Characterizing the Behavior and Microstructure of Cu-La2O3 Composite Processed via Equal Channel Angular Pressing

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental

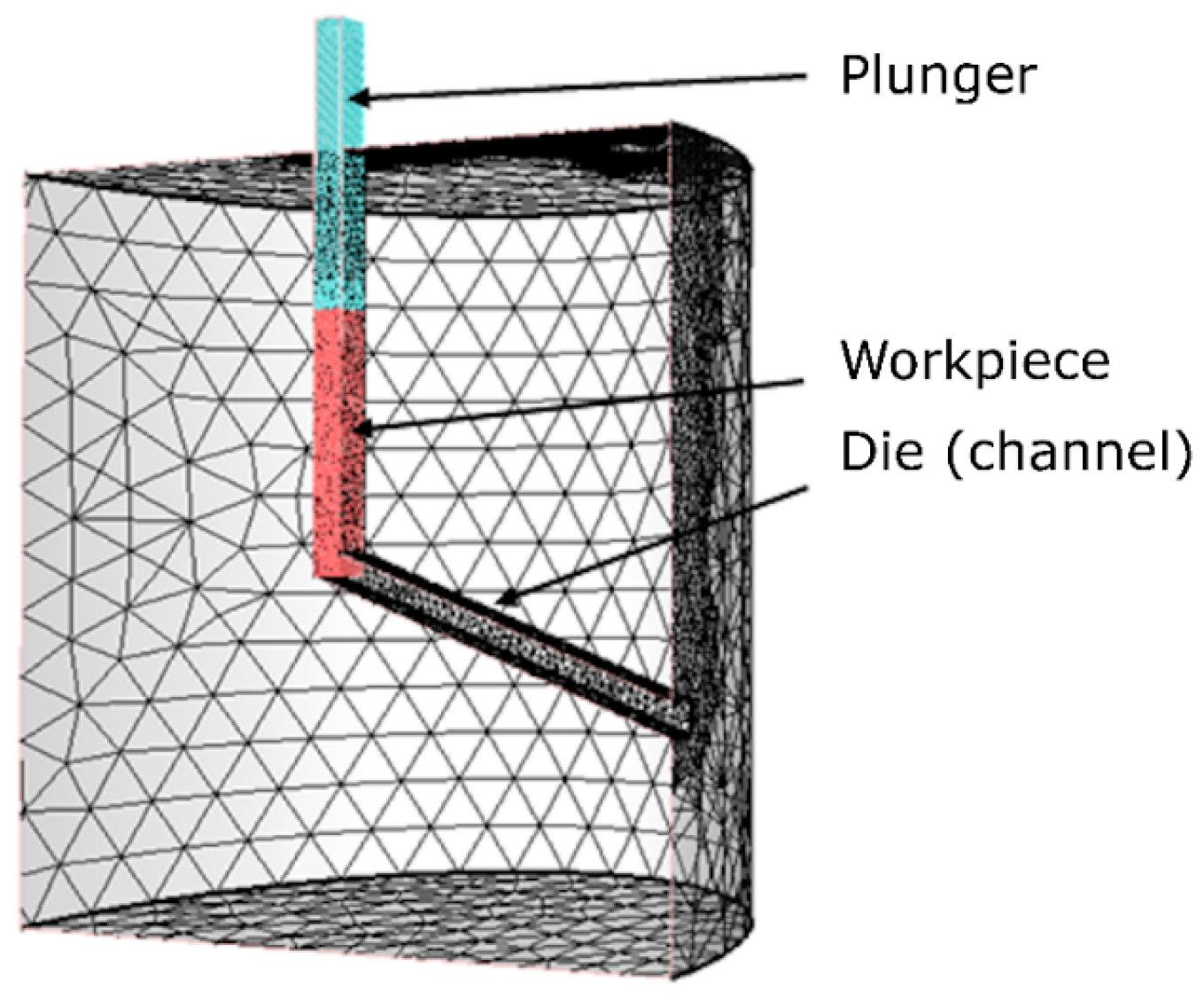

2.2. Numerical Simulation

3. Results and Discussions

3.1. Experimental Analysis

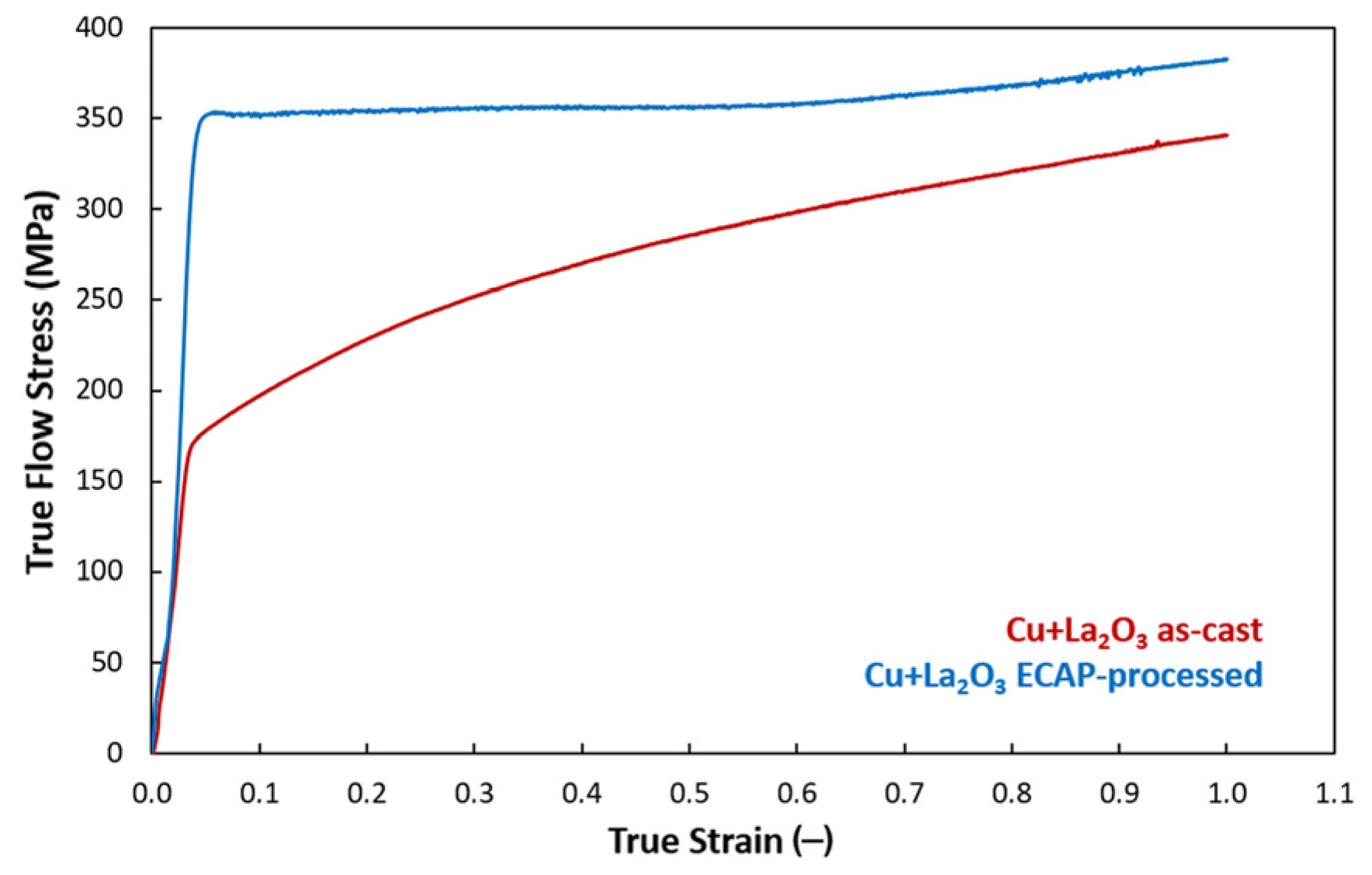

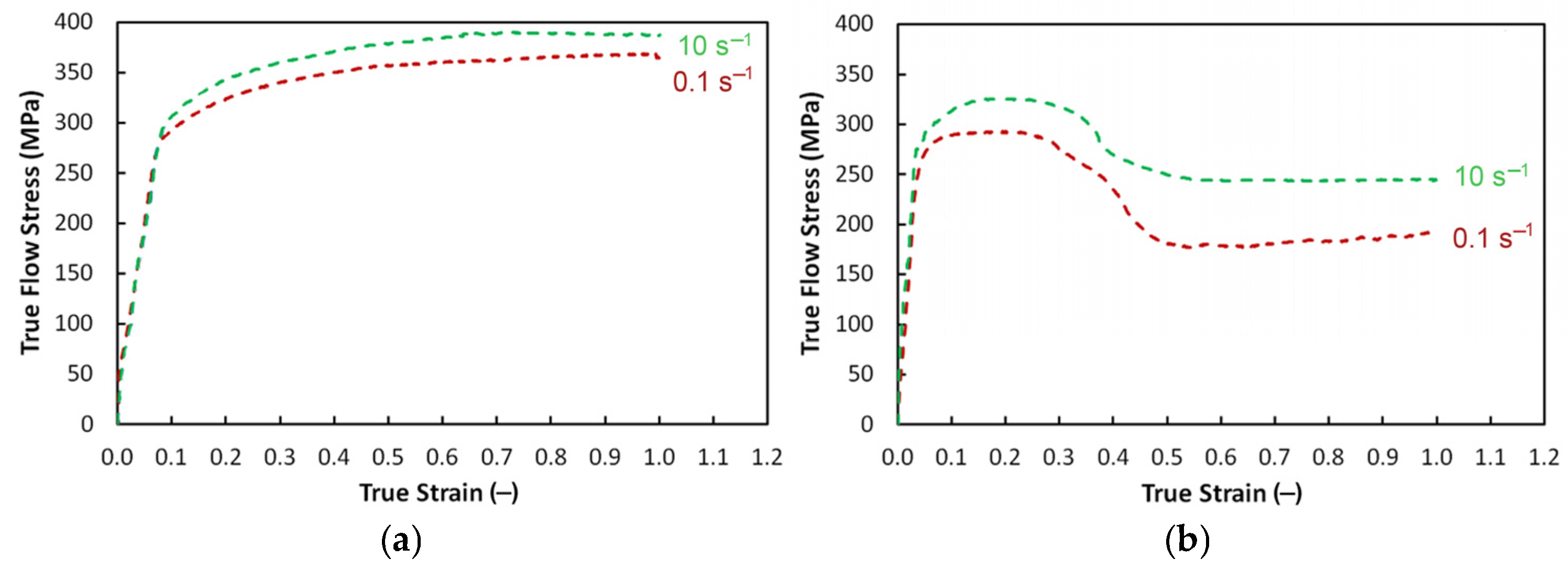

3.1.1. Mechanical Behavior

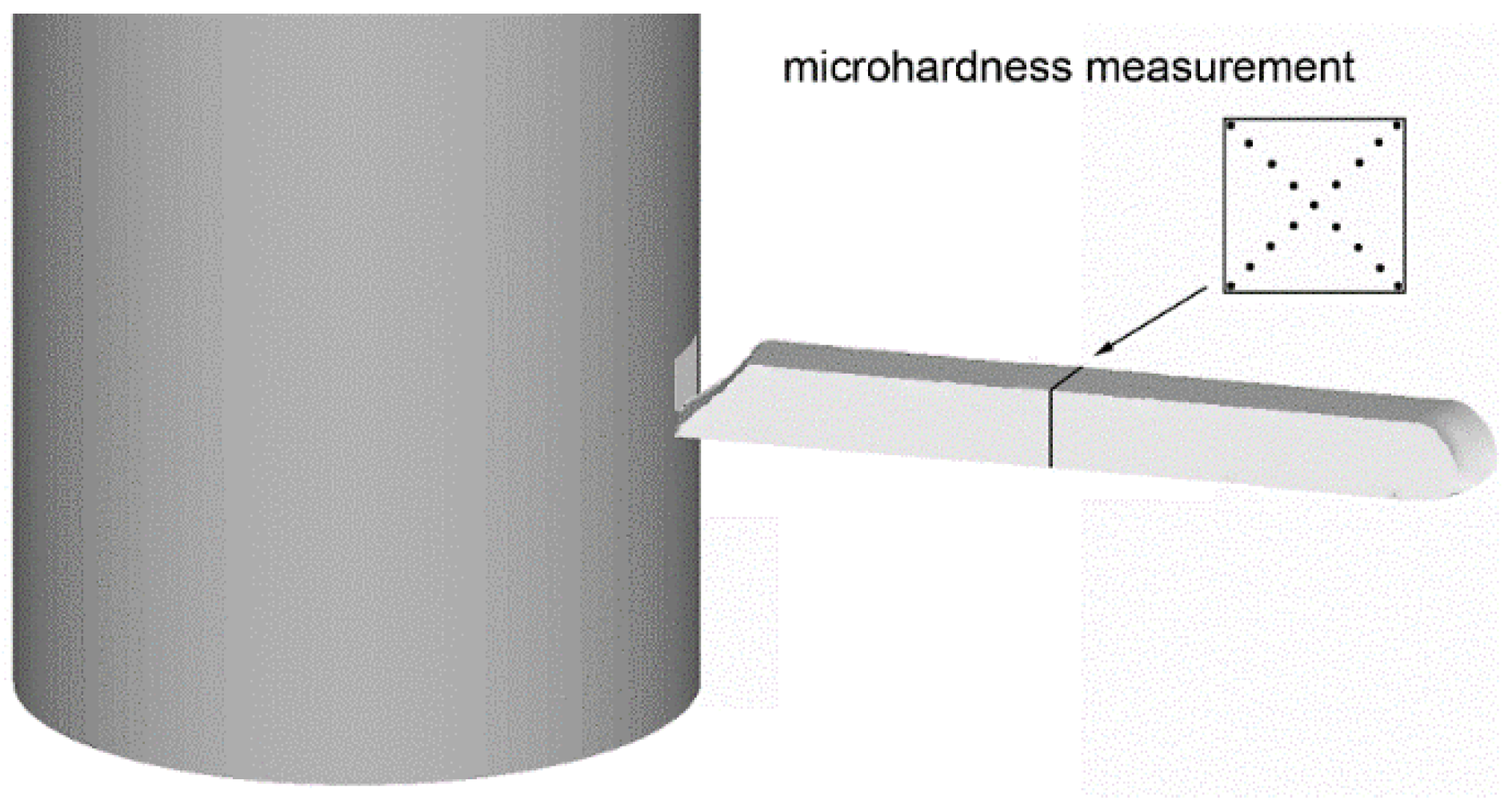

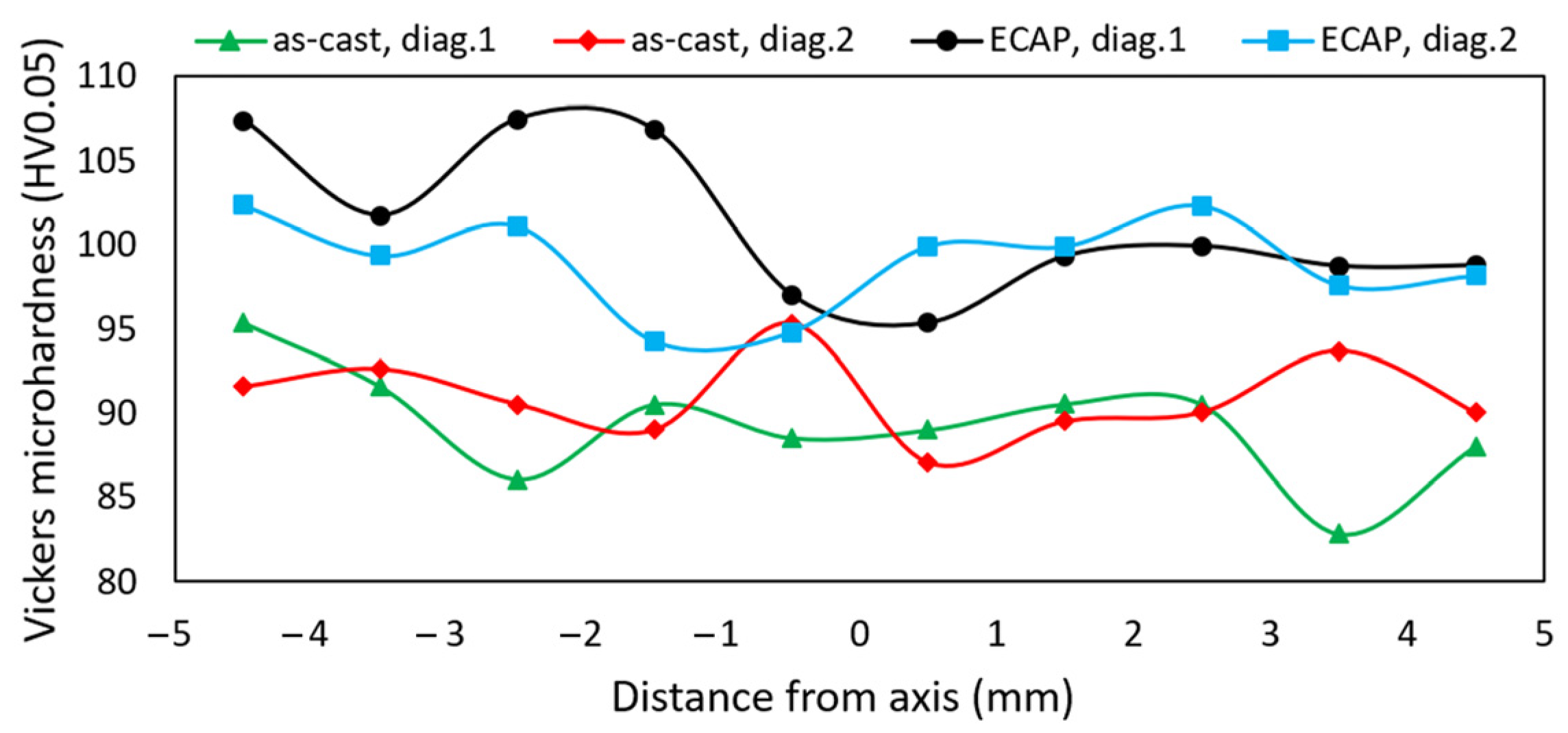

3.1.2. Vickers Microhardness

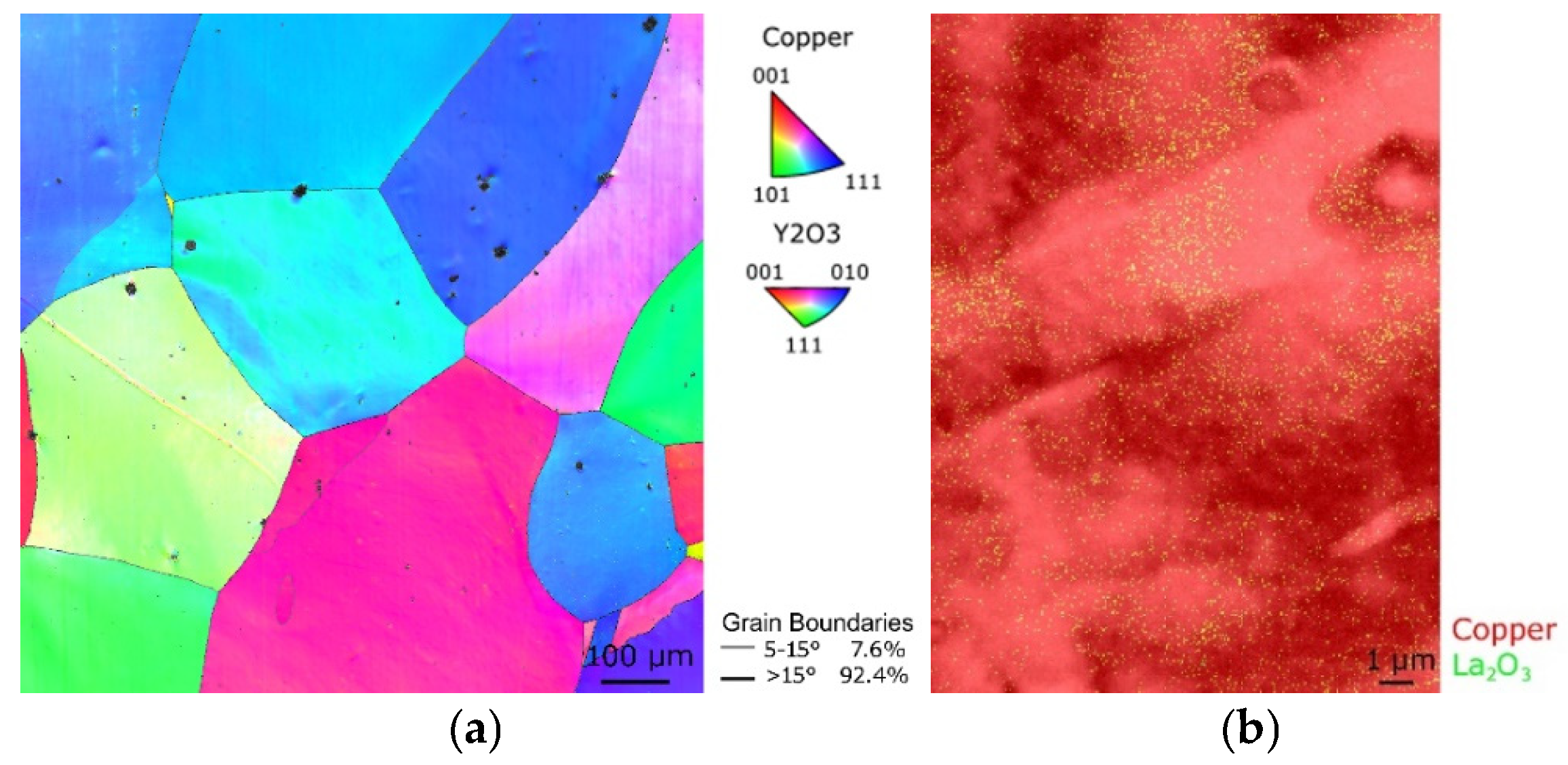

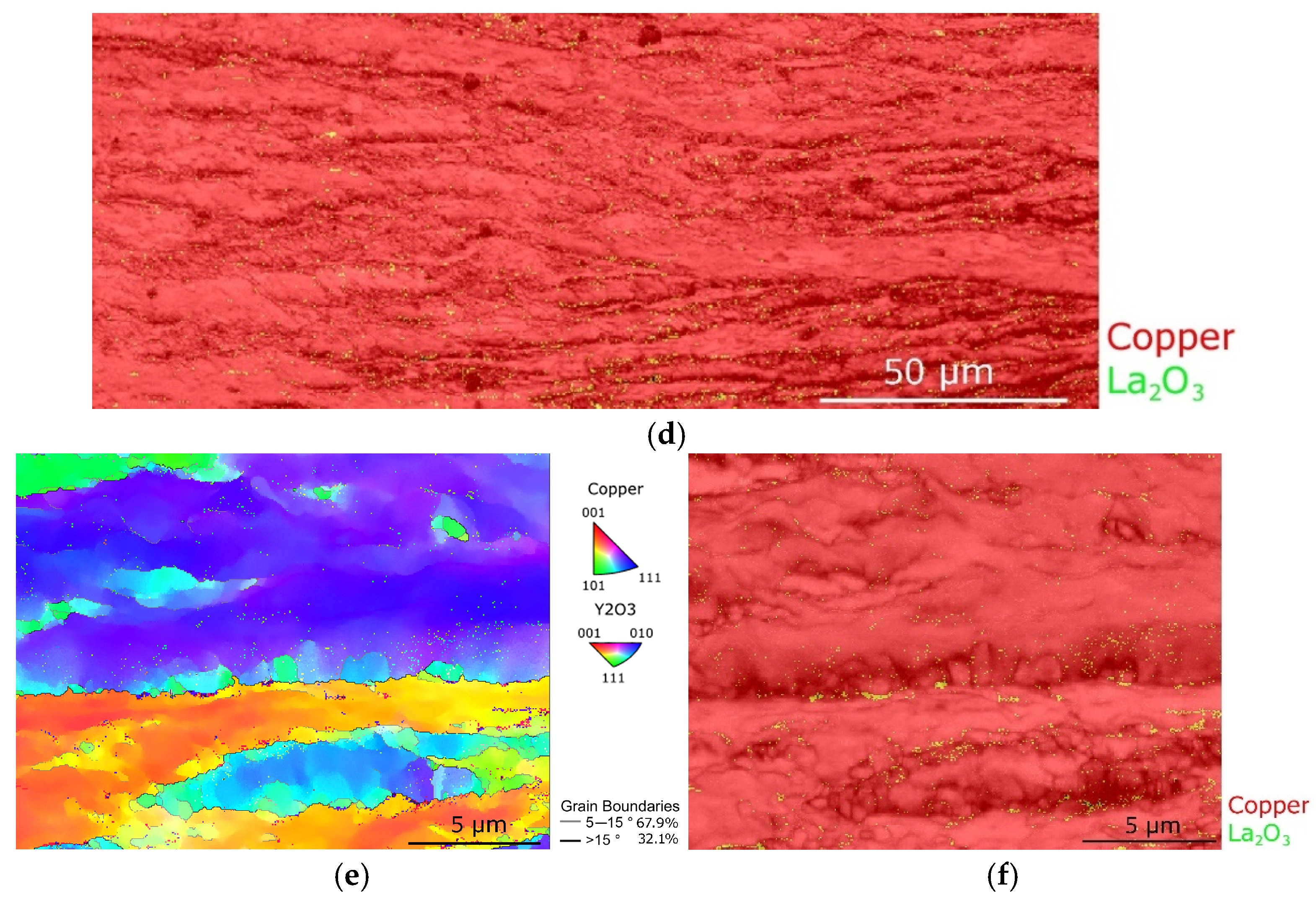

3.1.3. Microstructure

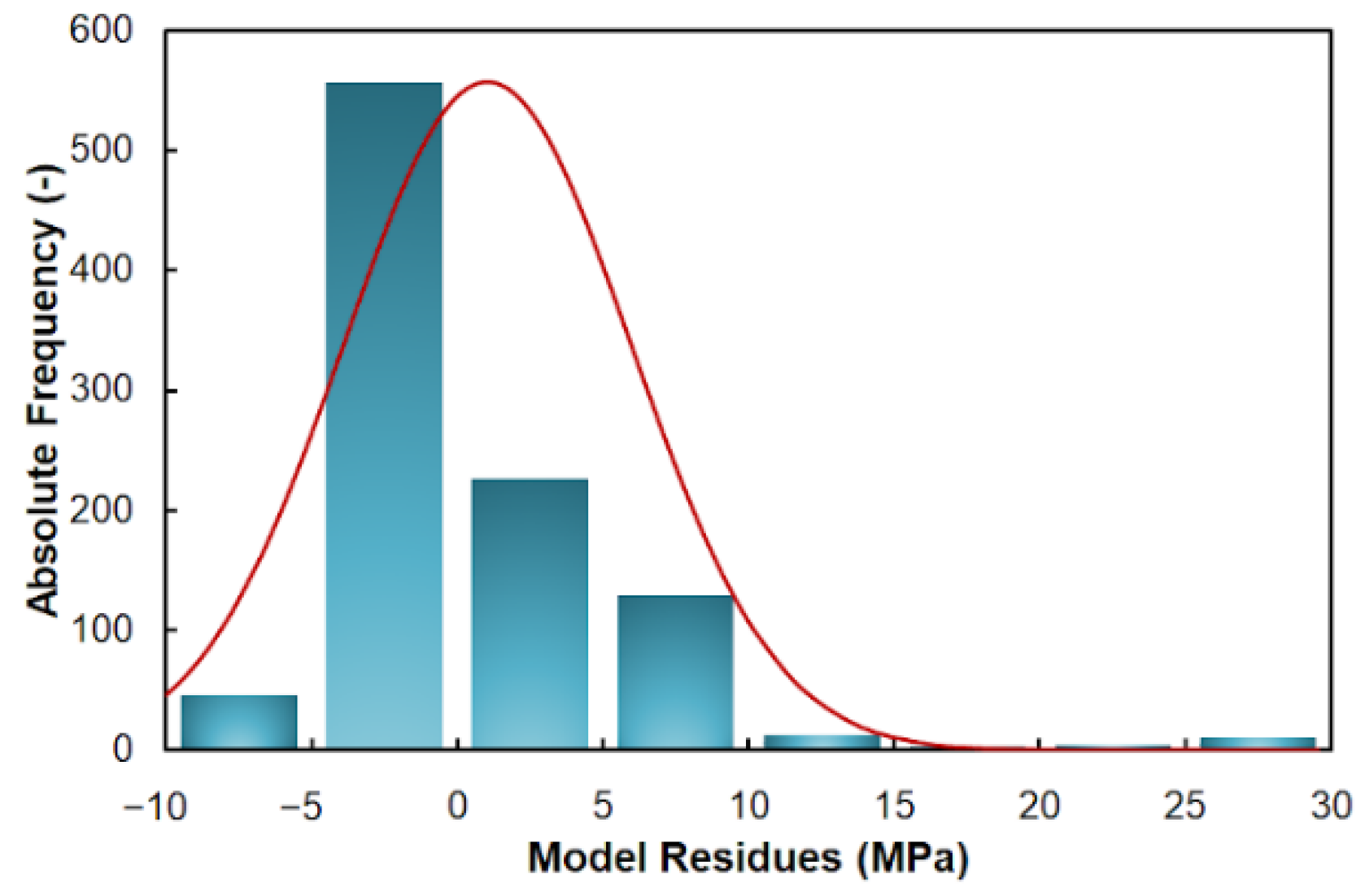

3.2. Numerical Prediction

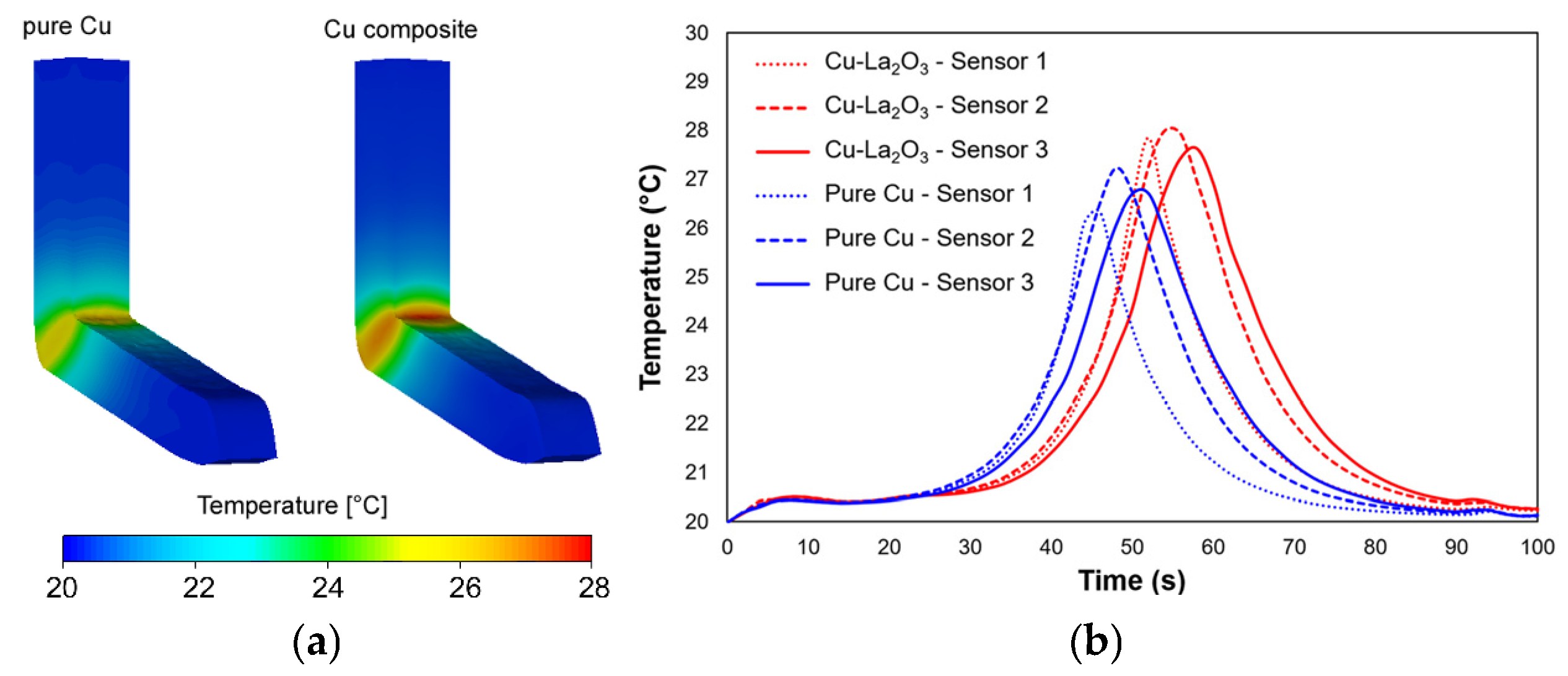

3.2.1. Deformation Temperature

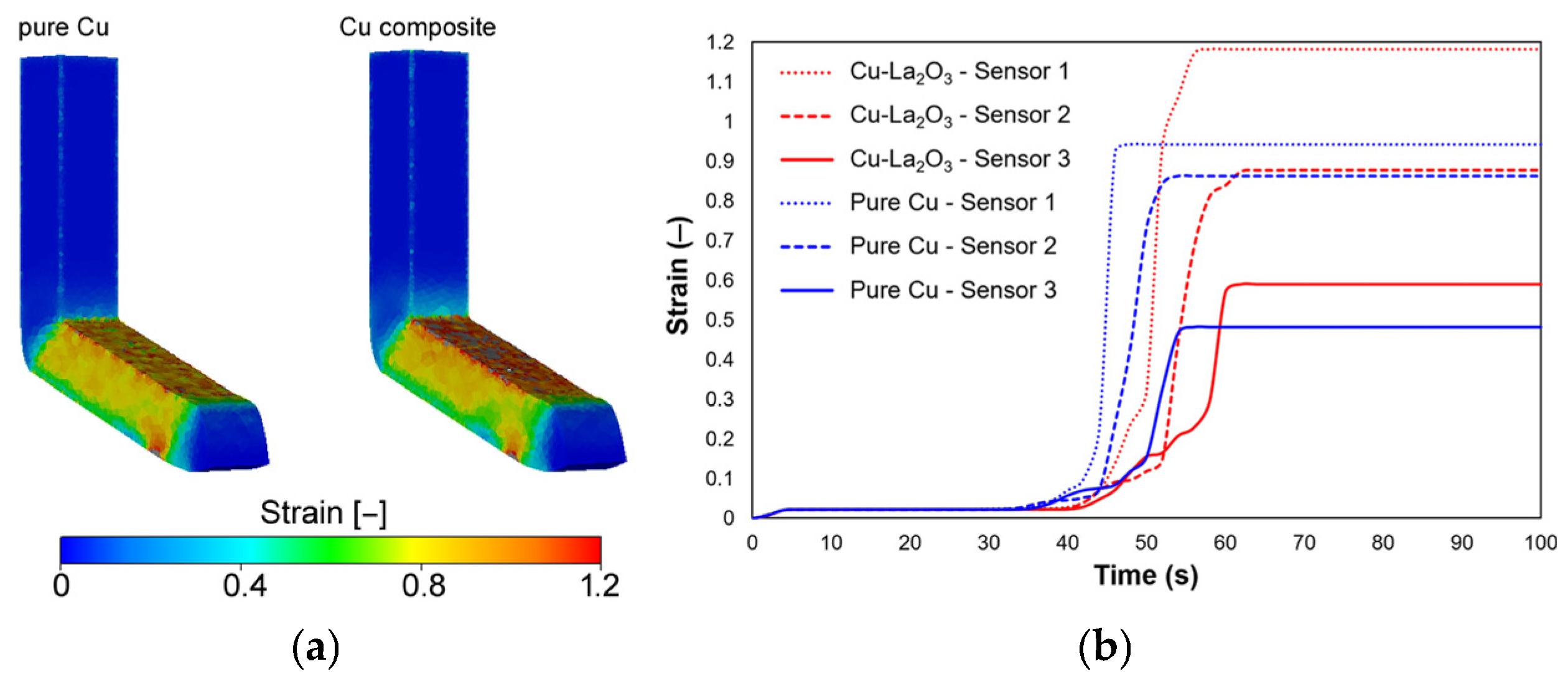

3.2.2. Effective Strain

3.2.3. Stress Distribution

3.2.4. Punch Load

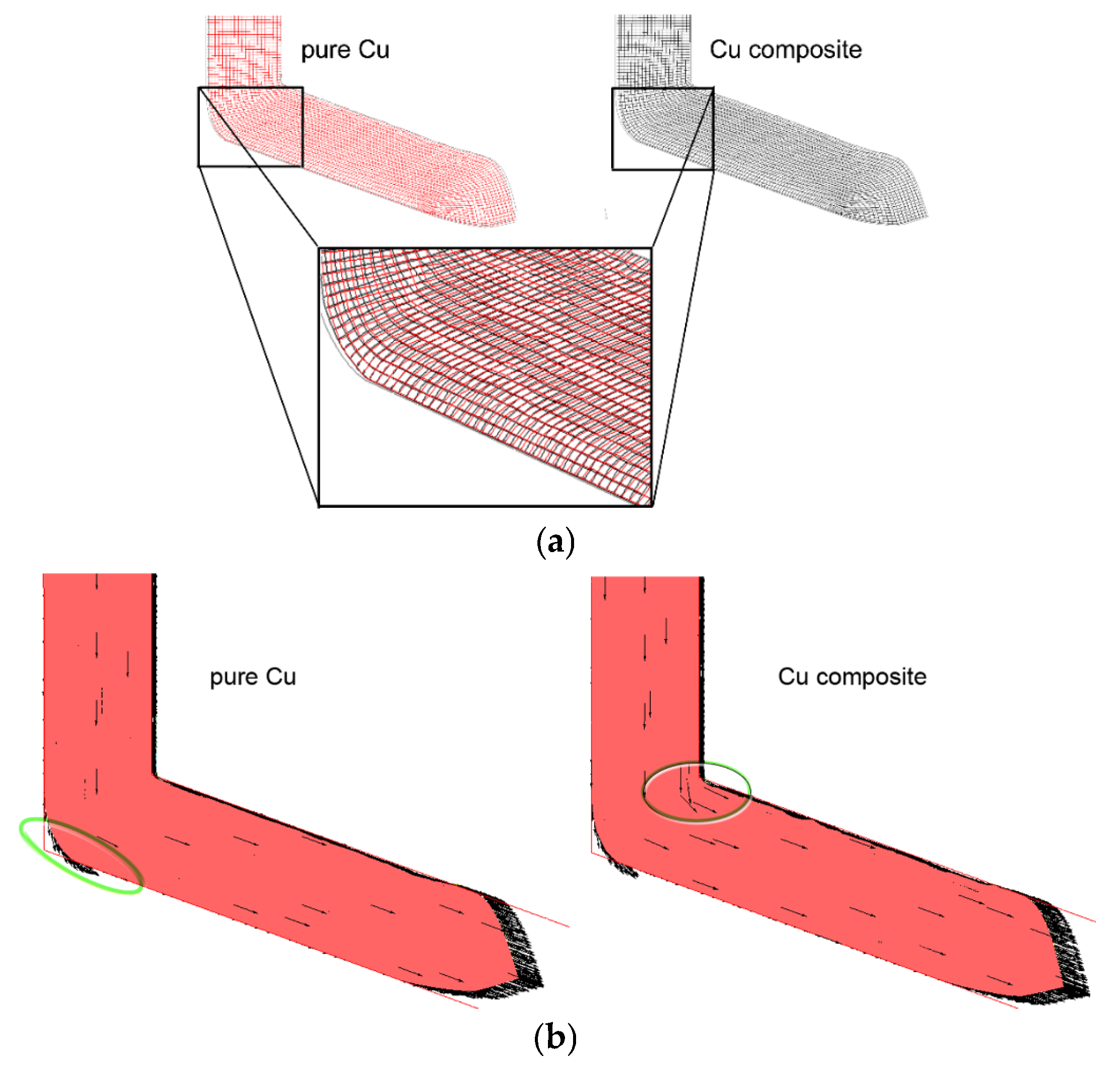

3.2.5. Plastic Flow

4. Conclusions

- -

- La2O3 hindered movement of dislocations and supported the development of shear bands and substructure during ECAP; their presence promoted formation of <111>||SD texture.

- -

- ECAP processing caused accumulation of dislocations and consequently increased the maximum flow stress of the composite to 382 MPa, average Vickers microhardness increased by 120% compared to CP Cu.

- -

- the composite exhibited substantial work hardening, which increased the effective imposed strain, but at the expense of tensile residual stress and increased punch load; the presence of La2O3 directly influenced the size of the dead zone in the ECAP die.

- -

- the energy accumulated during ECAP decreased the activation energy for dynamic recrystallization and influenced thermal stability of the mechanical properties.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Russell, A.; Lee, K.L. Structure-Property Relations in Nonferrous Metals, 1st ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2005; ISBN 978-0-471-64952-6. [Google Scholar]

- Konchakova, I.S.; Kolmakov, A.G.; Gvozdev, A.E. Features of the Influence of Thermal Action on Structural Changes in Copper Conductors. Inorg. Mater. Appl. Res. 2021, 12, 993–999. [Google Scholar] [CrossRef]

- Gilev, V.G.; Bezmaternykh, N.V.; Morozov, E.A. Study of Steel–Copper Pseudo Alloy Microstructure and Microhardness After Laser Heat Treatment. Met. Sci. Heat Treat. 2014, 56, 262–268. [Google Scholar] [CrossRef]

- Chu, Z.Q.; Wei, K.X.; Wei, W.; Alexandrov, I.V.; An, X.L.; Wang, D.D.; Liu, X.K. Simultaneously Enhancing Mechanical Properties and Electrical Conductivity of Cu-0.5%Cr Alloy as 5G Connector Material. J. Alloys Compd. 2023, 948, 169750. [Google Scholar] [CrossRef]

- Kocich, R.; Kunčická, L. Crossing the Limits of Electric Conductivity of Copper by Inducing Nanotwinning via Extreme Plastic Deformation at Cryogenic Conditions. Mater. Charact. 2024, 207, 113513. [Google Scholar] [CrossRef]

- Popovich, A.; Sufiiarov, V.; Polozov, I.; Borisov, E.; Masaylo, D.; Orlov, A. Microstructure and Mechanical Properties of Additive Manufactured Copper Alloy. Mater. Lett. 2016, 179, 38–41. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, W.; Li, Y.; Yang, F.; Liu, H.; Zou, J.; Jiang, J.; Fang, F.; Ma, A. An Overview of Microstructure Regulation Treatment of Cu-Fe Alloys to Improve Strength, Conductivity, and Electromagnetic Shielding. J. Alloys Compd. 2024, 1002, 175425. [Google Scholar] [CrossRef]

- Kunčická, L.; Kocich, R. Effect of Activated Slip Systems on Dynamic Recrystallization during Rotary Swaging of Electro-Conductive Al-Cu Composites. Mater. Lett. 2022, 321, 10–13. [Google Scholar] [CrossRef]

- Hu, X.; Hu, H.; Lai, R.; Xie, Q.; Zhi, Y. Cyclic Warm Rolling: A Path to Superior Properties in Mo Cu Composites. Int. J. Refract. Met. Hard Mater. 2025, 126, 106926. [Google Scholar] [CrossRef]

- Strunz, P.; Kunčická, L.; Beran, P.; Kocich, R.; Hervoches, C. Correlating Microstrain and Activated Slip Systems with Mechanical Properties within Rotary Swaged WNiCo Pseudoalloy. Materials 2020, 13, 208. [Google Scholar] [CrossRef]

- Kunčická, L.; Kocich, R.; Németh, G.; Dvořák, K.; Pagáč, M. Effect of Post Process Shear Straining on Structure and Mechanical Properties of 316 L Stainless Steel Manufactured via Powder Bed Fusion. Addit. Manuf. 2022, 59, 103128. [Google Scholar] [CrossRef]

- Canelo-Yubero, D.; Kocich, R.; Hervoches, C.; Strunz, P.; Kunčická, L.; Krátká, L. Neutron Diffraction Study of Residual Stresses in a W–Ni–Co Heavy Alloy Processed by Rotary Swaging at Room and High Temperatures. Met. Mater. Int. 2022, 28, 919–930. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, J.; Kocich, R.; Tardif, S.; Dolbnya, I.P.; Kunčická, L.; Micha, J.-S.; Liogas, K.; Magdysyuk, O.V.; Szurman, I.; et al. Grain Structure Engineering of NiTi Shape Memory Alloys by Intensive Plastic Deformation. ACS Appl. Mater. Interfaces 2022, 14, 31396–31410. [Google Scholar] [CrossRef] [PubMed]

- Kunčická, L.; Kocich, R.; Ryukhtin, V.; Cullen, J.C.T.; Lavery, N.P. Study of Structure of Naturally Aged Aluminium after Twist Channel Angular Pressing. Mater. Charact. 2019, 152, 94–100. [Google Scholar] [CrossRef]

- Segal, V. Review: Modes and Processes of Severe Plastic Deformation (SPD). Materials 2018, 11, 1175. [Google Scholar] [CrossRef]

- Arbuz, A.; Lutchenko, N.; Yordanova, R. FEM Method Study of the Advanced ECAP Die Channel and Tool Design. Modelling 2025, 6, 19. [Google Scholar] [CrossRef]

- Verlinden, B.; Driver, J.; Samajdar, I.; Doherty, R.D. Thermo-Mechanical Processing of Metallic Materials; Elsevier: Amsterdam, The Netherland, 2007; ISBN 9780080444970. [Google Scholar]

- Bodyakova, A.; Tkachev, M.; Raab, G.I.; Kaibyshev, R.; Belyakov, A.N. Regularities of Microstructure Evolution in a Cu-Cr-Zr Alloy during Severe Plastic Deformation. Materials 2022, 15, 5745. [Google Scholar] [CrossRef]

- Sukhov, I.A.; Shafeev, G.A.; Voronov, V.V.; Sygletou, M.; Stratakis, E.; Fotakis, C. Generation of Nanoparticles of Bronze and Brass by Laser Ablation in Liquid. Appl. Surf. Sci. 2014, 302, 79–82. [Google Scholar] [CrossRef]

- Muñoz, A.I.; Antón, J.G.; Guiñón, J.L.; Herranz, V.P. Corrosion Behavior and Galvanic Studies of Brass and Bronzes in Aqueous Lithium Bromide Solutions. Corrosion 2002, 58, 560–569. [Google Scholar] [CrossRef]

- Zhou, M.; Geng, Y.; Zhang, Y.; Ban, Y.; Li, X.; Jia, Y.; Liang, S.; Tian, B.; Liu, Y.; Volinsky, A.A. Enhanced Mechanical Properties and High Electrical Conductivity of Copper Alloy via Dual-Nanoprecipitation. Mater. Charact. 2023, 195, 112494. [Google Scholar] [CrossRef]

- Dubskii, G.A.; Vdovin, K.N.; Nefed’ev, A.A.; Egorova, L.G. Thermal Conductivity of Low-Alloy Copper for Molds. Russ. Metall. 2018, 2018, 252–258. [Google Scholar] [CrossRef]

- Tian, W.; Zhang, F.; Han, S.; Chen, X.; Gao, P.; Zheng, K. Analysis of Microstructure and Properties in Cold Rotary Swaged Copper-Clad Magnesium Wires. Metals 2023, 13, 467. [Google Scholar] [CrossRef]

- Volkov, A.Y.; Kalonov, A.A.; Zavalishin, V.A.; Glukhov, A.V.; Komkova, D.A.; Antonov, B.D. The Influence of Interfaces on the Physicomechanical Properties of Cu/Mg Composites. Phys. Met. Metallogr. 2020, 121, 568–574. [Google Scholar] [CrossRef]

- Volkov, A.Y.; Kalonov, A.A.; Komkova, D.A.; Glukhov, A.V. Structure and Properties of Cu/Mg Composites Produced by Hydrostatic Extrusion. Phys. Met. Metallogr. 2018, 119, 946–955. [Google Scholar] [CrossRef]

- Kocich, R.; Kunčická, L. Optimizing Structure and Properties of Al/Cu Laminated Conductors via Severe Shear Strain. J. Alloys Compd. 2023, 953, 170124. [Google Scholar] [CrossRef]

- Rogachev, S.O.; Sundeev, R.V.; Andreev, V.A.; Andreev, N.V.; Tabachkova, N.Y.; Korotkova, N.O. The Microstructure and Conductivity of Copper–Aluminum Composites Prepared by Rotary Swaging. Phys. Met. Metallogr. 2022, 123, 1193–1200. [Google Scholar] [CrossRef]

- Zhang, X.; Yu, Y.; Liu, B.; Ren, J. Mechanical Properties and Tensile Fracture Mechanism Investigation of Al/Cu/Ti/Cu/Al Laminated Composites Fabricated by Rolling. J. Alloys Compd. 2019, 805, 338–345. [Google Scholar] [CrossRef]

- Popova, E.N.; Deryagina, I.L.; Valova-Zaharevskaya, E.G.; Ruello, M.L.; Popov, V.V. Microstructural Features in Multicore Cu–Nb Composites. Materials 2021, 14, 7033. [Google Scholar] [CrossRef]

- Permyakova, I.E.; Glezer, A.M.; Karpov, M.I.; Vnukov, V.I.; Shtansky, D.V.; Gorshenkov, M.V.; Schetinin, I.V. Structure Amorphization and Mechanical Properties of Nanolaminates of the Copper–Niobium System During High-Pressure Torsion. Russ. Phys. J. 2018, 61, 428–438. [Google Scholar] [CrossRef]

- Deryagina, I.L.; Popova, E.N.; Valova-Zaharevskaya, E.G.; Patrakov, E.I. Structure and Thermal Stability of High-Strength Cu–18Nb Composite Depending on the Degree of Deformation. Phys. Met. Metallogr. 2018, 119, 92–102. [Google Scholar] [CrossRef]

- Bokstein, B.S.; Vnukov, V.I.; Golosov, E.V.; Karpov, M.I.; Kolobov, Y.R.; Kolesnikov, D.A.; Korzhov, V.P.; Rodin, A.O. Structure and Diffusion Processes in Laminated Composites of a Cu–Ti System. Russ. Phys. J. 2009, 52, 811–815. [Google Scholar] [CrossRef][Green Version]

- Liu, Z.; Wang, X.; Liu, M.; Liu, Y.; Liu, J.; Ignatov, A.V.; Wang, T. Microstructure and Mechanical Behavior of Ti/Cu/Ti Laminated Composites Produced by Corrugated and Flat Rolling. Trans. Nonferrous Met. Soc. China 2022, 32, 2598–2608. [Google Scholar] [CrossRef]

- Xu, Q.; Zhang, X.; Han, J.; He, X.; Kvanin, V.L. Combustion Synthesis and Densification of Titanium Diboride–Copper Matrix Composite. Mater. Lett. 2003, 57, 4439–4444. [Google Scholar] [CrossRef]

- Mali, V.I.; Bataev, A.A.; Maliutina, I.N.; Kurguzov, V.D.; Bataev, I.A.; Esikov, M.A.; Lozhkin, V.S. Microstructure and Mechanical Properties of Ti/Ta/Cu/Ni Alloy Laminate Composite Materials Produced by Explosive Welding. Int. J. Adv. Manuf. Technol. 2017, 93, 4285–4294. [Google Scholar] [CrossRef]

- Trykov, Y.; Gurevich, L.; Pronichev, D.; Trunov, M. Investigation of the Rupture of Ti/Steel Laminated Composite with Soft Interlayers. FME Trans. 2016, 44, 16–21. [Google Scholar] [CrossRef]

- Xu, W.; Qi, J.; Zhang, Y.; Zeng, G.; Zhou, Y.; Ou, H.; Zhou, H.; Wu, Y.; Yang, Y. Effect of Annealing Treatment on Electromagnetic Shielding Effectiveness of Double-Layer FeSiBCuNb/Cu Composite Strips. J. Mater. Sci. Mater. Electron. 2023, 34, 376. [Google Scholar] [CrossRef]

- Sheinerman, A.G.; Gutkin, M.Y. Multiple Cracking in Deformed Laminated Metal-Graphene Composites. Compos. Struct. 2018, 191, 113–118. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, Y.; Wang, W.; Yue, S.; Li, T. A Novel Approach to Achieve High Strength, High Plasticity and High Conductivity of Graphene/Cu Composites with Graphene Core-Shell Structure. J. Alloys Compd. 2024, 1002, 175207. [Google Scholar] [CrossRef]

- Wei, K.X.; Jia, F.L.; Wei, W.; Zhou, H.R.; Chu, F.Q.; Du, Q.B.; Alexandrov, I.V.; Hu, J. Flexible Nanotwinned Graphene/Copper Composites as Thermal Management Materials. ACS Appl. Nano Mater. 2020, 3, 4810–4817. [Google Scholar] [CrossRef]

- Akmal, J.; Salmi, M. Additive Manufacturing of Self-Sensing Parts through Material Extrusion. Virtual Phys. Prototyp. 2024, 19, e2321200. [Google Scholar] [CrossRef]

- Koltsova, T.S.; Bobrynina, E.V.; Larionova, T.V.; Salynova, M.A.; Tolochko, O.V. Structure and Properties of Copper-Based Composite with Different Types of Carbon Nanostructures. Diam. Relat. Mater. 2022, 124, 108933. [Google Scholar] [CrossRef]

- Han, K.; Goddard, R.E.; Toplosky, V.; Niu, R.; Lu, J.; Walsh, R. Alumina Particle Reinforced Cu Matrix Conductors. IEEE Trans. Appl. Supercond. 2018, 28, 1–5. [Google Scholar] [CrossRef]

- Grigoreva, T.F.; Talako, T.L.; Devyatkina, E.T.; Vosmerikov, S.V.; Ancharov, A.I.; Tsybulya, S.V.; Vityaz, P.A.; Lyakhov, N.Z. Modifying Copper with Alumina during a Mechanically Stimulated Reaction. Phys. Met. Metallogr. 2023, 124, 74–79. [Google Scholar] [CrossRef]

- Volkova, I.R.; Tyryshkina, L.E.; Volochaev, M.N.; Zaloga, A.N.; Shabanova, K.A.; Ovchinnikov, A.V.; Lyamkin, A.I. The Effect of Aluminum-Oxide Powders on the Structure and Properties of Copper Electrodeposited Composite Coatings. Prot. Met. Phys. Chem. Surf. 2023, 59, 71–75. [Google Scholar] [CrossRef]

- Ma, B.; Ding, H.; Jiang, F.; Hishinuma, Y.; Luo, L.; Zhang, Y.; Wang, J.; Sheng, X.; Noto, H.; Liu, J.; et al. Effect of Process Control Agent on the Synthesis of Cu-Y2O3 by Mechanical Alloying. Nucl. Mater. Energy 2024, 38, 101599. [Google Scholar] [CrossRef]

- Huang, F.; Wang, H.; Yang, B.; Liao, T.; Wang, Z. Pinning Effect of Y2O3 Network on Copper Grain Growth during High Temperature Annealing. Mater. Res. Express 2018, 5, 056520. [Google Scholar] [CrossRef]

- Sobahi, N.; El-Kady, O.A.; Nouh, F.; Banoqitah, E.; Ghoname, R.; Moustafa, E.B.; Elsheikh, A. Impact of Nano-Y2O3 on the Physical, Microstructure, and Mechanical Characteristics of Cu Composite Fabricated via Powder Metallurgy. J. Alloys Compd. 2025, 1010, 177042. [Google Scholar] [CrossRef]

- Huang, F.; Wang, H.; Yang, B.; Liao, T.; Wang, Z. Uniformly Dispersed Y2O3 Nanoparticles in Nanocrystalline Copper Matrix via Multi-Step Ball Milling and Reduction Process. Mater. Lett. 2019, 242, 119–122. [Google Scholar] [CrossRef]

- Zheng, R.G.; Zhan, Z.J.; Wang, W.K. Wear Behavior of Cu-La2O3 Composite. Rare Met. Mater. Eng. 2010, 39, 293–295. [Google Scholar]

- Li, X.; Wang, Y.; Yang, P.; Han, T.; Shi, X.; He, K.; Zu, C. Effect of Y2O3/La2O3 on Structure and Mechanical Properties of Li2O–Al2O3–SiO2 Glass. J. Non. Cryst. Solids 2022, 596, 121847. [Google Scholar] [CrossRef]

- Zheng, R.G.; Zhan, Z.J.; Liang, B.; Wang, W.K. Tribological Behavior of La2O3 Particulate Reinforced Copper Matrix Composites. Adv. Mater. Res. 2010, 150–151, 979–983. [Google Scholar] [CrossRef]

- Kocich, R.; Kursa, M.; Macháčková, A. FEA of Plastic Flow in AZ63 Alloy during ECAP Process. Acta Phys. Pol. A 2012, 122, 581–587. [Google Scholar]

- Kunčická, L.; Kocich, R. Comprehensive Characterisation of a Newly Developed Mg-Dy-Al-Zn-Zr Alloy Structure. Metals 2018, 8, 73. [Google Scholar] [CrossRef]

- Heidari, S.; Afsari, A.; Ranaei, M.A. Increasing Wear Resistance of Copper Electrode in Electrical Discharge Machining by Using Ultra-Fine-Grained Structure. Trans. Indian Inst. Met. 2020, 73, 2901–2910. [Google Scholar] [CrossRef]

- Volokitina, I.E. Evolution of the Microstructure and Mechanical Properties of Copper under ECAP with Intense Cooling. Met. Sci. Heat Treat. 2020, 62, 253–258. [Google Scholar] [CrossRef]

- Guo, T.; Wang, J.; Wu, Y.; Tai, X.; Jia, Z.; Ding, Y. Fabricate of High-Strength and High-Conductivity Cu–Cr–Si Alloys through ECAP-Bc and Aging Heat Treatment. Materials 2020, 13, 1603. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Oh-ishi, K.; Raab, G.I.; McNelley, T.R. Influence of ECAP Processing Parameters on Texture and Microstructure of Commercially Pure Aluminum. Mater. Sci. Eng. A 2006, 441, 245–252. [Google Scholar] [CrossRef]

- Chu, Z.; Pan, X.; Wei, W.; Wei, K.; Alexandrov, I.V.; An, X.; Wang, D.; Liu, X. High Strength and Electrical Conductivity of Nanostructured Cu–1Cr–0.1Zr Alloy Processed by Multi–Stage Deformation and Aging. J. Mater. Res. Technol. 2024, 29, 2051–2060. [Google Scholar] [CrossRef]

- Eivani, A.R.; Mirzakoochakshirazi, H.R.; Jafarian, H.R. Investigation of Joint Interface and Cracking Mechanism of Thick Cladding of Copper on Aluminum by Equal Channel Angular Pressing (ECAP). J. Mater. Res. Technol. 2020, 9, 3394–3405. [Google Scholar] [CrossRef]

- Volokitina, I.; Sapargaliyeva, B.; Agabekova, A.; Syrlybekkyzy, S.; Volokitin, A.; Nurshakhanova, L.; Nurbaeva, F.; Kolesnikov, A.; Sabyrbayeva, G.; Izbassar, A.; et al. Increasing Strength and Performance Properties of Bimetallic Rods during Severe Plastic Deformation. Case Stud. Constr. Mater. 2023, 19, e02256. [Google Scholar] [CrossRef]

- Kocich, R.; Kunčická, L. Development of Structure and Properties in Bimetallic Al/Cu Sandwich Composite during Cumulative Severe Plastic Deformation. J. Sandw. Struct. Mater. 2021, 23, 4252–4275. [Google Scholar] [CrossRef]

- Macháčková, A.; Kocich, R.; Bojko, M.; Kunčická, L.; Polko, K. Numerical and Experimental Investigation of Flue Gases Heat Recovery via Condensing Heat Exchanger. Int. J. Heat Mass Transf. 2018, 124, 1321–1333. [Google Scholar] [CrossRef]

- Fiedler, T.; Löffler, R.; Bernthaler, T.; Winkler, R.; Belova, I.V.; Murch, G.E.; Öchsner, A. Numerical Analyses of the Thermal Conductivity of Random Hollow Sphere Structures. Mater. Lett. 2009, 63, 1125–1127. [Google Scholar] [CrossRef]

- Borodin, E.N.; Morozova, A.; Bratov, V.; Belyakov, A.; Jivkov, A.P. Experimental and Numerical Analyses of Microstructure Evolution of Cu-Cr-Zr Alloys during Severe Plastic Deformation. Mater. Charact. 2019, 156, 109849. [Google Scholar] [CrossRef]

- Bratov, V.; Borodin, E.N. Comparison of Dislocation Density Based Approaches for Prediction of Defect Structure Evolution in Aluminium and Copper Processed by ECAP. Mater. Sci. Eng. A 2015, 631, 10–17. [Google Scholar] [CrossRef]

- Abd EL AAL, M.I. 3D FEM Simulations and Experimental Validation of Plastic Deformation of Pure Aluminum Deformed by ECAP and Combination of ECAP and Direct Extrusion. Trans. Nonferrous Met. Soc. China 2017, 27, 1338–1352. [Google Scholar] [CrossRef]

- Hongyu, W.; Jie, W.; Fei, T.; Ting, L.; Juncai, S.; Xiangwei, K.; Dianhua, Z.; Wen, P.; Shunhu, Z. Analysis and Simulation for Shape Control Effects of Square Aluminum Tube during ECAP. Int. J. Adv. Manuf. Technol. 2020, 108, 3859–3870. [Google Scholar] [CrossRef]

- Vafaeenezhad, H.; Chegini, M.; Kalaki, A.; Serajian, H. Micromechanical Finite Element Simulation of Low Cycle Fatigue Damage Occurring During Sliding Wear Test of ECAP-Processed AA7075 Alloy. Met. Mater. Int. 2024, 30, 143–166. [Google Scholar] [CrossRef]

- Ghosh, A.; Das, K.; Eivani, A.R.; Mohammadi, H.; Vafaeenezhad, H.; Murmu, U.K.; Jafarian, H.R.; Ghosh, M. Development of Mechanical Properties and Microstructure for Al–Zn–Mg–Cu Alloys through ECAP after Optimizing the Outer Corner Angles through FE Modeling. Arch. Civ. Mech. Eng. 2023, 23, 78. [Google Scholar] [CrossRef]

- ASTM D7012-23; Standard Test Methods for Compressive Strength and Elastic Moduli of Intact Rock Core Specimens under Varying States of Stress and Temperatures. ASTM International: West Conshohocken, PA, USA, 2023.

- Kunčická, L.; Kocich, R. Deformation Behaviour of Cu-Al Clad Composites Produced by Rotary Swaging. IOP Conf. Ser. Mater. Sci. Eng. 2018, 369, 012029. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Y.; Liogas, K.; Chen, J.; Vaughan, G.B.M.; Kocich, R.; Kunčická, L.; Uzun, F.; You, Z.; Korsunsky, A.M. In Situ Synchrotron X-Ray Diffraction Analysis of Two-Way Shape Memory Effect in Nitinol. Mater. Sci. Eng. A 2023, 878, 145226. [Google Scholar] [CrossRef]

- Churyumov, A.Y.; Kazakova, A.A. Prediction of True Stress at Hot Deformation of High Manganese Steel by Artificial Neural Network Modeling. Materials 2023, 16, 1083. [Google Scholar] [CrossRef] [PubMed]

- ASTM E384; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2022.

- Sajjad, M.; Agirre, J.; Plata, G.; Lozares, J.; Mendiguren, J. Characterization of the Heat Transfer Coefficient at near Solidus Forming Condition Using Columnar Pressing Test. Int. J. Adv. Manuf. Technol. 2024, 135, 721–733. [Google Scholar] [CrossRef]

- Dhondapure, P.; Rajakrishnan, N.; Nayak, S.; Champliaud, H.; Morin, J.-B.; Jahazi, M. Influence of Deformation Path on Microstructure Evolution during the Open Die Forging of Large Size Ingot of High Strength Steel: Experiments and FE Analysis. Int. J. Adv. Manuf. Technol. 2024, 134, 3733–3750. [Google Scholar] [CrossRef]

- Ghat, M.; Mohamed, A.; Afify, A.S. Physical Modelling of Ti–6Al–4V Alloy above β Transus at High Temperatures (1010–1150 °C) and High Strain Rates Using Garofalo and Hensel–Spittel Laws. High Temp. 2022, 60, 479–484. [Google Scholar] [CrossRef]

- Zhang, X.-H.; Yuan, H.-X.; Huang, F.; Wang, H.; Yang, B.; Zeng, L.-F.; Li, X.-H.; Huang, Y.-J.; Ahmad, T. Enhanced Strength–Plasticity Synergy of Copper Composites by Designing Uniformly Dispersed Yttria Nanoparticles and a Heterogeneous Grain Structure. Rare Met. 2024, 43, 6704–6716. [Google Scholar] [CrossRef]

- Tallan, N.M.; Vest, R.W. Electrical Properties and Defect Structure of Y2O3. J. Am. Ceram. Soc. 1966, 49, 401–404. [Google Scholar] [CrossRef]

- Chuvil’deev, V.N.; Shadrina, I.S.; Nokhrin, A.V.; Kopylov, V.I.; Bobrov, A.A.; Gryaznov, M.Y.; Shotin, S.V.; Tabachkova, N.Y.; Chegurov, M.K.; Melekhin, N.V. An Investigation of Thermal Stability of Structure and Mechanical Properties of Al-0.5Mg–Sc Ultrafine-Grained Aluminum Alloys. J. Alloys Compd. 2020, 831, 154805. [Google Scholar] [CrossRef]

- Qi, Y.; Kosinova, A.; Kilmametov, A.R.; Straumal, B.B.; Rabkin, E. Stabilization of Ultrafine-Grained Microstructure in High-Purity Copper by Gas-Filled Pores Produced by Severe Plastic Deformation. Scr. Mater. 2020, 178, 29–33. [Google Scholar] [CrossRef]

- Arivu, M.; Hoffman, A.; Duan, J.; Poplawsky, J.; Zhang, X.; Liou, F.; Islamgaliev, R.; Valiev, R.; Wen, H. Comparison of the Thermal Stability in Equal-Channel-Angular-Pressed and High-Pressure-Torsion-Processed Fe–21Cr–5Al Alloy. Adv. Eng. Mater. 2023, 25, 2300756. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hetherly, M.; Rollett, A.; Rohrer, G.S. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier Ltd.: Oxford, UK, 2004; ISBN 008-044164-5. [Google Scholar]

- Kocich, R.; Greger, M.; Macháčková, A. Finite Element Investigation of Influence of Selected Factors on ECAP Process. In Proceedings of the METAL 2010: 19th International Metallurgical and Materials Conference, Roznov pod Radhostem, Czech Republic, 18–20 May 2010; Tanger Ltd.: Greensboro, NC, USA, 2010; pp. 166–171. [Google Scholar]

- Zhao, X.; Yang, X.; Liu, X.; Wang, X.; Langdon, T.G. The Processing of Pure Titanium through Multiple Passes of ECAP at Room Temperature. Mater. Sci. Eng. A 2010, 527, 6335–6339. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Swisher, D.L.; Oh-ishi, K.; Langdon, T.G.; McNelley, T.R. Microtexture and Microstructure Evolution during Processing of Pure Aluminum by Repetitive ECAP. Mater. Sci. Eng. A 2006, 429, 137–148. [Google Scholar] [CrossRef]

- Sureshkumar, P.; Ganesan, L.; UmaRani, C.; Stalin, B.; Sasikumar, C.; Rajan, S.T.K.; Borek, W. Effect of Strain Rate on Fractography Texture Descriptor of AA6063/(Si3N4)x/(Cu(NO3)2)y (x = 12%, y = 2–6%)Composite after Multiple ECAP Passes: Second Order Statistical Texture Analysis Conjunction with Regression Analysis. J. Mater. Res. Technol. 2023, 23, 2750–2783. [Google Scholar] [CrossRef]

- Kocich, R.; Kunčická, L.; Macháčková, A. Twist Channel Multi-Angular Pressing (TCMAP) as a Method for Increasing the Efficiency of SPD. IOP Conf. Ser. Mater. Sci. Eng. 2014, 63, 012006. [Google Scholar] [CrossRef]

- de Sousa, T.G.; Sordi, V.L.; Brandão, L.P. Dislocation Density and Texture in Copper Deformed by Cold Rolling and Ecap. Mater. Res. 2017, 21, e20170515. [Google Scholar] [CrossRef]

- Medeiros, N.; Lins, J.F.C.; Moreira, L.P.; Gouvêa, J.P. The Role of the Friction during the Equal Channel Angular Pressing of an IF-Steel Billet. Mater. Sci. Eng. A 2008, 489, 363–372. [Google Scholar] [CrossRef]

- Agwa, M.A.; Ali, M.N.; Al-Shorbagy, A.E. Optimum Processing Parameters for Equal Channel Angular Pressing. Mech. Mater. 2016, 100, 1–11. [Google Scholar] [CrossRef]

- Lin, P.-C.; Li, J.-Y.; Chen, H.-J.; Lin, K.; Chen, M.-J.; Lin, K.-M.; Lin, H.-C. Indirect Enhancement of ALD Thin-Film Properties Induced by the ECAP Modification of an As-Extruded Mg-Ca Alloy. Micromachines 2024, 15, 1006. [Google Scholar] [CrossRef]

- Agarwal, K.M.; Singh, P.; Dixit, S.; Meshcheryakova, T.S.; Soloveva, O.V.; Solovev, S.A.; Kaushal, K. Optimization of die design parameters in ECAP for sustainable manufacturing using response surface methodology. Int. J. Interact. Des. Manuf. 2024, 18, 2903–2910. [Google Scholar] [CrossRef]

- Skryabina, N.; Aptukov, V.; Romanov, P.; Fruchart, D.; De Rango, P.; Girard, G.; Grandini, C.; Sandim, H.; Huot, J.; Lang, J.; et al. Microstructure Optimization of Mg-Alloys by the ECAP Process Including Numerical Simulation, SPD Treatments, Characterization, and Hydrogen Sorption Properties. Molecules 2019, 24, 89. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Microhardness and EBSD Microstructure Mapping in Partially-Pressed Al and Cu through 90° ECAP Die. Mater. Res. 2013, 16, 586–591. [Google Scholar] [CrossRef]

| Parameter | Cu 99.97 | Cu-La2O3 |

|---|---|---|

| A | 411.19 | 318.87 |

| m1 | −0.00121 | −0.01241 |

| m2 | 0.21554 | −0.10732 |

| m3 | 0.01472 | 0.00346 |

| m4 | −0.00935 | −0.01617 |

| m5 | 0 | 0.11678 |

| m7 | 0 | −0.90557 |

| m8 | 0 | 0.00054 |

| m9 | 0 | −0.11201 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kunčická, L.; Kocich, R. Characterizing the Behavior and Microstructure of Cu-La2O3 Composite Processed via Equal Channel Angular Pressing. Metals 2025, 15, 368. https://doi.org/10.3390/met15040368

Kunčická L, Kocich R. Characterizing the Behavior and Microstructure of Cu-La2O3 Composite Processed via Equal Channel Angular Pressing. Metals. 2025; 15(4):368. https://doi.org/10.3390/met15040368

Chicago/Turabian StyleKunčická, Lenka, and Radim Kocich. 2025. "Characterizing the Behavior and Microstructure of Cu-La2O3 Composite Processed via Equal Channel Angular Pressing" Metals 15, no. 4: 368. https://doi.org/10.3390/met15040368

APA StyleKunčická, L., & Kocich, R. (2025). Characterizing the Behavior and Microstructure of Cu-La2O3 Composite Processed via Equal Channel Angular Pressing. Metals, 15(4), 368. https://doi.org/10.3390/met15040368