Design and Evaluation of the Mechanical Performance of Hollow BCC Truss AlSi10Mg Lattice Structures

Abstract

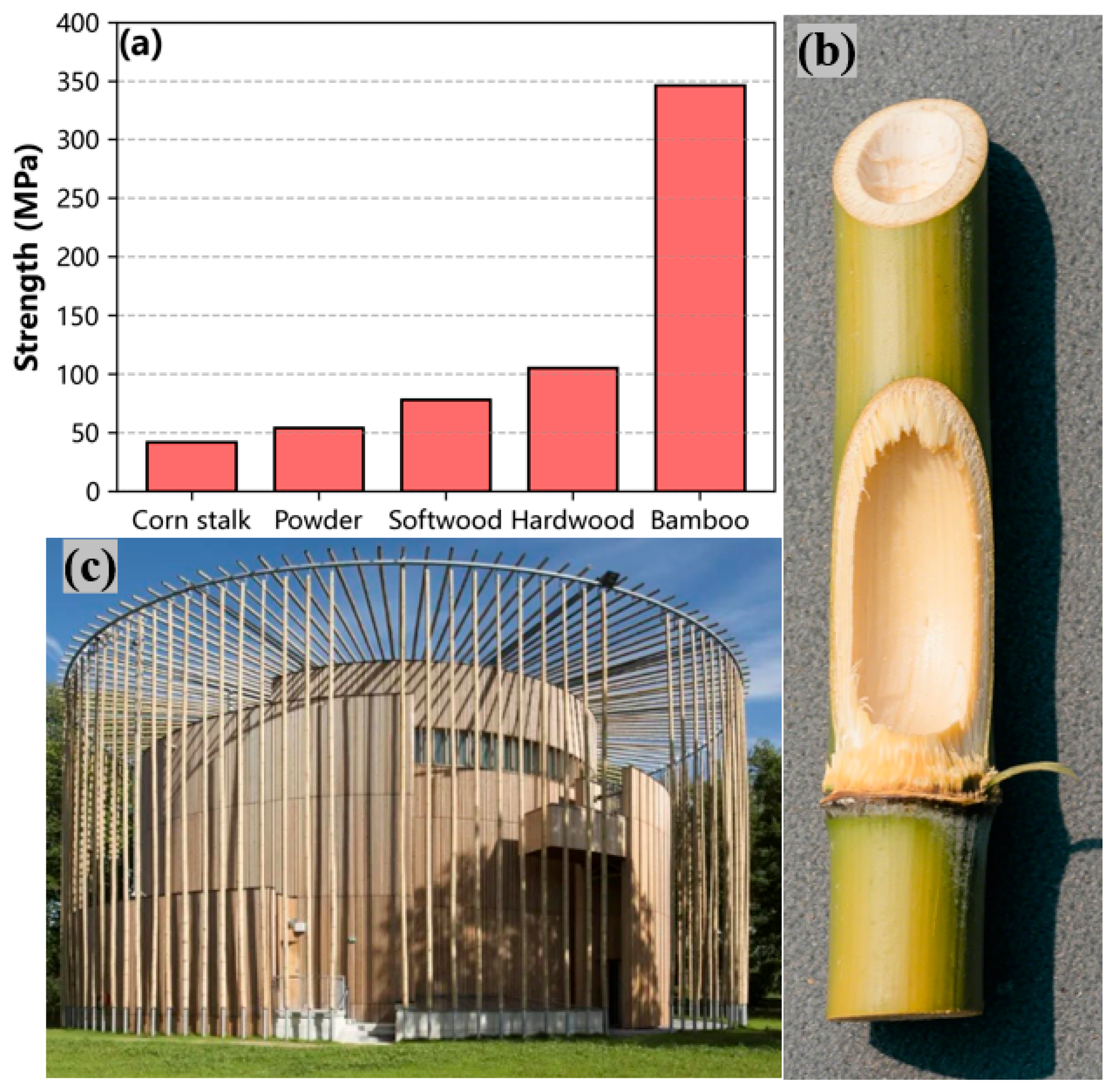

1. Introduction

2. Materials and Methods

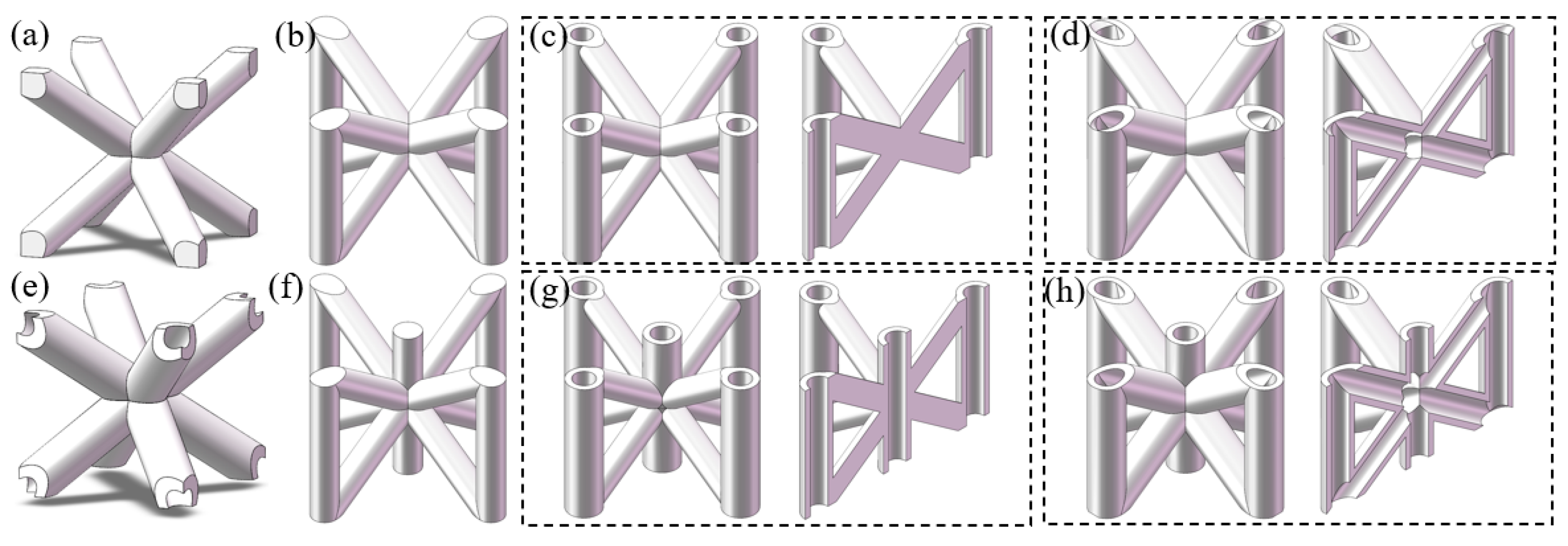

2.1. Structural Design

- Z: Incorporates vertical (Z-axis) struts into the parent BCC architecture; the numeral preceding “Z” denotes the quantity of added vertical struts (4 or 5);

- H (Hollow): All struts (including original BCC members and Z-struts) exhibit hollow cross-sections;

- PH (Partially Hollow): Only the Z-struts feature hollow morphology, while the original BCC struts remain solid.

2.2. Fabrication Methodology

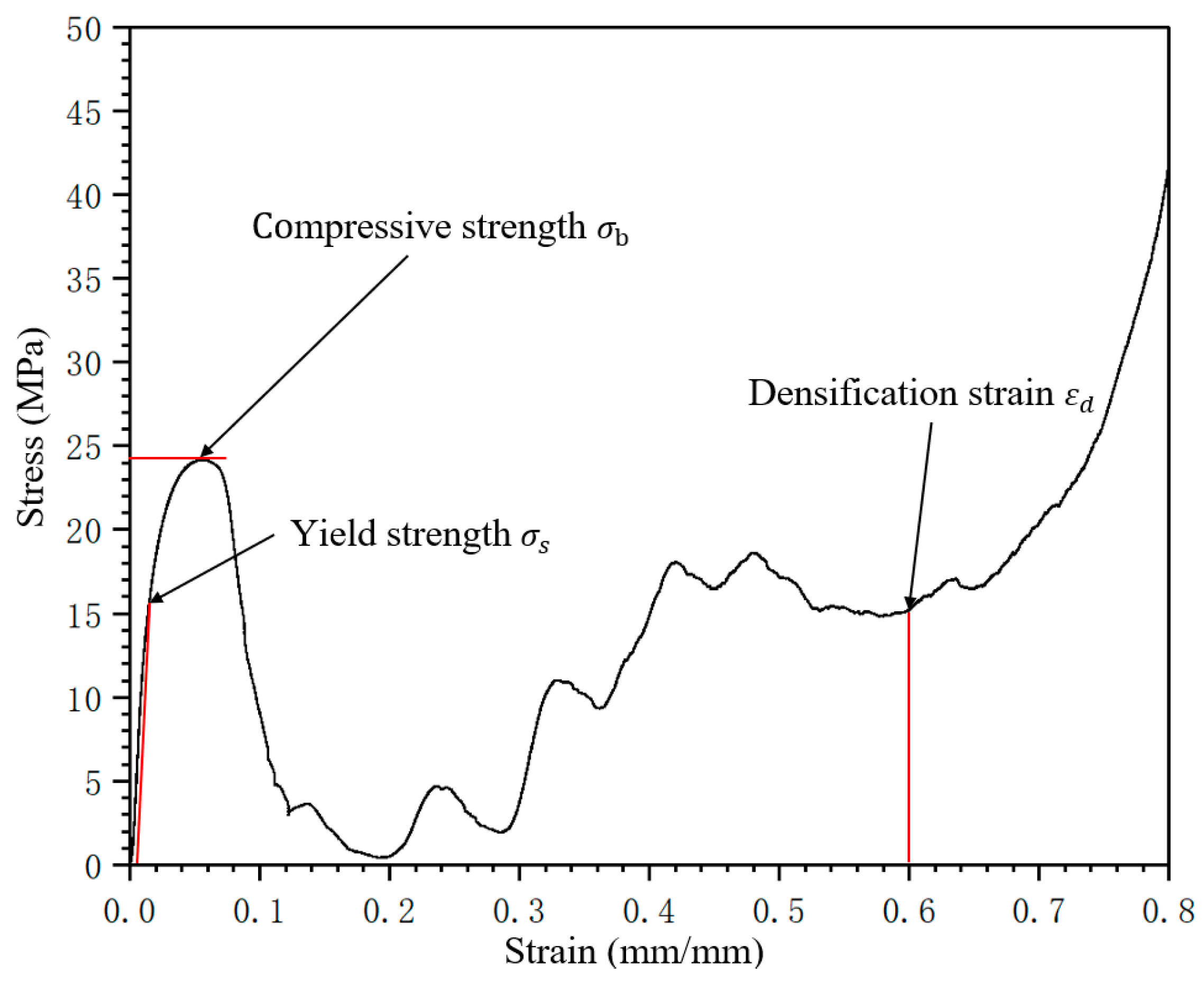

2.3. Quasi-Static Compression Testing Configuration

- F = Applied load (N);

- A0 = Initial cross-sectional area (mm2);

- L1 = Post-test specimen height (mm);

- L0 = Initial specimen height (mm);

- ΔL = Displacement variation (mm).

3. Results and Discussion

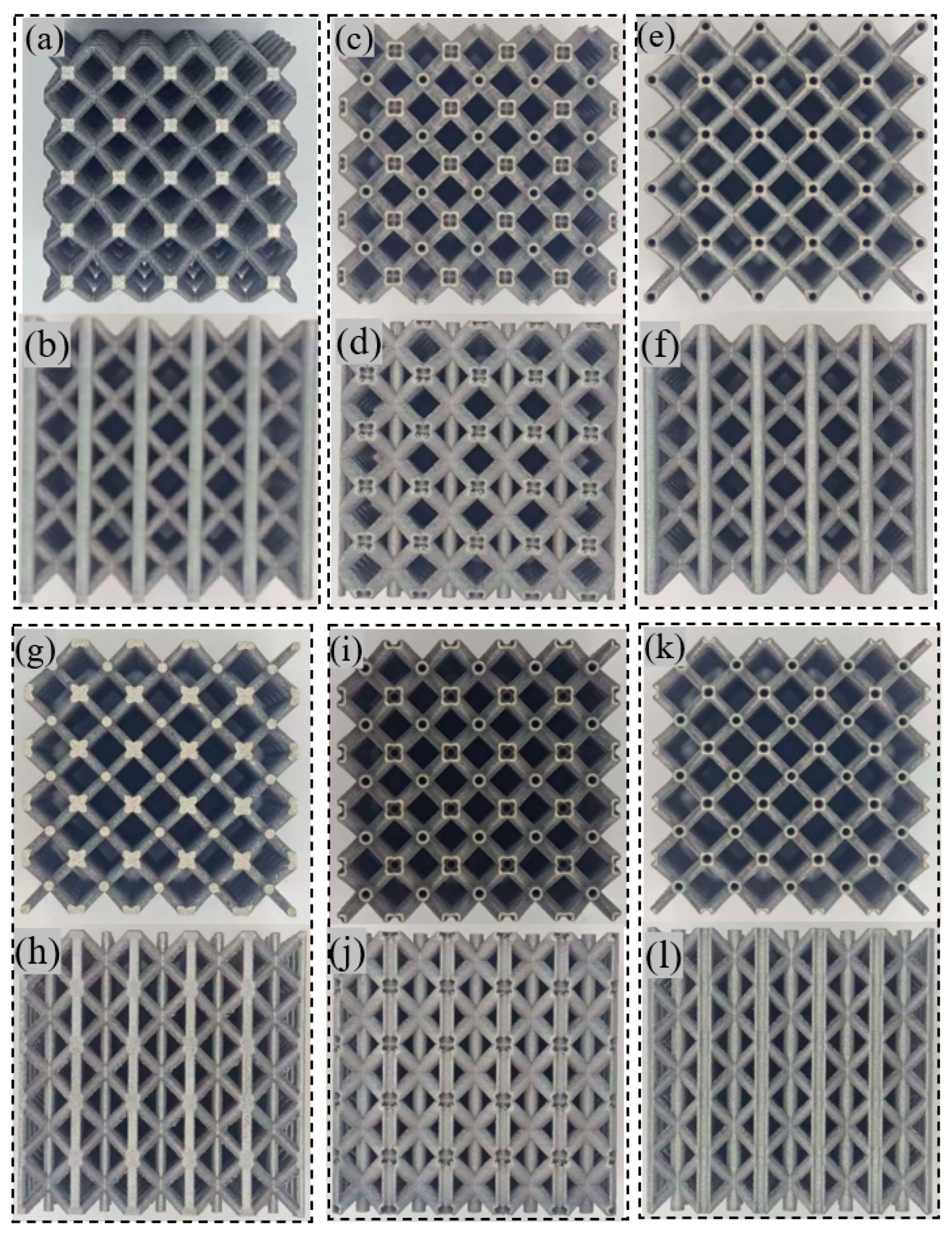

3.1. Macroscopic Morphology of Lattice Structures

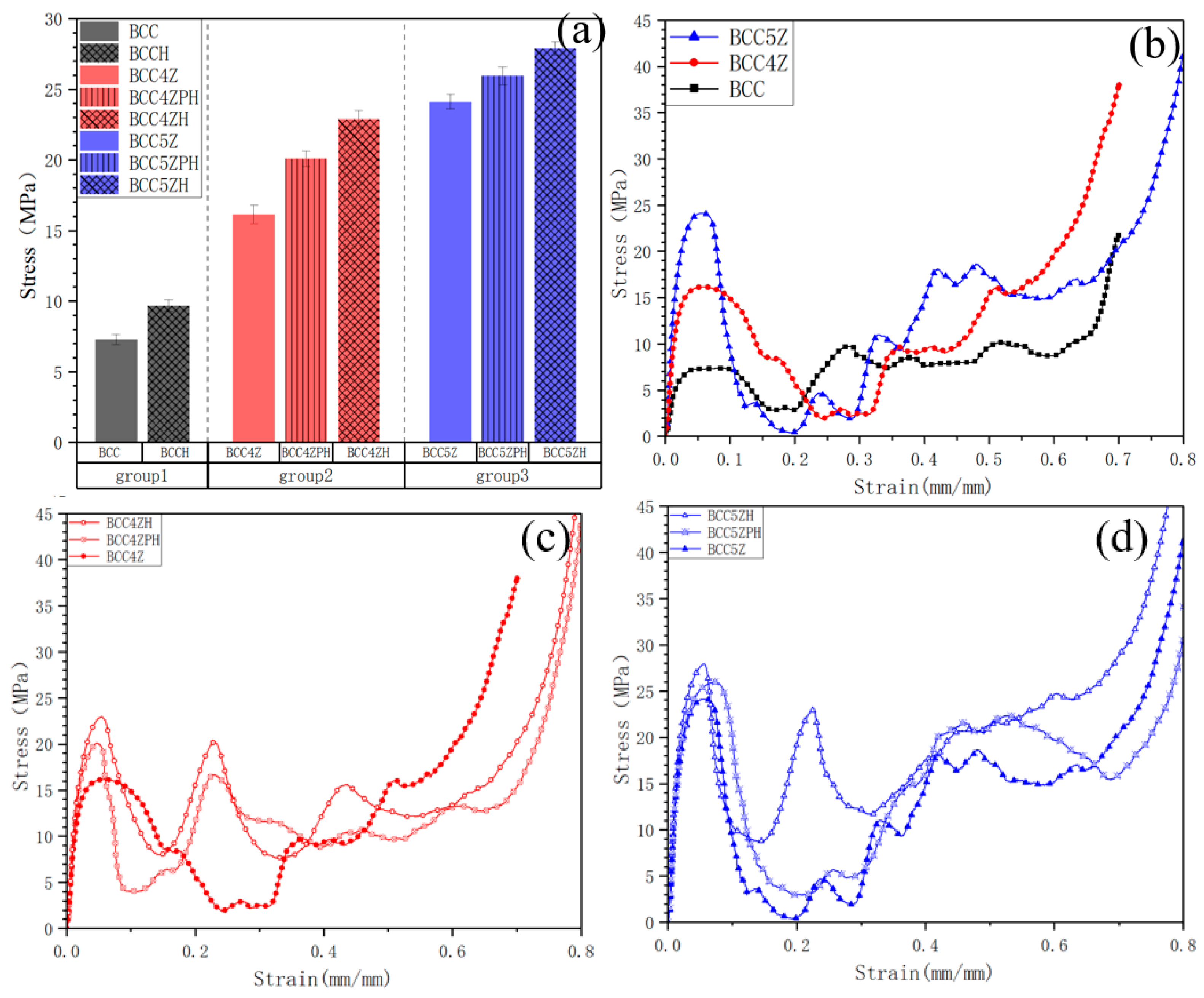

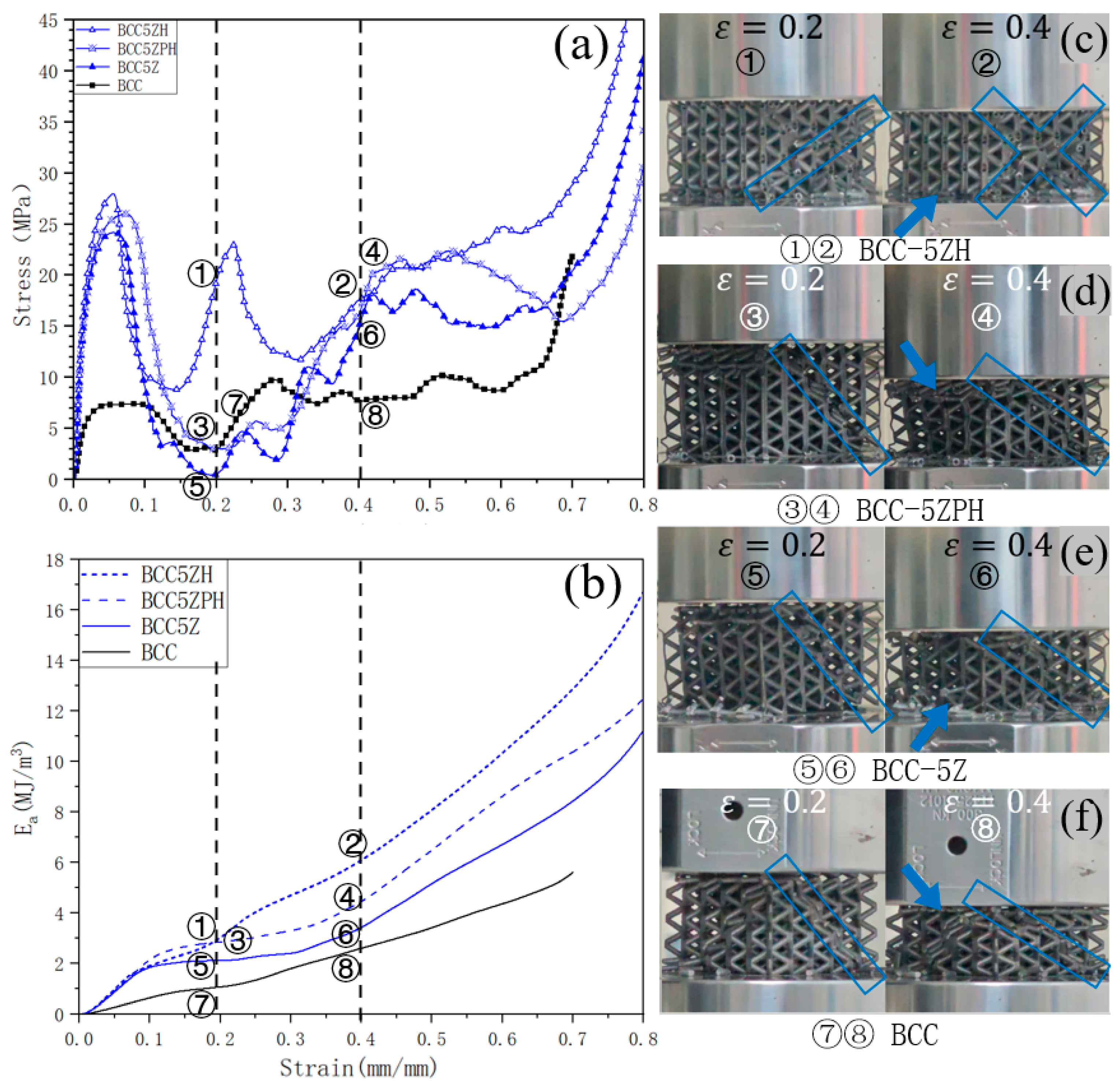

3.2. Effects of Bamboo-Inspired Design on Compressive Behavior

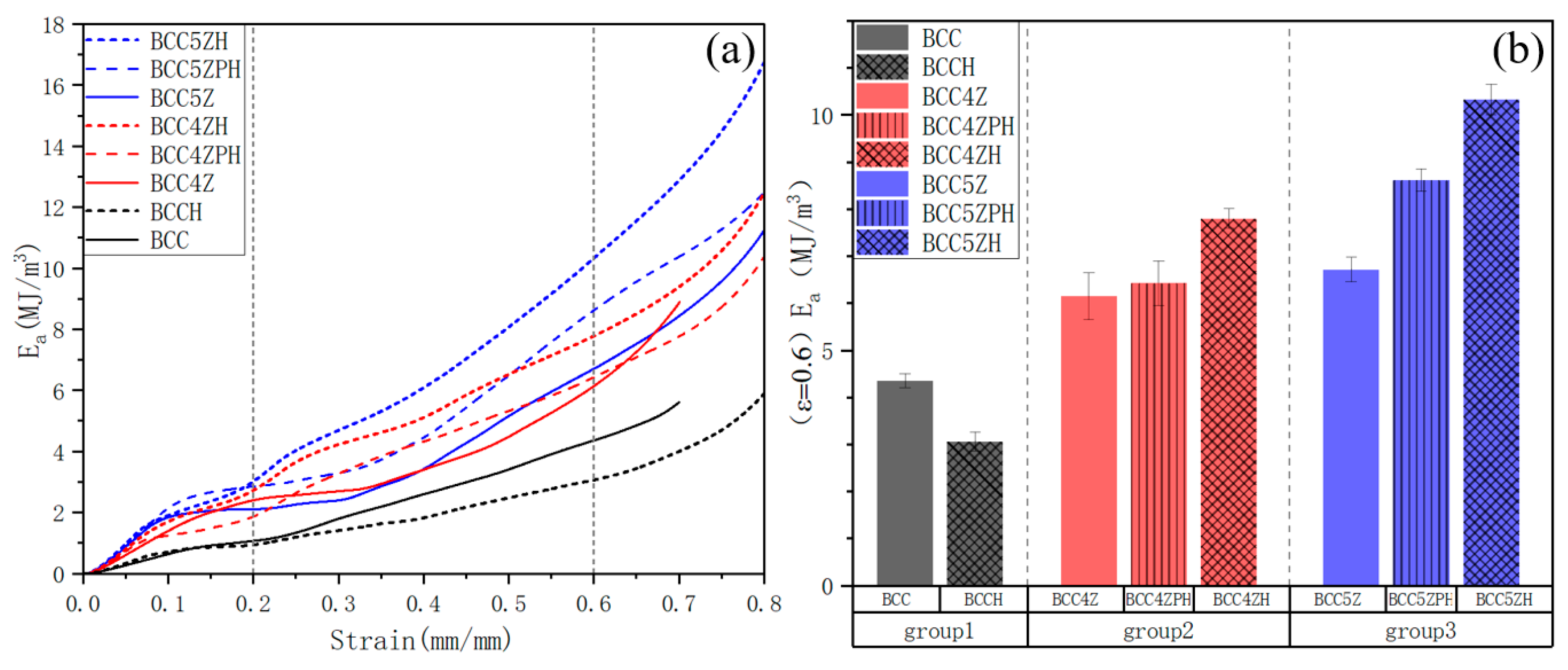

3.3. Effects of Bamboo-Inspired Design on Energy Absorption

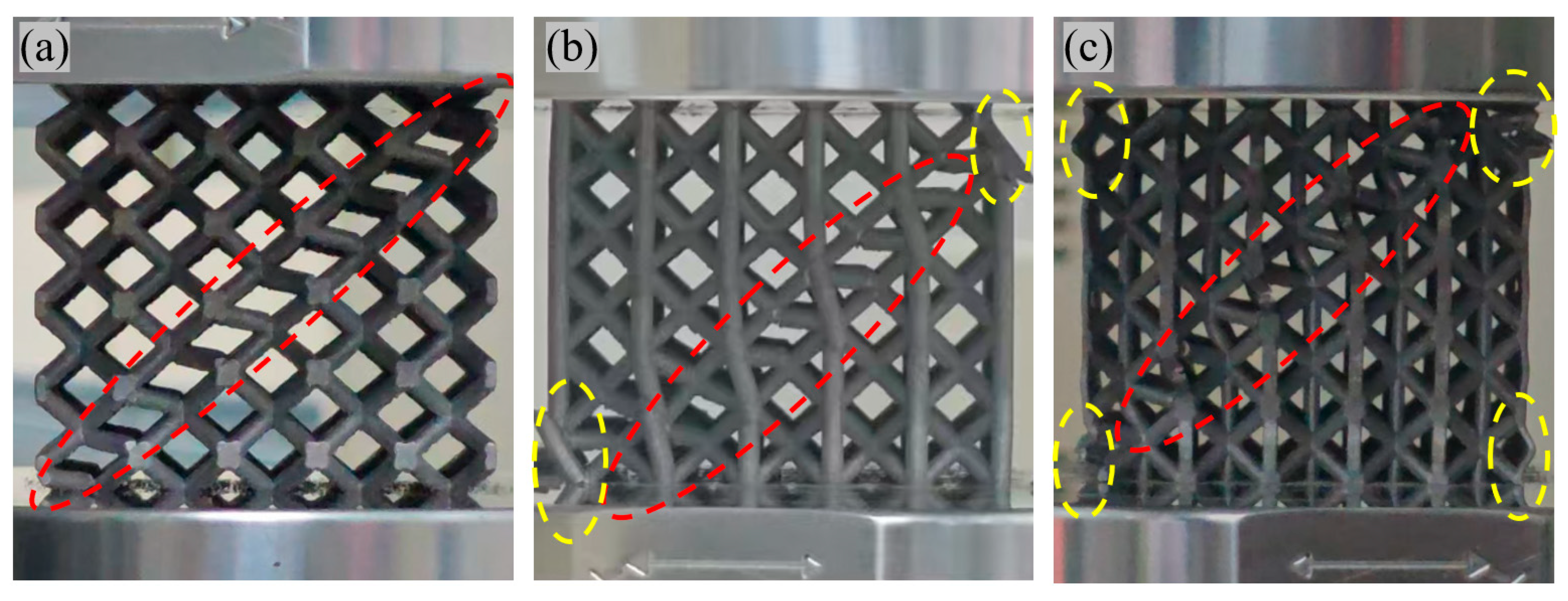

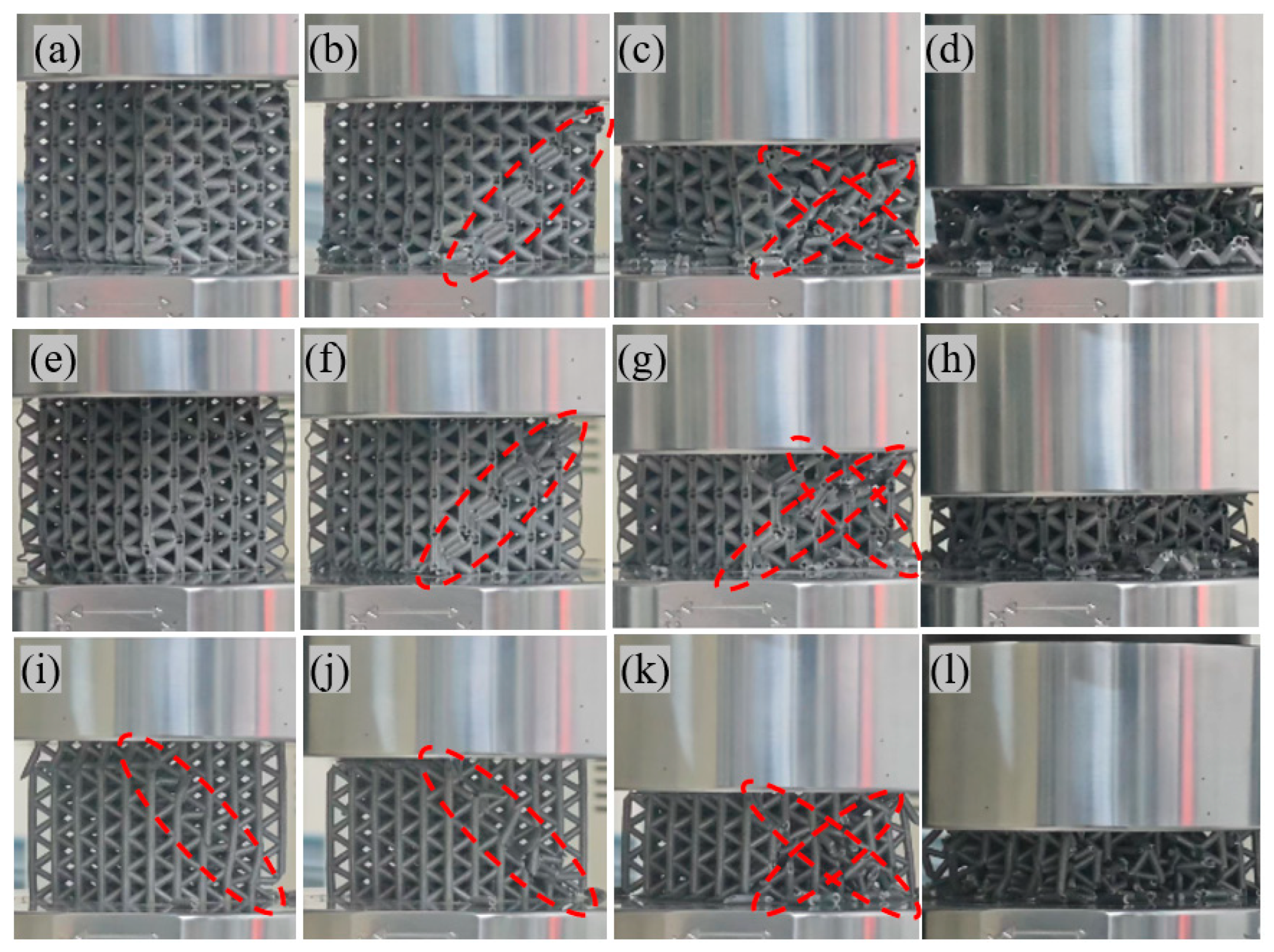

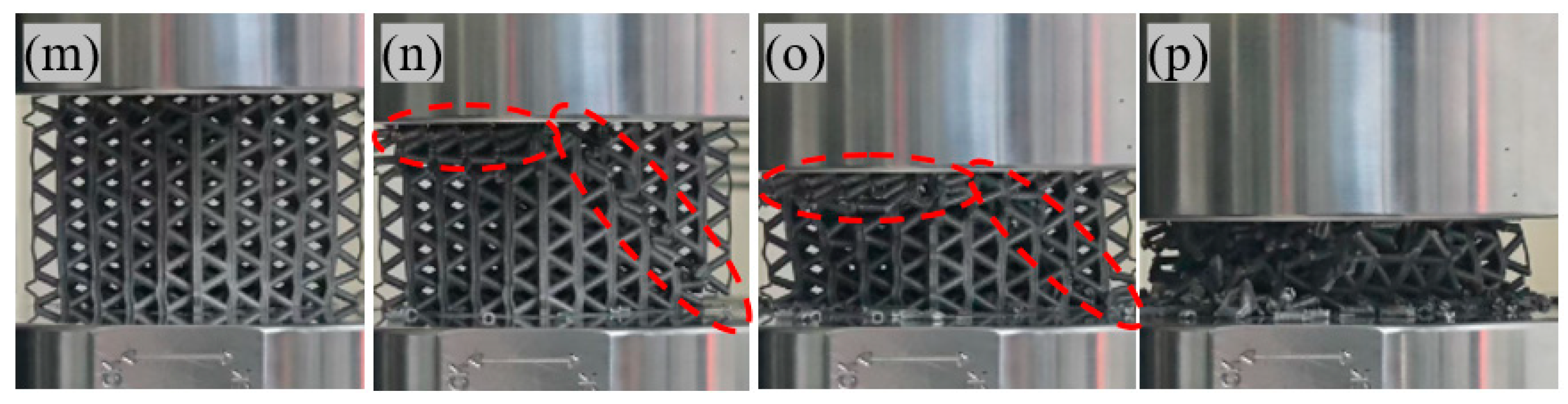

3.4. Effects of Bamboo-Inspired Design on Deformation Characteristics

- Increasing I;

- Reducing effective length;

- Selecting high-modulus materials;

- Strengthening constraints.

4. Conclusions

- Z-strut reinforcement significantly enhances yield and compressive strengths: BCC-5Z exhibits a yield strength of 14.38 MPa (188.7% increase over baseline BCCs 4.98 MPa) and 221.5% higher compressive strength.

- The hollow strut design demonstrates dual buckling resistance enhancement and energy absorption improvement mechanisms. This geometry increases the critical buckling load (Pcr) through an enhanced sectional moment of inertia I, significantly improving buckling resistance. Furthermore, hollow structures delay the densification of onset strain and extend the densification duration, ultimately enhancing lattice structures’ specific energy absorption (SEA).

- Synergistic interaction between Z-strut addition and hollow design modifies failure mechanisms: transitioning from single 45° shear bands in solid structures to dual X-shaped 45° shear bands per plane. This topological evolution manifests dual-peak characteristics in stress–strain curves, elevating plateau stress levels and enhancing compressive resistance and energy absorption efficiency. The observed interaction effects require further mechanistic validation through FEA-based modeling in future studies.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SLM | Selective Laser Melting |

| SEA | Specific Energy Absorption |

| EDM | Electrical Discharge Machining |

| BCC | Body-Centered Cubic |

| BCCH | Hollow Body-Centered Cubic |

| BCC-4Z | Body-Centered Cubic with four Z-struts |

| BCC-5Z | Body-Centered Cubic with five Z-struts |

| BCC-4ZH | Hollow Body-Centered Cubic with four Z-struts |

| BCC-5ZH | Hollow Body-Centered Cubic with five Z-struts |

| BCC-4ZPH | Partially Hollow Body-Centered Cubic with four Z-struts |

| BCC-5ZPH | Partially Hollow Body-Centered Cubic with five Z-struts |

References

- Zargarian, A.; Esfahanian, M.; Kadkhodapour, J.; Ziaei-Rad, S.; Zamani, D. On the fatigue behavior of additive manufactured lattice structures. Theor. Appl. Fract. Mech. 2019, 100, 225–232. [Google Scholar] [CrossRef]

- Yu, Z.; Xin, R.; Xu, Z.; Sha, L.; Chen, L.; Zhu, Y.; Liang, P.; Zhang, Z.; Liu, Z.; Cao, Q. Shock-Resistant and Energy-Absorbing Properties of Bionic NiTi Lattice Structure Manufactured by SLM. J. Bionic Eng. 2022, 19, 1684–1698. [Google Scholar] [CrossRef]

- Bai, Y.C.; Gao, J.Y.; Hou, C.X. Topology optimized design and validation of sandwich structures with pure-lattice/solid-lattice infill by additive manufacturing. Compos. Struct. 2023, 319, 117152. [Google Scholar] [CrossRef]

- Maconachie, T.; Leary, M.; Lozanovski, B.; Zhang, X.; Qian, M.; Faruque, O.; Brandt, M. SLM lattice structures: Properties, performance, applications and challenges. Mater. Des. 2019, 183, 108137. [Google Scholar] [CrossRef]

- Jin, N.; Wang, F.; Wang, Y.; Zhang, B.; Cheng, H.; Zhang, H. Effect of structural parameters on mechanical properties of pyramidal Kagome lattice material under impact loading. Int. J. Impact Eng. 2019, 132, 103313. [Google Scholar] [CrossRef]

- Zhu, J.; Yang, J.; Zhang, W.; Gu, X.; Zhou, H. Design and applications of morphing aircraft and their structures. Front. Mech. Eng. 2023, 18, 750–756. [Google Scholar] [CrossRef]

- Wei, Y.L.; Yang, Q.S.; Liu, X.; Tao, R. Multi-bionic mechanical metamaterials: A composite of FCC lattice and bone structures. Int. J. Mech. Sci. 2022, 213, 106857. [Google Scholar] [CrossRef]

- Maskery, I.; Aboulkhair, N.T.; Aremu, A.O.; Tuck, C.J.; Ashcroft, I.A.; Wildman, R.D.; Hague, R.J. A mechanical property evaluation of graded density Al-Si10-Mg lattice structures manufactured by selective laser melting. Mater. Sci. Eng. A 2016, 670, 264–274. [Google Scholar] [CrossRef]

- Xiang, J.W.; Du, J.X. Energy absorption characteristics of bio-inspired honeycomb structure under axial impact loading. Mater. Sci. Eng. A 2017, 696, 283–289. [Google Scholar] [CrossRef]

- Liu, S.; Tong, Z.; Tang, Z.; Liu, Y.; Zhang, Z. Bionic design modification of non-convex multi-corner thin-walled columns for improving energy absorption through adding bulkheads. Thin-Walled Struct. 2015, 88, 70–81. [Google Scholar] [CrossRef]

- Mishra, A.K.; Chavan, H.; Kumar, A. Effect of cell size and wall thickness on the compression performance of triply periodic minimal surface based AlSi10Mg lattice structures. Thin-Walled Struct. 2023, 193, 111214. [Google Scholar] [CrossRef]

- Xu, S.; Shen, J.; Zhou, S.; Huang, X.; Xie, Y.M. Design of lattice structures with controlled anisotropy. Mater. Des. 2016, 93, 443–447. [Google Scholar] [CrossRef]

- Wang, C.; Li, Y.; Zhao, W.; Zou, S.; Zhou, G.; Wang, Y. Structure design and multi-objective optimization of a novel crash box based on biomimetic structure. Int. J. Mech. Sci. 2018, 138, 489–501. [Google Scholar] [CrossRef]

- Ma, J.F.; Chen, W.Y.; Zhao, L.; Zhao, D.H. Elastic buckling of bionic cylindrical shells based on bamboo. J. Bionic Eng. 2008, 5, 231–238. [Google Scholar] [CrossRef]

- Zou, M.; Xu, S.; Wei, C.; Wang, H.; Liu, Z. A bionic method for the crashworthiness design of thin-walled structures inspired by bamboo. Thin-Walled Struct. 2016, 101, 222–230. [Google Scholar] [CrossRef]

- Qi, D.; Yu, H.; Liu, M.; Huang, H.; Xu, S.; Xia, Y.; Qian, G.; Wu, W. Mechanical behaviors of SLM additive manufactured octet-truss and truncated-octahedron lattice structures with uniform and taper beams. Int. J. Mech. Sci. 2019, 163, 105091. [Google Scholar] [CrossRef]

- Liu, L.; Kamm, P.; García-Moreno, F.; Banhart, J.; Pasini, D. Elastic and failure response of imperfect three-dimensional metallic lattices: The role of geometric defects induced by selective laser melting. J. Mech. Phys. Solids 2017, 109, 27–41. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Rowshan, R.; Abu Al-Rub, R.K. Topology-mechanical property relationship of 3D printed strut, skeletal, and sheet based periodic metallic cellular materials. Addit. Manuf. 2018, 19, 167–183. [Google Scholar] [CrossRef]

- Xiao, L.J.; Li, S.; Feng, G.Z.; Shi, G.Q.; Song, W.D. Research progress on mechanical properties characterization and mesoscopic optimization design of additive manufacturing three-dimensional micro-lattice materials. Chin. J. Solid Mech. 2023, 44, 718–754. [Google Scholar]

- Wu, Y.L. Study on Mechanical Properties of Titanium Alloy 3D Lattice Structures Fabricated by SLM. Master’s Thesis, Chongqing University, Chongqing, China, 2016. [Google Scholar]

- Ling, C.; Cernicchi, A.; Gilchrist, M.D.; Cardiff, P. Mechanical behaviour of additively-manufactured polymeric octet-truss lattice structures under quasi-static and dynamic compressive loading. Mater. Des. 2019, 162, 106–118. [Google Scholar] [CrossRef]

- Zheng, X.; Lee, H.; Weisgraber, T.H.; Shusteff, M.; DeOtte, J.; Duoss, E.B.; Kuntz, J.D.; Biener, M.M.; Ge, Q.; Jackson, J.A.; et al. Ultralight, ultrastiff mechanical metamaterials. Science 2014, 344, 1373–1377. [Google Scholar] [CrossRef]

- Tan, X.P.; Tan, Y.J.; Chow, C.S.; Tor, S.B.; Yeong, W.Y. Metallic powder-bed based 3D printing of cellular scaffolds for orthopaedic implants: A state-of-the-art review on manufacturing, topological design, mechanical properties and biocompatibility. Mater. Sci. Eng. C 2017, 76, 1328–1343. [Google Scholar] [CrossRef] [PubMed]

- Mechtcherine, V.; Bos, F.P.; Perrot, A.; Leal da Silva, W.R.; Nerella, V.N.; Fataei, S.; Wolfs, R.J.M.; Sonebi, M.; Roussel, N. Extrusion-based additive manufacturing with cement-based materials—Production steps, processes, and their underlying physics: A review. Cem. Concr. Res. 2020, 132, 106037. [Google Scholar]

- Rehme, O.; Emmelmann, C. Rapid manufacturing of lattice structures with selective laser melting. In Laser-Based Micropackaging; SPIE: San Diego, CA, USA, 2006. [Google Scholar]

- Deng, H.; Zhao, J.; Wang, C. Bionic design method of a non-uniform lattice structure for a landing footpad. Aerospace 2022, 9, 220. [Google Scholar] [CrossRef]

- Noronha, J.; Leary, M.; Brandt, M.; Qian, M. AlSi10Mg hollow-strut lattice metamaterials by laser powder bed fusion. Mater. Adv. 2024, 5, 3751–3770. [Google Scholar] [CrossRef]

- Noronha, J.; Qian, M.; Leary, M.; Kyriakou, E.; Brandt, M. Hollow-walled lattice materials by additive manufacturing: Design, manufacture, properties, applications and challenges. Curr. Opin. Solid State Mater. Sci. 2021, 25, 100940. [Google Scholar] [CrossRef]

- Noronha, J.; Dash, J.; Downing, D.; Rogers, J.; Qian, M.; Brandt, M.; Leary, M. Ti–6Al–4V hybrid-strut lattice metamaterials: A design strategy for improved performance. Mater. Sci. Eng. A 2024, 911, 146918. [Google Scholar] [CrossRef]

- Guo, Z.; Yang, F.; Li, P.; Li, L.; Zhao, M.; Shi, J.; Zhang, L.; Cai, Y. A partially hollow BCC lattice structure with capsule-shaped cavities for enhancing load-bearing and energy absorption properties. Eng. Struct. 2024, 305, 117777. [Google Scholar] [CrossRef]

- Zhou, W.; Li, M. Compressive properties of functionally graded bionic bamboo lattice structures fabricated by FDM. Materials 2021, 14, 4410. [Google Scholar] [CrossRef]

- Zhang, Z.; Song, B.; Qi, J.; Shi, Y. Designing and additive manufacturing of bamboo-imitated octet-truss lattice structure. J. Huazhong Univ. Sci. Technol. 2022, 50, 34–40. [Google Scholar]

| Lattice Type | Strut Diameter: do (Outer Diameter)/di (Inner Diameter) (mm/mm) | Relative Density ρ |

|---|---|---|

| BCC | 2 | 0.1784 |

| BCC-4Z | 2 | 0.1899 |

| BCC-5Z | 1.8 | 0.1841 |

| BCCH | 2.5/1.6 | 0.1676 |

| BCC-4ZPH | 2.5/1.6 | 0.1816 |

| BCC-5ZPH | 2.5/1.6 | 0.1879 |

| BCC-4ZH | 2.5/1.6 | 0.1738 |

| BCC-5ZH | 2.5/1.6 | 0.1835 |

| Si | Mg | Mn | Fe | Zn | Ni | O | N | |

|---|---|---|---|---|---|---|---|---|

| Detection value | 10.91 | 0.42 | 0.002 | 0.13 | 0.006 | 0.004 | 0.02 | 0.003 |

| Lattice Type | Designed Strut Diameter do/di (mm) | Measured Apparent Density ρc (g/cm3) | Designed Relative Density ρ | |

|---|---|---|---|---|

| BCC | 2 | 0.49 | 0.1784 | 0.1833 |

| BCC-4Z | 2 | 0.51 | 0.1899 | 0.1925 |

| BCC-5Z | 1.8 | 0.50 | 0.1841 | 0.1898 |

| BCC-4ZPH | 2.5/1.6 | 0.49 | 0.1816 | 0.1873 |

| BCC-5ZPH | 2.5/1.6 | 0.51 | 0.1879 | 0.1938 |

| BCC-4ZH | 2.5/1.6 | 0.48 | 0.1738 | 0.1810 |

| BCC-5ZH | 2.5/1.6 | 0.50 | 0.1835 | 0.1897 |

| Lattice Type | (MPa) | (±) | (MPa) | (±) |

|---|---|---|---|---|

| BCC | 4.98 | 0.05 | 7.28 | 0.07 |

| BCCH | 5.74 | 0.09 | 9.67 | 0.12 |

| BCC-4Z | 10.54 | 0.20 | 16.15 | 0.22 |

| BCC-5Z | 14.38 | 0.19 | 24.13 | 0.25 |

| BCC-4ZPH | 12.36 | 0.52 | 20.09 | 0.66 |

| BCC-5ZPH | 14.68 | 0.30 | 25.96 | 0.46 |

| BCC-4ZH | 14.52 | 0.24 | 22.88 | 0.54 |

| BCC-5ZH | 16.78 | 0.34 | 27.91 | 0.87 |

| Configuration | Hollow Strut Distribution | Z-Strut Count | Secondary Peak Presence | Dominant Failure Characteristic |

|---|---|---|---|---|

| BCC-4ZH | Fully Hollow | 4 | Yes | Localized buckling → Single shear band → Dual X-shaped shear band propagation → Global instability via hollow strut failure |

| BCC-5ZH | Fully Hollow | 5 | Yes | Localized buckling → Single shear band → Dual X-shaped shear band propagation → Global instability via hollow strut failure |

| BCC-4ZPH | Only Z-struts Hollow | 4 | Yes | Localized buckling → Single shear band → Dual X-shaped shear band propagation → Global instability induced by solid strut failure |

| BCC-5ZPH | Only Z-struts Hollow | 5 | No | Localized buckling → Direct shear band propagation → Layer-wise collapse |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, W.; Wang, Y.; Li, Q.; Jiang, B.; Zhu, J. Design and Evaluation of the Mechanical Performance of Hollow BCC Truss AlSi10Mg Lattice Structures. Metals 2025, 15, 464. https://doi.org/10.3390/met15040464

Ma W, Wang Y, Li Q, Jiang B, Zhu J. Design and Evaluation of the Mechanical Performance of Hollow BCC Truss AlSi10Mg Lattice Structures. Metals. 2025; 15(4):464. https://doi.org/10.3390/met15040464

Chicago/Turabian StyleMa, Wanqi, Yangwei Wang, Qingtang Li, Bingyue Jiang, and Jingbo Zhu. 2025. "Design and Evaluation of the Mechanical Performance of Hollow BCC Truss AlSi10Mg Lattice Structures" Metals 15, no. 4: 464. https://doi.org/10.3390/met15040464

APA StyleMa, W., Wang, Y., Li, Q., Jiang, B., & Zhu, J. (2025). Design and Evaluation of the Mechanical Performance of Hollow BCC Truss AlSi10Mg Lattice Structures. Metals, 15(4), 464. https://doi.org/10.3390/met15040464