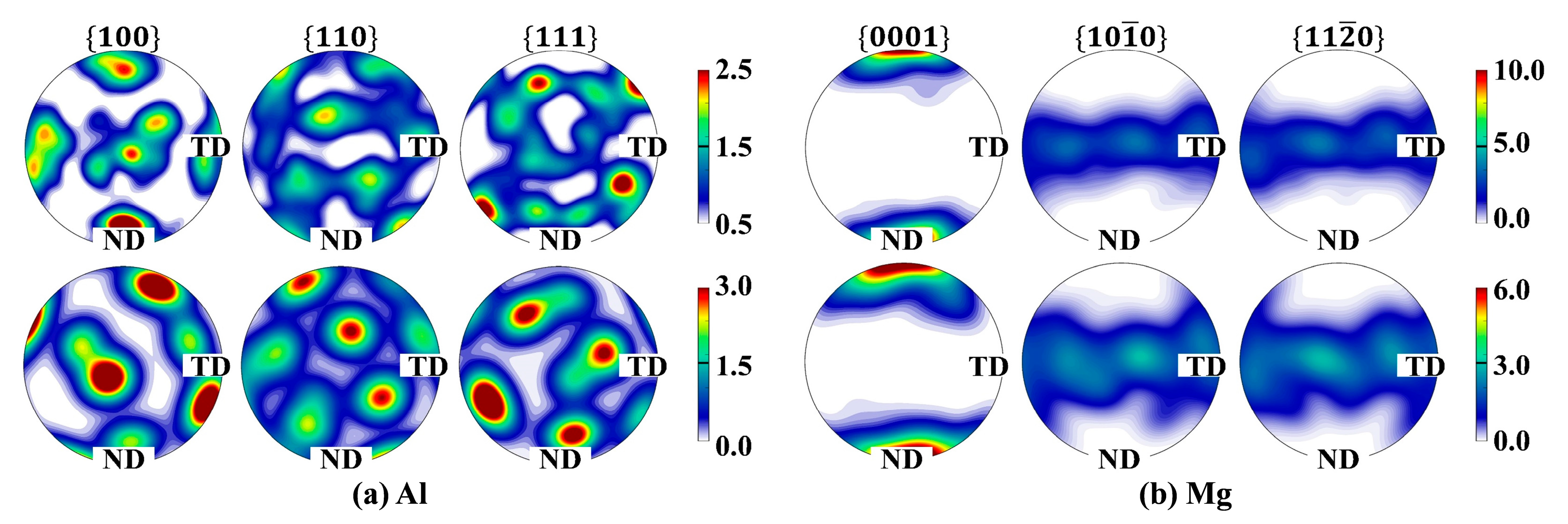

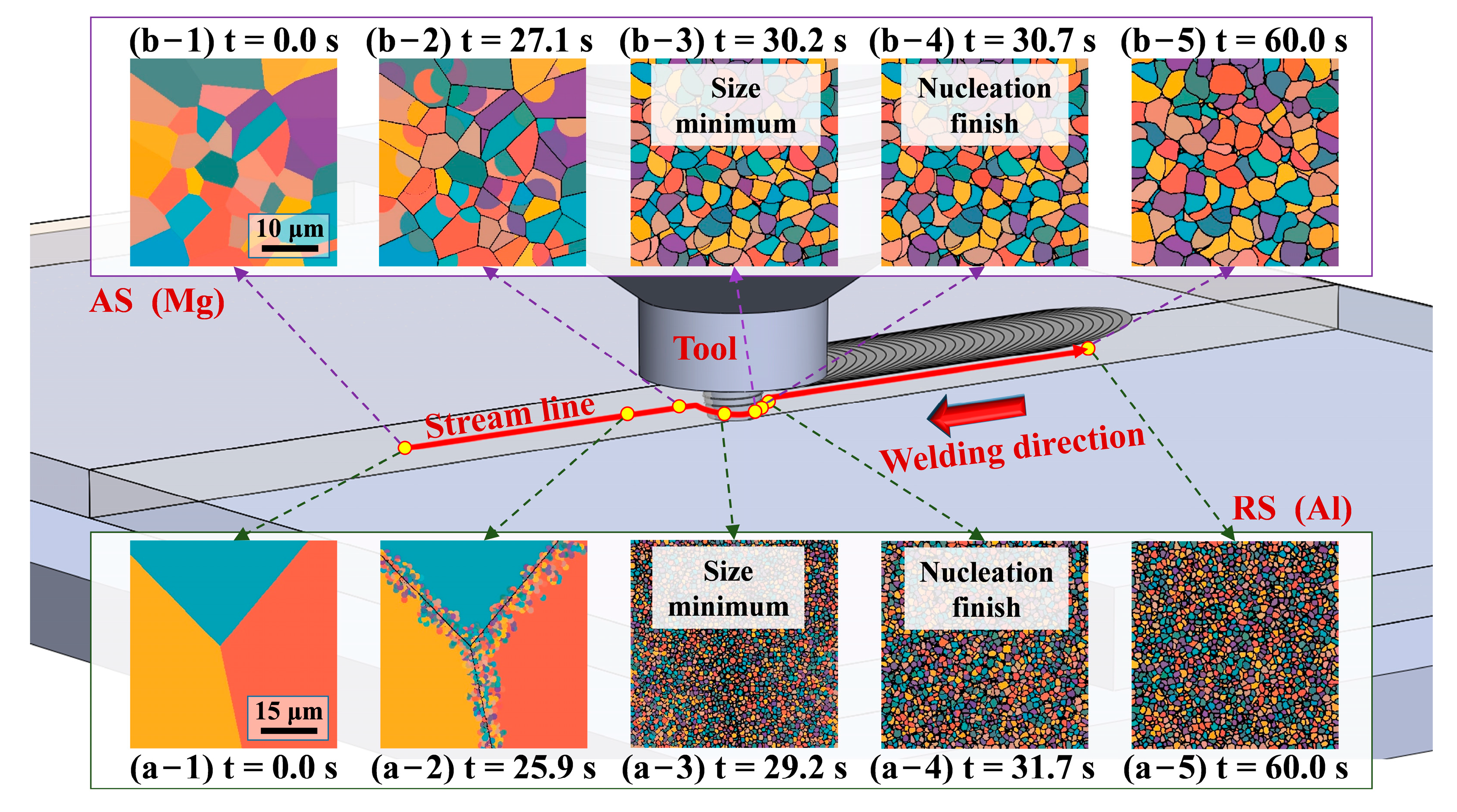

3. Results and Discussion

4. Conclusions

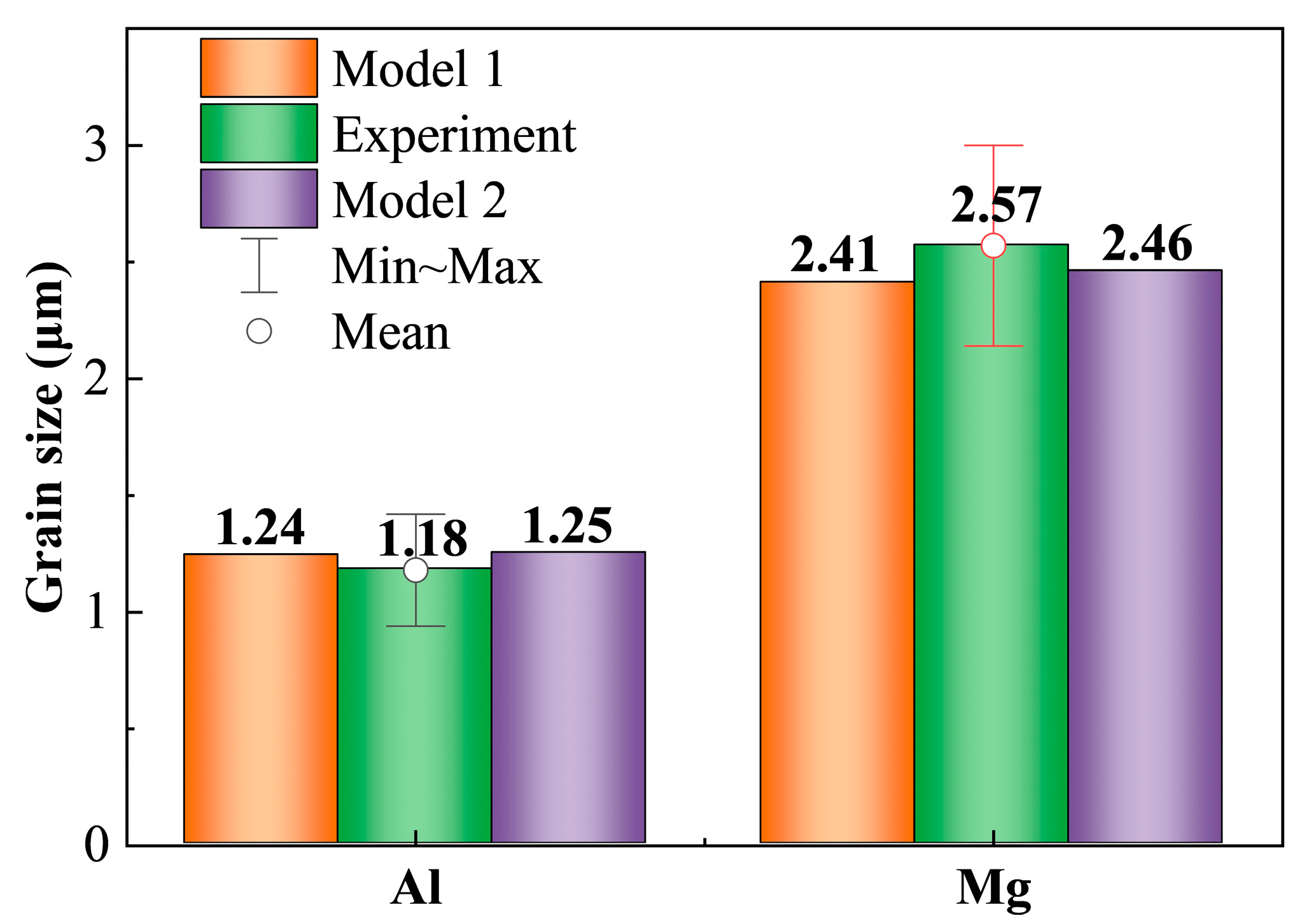

- The inclusion of elastic strain energy enhances boundary migration driving forces, producing marginally larger final grain dimensions relative to the conventional model—specifically 0.8% and 2.1% increases for the Al and Mg sides, respectively.

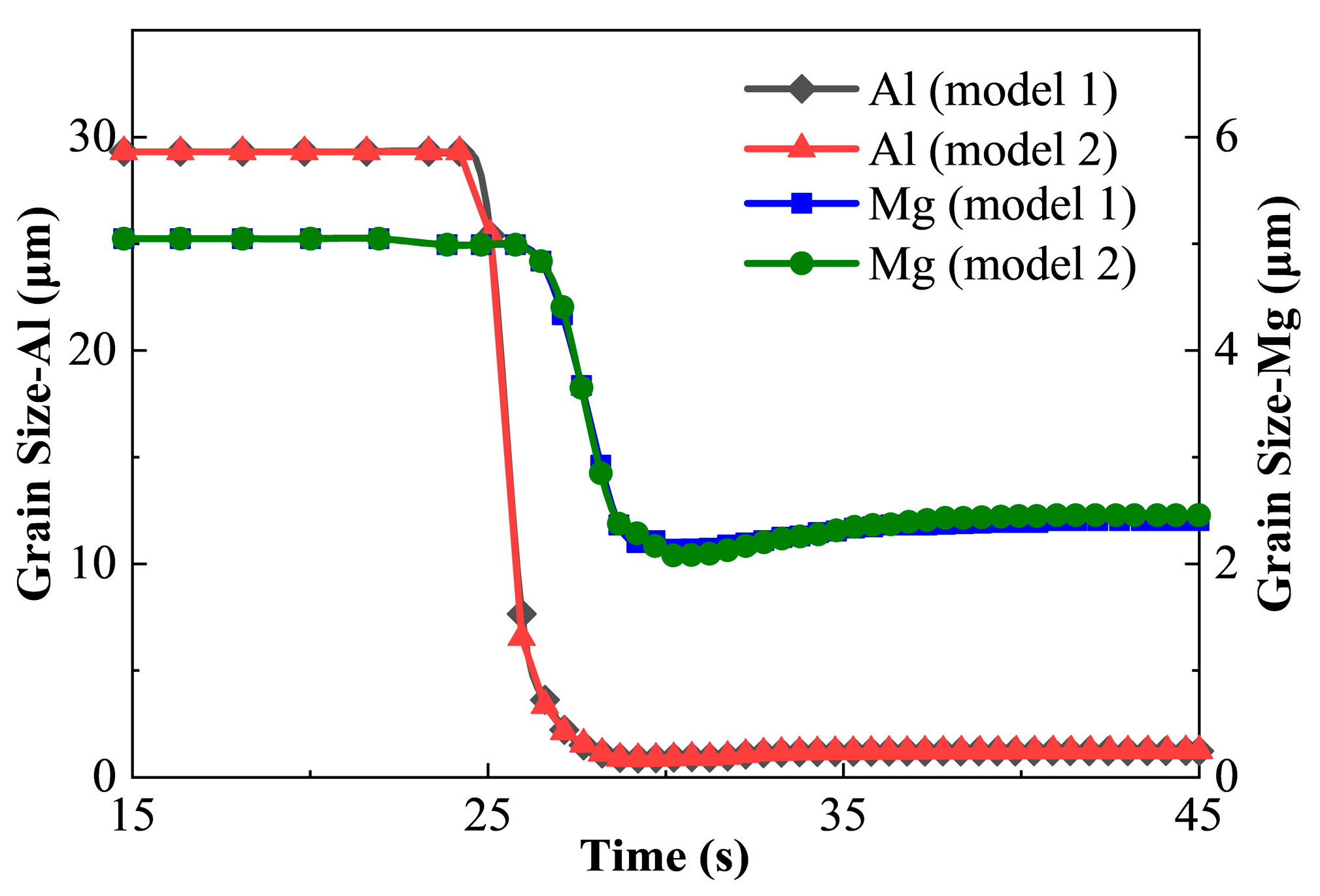

- The elastic strain energy exerts measurable though moderate effects on both nucleation and grain growth phenomena during FSW recrystallization. Quantitative evaluation demonstrates that the incorporated elastic strain energy decreases minimum grain size by 1.1% and 2.8% for the Al and Mg sides correspondingly. Concurrently, it augments grain growth by 2.8% and 5.7% during the coarsening stage for each material.

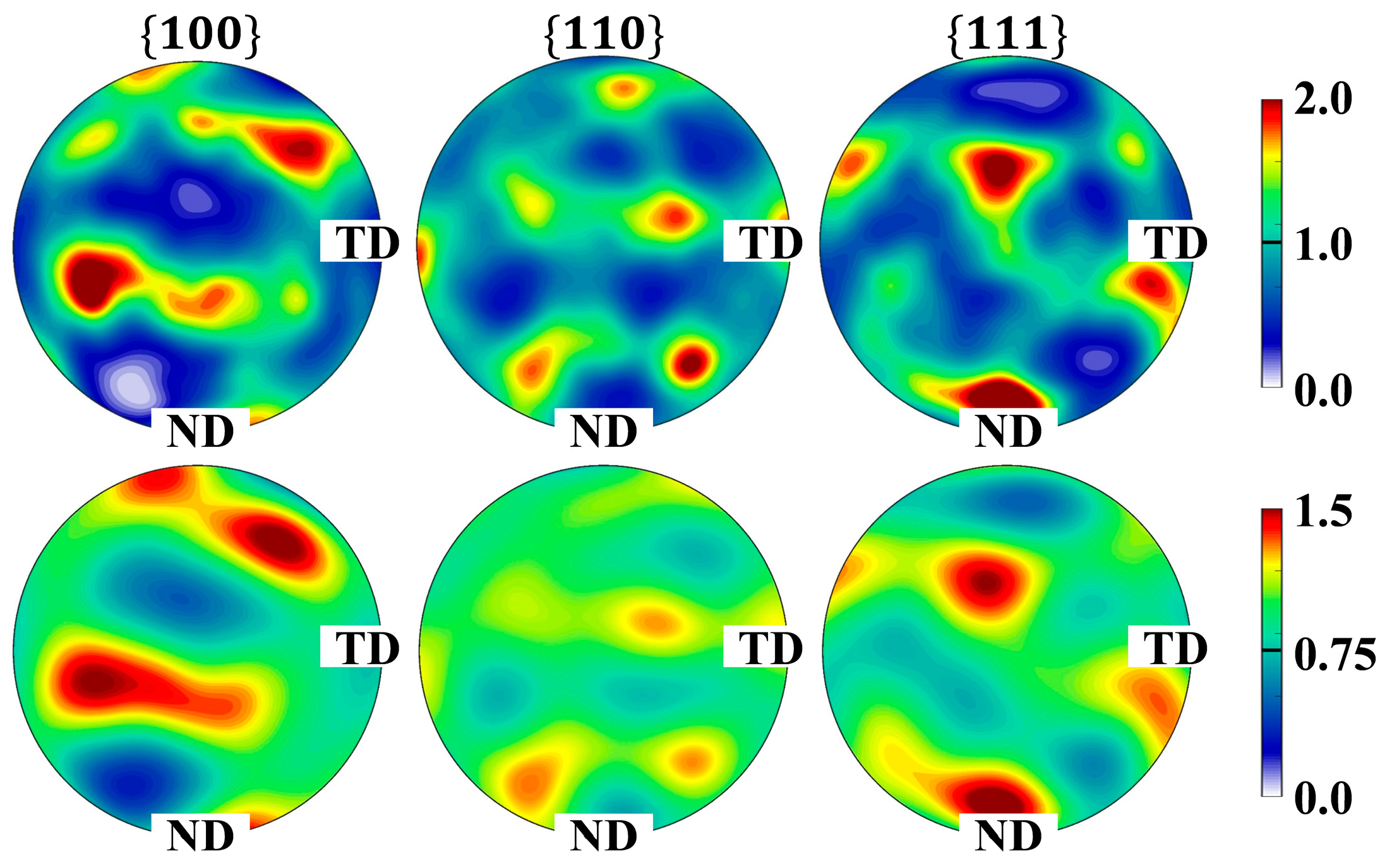

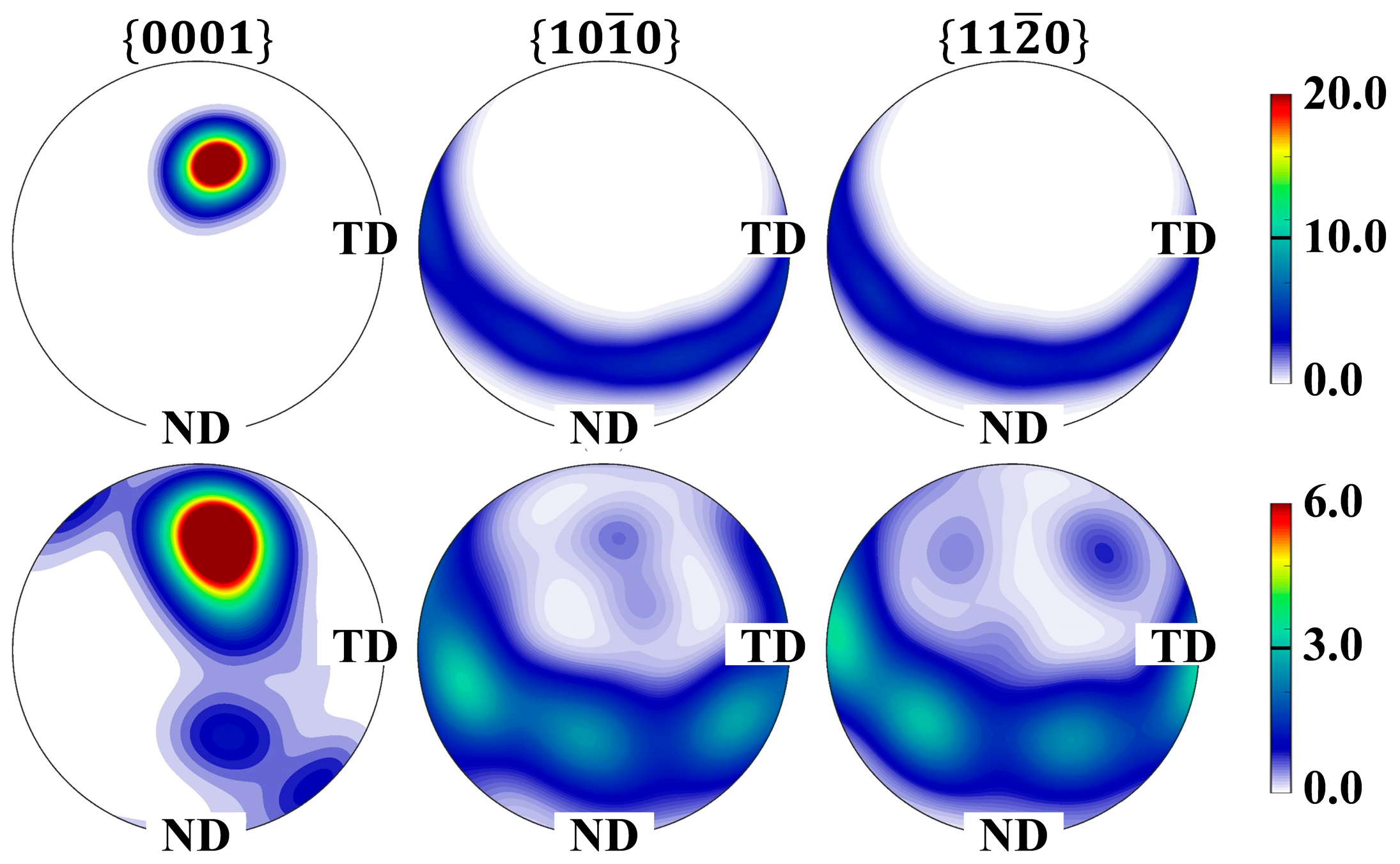

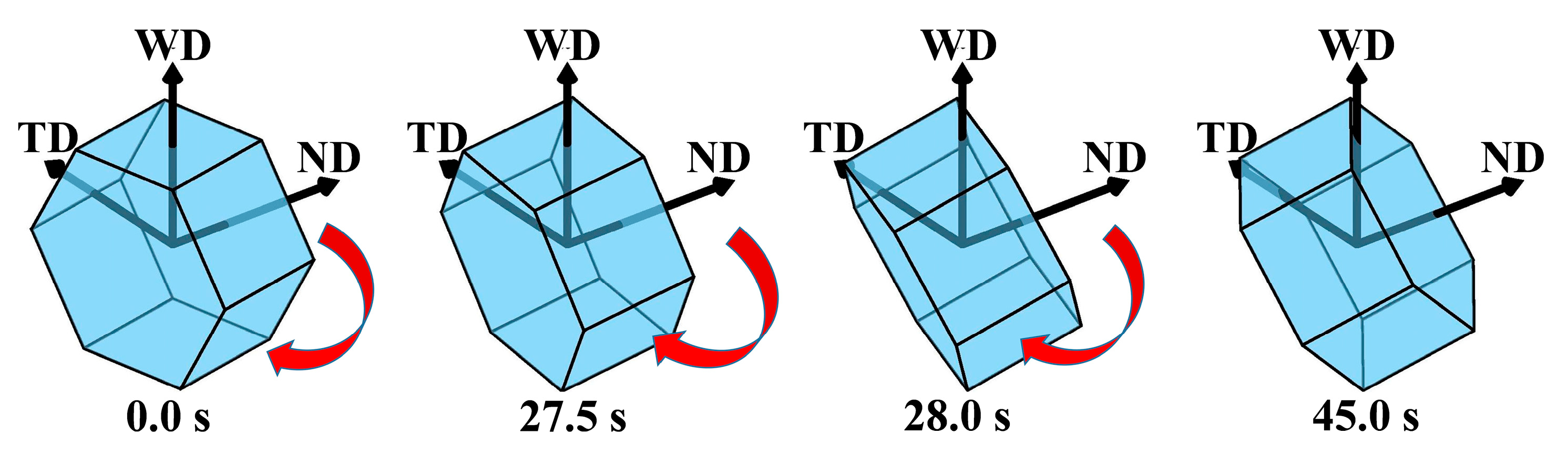

- The FSW process induces the systematic clockwise rotation of average grain orientations about the WD axis for both materials. Regarding the average orientation evolution, the Al side transitions from initial random orientations to a near-[001]//WD texture, whereas the Mg side reorients from its original [0001]//ND configuration to a characteristic [0001]//WD orientation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gaurav, S.; Mishra, R.S.; Zunaid, M. A critical review on mechanical and microstructural properties of issimilar aluminum (Al)-magnesium (Mg) alloys. J. Adhes. Sci. Technol. 2023, 37, 1117–1149. [Google Scholar] [CrossRef]

- Nagaraja, S.; Anand, P.B.; Mariswamy, M.; Alkahtani, M.Q.; Islam, S.; Khan, M.A.; Khan, W.A.; Bhutto, J.K. Friction stir welding of dissimilar Al–Mg alloys for aerospace applications: Prospects and future potential. Rev. Adv. Mater. Sci. 2024, 63, 20240033. [Google Scholar] [CrossRef]

- Mohammadi, J.; Behnamian, Y.; Mostafaei, A.; Izadi, H.; Saeid, T.; Kokabi, A.H.; Gerlich, A.P. Friction stir welding joint of dissimilar materials between AZ31B magnesium and 6061 aluminum alloys: Microstructure studies and mechanical characterizations. Mater. Charact. 2015, 101, 189–207. [Google Scholar] [CrossRef]

- Shah, L.H.; Othman, N.H.; Gerlich, A. Review of research progress on aluminium–magnesium dissimilar friction stir welding. Sci. Technol. Weld. Join. 2018, 23, 256–270. [Google Scholar] [CrossRef]

- Zhao, J.J.; Wu, C.S.; Shi, L. Effect of ultrasonic field on microstructure evolution in friction stir welding of dissimilar Al/Mg alloys. J. Mater. Res. Technol. 2022, 17, 1–21. [Google Scholar] [CrossRef]

- Jata, K.V.; Semiatin, S.L. Continuous dynamic recrystallization during friction stir welding of high strength aluminum alloys. Scripta Mater. 2000, 43, 743–749. [Google Scholar] [CrossRef]

- Zeng, X.H.; Xue, P.; Wu, L.H.; Ni, D.R.; Xiao, B.L.; Wang, K.S.; Ma, Z.Y. Microstructural evolution of aluminum alloy during friction stir welding under different tool rotation rates and cooling conditions. J. Mater. Sci. Technol. 2019, 35, 972–981. [Google Scholar] [CrossRef]

- Abbasi, M.; Bagheri, B.; Sharifi, F. Simulation and experimental study of dynamic recrystallization process during friction stir vibration welding of magnesium alloys. Trans. Nonferrous Met. Soc. China 2021, 31, 2626–2650. [Google Scholar] [CrossRef]

- Zhao, F.Y.; Shi, L.; Gao, J.Q.; Wu, C.S. Multiphase-field analysis of the intermetallic compounds formation & evolution in friction stir welding of dissimilar Al/Mg alloys. J. Mater. Res. Technol. 2024, 32, 1206–1222. [Google Scholar] [CrossRef]

- Steinbach, I.; Pezzolla, F.; Nestler, B.; Seeßelberg, M.; Prieler, R.; Schmitz, G.J.; Rezende, J.L.L. A phase field concept for multiphase systems. Physica D 1996, 94, 135–147. [Google Scholar] [CrossRef]

- Steinbach, I.; Pezzolla, F. A generalized field method for multiphase transformations using interface fields. Physica D 1999, 134, 385–393. [Google Scholar] [CrossRef]

- He, F.L.; Wu, C.S.; Shi, L. Phase-field simulation of dynamic recrystallization in friction stir weld nugget zone of dissimilar Al/Mg alloys. J. Mater. Res. Technol. 2023, 27, 2670–2683. [Google Scholar] [CrossRef]

- Yang, C.L.; Wu, C.S.; Lv, X.Q. Numerical analysis of mass transfer and material mixing in friction stir welding of aluminum/magnesium alloys. J. Manuf. Process. 2018, 32, 380–394. [Google Scholar] [CrossRef]

- Takaki, T.; Hisakuni, Y.; Hirouchi, T.; Yamanaka, A.; Tomita, Y. Multi-phase-field simulations for dynamic recrystallization. Comp. Mater. Sci. 2009, 45, 881–888. [Google Scholar] [CrossRef]

- Laasraoui, A.; Jonas, J.J. Prediction of steel flow stresses at high temperatures and strain rates. Metall. Mater. Trans. A 1991, 22, 1545–1558. [Google Scholar] [CrossRef]

- Simon, P.C.A.; Aagesen, L.K.; Motta, A.T.; Tonks, M.R. The effects of introducing elasticity using different interpolation schemes to the grand potential phase field model. Comp. Mater. Sci. 2020, 183, 109790. [Google Scholar] [CrossRef]

- Steinbach, I.; Apel, M. Multi phase field model for solid state transformation with elastic strain. Physica D 2006, 217, 153–160. [Google Scholar] [CrossRef]

- Durga, A.; Wollants, P.; Moelans, N. Evaluation of interfacial excess contributions in different phase-field models for elastically inhomogeneous systems. Model. Simul. Mater. Sci. Eng. 2013, 21, 055018. [Google Scholar] [CrossRef]

- Schneider, D.; Tschukin, O.; Choudhury, A.; Selzer, M.; Böhlke, T.; Nestler, B. Phase-field elasticity model based on mechanical jump conditions. Comput. Mech. 2015, 55, 887–901. [Google Scholar] [CrossRef]

- Voigt, W. Lehrbuch der Kristallphysik: (mit Ausschluss der Kristalloptik); BG Teubner: Berlin, Germany, 1910; Volume 34. [Google Scholar]

- Long, T.R.; Smith, C.S. Single-crystal elastic constants of magnesium and magnesium alloys. Acta Metall. 1957, 5, 200–207. [Google Scholar] [CrossRef]

- Vallin, J.; Mongy, M.; Salama, K.; Beckman, O. Elastic constants of aluminum. J. Appl. Phys. 1964, 35, 1825–1826. [Google Scholar] [CrossRef]

- Sun, G.Q.; Chen, Y.J.; Wei, X.H.; Shang, D.G.; Chen, S.J. Crystal plastic modeling on fatigue properties for aluminum alloy friction stir welded joint. Mat. Sci. Eng. A-Struct. 2018, 728, 165–174. [Google Scholar] [CrossRef]

- Kim, S.G.; Kim, D.I.; Kim, W.T.; Park, Y.B. Computer simulations of two-dimensional and three-dimensional ideal grain growth. Phys. Rev. E 2006, 74, 061605. [Google Scholar] [CrossRef]

- Ghosh, A.; Elasheri, A.; Parson, N.; Chen, X.G. Microstructure and texture evolution during high-temperature compression of Al-Mg-Si-Zr-Mn alloy. Mater. Charact. 2023, 205, 113312. [Google Scholar] [CrossRef]

- Ghosh, A.; Elasheri, A.; Parson, N.; Chen, X.G. Hot deformation behavior and processing maps for an Al-Mg-Si-Zr-Mn alloy. J. Alloy. Metall. Syst. 2024, 6, 100077. [Google Scholar] [CrossRef]

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ti | Zn | Al |

|---|---|---|---|---|---|---|---|---|---|

| 6061-T6 | 0.51 | 0.20 | 0.30 | 0.009 | 1.09 | 0.13 | - | 0.05 | Bal. |

| AZ31B-H24 | 0.016 | 0.001 | 0.003 | 0.44 | Bal. | - | - | 1.10 | 3.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, F.; Shi, L.; Wu, C. Effect of Elastic Strain Energy on Dynamic Recrystallization During Friction Stir Welding of Dissimilar Al/Mg Alloys. Metals 2025, 15, 577. https://doi.org/10.3390/met15060577

He F, Shi L, Wu C. Effect of Elastic Strain Energy on Dynamic Recrystallization During Friction Stir Welding of Dissimilar Al/Mg Alloys. Metals. 2025; 15(6):577. https://doi.org/10.3390/met15060577

Chicago/Turabian StyleHe, Faliang, Lei Shi, and Chuansong Wu. 2025. "Effect of Elastic Strain Energy on Dynamic Recrystallization During Friction Stir Welding of Dissimilar Al/Mg Alloys" Metals 15, no. 6: 577. https://doi.org/10.3390/met15060577

APA StyleHe, F., Shi, L., & Wu, C. (2025). Effect of Elastic Strain Energy on Dynamic Recrystallization During Friction Stir Welding of Dissimilar Al/Mg Alloys. Metals, 15(6), 577. https://doi.org/10.3390/met15060577