Observation and Analysis of Metallic Interface Bridging and Self-Healing Under Electromagnetic Shocking Treatment

Abstract

1. Introduction

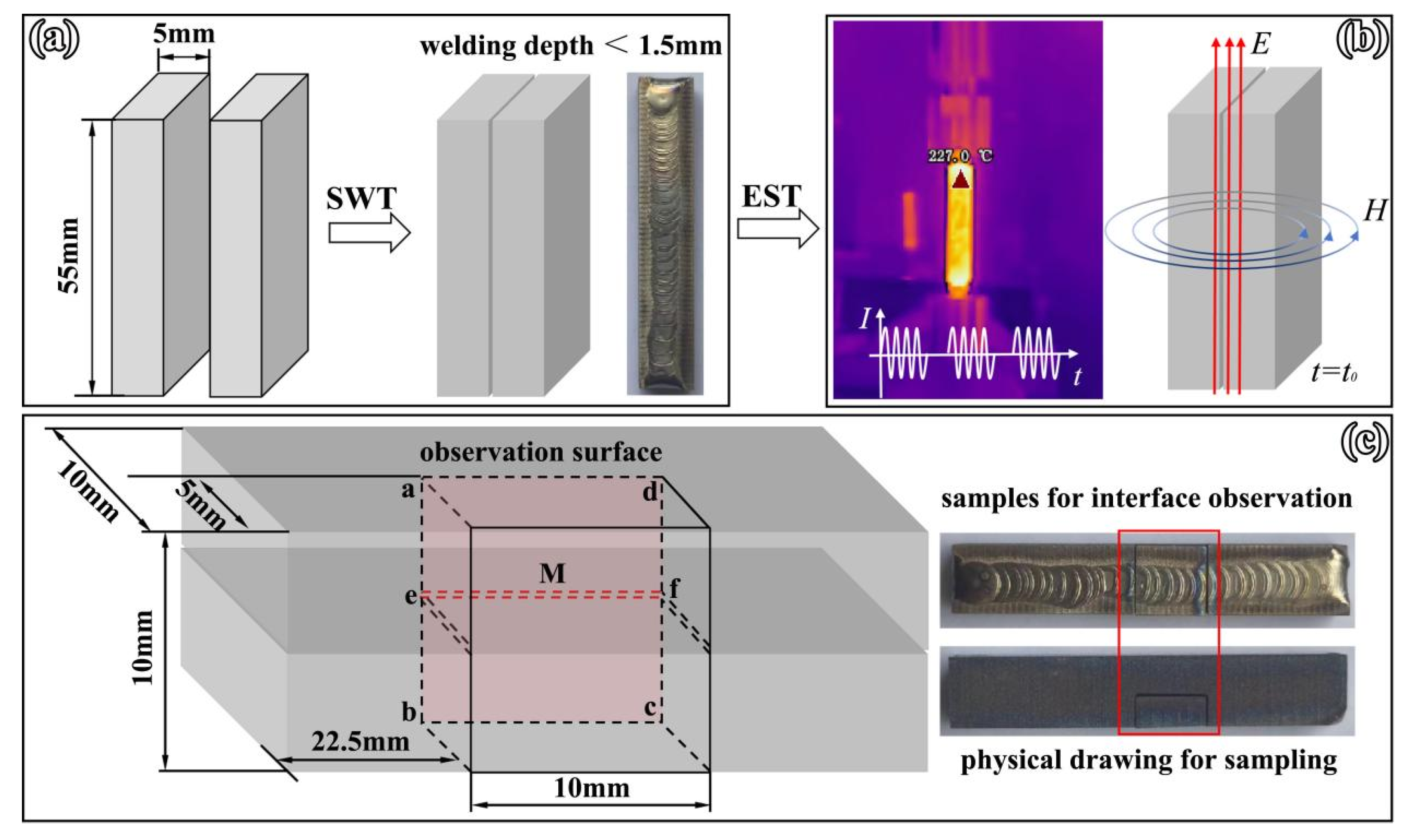

2. Materials and Methods

2.1. Raw Materials

2.2. Sealing Welding Treatment

2.3. Electromagnetic Shocking Treatment

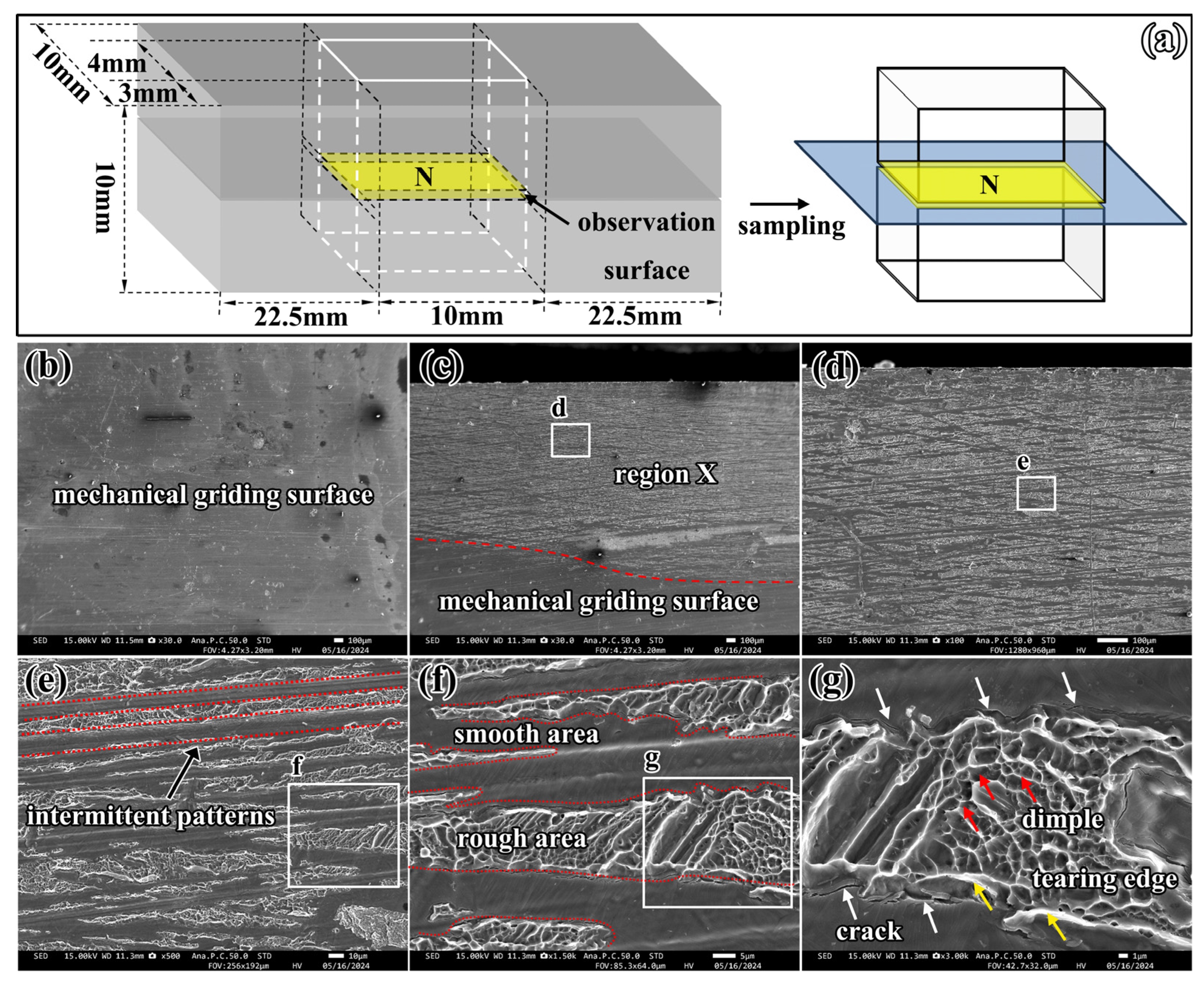

2.4. SEM Observation

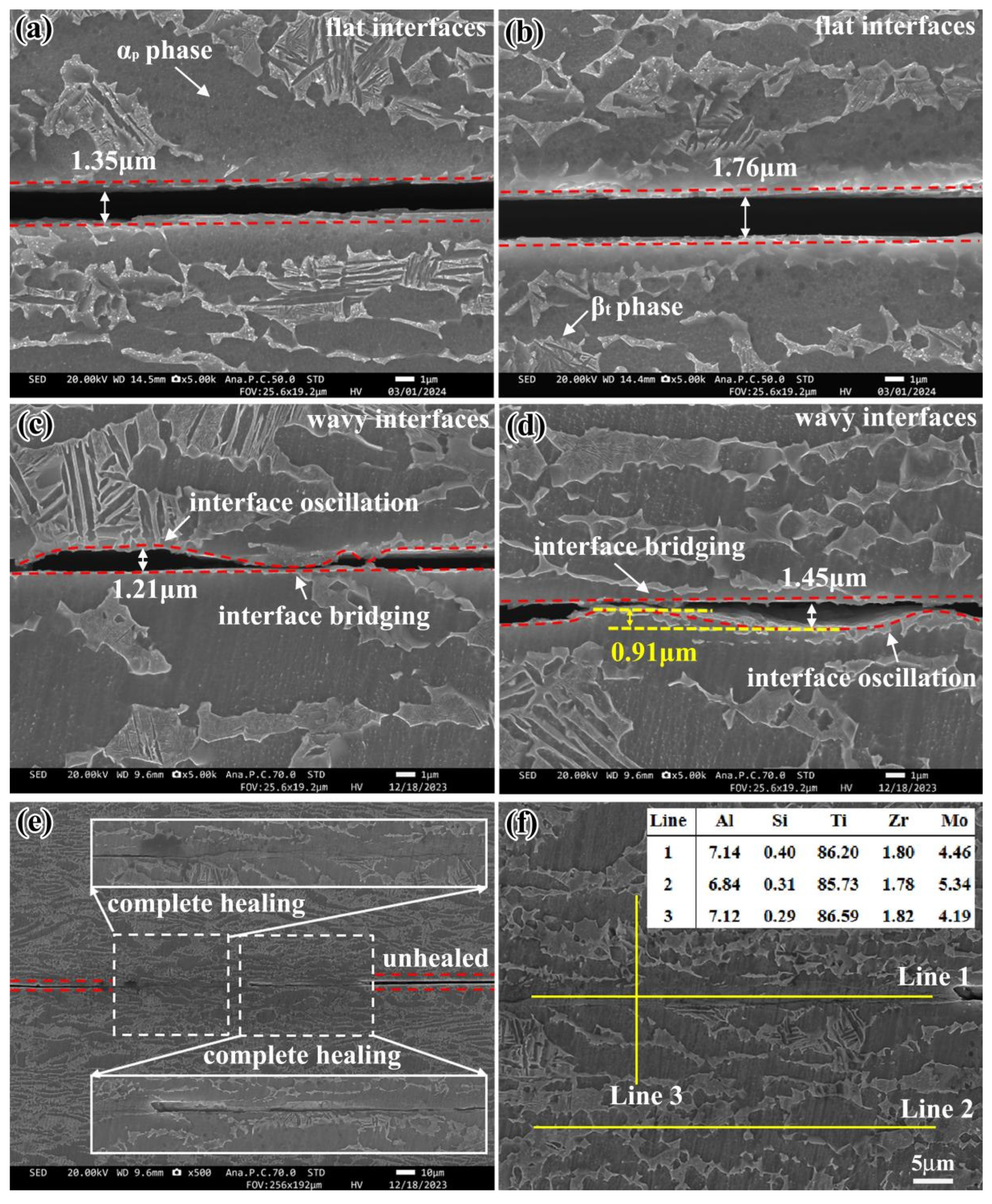

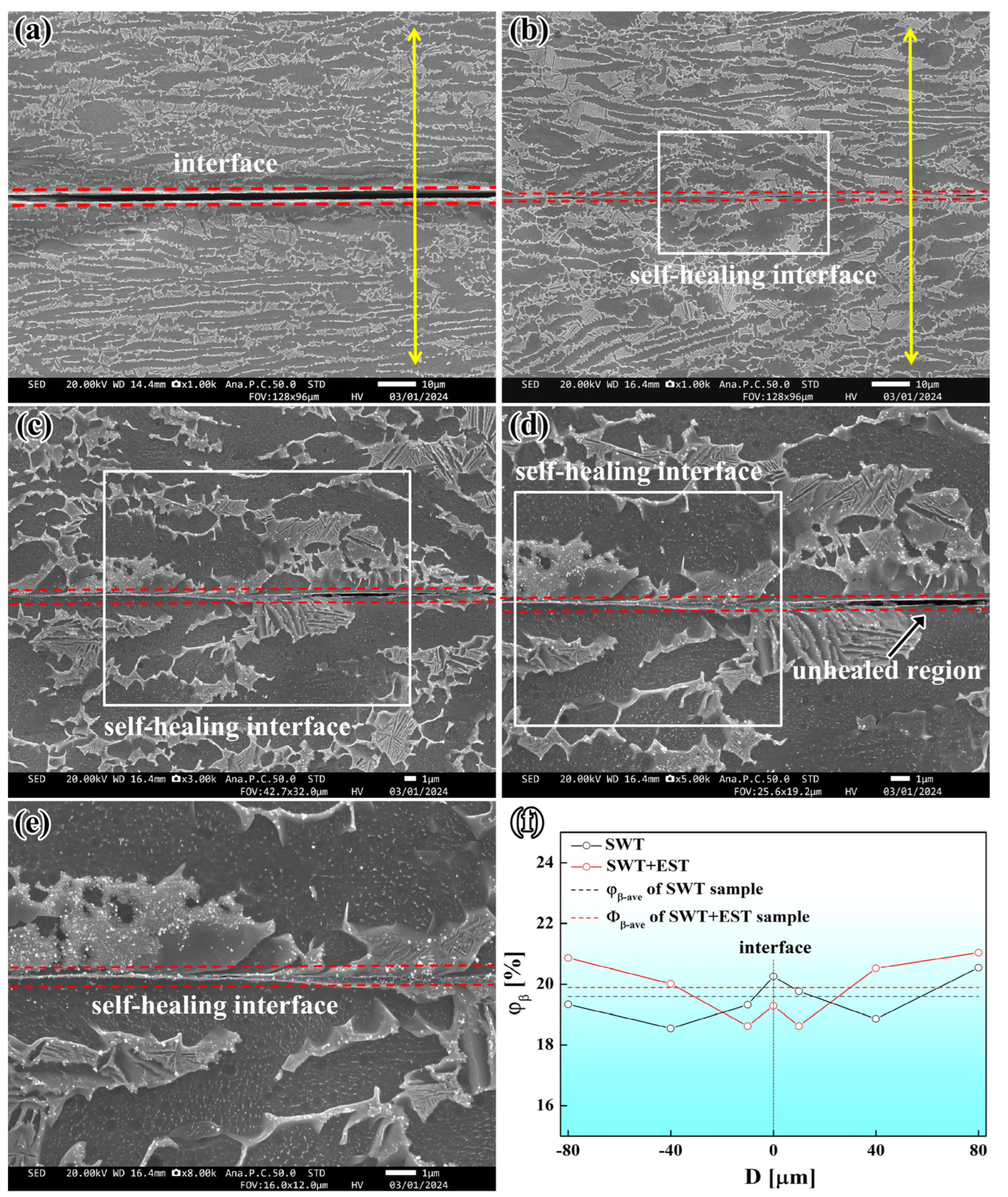

3. Results

4. Discussion

5. Conclusions

- (1)

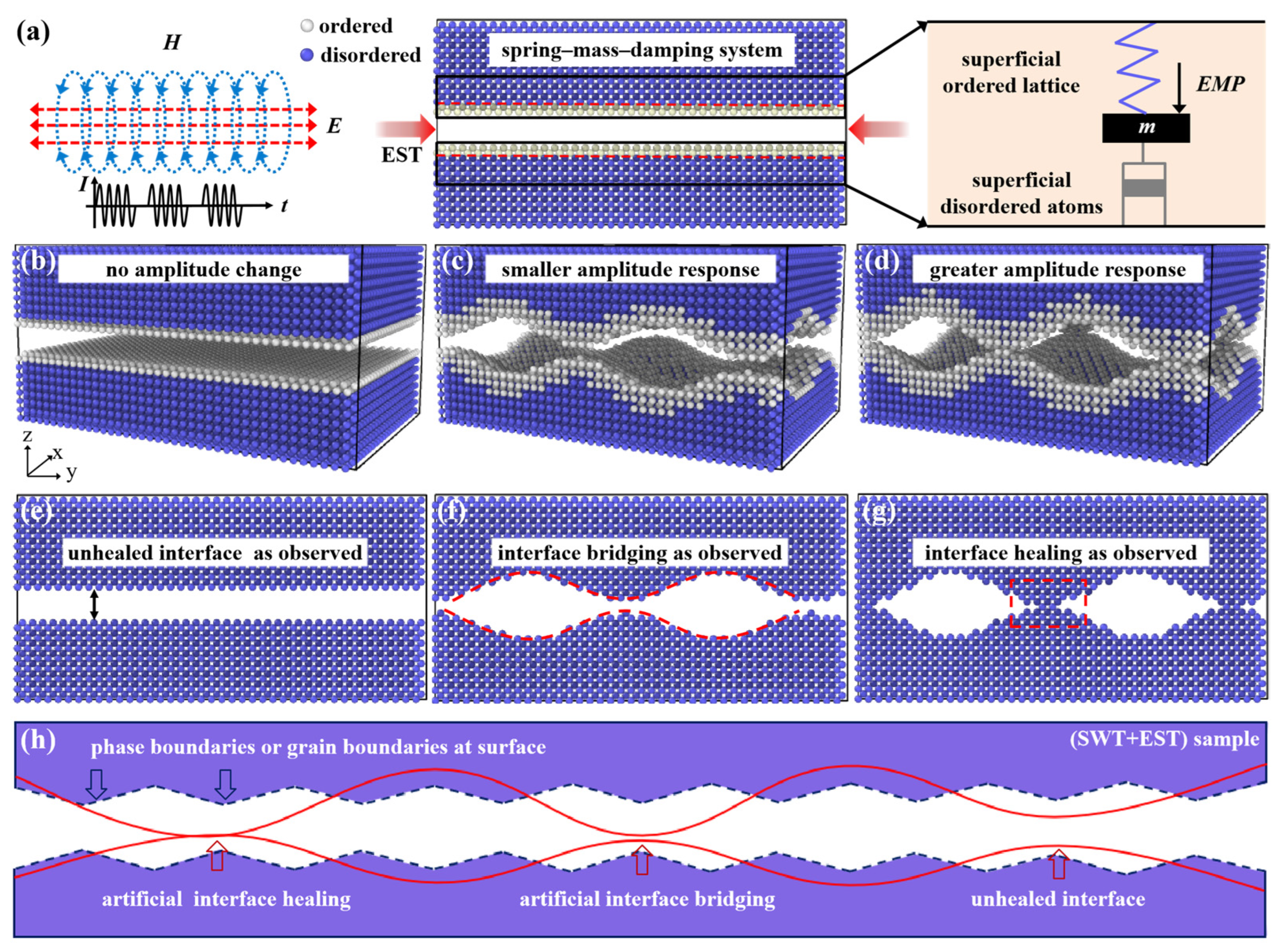

- Without macro deformation and significant temperature increasing, EST can targetedly adjust interface complexion by interface pre-melting, such as promoting interface bridging and self-healing.

- (2)

- Under the effect of EMP energy during the EST, coupling with appropriate thermal activation, alloy interface can energetically absorb EMP vibration energy and tends to occur nonlinear pre-melting.

- (3)

- This work might provide new insights for the interface evolution mechanism of the solid alloys under the effect of EMP energy or (quasi-) periodic energy fluctuation as well as new design strategy of interface complexion modification of solid alloys by utilizing EMP energy or (quasi-) periodic energy fluctuation.

- (4)

- Without significant surface temperature increasing and macro deformation, the EST can promote interface bridging and self-healing of the metals and alloys, which is benificial for the self-healing of micro cracks and the further improvement of the service performance of the metal parts.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dijk, N.V.; Zwaag, S.V.D. Self-Healing Phenomena in Metals. Adv. Mater. Interfaces 2018, 5, 1800226. [Google Scholar] [CrossRef]

- Barr, C.M.; Duong, T.; Bufford, D.C.; Milne, Z.; Molkeri, A.; Heckman, N.M.; Adams, D.P.; Srivastava, A.; Hattar, K.; Demkowicz, M.J.; et al. Autonomous healing of fatigue cracks via cold welding. Nature 2023, 620, 552–556. [Google Scholar] [CrossRef]

- Lu, Y.; Huang, J.Y.; Wang, C.; Sun, S.H.; Lou, J. Cold welding of ultrathin gold nanowires. Nat. Nanotechnol. 2010, 5, 218–224. [Google Scholar] [CrossRef]

- Hu, X.G.; Guo, C.; Huang, Y.H.; Xu, Z.; Shi, Z.F.; Zhou, F.; Li, G.; Zhou, Y.; Li, Y.; Li, Z.Y.; et al. Liquid-induced healing of cracks in nickel-based superalloy fabricated by laser powder bed fusion. Acta Mater. 2024, 267, 119731. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Sun, M.Y.; Xu, B.; Hu, X.; Liu, S.; Xie, B.J.; Li, D.Z. Evolution of the interfacial microstructure during the plastic deformation bonding of copper. Mater. Sci. Eng. A 2019, 746, 1–10. [Google Scholar] [CrossRef]

- Xie, B.J.; Yu, Z.X.; Jiang, H.Y.; Xu, B.; Wang, C.Y.; Zhang, J.Y.; Sun, M.Y.; Li, D.Z.; Li, Y.Y. Effects of surface roughness on interfacial dynamic recrystallization and mechanical properties of Ti-6Al-3Nb-2Zr-1Mo alloy joints produced by hot-compression bonding. J. Mater. Sci. Technol. 2022, 96, 199–211. [Google Scholar] [CrossRef]

- Zhang, Z.; Ning, B.K.; Qian, W.F.; Wang, S.; Wang, N.; Chen, Y.N.; Li, Y.; Zhang, Q.Y.; Li, H.Z.; Wang, S.P.; et al. Promoting crack self-healing of nanocomposite coating by double slip systemic semi-coherent interface dislocation. Mater. Res. Lett. 2024, 12, 467–476. [Google Scholar] [CrossRef]

- Song, H.; Wang, Z.J.; He, X.D.; Duan, J. Self-healing of damage inside metals triggered by electropulsing stimuli. Sci. Rep. 2017, 7, 7097. [Google Scholar] [CrossRef]

- Zheng, X.G.; Shi, Y.N.; Lu, K. Electro-Healing cracks in nickel. Mater. Sci. Eng. A 2013, 561, 52–59. [Google Scholar] [CrossRef]

- Lin, H.Q.; Zhao, Y.G.; Gao, Z.M.; Han, L.G. Effects of pulse current stimulation on the thermal fatigue crack propagation behavior of CHWD steel. Mater. Sci. Eng. A 2008, 478, 93–100. [Google Scholar] [CrossRef]

- Hosoi, A.; Nagahama, T.; Ju, Y. Fatigue crack healing by a controlled high density electric current field. Mater. Sci. Eng. A 2012, 533, 38–42. [Google Scholar] [CrossRef]

- Putz, B.; Glushko, O.; Cordill, M.J. Electromigration in Gold Films on Flexible Polyimide Substrates as a Self-healing Mechanism. Mater. Res. Lett. 2016, 4, 43–47. [Google Scholar] [CrossRef]

- Zhou, L.Y.; Feng, S.B.; Sun, M.Y.; Xu, B.; Li, D.Z. Interfacial microstructure evolution and bonding mechanisms of 14YWT alloys produced by hot compression bonding. J. Mater. Sci. Technol. 2019, 35, 1671–1680. [Google Scholar] [CrossRef]

- Wang, F.; Qian, D.S.; Hua, L.; Mao, H.J.; Xie, L.C. Voids healing and carbide refinement of cold rolled M50 bearing steel by electropulsing treatment. Sci. Rep. 2019, 9, 11315. [Google Scholar] [CrossRef]

- Xie, L.H.; Guo, H.J.; Song, Y.L.; Hua, L.; Wang, L.Q.; Zhang, L.C. Novel approach of electroshock treatment for defect repair in near-β titanium alloy manufactured via directed energy deposition. Metall. Mater. Trans. A 2021, 52, 457–461. [Google Scholar] [CrossRef]

- Cai, Z.P.; Qian, C.K.; Zhang, X.; Dai, N.; Wu, Y.; Ji, W. Mechanism and application of mechanical property improvements in engineering materials by pulsed magnetic treatment: A review. Friction 2024, 12, 2139–2166. [Google Scholar] [CrossRef]

- Qian, C.K.; Liu, Q.; Xiong, X.Y.; Ye, B.J.; Li, Z.Y.; Li, K.J.; Ying, S.J.; Zhang, H.J.; Huang, D.M.; Zhang, X.; et al. Mechanism for magnetic field induced structural relaxation and accompanying fracture toughness improvement of the thermal spraying coating. Mater. Des. 2022, 223, 111113. [Google Scholar] [CrossRef]

- Qian, C.K.; Liu, Q.; Li, K.J.; Ma, L.; Cai, Z.P. Electrochemical corrosion behavior variation of WC-10Co4Cr coating subjected to different magnetic treatments and its mechanism. Corros. Sci. 2024, 229, 111883. [Google Scholar] [CrossRef]

- Li, Z.; Li, K.J.; Qian, C.K.; Wang, D.X.; Ji, W.; Wu, Y.; Cai, Z.P.; Liu, Q. Effect of pulsed magnetic field on retained austenite of quenched 8Cr4Mo4V steel under cryogenic condition. J. Mater. Res. Technol. 2023, 23, 5004–5015. [Google Scholar] [CrossRef]

- Ye, Y.X.; Tang, C.; Zhang, Y.; Yang, Y.; Li, K.J.; Wang, F.; Huang, B.H.; Xu, L.J.; Gao, L.; Wang, J.H.; et al. Magnetic-assisted ultrasonic nanocrystal surface modification induced microstructures of titanium alloy. Surf. Coat. Technol. 2024, 485, 130892. [Google Scholar] [CrossRef]

- Ao, D.; Zhang, H.; Wang, H.; Bao, W.; Gao, J.; Chu, X. Investigation of deformation behavior during electric pulse assisted incremental forming of Ti-6Al-4V sheet with a water-cooling system. J. Manuf. Process. 2024, 126, 165–174. [Google Scholar] [CrossRef]

- Li, S.; Chen, L.; Chu, X.; Tang, J.; Zhao, G.; Zhang, C. Improvement in Mechanical Properties of Al-Zn-Mg Alloy by Applying Electric Pulse During Hot Extrusion. J. Mater. Res. Technol. 2020, 9, 1210–1220. [Google Scholar] [CrossRef]

- Sun, F.; Wan, S.; Liao, J.; Wang, D.; Xiao, G.; Niu, Q. Effect of Electric Pulse Treatment on the Microstructure and Machining Performance of Ti-6Al-4V. J. Mater. Eng. Perform. 2024, 33, 1169–1178. [Google Scholar]

- Kang, K.; Li, D.; Wang, A.; Shi, D.; Gao, G.; Xu, Z. Experimental Investigation on Aging Treatment of 7050 Alloy Assisted by Electric Pulse. Results Phys. 2020, 16, 103016. [Google Scholar] [CrossRef]

- Ma, R.; Zhang, X. Refining the Microstructure to Strengthen Casting Titanium Alloy by Electric Pulse. Mater. Sci. Eng. A 2022, 849, 143519. [Google Scholar] [CrossRef]

- Oboňa, J.V.; Ocelík, V.; Rao, J.C.; Skolski, J.Z.P.; Römer, G.R.B.E.; Huis, A.J.; De Hosson, J.T.M. Modification of Cu surface with picosecond laser pulses. Appl. Surf. Sci. 2014, 303, 118–124. [Google Scholar] [CrossRef]

- Gu, S.; Liu, C.; Kimura, Y.; Yoon, S.; Cui, Y.; Yan, X.; Ju, Y.; Toku, Y. Realizing strength–ductility synergy in a lean duplex stainless steel through enhanced TRIP effect via pulsed electric current treatment. Mater. Sci. Eng. A 2023, 883, 145534. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, J.; Yao, Y.; Qiao, Q.; Zhao, L.; Liu, L.; Jin, F.; Zhan, M.; Li, H. Anomalous enhancing effects of electric pulse treatment on strength and ductility of TC17 linear friction welding joints. J. Mater. Sci. Technol. 2024, 203, 155–166. [Google Scholar] [CrossRef]

- Liu, D.; Liu, X.; Zhou, Y.; Zhang, Y.; Geng, G. Influence of electric pulse on microstructural characteristics and mechanical properties of cast AZ91D magnesium alloy. J. Alloys Compd. 2025, 1010, 177303. [Google Scholar] [CrossRef]

- Ren, L.; Liu, C.H.; Zhang, X.F. Rapid repair of thermal aging embrittlement in 17-4PH martensitic stainless steel using pulsed electric current. Mater. Charact. 2024, 208, 113650. [Google Scholar] [CrossRef]

- Xu, G.L.; Zhu, Y.Q.; Peng, L.J.; Mi, X.J.; Xie, H.F.; Cao, Y.C.; Li, X.H. Simultaneously enhancing the strength and ductility of Cu-Ti-Fe alloy through electric current pulse induced precipitation. Scr. Mater. 2025, 255, 116387. [Google Scholar] [CrossRef]

- Sun, Q.; Liu, L.H.; Yu, S.; Wang, H.; Wang, H.J. Gradient phase transformation of Al-Zn-Mg-Cu alloy induced by nonlinear interface wetting under electromagnetic shocking treatment. J. Mater. Sci. 2023, 58, 16239–16255. [Google Scholar] [CrossRef]

- Li, Y.F.; Wang, F.L.; Sun, Q.; Qian, D.S.; Song, Y.L.; Hua, L. Study on the microstructure and impact toughness of TC11 titanium alloy by a novel electromagnetic shocking treatment. Mater. Sci. Eng. A 2023, 876, 145149. [Google Scholar] [CrossRef]

- Sun, Q.; Hua, L. Micro texture of titanium alloys excited nonlinearly by electromagnetic pulse. Scr. Mater. 2021, 200, 113828. [Google Scholar] [CrossRef]

- Sun, Q.; Yu, Y.M.; Wang, F. A novel electromagnetic shock treatment to selectively modify grain boundary and improve the corrosion resistance of aluminium alloy. Mater. Lett. 2023, 334, 133703. [Google Scholar] [CrossRef]

- Sun, Q.; Wang, H.J.; Yu, S.; Wang, F.; Song, Y.L.; Hua, L.; Qian, D.S. Reducing stress corrosion cracking susceptibility of high-strength aluminum alloy and its fastener by a novel electromagnetic shocking treatment. J. Alloys Compd. 2023, 960, 170917. [Google Scholar] [CrossRef]

- Cahn, R.W. Materials science: Melting and the surface. Nature 1986, 323, 668–669. [Google Scholar] [CrossRef]

- Tartaglino, U.; Zykova-Timan, T.; Ercolessi, F.; Tosatti, E. Melting and nonmelting of solid surfaces and nanosystems. Phys. Rep. 2005, 411, 291–321. [Google Scholar] [CrossRef]

- Ding, K.; Oue, D.; Chan, C.T.; Pendry, J.B. Casimir-Induced Instabilities at Metallic Surfaces and Interfaces. Phys. Rev. Lett. 2021, 126, 046802. [Google Scholar] [CrossRef]

- Jiang, W.B.; Kong, Q.P.; Cui, P. Further evidence of grain boundary internal friction in bicrystals. Mater. Sci. Eng. A 2010, 527, 6028–6032. [Google Scholar] [CrossRef]

- Hong, J.N.; Tian, Y.; Liang, T.C.; Liu, X.M.; Song, Y.Z.; Guan, D.; Yan, Z.X.; Guo, J.D.; Tang, B.Z.; Cao, D.Y.; et al. Imaging surface structure and premelting of ice Ih with atomic resolution. Nature 2024, 630, 375–380. [Google Scholar] [CrossRef] [PubMed]

- Slater, B.; Michaelides, A. Surface premelting of water ice. Nat. Rev. Chem. 2019, 3, 172–188. [Google Scholar] [CrossRef]

- Kong, Q.P.; Fang, Q.F. Progress in the Investigations of Grain Boundary Relaxation. Crit. Rev. Solid State Mater. Sci. 2016, 41, 192–216. [Google Scholar] [CrossRef]

- Danzig, A.; Scaly, O.; Polturak, E. Is the surface fluid during premelting? A study of the surface shear resistance of solid Gallium. Surf. Sci. 2021, 705, 121779. [Google Scholar] [CrossRef]

- Li, X.; Zhu, Q.; Hong, Y.R.; Zhang, H.; Wang, J.; Wang, J.W.; Zhang, Z. Revealing the pulse-induced electroplasticity by decoupling electron wind force. Nat. Commun. 2022, 13, 6503. [Google Scholar] [CrossRef]

- Bai, Z.T.; Misra, A.; Fan, Y. Universal Trend in the dynamic relaxations of tilted metastable grain boundaries during ultrafast thermal cycle. Mater. Res. Lett. 2022, 10, 343–351. [Google Scholar] [CrossRef]

- Dillon, S.J.; Tang, M.; Carter, W.C.; Harmer, M.P. Complexion: A new concept for kinetic engineering in materials science. Acta Mater. 2007, 55, 6208–6218. [Google Scholar] [CrossRef]

- Cantwell, P.R.; Tang, M.; Dillon, S.J.; Luo, J.; Rohrer, G.S.; Harmer, M.P. Grain boundary complexions. Acta Mater. 2014, 62, 1–48. [Google Scholar] [CrossRef]

- Liss, K.D.; Xu, P.G.; Shiro, A.; Zhang, S.Y.; Yukutake, E.; Shobu, T.; Akita, K. Abnormal grain growth: A spontaneous activation of competing grain rotation. Adv. Eng. Mater. 2024, 26, 2300470. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Q.; Duan, Y.; Wang, F.; Jie, W.; Liang, S. Observation and Analysis of Metallic Interface Bridging and Self-Healing Under Electromagnetic Shocking Treatment. Metals 2025, 15, 422. https://doi.org/10.3390/met15040422

Sun Q, Duan Y, Wang F, Jie W, Liang S. Observation and Analysis of Metallic Interface Bridging and Self-Healing Under Electromagnetic Shocking Treatment. Metals. 2025; 15(4):422. https://doi.org/10.3390/met15040422

Chicago/Turabian StyleSun, Qian, Yaxuan Duan, Fanglei Wang, Weibing Jie, and Suohui Liang. 2025. "Observation and Analysis of Metallic Interface Bridging and Self-Healing Under Electromagnetic Shocking Treatment" Metals 15, no. 4: 422. https://doi.org/10.3390/met15040422

APA StyleSun, Q., Duan, Y., Wang, F., Jie, W., & Liang, S. (2025). Observation and Analysis of Metallic Interface Bridging and Self-Healing Under Electromagnetic Shocking Treatment. Metals, 15(4), 422. https://doi.org/10.3390/met15040422