Microstructure and Properties of 6061 Aluminum Alloy by Additive Friction Stir Deposition

Abstract

1. Introduction

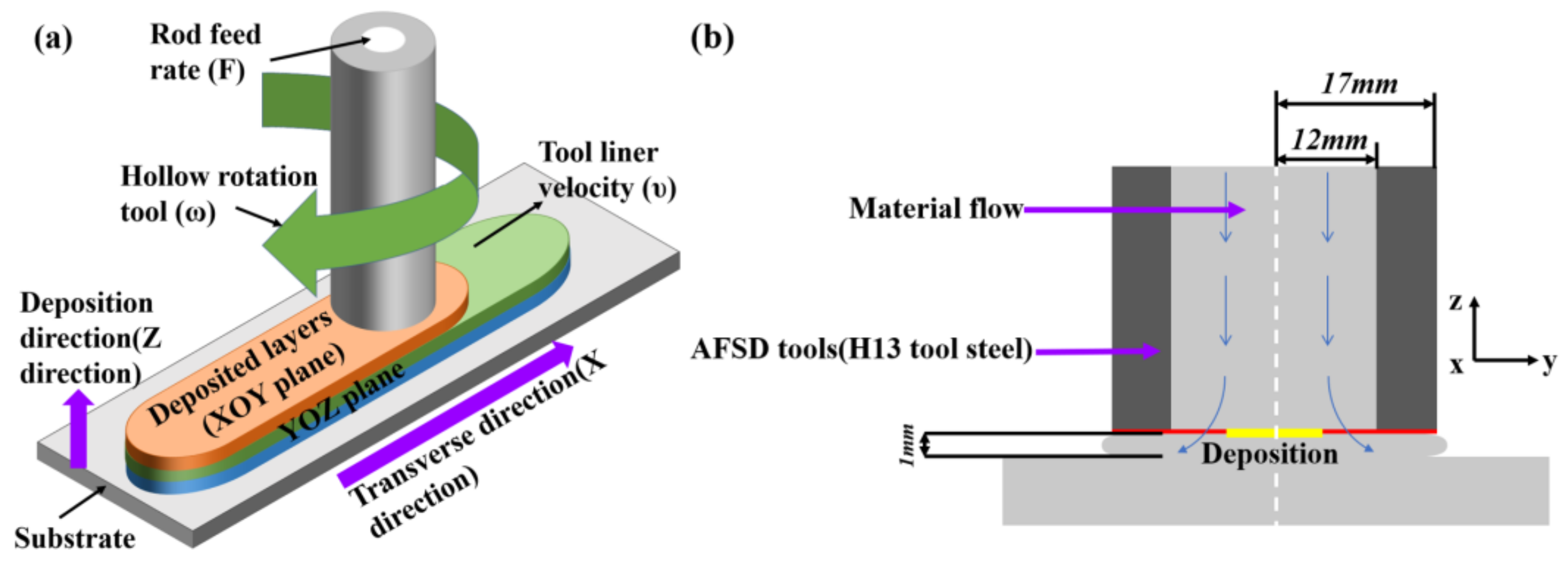

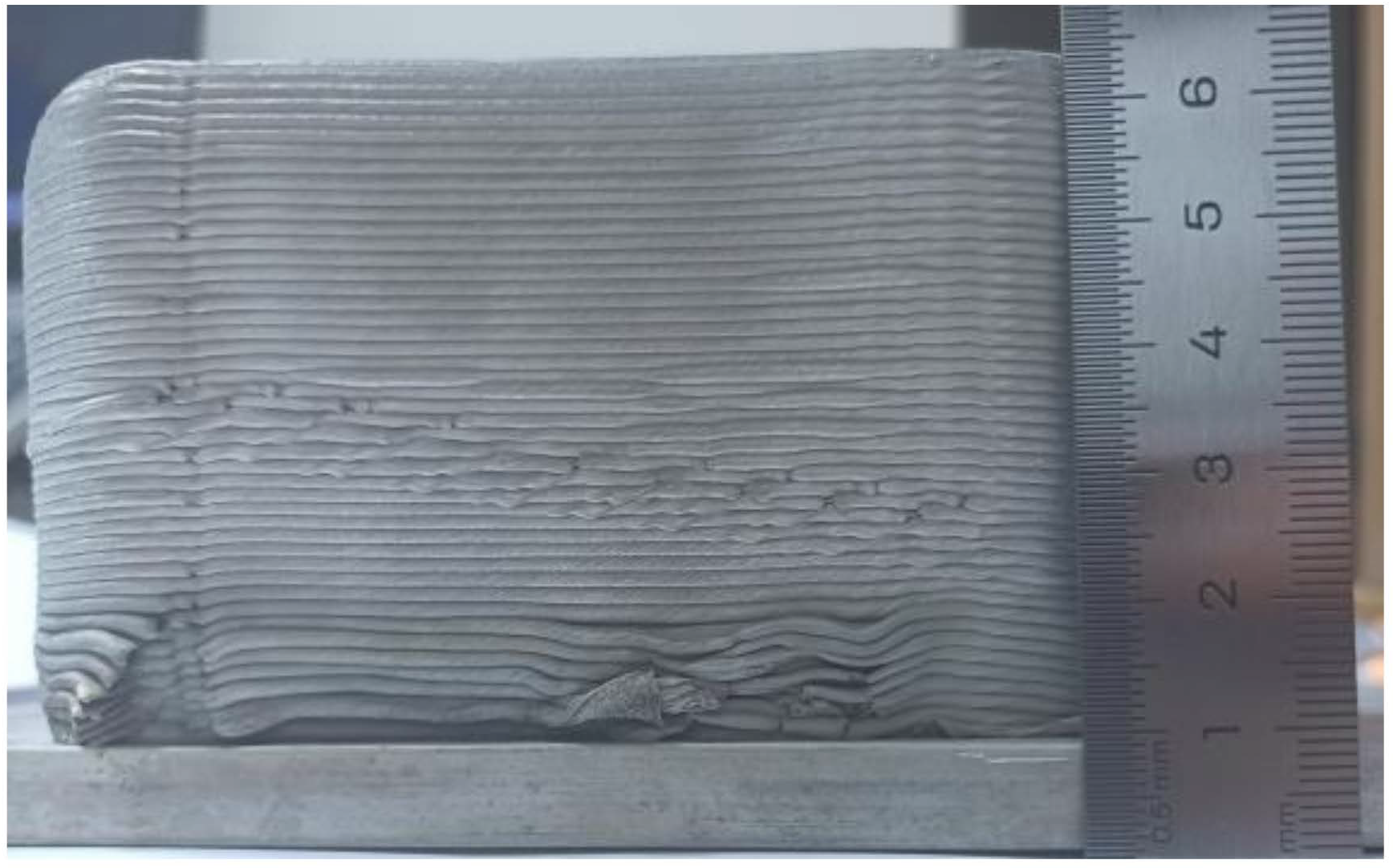

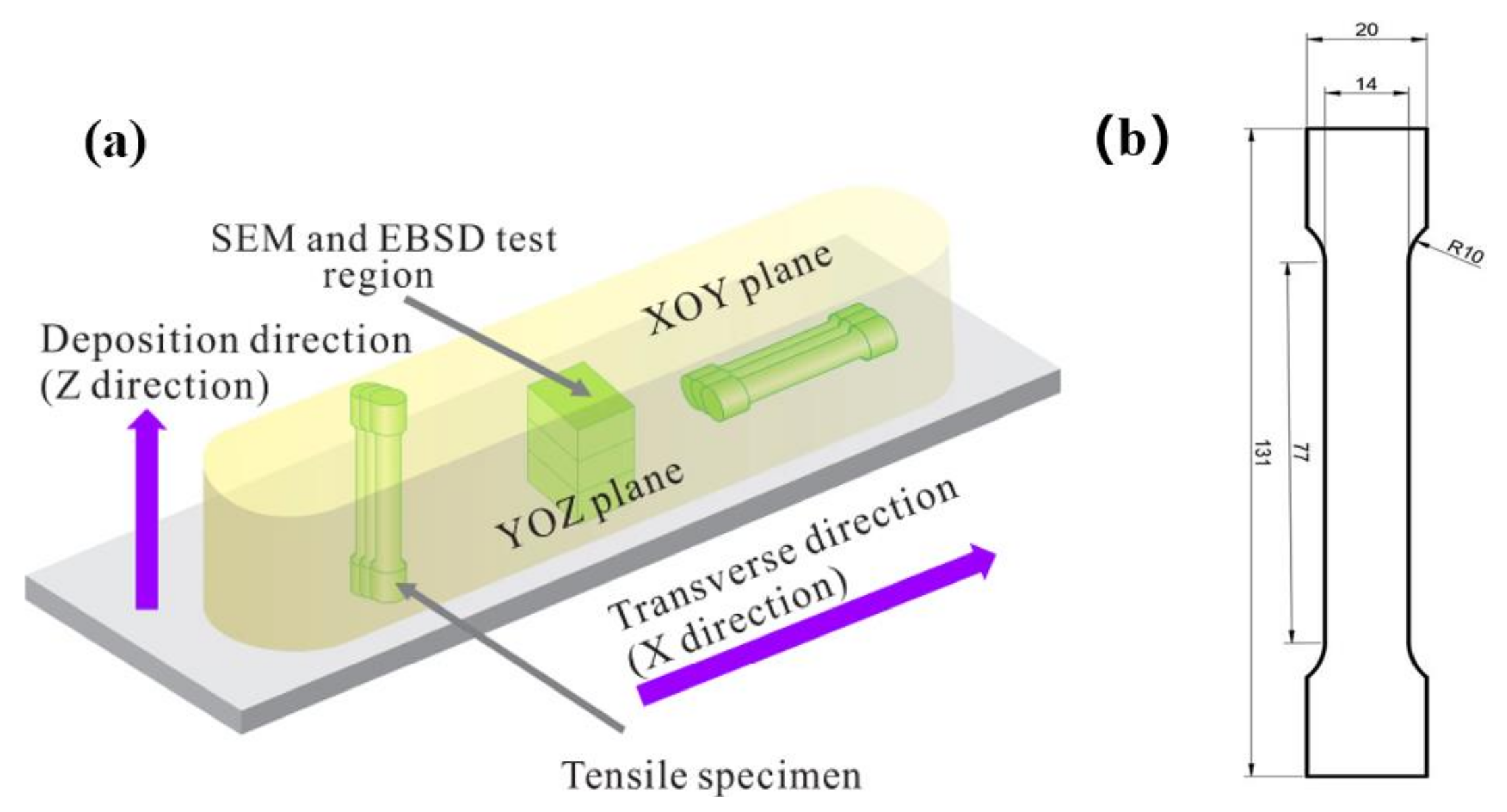

2. Materials and Methods

3. Results and Discussion

3.1. XRD Phase Analysis of Additive Samples

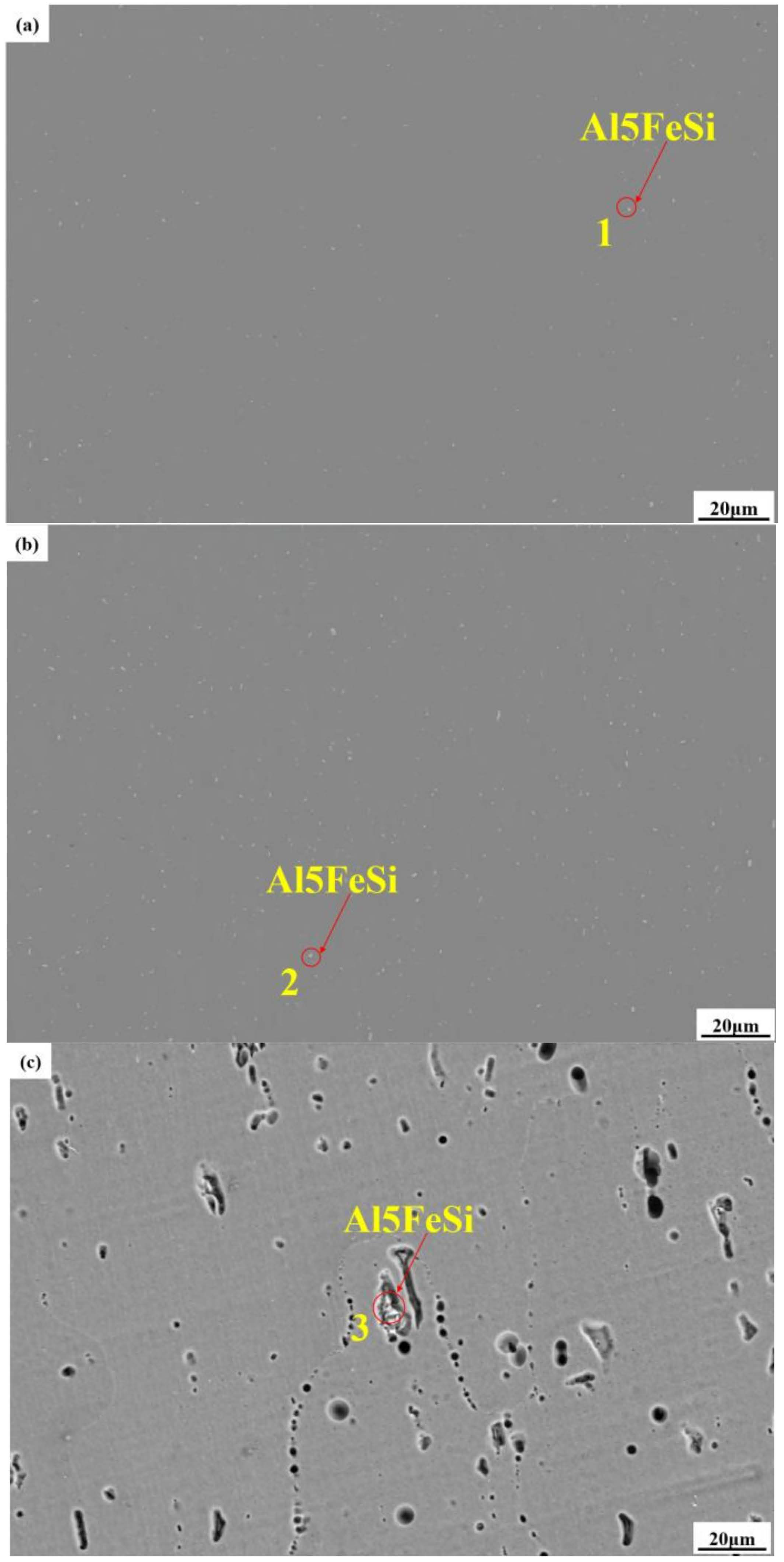

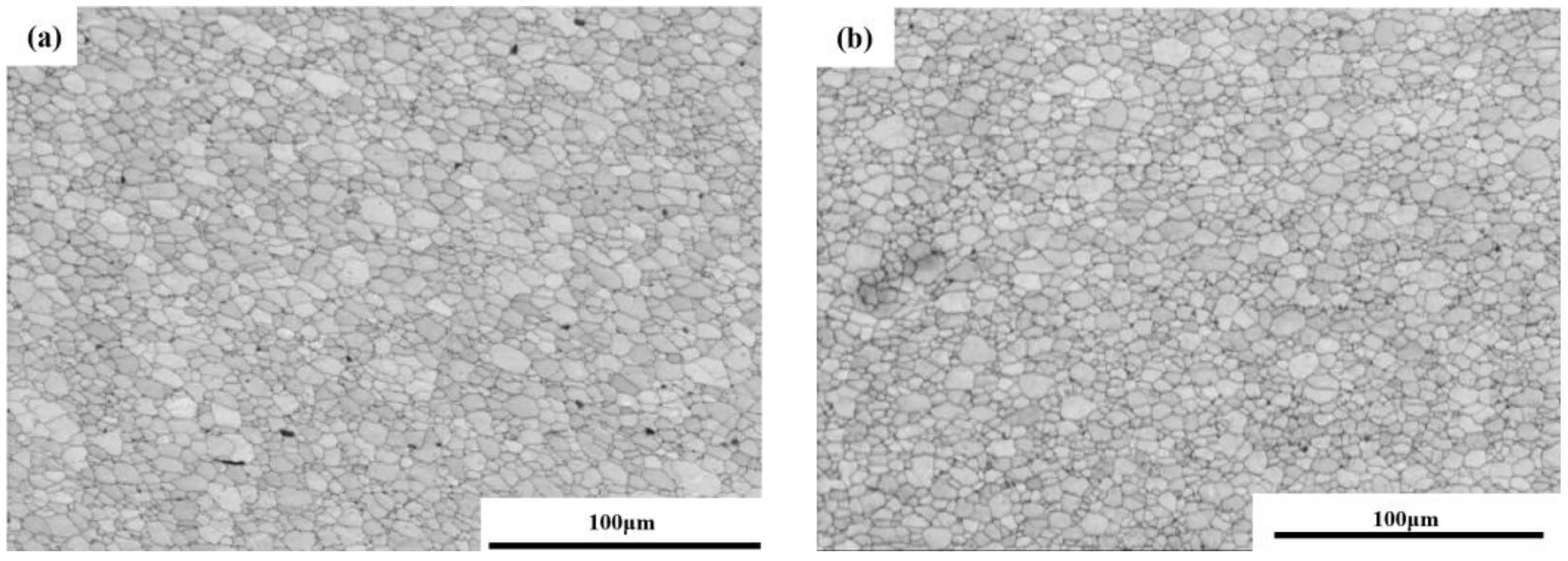

3.2. Microscopic Morphology of Samples in Different Construction Directions

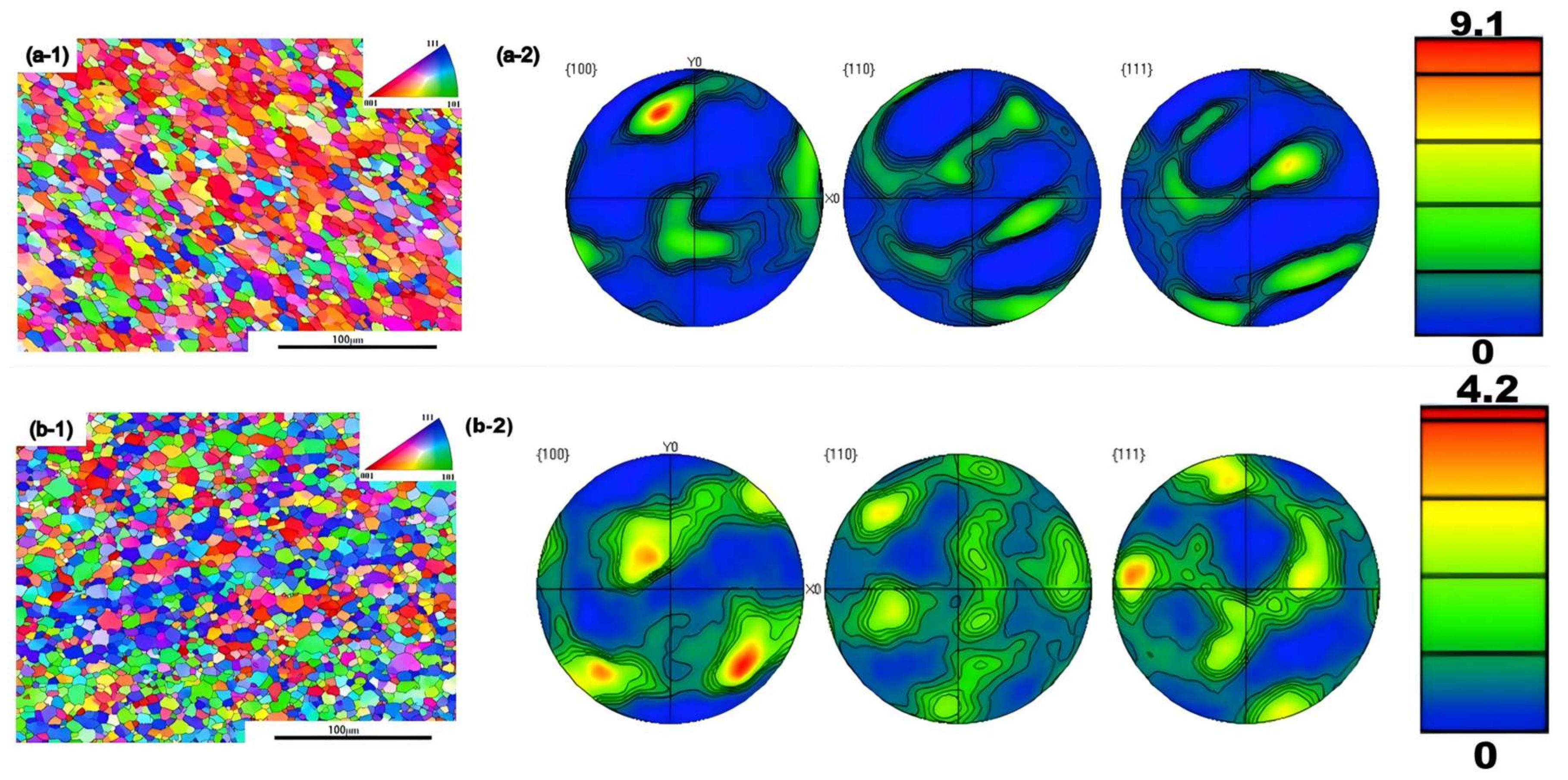

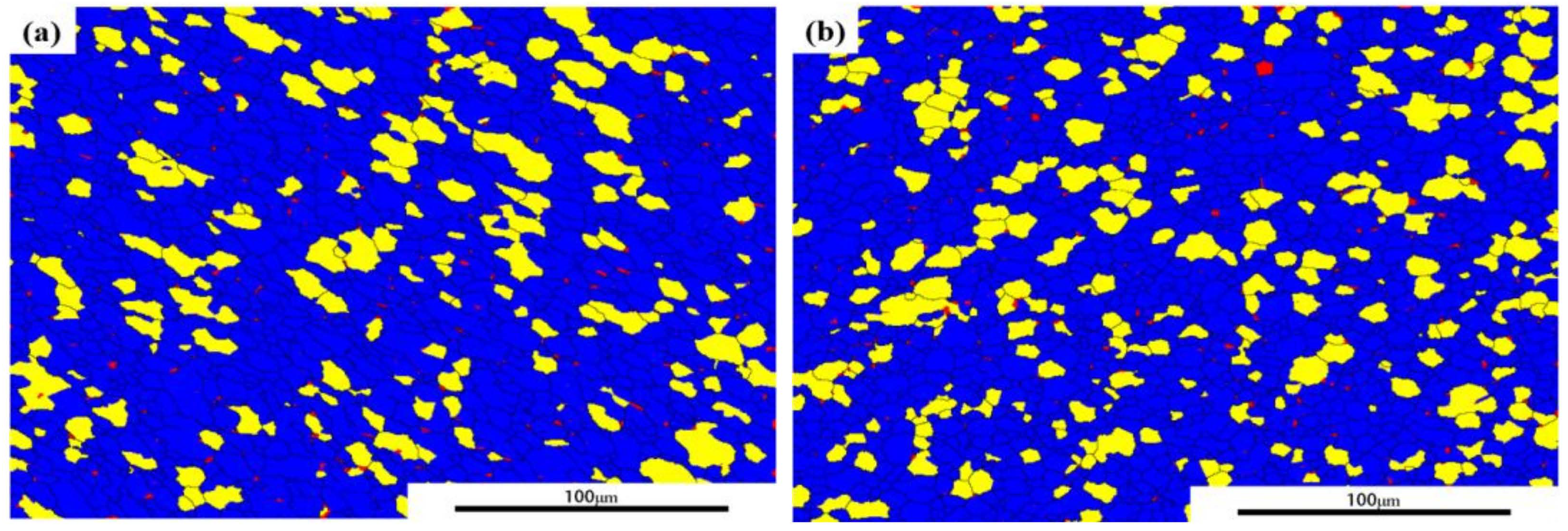

3.3. EBSD Analysis

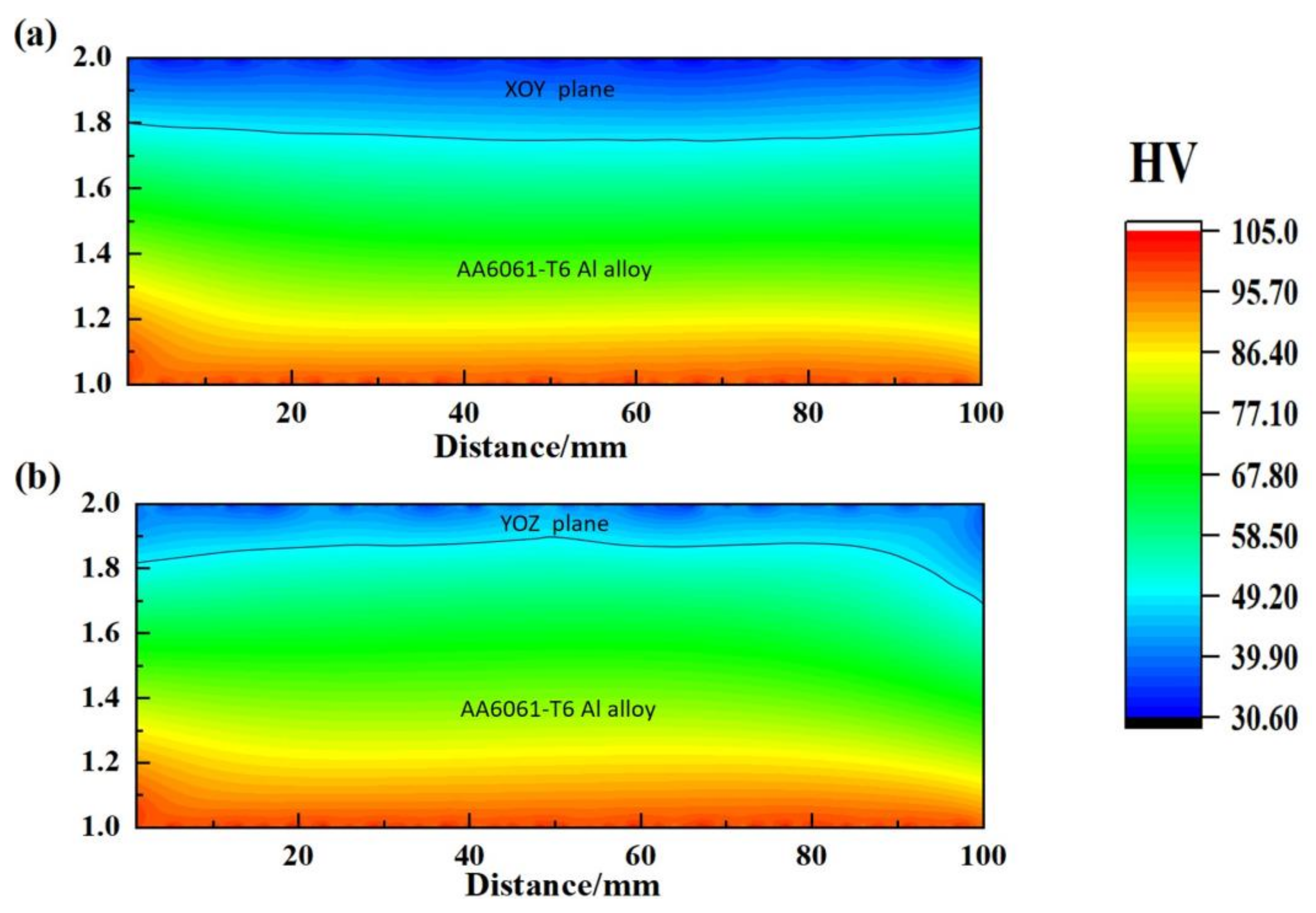

3.4. Hardness Analysis

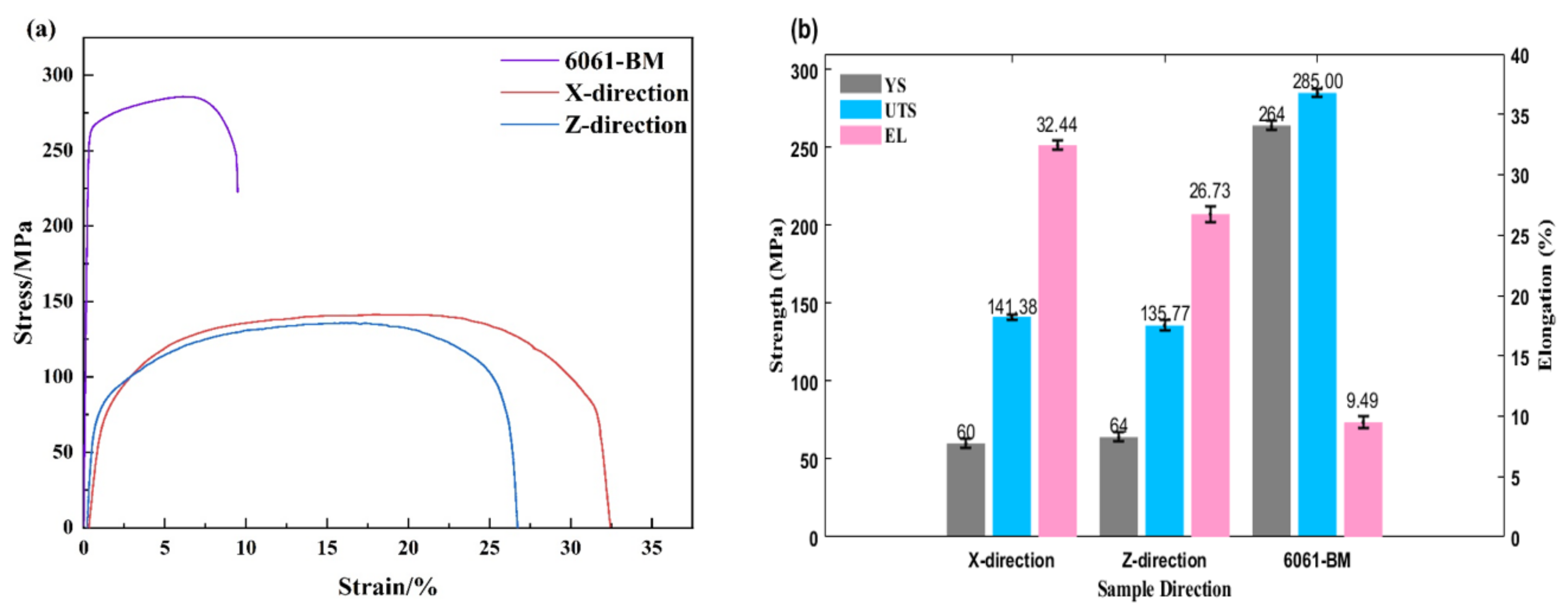

3.5. Tensile Performance

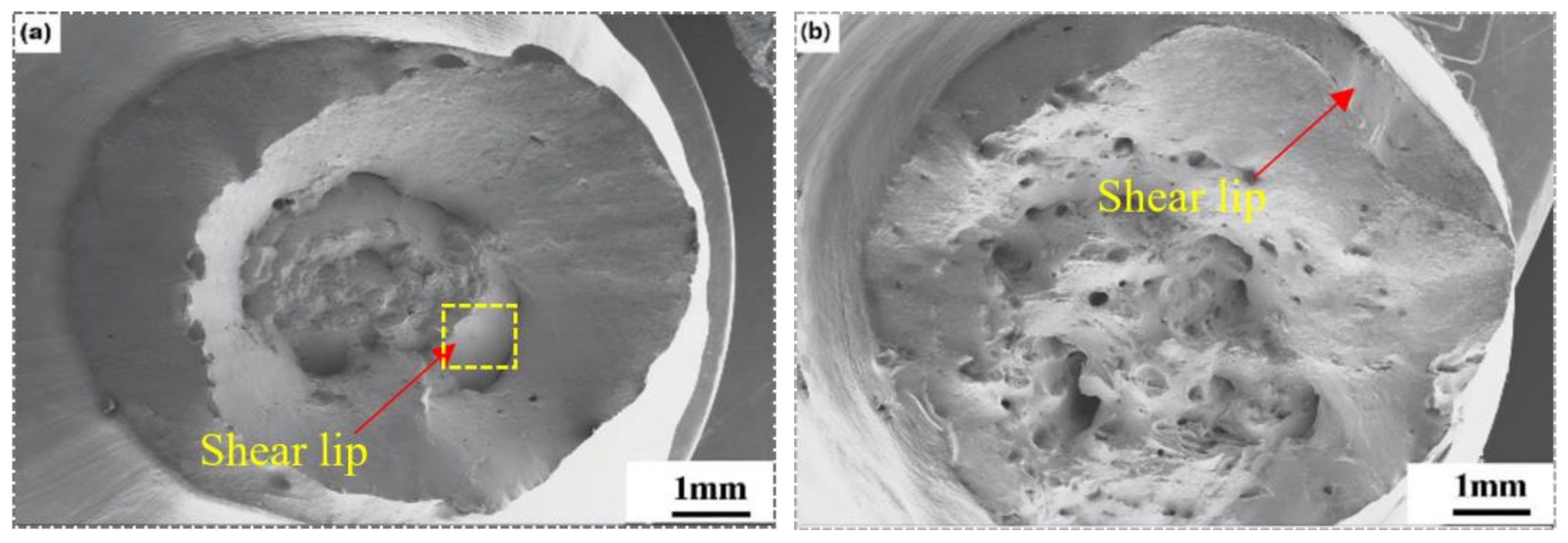

3.6. Fracture Mode

4. Conclusions

- Variation in coherent diffraction domain size by AFSD: X-ray diffraction revealed that the coherent diffraction domain size in the AA6061-T6 substrate (60 nm) decreases to approximately 25 nm in the transverse (XOY) specimens and to 30 nm in the deposition (YOZ) specimens.

- Directional microstructural variation: SEM–EDS and EBSD analyses showed that the X-direction specimens feature uniformly dispersed Al5FeSi particles and a strong {100} <001> cube texture (peak MRD = 9.1), whereas the Z direction specimens exhibit aggregated secondary phases and a weaker preferred orientation (peak MRD = 4.2), reflecting the influence of shear deformation on texture development.

- Hardness distribution: Vickers microhardness mapping demonstrated that the AFSD-deposited regions possess lower hardness than the AA6061-T6 substrate, with the XOY plane exhibiting slightly higher values than the YOZ plane due to differences in dynamic recrystallization and thermal cycling effects, which influenced grain dimensions in the X and Z directions.

- Mechanical performance and anisotropy: Tensile testing showed that, relative to the substrate’s high strength (285 MPa) and low elongation (9.49%), AFSD-deposited material displays reduced tensile strength but markedly improved ductility (elongation of 32.44% in X direction and 26.73% in Z direction), with the X-direction specimens achieving marginally higher ultimate strength than Z-direction specimens owing to dynamic recrystallization and more uniform material flow. The YS in the Z direction is slightly higher than in the X direction (64 MPa vs. 60 MPa); microstructural analysis shows that the X direction undergoes more extensive dynamic recrystallization—sustained frictional heating and plastic deformation produce equiaxed grains, enhancing ductility at the expense of yield strength.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gao, Q.W.; Zhao, J.; Shu, F.Y.; Lyu, C.C.; Qi, B.L.; Yu, Z.S. Research progress in aluminum alloy additive manufacturing. J. Mater. Eng. 2019, 47, 32–42. [Google Scholar] [CrossRef]

- Palanivel, S.; Mishra, R.S. Building without melting: A short review of friction-based additive manufacturing techniques. Int. J. Addit. Subtractive Mater. Manuf. 2017, 1, 82–103. [Google Scholar] [CrossRef]

- Labonnote, N.; Rønnquist, A.; Manum, B.; Rüther, P. Additive construction: State-of-the-art, challenges and opportunities. Autom. Constr. 2016, 72, 347–366. [Google Scholar] [CrossRef]

- Attaran, M. The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Thomas, D. Costs, benefits, and adoption of additive manufacturing: A supply chain perspective. Int. J. Adv. Manuf. Technol. 2016, 85, 1857–1876. [Google Scholar] [CrossRef]

- Chen, G.; Wu, K.; Sun, Y.; Jia, H.; Zhu, Z.; Hu, F. Research progress in additive friction stir deposition. J. Mater. Eng. 2023, 51, 52–63. [Google Scholar] [CrossRef]

- Wang, H.M. Materials’ fundamental issues of laser additive manufacturing for high-performance large metallic components. Acta Aeronaut. Et Astronaut. Sin. 2014, 35, 2690–2698. [Google Scholar]

- Shi, L.; Li, Y.; Xiao, Y.; Wu, C.; Liu, H. Research progress of metal solid phase additive manufacturing based on friction stir. J. Mater. Eng. 2022, 50, 1–14. [Google Scholar] [CrossRef]

- Ghadimi, H.; Ding, H.; Emanet, S.; Talachian, M.; Cox, C.; Eller, M.; Guo, S. Hardness Distribution of Al2050 Parts Fabricated Using Additive Friction Stir Deposition. Materials 2023, 16, 1278. [Google Scholar] [CrossRef]

- Patil, S.M.; Krishna, K.M.; Sharma, S.; Joshi, S.S.; Radhakrishnan, M.; Banerjee, R.; Dahotre, N.B. Thermo-mechanical process variables driven microstructure evolution during additive friction stir deposition of IN625. Addit. Manuf. 2024, 80, 103958. [Google Scholar] [CrossRef]

- Li, W.Y.; Cao, C.C.; Yang, X.W.; Xu, Y.X. Cold spraying hybrid processing technology and its application. J. Mater. Eng. 2019, 47, 53–63. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Kumar, N.; Dixit, A.R. Friction stir additive manufacturing—An innovative tool to enhance mechanical and microstructural properties. Mater. Sci. Eng. B 2021, 263, 114832. [Google Scholar] [CrossRef]

- Gopan, V.; Wins, K.L.D.; Surendran, A. Innovative potential of additive friction stir deposition among current laser based metal additive manufacturing processes: A review. CIRP J. Manuf. Sci. Technol. 2021, 32, 228–248. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Gerlich, A. Potentials and strategies of solid-state additive friction-stir manufacturing technology: A critical review. J. Manuf. Process. 2018, 36, 77–92. [Google Scholar] [CrossRef]

- Yu, H.Z.; Mishra, R.S. Additive friction stir deposition: A deformation processing route to metal additive manufacturing. Mater. Res. Lett. 2020, 9, 71–83. [Google Scholar] [CrossRef]

- Shen, Y.Z.; Zhou, Z.X.; Lv, W.C.; Guo, X.; Chen, X.; Wang, X. Research Progress on Solid-State Additive Friction Stir Deposition Manufacturing Technology. J. Nanjing Univ. Aeronaut. Astronaut. 2024, 56, 1–16. [Google Scholar] [CrossRef]

- Perry, M.E.; Griffiths, R.J.; Garcia, D.; Sietins, J.M.; Zhu, Y.; Yu, H.Z. Morphological and microstructural investigation of the non-planar interface formed in solid-state metal additive manufacturing by additive friction stir deposition. Addit. Manuf. 2020, 35, 101293. [Google Scholar] [CrossRef]

- Phillips, B.; Avery, D.; Liu, T.; Rodriguez, O.; Mason, C.; Jordon, J.; Brewer, L.; Allison, P. Microstructure-deformation relationship of additive friction stir-deposition Al–Mg–Si. Materialia 2019, 7, 100387. [Google Scholar] [CrossRef]

- Phillips, B.J.; Williamson, C.J.; Kinser, R.P.; Jordon, J.B.; Doherty, K.J.; Allison, P.G. Microstructural and Mechanical Characterization of Additive Friction Stir-Deposition of Aluminum Alloy 5083 Effect of Lubrication on Material Anisotropy. Materials 2021, 14, 6732. [Google Scholar] [CrossRef]

- Rivera, O.; Allison, P.; Brewer, L.; Rodriguez, O.; Jordon, J.; Liu, T.; Whittington, W.; Martens, R.; McClelland, Z.; Mason, C.; et al. Influence of texture and grain refinement on the mechanical behavior of AA2219 fabricated by high shear solid state material deposition. Mater. Sci. Eng. A 2018, 724, 547–558. [Google Scholar] [CrossRef]

- Lyu, W.; Shen, Y.; Huang, C.; Liu, F.; Wang, X.; Zhou, Z.; Chen, X.; Xia, Y.; Guo, X. Relationship between grain structure evolution and tensile anisotropy in Al-Zn-Mg-Cu cylindrical part formed by additive friction stir deposition. Mater. Sci. Eng. A 2024, 918, 1. [Google Scholar] [CrossRef]

- ASTM E384-17; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM E8/E8M-22; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2022.

- Zeng, C.; Ghadimi, H.; Ding, H.; Nemati, S.; Garbie, A.; Raush, J.; Guo, S. Microstructure Evolution of Al6061 Alloy Made by Additive Friction Stir Deposition. Materials 2022, 15, 3676. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.; Wang, R.; Wang, L.; Liu, M.; Li, S. Effect of Rotational Shear and Heat Input on the Microstructure and Mechanical Properties of Large-Diameter 6061 Aluminium Alloy Additive Friction Stir Deposition. Crystals 2024, 14, 581. [Google Scholar] [CrossRef]

- Chen, L.; Li, Y.; Lu, L.; Yang, Z.; Ren, X.; Zhang, X. The effect of heat treatment on the microstructure and mechanical properties of multilayer AA6061 alloy fabricated by additive friction stir deposition. Mater. Today Commun. 2024, 38, 108078. [Google Scholar] [CrossRef]

- Sridharan, N.; Gussev, M.; Seibert, R.; Parish, C.; Norfolk, M.; Terrani, K.; Babu, S.S. Rationalization of anisotropic mechanical properties of Al-6061 fabricated using ultrasonic additive manufacturing. Acta Mater. 2016, 117, 228–237. [Google Scholar] [CrossRef]

- Zhu, N.; Avery, D.Z.; Chen, Y.; An, K.; Jordon, J.B.; Allison, P.G.; Brewer, L.N. Residual Stress Distributions in AA6061 Material Produced by Additive Friction Stir Deposition. J. Mater. Eng. Perform. 2023, 32, 5535–5544. [Google Scholar] [CrossRef]

- Wells, M.C. Mechanical and Physical Properties in Additive Friction Stir Deposited Aluminum. Master’s Thesis, Virginia Tech, Blacksburg, VA, USA, 2022. Available online: http://hdl.handle.net/10919/111285 (accessed on 1 March 2025).

- Kinser, R.; Zhu, N.; Williams, M.; Rushing, T.; Doherty, K.; Allison, P.; Jordon, J. Effects on microstructure and mechanical properties of aluminum alloy 6061 processed via underwater additive friction stir deposition. J. Manuf. Process. 2025, 134, 932–942. [Google Scholar] [CrossRef]

- Kalinenko, A.; Kim, K.; Vysotskiy, I.; Zuiko, I.; Malopheyev, S.; Mironov, S.; Kaibyshev, R. Microstructure-strength relationship in friction-stir welded 6061-T6 aluminum alloy. Mater. Sci. Eng. A 2020, 793, 139858. [Google Scholar] [CrossRef]

- Khalfallah, A.; Azzeddine, H.; Baudin, T.; Brisset, F.; Huang, Y.; Langdon, T.G. Texture and microstructural evolution in an Al-6061 alloy processed by high-pressure torsion. Mater. Charact. 2024, 212, 114020. [Google Scholar] [CrossRef]

- Liu, W.; Wu, Y.; Deng, B.; Liu, A.; Liu, W.; Xu, Z.; Ye, T. Mechanical properties and microstructure of extruded 6061 aluminum alloy. Heat Treat. Met. 2020, 45, 172–177. [Google Scholar]

- Alam, C.S.; Karami, V.; Guo, S.; Rahman, M.S. Thermo-mechanical response of aluminum alloy in the additive friction-stir deposition process. Addit. Manuf. Lett. 2025, 12, 100263. [Google Scholar] [CrossRef]

- Stubblefield, G.; Fraser, K.; Phillips, B.; Jordon, J.; Allison, P. A meshfree computational framework for the numerical simulation of the solid-state additive manufacturing process, additive friction stir-deposition (AFS-D). Mater. Des. 2021, 202, 109514. [Google Scholar] [CrossRef]

- Modina, I.M.; Dyakonov, G.S.; Stotskiy, A.G.; Yakovleva, T.V.; Semenova, I.P. Effect of the Texture of the Ultrafine-Grained Ti-6Al-4V Titanium Alloy on Impact Toughness. Materials 2023, 16, 1318. [Google Scholar] [CrossRef] [PubMed]

- Tang, W.; Yang, X.; Tian, C. Influence of rotation speed on interfacial bonding mechanism and mechanical performance of aluminum 6061 fabricated by multilayer friction-based additive manufacturing. Int. J. Adv. Manuf. Technol. 2023, 126, 4119–4133. [Google Scholar] [CrossRef]

- Cheng, L.; Yang, X.; Tang, W.; Luo, T.; Wang, R. Processes and repair area properties of AA6061 repaired via additive friction stir deposition. Trans. China Weld. Inst. 2024, 45, 12–23. [Google Scholar] [CrossRef]

- Chen, L.; Lu, L.; Zhu, L.; Yang, Z.; Zhou, W.; Ren, X.; Zhang, X. Microstructure Evolution and Mechanical Properties of Multilayer AA6061 Alloy Fabricated by Additive Friction Stir Deposition. Met. Mater. Trans. A 2024, 55, 1049–1064. [Google Scholar] [CrossRef]

- Ghadimi, H.; Talachian, M.; Ding, H.; Emanet, S.; Guo, S. The Effects of Layer Thickness on the Mechanical Properties of Additive Friction Stir Deposition-Fabricated Aluminum Alloy 6061 Parts. Metals 2024, 14, 101. [Google Scholar] [CrossRef]

- Yang, F.; Pei, S.C.; Luo, X.R.; Chen, Y.X.; Li, N.Y.; Chang, Y.Q. Microstructure Evolution and Mechanical Properties of 6061 Aluminum Alloy Fabricated by Friction Stir Additive Manufacturing. Acta Metall. Sin. 2024, 1–18. [Google Scholar] [CrossRef]

- Chen, L.; Zhu, L.; Lu, L.; Yang, Z.; Ren, X.; Zhang, X. The effect of heat treatment on the microstructure and electrochemical corrosion behavior of multilayer AA6061 alloy fabricated by additive friction stir deposition. Appl. Surf. Sci. 2024, 650, 159167. [Google Scholar] [CrossRef]

| AM Technology | Benefit | Limitation |

|---|---|---|

| Solid-phase AM | Green manufacturing (eliminates most fusion-based defects), lower energy consumption, broad material range, facile multi-material and functionally graded fabrication, higher lateral strength versus fusion AM, high deposition rate, low distortion | Lower dimensional accuracy requires subsequent subtractive processing, difficult to apply to complex geometries |

| Fusion-based AM | High flexibility for small, accurate, intricate parts (especially with laser heating), lower cost for small-batch production | Susceptible to porosity, cracking, delamination, and loss of alloying elements |

| Mg | Si | Fe | Mn | Cu | Cr | Ti | Al |

|---|---|---|---|---|---|---|---|

| 0.90 | 0.54 | 0.12 | 0.10 | 0.28 | 0.18 | 0.04 | Bal. |

| Crystal Plane | Sample | 2θ (°) | FWHM (°) | dhkl (nm) | a (nm) |

|---|---|---|---|---|---|

| (022) | BM | 38.366 | 0.1617 | 2.3443 | 6.6306 |

| AFSD-Z | 38.406 | 0.1436 | 2.3419 | 6.624 | |

| AFSD-X | 38.4314 | 0.1451 | 2.3401 | 6.6193 | |

| (200) | BM | 44.5754 | 0.2335 | 2.0311 | 6.6306 |

| AFSD-Z | 44.6574 | 0.1620 | 2.0275 | 4.0551 | |

| AFSD-X | 44.6846 | 0.1662 | 2.0251 | 4.0519 | |

| (311) | BM | 78.1229 | 0.3430 | 1.2224 | 6.6306 |

| AFSD-Z | 78.1483 | 0.0945 | 1.2217 | 4.0533 | |

| AFSD-X | 78.1781 | 0.0994 | 1.2209 | 4.0528 |

| Point | Al | Mg | Si | Mn | Fe | Cr |

|---|---|---|---|---|---|---|

| 1 | 84.65 | 0.30 | 6.50 | - | 7.00 | 1.55 |

| 2 | 83.72 | 0.40 | 7.50 | 0.20 | 7.08 | 1.10 |

| 3 | 82.85 | - | 6.10 | - | 10.90 | 0.15 |

| Samples | Recrystallized | Substructured | Deformed |

|---|---|---|---|

| The XOY plane (X direction) | 80.3565 ± 1.74 | 18.69374 ± 1.74 | 0.9497579 ± 0.10 |

| The YOZ plane (Z direction) | 77.74907 ± 3.85 | 21.24078 ± 3.67 | 1.01015 ± 0.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, H.; Dong, P.; Wei, Z. Microstructure and Properties of 6061 Aluminum Alloy by Additive Friction Stir Deposition. Metals 2025, 15, 539. https://doi.org/10.3390/met15050539

Gao H, Dong P, Wei Z. Microstructure and Properties of 6061 Aluminum Alloy by Additive Friction Stir Deposition. Metals. 2025; 15(5):539. https://doi.org/10.3390/met15050539

Chicago/Turabian StyleGao, Han, Peng Dong, and Zhiwei Wei. 2025. "Microstructure and Properties of 6061 Aluminum Alloy by Additive Friction Stir Deposition" Metals 15, no. 5: 539. https://doi.org/10.3390/met15050539

APA StyleGao, H., Dong, P., & Wei, Z. (2025). Microstructure and Properties of 6061 Aluminum Alloy by Additive Friction Stir Deposition. Metals, 15(5), 539. https://doi.org/10.3390/met15050539