Bonding Strength and Its Enhancing Mechanism of CuCr/In718 Dissimilar Materials with Mortise and Tenon Structure Interface Manufactured by Laser-Based Direct Energy Deposition (DED-LB) Using Powder Feedstock

Abstract

1. Introduction

2. Materials and Methods

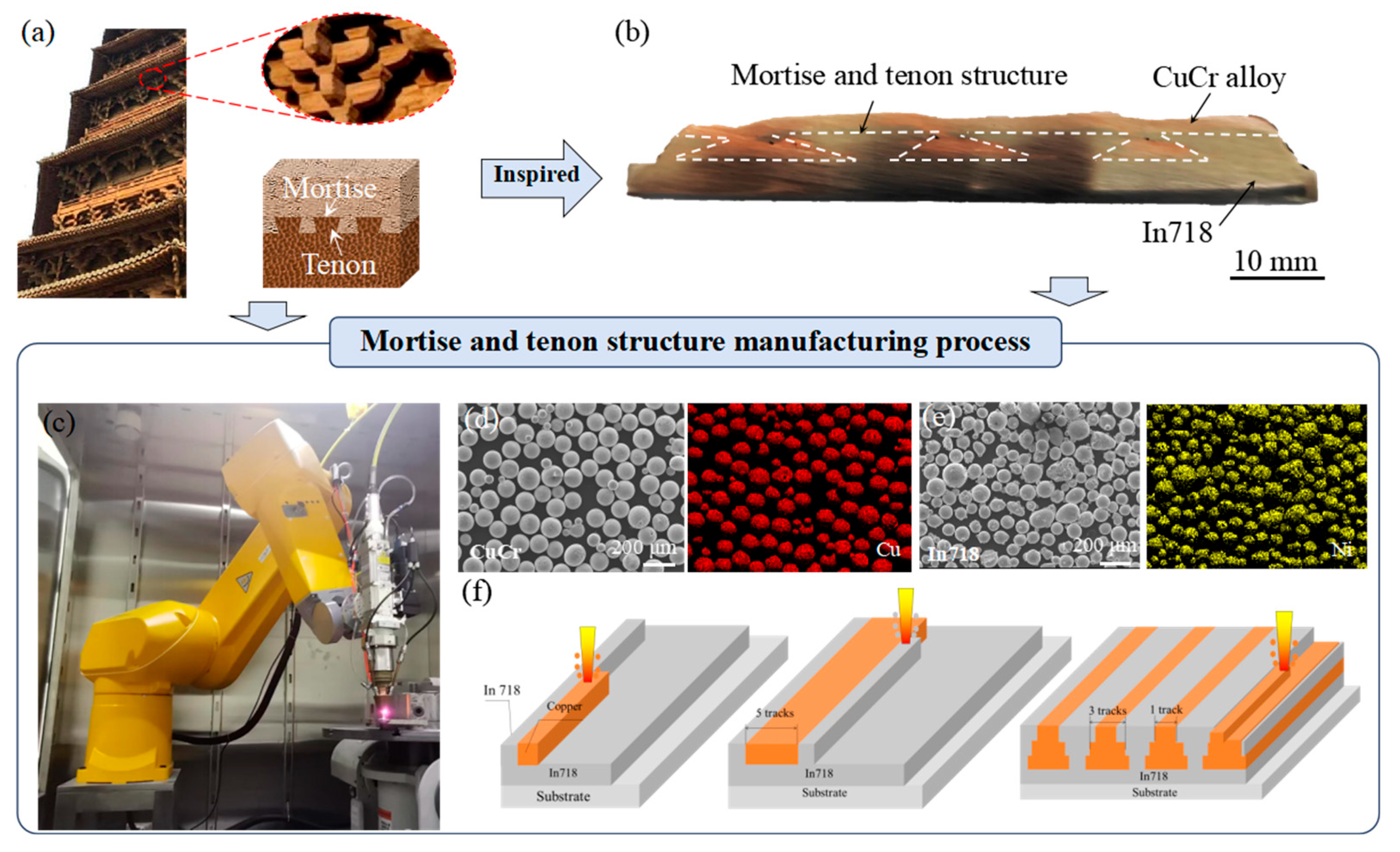

2.1. Materials and Powder DED-LB Process

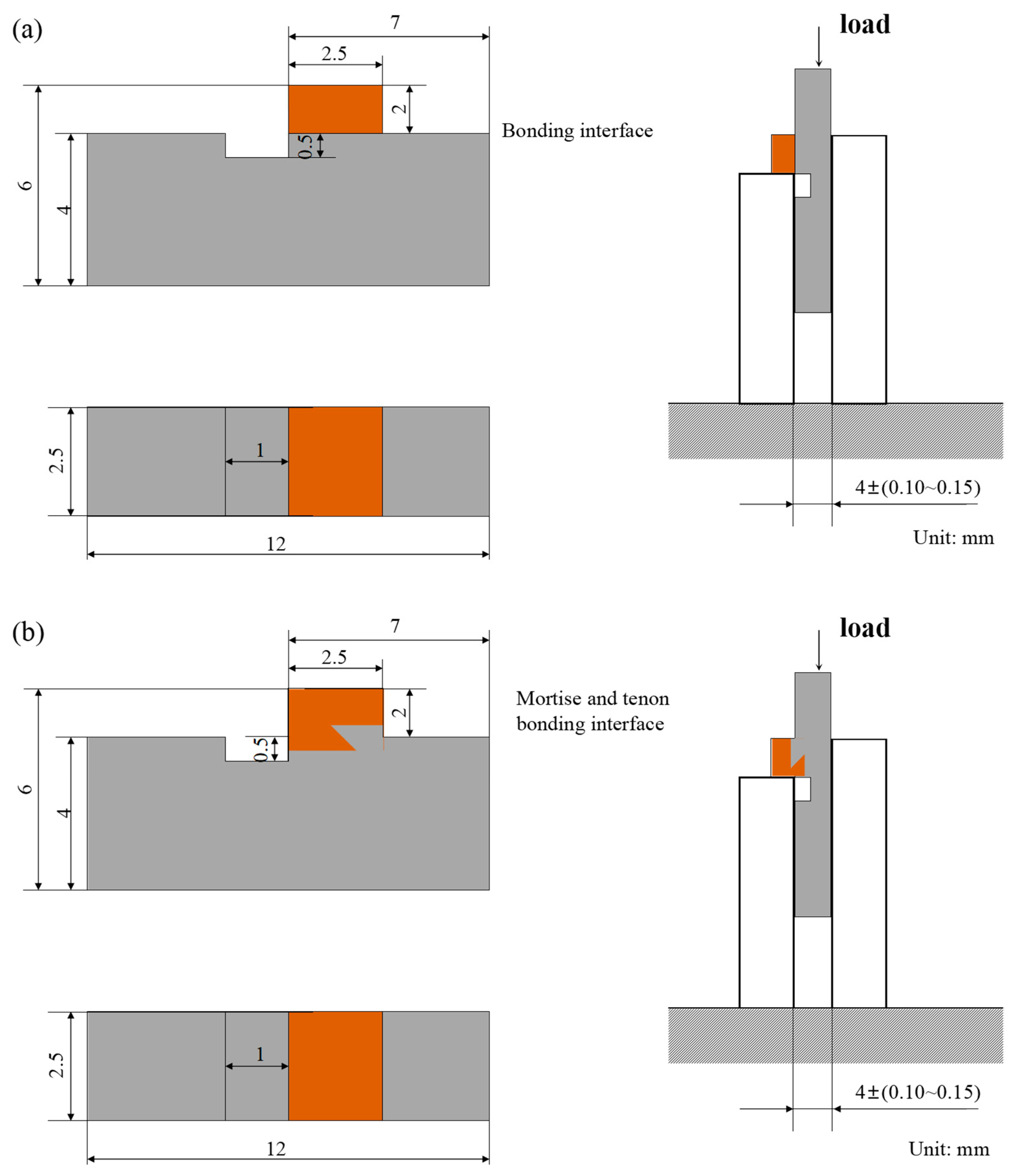

2.2. Microstructural Characterizations and Mechanical Property Testing

3. Results

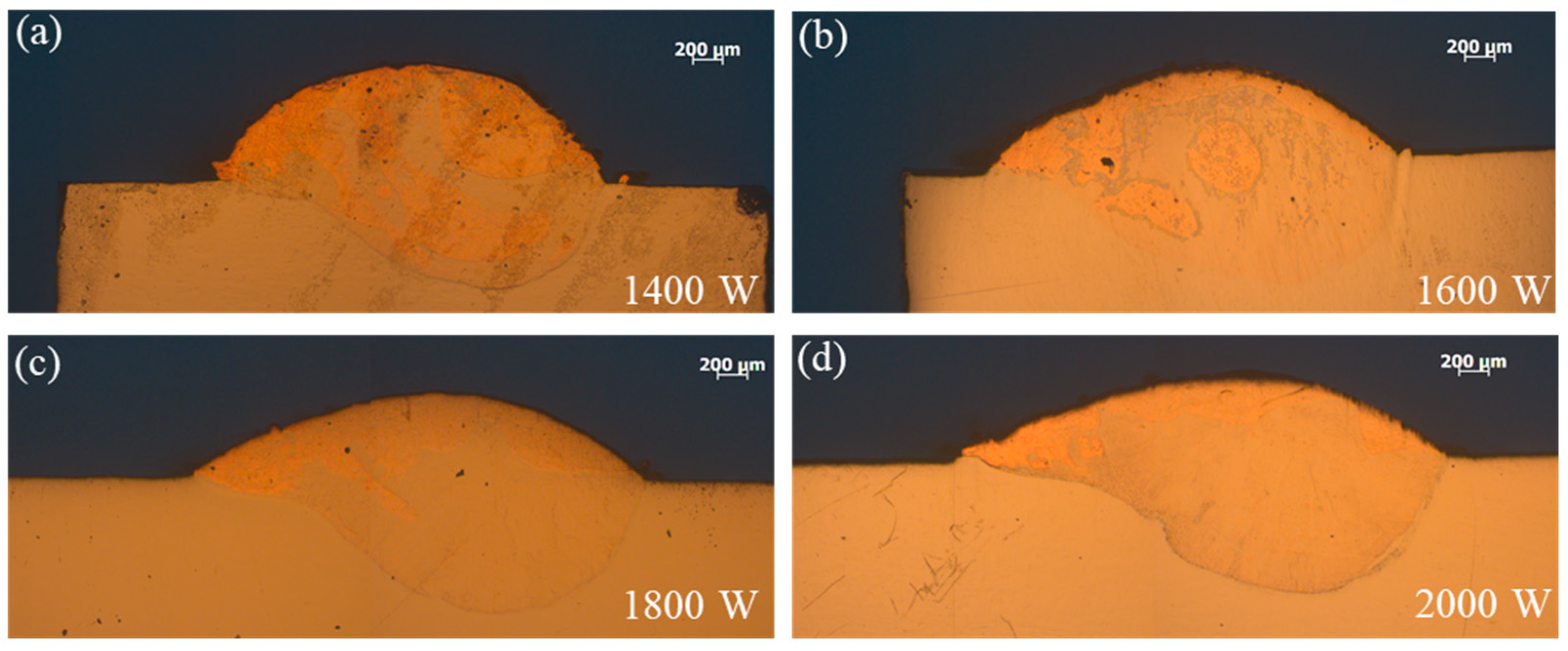

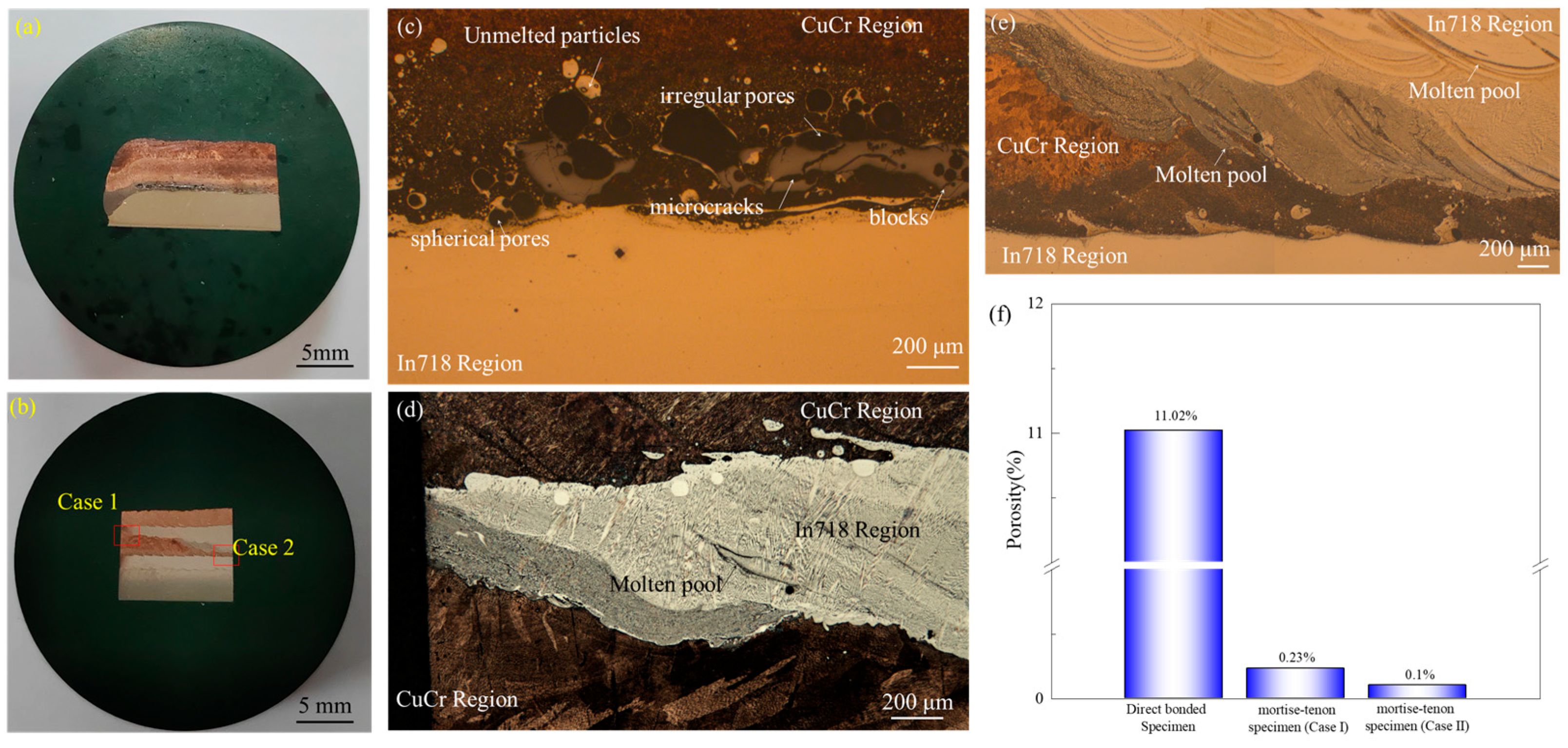

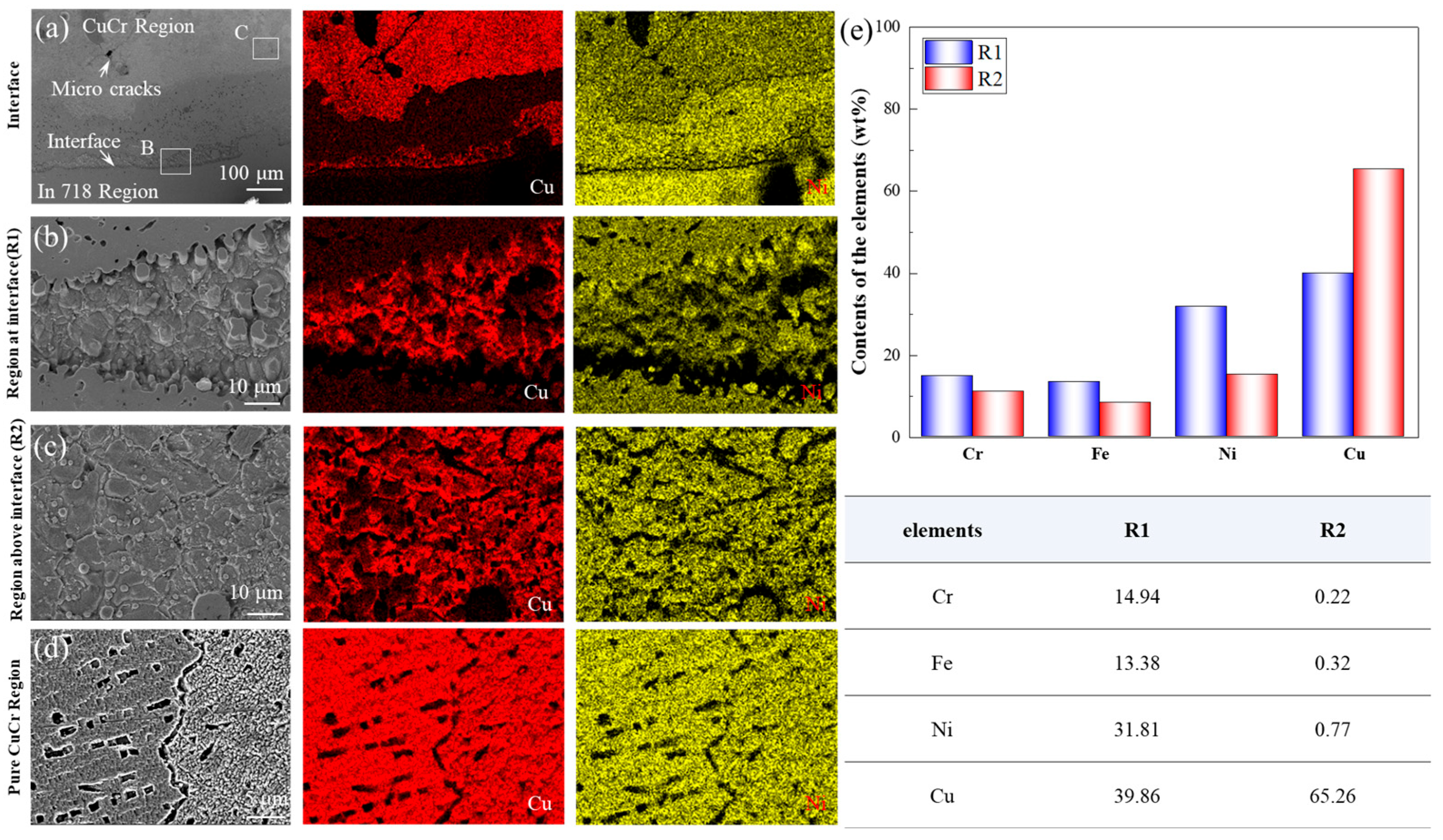

3.1. Interfacial Defects Analysis

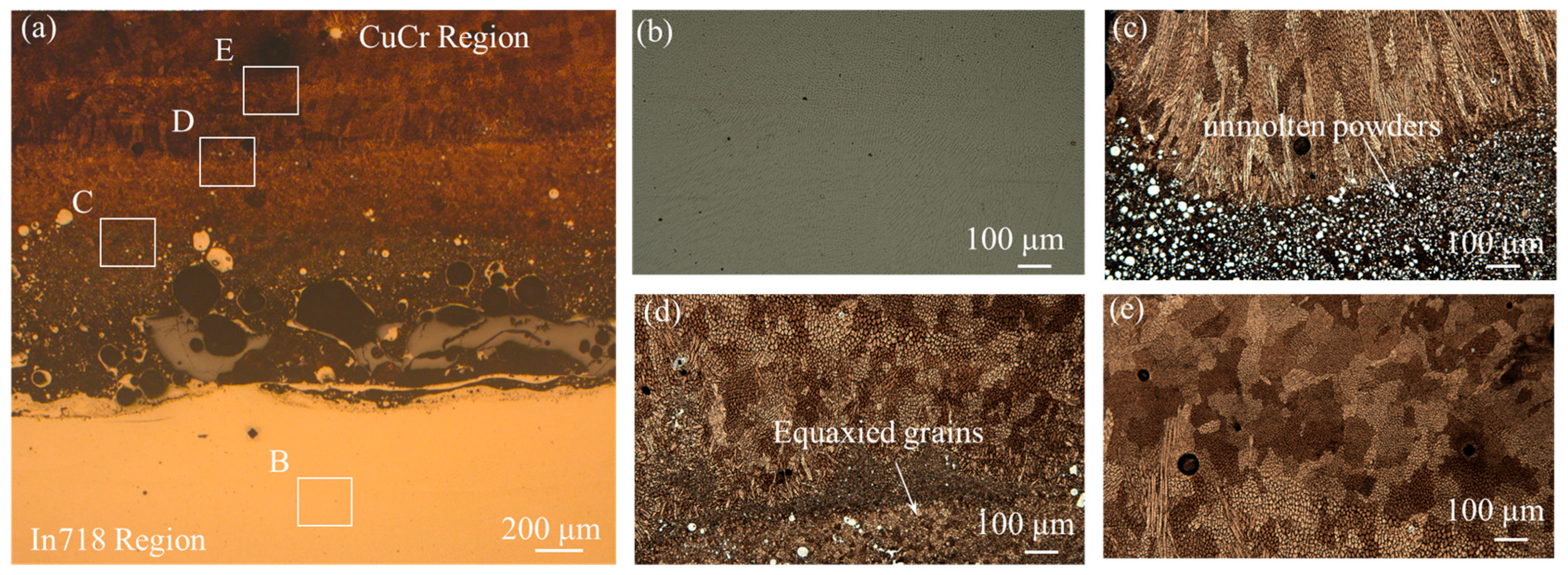

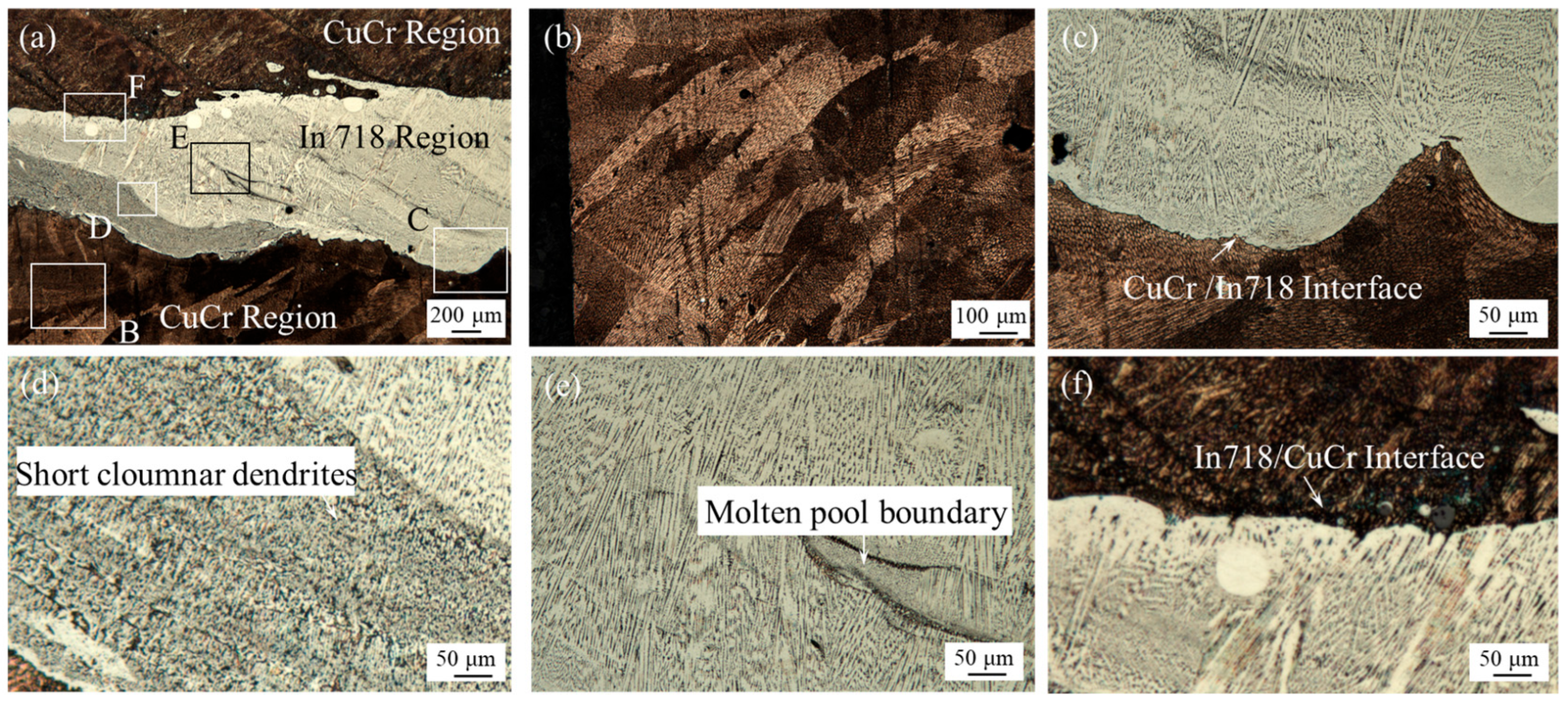

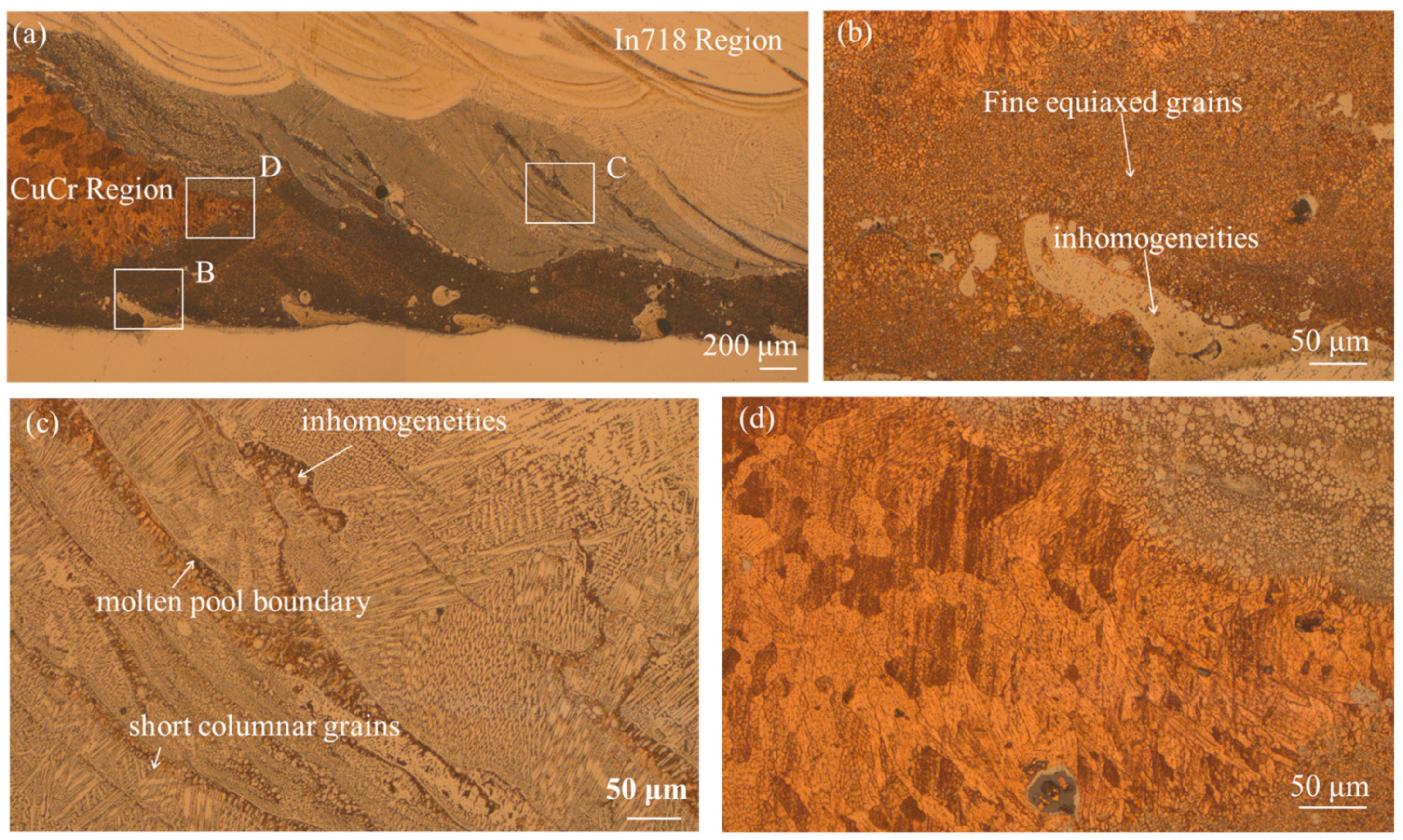

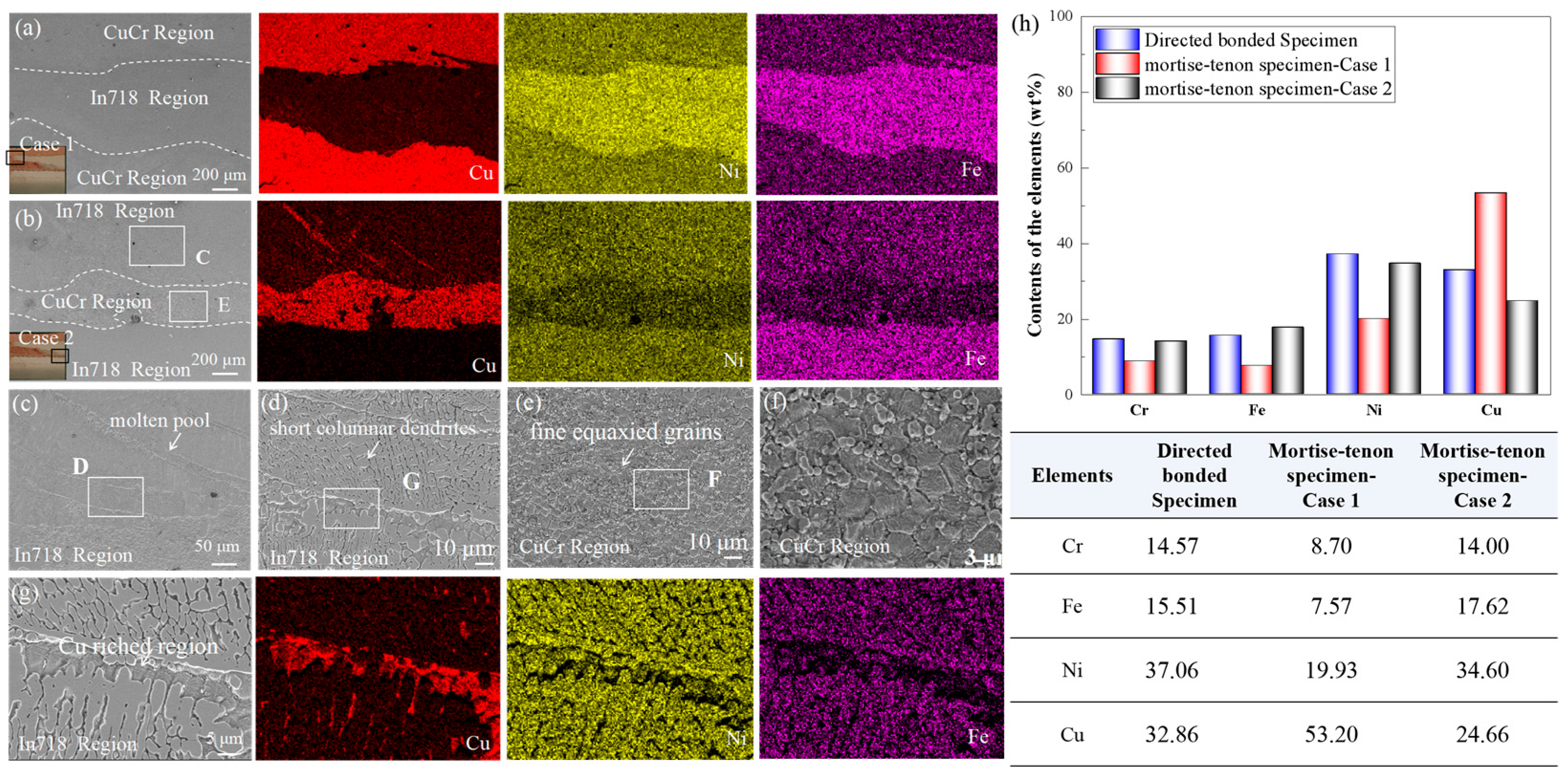

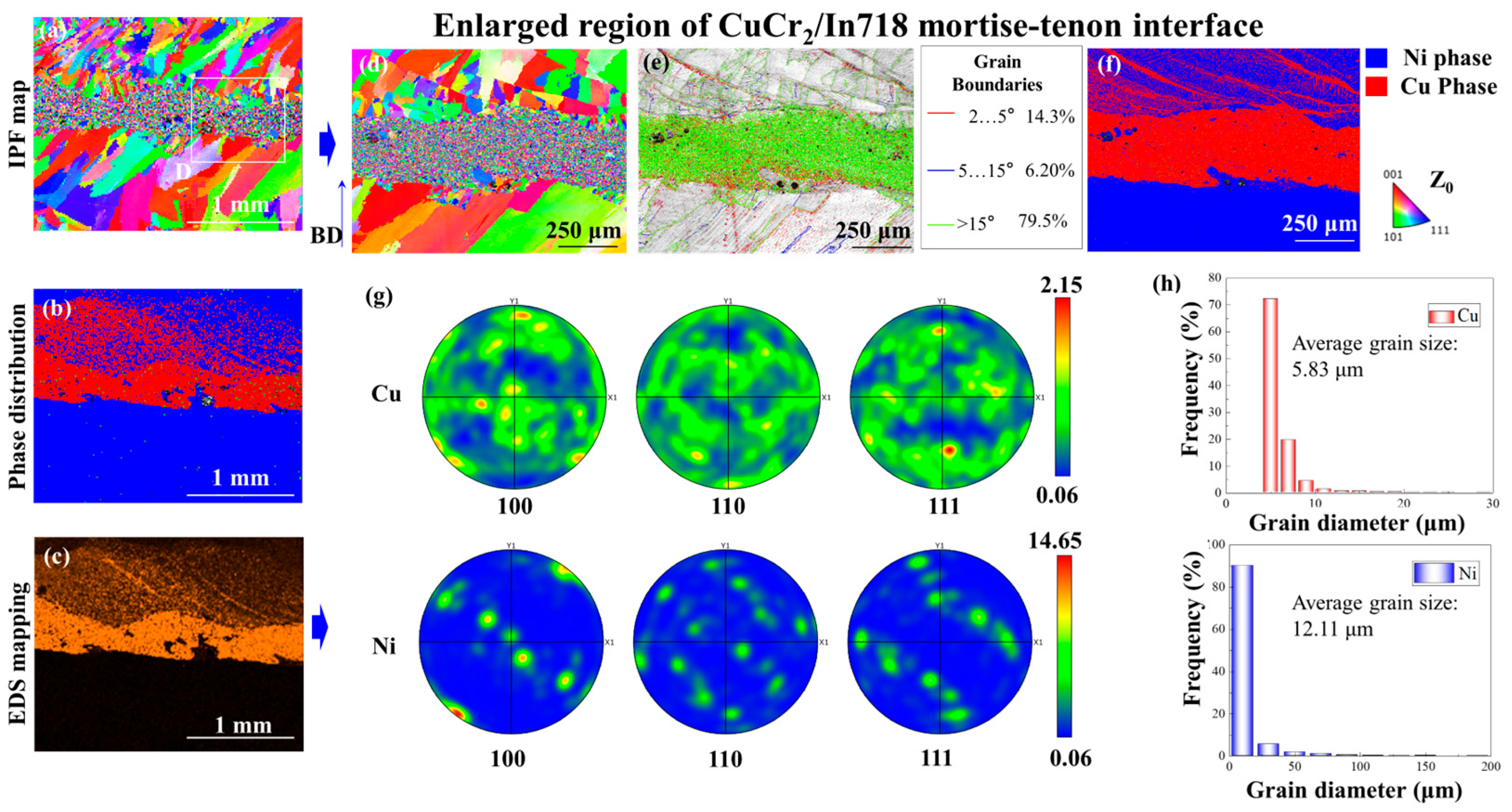

3.2. Interfacial Microstructure

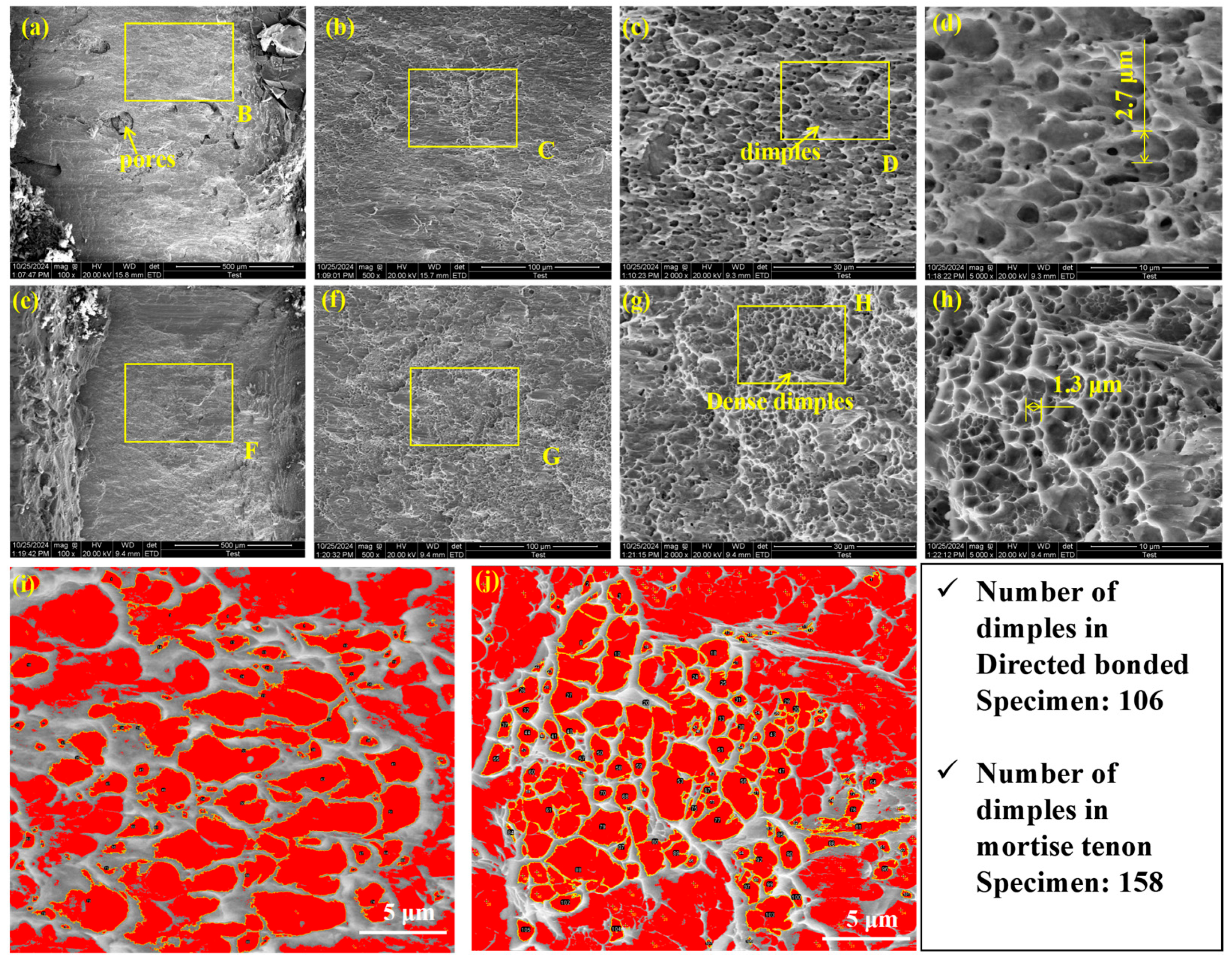

3.3. Shear Property

4. Discussion

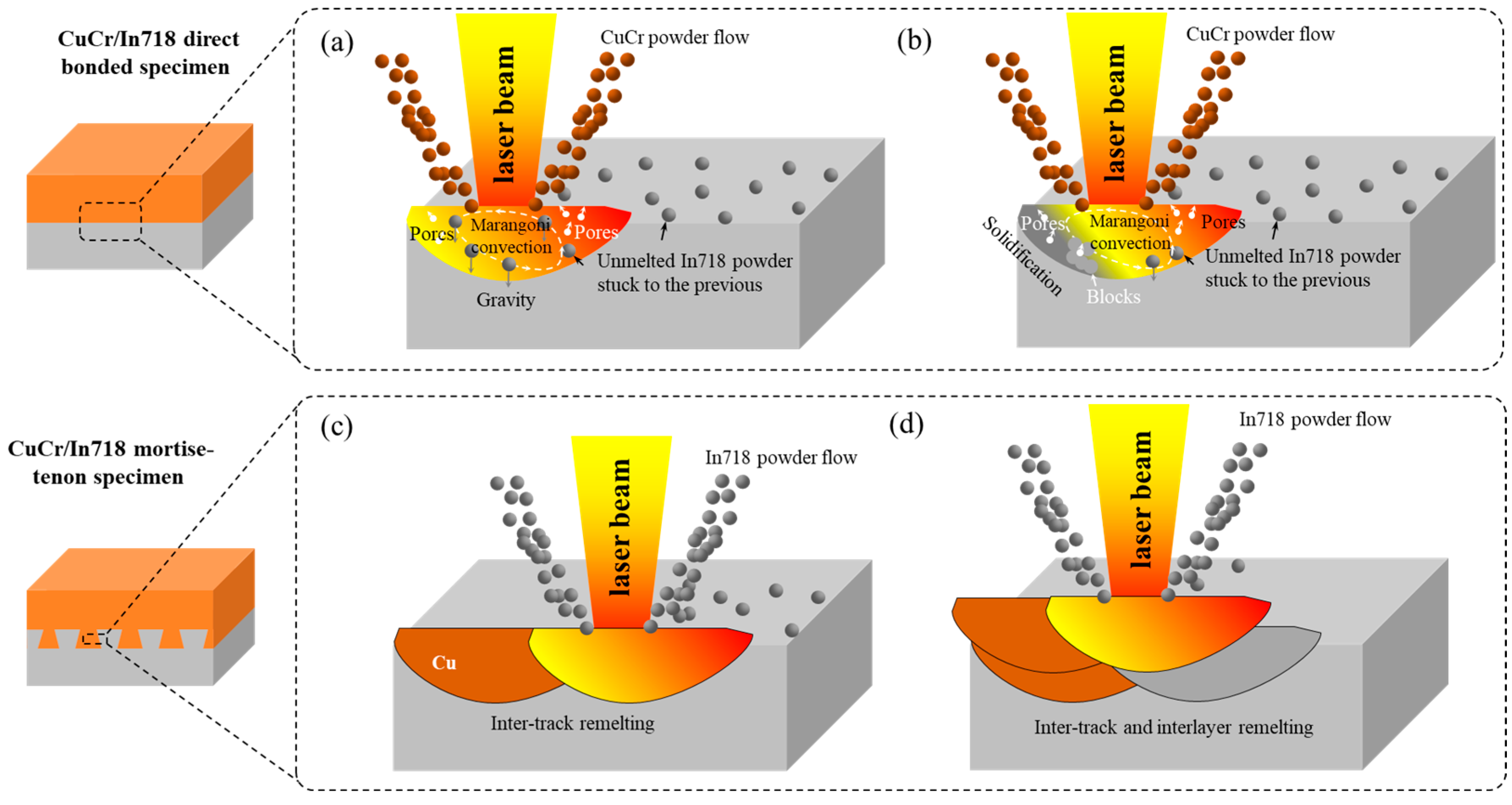

4.1. Interfacial Formation Mechanism

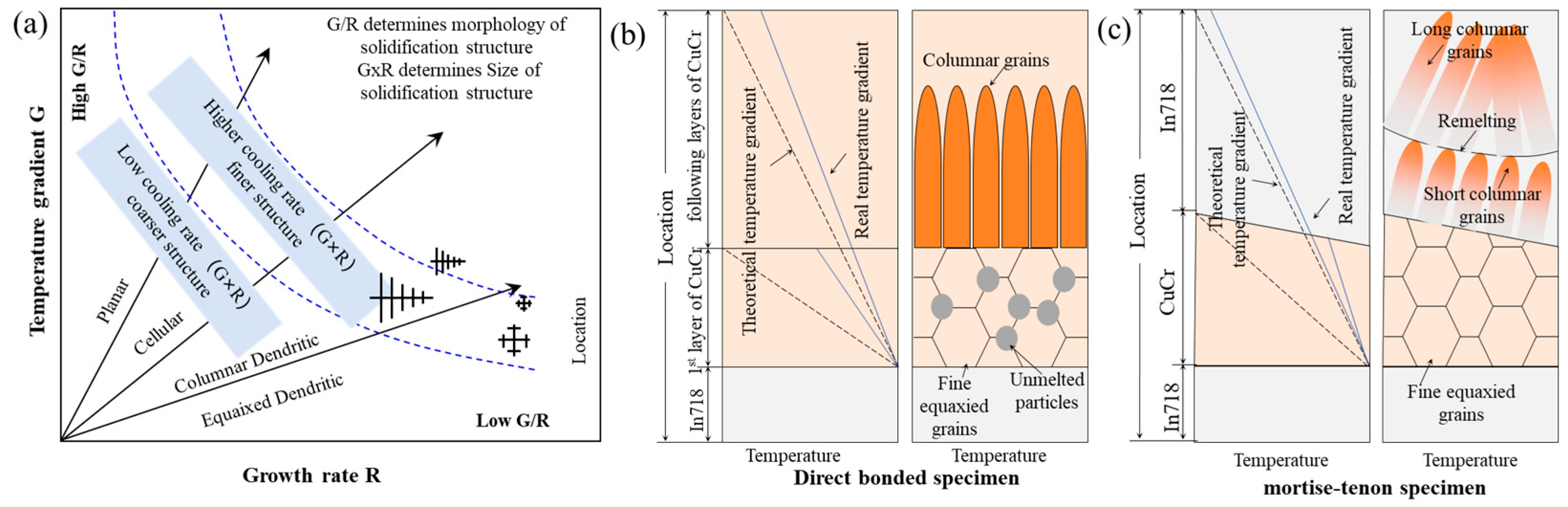

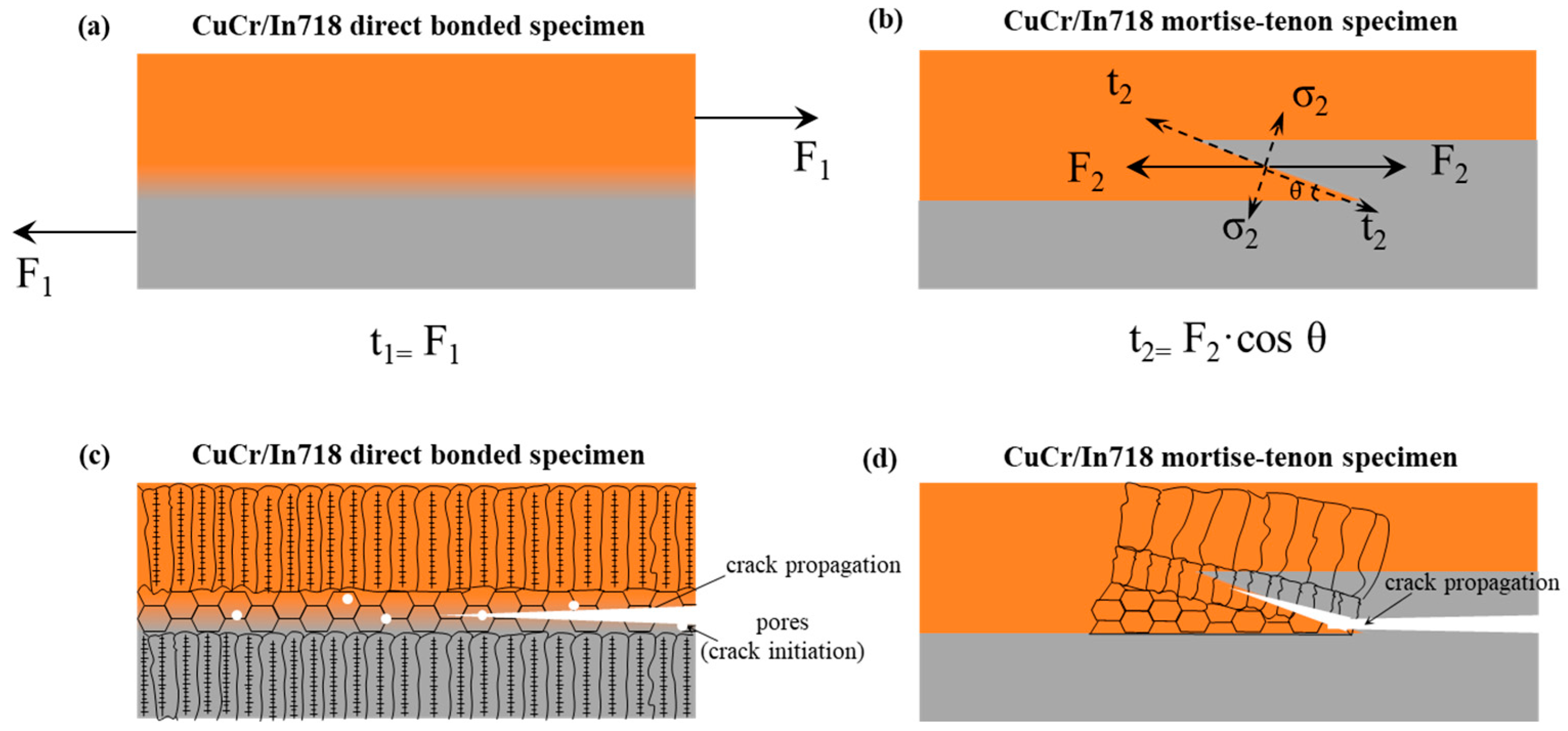

4.2. Interfacial Bonding Mechanism

5. Conclusions

- (1)

- For the direct-bonded specimen, unmelted spherical Ni-rich particles, spherical and irregular shape pores, microcracks, and blocks were formed at the interface because the remelting of CuCr on In718 was not enough. In contrast, no naked defects could be observed at the interface of the mortise-tenon specimen due to the alternating inter-track and inter-layer remelting during the deposition of the mortise-tenon structure.

- (2)

- More obvious Cu elemental diffusion can be observed in the molten pool boundaries of the mortise-tenon interface. The sandwich-shaped fine equiaxed-columnar grains were formed in the direct-bonded specimen because of the high thermal conductivity of CuCr and continuous heat accumulation in powder DED-LB. The heterogeneous microstructure consisting of large columnar grains, short columnar grains, and fine equiaxed grains is formed in the mortise-tenon specimen due to the high thermal conductivity of the CuCr, remelting of In718, and Cu elemental diffusion.

- (3)

- The metallurgical bonding strength of the mortise-tenon specimen was better than that of the direct-bonded specimen because its remelting-induced elemental diffusion was significantly increased. The mortise-tenon macroscopic morphology makes the shear load smaller and crack propagation difficult. Furthermore, the smaller grain size of the heterogeneous microstructure in the mortise-tenon specimen leads to greater strength. Hence, the shear strength was increased by 45.34% by depositing a mortise-tenon structure at the interface.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Powder DED-LB | Laser-Based Direct Energy Deposition (DED-LB) using Pow-der Feedstock |

| DMs | Dissimilar materials |

| USS | ultimate shear strength |

| FE-SEM | Field emission scanning electron microscope |

| EDS | Energy dispersive spectroscopy |

| EBSD | Electron backscatter diffraction |

References

- Yao, X.J.; Zhu, Y.Y.; Han, X.; Yang, J.W.; Chen, L.; Wang, X.Y.; Wang, H.M. Preparation of copper/nickel dissimilar metals by laser additive manufacturing based on copper alloy surface pretreatment. Chin. J. Lasers 2025, 52, 0402301. [Google Scholar]

- Paul, G.L.; Omar, R.M.; Colton, K.; Timothy, M.S.; Jeff, S.; Alison, P.; Chen, P.S.; Darren, C.T.; Christopher, P.; Tom, T.; et al. Advancement of extreme environment additively manufactured alloys for next generation space propulsion applications. Acta Astronaut. 2023, 211, 483–497. [Google Scholar]

- Tran, T.Q.; Chinnappan, A.; Lee, J.K.Y.; Loc, N.H.; Tran, L.T.; Wang, G.; Kumar, V.V.; Jayathilaka, W.A.D.M.; Ji, D.; Doddamani, M.; et al. 3D printing of highly pure copper. Metals 2019, 9, 756. [Google Scholar] [CrossRef]

- Sun, Z.; Karppi, R. The application of electron beam welding for the joining of dissimilar metals: An overview. J. Mech. Work. Technol. 1996, 59, 257–267. [Google Scholar] [CrossRef]

- Chen, H.-C.; Pinkerton, A.J.; Li, L. Fibre laser welding of dissimilar alloys of Ti-6Al-4V and Inconel 718 for aerospace applications. Int. J. Adv. Manuf. Technol. 2011, 52, 977–987. [Google Scholar] [CrossRef]

- Xue, P.; Ni, D.; Wang, D.; Xiao, B.; Ma, Z. Effect of friction stir welding parameters on the microstructure and mechanical properties of the dissimilar Al–Cu joints. Mater. Sci. Eng. A 2011, 528, 4683–4689. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, G.; Jin, H.; Shi, Z.; Qiao, G. Intermetallic phase formation in diffusion-bonded Cu/Al laminates. J. Mater. Sci. 2011, 46, 2467–2473. [Google Scholar] [CrossRef]

- Huang, X.; Dong, X.; Ma, J.; Liu, K.; Ahmed, S.; Lin, J.; Ahmad, F.; Qiu, B. Evaluation and Experiment of Flight Parameter Quality of the Plant Protection UAV Based on Laser Tracker. Agriculture 2021, 11, 628. [Google Scholar] [CrossRef]

- Shen, Y.; Zhu, H.; Liu, H.; Chen, Y.; Ozkan, E. Development of a Laser-Guided, Embedded-Computer-Controlled, Air-Assisted Precision Sprayer. Trans. ASABE 2017, 60, 1827–1838. [Google Scholar] [CrossRef]

- Liu, H.; Zhu, H.P. Evaluation of a Laser Scanning Sensor in Detection of Complex-Shaped Targets for Variable-Rate Sprayer Development. Trans. ASABE 2016, 59, 1181–1192. [Google Scholar]

- Bandyopadhyay, A.; Heer, B. Additive manufacturing of multi-material structures. Mater. Sci. Eng. R Rep. 2018, 129, 1–16. [Google Scholar] [CrossRef]

- Gu, D.; Shi, X.; Poprawe, R.; Bourell, D.L.; Setchi, R.; Zhu, J. Material-structure-performance integrated laser-metal additive manufacturing. Science 2021, 372, 932. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Xu, W.; Leng, J.; Liu, X.; Xu, H.; Ding, H.; Zhou, J.; Cui, L.F. Review and Research Prospects on Additive Manufacturing Technology for Agricultural Manufacturing. Agriculture 2024, 14, 1207. [Google Scholar] [CrossRef]

- Gradl, P.R.; Teasley, T.W.; Protz, C.S.; Garcia, M.B.; Ellis, D.; Kantzos, C. Advancing GRCop-based Bimetallic Additive Manufacturing to Optimize Component Design and Applications for Liquid Rocket Engines. In Proceedings of the AIAA Propulsion and Energy 2021 Forum, Virtual Event, 9–11 August 2021; p. 3231. [Google Scholar]

- Chang, T.; Fang, X.; Zhou, Y.; Zhang, H.; Xi, N.; Ghafoor, S.; Huang, K. Heterogeneous interfaces of aluminum bronze/Inconel 718 dissimilar alloys under different wire arc directed energy deposition sequences. Int. J. Extreme Manuf. 2025, 7, 015003. [Google Scholar] [CrossRef]

- Sutton, G.P.; Biblarz, O. Fundamentals of Rocket Propulsion; Beijing Institute of Technology Press: Beijing, China, 2019. [Google Scholar]

- Onuike, B.; Bandyopadhyay, A. Bond strength measurement for additively manufactured Inconel 718-GRCop84 copper alloy bimetallic joints. Addi Manuf. 2019, 27, 576–585. [Google Scholar] [CrossRef]

- Ryan, A.; Jordan, T.; Judy, S.; Sean, T.; Gual, P. Characteristics of bi-metallic interfaces formed during direct energy deposition additive manufacturing processing. Metall. Mater. Trans. B 2022, 50, 1925. [Google Scholar]

- Zhang, B.; Xiao, H.; Zhang, W.; Yang, H.; Wang, Y.; Peng, D.; Zhu, H.; Chen, B. Influence of the thermal conductivity of different CuCr0.8 substrate state on the formability of laser directed energy deposition Inconel718 single track. Mater. Charact. 2023, 202, 113015. [Google Scholar] [CrossRef]

- Foteinopoulos, P.; Papacharalampopoulos, A.; Stavropoulos, P. Additive manufacturing simulations: An approach based on space partitioning and dynamic 3D mesh adaptation. Addit. Manuf. Lett. 2024, 11, 100256. [Google Scholar] [CrossRef]

- Wei, C.; Liu, L.; Cao, H.; Zhong, X.; Xu, X.; Gu, Y.; Cheng, D.; Huang, Y.; Li, Z.; Guo, W.; et al. Cu10Sn to Ti6Al4V bonding mechanisms in laser-based powder bed fusion multiple material additive manufacturing with different build strategies. Addit. Manuf. 2022, 51, 102588. [Google Scholar] [CrossRef]

- He, Y.; Zhang, X.; Zhao, Z.; Xu, S.; Xia, M.; Zhang, C.; Hu, Y. Wire-feed laser additive manufacturing of dissimilar metals via dual molten pool interface interlocking mechanism. Sci. China Technol. Sci. 2023, 66, 976–986. [Google Scholar] [CrossRef]

- Chueh, Y.-H.; Wei, C.; Zhang, X.; Li, L. Integrated laser-based powder bed fusion and fused filament fabrication for three-dimensional printing of hybrid metal/polymer objects. Addit. Manuf. 2020, 31, 100928. [Google Scholar] [CrossRef]

- Judd, J.P.; Fonseca, F.S.; Walker, C.R.; Thorley, P.R. Tensile Strength of Varied-Angle Mortise and Tenon Connections in Timber Frames. J. Struct. Eng. 2012, 138, 636–644. [Google Scholar] [CrossRef]

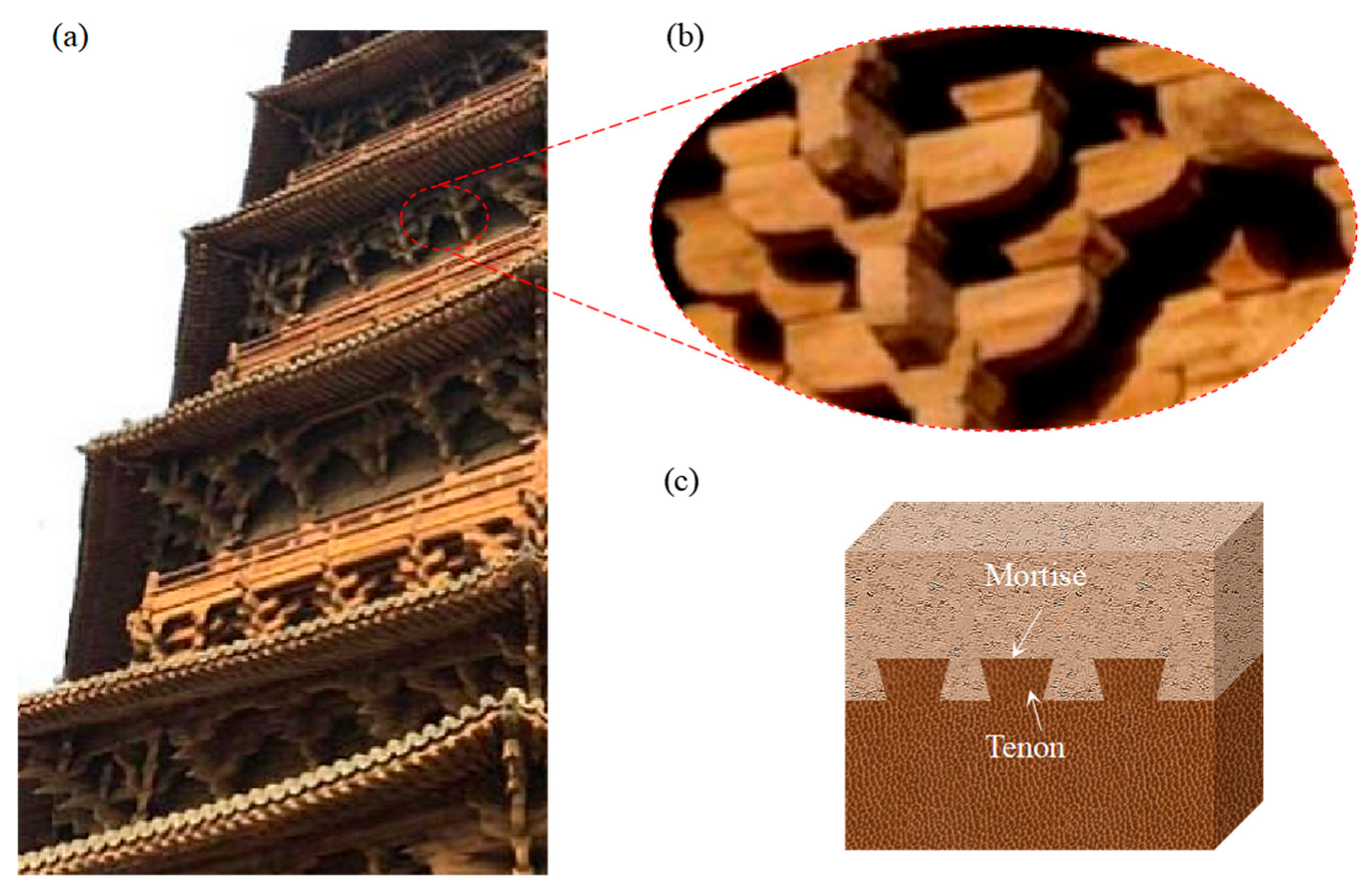

- Hu, J.; Qiu, Y.; Wang, X.; Jiang, L.; Lu, X.; Li, M.; Wang, Z.; Pang, K.; Tian, Y.; Zhang, W.; et al. Flexible six-dimensional force sensor inspired by the tenon-and-mortise structure of ancient Chinese architecture for orthodontics. Nano Energy 2022, 96, 107073. [Google Scholar] [CrossRef]

- Zhu, Y.; Gao, D.; Shao, Y.; Chen, H.; Yu, C.; Wang, Q. A novel prefabricated auxetic honeycomb meta-structure based on mortise and tenon principle. Compos. Struct. 2024, 329, 117782. [Google Scholar] [CrossRef]

- Zhou, S.; Liu, H.; Li, B.; Yang, X.; Yang, J. A detachable chain tensile energy absorber inspired by mortise and tenon joint. Int. J. Mech. Sci. 2022, 223, 107290. [Google Scholar] [CrossRef]

- Yan, H.; Xie, S.; Zhang, F.; Jing, K.; He, L. Sound absorption performance of honeycomb metamaterials inspired by mortise-and-tenon structures. Appl. Acoust. 2025, 228, 110292. [Google Scholar] [CrossRef]

- Mills, K. Recommended Values of Thermophysical Properties for Selected Commercial Alloys; Woodhead Publishing: Cambridge, UK, 2001. [Google Scholar]

- Xu, G.; Wu, R.; Luo, K.; Lu, J. Effects of heat treatment on hot corrosion behavior of directed energy deposited In718/316L functionally graded material. Corros. Sci. 2022, 197, 110068. [Google Scholar] [CrossRef]

- Kuai, Z.; Li, Z.; Liu, B.; Chen, Y.; Lu, S.; Tang, X.; Liu, T. Selective laser melting of CuCrZr alloy: Processing optimisation, microstructure and mechanical properties. J. Mater. Res. Technol. 2022, 19, 4915–4931. [Google Scholar] [CrossRef]

- Liu, X.; Tan, C.; Zhang, J.; Hu, Y.; Ma, H.; Wang, F.; Cai, H. Influence of microstructure and strain rate on adiabatic shearing behavior in Ti–6Al–4V alloys. Mater. Sci. Eng. A 2009, 501, 30–36. [Google Scholar] [CrossRef]

- Sun, Y.; Li, X.; Yu, X.; Ge, D.; Chen, J.; Chen, J. Fracture Morphologies of Advanced High Strength Steel During Deformation. Acta Met. Sin. English Lett. 2014, 27, 101–106. [Google Scholar] [CrossRef]

- Sui, S.; Tan, H.; Chen, J.; Zhong, C.; Li, Z.; Fan, W.; Gasser, A.; Huang, W. The influence of Laves phases on the room temperature tensile properties of Inconel 718 fabricated by powder feeding laser additive manufacturing. Acta Mater. 2019, 164, 413–427. [Google Scholar] [CrossRef]

- Wei, H.; Knapp, G.; Mukherjee, T.; DebRoy, T. Three-dimensional grain growth during multi-layer printing of a nickel-based alloy Inconel 718. Addit. Manuf. 2019, 25, 448–459. [Google Scholar] [CrossRef]

- Wang, H.Y.; Lu, W.; Liu, J.H. Effects of high pressure heat treatment on the thermal physical properties of aluminum bronze. Chin. J. High Press. Phys. 2010, 24, 300–304. [Google Scholar]

- Zhang, Q.W.; Wang, X.T.; Qin, Y.; He, G.N.; Zhang, S.Y.; Huang, K.L.; Wang, J. Improving thermal conductivity of a nickel-based alloy through advanced electromagnetic coupling treatment. J. Mater. Res. Technol. 2022, 21, 4708–4723. [Google Scholar] [CrossRef]

- Liu, L.; Wang, D.; Wang, T.; Han, C.; Li, Y.; Tan, H.; Zhou, W.; Yan, X.; Lei, L.; Yang, Y. Laser additive manufacturing of multimaterials with hierarchical interlocking interface via a flexible scraper-based method. Int. J. Mach. Tools Manuf. 2025, 205, 104236. [Google Scholar] [CrossRef]

- Tey, C.F.; Tan, X.; Sing, S.L.; Yeong, W.Y. Additive manufacturing of multiple materials by selective laser melting: Ti-alloy to stainless steel via a Cu-alloy interlayer. Addit. Manuf. 2020, 31, 100970. [Google Scholar] [CrossRef]

- Wei, W.; Yongqiang, Y.; Guishengi, M.; Di, W.; Changhui, S. Free manufacturing of heterogeneous materials part by selective laser melting. Opt. Precis. Eng. 2019, 27, 517–526. [Google Scholar] [CrossRef]

- Xu, G.; Wu, L.; Su, Y.; Wang, Z.; Luo, K.; Lu, J. Microstructure and mechanical properties of directed energy deposited 316L/Ti6Al4V functionally graded materials via constant/gradient power. Mater. Sci. Eng. A 2022, 839, 142870. [Google Scholar] [CrossRef]

| Problems in Additive Manufacturing of Nickel/Copper Dissimilar Alloys | |||||

|---|---|---|---|---|---|

| Author | Method | Materials | Problems | Conclusion | |

| Onuike et al. [17]. | Powder DED-LB | GRCop-84 and In718 | Shear strength of the bimetallic is smaller than the matrix | Defects and poor strength of interface are common issues in copper and Inconel dissimilar alloys | |

| Ryan et al. [18]. | DED-LB and wire-fed processes | Inconel and C18150 | pores and unmelted particles | ||

| Methods to improve the property of dissimilar alloys | |||||

| Process parameters optimization | |||||

| Author | Method | Results | Limitation and Research gap | ||

| Zhang et al. [19] | Change the state of Copper substrate in DED-LB | Thermal conductivity has a significant effect on the formability and microstructure |

| ||

| Chang et al. [15] | Change the Deposition sequences in Wire arc DED of aluminum bronze/Inconel 718 dissimilar alloys | Cu-Ni demonstrates better interfacial property | |||

| Foteinopoulos et al. [20] | Simulation | simulation is one of the most widely used methods for process optimization | |||

| Interfacial structure construction | |||||

| Author | Method | Results | Limitation and Research gap | ||

| Wei et al. [21] | Using laser remelting at the interface of SLMed Ti6Al4V/Cu10Sn dissimilar alloys to build the keyhole structures | Keyhole structure can promote the elemental diffusion |

| ||

| Hu et al. [22] | Using dual lasers in wire-feed additive manufacturing of 7075-aluminum alloy/304-stainless steel dissimilar alloys to build the dimple structures | Dimple structures can effectively reduce the intermetallic compound layer | |||

| Chueh et al. [23] | Integrated fused filament fabrication (FFF) and laser-based powder bed fusion (PBF) to produce hybrid metal and polymer components with macroscopic interlocking structures | The printed metal/polymer joints exhibited reliable strength by introducing macroscopic interlocking structures |

| ||

| Element | C | S | Cu | Cr | P | Fe | Sn |

|---|---|---|---|---|---|---|---|

| Content | 0.0125 | 0.0034 | Bal. | 1.36 | 0.0047 | 0.0066 | 0.0041 |

| Element | C | Cu | Mn | Si | Mo | Nb | Fe | Cr | Ni |

|---|---|---|---|---|---|---|---|---|---|

| Content | 0.04 | 0.12 | 0.27 | 1.04 | 3.31 | 5.49 | 14.19 | 20.67 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, G.; Zhang, H. Bonding Strength and Its Enhancing Mechanism of CuCr/In718 Dissimilar Materials with Mortise and Tenon Structure Interface Manufactured by Laser-Based Direct Energy Deposition (DED-LB) Using Powder Feedstock. Metals 2025, 15, 557. https://doi.org/10.3390/met15050557

Xu G, Zhang H. Bonding Strength and Its Enhancing Mechanism of CuCr/In718 Dissimilar Materials with Mortise and Tenon Structure Interface Manufactured by Laser-Based Direct Energy Deposition (DED-LB) Using Powder Feedstock. Metals. 2025; 15(5):557. https://doi.org/10.3390/met15050557

Chicago/Turabian StyleXu, Gang, and Hongmei Zhang. 2025. "Bonding Strength and Its Enhancing Mechanism of CuCr/In718 Dissimilar Materials with Mortise and Tenon Structure Interface Manufactured by Laser-Based Direct Energy Deposition (DED-LB) Using Powder Feedstock" Metals 15, no. 5: 557. https://doi.org/10.3390/met15050557

APA StyleXu, G., & Zhang, H. (2025). Bonding Strength and Its Enhancing Mechanism of CuCr/In718 Dissimilar Materials with Mortise and Tenon Structure Interface Manufactured by Laser-Based Direct Energy Deposition (DED-LB) Using Powder Feedstock. Metals, 15(5), 557. https://doi.org/10.3390/met15050557