Dynamic Response of WMoZrNiFe Energetic Structural Material Based on SHPB

Abstract

1. Introduction

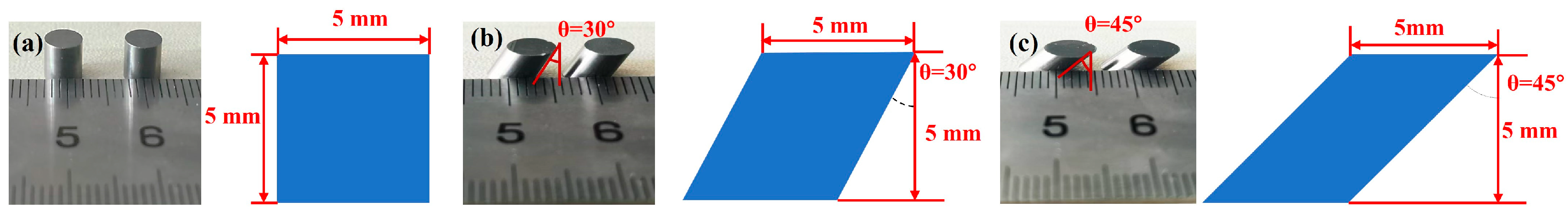

2. Materials Preparation and Experimental Methods

2.1. Materials Preparation

2.2. Microstructure Characterization Methods

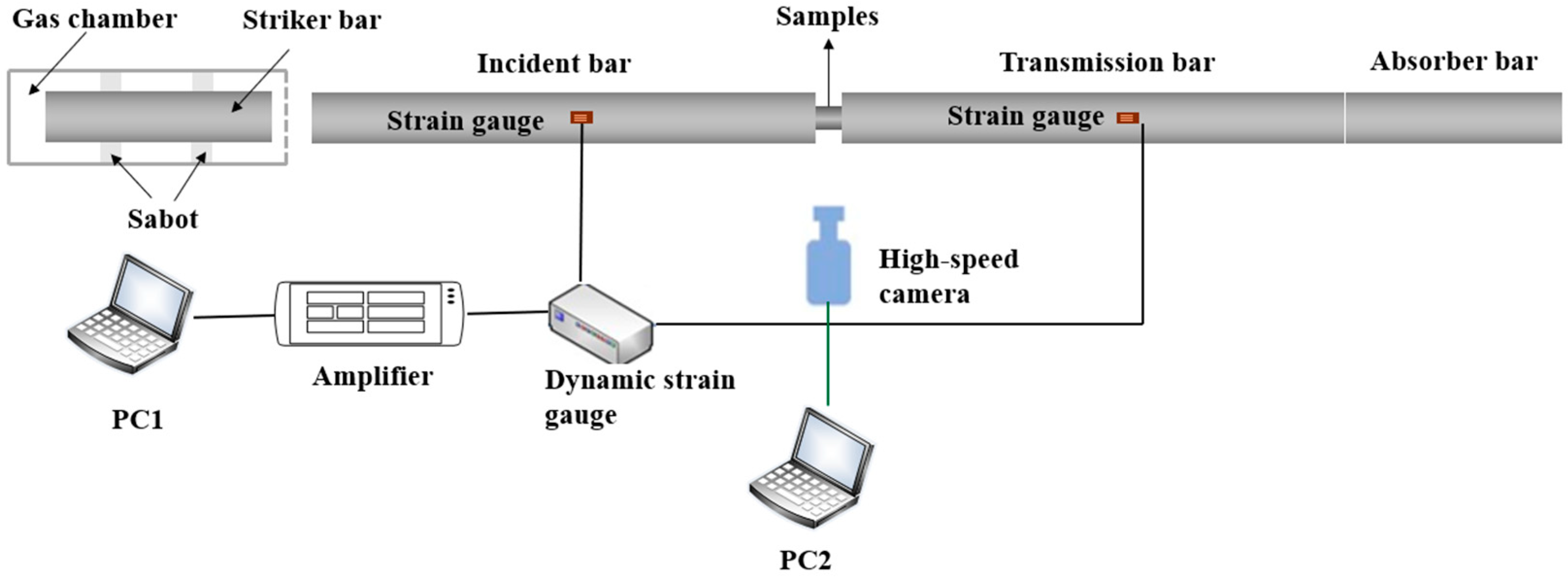

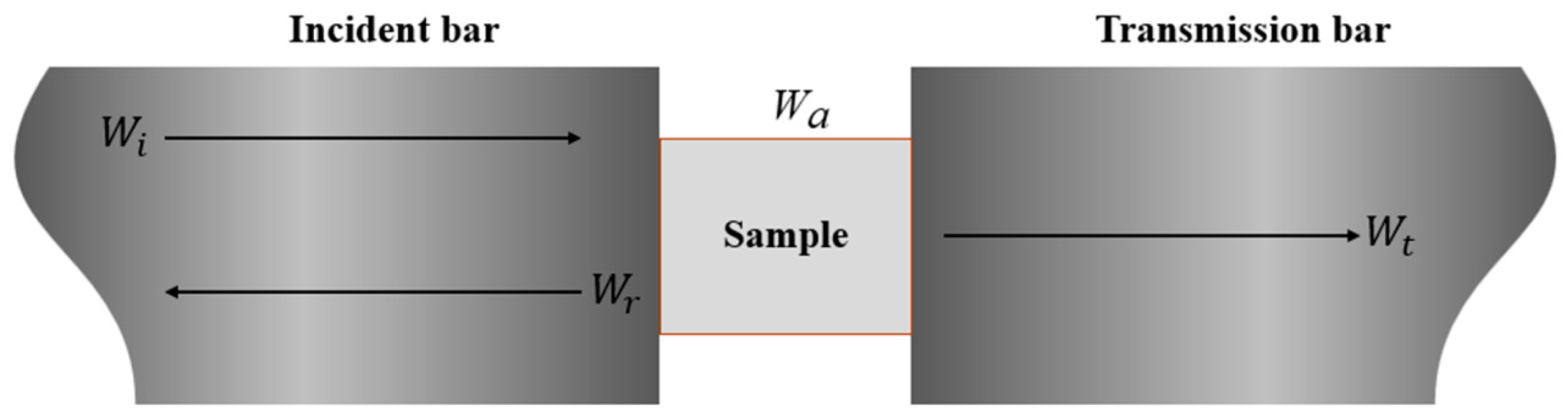

2.3. Mechanical Property Testing Methods

3. Experimental Results and Analysis

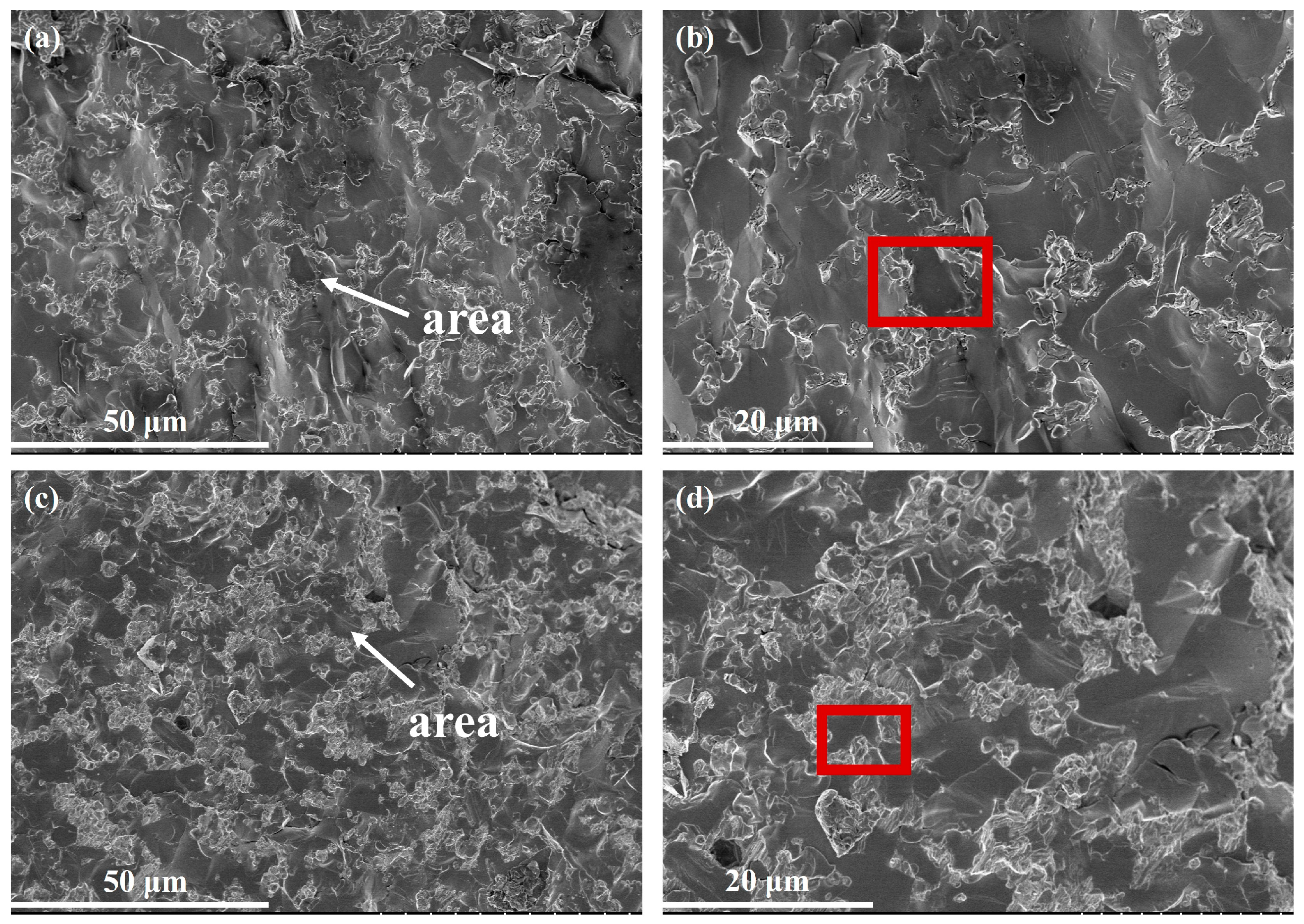

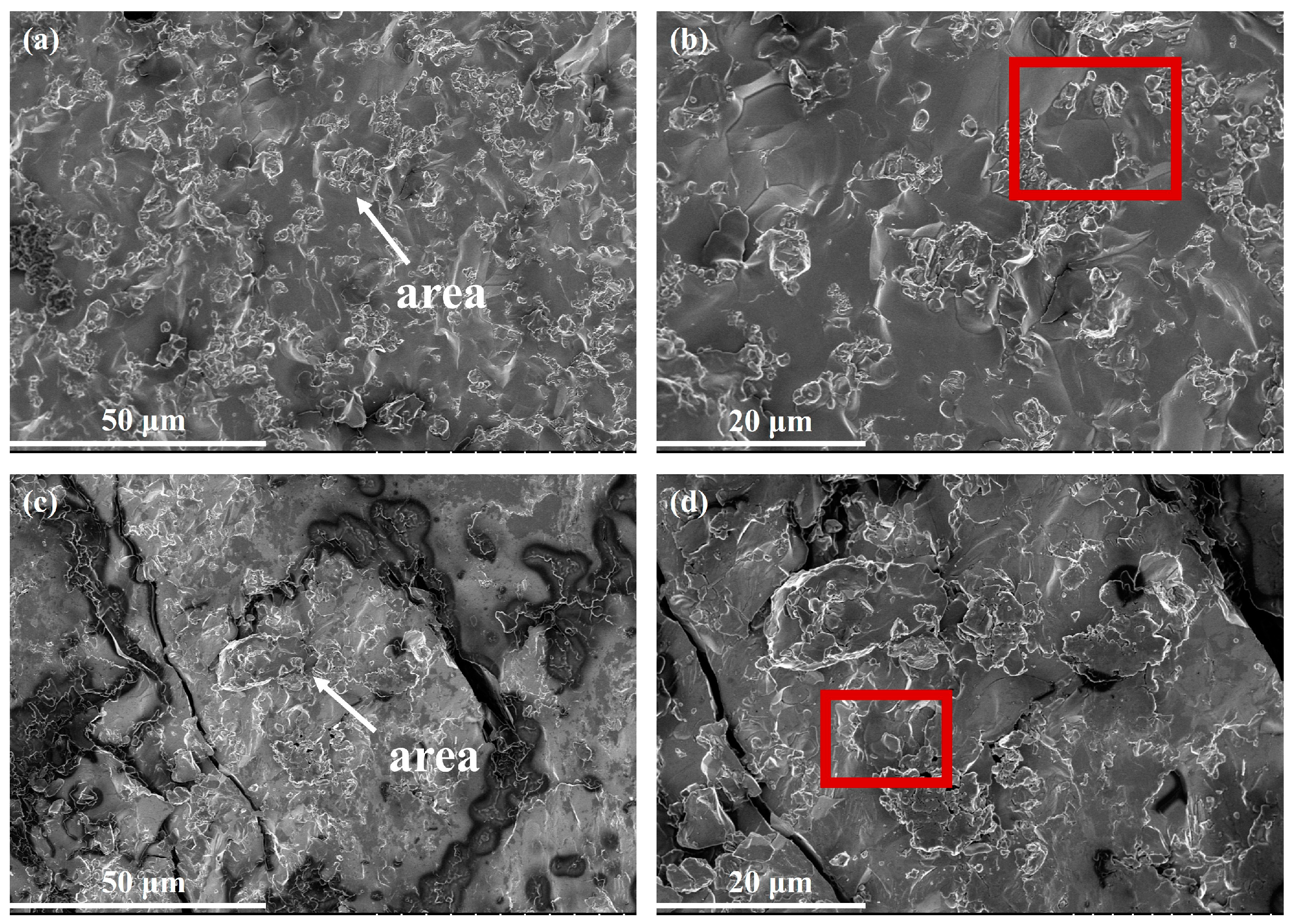

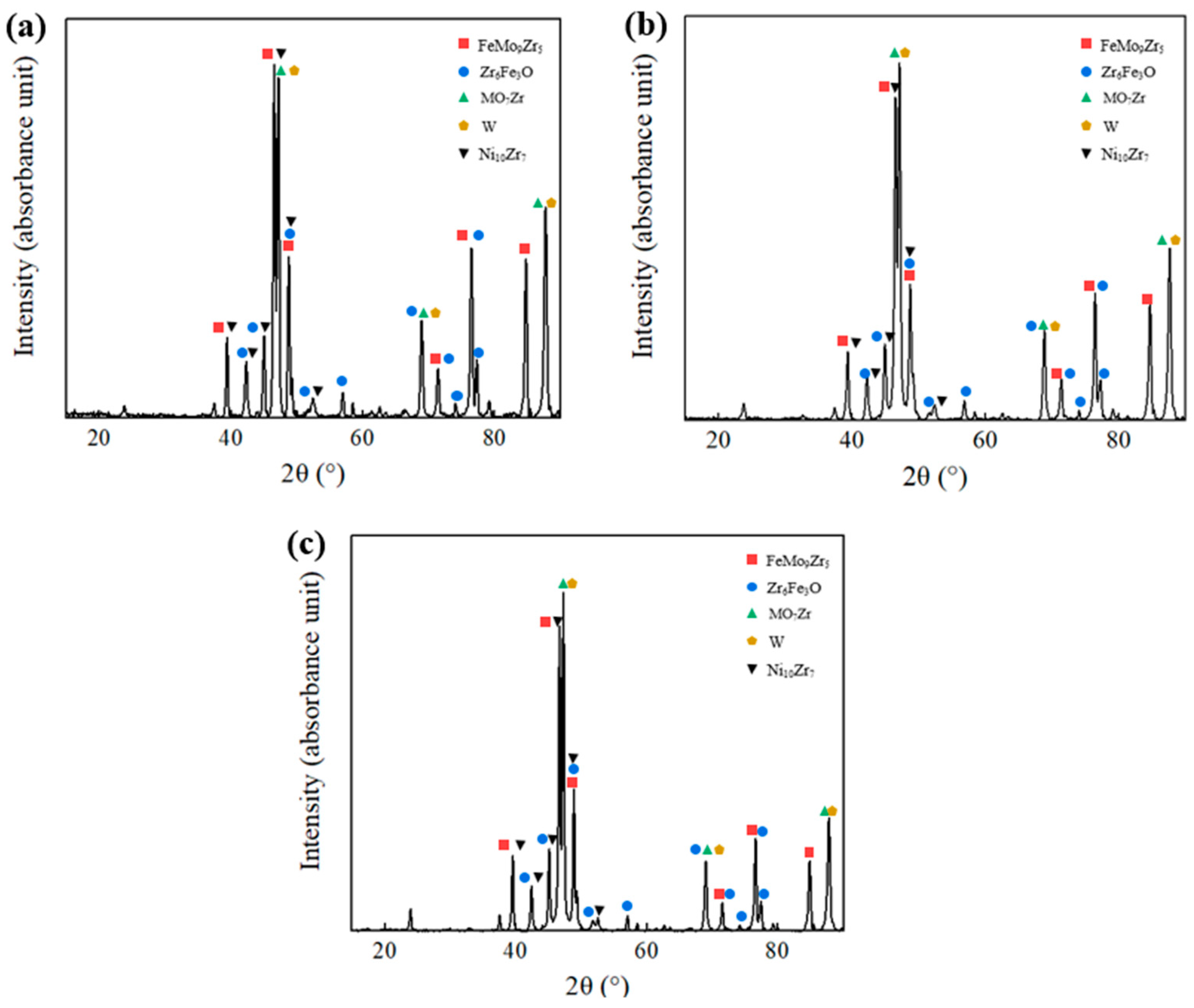

3.1. Microstructure Characteristics

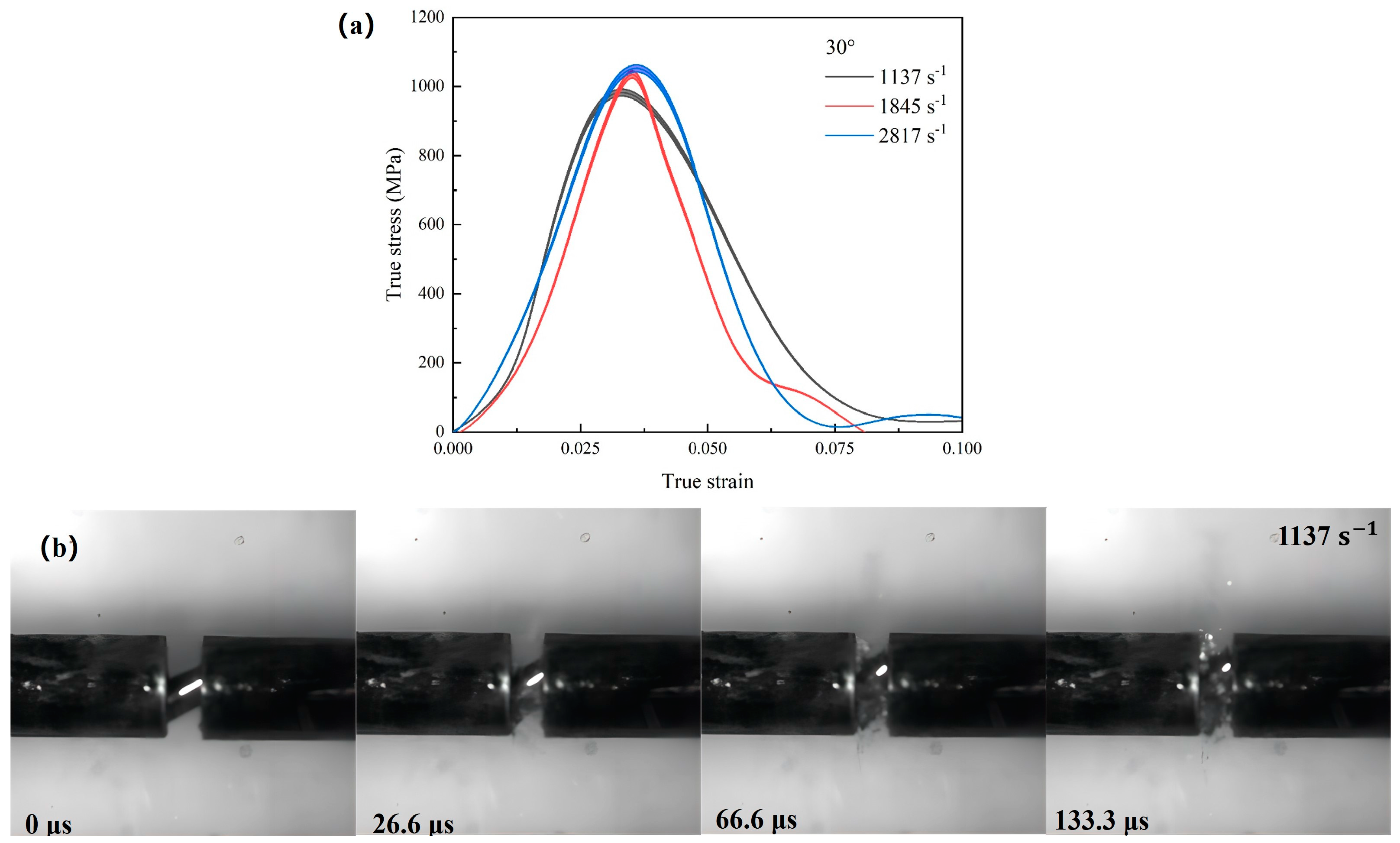

3.2. Mechanical Properties

4. Dynamic Ignition Behavior

5. Conclusions

- (1)

- The WMoZrNiFe energetic structural materials exhibit a certain strain rate effect. As the strain rate increases, the yield strength of the 0° material increases from 1468 MPa to 1837 MPa, the yield strength of the 30° material increases from 982 MPa to 1053 MPa, and the yield strength of the 45° material increases from 420 MPa to 812 MPa. The material exhibits higher critical failure strain and compressive strength. Moreover, at similar strain rates, increasing the inclination angle of the sample results in a decrease in fracture strength.

- (2)

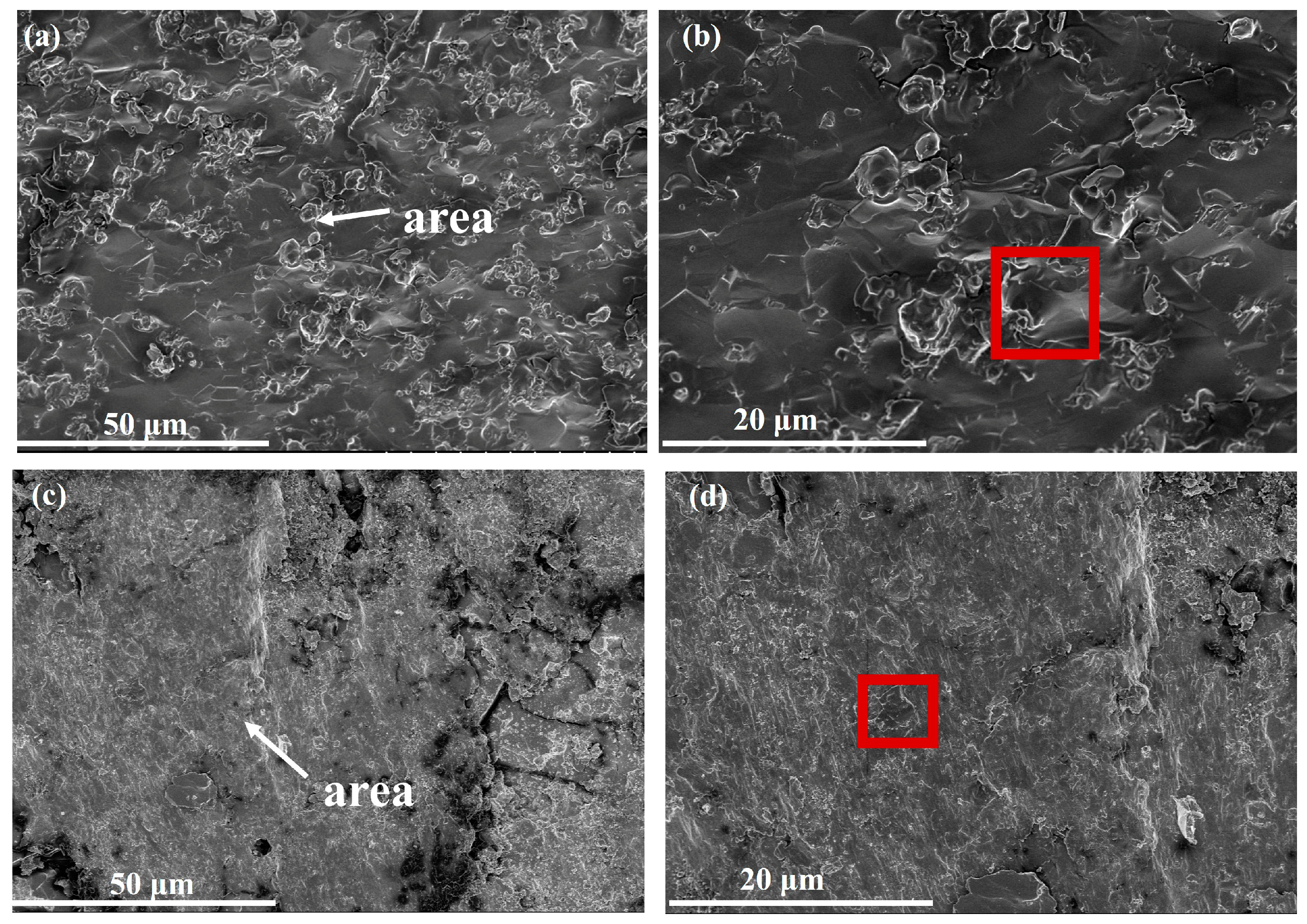

- The excellent mechanical properties of WMoZrNiFe energetic structural materials are related to their microstructure. At higher strain rates, the fracture morphology of the sample is characterized by partial step-like features and ductile dimples, indicating a ductile–brittle mixed fracture mode.

- (3)

- In dynamic compression experiments, the main elements involved in the reaction with oxygen in the air are W and Mo. For dynamic compression experiments at similar strain rates, the reaction degree between the 0° WMoZrNiFe energetic structural material and oxygen in the air is higher than those of the 30° and 45° materials.

- (4)

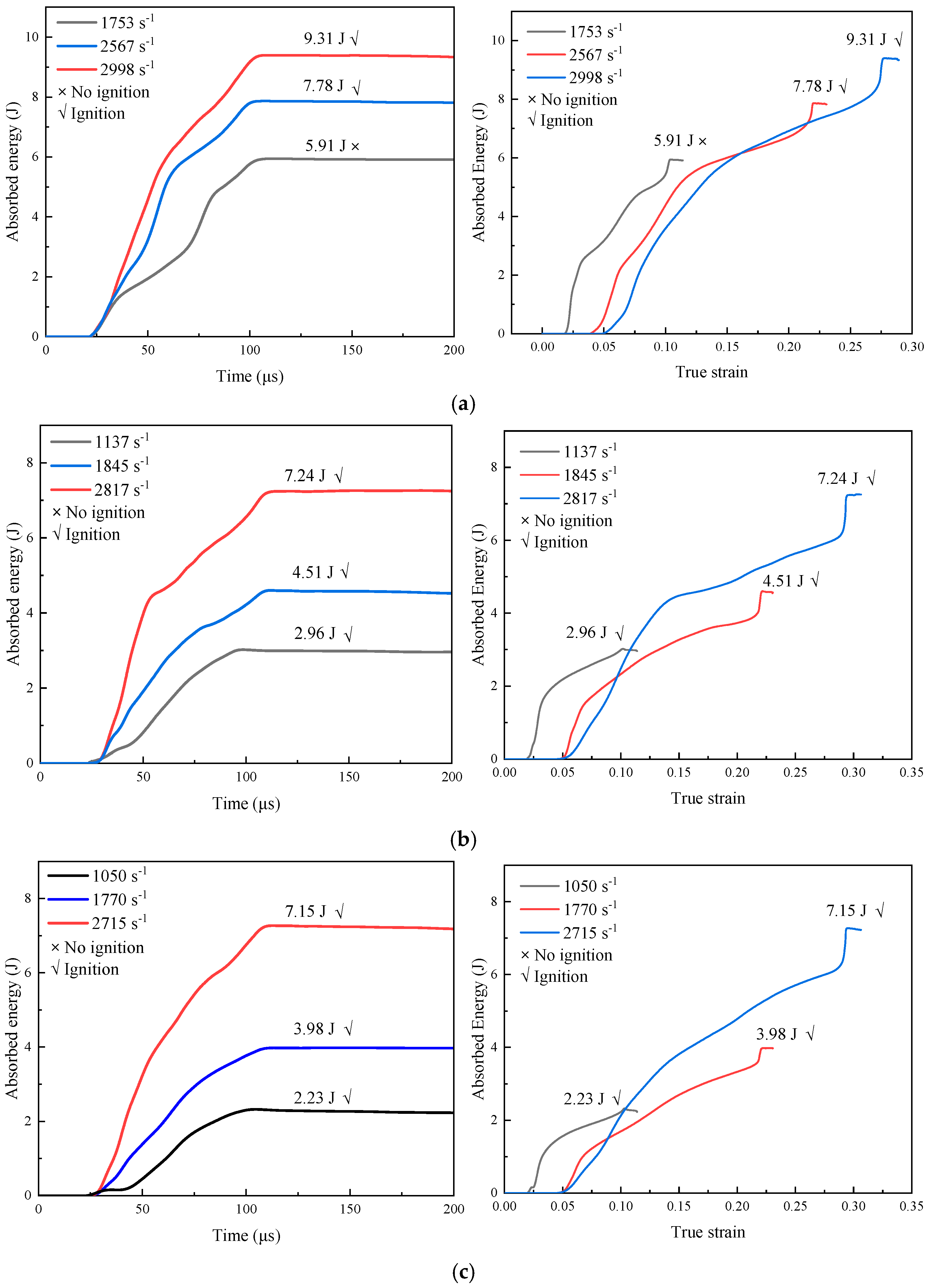

- The energy absorption thresholds for the 0°, 30°, and 45° samples are 7.78 J, 2.96 J, and 2.23 J, respectively. The energy threshold decreases as the inclination angle increases, with the 45° sample having the lowest ignition threshold, making it more prone to ignition.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zheng, Z.; Jiang, X.; Zhao, J. Structural, electronic and elastic properties of several metal organic frameworks as a new kind of energetic materials. Chem. Phys. Lett. 2015, 628, 76–80. [Google Scholar] [CrossRef]

- Wang, M.; Qiu, L.; Zhao, X.; Li, Y.; Rao, T.; He, S.; Qin, L.; Tao, J. Multilayered Al/Ni energetic structural materials with high energy density and mechanical properties prepared by a facile approach of electrodeposition and hot pressin. Mater. Sci. Eng. A 2019, 757, 23–31. [Google Scholar] [CrossRef]

- Semin, V.O.; Yamada, R.; Hamasaki, Y.; Miyajima, Y.; Ishikawa, K.; Watanabe, A.; Kwon, H.; Kim, H.; Kato, H.; Louzguine-Luzgin, D. The effect of some late 3d transition metals additions to a Fe-Mn-Al-C alloy on the development of high-entropy alloys. Intermetallics 2025, 177, 108589. [Google Scholar] [CrossRef]

- Millar, D.I.; Marshall, W.G.; Oswald, I.D.; Pulham, C.R. High-pressure structural studies of energetic materials. Crystallogr. Rev. 2010, 16, 115–132. [Google Scholar] [CrossRef]

- Hu, Q.; Liu, R.; Zhou, Q.; Geng, H.; Ge, C.; Wang, H.; Xiao, C.; Chen, P. Characterization of Ta-Ni-Al energetic structural material fabricated by explosive consolidation. J. Alloys Compd. 2022, 924, 166191. [Google Scholar] [CrossRef]

- Huang, C. Research on Prepartion, Mechanical and Thermal Characteristics of Metallic Energetic Structural Materials. Ph.D. Thesis, National University of Defense Technology, Changsha, China, 2020. (In Chinese). [Google Scholar]

- Tao, Y.; Bai, S.X.; Yang, S.; Li, S. Research status of preparation technology for reactive material structures. Chin. J. Nonferrous Met. 2017, 27, 2079–2090. (In Chinese) [Google Scholar]

- Zhao, P.; Lu, F.; Li, J.; Chen, R.; Xu, S.; Yang, S. The Dynamic Compressive Properties of PTFE/Al Reactive Materials. Energetic Mater. 2009, 17, 4. [Google Scholar]

- Ren, K.; Chen, R.; Lin, Y.; Li, S.; Zhang, X.; Dong, J. Probing the Impact Energy Release Behavior of Al/Ni-Based Reactive Metals with Experimental and Numerical Methods. Metals 2019, 9, 499. [Google Scholar] [CrossRef]

- Wang, B.; Fu, A.; Huang, X.; Liu, B.; Liu, Y.; Li, Z.; Zan, X. Mechanical Properties and Microstructure of the CoCrFeMnNi High Entropy Alloy Under High Strain Rate Compression. J. Mater. Eng. Perform. 2016, 25, 2985–2992. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, X.; Xiong, W.; Liu, C.; Wei, H.; Wang, H.; Dai, L. Dynamic mechanical behavior and penetration performance of WFeNiMo high-entropy alloy. Chin. J. Theor. Appl. Mech. 2020, 52, 1443–1453. (In Chinese) [Google Scholar]

- Hou, X.; Xiong, W.; Chen, H.; Zhang, X.; Wang, H.; Dai, L. Impact energy release and damage characteristics of two high-entropy alloys. Chin. J. Theor. Appl. Mech. 2021, 53, 2528–2540. (In Chinese) [Google Scholar]

- Ren, H.; Li, W.; Ning, J.; Liu, Y. The Influence of Initial Defects on Impact Ignition of Aluminum/Polytetrafluoroethylene Reactive Material. Adv. Eng. Mater. 2020, 22, 1900821. [Google Scholar] [CrossRef]

- Ren, H.; Li, W.; Ning, J. Effect of temperature on the impact ignition behavior of the aluminum/polytetrafluoroethylene reactive material under multiple pulse loading. Mater. Des. 2020, 189, 108522. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, R.; Ran, C.; Arab, A.; Geng, H.; Gao, M.; Guo, B.; Zhou, Q.; Chen, P. Ignition and energy release characteristics of energetic high-entropy alloy HfZrTiTa0.2Al0.8 under dynamic loading. J. Mater. Res. Technol. 2024, 28, 2819–2830. [Google Scholar] [CrossRef]

- Zhang, Z. Microstructure and Mechanical Properties of HfZrTiTax High-Entropy Alloys Energetic Structural Materials. Master’s Thesis, National University of Defense Technology, Changsha, China, 2017. (In Chinese). [Google Scholar]

- Ren, K.; Liu, H.; Chen, R.; Tang, Y.; Guo, B.; Li, S.; Wang, J.; Wang, R.; Lu, F. Compression properties and impact energy release characteristics of TiZrNbV high-entropy alloy. Mater. Sci. Eng. A 2021, 827, 142074. [Google Scholar] [CrossRef]

- Wang, R. Micro Structure Evolution and Energetic Structural Properties of NbZrTiTa High-Entropy Alloy. Master’s Thesis, National University of Defense Technology, Changsha, China, 2018. (In Chinese). [Google Scholar]

- Li, M.; Qiao, L.; Li, Q. Energy dissipation of rock specimens under high strain rate with single joint in SHPB tensile tests. Chin. J. Geotech. Eng. 2017, 39, 1336–1343. (In Chinese) [Google Scholar]

| Name | Purity (%) | Particle Size (μm) |

|---|---|---|

| W powder | ≥99.99 | 1–5 |

| Mo powder | ≥99.9 | 1–5 |

| Zr powder | ≥99 | 1–5 |

| Ni powder | ≥99.9 | 1–5 |

| Fe powder | ≥99.9 | 1–5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pei, G.; Peng, Z.; Bi, X.; Jiao, Q.; Liu, R.; Nie, J. Dynamic Response of WMoZrNiFe Energetic Structural Material Based on SHPB. Metals 2025, 15, 516. https://doi.org/10.3390/met15050516

Pei G, Peng Z, Bi X, Jiao Q, Liu R, Nie J. Dynamic Response of WMoZrNiFe Energetic Structural Material Based on SHPB. Metals. 2025; 15(5):516. https://doi.org/10.3390/met15050516

Chicago/Turabian StylePei, Guiyan, Zhe Peng, Xiaolu Bi, Qingjie Jiao, Rui Liu, and Jianxin Nie. 2025. "Dynamic Response of WMoZrNiFe Energetic Structural Material Based on SHPB" Metals 15, no. 5: 516. https://doi.org/10.3390/met15050516

APA StylePei, G., Peng, Z., Bi, X., Jiao, Q., Liu, R., & Nie, J. (2025). Dynamic Response of WMoZrNiFe Energetic Structural Material Based on SHPB. Metals, 15(5), 516. https://doi.org/10.3390/met15050516