Microwave Dielectric Behavior of CoTiTa2O8-MgNb2O6 Composite Ceramics: A Focus on Temperature Stability and Compositional Effects

Abstract

1. Introduction

2. Experimental Section

2.1. Sample Preparation

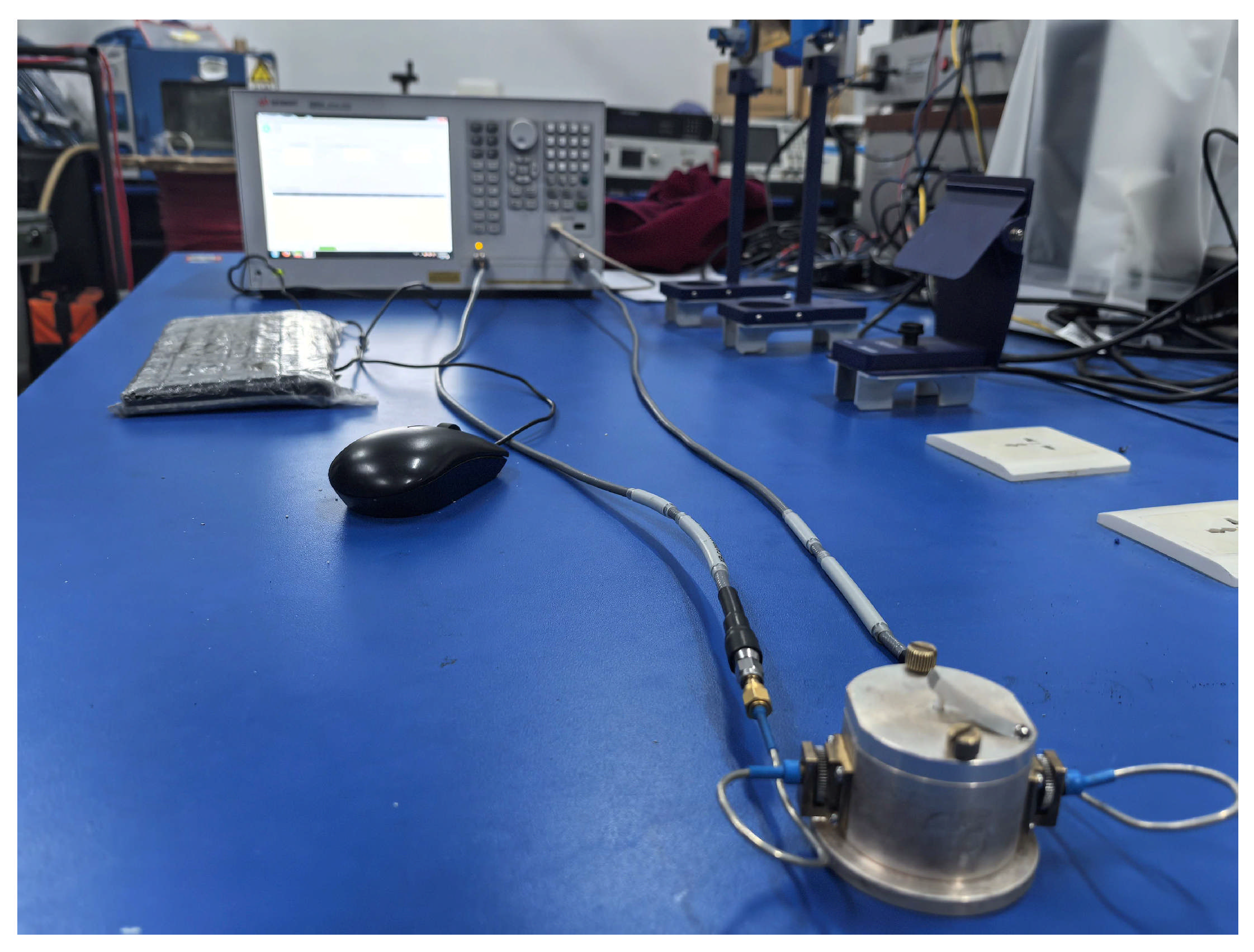

2.2. Materials Characterization

3. Results and Discussion

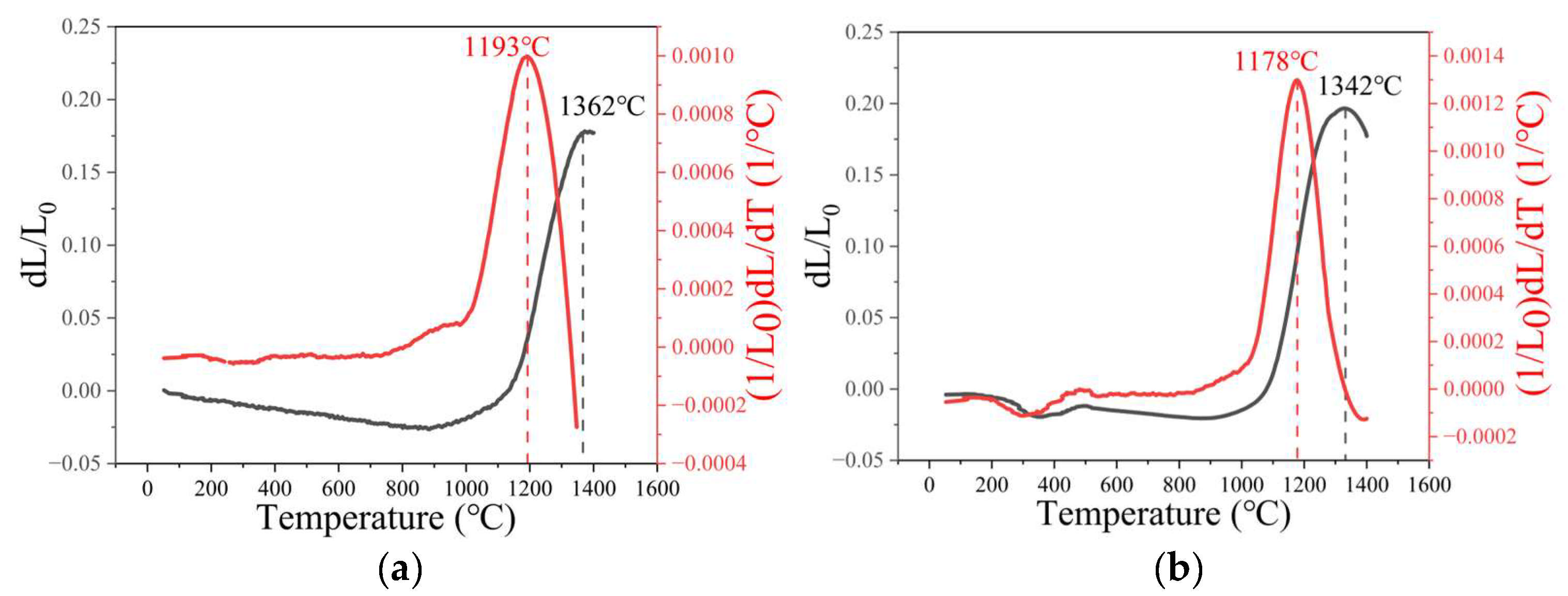

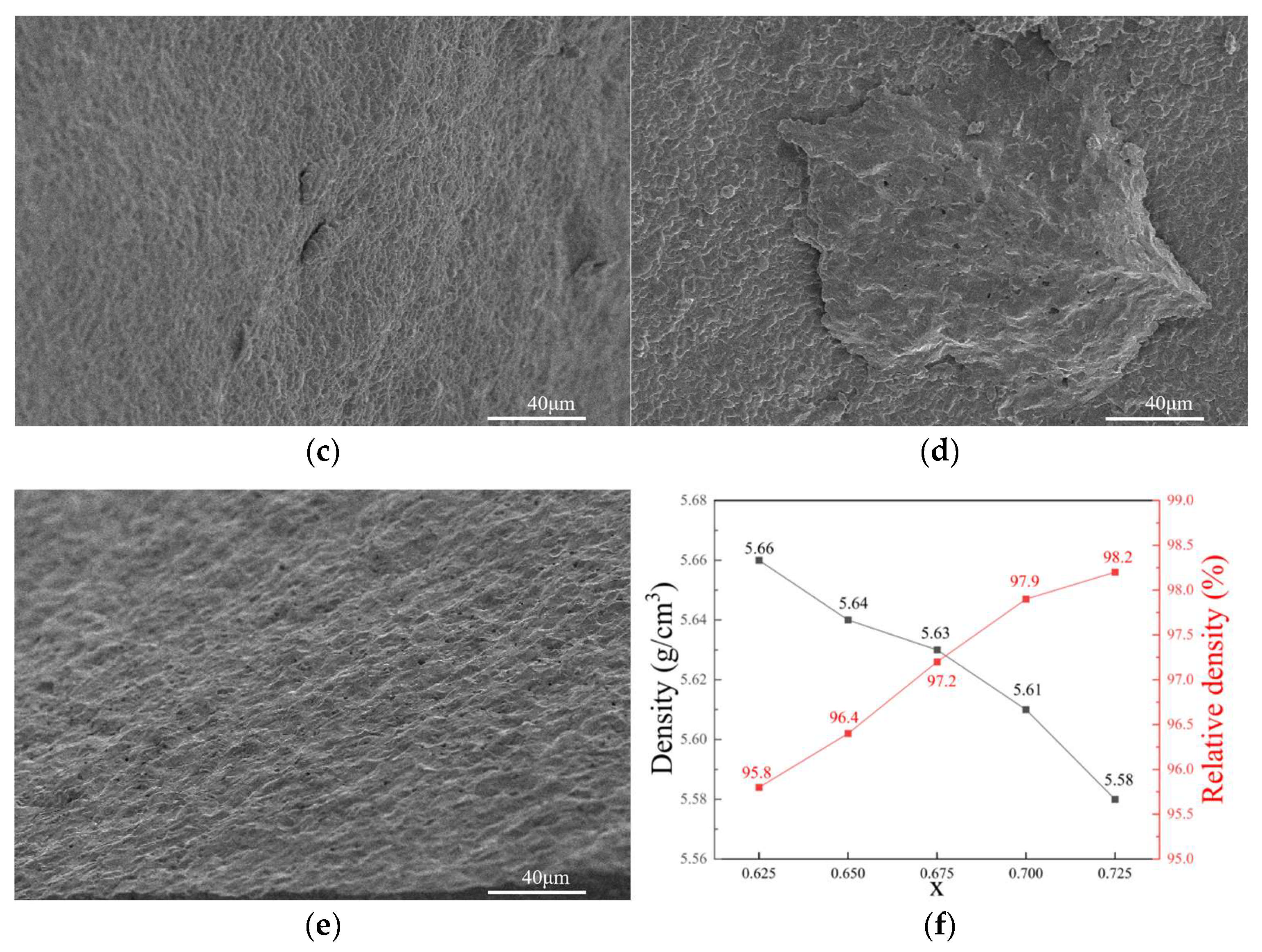

3.1. Sintering Behavior

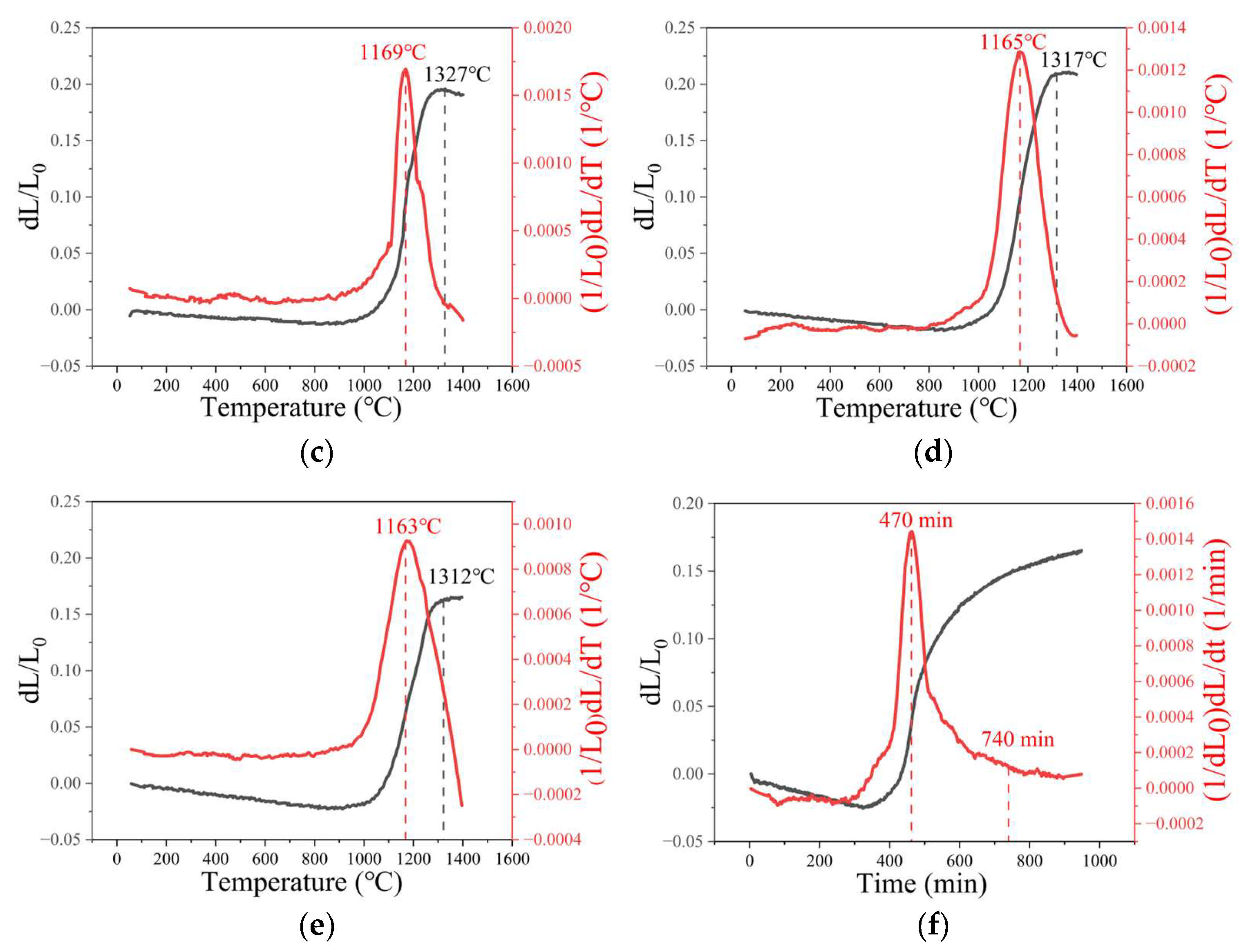

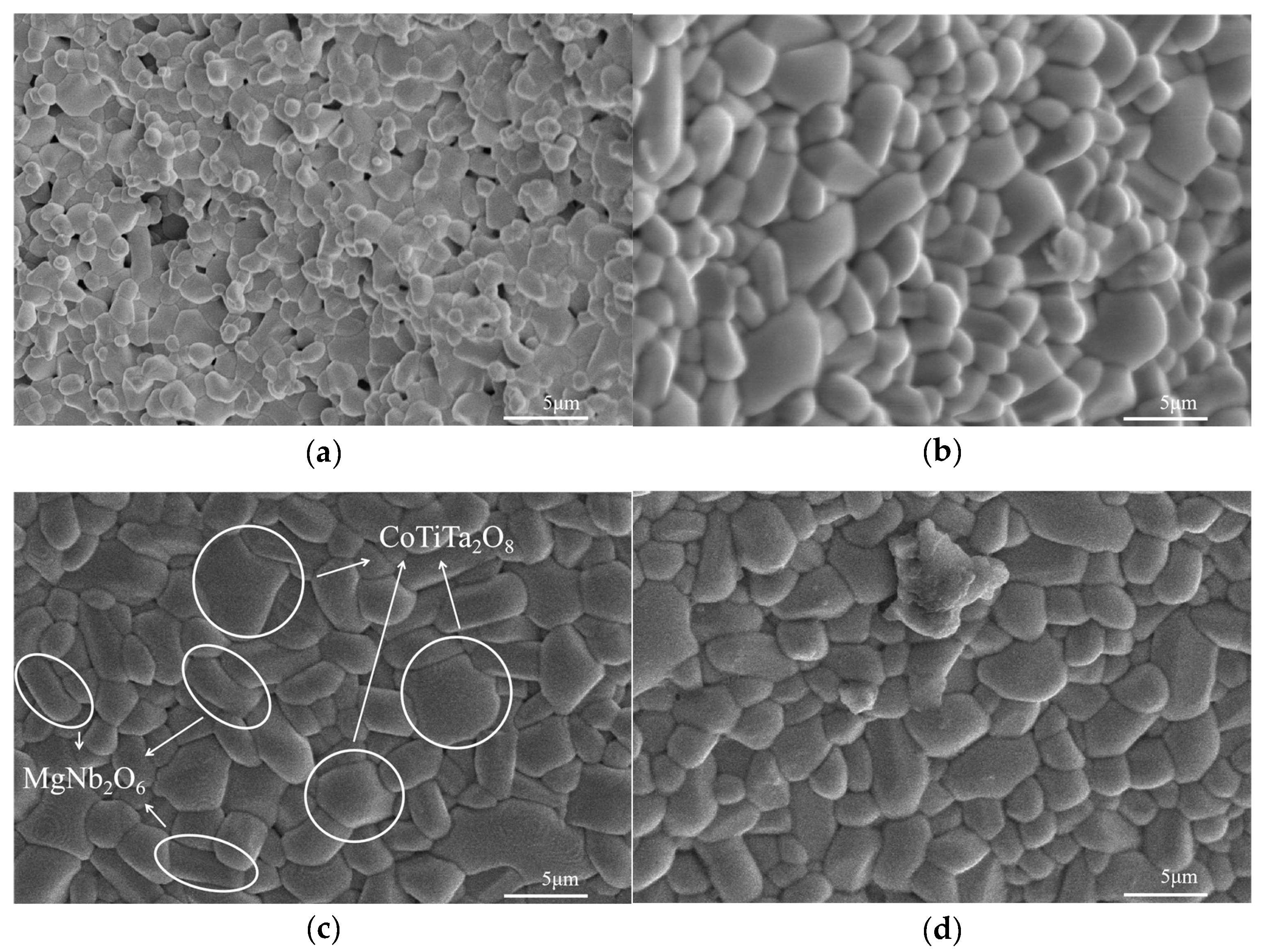

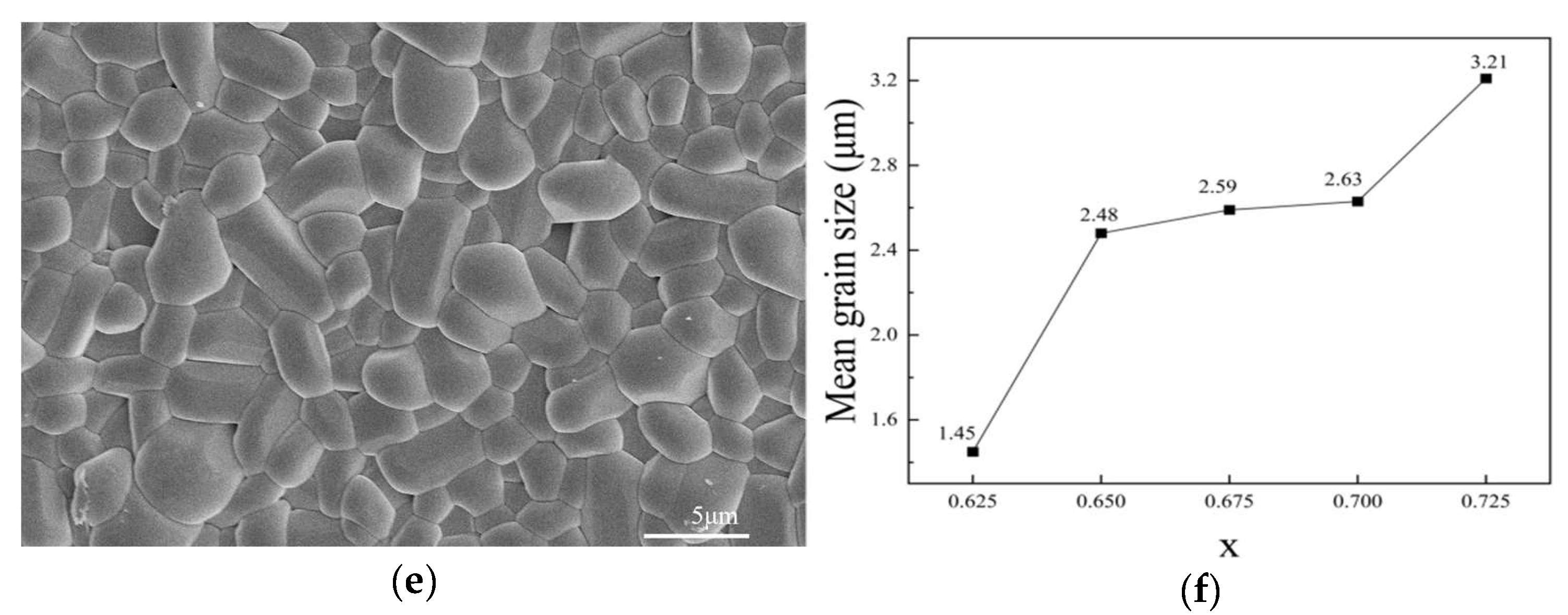

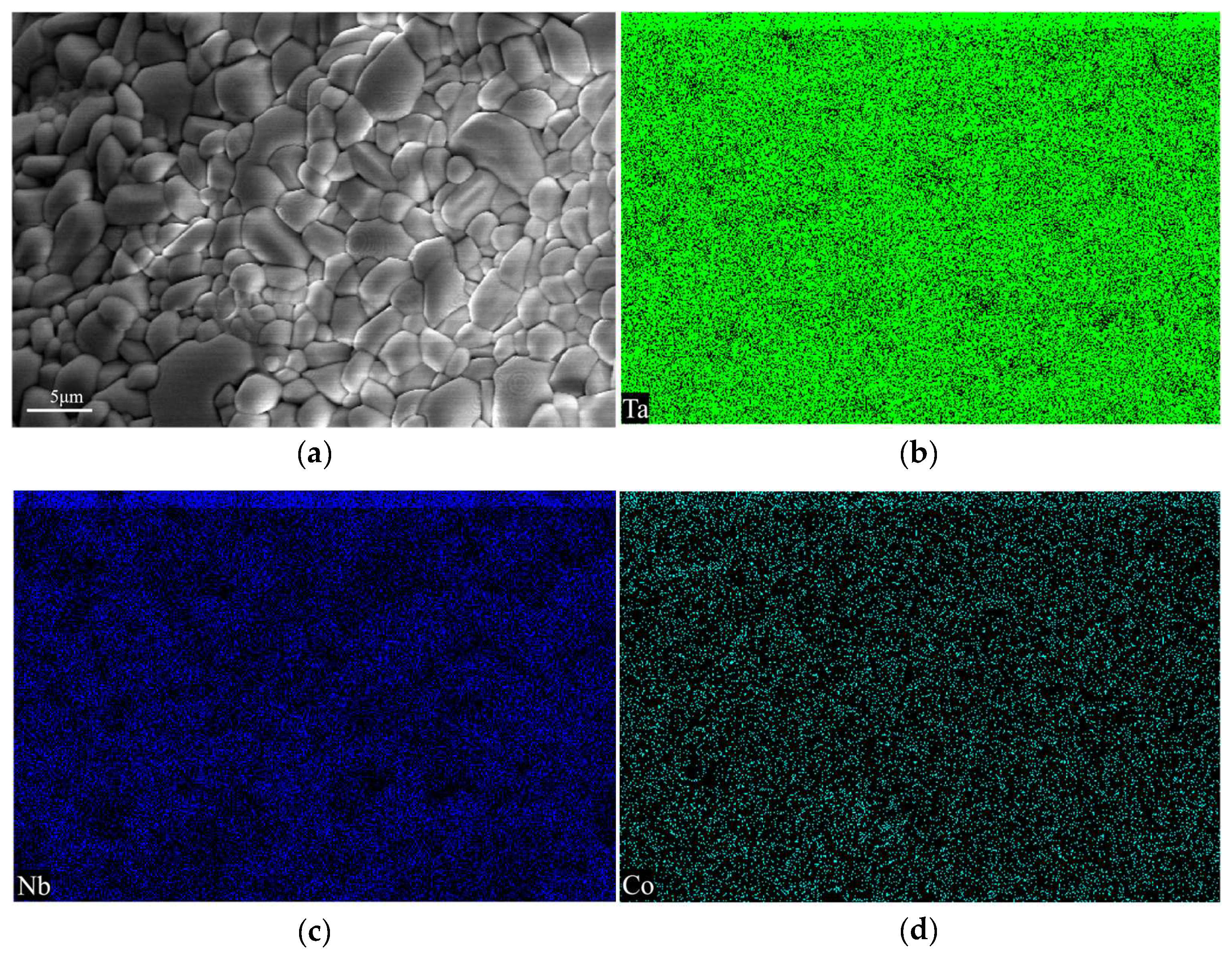

3.2. Phase Composition and Microstructure

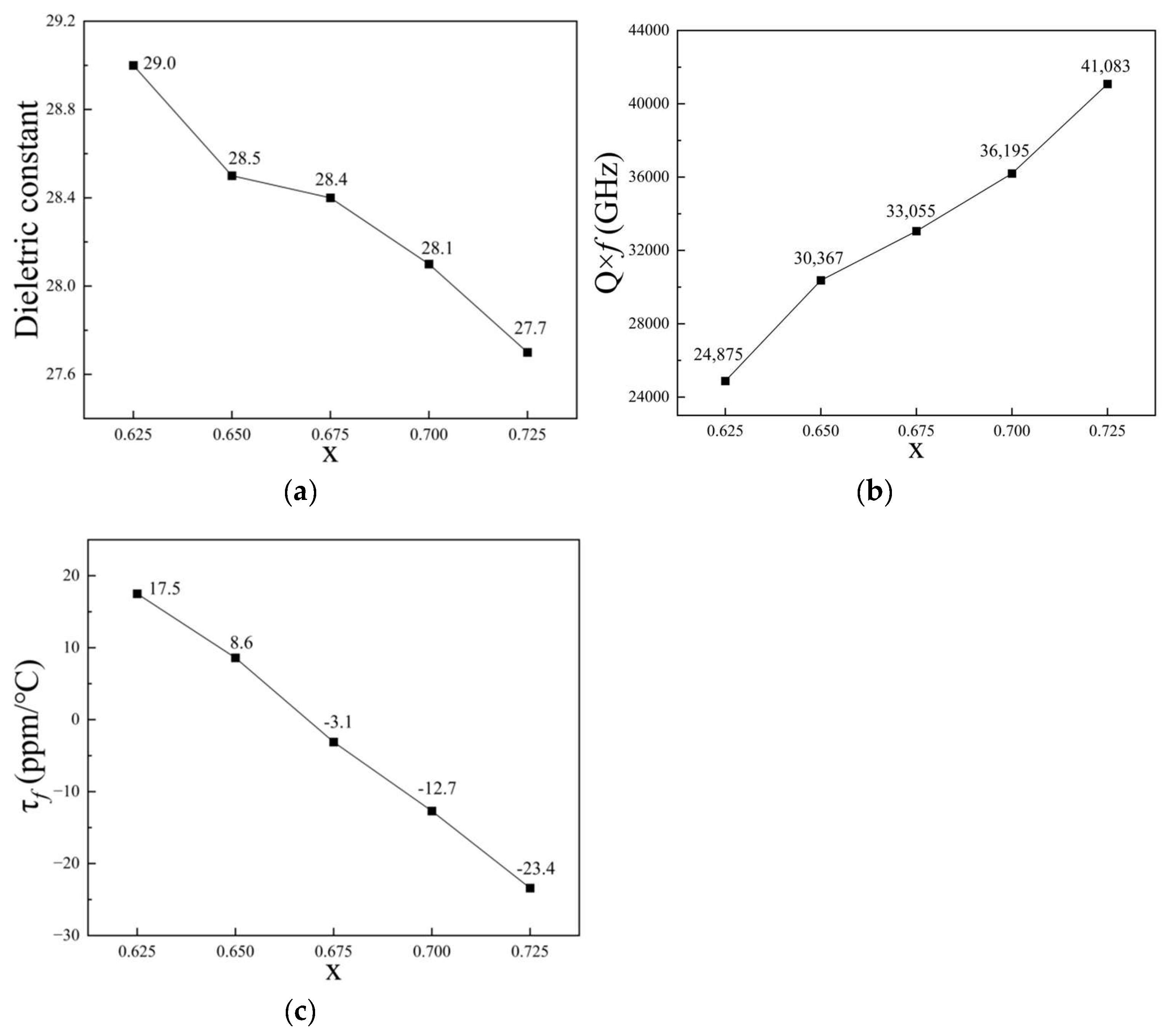

3.3. Microwave Dielectric Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Miao, Y.; Yang, K.; Zhao, P.; Yang, Z.H.; Yu, X.Y.; Duan, X.M.; Jia, D.C.; Zhou, Y. Development of industry system of microwave dielectric ceramics. Strateg. Study Chin. Acad. Eng. 2024, 26, 34–41. [Google Scholar]

- Raveendran, A.; Sebastian, M.T.; Raman, S. Applications of microwave materials: A review. J. Electron. Mater. 2019, 48, 2601–2634. [Google Scholar]

- Pang, Q.Y.; Chen, Y.; Wang, Z.X.; Zhou, B.; Li, X.; Mu, C.; Gu, G.P.; Wang, G.S. Structure, electric, and dielectric properties of (Sr0.7Ca0.3)1.02(Zr0.95−xTi0.05Mnx)O3+δ ceramics for BME-MLCCs application. J. Adv. Ceram. 2024, 13, 1382–1393. [Google Scholar]

- Feng, C.; Zhou, X.; Tao, B.J.; Wu, H.T.; Huang, S.F. Crystal structure and enhanced microwave dielectric properties of the Ce2[Zr1-x(Al1/2Ta1/2)x]3(MoO4)9 ceramics at microwave frequency. J. Adv. Ceram. 2022, 11, 392–402. [Google Scholar] [CrossRef]

- Guo, W.J.; Ma, Z.Y.; Luo, Y.; Chen, Y.G.; Yue, Z.X.; Li, L.T. Structure, defects, and microwave dielectric properties of Al-doped and Al/Nd co-doped Ba4Nd9.33Ti18O54 ceramics. J. Adv. Ceram. 2022, 11, 629–640. [Google Scholar] [CrossRef]

- Tan, K.; Song, T.; Shen, T.; Yu, H.L.; Zhang, Y.C.; Cui, K.; Xu, X.B.; Li, W.; Wang, H.R. Research progress of low permittivity microwave dielectric ceramics. Adv. Ceram. 2022, 43, 11–29. [Google Scholar]

- Bao, J.; Zhang, Y.P.; Kimura, H.D.; Wu, H.T.; Yue, Z.X. Crystal structure, chemical bond characteristics, infrared reflection spectrum, and microwave dielectric properties of Nd2(Zr1−xTix)3(MoO4)9 ceramics. J. Adv. Ceram. 2023, 12, 82–92. [Google Scholar]

- Tian, H.; Zhang, X.H.; Zhang, Z.D.; Liu, Y.; Wu, H. Low-permittivity LiLn(PO3)4 (Ln = La, Sm, Eu) dielectric ceramics for microwave/millimeter-wave communication. J. Adv. Ceram. 2024, 13, 602–620. [Google Scholar] [CrossRef]

- Du, Q.B.; Jiang, L.X.; Ma, L.Z.; Duan, J.H.; Zhou, Z.Y.; Li, H. Lattice evolution, order transformation, and microwave dielectric properties of the Zn1−xLi2xTiO3 (0 ≤ x ≤ 1) system ceramics. J. Adv. Ceram. 2024, 13, 1178–1188. [Google Scholar]

- Li, J.M.; Wang, Z.X.; Guo, Y.F.; Ran, S.L. Influences of substituting of (Ni1/3Nb2/3)4+ for Ti4+ on the phase compositions, microstructures, and dielectric properties of Li2Zn[Ti1−x(Ni1/3Nb2/3)x]3O8 (0 ≤ x ≤ 0.3) microwave ceramics. J. Adv. Ceram. 2023, 12, 760–777. [Google Scholar]

- Zhang, Y.H.; Xiang, H.C.; Wu, X.Y.; Zhou, Y.; Tang, Y.; Fang, L. Low dielectric loss in vanadium-based zircon ceramics via high-entropy strategy. J. Adv. Ceram. 2025, 14, 9221012. [Google Scholar]

- Yang, Y.; Fang, W.S.; Lin, H.X.; Li, J.; Xiang, H.C.; Tang, Y.; Li, L.; Fang, L. SrGa12O19: The first low-εr Ga-based microwave dielectric ceramic with anomalous positive τf. J. Adv. Ceram. 2024, 13, 1432–1441. [Google Scholar]

- Zhang, P.; Lin, J.; Jia, Q.; Yang, X.J.; Li, H. Research progress and prospect of microwave dielectric ceramic materials for 5G communication. Adv. Ceram. 2024, 45, 44–58. [Google Scholar]

- Pan, H.L.; Cheng, L.; Mao, Y.X. Investigation and characterization on crystal structure of ixiolite structure ATiNb2O8 (A = Mg, Zn) ceramics at microwave frequency based on the complex chemical bond theory. J. Alloys Compd. 2017, 693, 792–798. [Google Scholar]

- Yang, H.Y.; Zhang, S.R.; Chen, Y.W.; Yang, H.C.; Yuan, Y.; Li, E.Z. Crystal chemistry, raman spectra, and bond characteristics of trirutile-type Co0.5Ti0.5TaO4 microwave dielectric ceramics. Inorg. Chem. 2019, 58, 968–976. [Google Scholar]

- Kumada, N.; Koike, N.; Nakanome, K.; Yanagida, S.; Takei, T.; Miura, A.; Magome, E.; Moriyoshi, C.; Kuroiwa, Y. Synthesis of rutile-type solid solution Ni1-xCoxTi(Nb1-yTay)2O8 (0 ≤ x ≤ 1, 0 ≤ y ≤ 1) and its optical property. J. Asian Ceram. Soc. 2017, 5, 284–289. [Google Scholar]

- Liao, Q.W.; Li, L.X.; Zhang, P.; Cao, L.F.; Han, Y.M. Correlation of crystal structure and microwave dielectric properties for ZnTi (Nb1-xTax)2O8 ceramics. Solid State Sci. 2011, 13, 1201–1204. [Google Scholar]

- Park, J.H.; Choi, Y.J.; Nahm, S.; Park, J.G. Crystal structure and microwave dielectric properties of ZnTi(Nb1-xTax)2O8 ceramics. J. Alloys Compd. 2011, 509, 6908–6912. [Google Scholar]

- Zhang, Y.; Ding, S.H.; You, L.; Zhang, Y.C. Temperature stable microwave dielectric ceramic CoTiNb2O8-Zn1.01Nb2O6 with ultra-low dielectric loss. J. Electron. Mater. 2019, 48, 867–872. [Google Scholar]

- Wu, M.J.; Zhang, Y.C.; Xiang, M.Q. Synthesis, characterization and dielectric properties of a novel temperature stable (1-x)CoTiNb2O8-xZnNb2O6 ceramic. J. Adv. Ceram. 2019, 8, 228–237. [Google Scholar]

- Jiang, X.; Guo, X.R.; Zhang, Y.; Ding, S.H.; Song, T.X. A novel (1-x)MgZrTa2O8-xMgTa2O6 microwave dielectric composite ceramic with near-zero temperature coefficient. J. Mater. Sci. Mater. Electron. 2023, 34, 660. [Google Scholar]

- Yang, H.Y.; Chai, L.; Liang, G.C.; Xing, M.J.; Fang, Z.X.; Zhang, X.; Qin, T.Y.; Li, E.Z. Structure, far-infrared spectroscopy, microwave dielectric properties, and improved low-temperature sintering characteristics of tri-rutile Mg0.5Ti0.5TaO4 ceramics. J. Adv. Ceram. 2023, 12, 296–308. [Google Scholar] [CrossRef]

- Cai, J.; Qi, J.; Yang, Y. Colossal permittivity and ultra-low dielectric loss in Nb-doped SrTiO3 ceramics. J. Adv. Ceram. 2023, 12, 2247–2256. [Google Scholar] [CrossRef]

- Liao, Q.W. Investigation on the Structure-Properties Relationship of Ultra-Low Loss AB(Nb, Ta)2O8 Microwave Dielectric Ceramics. Ph.D. Thesis, Tianjin University, Tianjin, China, 2012. [Google Scholar]

- Hu, Z.C.; Yang, H.Y.; Yang, H.C.; Sun, C.L.; Yang, J.; Li, E.Z. Usage of P-V-L bond theory in regulating properties of microwave dielectric ceramics. J. Inorg. Mater. 2025. [Google Scholar] [CrossRef]

- Tzou, W.C.; Chen, Y.C.; Yang, C.F.; Cheng, C.M. Microwave dielectric characteristics of Mg(Ta1-xNbx)2O6 ceramics. Mater. Res. Bull. 2006, 41, 1357–1363. [Google Scholar]

- Luo, W.J.; Wang, S.; Zheng, S.Y.; Li, J.N.; Wang, M.L.; Wen, Y.Z.; Li, L.X.; Zhou, J. Dielectric response of ANb2O6 (A = Zn, Co, Mn, Ni) columbite niobates: From microwave to terahertz. J. Adv. Ceram. 2024, 13, 1189–1197. [Google Scholar]

- Yang, H. Research on Preparation and Property Modification of New Niobate-Based Microwave Dielectric Ceramics. Ph.D. Thesis, University of Electronic Science and Technology of China, Chengdu, China, 2019. [Google Scholar]

- Shi, L. Research on the Microwave Dielectric Performance Regulation and 5G Communication Applications of Tantalate Ceramics. Ph.D. Thesis, University of Electronic Science and Technology of China, Chengdu, China, 2023. [Google Scholar]

- Tang, L.; Yang, H.C.; Li, E.Z.; Zhong, C.W. A novel Na1−xKxTaO3 perovskite microwave dielectric ceramic with high permittivity and high positive temperature coefficient. J. Adv. Ceram. 2023, 12, 2053–2061. [Google Scholar]

- Ali, M.; Iqbal, Y.; Muhammad, R. Phase evolution and microwave dielectric properties of A5M5O17-type ceramics. Mater. Sci. Pol. 2017, 35, 362–367. [Google Scholar]

- Liu, X.S. Investigation on the Novel Niobate-Tantalate-Based Microwave Dielectric Ceramics with Medium Permittivity. Ph.D. Thesis, Tianjin University, Tianjin, China, 2017. [Google Scholar]

- Wu, X.H. Research on Low Loss Medium Niobium/Tantalate Microwave Dielectric Materials and Its Application. Ph.D. Thesis, University of Electronic Science and Technology of China, Chengdu, China, 2024. [Google Scholar]

- Fu, Z.F.; Ma, J.L.; Gao, J.; Liu, P. Preparation of MgNb2O6 powders by using high-energy ball-milling method and the properties of MgNb2O6 ceramics. Sci. Technol. Rev. 2013, 31, 62–65. [Google Scholar]

- Hu, J.; Lv, X.P.; Zhang, J.; Li, S.; Xv, W.S.; Xv, Q.H. Research progress in the preparation technology of microwave dielectric ceramics. Inf. Rec. Mater. 2018, 19, 6–8. [Google Scholar]

- Liao, L.W.; Zuo, J.; Yang, P.; Liang, J.J.; Peng, Z.J.; Fu, X.L. Synthesis, phase structure and dielectric properties of CoTiTa2O8 by molten salt method for LTCC application. J. Mater. Sci. Mater. Electron. 2024, 35, 1179. [Google Scholar] [CrossRef]

- Liou, Y.C.; Sung, Y.L. Preparation of columbite MgNb2O6 and ZnNb2O6 ceramics by reaction-sintering. Ceram. Int. 2008, 34, 371–377. [Google Scholar] [CrossRef]

- Zhang, L.L.; Yu, H.L.; Song, T.; Shen, T.; Ma, G.H.; Zhang, Y.C.; Wang, H.R.; Tan, K. Research status of low temperature co-firing of microwave dielectric ceramics. Adv. Ceram. 2022, 43, 246–261. [Google Scholar]

- Xue, X.; Li, X.M.; Fu, C.L.; Zhang, Y.; Guo, J.; Wang, H. Sintering characteristics, phase transitions, and microwave dielectric properties of low-firing [(Na0.5Bi0.5)xBi1−x](WxV1−x)O4 solid solution ceramics. J. Adv. Ceram. 2023, 12, 1178–1188. [Google Scholar] [CrossRef]

- Liu, Y.S. Preparation and Characterization of MgNb2O6-Based Composite Microwave Dielectric Ceramics. Master’s Thesis, China University of Geosciences (Beijing), Beijing, China, 2023. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zuo, J.; Wang, H.; Fu, X.; Peng, Z. Microwave Dielectric Behavior of CoTiTa2O8-MgNb2O6 Composite Ceramics: A Focus on Temperature Stability and Compositional Effects. Metals 2025, 15, 407. https://doi.org/10.3390/met15040407

Zuo J, Wang H, Fu X, Peng Z. Microwave Dielectric Behavior of CoTiTa2O8-MgNb2O6 Composite Ceramics: A Focus on Temperature Stability and Compositional Effects. Metals. 2025; 15(4):407. https://doi.org/10.3390/met15040407

Chicago/Turabian StyleZuo, Jun, Haodong Wang, Xiuli Fu, and Zhijian Peng. 2025. "Microwave Dielectric Behavior of CoTiTa2O8-MgNb2O6 Composite Ceramics: A Focus on Temperature Stability and Compositional Effects" Metals 15, no. 4: 407. https://doi.org/10.3390/met15040407

APA StyleZuo, J., Wang, H., Fu, X., & Peng, Z. (2025). Microwave Dielectric Behavior of CoTiTa2O8-MgNb2O6 Composite Ceramics: A Focus on Temperature Stability and Compositional Effects. Metals, 15(4), 407. https://doi.org/10.3390/met15040407