Atomic-Scale Study on the Composition Optimization and Deformation Mechanism of FeNiAl Alloys

Abstract

1. Introduction

2. Simulation Methods

2.1. Model

2.2. Definition Criteria

2.3. Phase Diagram Validation

3. Results and Discussion

3.1. Lattice Parameters

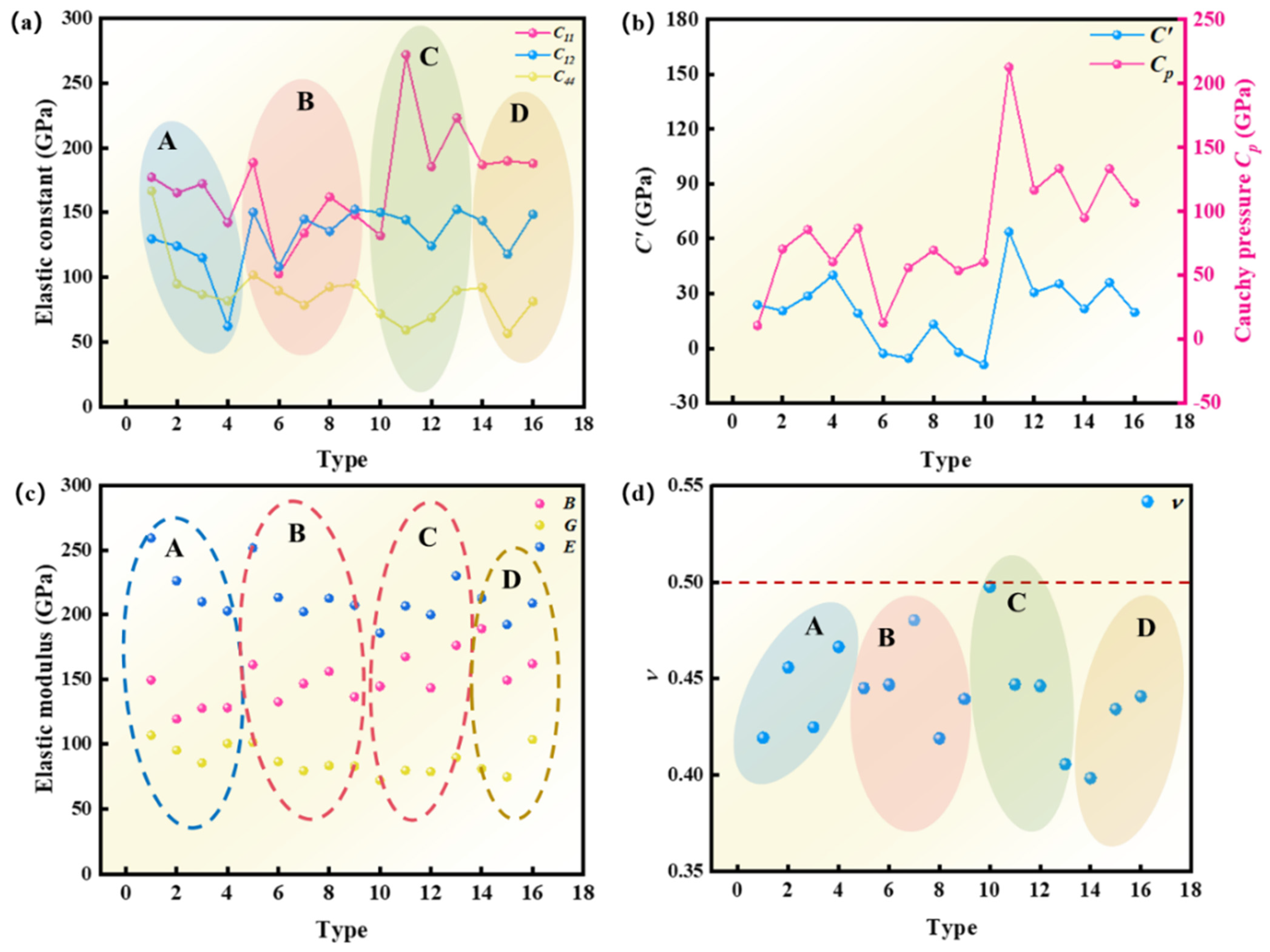

3.2. Mechanical Properties

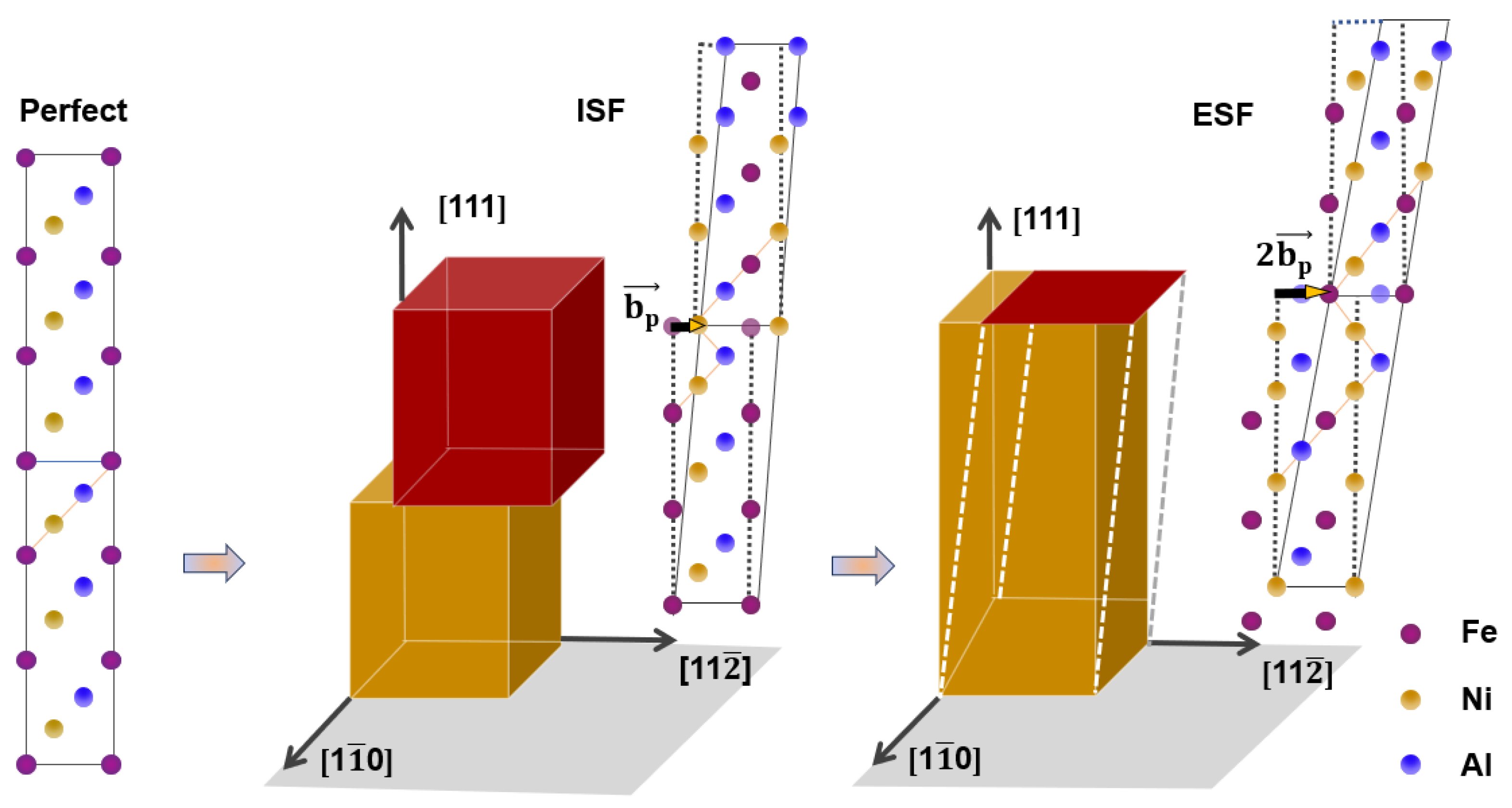

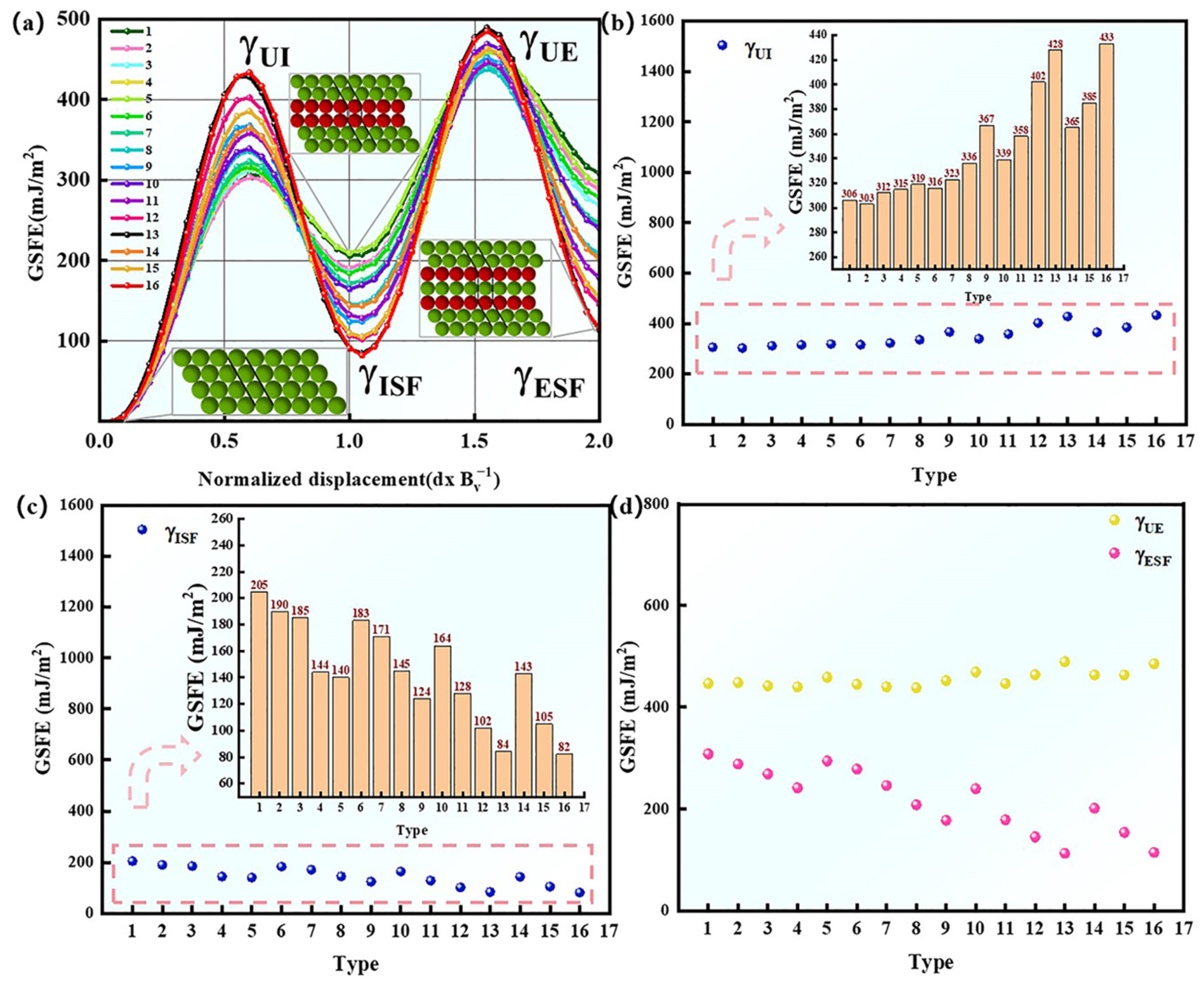

3.3. SFE and Deformation Mechanisms

3.4. Optimal Ingredient Selection

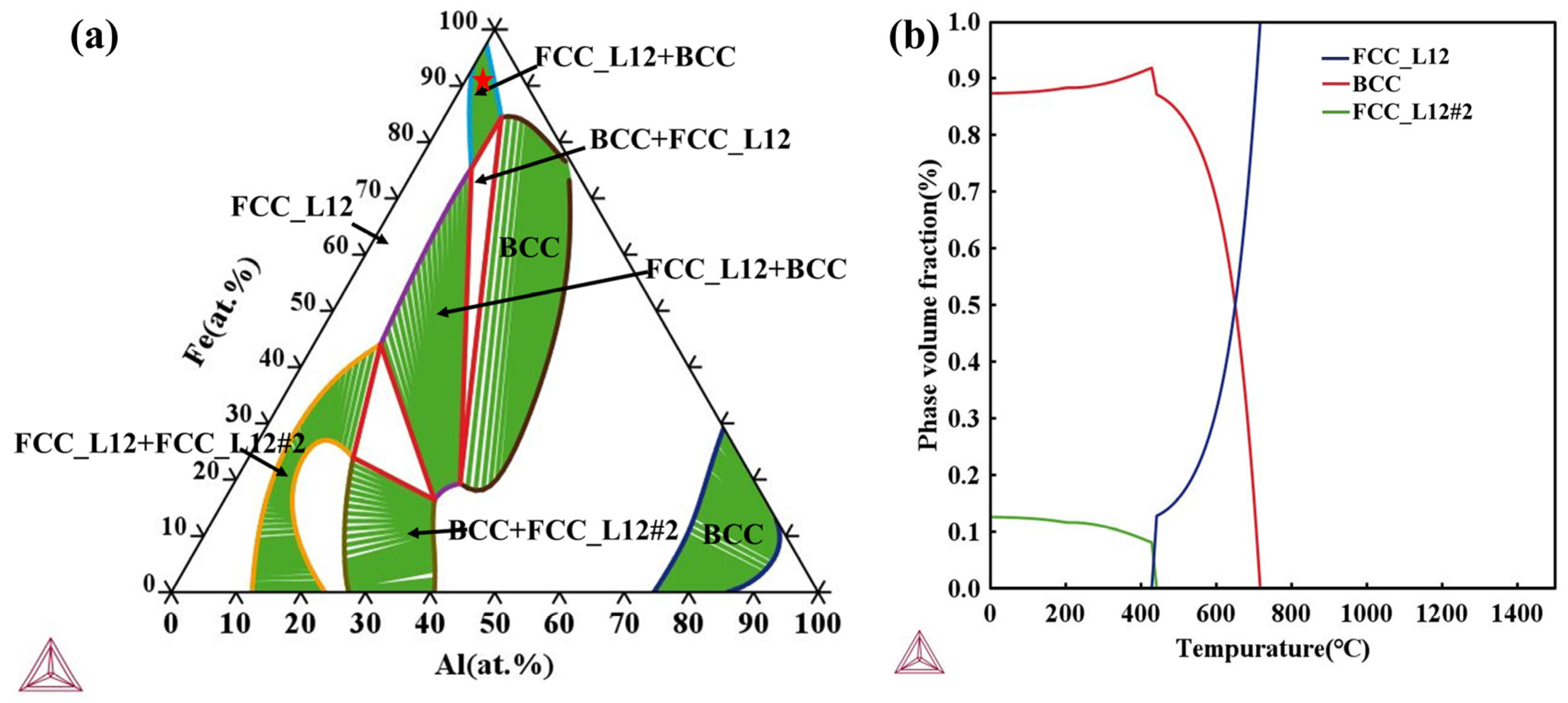

3.5. Equilibrium Phase Diagram Analysis

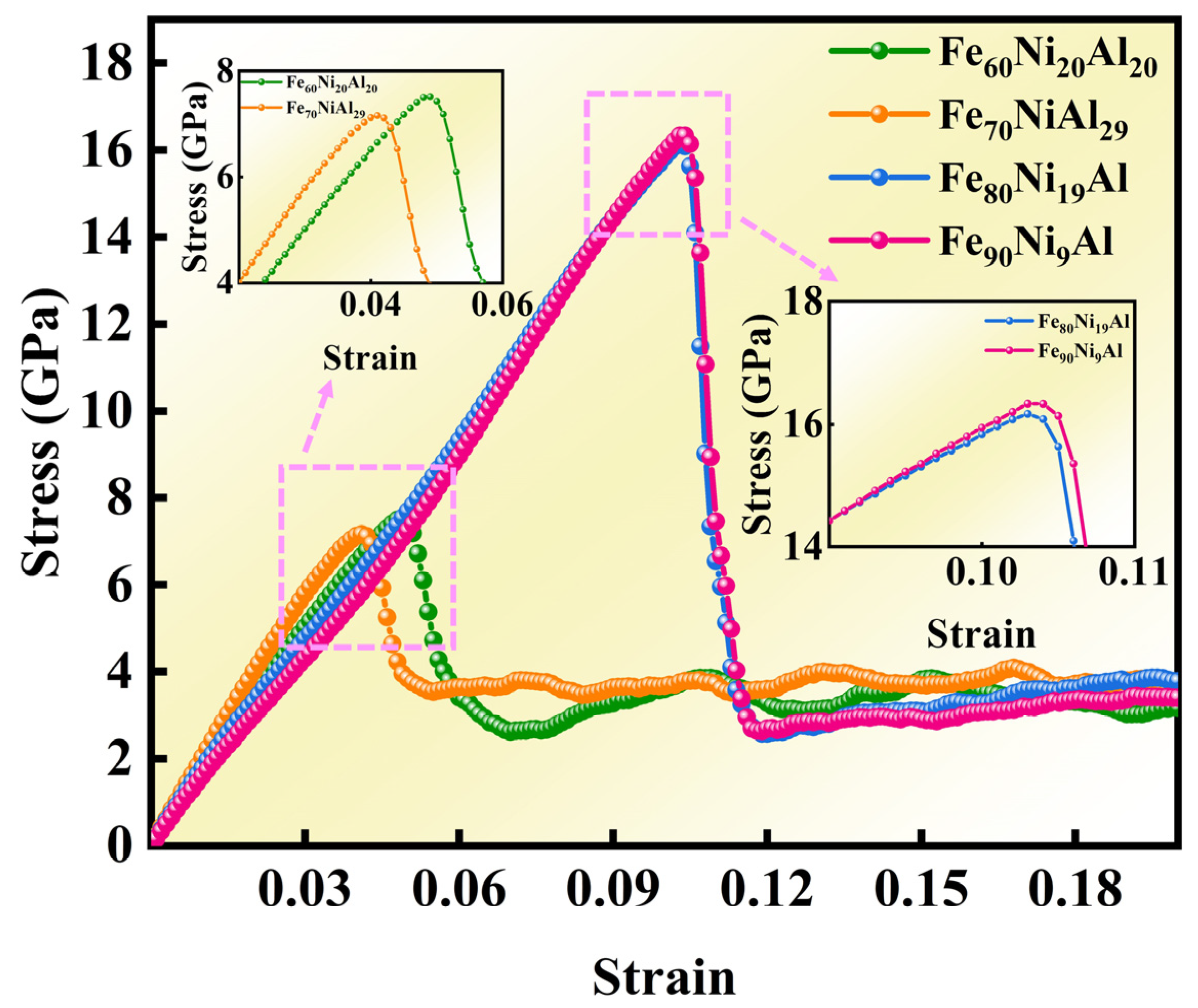

3.6. Tensile Properties and Dislocation Evolution

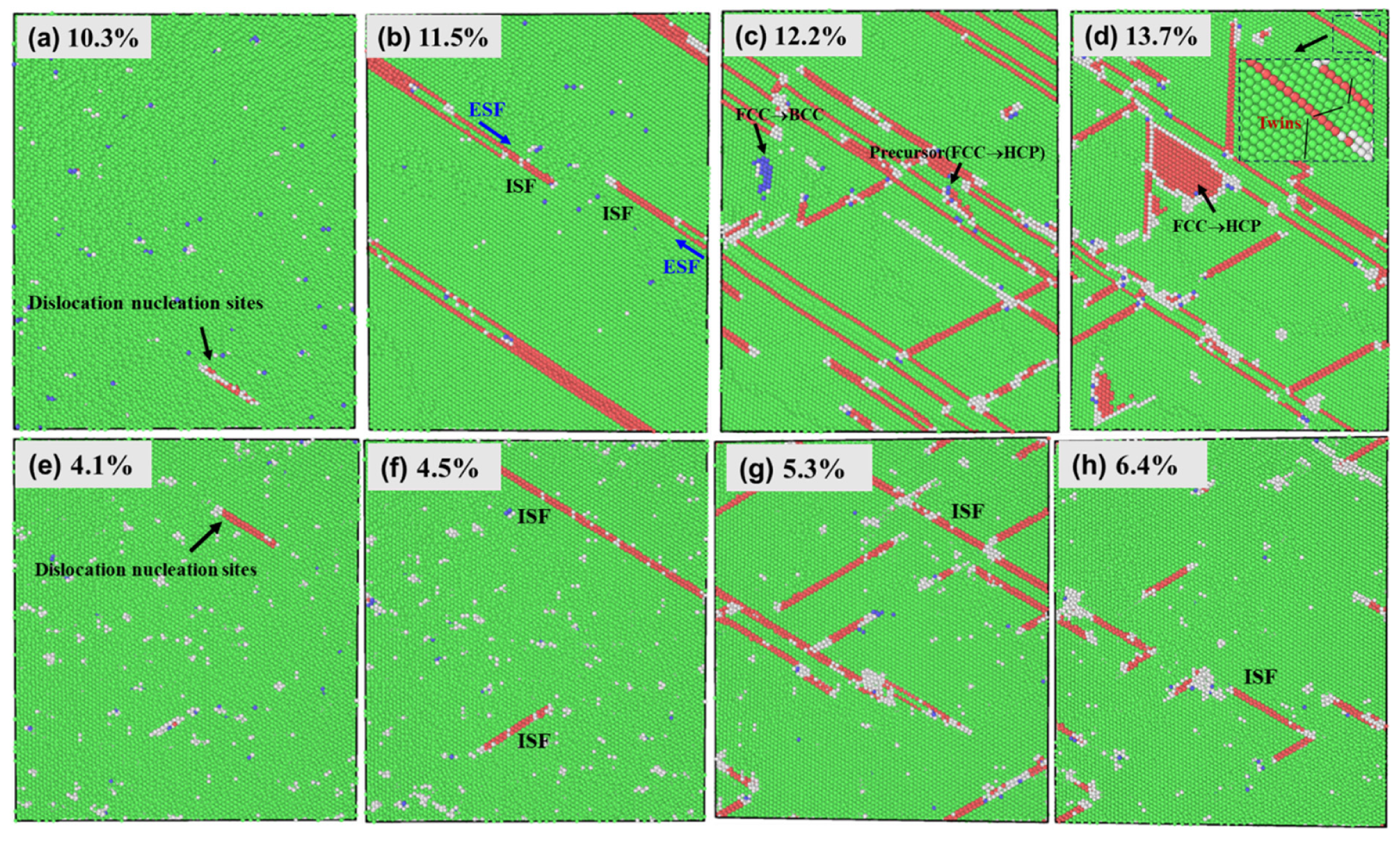

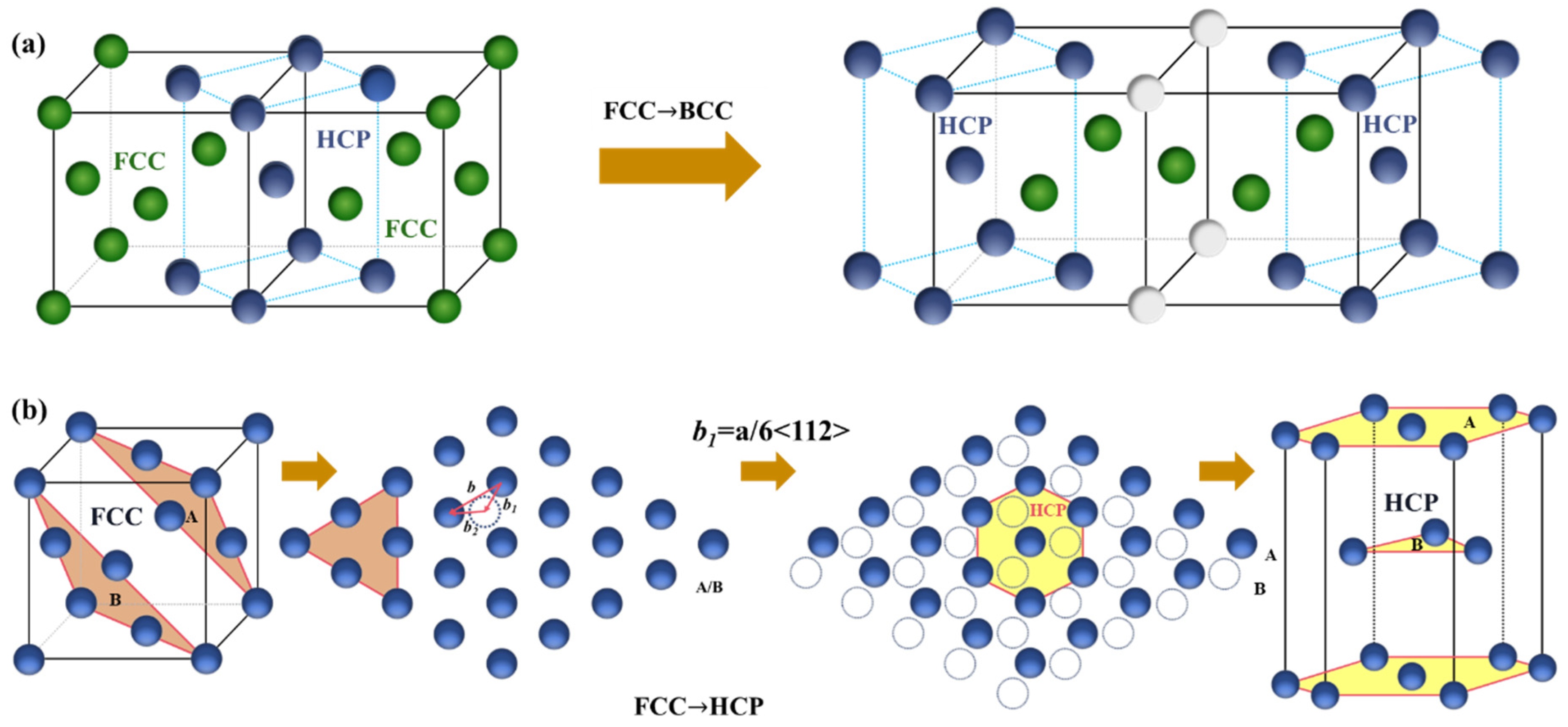

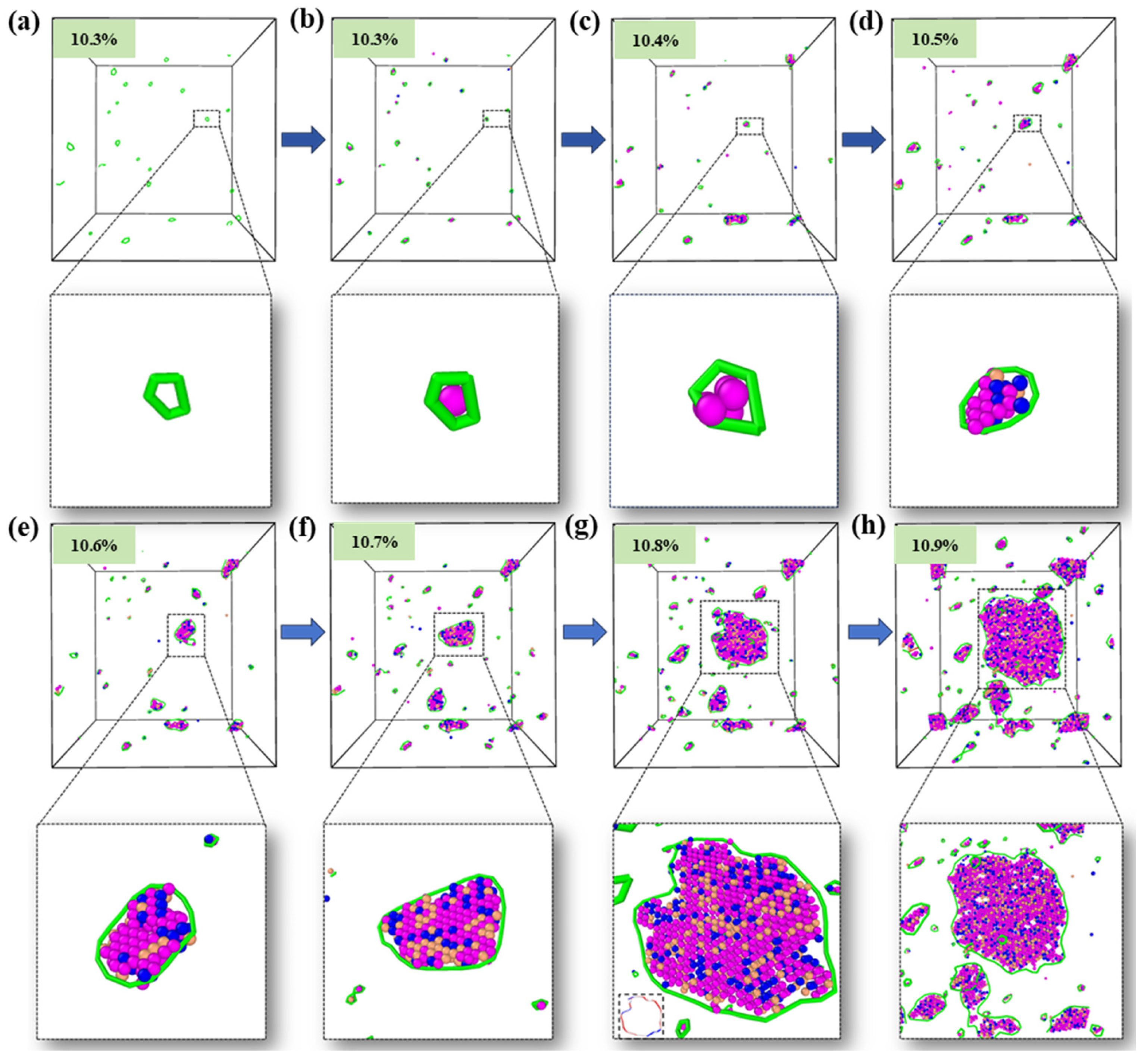

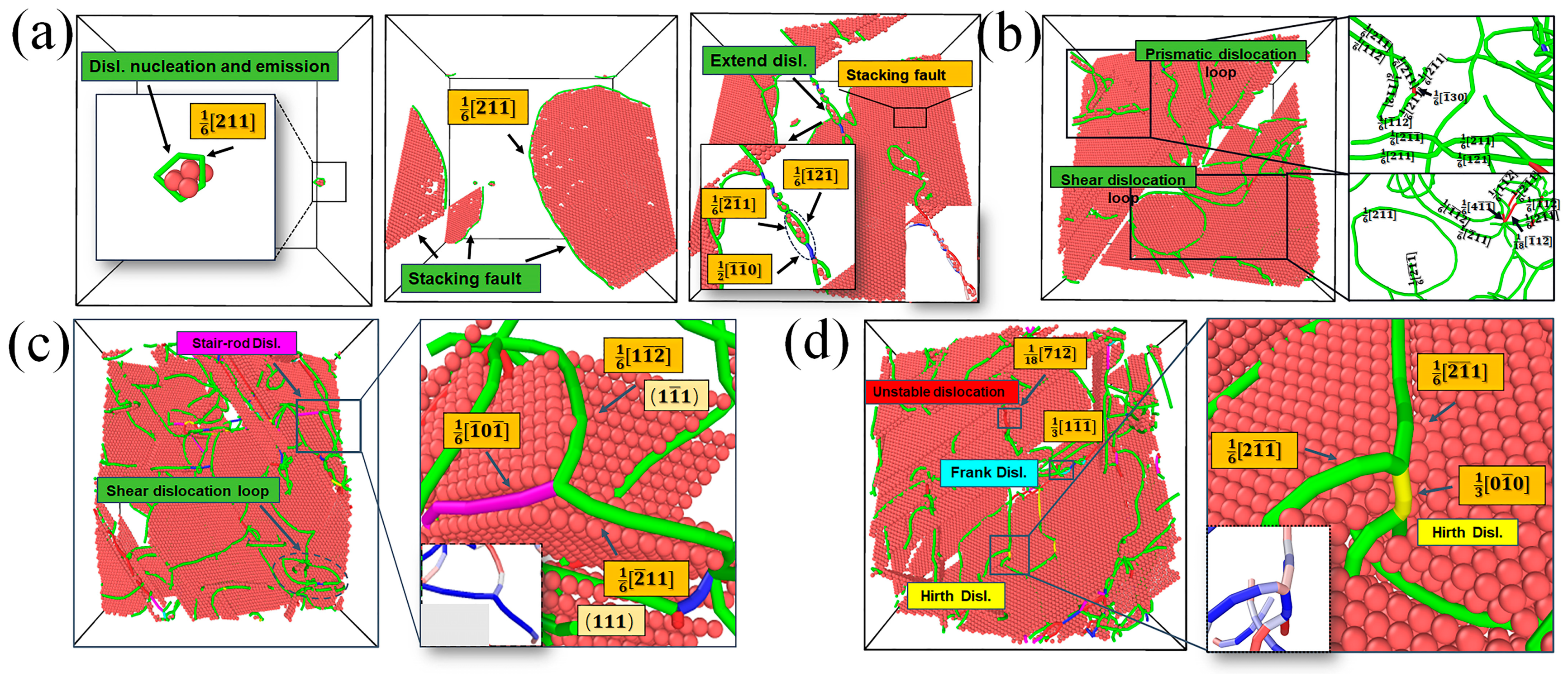

3.7. Deformation Mechanism Evolution

4. Conclusions

- With the increase in Fe content, the lattice constant shows an overall decreasing trend, primarily due to the reduced lattice distortion caused by the higher Fe content, making the lattice structure closer to the pure Fe matrix.

- As the Fe and Ni content increases and the Al content decreases, γISF exhibits a monotonic decreasing trend. Therefore, higher Fe and Ni content, along with lower Al content, enhances the strength and ductility of FeNiAl alloys.

- Four compositions meeting the selection criteria were subjected to tensile testing. The results revealed that Composition 16 (Fe90Ni9Al) demonstrated the best strength–ductility combination. During tensile deformation, minor FCC → BCC and FCC → HCP phase transitions occurred, along with deformation twinning, leading to TRIP and TWIP effects.

- The plastic deformation mechanisms primarily include ISFs, ESFs, FCC → HCP phase transitions, FCC → BCC phase transitions, deformation twinning, Lomer–Cottrell dislocation locks, and dislocation reactions. These mechanisms evolve with increasing strain, contributing to the continuous strengthening of the FeNiAl alloy.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.; Fang, C.; Wang, W.; Chen, Y. Material Properties of Fe-SMA and Its Application in Civil Engineering. Disaster Prev. Mitig. Eng. 2022, 42, 411–424. [Google Scholar]

- Sun, Z.; Gao, D.; Yang, W.; Huang, X.; Huang, J. Research of Fe3Al Intermetallics in Application to Structural Material. Chin. J. Mater. Res. 2001, 15, 69–76. [Google Scholar]

- Zhang, B.; He, B.; Wang, H. Investigation on Laser Cladding Fe-based Gradient Coatings with Hierarchical Enhanced Wear Resistance on U75V Railway Steel. Wear 2024, 552–553, 205444. [Google Scholar] [CrossRef]

- Lee, D.W.; Shin, D.S.; Ha, H.; Park, S.J.; Lee, K.A.; Kim, H.S. Modulated Heating Rate Effect on Optimizing Sintered Density and Microstructure in CoCrFeMnNi High-entropy alloy Fabricated Through Metal Injection Molding. Mater. Charact. 2024, 214, 114037. [Google Scholar] [CrossRef]

- Xu, K.; An, J.-H.; Zhang, L.; Bai, C.Y.; Tu, J.; Luo, J.-R. Composition Optimization of Cobalt-free Fe-Cr-Ni-Al/Ti multi-principal Element Alloys for Strength-ductility Trade-off based on Machine Learning. Mater. Today Commun. 2023, 36, 106498. [Google Scholar] [CrossRef]

- Qi, W.; Wang, W.; Yang, X.; Zhang, G.N.; Ye, W.; Su, Y.T.; Li, Y.; Chen, S.Y. Effects of Al and Ti co-doping on the Strength-ductility-corrosion Resistance of CoCrFeNi-AlTi High-entropy Alloys. J. Alloys Compd. 2022, 925, 166751. [Google Scholar] [CrossRef]

- Yang, D.; Liu, Y.; Jiang, H.; Liao, M.Q.; Qu, N.; Han, T.Y.; Lai, Z.H.; Zhu, J.H. A Novel FeCrNiAlTi-based High Entropy Alloy Strengthened by Refined Grains. J. Alloys Compd. 2020, 823, 153729. [Google Scholar] [CrossRef]

- Xin, G.A.; Zhou, M.; Jing, K.; Hu, H.Y.; Li, Z.A.; Zhang, Y.; Bai, Q.; Tian, C.J.; Tian, B.H.; Li, X.; et al. Heat Treatment Effects on Microstructure and Properties of Cu–Ti–Fe Alloys. Mater. Sci. Eng. A 2024, 892, 146068. [Google Scholar] [CrossRef]

- Yang, G.; Kang, J.; Carsbring, A.; Mu, W.Z.; Hedström, P.; Kim, J.K.; Park, J.H. Heterogeneous Grain Size and Enhanced Hardness by Precipitation of the BCC Particles in Medium Entropy Fe–Ni–Cr Alloys. J. Alloys Compd. 2023, 931, 167580. [Google Scholar] [CrossRef]

- Li, X.; Li, Z.; Wu, Z.; Zhao, S.; Zhang, W.; Bei, H.; Gao, Y. Strengthening in Al-, Mo- or Ti-doped CoCrFeNi High Entropy Alloys: A Parallel Comparison. J. Mater. Sci. Technol. 2021, 94, 264–274. [Google Scholar] [CrossRef]

- Zhang, L.; Qian, K.; Huang, J.; Liu, M.; Shibuta, Y. Molecular Dynamics Simulation and Machine Learning of Mechanical Response in Non-equiatomic FeCrNiCoMn High-entropy Alloy. J. Mater. Res. Technol. 2021, 13, 2043–2054. [Google Scholar] [CrossRef]

- Zhu, J.; Sun, L.; Li, D.; Zhu, L.; He, X. Compositional Undulation Induced Strain Hardening and Delocalization in Multi-principal Element Alloys. Int. J. Mech. Sci. 2023, 241, 107931. [Google Scholar] [CrossRef]

- Wan, W.; Liang, K.; Zhu, P.; He, P.; Zhang, S. Recent Advances in the Synthesis and Fabrication Methods of High-entropy Alloy Nanoparticles. J. Mater. Sci. Technol. 2024, 178, 226–246. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural Development in Equiatomic Multicomponent Alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Han, Z.D.; Luan, H.W.; Liu, X.; Chen, N.; Li, X.Y.; Shao, Y.; Yao, K.F. Microstructures and Mechanical Properties of TixNbMoTaW Refractory High-entropy Alloys. Mater. Sci. Eng. A 2018, 712, 380–385. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T. Microstructures and Properties of High-entropy Alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Wang, J.; Jiang, F.; Yang, G.; Xu, M.; Yi, J. Cr Addition-mediated Simultaneous Achievement of Excellent Strength and Plasticity in Non-equiatomic Nb-Ti-Zr-Ta-base Refractory High-entropy Alloys. J. Alloys Compd. 2023, 946, 169423. [Google Scholar] [CrossRef]

- Xu, H.; Zhang, Z.J.; Zhang, P.; Cui, C.Y.; Jin, T.; Zhang, T. The Synchronous Improvement of Strength and Plasticity (SISP) in New Ni-Co based Disc Superalloys by Controling Stacking Fault Energy. Sci. Rep. 2017, 7, 8046. [Google Scholar] [CrossRef]

- Laplanche, G.; Horst, O.; Otto, F.; Eggeler, G.; George, E.P. Microstructural Evolution of a CoCrFeMnNi High-entropy Alloy after Swaging and Annealing. J. Alloys Compd. 2015, 647, 548–557. [Google Scholar] [CrossRef]

- Schneider, M.; Laplanche, G. Effects of Temperature on Mechanical Properties and Deformation Mechanisms of the Equiatomic CrFeNi Medium-entropy Alloy. Acta Mater. 2021, 204, 116470. [Google Scholar] [CrossRef]

- Wu, M.; Sim, R.K.; He, A.; Diao, G.; Chen, D.; Li, D. Enhancing Mechanical Performance and Wear Resistance of Co-free B2/A2 CrFeNiAl Alloy via Cr and Ti Adjustment. MRS Bull. 2024, 49, 25–37. [Google Scholar] [CrossRef]

- Gao, Q.; Wang, W.; Ren, J.; Li, W.; Sang, B.; Li, L.; Wang, Q.; Lu, X.; Qiao, J. Optimizing Strength-ductility in NiCoMn Medium Entropy Alloys with Atomic-scale Rapid Composition Design. J. Mater. Sci. Technol. 2025, 215, 71–85. [Google Scholar] [CrossRef]

- Tang, K.; Wu, Y.K.; Wei, R.; Chen, L.B.; Lu, S.; Qi, Y.L.; Jiang, F.; Sun, J. Achieving Superior Cryogenic Tensile Properties in a Ti-doped (Fe40Mn40Co10Cr10)96.7C3.3 High-entropy Alloy by Recovering Deformation Twinning. Mater. Sci. Eng. A 2021, 808, 140927. [Google Scholar] [CrossRef]

- Jiang, D.; Xie, L.; Wang, L. Current Application Status of Multi-scale Simulation and Machine Learning in Research on High-entropy Alloys. J. Mater. Res. Technol. 2023, 26, 1341–1374. [Google Scholar] [CrossRef]

- Borovikov, V.V.; Mendelev, M.I.; Smith, T.M.; Lawson, J.W. Molecular Dynamics Simulation of Twin Nucleation and Growth in Ni-based Superalloys. Int. J. Plast. 2023, 166, 103645. [Google Scholar] [CrossRef]

- Branicio, P.S.; Rino, J.P.; Gan, C.K.; Tsuzuki, H. Interaction Potential for Indium Phosphide: A Molecular Dynamics and First-principles Study of the Elastic Constants, Generalized Stacking Fault and Surface Energies. J. Phys. Condens. Matter 2009, 21, 095002. [Google Scholar] [CrossRef]

- Jarlöv, A.; Ji, W.; Zhu, Z.; Tian, Y.; Babicheva, R.; An, R.; Seet, H.L.; Sharon, M.L.; Zhou, N.K. Molecular Dynamics Study on the Strengthening Mechanisms of Cr–Fe–Co–Ni High-entropy Alloys based on the Generalized Stacking Fault Energy. J. Alloys Compd. 2022, 905, 164137. [Google Scholar] [CrossRef]

- Yan, J.X.; Zhang, Z.J.; Li, K.Q.; Yang, J.B.; Zhang, Z.F. Cross-slip Mechanisms of <111> Screw Super dislocations in FeAl. Comput. Mater. Sci. 2021, 189, 110261. [Google Scholar] [CrossRef]

- Liu, P.; Xie, J.; Wang, A.; Ma, D.; Mao, Z. Molecular Dynamics Simulation on the Deformation Mechanism of Monocrystalline and Nano-twinned TiN under Nanoindentation. Mater. Chem. Phys. 2020, 252, 123263. [Google Scholar] [CrossRef]

- Gao, T.; Song, H.; Wang, B.; Gao, Y.; Liu, Y.; Xie, Q.; Chen, Q.; Xiao, Q.; Liang, Y. Molecular Dynamics Simulations of Tensile Response for FeNiCrCoCu High-entropy Alloy with Voids. Int. J. Mech. Sci. 2023, 237, 107800. [Google Scholar] [CrossRef]

- Fang, Q.; Chen, Y.; Li, J.; Jiang, C.; Liu, B.; Liu, Y.; Liaw, P.K. Probing the Phase Transformation and Dislocation Evolution in Dual-phase High-entropy Alloys. Int. J. Plast. 2019, 114, 161–173. [Google Scholar] [CrossRef]

- Plimpton, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Farkas, D.; Caro, A. Model Interatomic Potentials for Fe-Ni-Cr-Co-Al High-entropy Alloys. J. Mater. Res. 2020, 35, 3031–3040. [Google Scholar] [CrossRef]

- Hirel, P. Atomsk: A Tool for Manipulating and Converting Atomic Data Files. Comput. Phys. Commun. 2015, 197, 212–219. [Google Scholar] [CrossRef]

- Khan, T.Z.; Kirk, T.; Vazquez, G.; Singh, P.; Smirnov, A.V.; Johnson, D.D.; Youssef, K.; Arróyave, R. Towards Stacking Fault Energy Engineering in FCC High Entropy Alloys. Acta Mater. 2022, 224, 117472. [Google Scholar] [CrossRef]

- Choi, W.S.; Pang, E.L.; Ko, W.-S.; Jun, H.; Bong, H.J.; Kirchlechner, C.; Raabe, D.; Choi, P.P. Orientation-dependent Plastic Deformation Mechanisms and Competition with Stress-induced Phase Transformation in Microscale NiTi. Acta Mater. 2021, 208, 116731. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, C.; Shi, S.; Li, T.; Zou, L.; Lu, Y.; Liaw, P.K. Tuning Deformation Mechanisms of Face-centered-cubic High-entropy Alloys via Boron Doping. J. Alloys Compd. 2022, 911, 165103. [Google Scholar] [CrossRef]

- Hu, X.; Huang, M.; Zhu, Y.; Zhao, L.; Li, Z.H. Investigation of Physical Properties and Superdislocation Characters of Ni3Al under Uniaxial Tension/compression Normal to Slip Plane. Intermetallics 2021, 136, 107258. [Google Scholar] [CrossRef]

- Rao, S.I.; Varvenne, C.; Woodward, C.; Parthasarathy, T.A.; Miracle, D.; Senkov, O.N.; Curtin, W.A. Atomistic Simulations of Dislocations in a Model BCC Multicomponent Concentrated Solid Solution Alloy. Acta Mater. 2017, 125, 311–320. [Google Scholar] [CrossRef]

- Li, W.; Gao, Q.; Ren, J.; Wang, Q.; Li, J.; Xue, H.; Lu, X.; Tang, F. Designing the Composition and Optimizing the Mechanical Properties of Non-equiatomic FeCoNiTi High-entropy Alloys. J. Mater. Res. Technol. 2024, 29, 376–385. [Google Scholar] [CrossRef]

- Chmelko, V.; Koščo, T.; Šulko, M.; Margetin, M.; Škriniarová, J. Poisson’s Ratio of Selected Metallic Materials in the Elastic–Plastic Region. Metals 2024, 14, 433. [Google Scholar] [CrossRef]

- Zuo, L.; Humbert, M.; Esling, C. Elastic Properties of Polycrystals in the Voigt-Reuss-Hill Approximation. J. Appl. Crystallogr. 1992, 25, 751–755. [Google Scholar] [CrossRef]

- Rao, S.I.; Woodward, C.; Parthasarathy, T.A.; Senkov, O. Atomistic Simulations of Dislocation Behavior in a Model FCC Multicomponent Concentrated Solid Solution Alloy. Acta Mater. 2017, 134, 188–194. [Google Scholar] [CrossRef]

- Zhang, W.X.; Cong, Y.B.; Wang, J.; Li, C.; Wan, J.; Chen, Y.Z. Revealing the effects of martensitic transformation and dislocation slip in austenite on the micromechanical behaviors of a 9Ni steel using crystal plasticity finite element method. Int. J. Plast. 2024, 174, 103869. [Google Scholar] [CrossRef]

- Qi, Y.; Zhao, M.; Feng, M. Molecular Simulation of Microstructure Evolution and Plastic Deformation of Nanocrystalline CoCrFeMnNi High-entropy Alloy under Tension and Compression. J. Alloys Compd. 2021, 851, 156923. [Google Scholar] [CrossRef]

- Yang, R.; Yang, L.; Wang, T.; Wang, Q. Untra-fine-grained Equiatomic CoCrNi Medium Entropy Alloys with High Density Stacking Faults and Strengthening Mechanisms. Mater. Sci. Eng. A 2023, 870, 144880. [Google Scholar] [CrossRef]

- Yan, Z.; Lin, Y. Lomer-Cottrell Locks with Multiple Stair-rod Dislocations in a Nanostructured Al Alloy Processed by Severe Plastic Deformation. Mater. Sci. Eng. A 2019, 747, 177–184. [Google Scholar] [CrossRef]

- Gao, J.; Jiang, S.; Zhao, H. Enhancing Strength and Ductility in a Near Medium Mn Austenitic Steel via Multiple Deformation Mechanisms through Nanoprecipitation. Acta Mater. 2023, 243, 118538. [Google Scholar] [CrossRef]

- Alabd Alhafez, I.; Ruestes, C.J.; Zhao, S.; Minor, A.M.; Urbassek, H.M. Dislocation Structures below a Nano-indent of the CoCrNi Medium-entropy Alloy. Mater. Lett. 2021, 283, 128821. [Google Scholar] [CrossRef]

- Remington, T.P.; Ruestes, C.J.; Bringa, E.M.; Remington, B.A.; Lu, C.H.; Kad, B.; Meyers, M.A. Plastic Deformation in Nanoindentation of Tantalum: A New Mechanism for Prismatic Loop Formation. Acta Mater. 2014, 78, 378–393. [Google Scholar] [CrossRef]

- Erel, C.; Po, G.; Crosby, T.; Ghoniem, N. Generation and Interaction Mechanisms of Prismatic Dislocation Loops in FCC Metals. Comput. Mater. Sci. 2017, 140, 32–46. [Google Scholar] [CrossRef]

- Sun, B.; Ouyang, W.; Ren, J.; Mi, L.; Guo, W. Fcc → bcc → hcp Successive Phase Transformations in the Strained Ultrathin Copper Film: A Molecular Dynamic Simulation Study. Mater. Chem. Phys. 2019, 223, 171–182. [Google Scholar] [CrossRef]

- Li, Q.; Jiang, C.L.; Du, Y. Molecular Dynamics Study on Dynamic Mechanical Behaviour of FeCoCrCuNi High Entropy Alloy. Mater. Technol. 2023, 38, 2200660. [Google Scholar] [CrossRef]

- Zhang, J.; Yan, J.; Liu, C.; Yao, Z.; Huang, J.; Yu, H.; Xie, H.; Yin, F.; Fang, W. Dislocation Behavior in Initial Stage of Plastic Deformation for CoCrNi Medium Entropy Alloy. J. Alloys Compd. 2023, 943, 169057. [Google Scholar]

- Liang, Q.; Weng, S.; Fu, T.; Hu, S.; Peng, X. Dislocation Reaction-based Formation Mechanism of Stacking Fault Tetrahedra in FCC High-entropy Alloy. Mater. Chem. Phys. 2022, 282, 125997. [Google Scholar] [CrossRef]

| Type | Composition | Lattice Constant |

|---|---|---|

| 1 | Fe60Ni5Al35 | 3.76 |

| 2 | Fe60Ni10Al30 | 3.76 |

| 3 | Fe60Ni15Al25 | 3.71 |

| 4 | Fe60Ni20Al20 | 3.68 |

| 5 | Fe70NiAl29 | 3.76 |

| 6 | Fe70Ni5Al25 | 3.73 |

| 7 | Fe70Ni10Al20 | 3.69 |

| 8 | Fe70Ni15Al15 | 3.68 |

| 9 | Fe70Ni20Al10 | 3.61 |

| 10 | Fe80Ni5Al15 | 3.68 |

| 11 | Fe80Ni10Al10 | 3.63 |

| 12 | Fe80Ni15Al5 | 3.59 |

| 13 | Fe80Ni19Al | 3.58 |

| 14 | Fe90NiAl19 | 3.64 |

| 15 | Fe90Ni5Al5 | 3.59 |

| 16 | Fe90Ni9Al | 3.56 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| C11 | 177.26 | 165.26 | 172.30 | 142.28 | 188.55 | 102.53 | 134.13 | 162.05 |

| C12 | 129.60 | 124.11 | 115 | 62.04 | 150.23 | 108.15 | 144.89 | 135.59 |

| C44 | 166.60 | 94.73 | 86.70 | 81.74 | 101.89 | 89.65 | 78.35 | 92.50 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | |

| C11 | 148.17 | 132.10 | 271.92 | 185.39 | 223.15 | 186.98 | 189.79 | 187.97 |

| C12 | 152.39 | 150.08 | 144.36 | 124.16 | 152.45 | 143.59 | 117.85 | 148.60 |

| C44 | 94.61 | 71.73 | 59.19 | 68.87 | 89.76 | 92.12 | 56.54 | 81.31 |

| Alloys | Yield Strength (GPa) | Yield Strain (%) |

|---|---|---|

| (4) Fe60Ni20Al20 | 7.51 | 4.1 |

| (5) Fe70NiAl29 | 7.16 | 4.9 |

| (13) Fe80Ni19Al | 16.16 | 10.3 |

| (16) Fe90Ni9Al | 16.33 | 10.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.; Gui, Y.; Tang, X.; Li, Y.; Wang, C.; Sheng, J.; Zhang, Z.; Lu, X.; Ren, J. Atomic-Scale Study on the Composition Optimization and Deformation Mechanism of FeNiAl Alloys. Metals 2025, 15, 460. https://doi.org/10.3390/met15040460

Chen C, Gui Y, Tang X, Li Y, Wang C, Sheng J, Zhang Z, Lu X, Ren J. Atomic-Scale Study on the Composition Optimization and Deformation Mechanism of FeNiAl Alloys. Metals. 2025; 15(4):460. https://doi.org/10.3390/met15040460

Chicago/Turabian StyleChen, Chen, Yachen Gui, Xingchang Tang, Yufeng Li, Changbo Wang, Jie Sheng, Zhijian Zhang, Xuefeng Lu, and Junqiang Ren. 2025. "Atomic-Scale Study on the Composition Optimization and Deformation Mechanism of FeNiAl Alloys" Metals 15, no. 4: 460. https://doi.org/10.3390/met15040460

APA StyleChen, C., Gui, Y., Tang, X., Li, Y., Wang, C., Sheng, J., Zhang, Z., Lu, X., & Ren, J. (2025). Atomic-Scale Study on the Composition Optimization and Deformation Mechanism of FeNiAl Alloys. Metals, 15(4), 460. https://doi.org/10.3390/met15040460