Effect of In Situ Al Roll Coating on Strip Surface Quality in Traditional Twin-Roll Casting of Aluminum Alloys

Abstract

1. Introduction

2. Materials and Methods

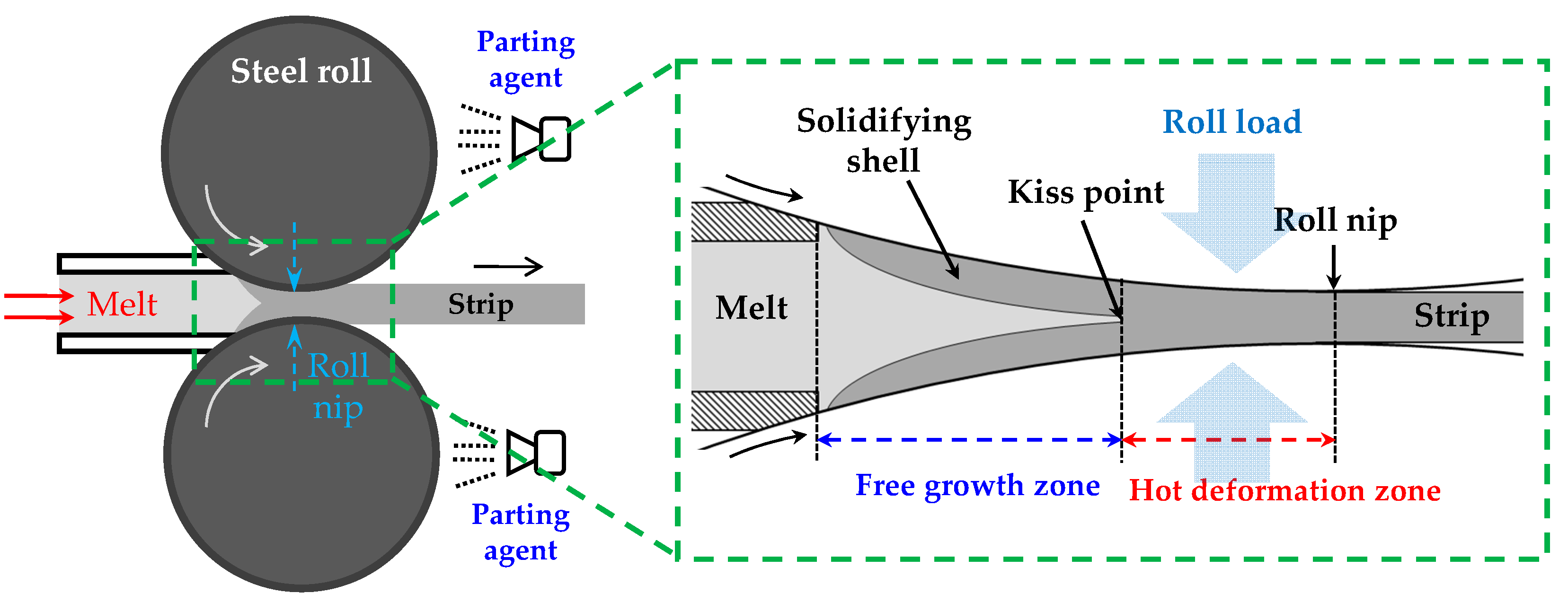

2.1. Strip Fabrication Using Twin-Roll Casting Process

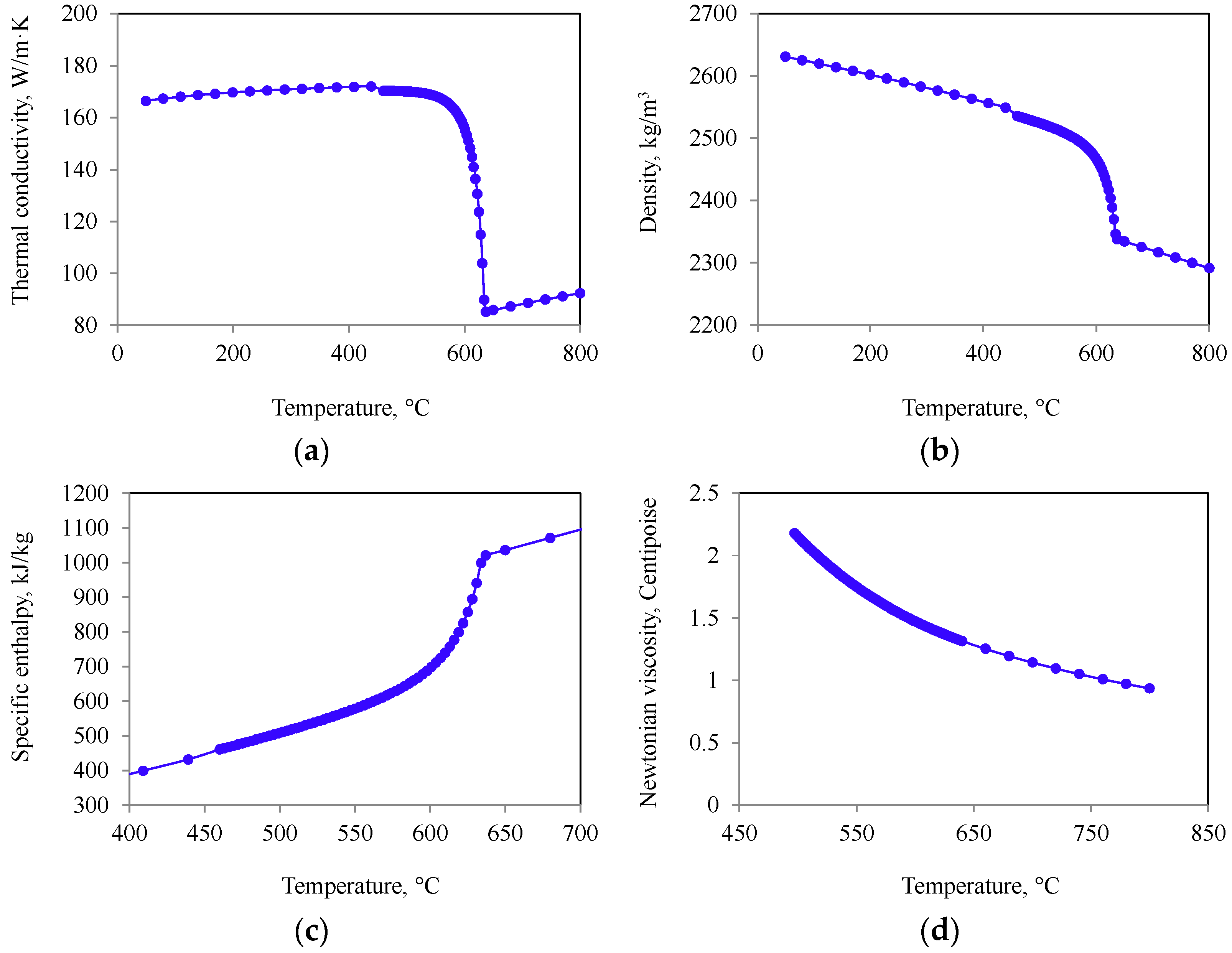

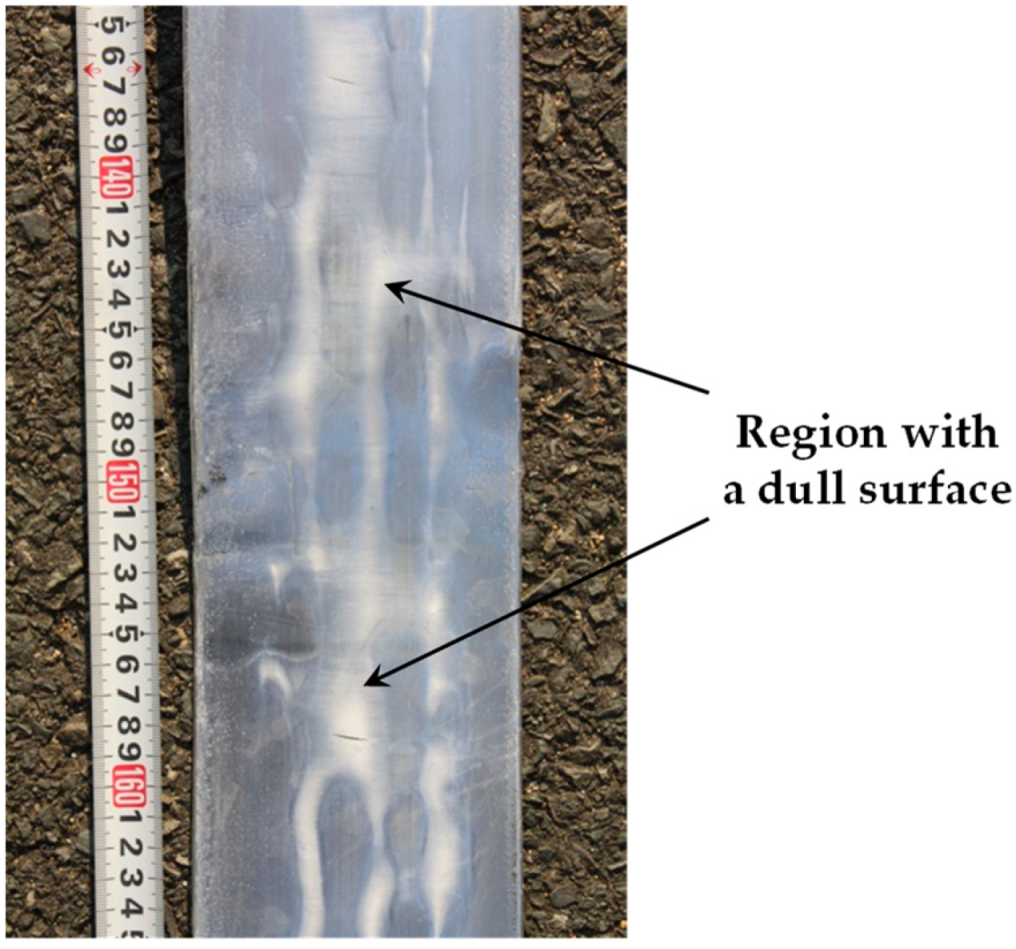

2.2. Simulation Model for Twin-Roll Casting Process

3. Results and Discussion

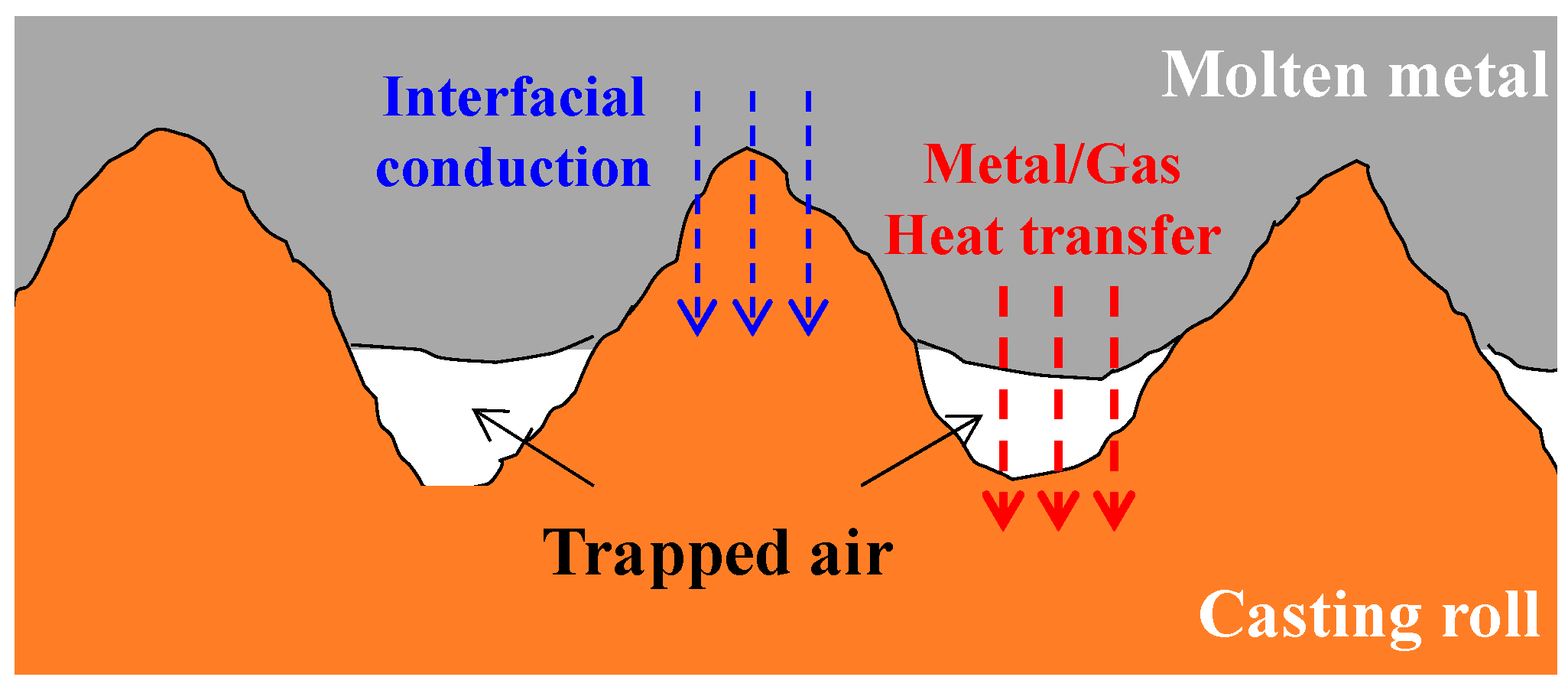

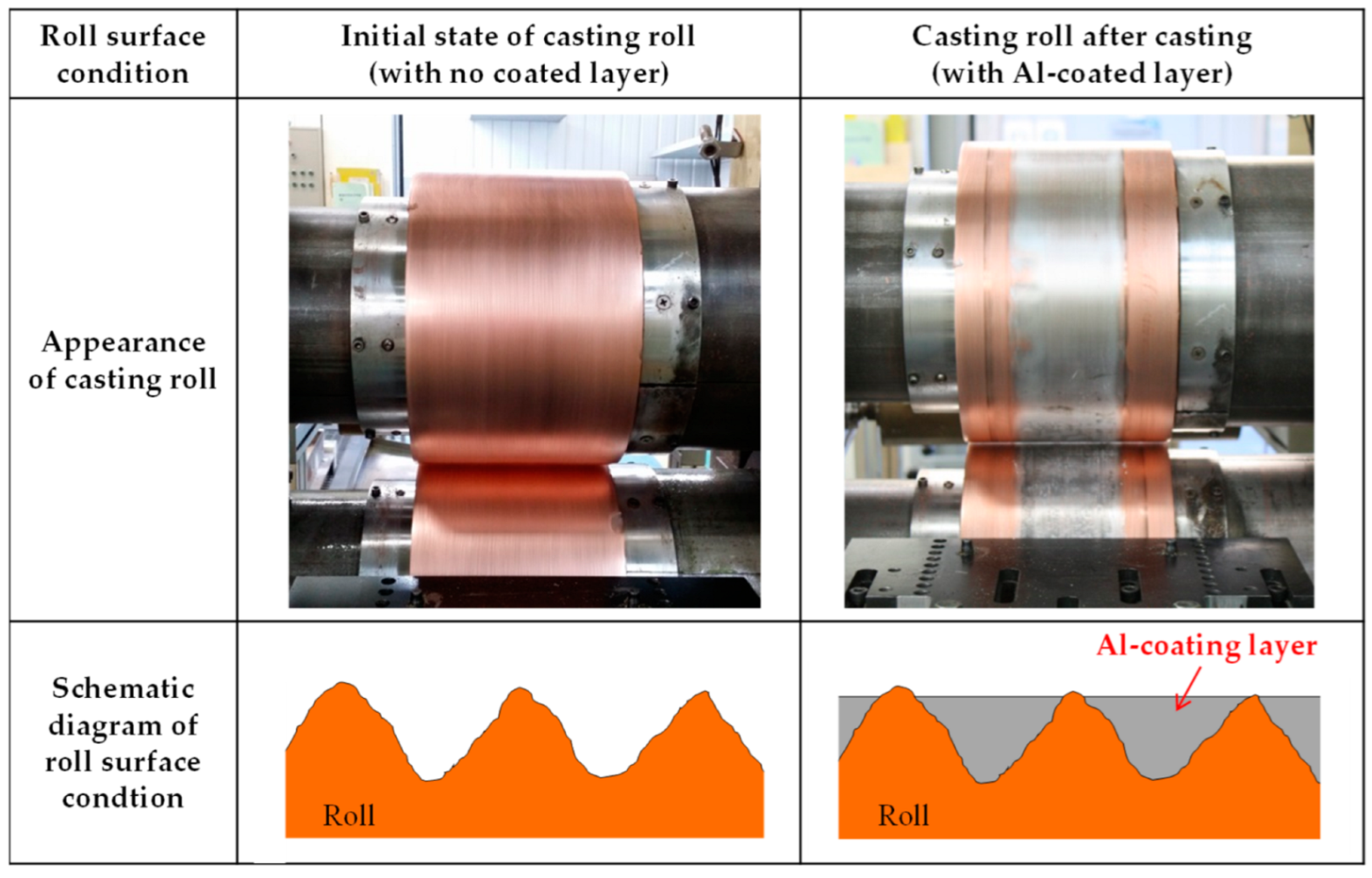

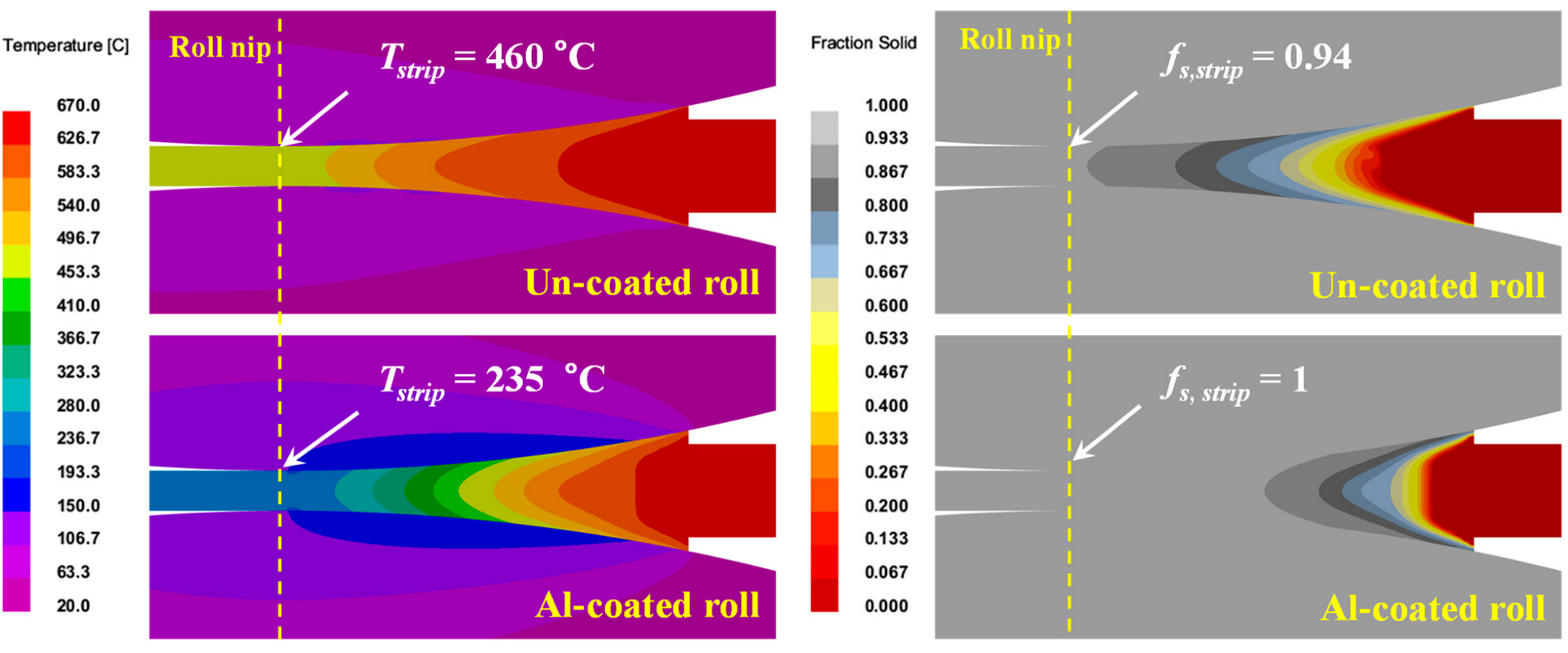

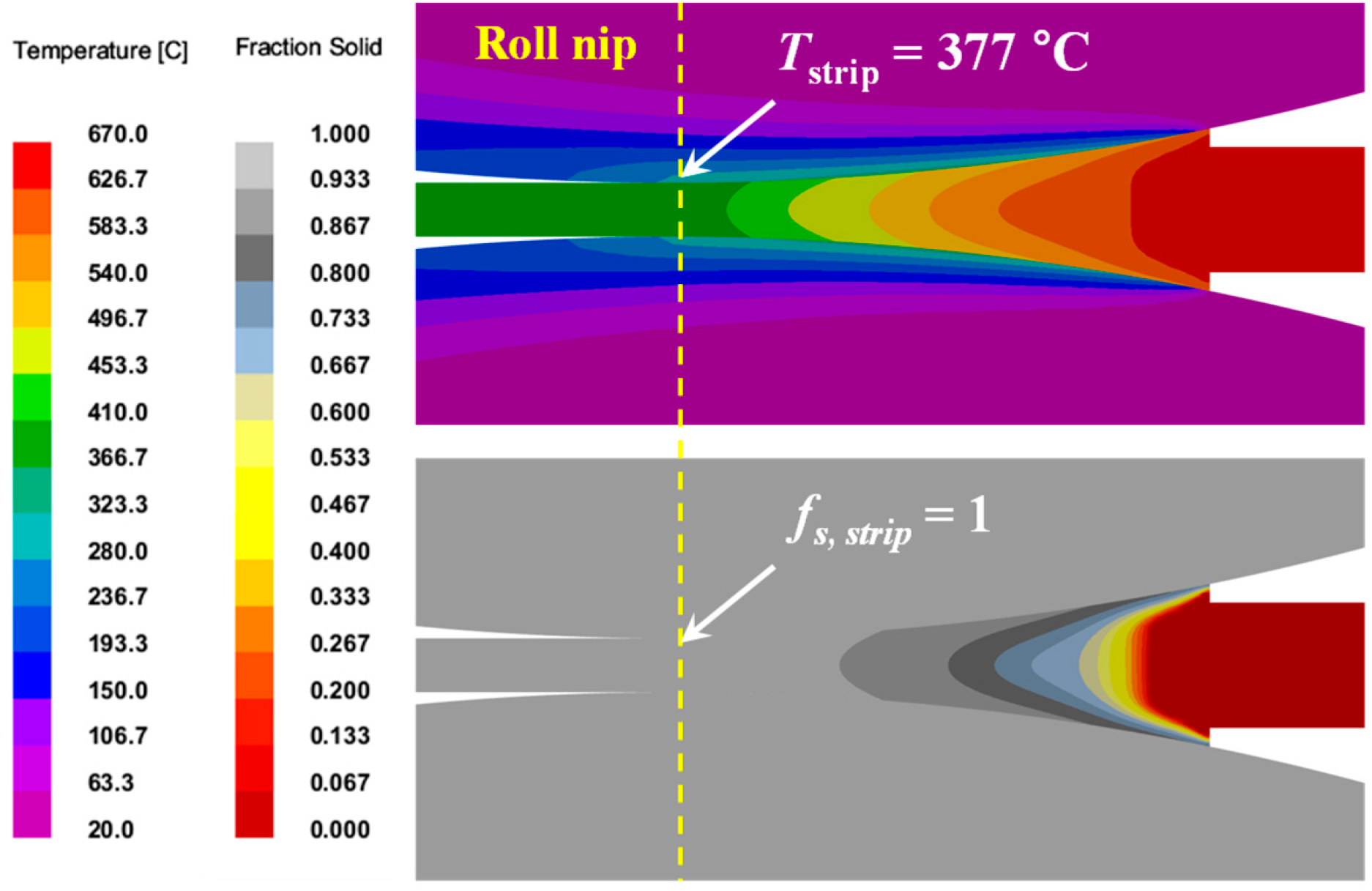

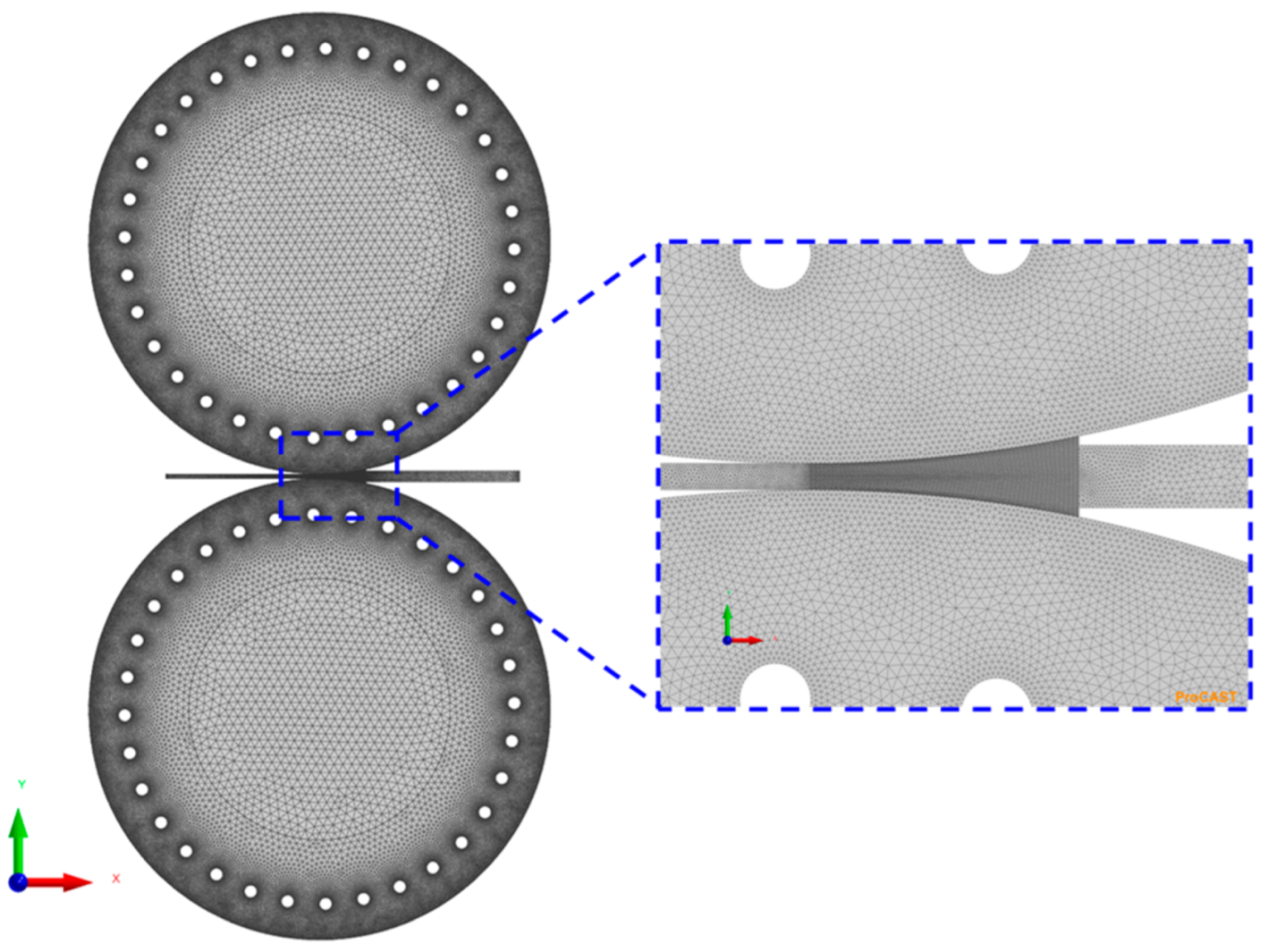

3.1. Effect of Roll Surface Condition on Solidification Behavior in TRC

3.2. Effect of Interfacial HTC on Solidification Behavior in TRC Simulation

3.3. Effect of Roll Material on Solidification Behavior in TRC

3.4. Technical Notes on the Formation of the Al Coating Layer on the Roll Surface

4. Conclusions

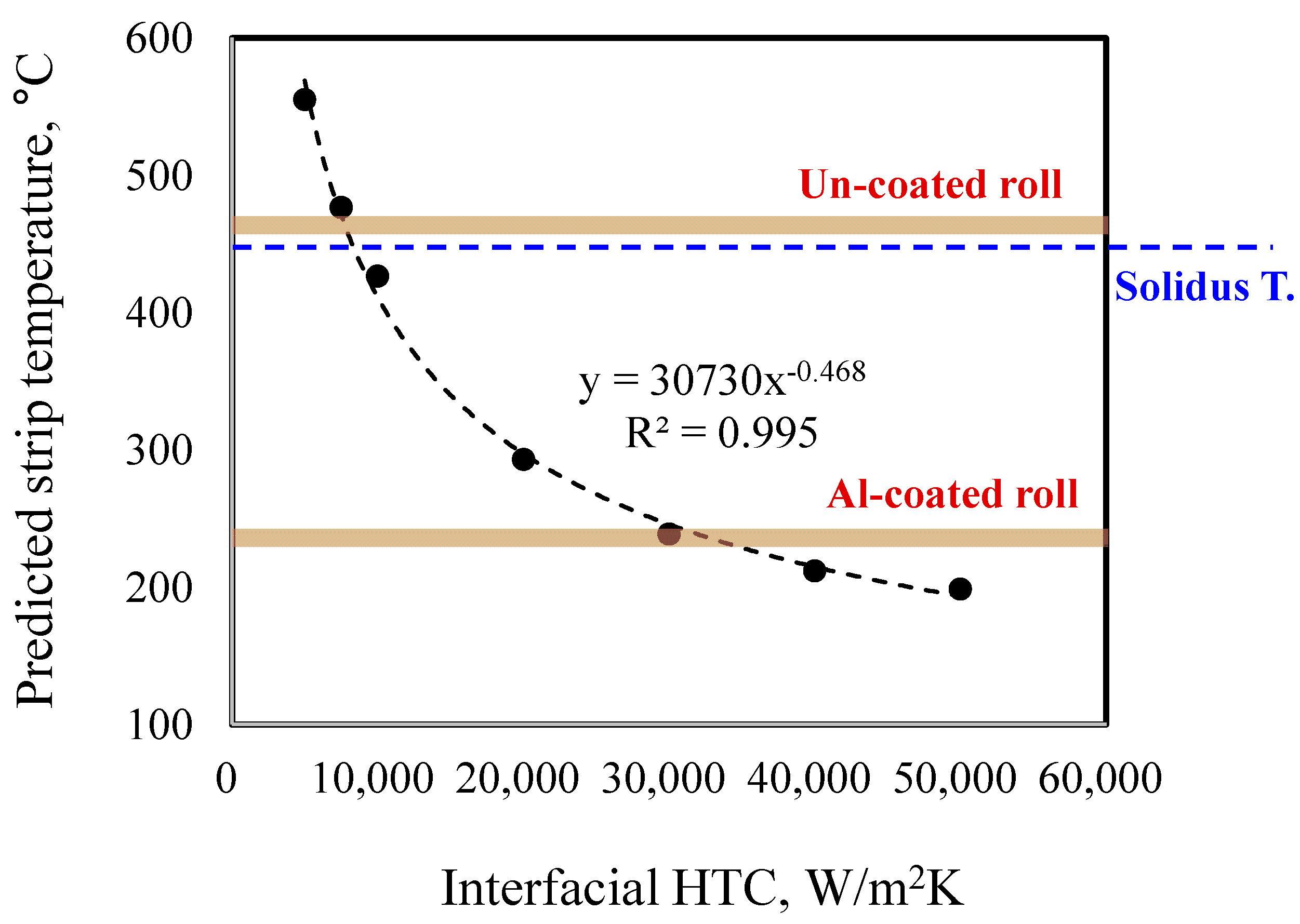

- The formation of a stable aluminum coating layer on the roll surface significantly enhanced interfacial heat transfer, leading to improved cooling efficiency and more uniform solidification. The average interfacial heat transfer coefficient (HTC) increased markedly from approximately 8000 W/m2K under uncoated conditions to 30,000 W/m2K when a coating layer was present.

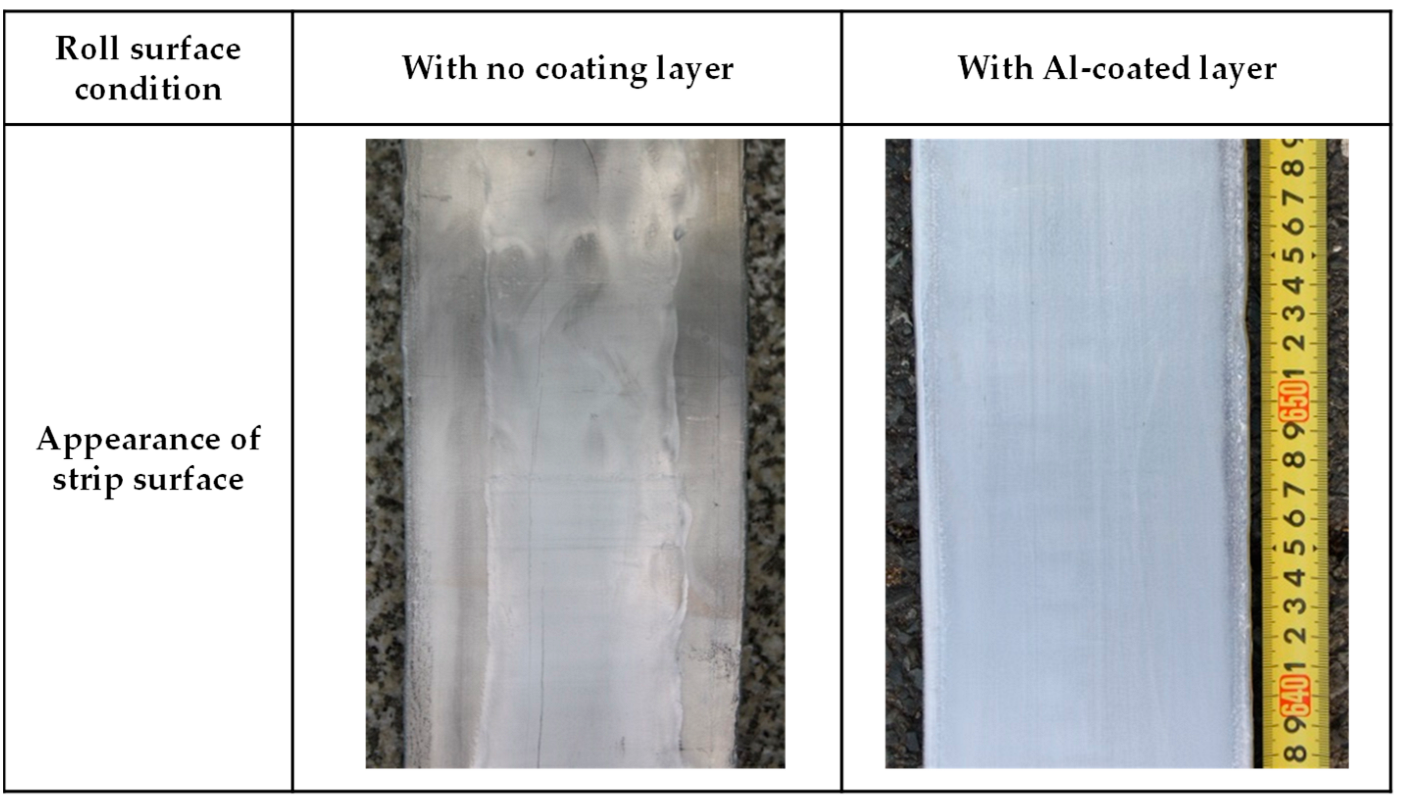

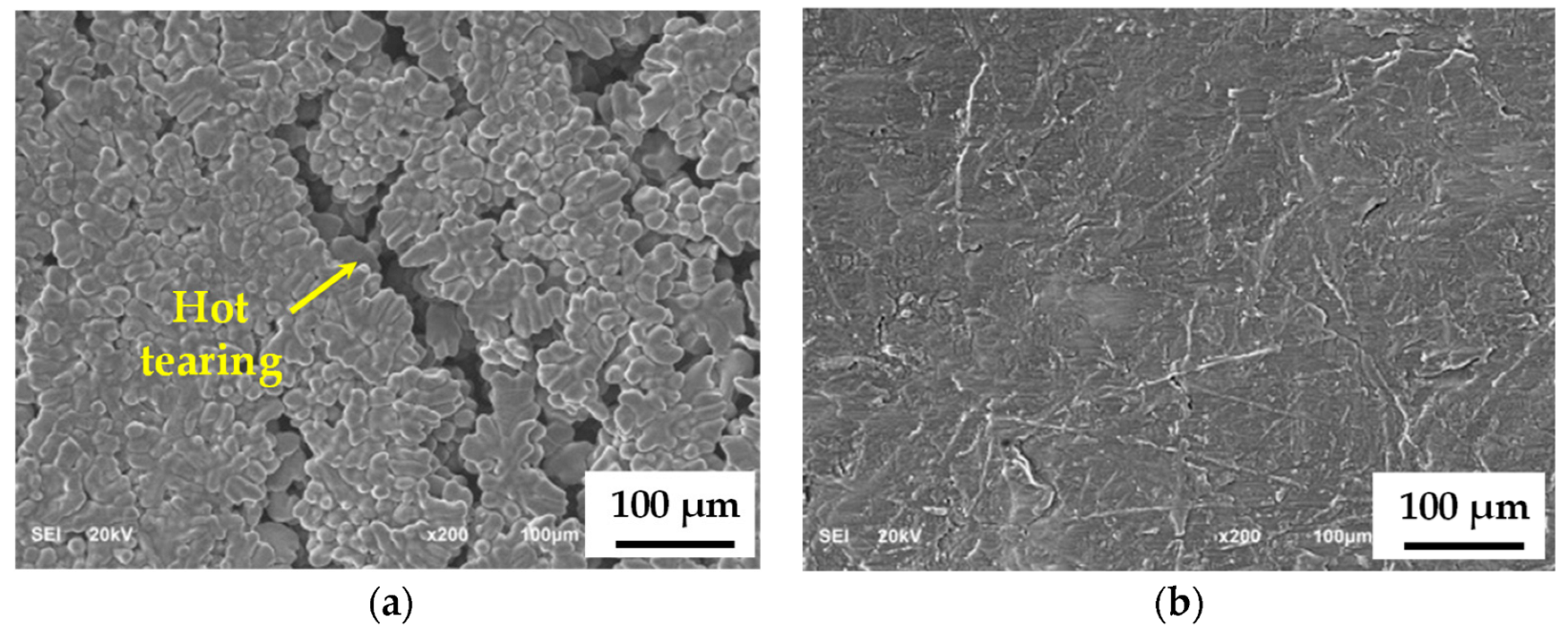

- Experimental observations revealed that strips cast without the coating layer exhibited poor surface quality, characterized by visible hot tearing, surface porosity, and a dull, non-uniform surface appearance.

- In contrast, strips cast under conditions with a uniform Al coating layer showed excellent surface quality, exhibiting smooth, glossy surfaces with no significant surface defects.

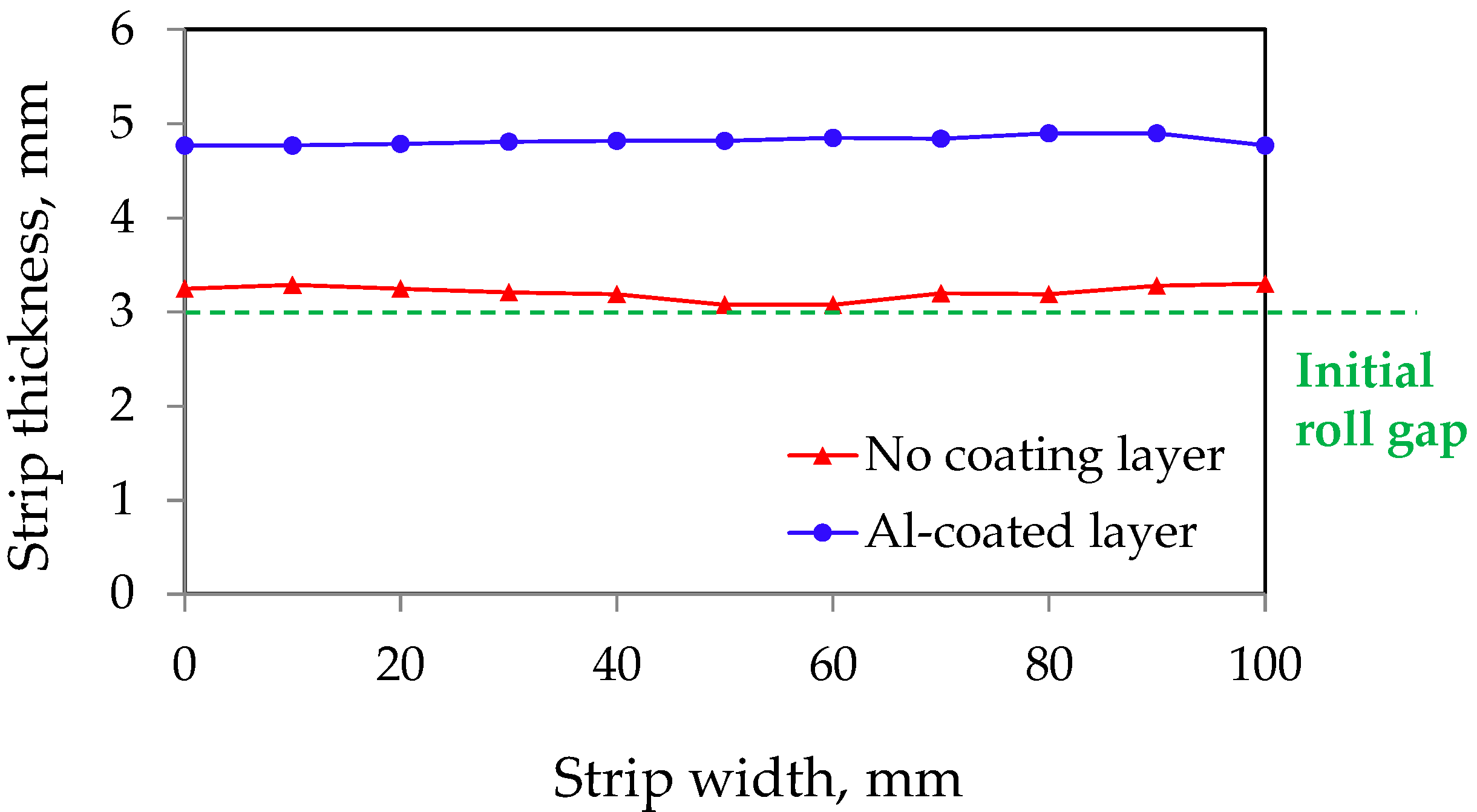

- Despite identical process parameters, the final strip thickness differed significantly depending on the roll surface condition. The strip cast without a coating layer had a thickness of approximately 3.0 mm, whereas the strip cast with the coating layer reached 4.8 mm, indicating more effective shell growth and solidification due to improved thermal contact.

- Numerical simulations confirmed that higher HTC values associated with coated roll surfaces facilitated complete solidification before the strip exited the roll nip, thereby reducing the risk of surface defect formation.

- Simulation results also demonstrated the feasibility of employing steel rolls for industrial TRC applications, provided that a stable aluminum coating layer forms to ensure sufficient interfacial heat transfer and solidification.

- The formation and stability of the Al coating layer were found to be highly dependent on the initial roll load. Sufficient roll pressure during the early stages of casting enabled the spontaneous formation of a continuous coating layer, which is critical for maintaining stable casting conditions and achieving high strip surface quality in traditional TRC processes.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Edmonds, D.V. Innovation in the processing of tannage materials: Examples from the steel and aluminum industries. J. Mater. Process. Technol. 1998, 83, 1–13. [Google Scholar]

- Barekar, N.S.; Dhindaw, B.K. Twin-roll casting of aluminum alloys—An overview. Mater. Manuf. Process. 2014, 29, 651–661. [Google Scholar]

- Zhu, Y.Z.; Huang, R.Y.; Zhu, Z.; Xiang, Z.D. Comparative study on effects of microstructures of hot rolled and twin roll casting 1235 aluminum alloy on surface quality of aluminum foils produced. Mater. Sci. Technol. 2011, 27, 761–766. [Google Scholar]

- Wang, J.; Zhou, X.; Thompson, G.E.; Hunter, J.A.; Yuan, Y. Microstructure evolution in the near-surface region during homogenization of a twin-roll cast AlFeMnSi alloy. Metall. Mater. Trans. A 2016, 47, 4268–4275. [Google Scholar]

- Sun, N.; Patterson, B.R.; Suni, J.P.; Simielli, E.A.; Weiland, H.; Allard, L.F. Microstructural evolution in twin roll cast AA3105 during homogenization. Mater. Sci. Eng. A 2006, 416, 232–239. [Google Scholar] [CrossRef]

- Wu, X.; Guan, Z.P.; Yang, H.Y.; Dong, B.X.; Zhang, L.C.; Meng, J.; Luo, C.J.; Wang, C.G.; Gao, K.; Qiao, J.; et al. Sub-rapid solidification microstructure characteristics and control mechanisms of twin-roll cast aluminum alloys: A review. J. Mater. Res. Technol. 2024, 32, 874–914. [Google Scholar]

- Jin, J.W.; Zhang, Z.J.; Li, R.H.; Li, Y.; Gong, B.S.; Hou, J.P.; Wang, H.W.; Zhou, X.H.; Purcek, G.; Zhang, Z.F. Mechanical properties of three typical aluminum alloy strips prepared by twin-roll casting. J. Mater. Res. Technol. 2024, 28, 500–511. [Google Scholar] [CrossRef]

- Kim, M.S. Control of surface inverse segregation in Al–4.5Mg strips produced by industrial twin-roll casting process. Scr. Mater. 2025, 258, 116528. [Google Scholar]

- Lee, Y.S.; Koh, D.H.; Kim, H.W.; Ahn, Y.S. Improved bake-hardening response of Al-Zn-Mg-Cu alloy through pre-aging treatment. Scr. Mater. 2018, 147, 46–49. [Google Scholar]

- Jo, Y.H.; Moon, H.R.; Bae, J.W.; Yoo, J.; Lee, S.G.; Lee, Y.S.; Kim, H.W. Effects of casting speed on microstructural and tensile properties of Al−Mg−Si alloy fabricated by horizontal and vertical twin-roll casting. J. Mater. Res. Technol. 2023, 26, 8010–8024. [Google Scholar]

- Zhang, S.Y.; Mo, Y.T.; Hua, Z.M.; Liu, X.; Liu, Z.T. Improving long-term thermal stability in twin-roll cast Al-Mg-Si-Cu alloys by optimizing Mg/Si ratios. J. Mater. Res. Technol. 2025, 206, 164–175. [Google Scholar] [CrossRef]

- Kim, M.S.; Kim, S.H.; Kim, H.W. Deformation-induced center segregation in twin-roll cast high-Mg Al-Mg strips. Scr. Mater. 2018, 152, 69–73. [Google Scholar] [CrossRef]

- Jeong, D.H.; Lee, Y.S.; Kim, H.W.; Kim, Y.D.; Zang, Q. Microstructure and mechanical properties of high-strength Al−Zn−Mg−Ni alloys with excellent twin-roll castability. J. Mater. Res. Technol. 2024, 33, 5064–5074. [Google Scholar] [CrossRef]

- Mo, A. Mathematical modelling of surface segregation in aluminum DC casting caused by exudation. Int. J. Heat Mass Transf. 1993, 36, 4335–4340. [Google Scholar] [CrossRef]

- Kikuchi, D.; Harada, Y.; Kumai, S. Surface quality and microstructure of Al-Mg alloy strips fabricated by vertical-type high-speed twin-roll casting. J. Manuf. Process. 2019, 37, 332–338. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, A.; Tian, H.; Xie, J.; Wang, X. Study on optimization of nozzle for copper-aluminum clad plate twin-roll cast-rolling. J. Manuf. Process. 2021, 10, 1075–1085. [Google Scholar]

- Park, C.M.; Choi, J.T.; Monn, H.K.; Park, G.J. Thermal crown analysis of the roll in the strip casting process. J. Mater. Process. Technol. 2009, 209, 3714–3723. [Google Scholar] [CrossRef]

- Cook, R.; Grocock, P.G.; Thomas, P.M.; Edmonds, D.V.; Hunt, J.D. Development of the twin-roll casting process. J. Mater. Process. Technol. 1995, 55, 76–84. [Google Scholar] [CrossRef]

- Suresh, K.; Regalla, S.P. Effect of mesh parameters in finite element simulation of single point incremental sheet forming process. Procedia Mater. Sci. 2014, 6, 376–382. [Google Scholar] [CrossRef]

- Loulou, T.; Artyukhin, E.A.; Bardon, J.P. Estimation of thermal contract resistance during the first stages of metal solidification process: Ⅱ−experimental setup and results. Int. J. Heat Mass Transf. 1999, 42, 2129–2142. [Google Scholar] [CrossRef]

- Kim, H.S.; Cho, I.S.; Shin, J.S.; Lee, S.M.; Moon, B.M. Solidification parameters dependent on interfacial heat transfer coefficient between aluminum casting and copper mold. ISIJ Int. 2005, 45, 192–198. [Google Scholar] [CrossRef]

- Hamasaid, A.; Dargusch, M.S.; Davidson, C.J.; Tovar, S.; Loulou, T.; Rezai-aria, F.; Dour, G. Effect of mold coating and thickness on heat transfer in permanent mold casting of aluminum alloys. Metall. Mater. Trans. A 2007, 38, 1303–1316. [Google Scholar]

- Kim, M.S.; Kim, H.W.; Kumai, S. Direct temperature measurement of Al-2mss%Si alloy strips during high-speed twin-roll casting and its application in determining melt/roll heat transfer coefficient for simulation. Mater. Trans. 2017, 58, 967–970. [Google Scholar]

| ||

| Condition | Value | |

|---|---|---|

| Initial melt temperature | 670 °C | |

| Initial roll temperature | 25 °C | |

| Ambient temperature | 25 °C | |

| Interfacial heat transfer coefficient, h | hmelt/nozzle | Adiabatic |

| hstrip/air | 12 W/m2K | |

| hmelt/casting roll | Variable | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cho, H.-G.; Kim, Y.D.; Kim, M.-S. Effect of In Situ Al Roll Coating on Strip Surface Quality in Traditional Twin-Roll Casting of Aluminum Alloys. Metals 2025, 15, 377. https://doi.org/10.3390/met15040377

Cho H-G, Kim YD, Kim M-S. Effect of In Situ Al Roll Coating on Strip Surface Quality in Traditional Twin-Roll Casting of Aluminum Alloys. Metals. 2025; 15(4):377. https://doi.org/10.3390/met15040377

Chicago/Turabian StyleCho, Han-Gyoung, Young Do Kim, and Min-Seok Kim. 2025. "Effect of In Situ Al Roll Coating on Strip Surface Quality in Traditional Twin-Roll Casting of Aluminum Alloys" Metals 15, no. 4: 377. https://doi.org/10.3390/met15040377

APA StyleCho, H.-G., Kim, Y. D., & Kim, M.-S. (2025). Effect of In Situ Al Roll Coating on Strip Surface Quality in Traditional Twin-Roll Casting of Aluminum Alloys. Metals, 15(4), 377. https://doi.org/10.3390/met15040377