Influence of Deposition Rate on Fatigue Behavior of 316L Stainless Steel Prepared via Hybrid Laser Wire Direct Energy Deposition

Abstract

1. Introduction

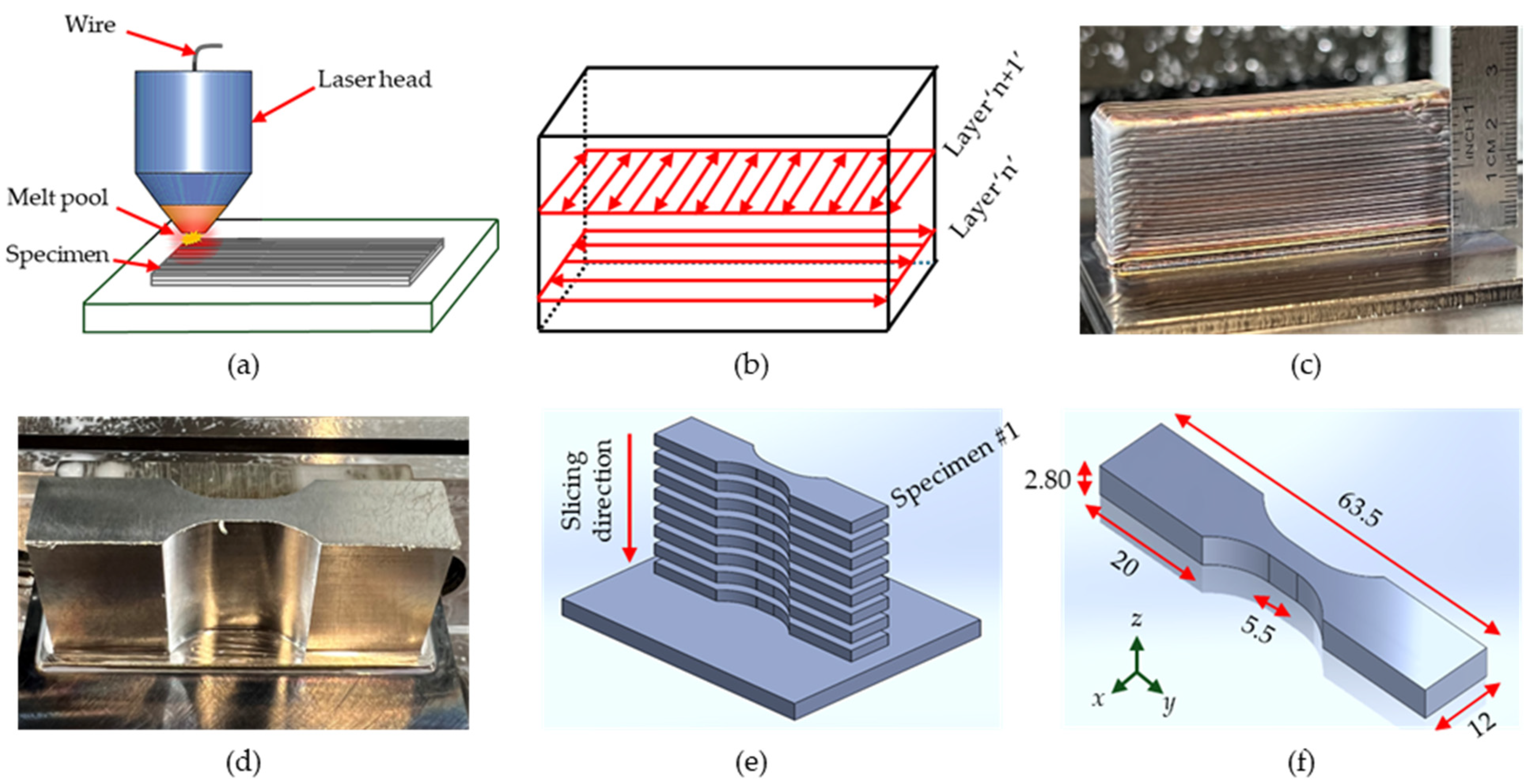

2. Materials and Methods

2.1. Specimen Preparation

2.2. X-Ray Computed Tomography (CT)

2.3. High-Cycle Fatigue (HCF) Testing Method

2.4. Fractography Characterization Method

3. Results and Discussion

3.1. Effect of Deposition Rate on Internal Porosity

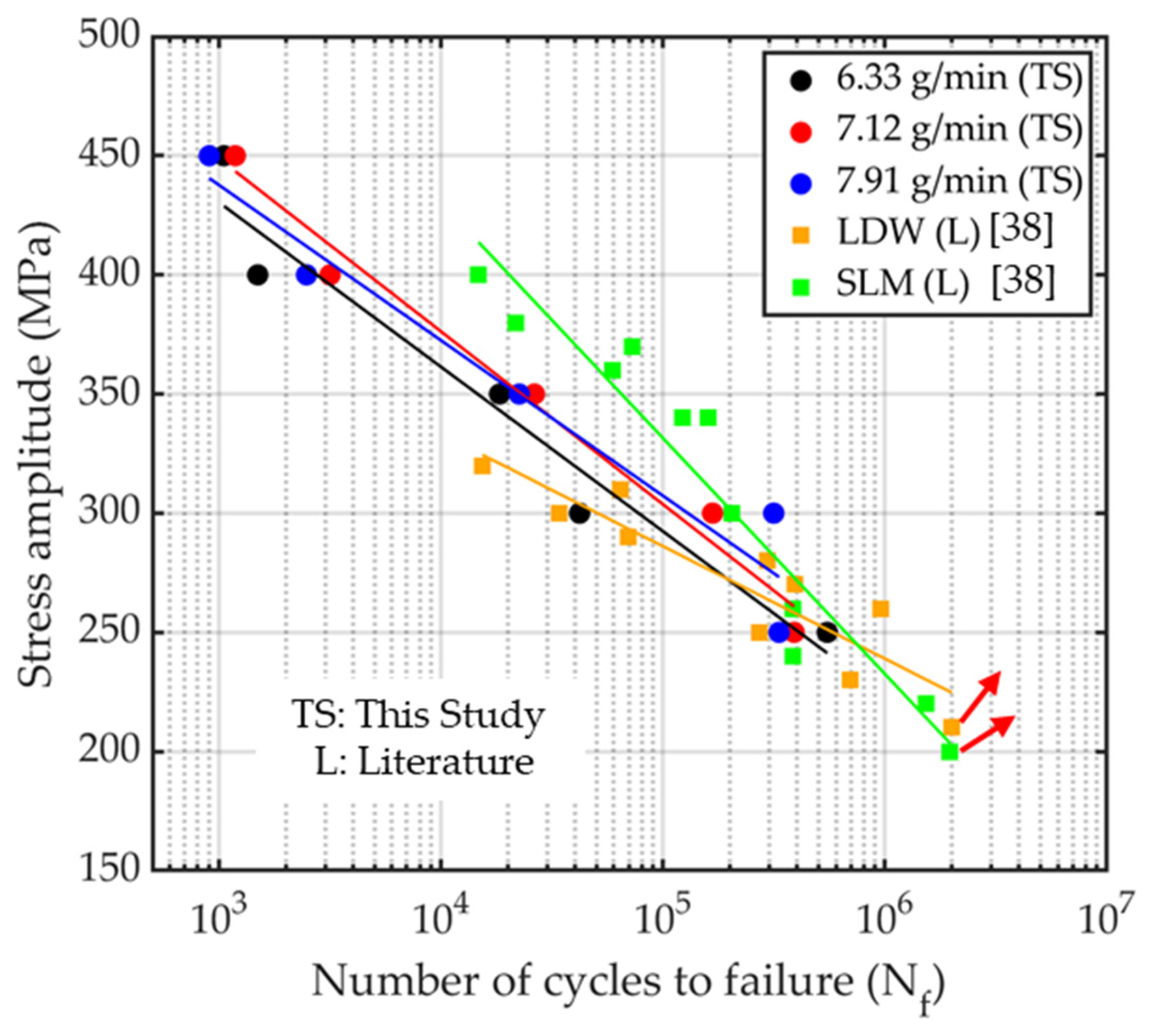

3.2. Influence of Deposition Rates on Fatigue Behavior

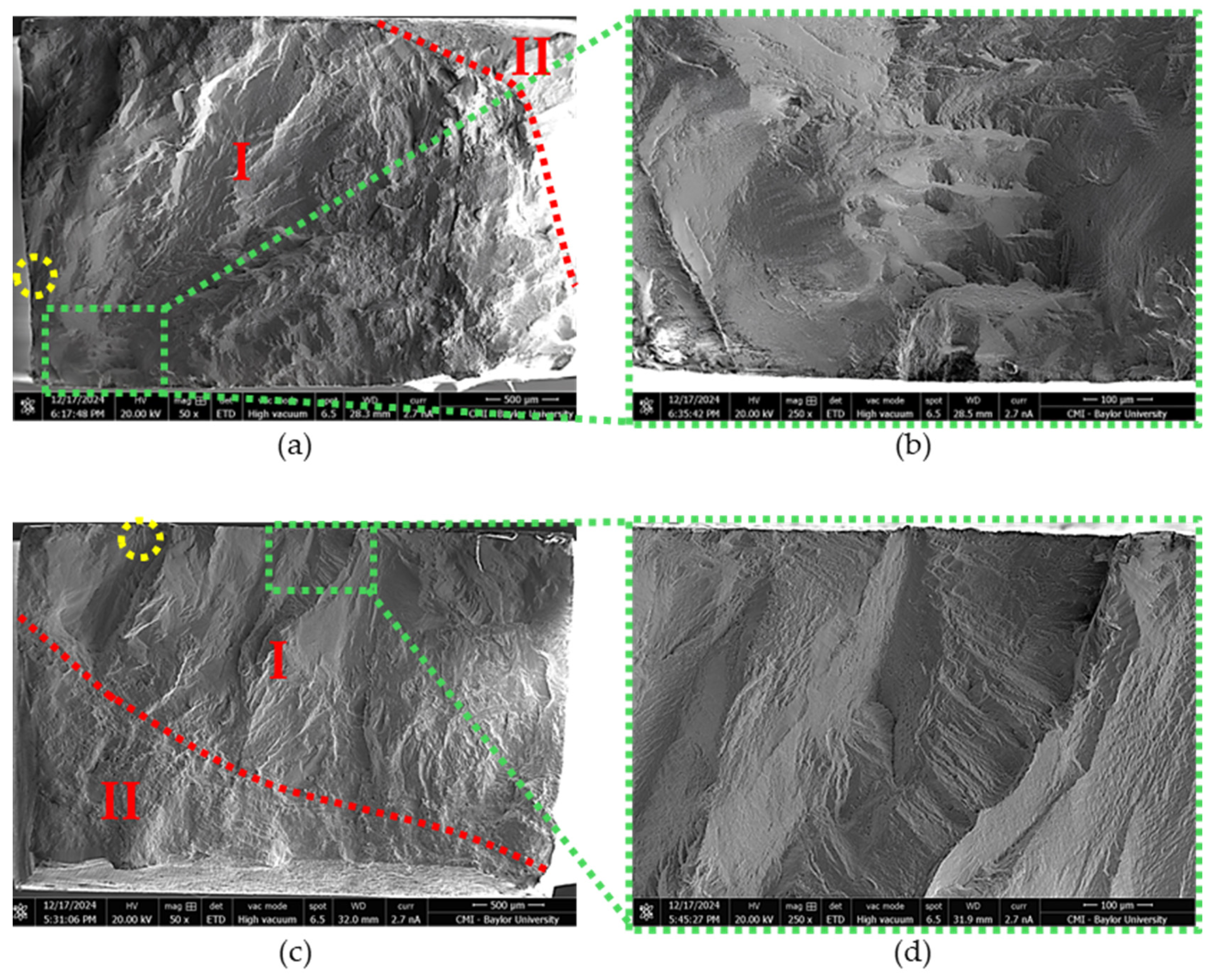

3.3. Fractography Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vinoth, V.; Sekar, T.; Kumaran, M. Investigations on the Mechanical Characteristics of the Stainless Steel 316L Alloy Fabricated by Directed Energy Deposition for Repairing Application. J. Mater. Eng. Perform. 2023, 32, 4138–4150. [Google Scholar] [CrossRef]

- Menon, N.; Sawyer, B.A.; Jamieson, C.D.; Reutzel, E.W.; Basak, A. A Comparison of Microstructure and Microhardness Properties of IN718 Fabricated via Powder- and Wire-Fed Laser-Directed Energy Deposition. Materials 2023, 16, 1129. [Google Scholar] [CrossRef] [PubMed]

- Kushwaha, A.; Basak, A. Evaluating Deposits of SS316L Powder and Wire Consolidated Using Co-Axial Laser Directed Energy Deposition. Int. J. Adv. Manuf. Technol. 2024, 132, 1627–1647. [Google Scholar] [CrossRef]

- Abuabiah, M.; Mbodj, N.G.; Shaqour, B.; Herzallah, L.; Juaidi, A.; Abdallah, R.; Plapper, P. Advancements in Laser Wire-Feed Metal Additive Manufacturing: A Brief Review. Materials 2023, 16, 2030. [Google Scholar] [CrossRef]

- Costello, S.C.A.; Cunningham, C.R.; Xu, F.; Shokrani, A.; Dhokia, V.; Newman, S.T. The State-of-the-Art of Wire Arc Directed Energy Deposition (WA-DED) as an Additive Manufacturing Process for Large Metallic Component Manufacture. Int. J. Comput. Integr. Manuf. 2023, 36, 469–510. [Google Scholar] [CrossRef]

- Blinn, B.; Lion, P.; Jordan, O.; Meiniger, S.; Mischliwski, S.; Tepper, C.; Gläßner, C.; Aurich, J.C.; Weigold, M.; Beck, T. Process-Influenced Fatigue Behavior of AISI 316L Manufactured by Powder- and Wire-Based Laser Direct Energy Deposition. Mater. Sci. Eng. A 2021, 818, 141383. [Google Scholar] [CrossRef]

- Ningthemba Singh, S.; Deoghare, A.B. High Layer Thickness Laser Directed Energy Deposition of Ti6Al4V Alloy: Microstructure, Fatigue Behavior and Fractography. Eng. Fail. Anal. 2023, 148, 107208. [Google Scholar] [CrossRef]

- Ghafoori, E.; Dahaghin, H.; Diao, C.; Pichler, N.; Li, L.; Mohri, M.; Ding, J.; Ganguly, S.; Williams, S. Fatigue Strengthening of Damaged Steel Members Using Wire Arc Additive Manufacturing. Eng. Struct. 2023, 284, 115911. [Google Scholar] [CrossRef]

- Bernauer, C.; Sigl, M.E.; Grabmann, S.; Merk, T.; Zapata, A.; Zaeh, M.F. Effects of the Thermal History on the Microstructural and the Mechanical Properties of Stainless Steel 316L Parts Produced by Wire-Based Laser Metal Deposition. Mater. Sci. Eng. A 2024, 889, 145862. [Google Scholar] [CrossRef]

- Gao, L.; Bhattacharyya, J.; Lin, W.; Ren, Z.; Chuang, A.C.; Shevchenko, P.D.; Nikitin, V.; Ma, J.; Agnew, S.R.; Sun, T. Tailoring Material Microstructure and Property in Wire-Laser Directed Energy Deposition through a Wiggle Deposition Strategy. Addit. Manuf. 2023, 77, 103801. [Google Scholar] [CrossRef]

- Brubaker, N.; Ali, H.; Dhakal, S.; van Rooyen, N.; Jaster, M.L.; Charit, I.; Jaques, B.; Maughan, M.R. Investigating Microstructure and Properties of 316L Stainless Steel Produced by Wire-Fed Laser Metal Deposition. J. Mater. Eng. Perform. 2022, 31, 3508–3519. [Google Scholar] [CrossRef]

- Gao, S.; Liu, R.; Huang, R.; Song, X.; Seita, M. A Hybrid Directed Energy Deposition Process to Manipulate Microstructure and Properties of Austenitic Stainless Steel. Mater. Des. 2022, 213, 110360. [Google Scholar] [CrossRef]

- Li, Y.; Podaný, P.; Salvetr, P.; Brázda, M.; Džugan, J. Building Rate Effect on Microstructure and High Temperature Mechanical Properties of Austenitic 316L Stainless Steel Manufactured by Laser Directed Energy Deposition. Opt. Laser Technol. 2024, 172, 110535. [Google Scholar] [CrossRef]

- D’Andrea, D. Additive Manufacturing of AISI 316L Stainless Steel: A Review. Metals 2023, 13, 1370. [Google Scholar] [CrossRef]

- Lin, Y.-T.; Tsai, M.-Y.; Yen, S.-Y.; Lung, G.-H.; Yei, J.-T.; Hsu, K.-J.; Chen, K.-J. Comparing the Performance of Rolled Steel and 3D-Printed 316L Stainless Steel. Micromachines 2024, 15, 353. [Google Scholar] [CrossRef]

- Renjith Kumar, R.; Devasena, T.; Abeens, M. Improved Mechanical Properties of Nano Structured 316 L Stainless Steel by Statistically Optimized Low Pulsed Laser Shock Peening Process for Aeronautical Application. Optik 2023, 276, 170654. [Google Scholar] [CrossRef]

- Türkmen, M.; Tanouz, A.M.; Akgün, M.; Erden, M.A. The Effect of Mn and Ti Ratio on Microstructure and Mechanical and Machinability Properties of 316 L Stainless Steel Used in Biomedical Applications. Metals 2023, 13, 1804. [Google Scholar] [CrossRef]

- Hong, M.; Samuha, S.; Hosemann, P. Corrosion Mechanism of Cold Forged 316 Stainless Steel in Molten FLiNaK Salt. Corros. Sci. 2024, 232, 111990. [Google Scholar] [CrossRef]

- Ponticelli, G.S.; Panciroli, R.; Venettacci, S.; Tagliaferri, F.; Guarino, S. Experimental Investigation on the Fatigue Behavior of Laser Powder Bed Fused 316L Stainless Steel. CIRP J. Manuf. Sci. Technol. 2022, 38, 787–800. [Google Scholar] [CrossRef]

- Hamada, A.; Jaskari, M.; Gundgire, T.; Järvenpää, A. Enhancement and Underlying Fatigue Mechanisms of Laser Powder Bed Fusion Additive-Manufactured 316L Stainless Steel. Mater. Sci. Eng. A 2023, 873, 145021. [Google Scholar] [CrossRef]

- Kumar, A.S.; Sharma, S.K.; Shukla, A.K. Microstructural, Mechanical, and Thermal Analysis of SS316L Weldment for Marine Engineering Application. J. Mater. Eng. Perform. 2024, 33, 13502–13515. [Google Scholar] [CrossRef]

- Lee, S.; Ghiaasiaan, R.; Gradl, P.R.; Shao, S.; Shamsaei, N. Additively Manufactured 316L Stainless Steel via Laser Powder Directed Energy Deposition (LP-DED): Mechanical Properties at Cryogenic and Elevated Temperatures. Int. J. Fatigue 2024, 182, 108197. [Google Scholar] [CrossRef]

- Duan, C.; Shang, D.; Luo, X.; Hao, X.; Cao, X. Effects of Residual Stress Induced by Laser Shock Peening on Fatigue Crack Propagation Behavior in Directed Energy Deposition Stainless Steel. Steel Res. Int. 2024, 95, 2300328. [Google Scholar] [CrossRef]

- Andrade, M.F.; Pereira, M.V.; Teixeira, M.C.; Junior, A.T.; Gutjar, J. Fatigue Life Assessment in the Very High Cycle Regime of AISI 316L Stainless Steel Processed by L-DED Additive Manufacturing. Procedia Struct. Integr. 2022, 42, 1008–1016. [Google Scholar] [CrossRef]

- Ye, W.; Zhang, X.; Hohl, J.; Liao, Y.; Mushongera, L.T. Life Prediction for Directed Energy Deposition-Manufactured 316L Stainless Steel Using a Coupled Crystal Plasticity–Machine Learning Framework. Adv. Eng. Mater. 2023, 25, 2201429. [Google Scholar] [CrossRef]

- Jiang, D.; Ning, F. Additive Manufacturing of 316L Stainless Steel by a Printing-Debinding-Sintering Method: Effects of Microstructure on Fatigue Property. J. Manuf. Sci. Eng. 2021, 143, 091007. [Google Scholar] [CrossRef]

- Tang, D.; He, X.; Wu, B.; Wang, X.; Wang, T.; Li, Y. The Effect of Porosity Defects on the Mid-Cycle Fatigue Behavior of Directed Energy Deposited Ti-6Al-4V. Theor. Appl. Fract. Mech. 2022, 119, 103322. [Google Scholar] [CrossRef]

- Dantas, R.; Correia, J.; Lesiuk, G.; Rozumek, D.; Zhu, S.-P.; De Jesus, A.; Susmel, L.; Berto, F. Evaluation of Multiaxial High-Cycle Fatigue Criteria under Proportional Loading for S355 Steel. Eng. Fail. Anal. 2021, 120, 105037. [Google Scholar] [CrossRef]

- Sarafan, S.; Wanjara, P.; Gholipour, J.; Bernier, F.; Osman, M.; Sikan, F.; Soost, J.; Amos, R.; Patnaik, P.; Brochu, M. Benchmarking of 316L Stainless Steel Manufactured by a Hybrid Additive/Subtractive Technology. J. Manuf. Mater. Process. 2022, 6, 30. [Google Scholar] [CrossRef]

- Yang, Y.; Gong, Y.; Li, C.; Wen, X.; Sun, J. Mechanical Performance of 316 L Stainless Steel by Hybrid Directed Energy Deposition and Thermal Milling Process. J. Mater. Process. Technol. 2021, 291, 117023. [Google Scholar] [CrossRef]

- Ding, H.; Zou, B.; Wang, X.; Liu, J.; Li, L. Microstructure, Mechanical Properties and Machinability of 316L Stainless Steel Fabricated by Direct Energy Deposition. Int. J. Mech. Sci. 2023, 243, 108046. [Google Scholar] [CrossRef]

- Luo, Y.; Zheng, K.; Zhao, P.; Zhang, Y. Machining Characteristics of 316L Stainless Steel in Hybrid Manufacturing via a Three-Dimensional Thermal-Mechanical Coupled Model. J. Manuf. Process. 2023, 102, 275–296. [Google Scholar] [CrossRef]

- Yue, W.; Zhang, Y.; Zheng, Z.; Lai, Y. Hybrid Laser Additive Manufacturing of Metals: A Review. Coatings 2024, 14, 315. [Google Scholar] [CrossRef]

- Haley, J.; Karandikar, J.; Herberger, C.; MacDonald, E.; Feldhausen, T.; Lee, Y. Review of in Situ Process Monitoring for Metal Hybrid Directed Energy Deposition. J. Manuf. Process. 2024, 109, 128–139. [Google Scholar] [CrossRef]

- Rutherford, B.A.; Avery, D.Z.; Phillips, B.J.; Rao, H.M.; Doherty, K.J.; Allison, P.G.; Brewer, L.N.; Jordon, J.B. Effect of Thermomechanical Processing on Fatigue Behavior in Solid-State Additive Manufacturing of Al-Mg-Si Alloy. Metals 2020, 10, 947. [Google Scholar] [CrossRef]

- El-Azab, S.A.; Zhang, C.; Jiang, S.; Vyatskikh, A.L.; Valdevit, L.; Lavernia, E.J.; Schoenung, J.M. In Situ Observation of Melt Pool Evolution in Ultrasonic Vibration-Assisted Directed Energy Deposition. Sci. Rep. 2023, 13, 17705. [Google Scholar] [CrossRef]

- Werner, T.; Madia, M.; Zerbst, U. Comparison of the Fatigue Behavior of Wrought and Additively Manufactured AISI 316L. Procedia Struct. Integr. 2022, 38, 554–563. [Google Scholar] [CrossRef]

- Blinn, B.; Klein, M.; Gläßner, C.; Smaga, M.; Aurich, J.C.; Beck, T. An Investigation of the Microstructure and Fatigue Behavior of Additively Manufactured AISI 316L Stainless Steel with Regard to the Influence of Heat Treatment. Metals 2018, 8, 220. [Google Scholar] [CrossRef]

| Ultimate Tensile Strength | Yield Strength | Elongation | Hardness [HV-30] |

|---|---|---|---|

| 643 [MPa] | 429 [MPa] | 38 [%] | 950 |

| Process Parameters | Type A | Type B | Type C |

|---|---|---|---|

| Laser Power [W] | 950 | 950 | 950 |

| Gas Flow [lpm] | 15 | 15 | 15 |

| Wire Feed Rate [mm/min] | 1008 | 1134 | 1260 |

| Traverse Speed [mm/min] | 546 | 612 | 684 |

| Deposition Rate [g/min] | 6.33 | 7.12 | 7.91 |

| Linear Heat Input [J/mm] | 104.40 | 93.14 | 83.33 |

| Volumetric Feed Rate [mm3/min] | 792 | 888 | 990 |

| Volumetric Ratio [mm3/mm] | 1.45 | 1.45 | 1.45 |

| Specimen Type | Deposition Rate (g/min) | Volumetric Porosity (%) |

|---|---|---|

| A | 6.33 | 0 |

| B | 7.12 | 0.105 |

| C | 7.91 | 0.873 |

| Parameters | 6.33 [g/min] | 7.12 [g/min] | 7.91 [g/min] |

|---|---|---|---|

| C [MPa] | 802.786 | 861.589 | 779.292 |

| b | −0.089 | −0.092 | −0.082 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jafor, M.A.; Kinser, R.; Zhu, N.; Matalgah, K.; Allison, P.G.; Jordon, J.B.; Fleck, T.J. Influence of Deposition Rate on Fatigue Behavior of 316L Stainless Steel Prepared via Hybrid Laser Wire Direct Energy Deposition. Metals 2025, 15, 543. https://doi.org/10.3390/met15050543

Jafor MA, Kinser R, Zhu N, Matalgah K, Allison PG, Jordon JB, Fleck TJ. Influence of Deposition Rate on Fatigue Behavior of 316L Stainless Steel Prepared via Hybrid Laser Wire Direct Energy Deposition. Metals. 2025; 15(5):543. https://doi.org/10.3390/met15050543

Chicago/Turabian StyleJafor, Md Abu, Ryan Kinser, Ning Zhu, Khaled Matalgah, Paul G. Allison, J. Brian Jordon, and Trevor J. Fleck. 2025. "Influence of Deposition Rate on Fatigue Behavior of 316L Stainless Steel Prepared via Hybrid Laser Wire Direct Energy Deposition" Metals 15, no. 5: 543. https://doi.org/10.3390/met15050543

APA StyleJafor, M. A., Kinser, R., Zhu, N., Matalgah, K., Allison, P. G., Jordon, J. B., & Fleck, T. J. (2025). Influence of Deposition Rate on Fatigue Behavior of 316L Stainless Steel Prepared via Hybrid Laser Wire Direct Energy Deposition. Metals, 15(5), 543. https://doi.org/10.3390/met15050543