Springback Control of Profile by Multi-Point Stretch-Bending and Torsion Automatic Forming Based on FE-BPNN

Abstract

1. Introduction

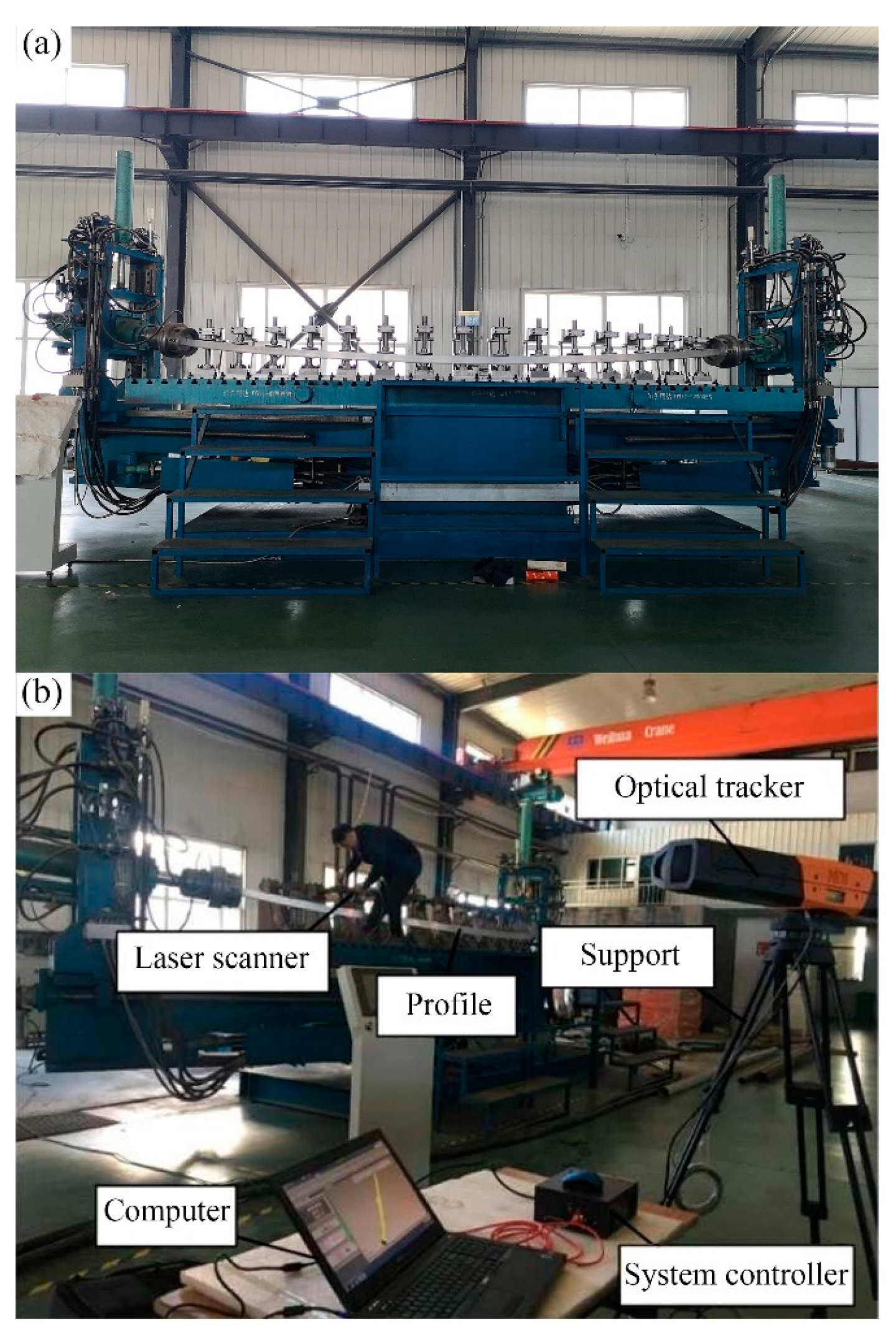

2. Automatic Control Process and Methods for Multi-Point Stretch-Bending-Torsion of Profiles

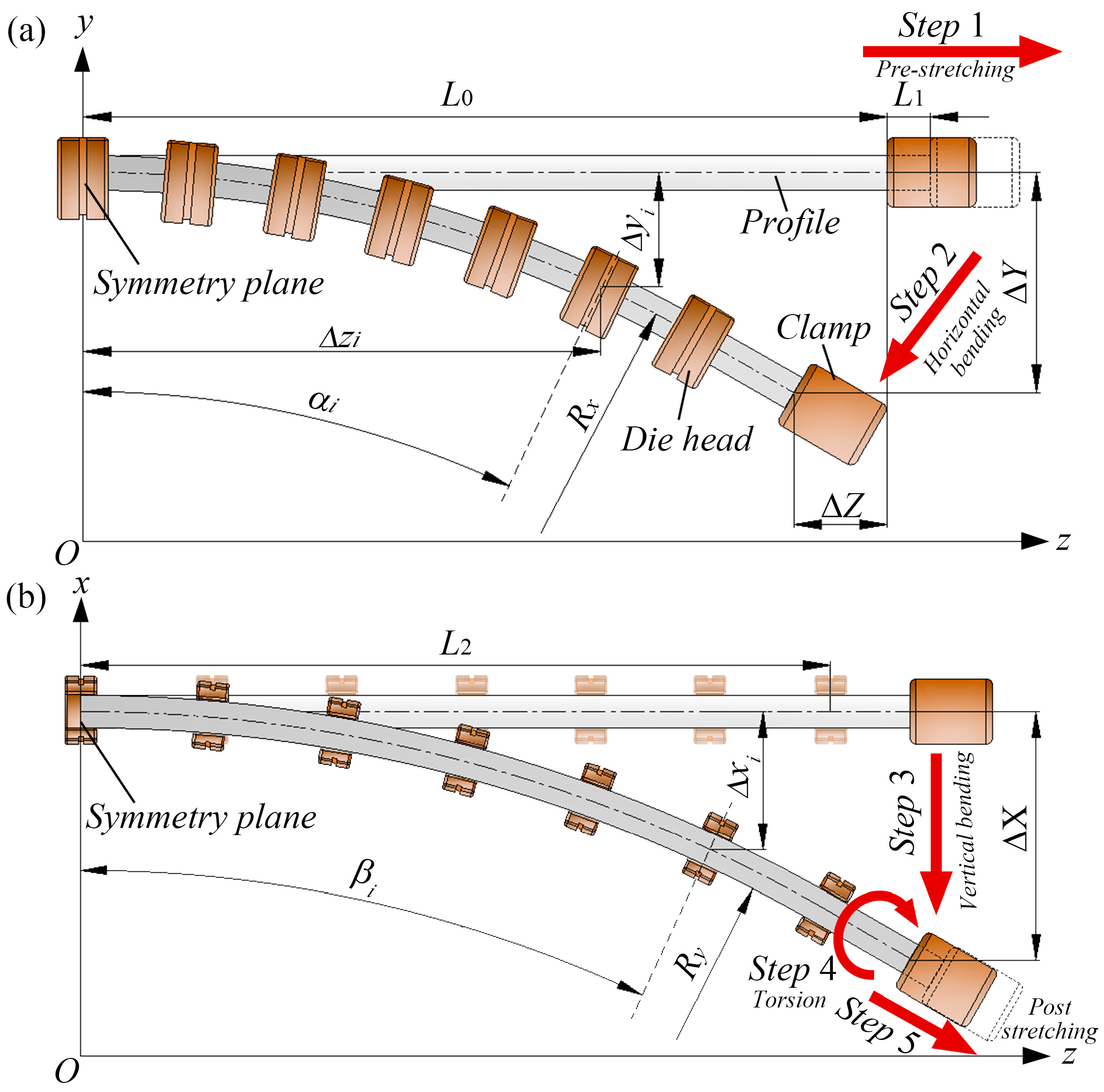

2.1. Multi-Point Stretch-Bending-Torsion Forming Process

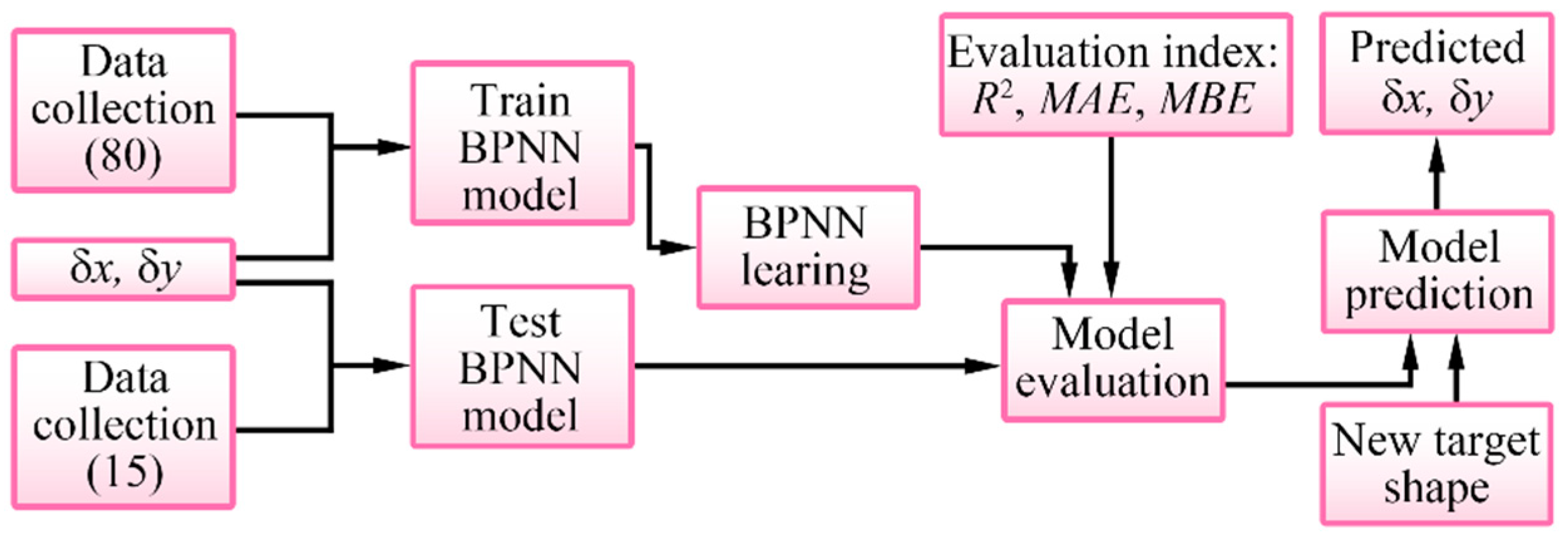

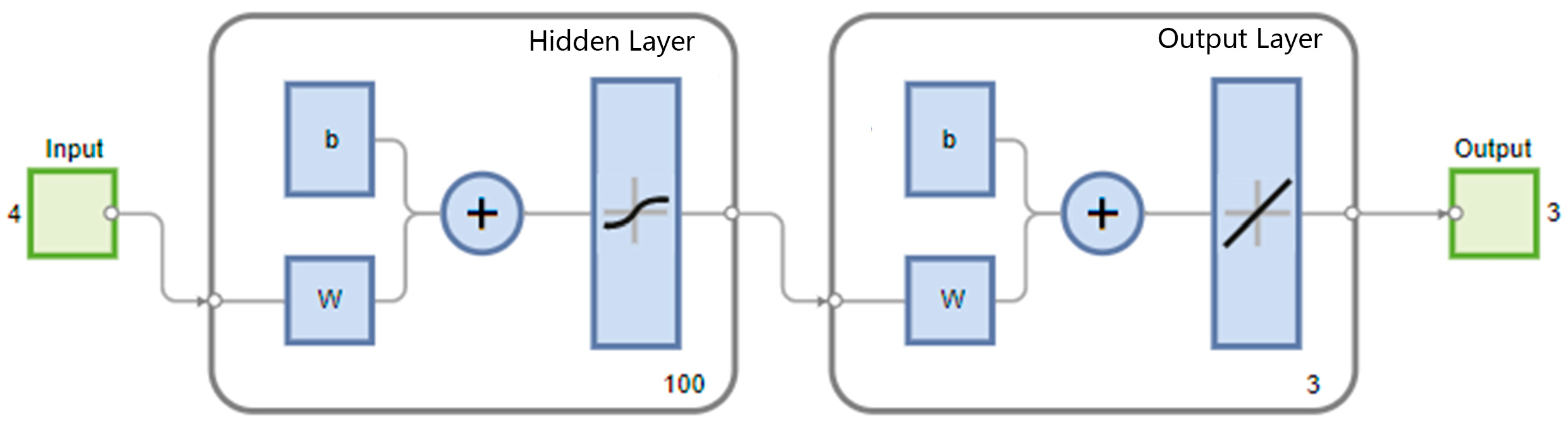

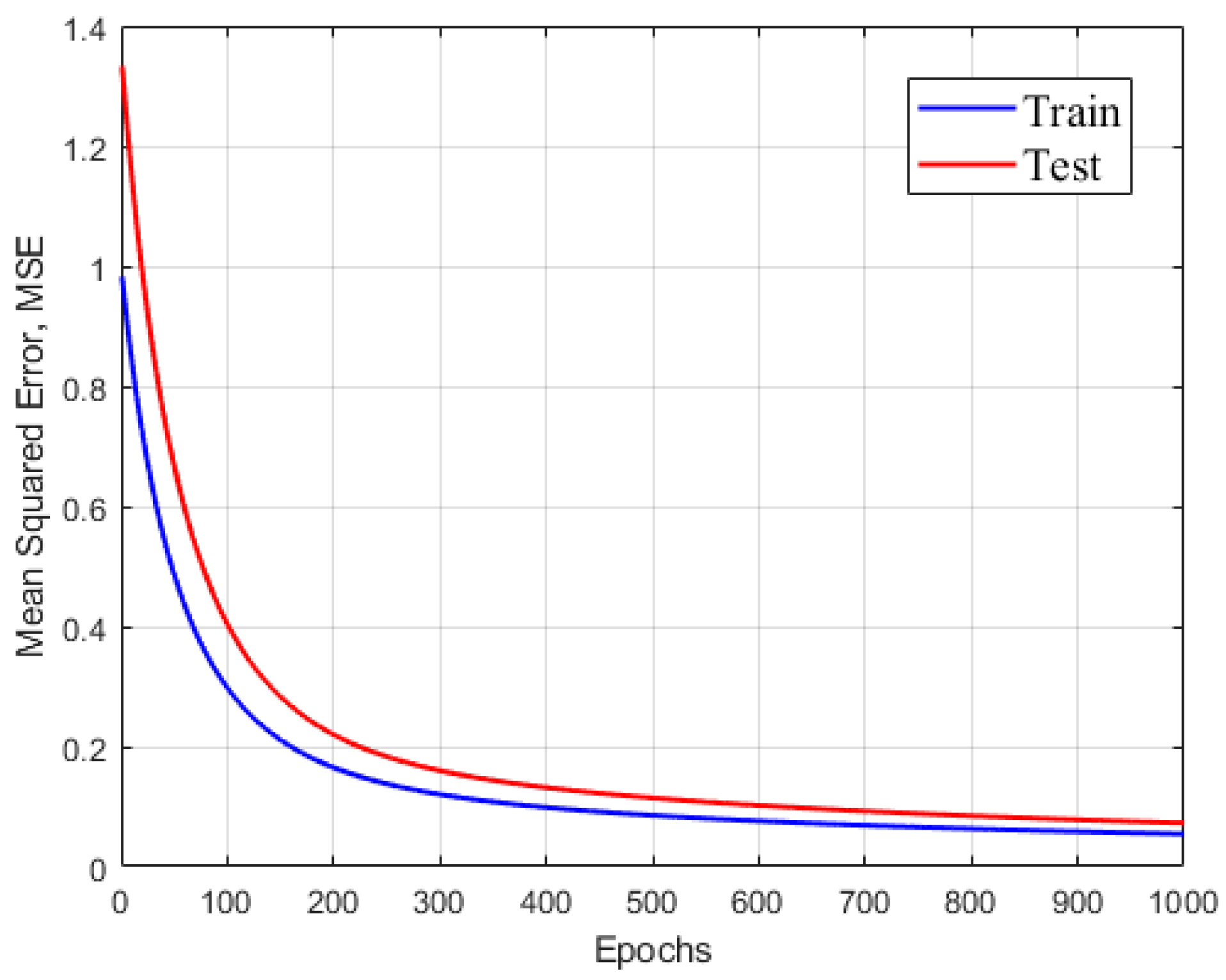

2.2. Establishing the BP Neural Network Model

2.3. Automatic Control Method

3. Numerical Simulation and Experiment

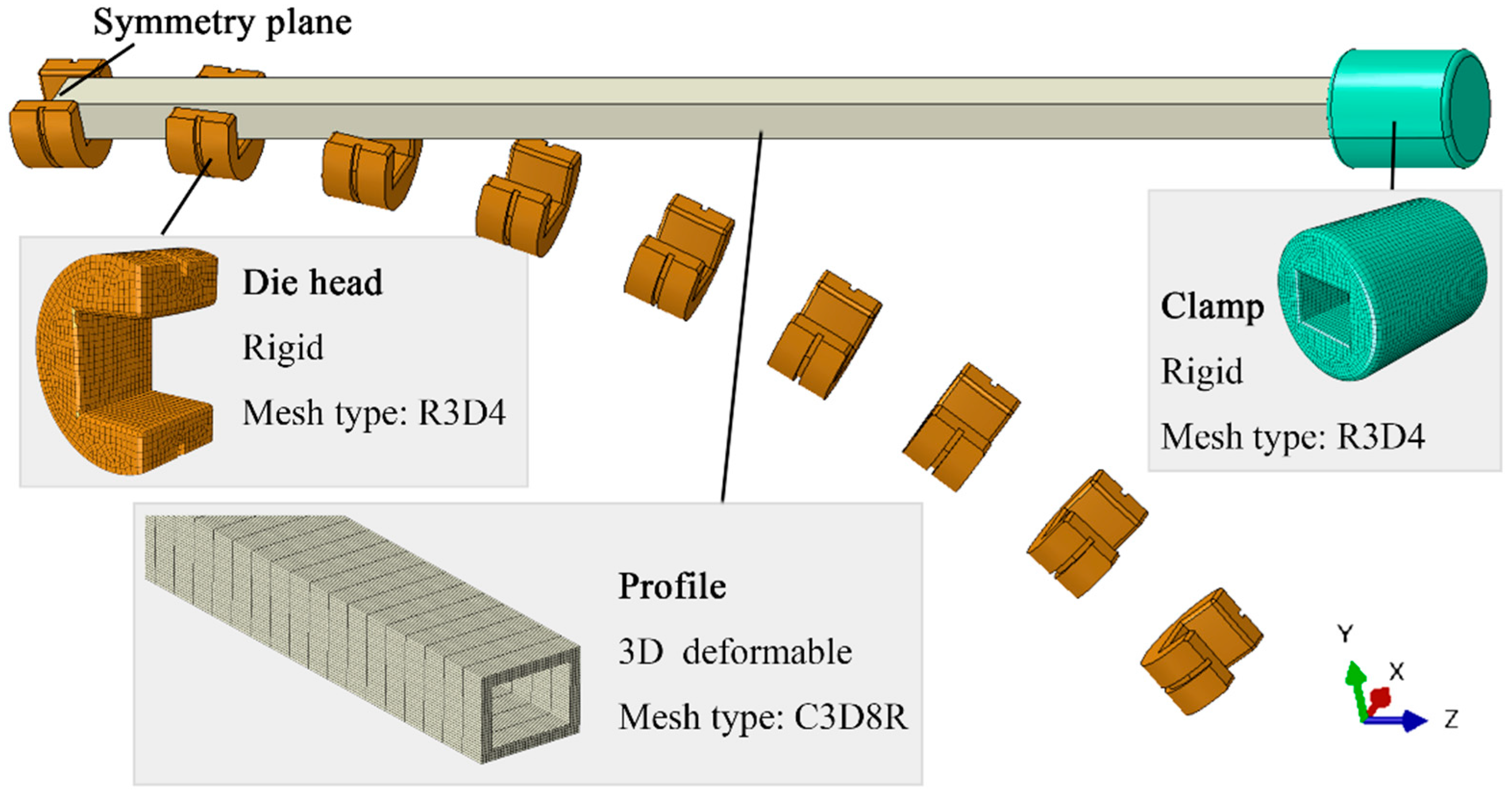

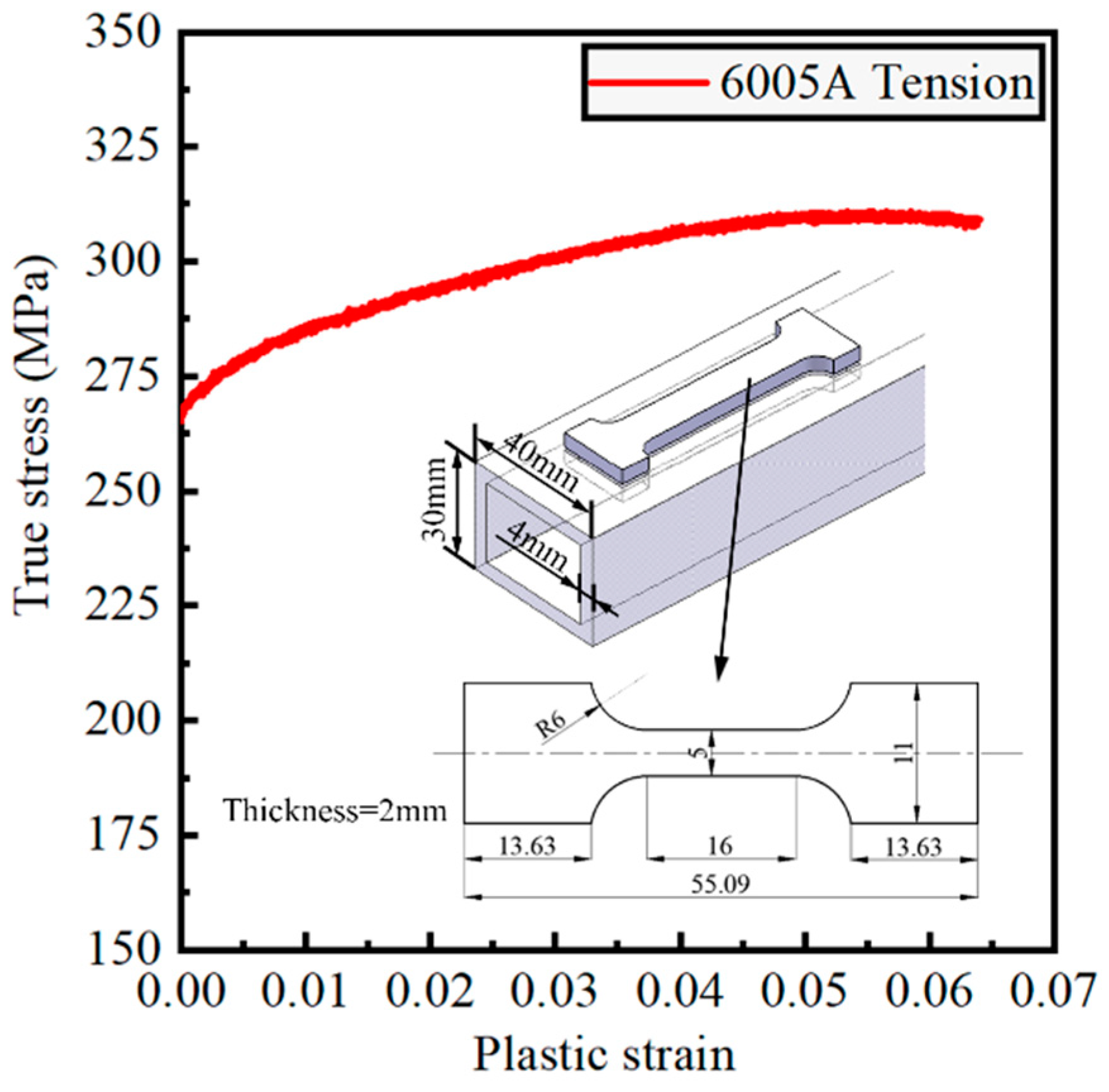

3.1. Numerical Model

3.2. Experimental Analysis

4. Results and Discussion

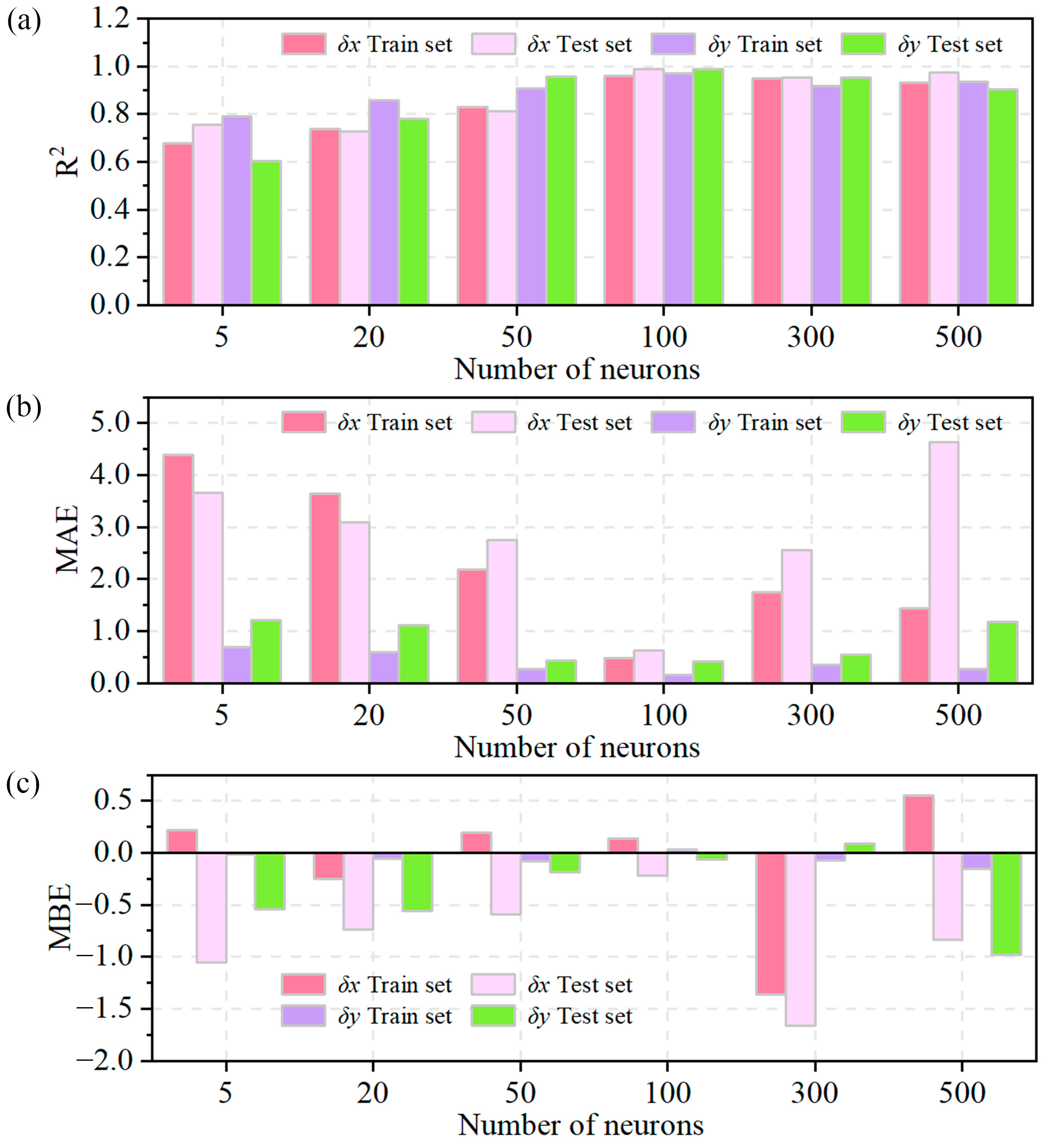

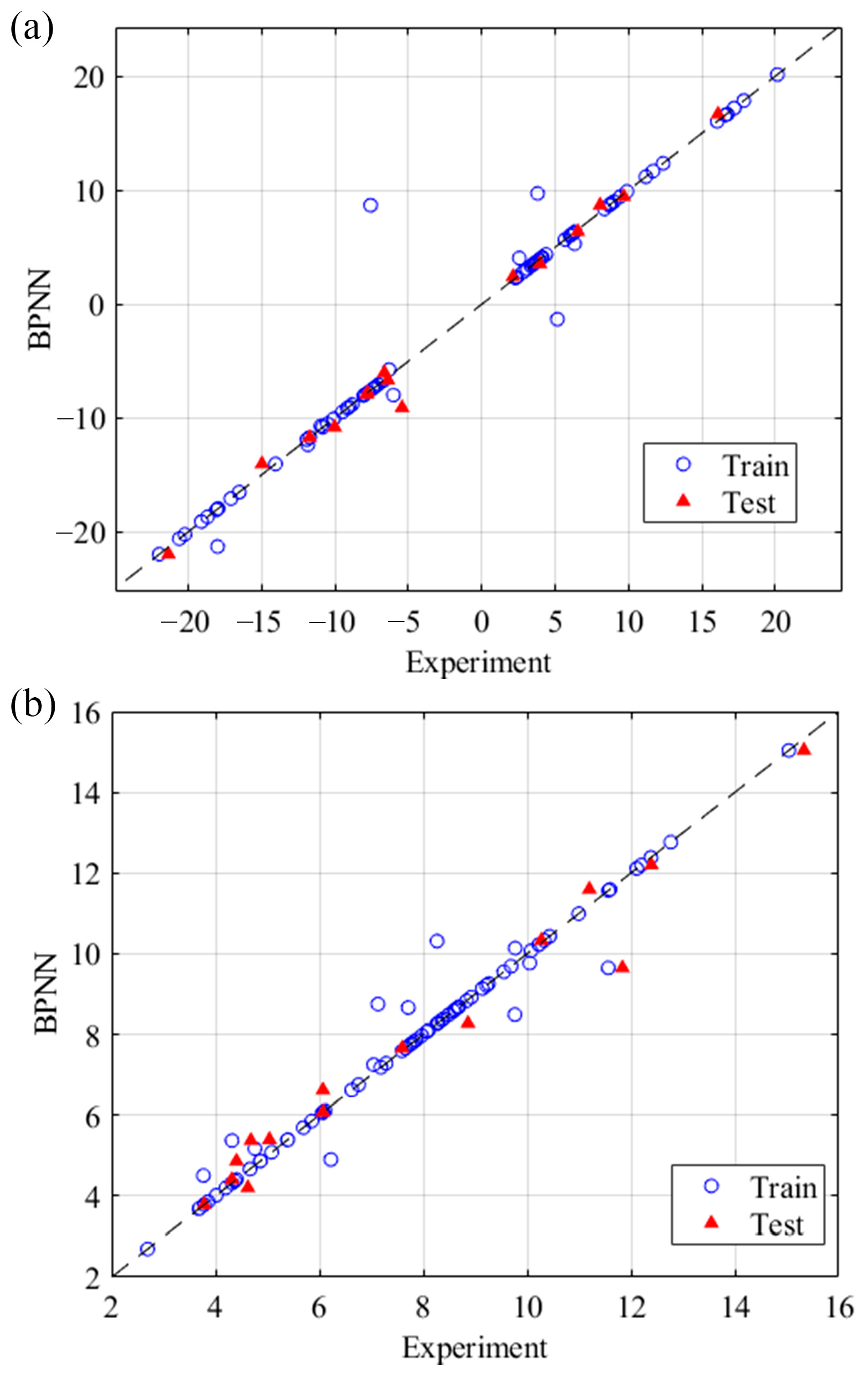

4.1. Neural Network Prediction Accuracy Analysis

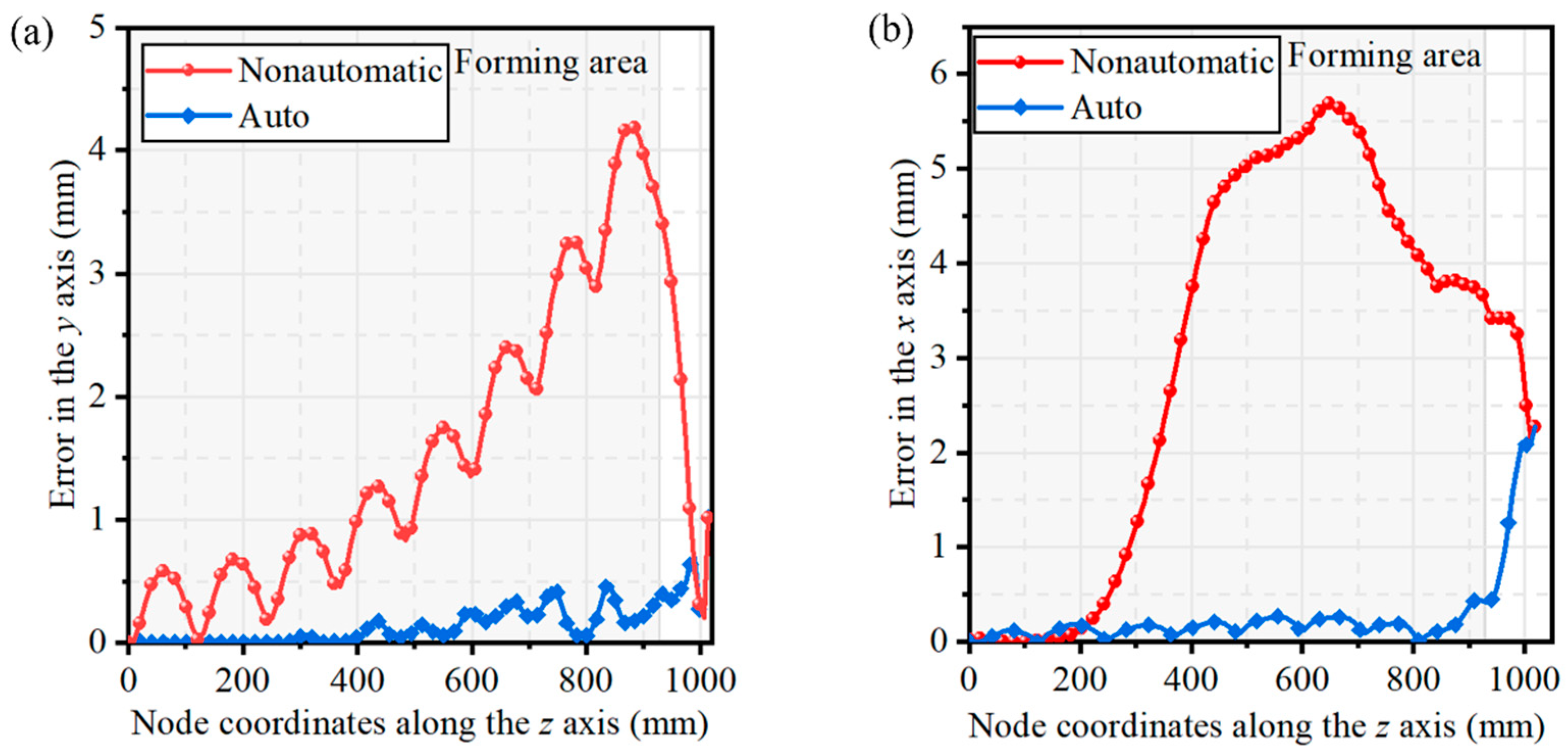

4.2. Analysis of Automatic Forming Accuracy

4.3. Comparison with Springback Factor Control

5. Conclusions

- Based on the 3D flexible multi-point stretch-bending and torsion machine, a 3D MPSBT-forming numerical model for profiles was established. The effectiveness of the numerical model was verified by comparing the test results with those of the numerical model, which was used for subsequent analysis.

- A total of 95 test schemes were designed considering the profiles’ horizontal bending radius Rx, vertical bending radius Ry, torsion angle and direction θ, and wall thickness t. The springback of different combinations was obtained by numerical simulation. Based on the simulation results, the FE-BPNN model of springback prediction is established, and different indices verify its correctness. The automatic profile-forming control system uses the model to form the profile with high precision.

- By comparing the shape difference between automatic forming and non-automatic forming, it is proved that automatic forming can obtain a high-precision shape contour. The effect of the automatic forming control method based on FE-BPNN proposed in this paper is compared with that of the springback factor proposed in other studies. The results show that under the target shape selected in this paper, the springback control method based on the springback factor needs three forming times to obtain qualified parts. The FE-BPNN-based automatic profile forming control method needs one forming time to obtain qualified parts, and the forming errors are reduced by 35.05% and 32.41% in two directions, respectively. The automatic control forming method based on BPNN can significantly improve the forming precision and save processing time.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rosenthal, S.; Maaß, F.; Kamaliev, M.; Hahn, M.; Gies, S.; Tekkaya, A.E. Lightweight in Automotive Components by Forming Technology. Automot. Innov. 2020, 3, 195–209. [Google Scholar] [CrossRef]

- Fröck, H.; Graser, M.; Reich, M.; Lechner, M.; Merklein, M.; Kessler, O. Numerical modelling of the process chain for aluminium Tailored Heat-Treated Profiles. Adv. Model. Simul. Eng. Sci. 2023, 10, 8. [Google Scholar] [CrossRef]

- Gantner, P.; Bauer, H.; Harrison, D.K.; De Silva, A.K.M. Free-Bending—A new bending technique in the hydroforming process chain. J. Mater. Process. Technol. 2005, 167, 302–308. [Google Scholar] [CrossRef]

- Chatti, S.; Hermes, M.; Weinrich, A.; Ben-Khalifa, N.; Tekkaya, A.E. New incremental methods for springback compensation by stress superposition. Int. J. Mater. Form. 2009, 2, 817–820. [Google Scholar] [CrossRef]

- Xu, L.; Pei, Y.; Liu, Z.; Gao, C.; Xie, P.; Xu, C.; Li, L. Manufacturing of curved profiles using an extrusion-bending continuous forming process. Thin-Walled Struct. 2024, 199, 111831. [Google Scholar] [CrossRef]

- Zhao, J.; Yin, J.; Ma, R.; Ma, L. Springback equation of small curvature plane bending. Sci. China Technol. Sci. 2011, 54, 2386–2396. [Google Scholar] [CrossRef]

- Yu, C.; Li, X. Theoretical analysis on springback of L-section extrusion in rotary stretch bending process. Trans. Nonferrous Met. Soc. China 2011, 21, 2705–2710. [Google Scholar] [CrossRef]

- Zhao, J.; Zhai, R.; Qian, Z.; Ma, R. A study on springback of profile plane stretch–bending in the loading method of pretension and moment. Int. J. Mech. Sci. 2013, 75, 45–54. [Google Scholar] [CrossRef]

- Ma, J.; Welo, T. Analytical springback assessment in flexible stretch bending of complex shapes. Int. J. Mach. Tools Manuf. 2021, 160, 103653. [Google Scholar] [CrossRef]

- Fu, Z.; Mo, J. Springback prediction of high-strength sheet metal under air bending forming and tool design based on GA–BPNN. Int. J. Adv. Manuf. Technol. 2011, 53, 473–483. [Google Scholar] [CrossRef]

- Ruan, F.; Feng, Y.; Liu, W. Springback Prediction for Complex Sheet Metal Forming Parts Based on Genetic Neural Network. In Proceedings of the 2008 Second International Symposium on Intelligent Information Technology Application, Shanghai, China, 20–22 December 2008; IEEE: New York, NY, USA, 2008; pp. 157–161. [Google Scholar] [CrossRef]

- Xu, B.; Li, L.; Wang, Z.; Zhou, H.; Liu, D. Prediction of springback in local bending of hull plates using an optimized backpropagation neural network. Mech. Sci. 2021, 12, 777–789. [Google Scholar] [CrossRef]

- El Mrabti, I.; Touache, A.; El Hakimi, A.; Chamat, A. Springback optimization of deep drawing process based on FEM-ANN-PSO strategy. Struct. Multidisc. Optim. 2021, 64, 321–333. [Google Scholar] [CrossRef]

- Jeffery, H.C.K.; Behdinan, K. Neural networks with dimensionality reduction for efficient springback prediction in deep drawing of multi-material cylindrical cups. J. Exp. Theor. Artif. Intell. 2023, 37, 111–130. [Google Scholar] [CrossRef]

- Kongnoo, S.; Sonthipermpoon, K.; Wannarumon, K. Springback optimization for CNC tube bending machine based on an artificial neural networks (ANNs). FME Trans. 2023, 51, 405–414. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, C.; Zhang, S.; Qiu, L.; Lin, Y.; Tan, J.; Sun, C. Towards high-accuracy axial springback: Mesh-based simulation of metal tube bending via geometry/process-integrated graph neural networks. Expert Syst. Appl. 2024, 255, 124577. [Google Scholar] [CrossRef]

- Ha, T.; Welo, T.; Ringen, G.; Wang, J. Smart Control of Springback in Stretch Bending of a Rectangular Tube by an Artificial Neural Network. J. Manuf. Sci. Eng. 2023, 1–42. [Google Scholar] [CrossRef]

- Chen, C.; Liang, J.; Teng, F.; Li, Y.; Liang, C. Research on springback compensation method of 3D flexible stretch bending of multi-point roller dies. Int. J. Adv. Manuf. Technol. 2021, 112, 563–575. [Google Scholar] [CrossRef]

| Dimensions | Value |

|---|---|

| Bending radius in the Oyz plane Rx/mm | 1000, 1500, 2000, 2500 |

| Bending radius in the Oxz plane Ry/mm | 4500, 5000, 5500, 6000 |

| Torsion angle θ/° | −40, −20, 20, 40 |

| Wall thickness t/mm | 2, 3, 4 |

| Forming Parameter | Springback Value/mm | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Rx/mm | Ry/mm | θ/° | t/mm | δx | δy | |||||

| EXP | FE | ERR/% | EXP | FE | ERR/% | |||||

| 1 | 1000 | 4500 | −40 | 4 | 18.19 | 17.211 | 5.38 | 11.95 | 11.568 | 3.2 |

| 2 | 1500 | 4500 | 20 | 2 | −10.87 | −10.13 | 6.85 | 6.38 | 6.058 | 5.07 |

| 3 | 1500 | 6000 | −20 | 3 | 6.69 | 6.322 | 5.50 | 10.73 | 10.051 | 6.32 |

| 4 | 2000 | 5000 | 40 | 4 | −9.43 | −8.842 | 6.24 | 5.06 | 4.870 | 3.76 |

| 5 | 2500 | 5500 | 20 | 2 | 6.58 | 6.225 | 5.40 | 4.62 | 4.318 | 6.55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, Y.; Liang, J.; Li, Y.; Liang, C. Springback Control of Profile by Multi-Point Stretch-Bending and Torsion Automatic Forming Based on FE-BPNN. Metals 2025, 15, 544. https://doi.org/10.3390/met15050544

Wen Y, Liang J, Li Y, Liang C. Springback Control of Profile by Multi-Point Stretch-Bending and Torsion Automatic Forming Based on FE-BPNN. Metals. 2025; 15(5):544. https://doi.org/10.3390/met15050544

Chicago/Turabian StyleWen, Yu, Jicai Liang, Yi Li, and Ce Liang. 2025. "Springback Control of Profile by Multi-Point Stretch-Bending and Torsion Automatic Forming Based on FE-BPNN" Metals 15, no. 5: 544. https://doi.org/10.3390/met15050544

APA StyleWen, Y., Liang, J., Li, Y., & Liang, C. (2025). Springback Control of Profile by Multi-Point Stretch-Bending and Torsion Automatic Forming Based on FE-BPNN. Metals, 15(5), 544. https://doi.org/10.3390/met15050544