Microstructure and Properties of Mooring Chain Steel Prepared by Selective Laser Melting

Abstract

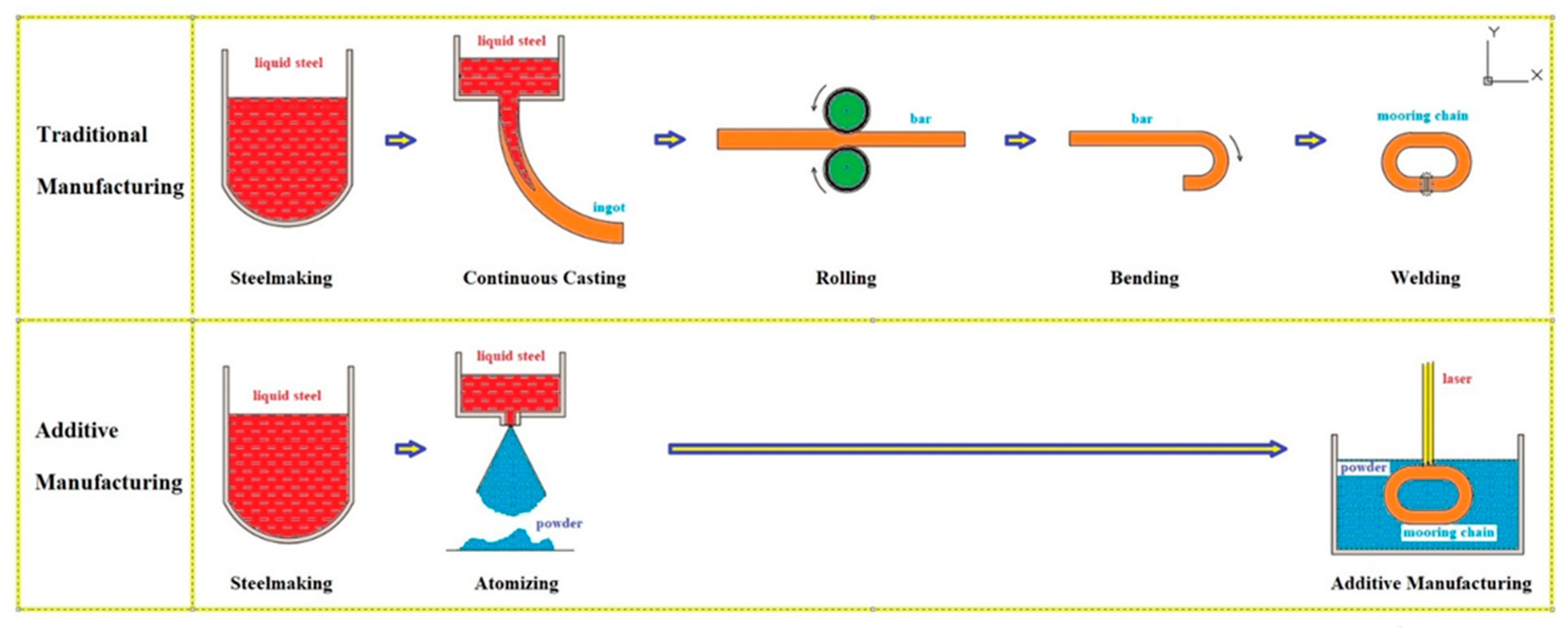

1. Introduction

2. Experimental Materials and Methods

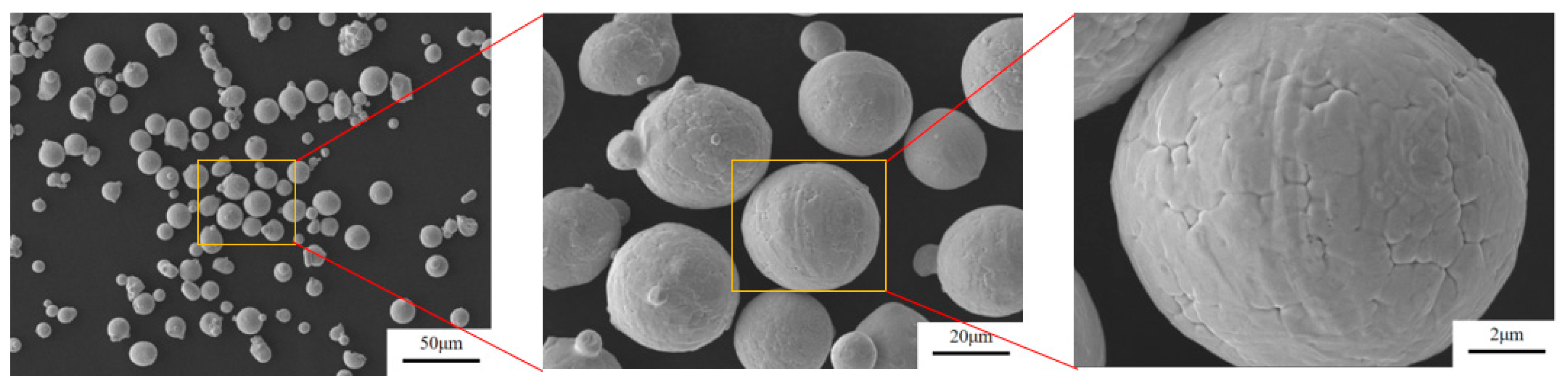

2.1. Mooring Chain Steel Experimental Materials

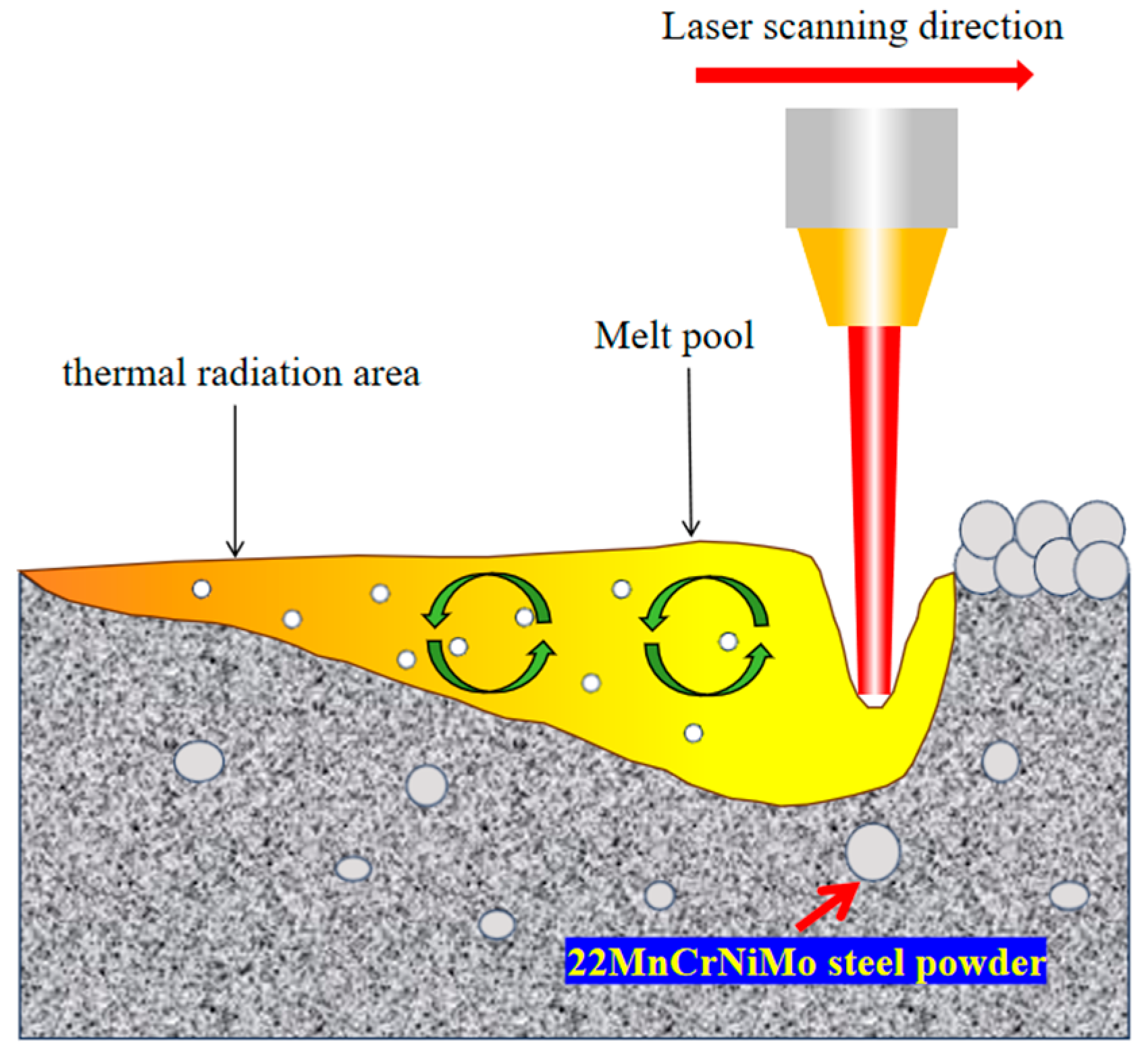

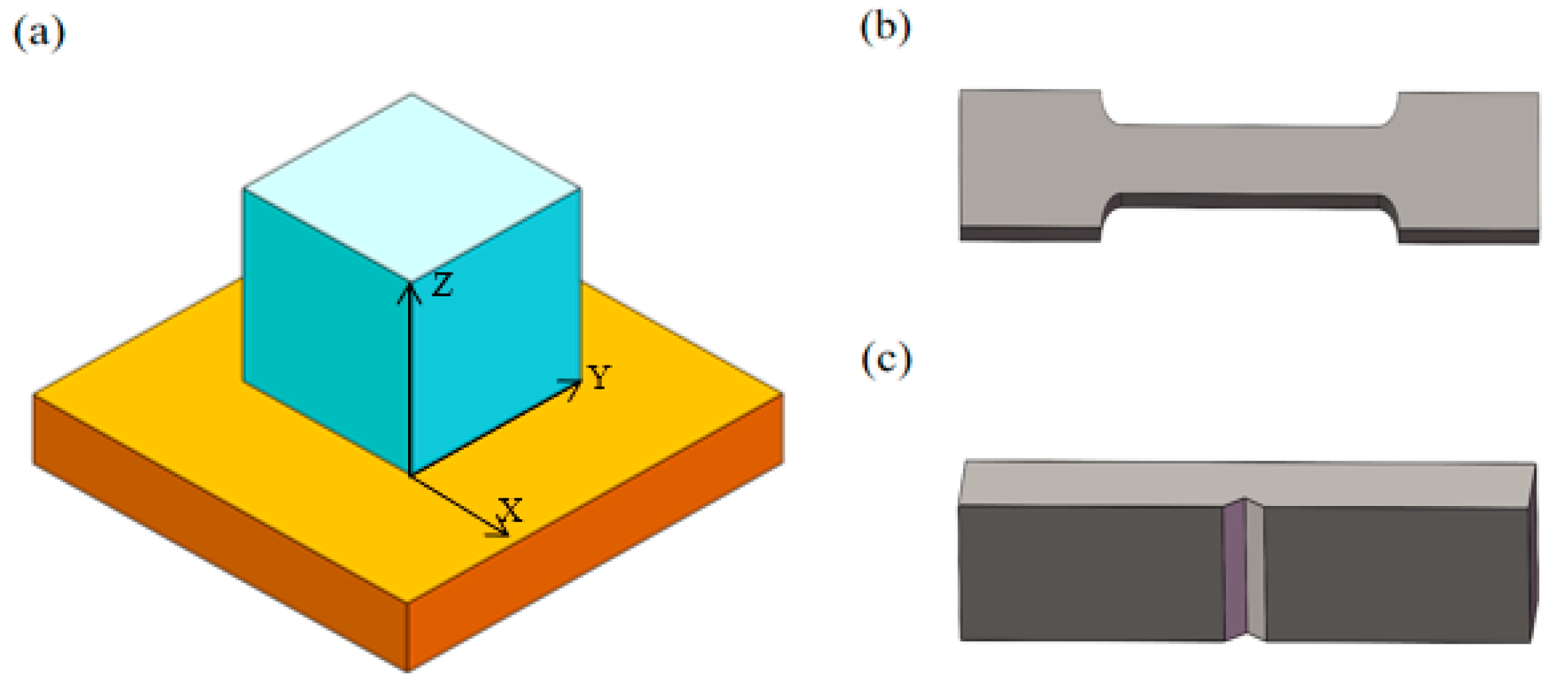

2.2. Method for Preparing Mooring Chain Steel by Selective Laser Melting

2.3. Testing Methods and Equipment for Microstructure and Properties of 22MnCrNiMo Steel

3. Experimental Results and Analysis

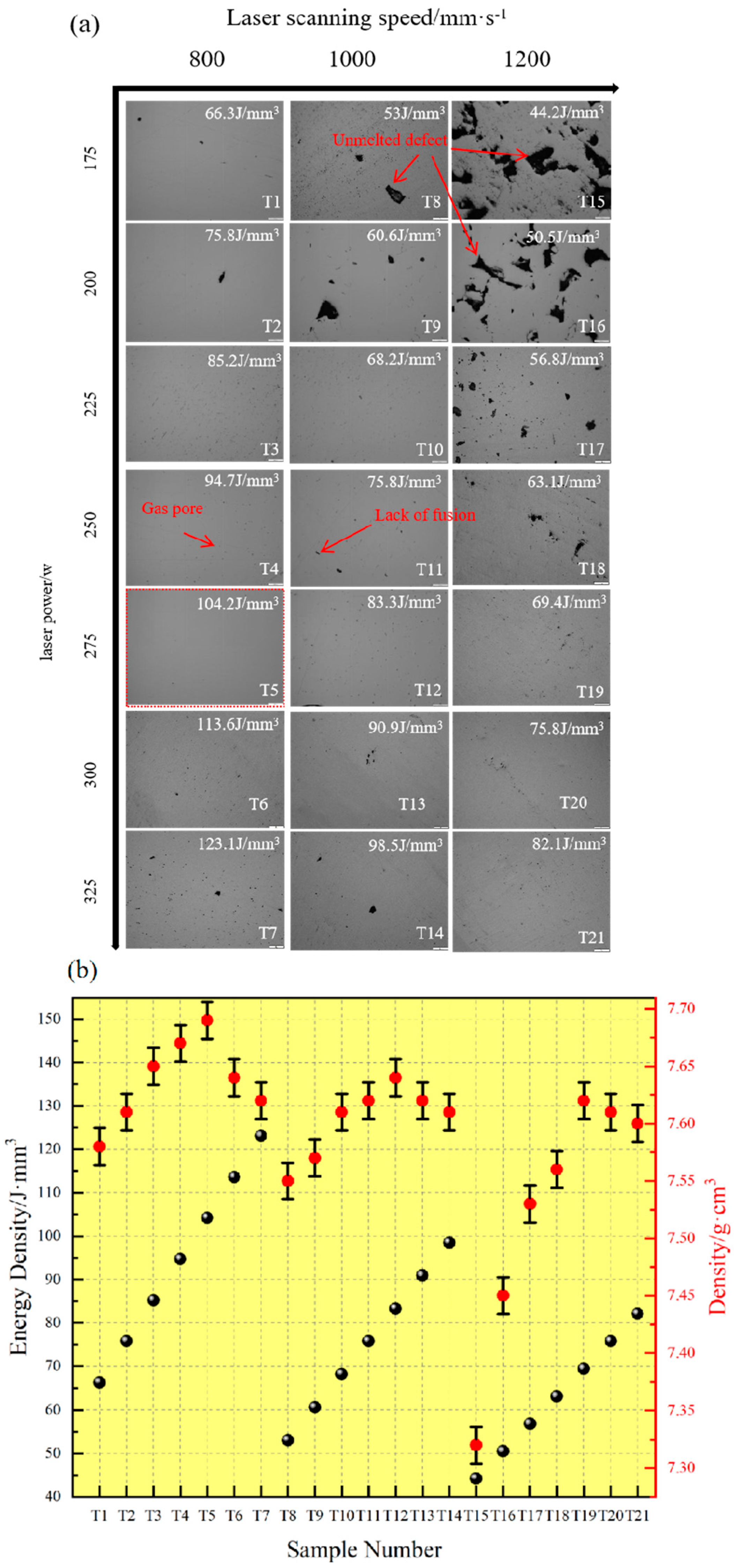

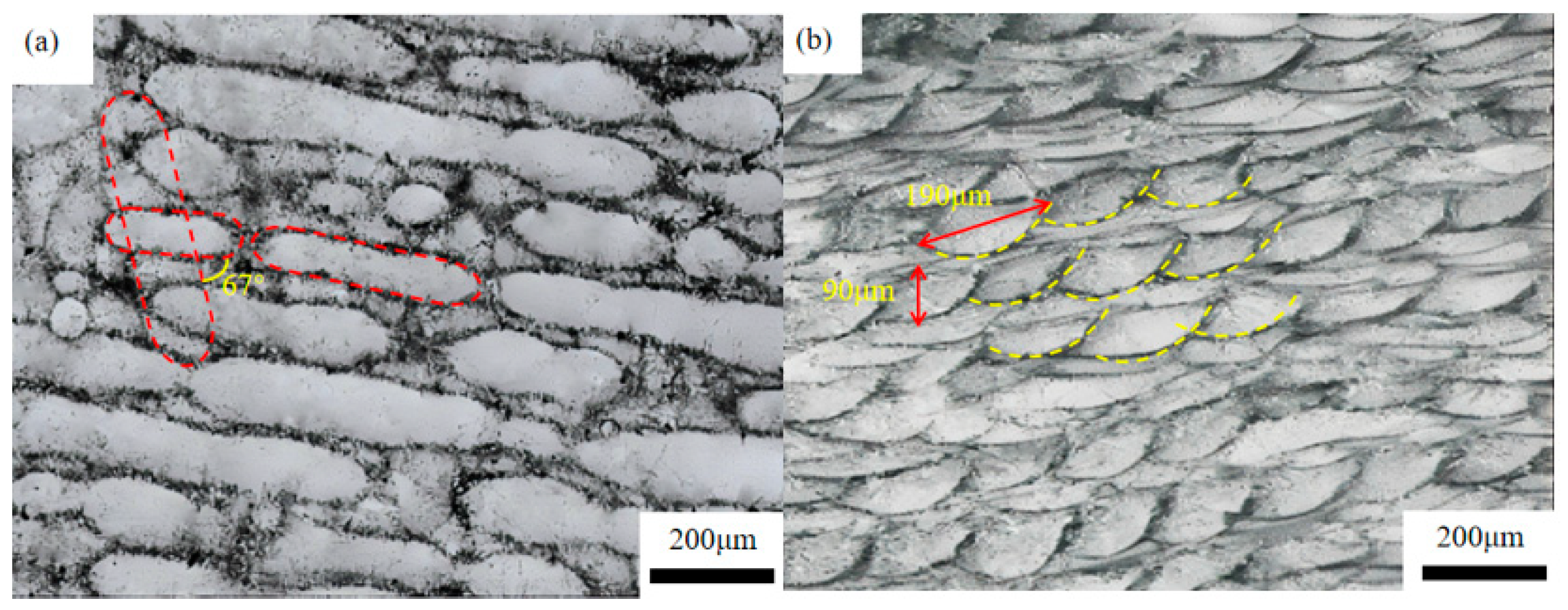

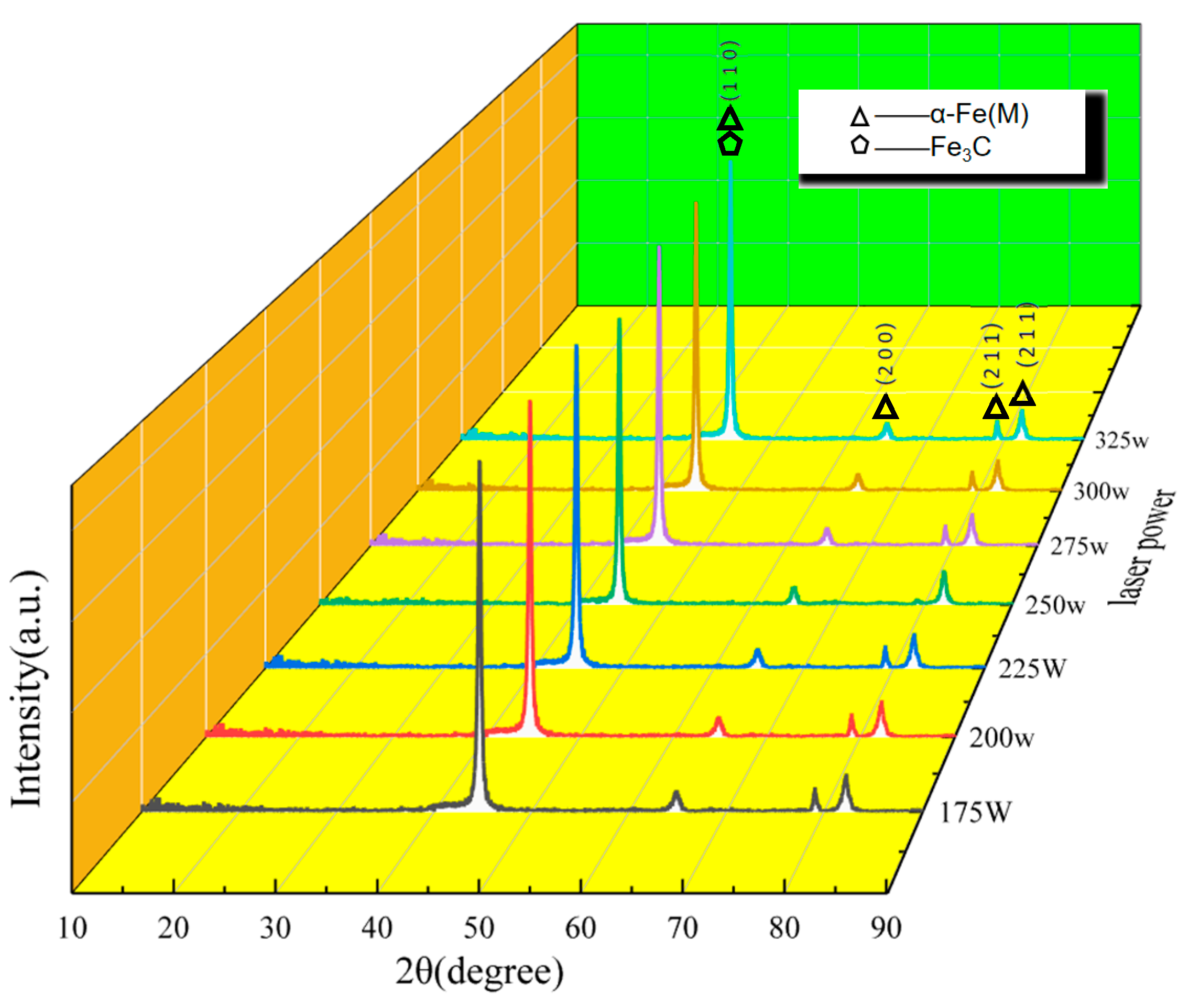

3.1. Parameter Optimization and Micro-Molten Pool Morphology of 22MnCrNiMo Steel Prepared by SLM

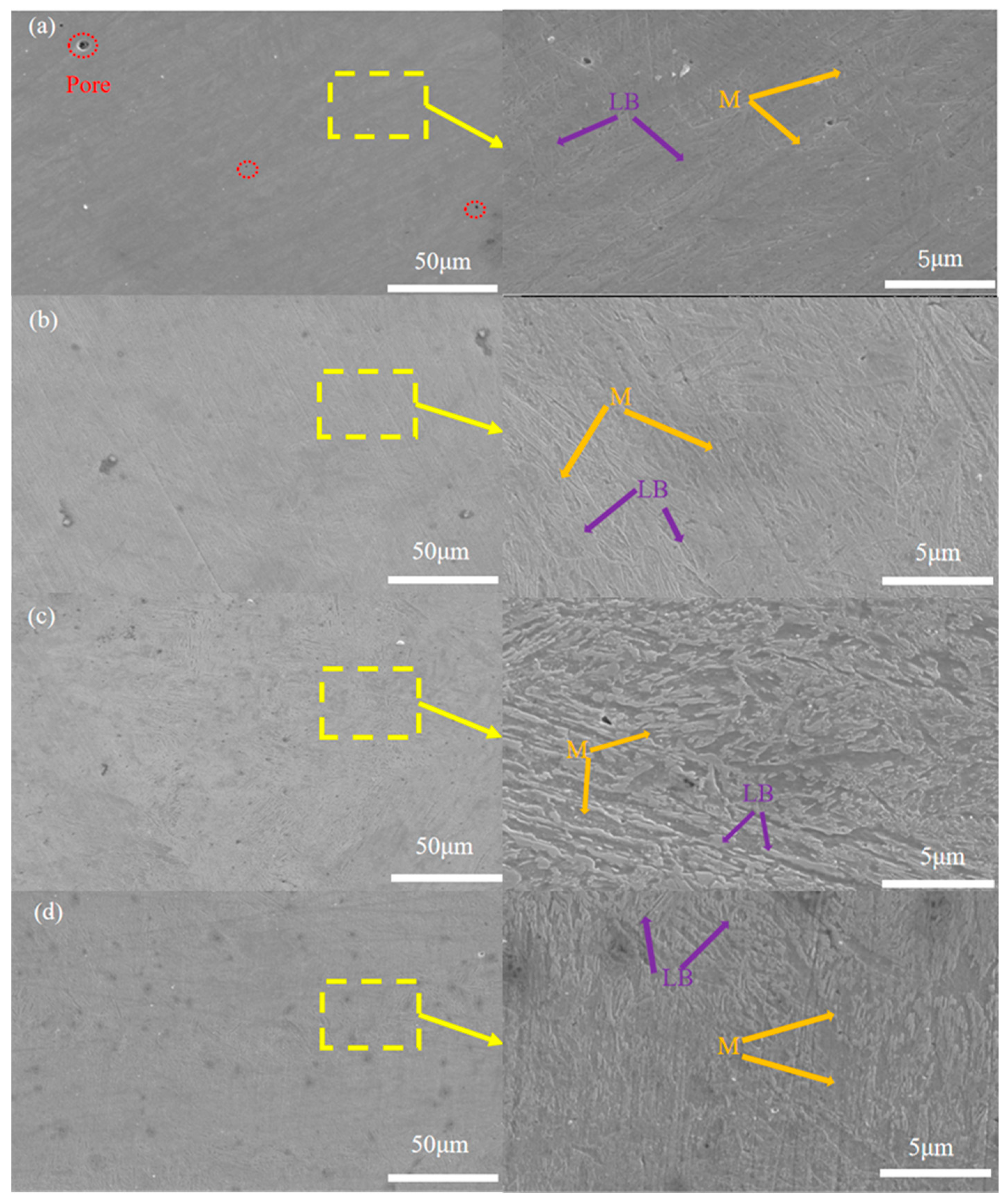

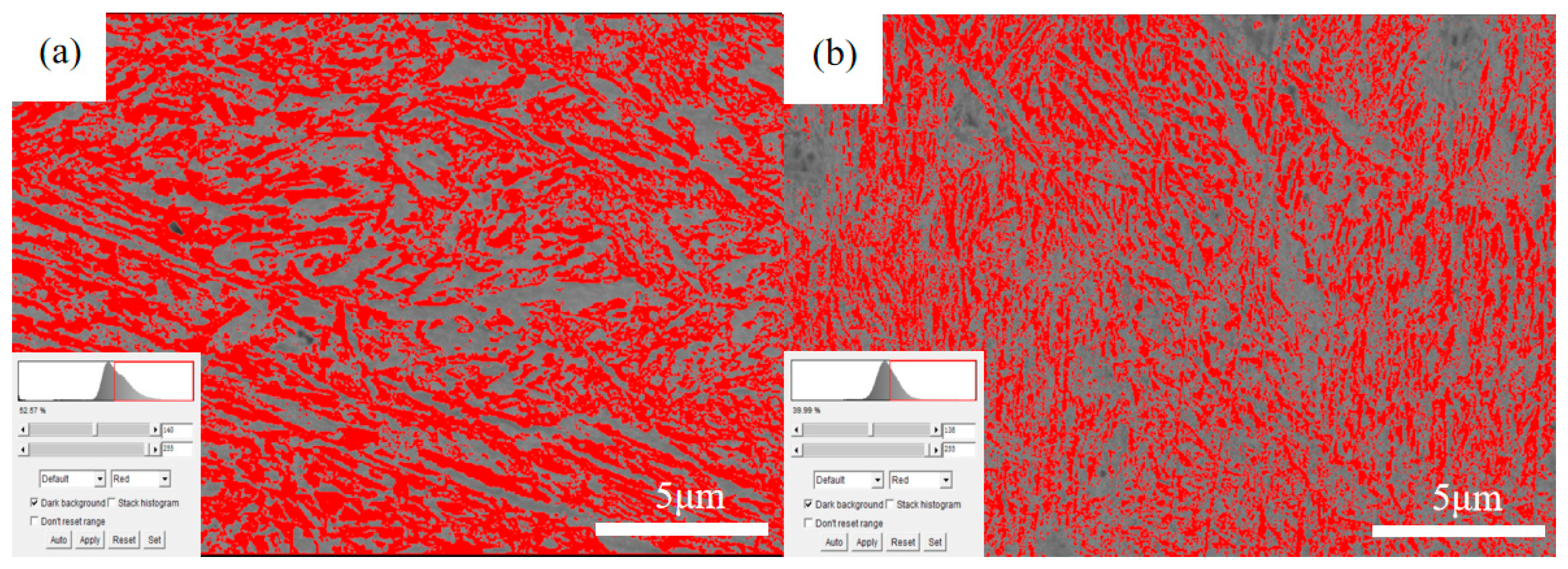

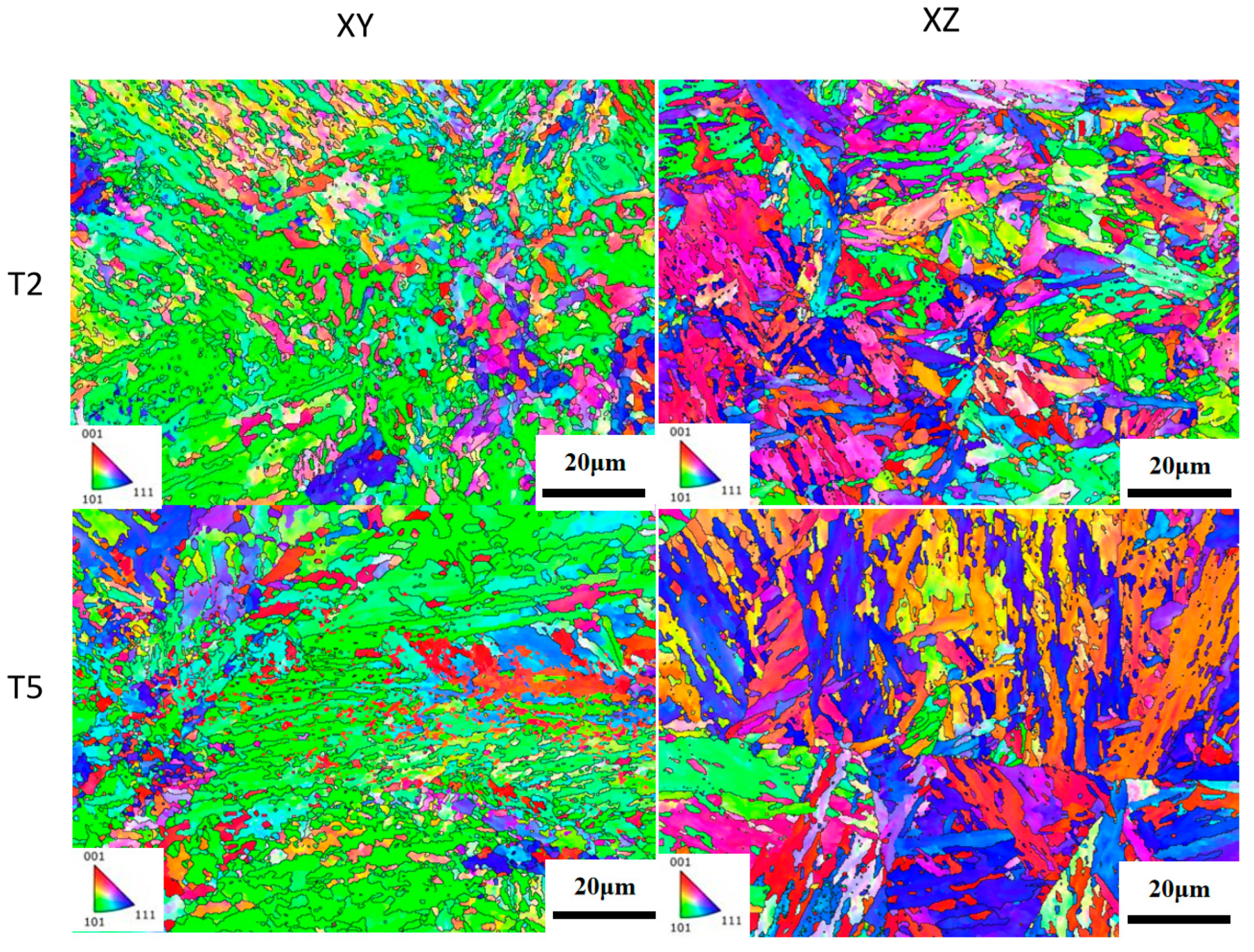

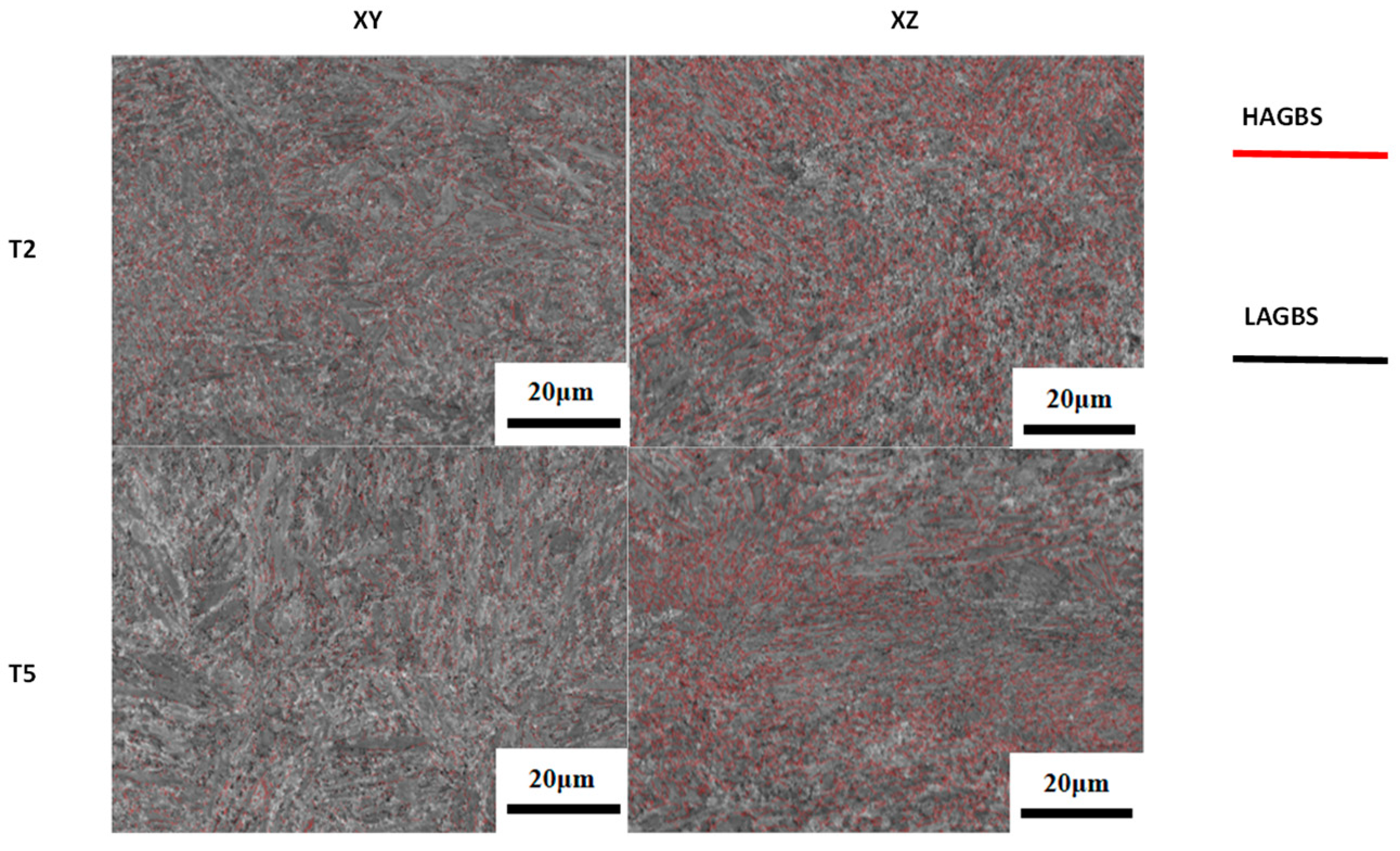

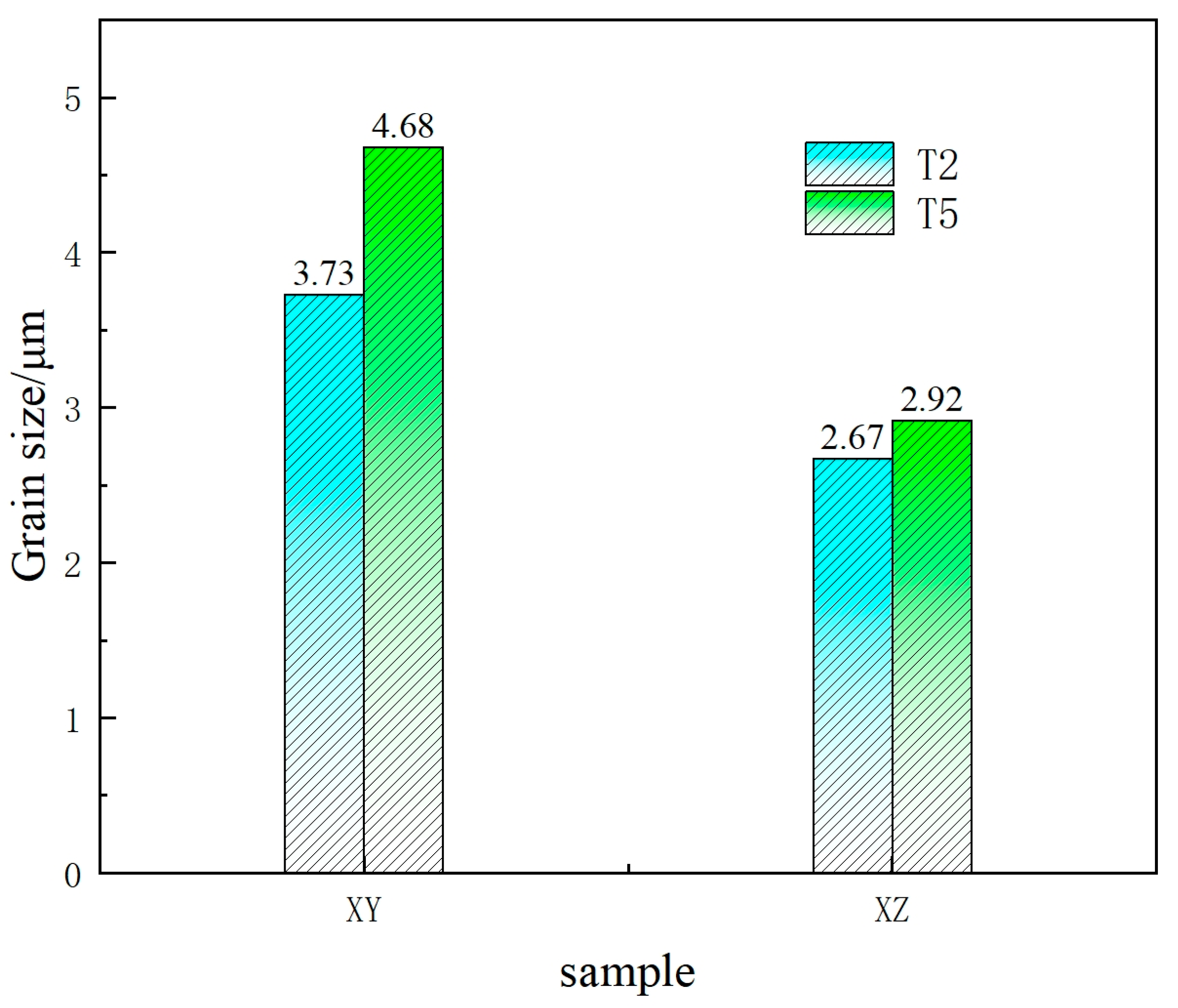

3.2. Microstructure of 22MnCrNiMo Steel Prepared by SLM

3.3. Mechanical Properties of 22MnCrNiMo Steel

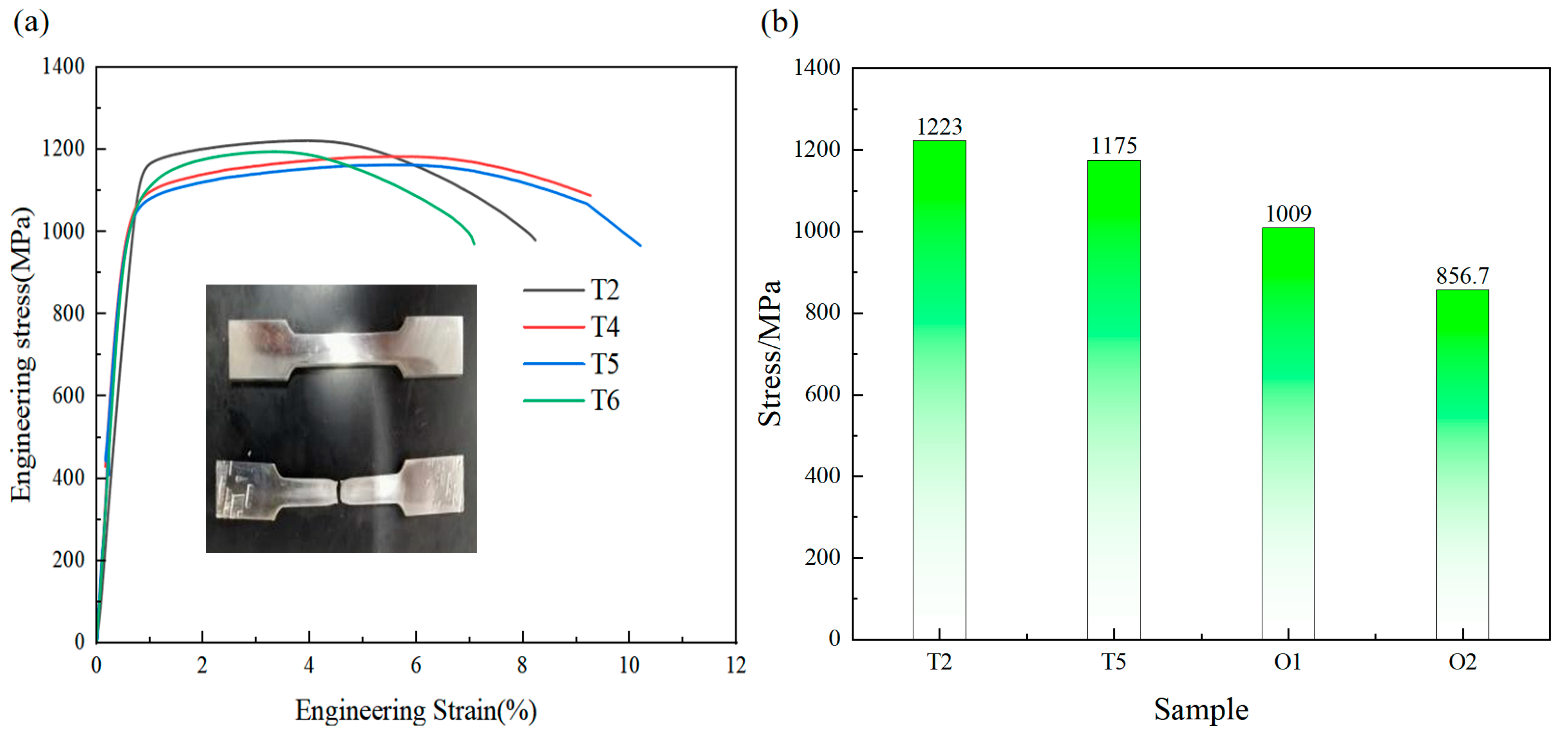

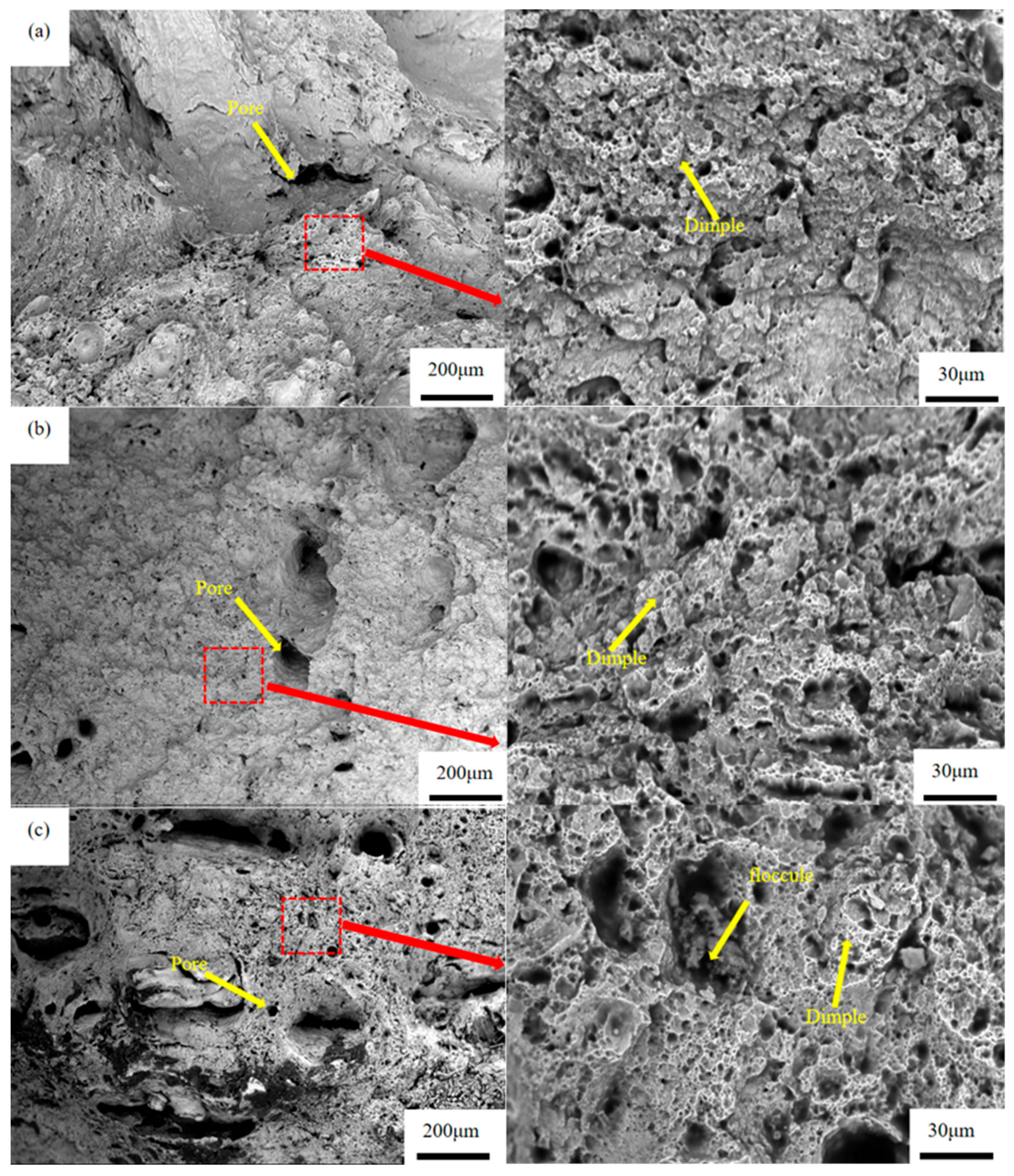

3.3.1. Tensile Properties of Mooring Chain Steel

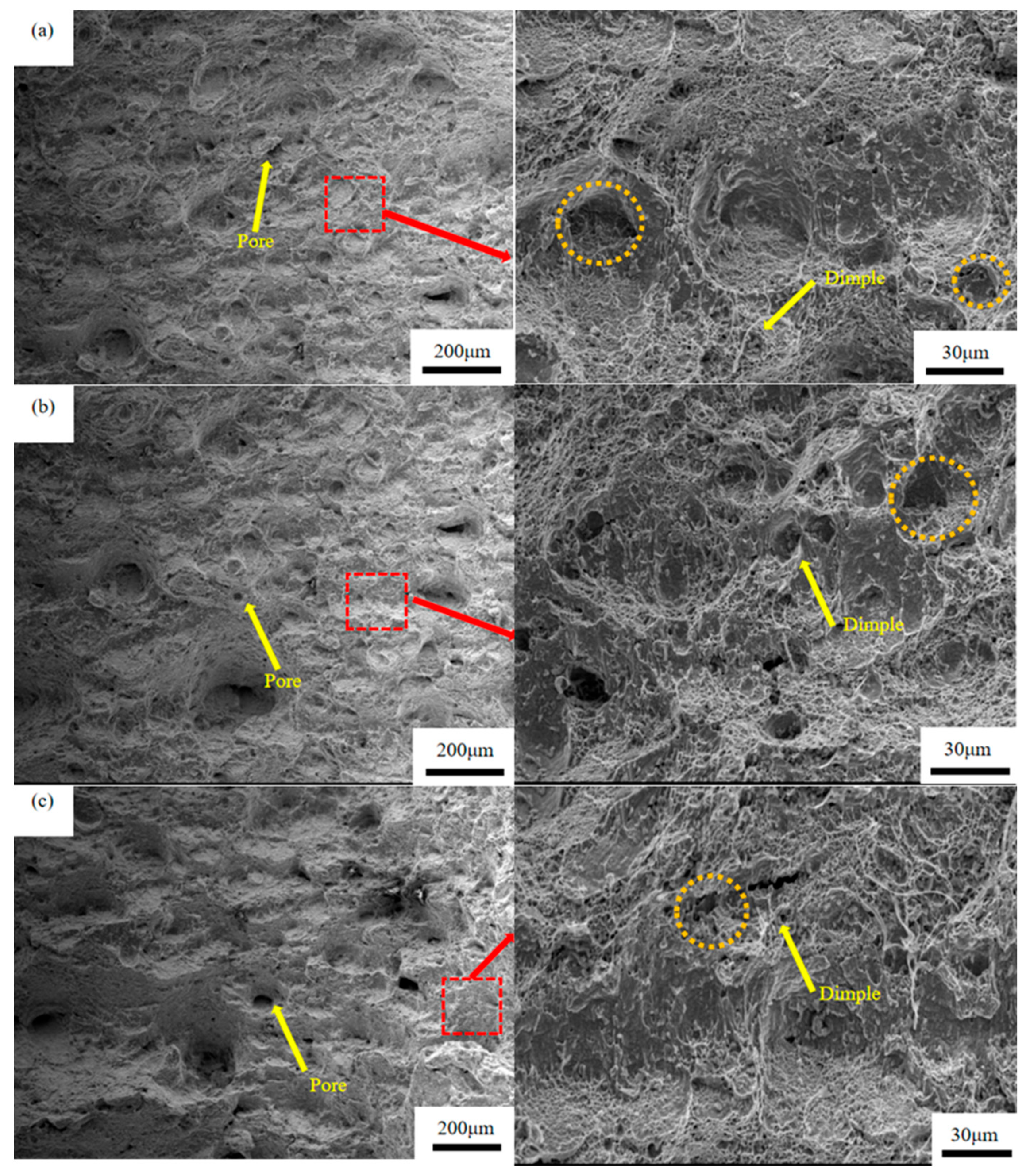

3.3.2. Impact Toughness of Mooring Chain Steel

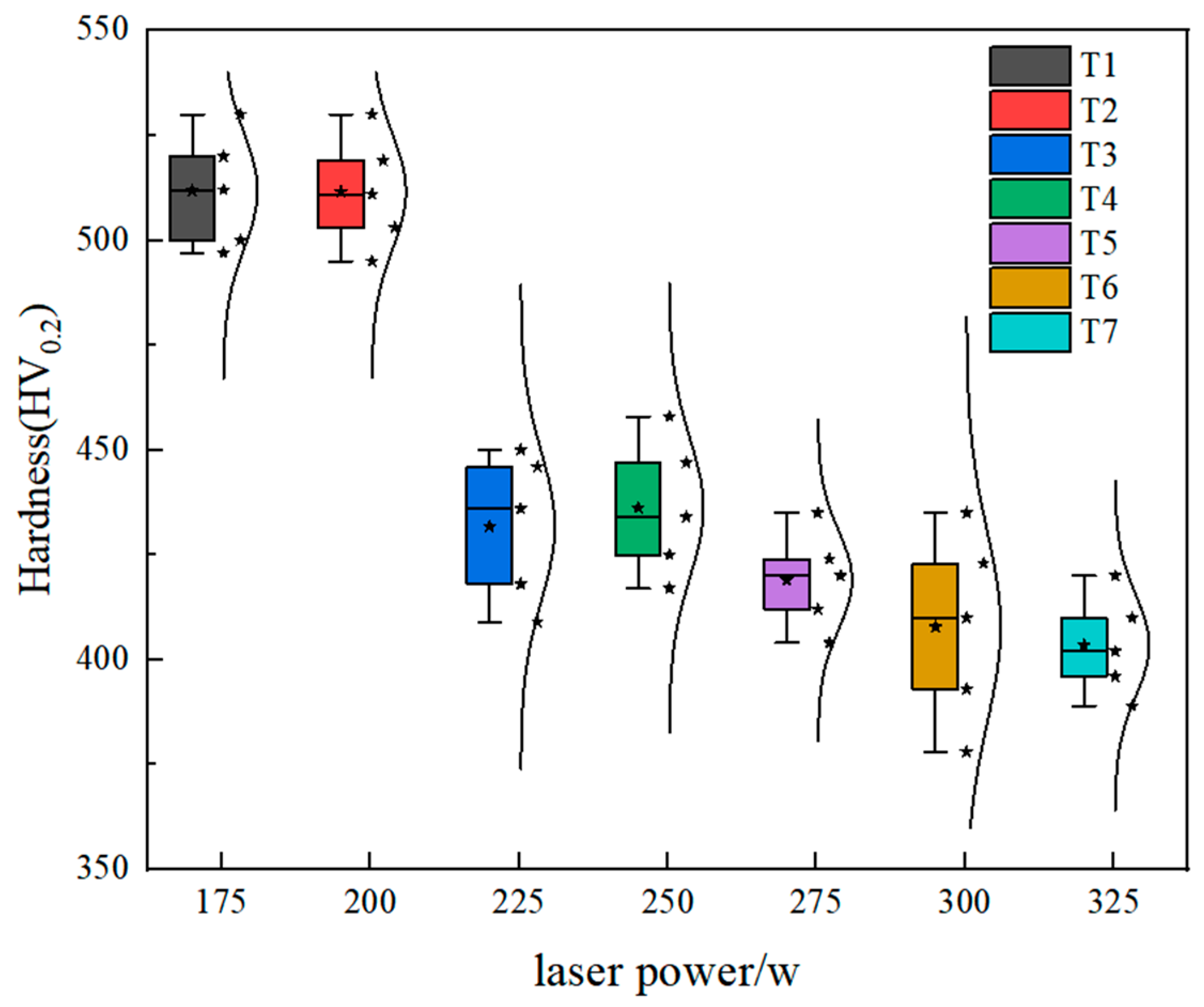

3.3.3. Hardness Properties of Mooring Chain Steel

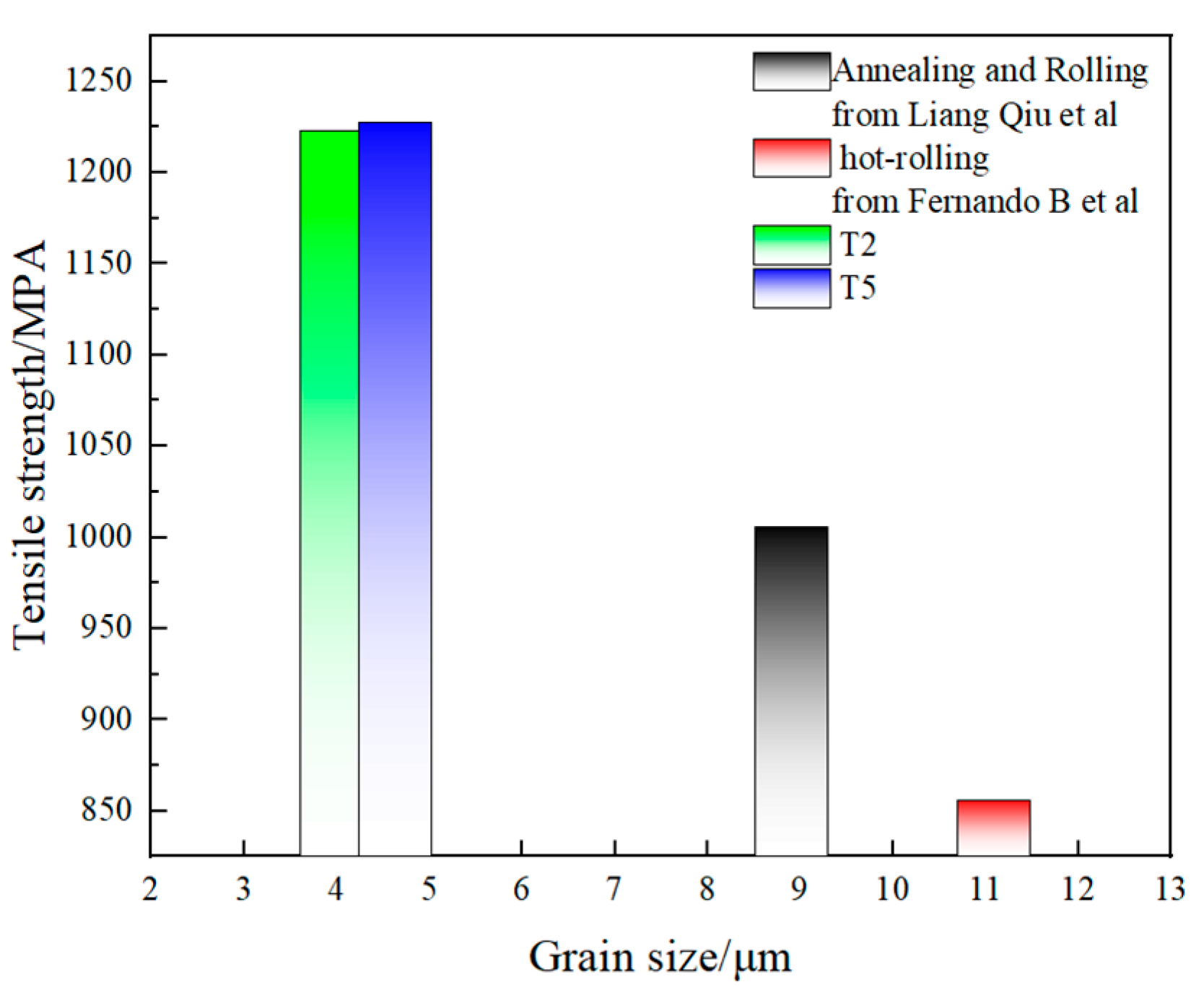

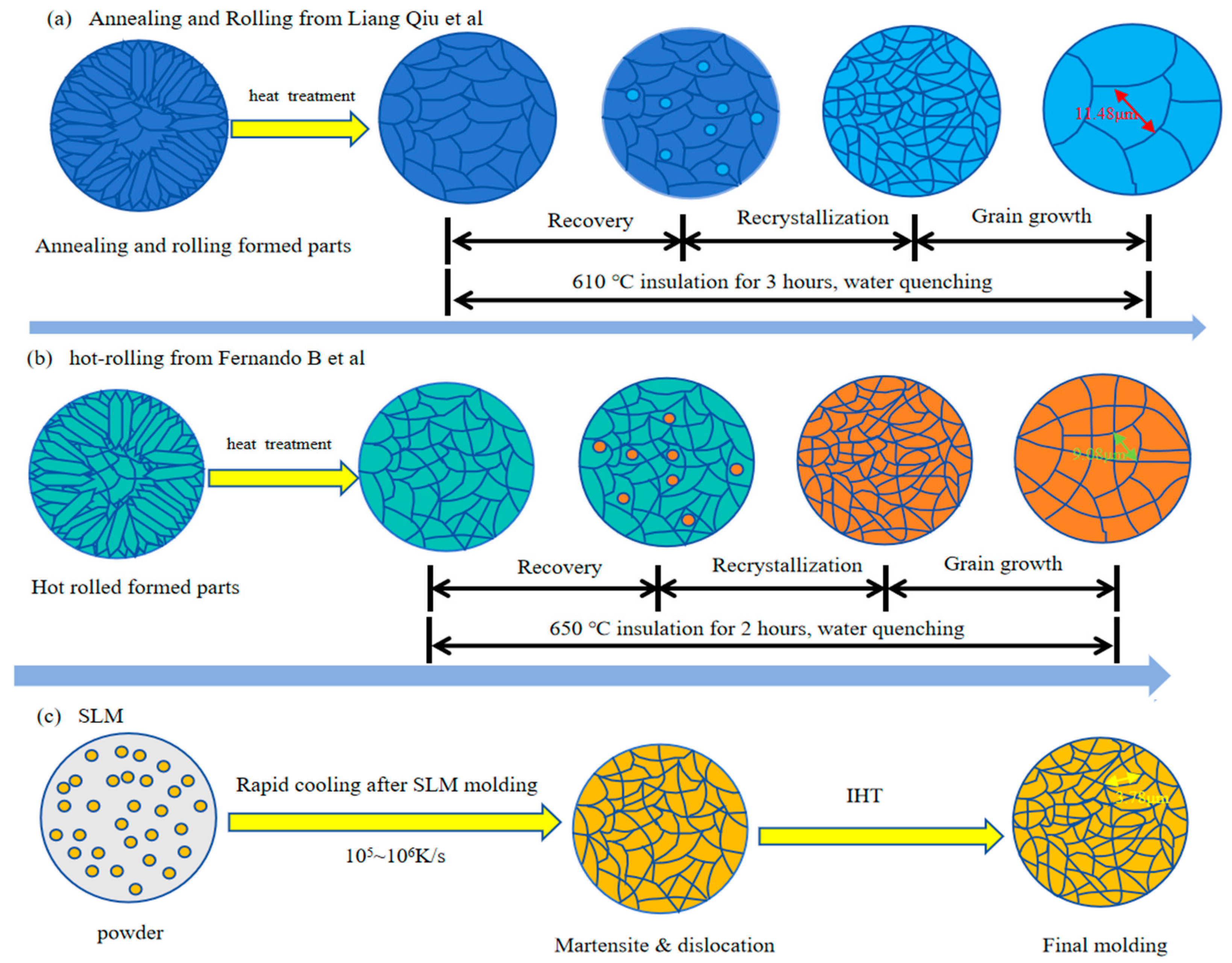

3.4. Grain Refinement Enhancement Mechanism of SLM Forming for Mooring Chain Steel

4. Conclusions

- The microstructure of 22MnCrNiMo steel primarily consists of martensite and lower bainite. As the laser power increases, the area of the heat-affected zone (HAZ) expands, leading to a higher proportion of bainite structures. Optimal results are achieved at a laser power of 200 W, where the grain size becomes fine and the grain orientation is irregular, resulting in a uniform sample microstructure. This uniformity is beneficial for enhancing the mechanical properties of the steel.

- Under the laser parameters of 200 W laser power, a scanning speed of 800 mm/s, a layer thickness of 30 μm, and a scan spacing of 110 μm, the 22MnCrNiMo steel samples exhibit the best comprehensive mechanical properties. Specifically, the microhardness reaches 513.2 HV0.5, the tensile strength is 1223 MPa, the yield strength is 1114 MPa, the elongation is 8.5%, and the impact energy is 127 J.

- The selective laser melting (SLM) process creates micro-melt pools with a high solidification rate, which refines the grains of the mooring chain steel, significantly enhancing the sample’s strength. Compared with traditional manufacturing processes, the strength of 22MnCrNiMo steel produced using the SLM additive manufacturing process is increased by over 20%. This enhanced strength lays the foundation for the production of high-strength and high-toughness mooring chains.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qvale, P.; Nordhagen, H.O.; Ås, S.K.; Skallerud, B.H. Effect of long periods of corrosion on the fatigue lifetime of offshore mooring chain steel. Mar. Struct. 2022, 85, 103236. [Google Scholar] [CrossRef]

- Fernandez, J.; Storesund, W.; Navas, J. Fatigue performance of grade R4 and R5 mooring chains in seawater. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Rio de Janeiro, Brazil, 1–6 July 2012; American Society of Mechanical Engineers: New York, NY, USA, 2014; pp. 1–6. [Google Scholar]

- Ma, K.T.; Luo, Y.; Kwan, T.; Wu, Y. Mooring for floating wind turbines. Mooring Syst. Offshore Struct. 2019, 392, 299–315. [Google Scholar]

- Kang, J.; Sun, L.; Sun, H.; Wu, C. Risk assessment of floating offshore wind turbine based on correlation-FMEA. Ocean. Eng. 2017, 129, 382–388. [Google Scholar] [CrossRef]

- Pham, H.D.; Schoefs, F.; Cartraud, P.; Soulard, T.; Pham, H.H.; Berhault, C. Methodology for modeling and service life monitoring of mooring lines of floating wind turbines. Ocean. Eng. 2019, 193, 106603. [Google Scholar] [CrossRef]

- Gotoh, K.; Murakami, K.; Nakagawa, M.; Utsunomiya, T. Wear performance of the mooring chain used in floating wind turbines. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Rio de Janeiro, Brazil, 1–6 July 2012; American Society of Mechanical Engineers: New York, NY, USA, 2017; pp. 1–6. [Google Scholar]

- Barrera, C.; Battistella, T.; Guanche, R.; Losada, I.J. Mooring system fatigue analysis of a floating offshore wind turbine. Ocean Eng. 2020, 195, 106670. [Google Scholar] [CrossRef]

- Sidhar, H.; Fenske, J.A.; Xu, W.; Baker, D.A.; Jin, H.W.; Neerav, V.; Xin, Y. High Manganese Steel for Mooring Chain Applications. Berg. Huettenmaenn. Monatsh. 2022, 167, 530–533. [Google Scholar] [CrossRef]

- Ankit, S.; Yoo Sang, C. Mooring chain strength tests and ductile failure modeling using micromechanics and phenomenology based failure models. Ocean. Eng. 2020, 195, 106663. [Google Scholar]

- Bergara, A.; Arredondo, A.; Altuzarra, J.; Martínez-Espanola, J.M. Calculation of stress intensity factors in offshore mooring chains. Ocean. Eng. 2020, 214, 107762. [Google Scholar] [CrossRef]

- Wei, M.W.; Chen, S.Y.; Xi, L.Y.; Liang, J.; Liu, C.S. Selective laser melting of 24CrNiMo steel for brake disc: Fabrication efficiency, microstructure evolution, and properties. Laser Technol. 2018, 107, 99–109. [Google Scholar] [CrossRef]

- Guenther, D.; Heymel, B.; Guenther, J.F.; Ederer, I. Continuous 3D-printing for additive manufacturing. Rapid Prototyp. 2014, 20, 320. [Google Scholar] [CrossRef]

- Kong, Z.; Wang, X.; Hu, N.; Jin, Y.; Tao, Q.; Xia, W.; Lin, X.-M.; Vasdravellis, G. Mechanical properties of SLM 316L stainless steel plate before and after exposure to elevated temperature. Constr. Build. Mater. 2024, 444, 137786. [Google Scholar] [CrossRef]

- Chen, M.T.; Gong, Z.; Zhang, T.; Zuo, W.; Zhao, Y.; Zhao, O.; Wang, Z. Mechanical behavior of austenitic stainless steels produced by wire arc additive manufacturing. Thin Walled Struct. 2023, 196, 111455. [Google Scholar] [CrossRef]

- Liverani, E.; Toschi, S.; Ceschini, L.A.; Fortunato, A. Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel. Mater. Process. Technol. 2017, 249, 255–263. [Google Scholar] [CrossRef]

- Marattukalam, J.J.; Karlsson, D.; Pacheco, V.; Beran, P.; Wiklund, U.; Jansson, U.; Sahlberg, M. The effect of laser scanning strategies on texture, mechanical properties and site-specific grain orientation in selective laser melted 316L. Mater. Des. 2020, 193, 108852. [Google Scholar] [CrossRef]

- Zhang, A.; Wu, W.; Wu, M.; Liu, Y.; Zhang, Y.; Wang, Q. Influence of laser power on mechanical properties and pitting corrosion behavior of additively manufactured 316L stainless steel by laser powder bed fusion (L-PBF). Laser Technol. 2024, 176, 110886. [Google Scholar] [CrossRef]

- Qiu, C.; Kindi, M.A.; Aladawi, S.; Hatmi, I.A. A comprehensive study on microstructure and tensile behaviour of a selectively laser melted stainless steel. Sci. Rep. 2018, 8, 7785. [Google Scholar] [CrossRef]

- Montero-Sistiaga, M.L.; Godino-Martinez, M.K.; Boschmans, J.; Kruth, P.; Van Humbeeck, J.; Vanmeensel, K. Microstructure evolution of 316L produced by HP-SLM (high power selective laser melting). Addit. Manuf. 2018, 23, 402–410. [Google Scholar] [CrossRef]

- Wan, Y.C.; Xu, S.Y.; Liu, C.M.; Gao, Y.H.; Jiang, S.N.; Chen, Z.Y. Enhanced strength and corrosion resistance of Mg-Gd-Y-Zr alloy with ultrafine grains. Mater Lett. 2018, 213, 213–224. [Google Scholar] [CrossRef]

- Sun, J.J.; Liu, Y.N.; Zhu, Y.T.; Lian, F.L. Super-strong dislocation-structured high-carbon martensite steel. Sci. Rep. 2017, 7, 6596. [Google Scholar] [CrossRef]

- Zhang, Y.; Fang, Y.; Kim, M.K.; Duan, Z.; Yuan, Q.; Oh, E.; Suhr, J. In-situ TiCxNy nanoparticle reinforced crack-free CoCrFeNi medium-entropy alloy matrix nanocomposites with high strength and ductility via laser powder bed fusion. Compos. Part B-Eng. 2024, 273, 111237. [Google Scholar] [CrossRef]

- Kim, W.R.; Bang, G.B.; Park, J.H.; Lee, T.W.; Lee, B.S.; Yang, S.M.; Kim, G.H.; Lee, K.H.; Kim, G. Microstructural study on a Fe-10Cu alloy fabricated by selective laser melting for defect-free process optimization based on the energy density. J. Mater. Res. Technol. 2020, 9, 12834–12839. [Google Scholar] [CrossRef]

- Li, J.; Qu, H.; Bai, J. Grain boundary engineering during the laser powder bed fusion of TiC/316L stainless steel composites: New mechanism for forming TiC-induced special grain boundaries. Acta. Mater. 2022, 226, 117605. [Google Scholar] [CrossRef]

- King, W.E.; Barth, H.D.; Castillo, V.M.; Gallegos, G.F.; Gibbs, J.W.; Hahn, D.E.; Kamath, C.; Rubenchik, A.M. Observation of keyhole-mode laser melting in laser powder-bed fusion additive manufacturing. J. Mater. Process. Technol. 2014, 214, 2915–2925. [Google Scholar] [CrossRef]

- Bai, S.; Perevoshchikova, N.; Sha, Y.; Wu, X. The effects of selective laser melting process parameters on relative density of the AlSi10Mg parts and suitable procedures of the archimedes method. Appl. Sci. 2019, 9, 583. [Google Scholar] [CrossRef]

- Sun, M.; Chen, S.Y.; Wei, M.W.; Liang, J.; Liu, C.S.; Wang, M. Microstructure and properties of high power-SLM 24CrNiMoY alloy steel at different laser energy density and tempering temperature. Powder Metall 2021, 64, 1–7. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A. Mesoscopic simulation model of selection laser melting of stainless steel power. J. Mater. Res. Technol. 2014, 214, 2627–2636. [Google Scholar] [CrossRef]

- Cui, X.; Zhang, S.; Wang, C.; Zhang, C.H.; Chen, J.; Zhang, J.B. Microstructure and fatigue behavior of a laser additive manufactured 12CrNi2 low alloy steels. Mater. Sci. Eng. A 2020, 772, 138685. [Google Scholar] [CrossRef]

- Zinoviev, A.; Zinovieva, O.; Ploshikhin, V.; Romanova, V.; Balokhonov, R. Evolution of grain structure during laser additive manufacturing. Simulation by a cellular automata method. Mater. Des. 2016, 106, 321–329. [Google Scholar] [CrossRef]

- Liang, Q.; Junru, L.; Pengfei, Z.; Leiying, W.; Guojun, M. Effect of Niobium Microalloying on the Mechanical Properties in Grade R4 Mooring Chain Steel. Metall. Mater. Trans. 2024, 55, 695–705. [Google Scholar]

- Mainier, F.B.; Canto, M.O.; Meiriño, M.J. Characteristics of Grade R4 Steel Manufactured by Ingot Casting and Used in the Production of Offshore Mooring Chains. Trans. Marit. Sci. 2023, 12. [Google Scholar] [CrossRef]

- Augustin, A.; Huilgol, P.; Udupa, K.R.; Bhat, K.U. Effect of current density during electrodeposition on microstructure and hardness of textured Cu coating in the application of antimicrobial Al touch surface. J. Mech. Behav. Biomed. 2016, 63, 352–360. [Google Scholar] [CrossRef] [PubMed]

- AlMangour, B.; Grzesiak, D.; Cheng, J.; Ertas, Y. Thermal behavior of the molten pool, microstructural evolution and tribological performance during selective laser melting of TiC/316L stainless steel nanocomposites: Experimental and simulation methods. J. Mater. Res. Technol. 2018, 257, 288–301. [Google Scholar] [CrossRef]

- Sang Gun, L.; Massoud, K.; Jungho, L. Role of quenching method on cooling rate and microstructure of steels: Variations in coolant and its flow arrangement. Int. J. Heat Mass Transf. 2022, 189, 122702. [Google Scholar]

- Chaolin, T.; Qian, L.; Xiling, Y.; Lequn, C.; Jinlong, S.; Fern Lan, N.; Yuchan, L.; Tao, Y.; Youxiang, C.; Chain, T.L.; et al. Machine Learning Customized Novel Material for Energy-Efficient 4D Printing. Adv. Sci. 2023, 10, 2206607. [Google Scholar]

| Element | C | Si | Mn | S | P | Cr | Mo | Ni | Nb | Cu | Al | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Actual composition | 0.229 | 0.236 | 1.396 | 0.001 | 0.003 | 0.946 | 0.390 | 0.815 | 0.001 | 0.026 | 0.028 | bal. * |

| R4 standard ingredient | 0.18~0.28 | 0.15~0.30 | 1.20~1.75 | ≤0.025 | ≤0.025 | 0.40~1.30 | 0.20~0.60 | 0.40~1.40 | ≤0.06 | ≤0.20 | 0.020~0.05 | bal. * |

| Serial Number | Laser Power/W | Scanning Speed/mm·s−1 | Scanning Spacing/μm | Layer Thickness/μm | Energy Density/J·mm−3 |

|---|---|---|---|---|---|

| T1 | 175 | 800 | 110 | 30 | 66.3 |

| T2 | 200 | 75.8 | |||

| T3 | 225 | 85.2 | |||

| T4 | 250 | 94.7 | |||

| T5 | 275 | 104.2 | |||

| T6 | 300 | 113.6 | |||

| T7 | 325 | 123.1 | |||

| T8 | 175 | 1000 | 53.0 | ||

| T9 | 200 | 60.6 | |||

| T10 | 225 | 68.2 | |||

| T11 | 250 | 75.8 | |||

| T12 | 275 | 83.3 | |||

| T13 | 300 | 90.9 | |||

| T14 | 325 | 98.5 | |||

| T15 | 175 | 1200 | 44.2 | ||

| T16 | 200 | 50.5 | |||

| T17 | 225 | 56.8 | |||

| T18 | 250 | 63.1 | |||

| T19 | 275 | 69.4 | |||

| T20 | 300 | 75.8 | |||

| T21 | 325 | 82.1 |

| Sample | Laser Power/W | Tensile Strength/MPa | Yield Strength/MPa | Elongation/% |

|---|---|---|---|---|

| T1 | 175 | 1281 | 1121 | 6.7 |

| T2 | 200 | 1223 | 1114 | 8.5 |

| T3 | 225 | 1195 | 1089 | 8.9 |

| T4 | 250 | 1184 | 1035 | 9.2 |

| T5 | 275 | 1175 | 1010 | 10.2 |

| T6 | 300 | 1190 | 1046 | 7.2 |

| T7 | 325 | 1194 | 1051 | 6.9 |

| S1 | standard | >860 MPa | >580 MPa | >12 |

| O1 | Liang et al. [31] | 1009 | 929.5 | 18 |

| O2 | Mainier et al. [32] | 857 | 937 | 16.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, X.; Li, X.; Hu, C.; Zhao, D.; Liu, Y.; Wang, S. Microstructure and Properties of Mooring Chain Steel Prepared by Selective Laser Melting. Metals 2025, 15, 541. https://doi.org/10.3390/met15050541

Cui X, Li X, Hu C, Zhao D, Liu Y, Wang S. Microstructure and Properties of Mooring Chain Steel Prepared by Selective Laser Melting. Metals. 2025; 15(5):541. https://doi.org/10.3390/met15050541

Chicago/Turabian StyleCui, Xiaojie, Xiaoxin Li, Changqing Hu, Dingguo Zhao, Yan Liu, and Shuhuan Wang. 2025. "Microstructure and Properties of Mooring Chain Steel Prepared by Selective Laser Melting" Metals 15, no. 5: 541. https://doi.org/10.3390/met15050541

APA StyleCui, X., Li, X., Hu, C., Zhao, D., Liu, Y., & Wang, S. (2025). Microstructure and Properties of Mooring Chain Steel Prepared by Selective Laser Melting. Metals, 15(5), 541. https://doi.org/10.3390/met15050541