Investigation of the Effect of Coil Current Waveform on Electromagnetic Tube Forming

Abstract

1. Introduction

- (1)

- By adjusting the discharge voltage. This is a common method to change the current size. Usually, the greater the discharge voltage, the greater the amplitude of the current and the greater the Lorentz force produced. Paese et al. [11] discovered that the forming depth of sheet metal increases as discharge voltage rises, and similar results can be found in tube metal forming reported by Ouyang et al. [12]. It should be noted that changing the voltage can only change the current amplitude, and cannot change the current frequency or waveform.

- (2)

- By adjusting the discharge capacitance. This is the most widely used method to adjust the current frequency. Typically, the larger the capacitance, the smaller the frequency of the generated current. Based on this, Yu et al. [13] investigated the impact of current frequency on tube compression and found that a decrease in frequency results in a longer current period and reduced amplitude, leading to extended delay time and overall forming process. Further, there exists an optimum frequency to increase forming efficiency, which is located at a frequency where the relative skin depth is between 0.61 and 0.70. Dong et al. [14] explored how current frequency impacts the tube expansion, showing that the maximum expansion occurs at a frequency where the relative skin depth is below 1. They also found that the optimal frequency varies with the system’s resistance and inductance. Cao et al. [15] investigated the impact of current frequency on electromagnetic sheet forming and found that maximum deformation occurs at two optimal frequencies, corresponding to relative skin depths of 1 and 1.6. However, these works are mainly accomplished through finite element simulations.

- (3)

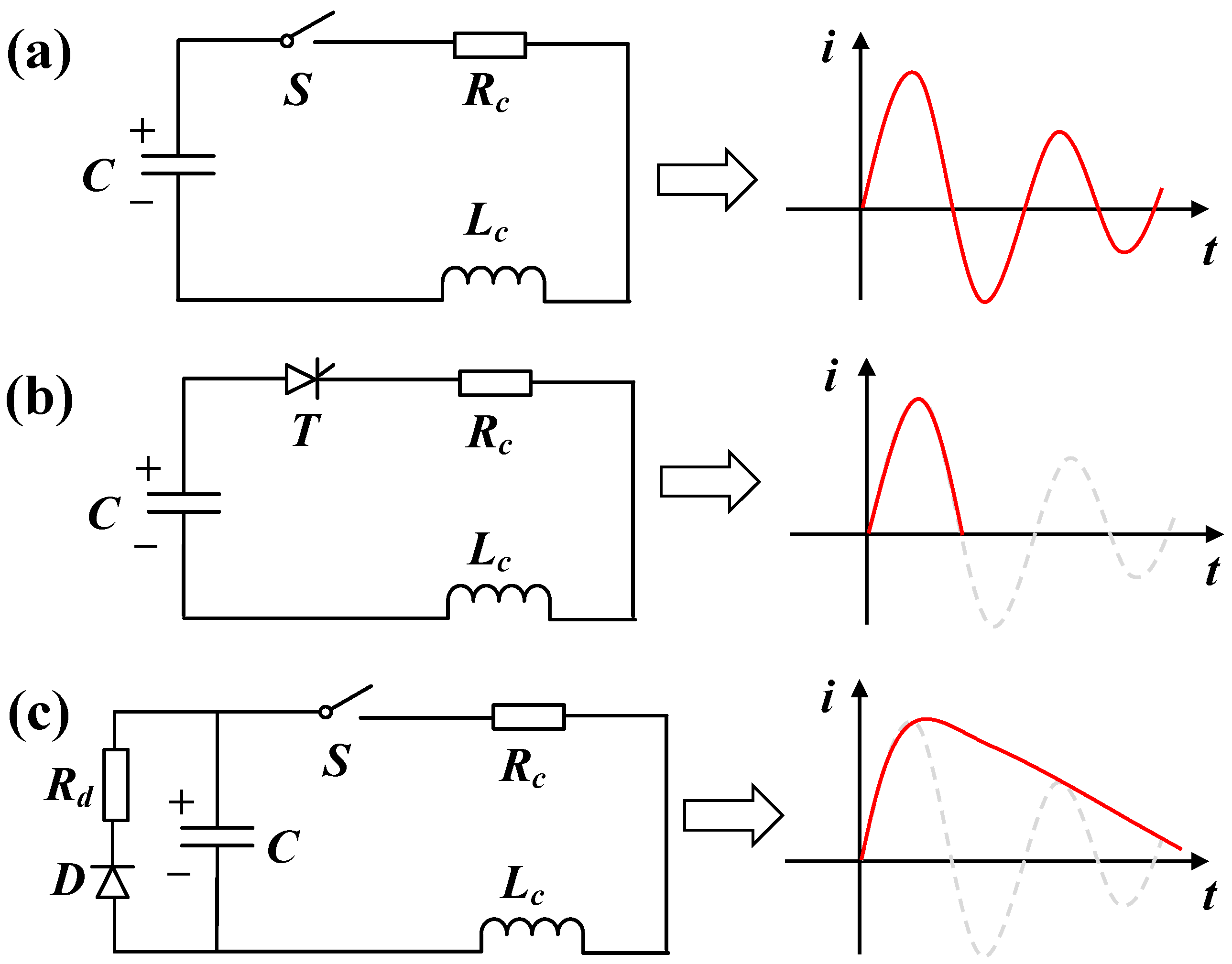

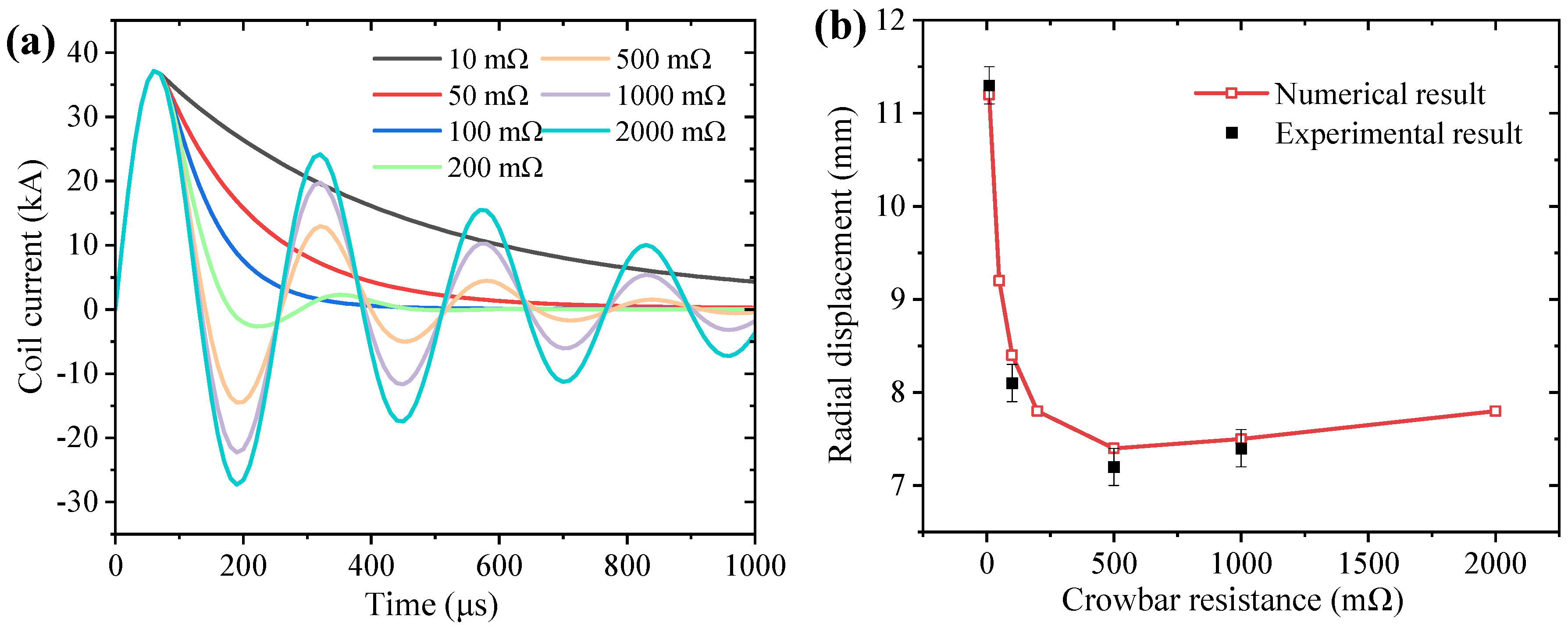

- By developing new discharge circuit structure. The above ways can only adjust the amplitude and frequency of the current, but cannot change the current waveform, where the current waveform is always distributed as an attenuated oscillating sinusoidal waveform consisting of several pulse half-waves. Cui et al. [16] demonstrated that the forming process of sheet is mainly done in the first current pulse, and Qiu et al. [17] indicated that the current after the first current pulse increases the thermal load on the coil. To solve this, several novel discharge circuit structures have been proposed in recent years. For instance, Cao et al. [18] proposed a crowbar circuit with a diode and resistor placed across the capacitor, allowing control of the current decay rate through adjustment of the crowbar resistance. This circuit has been proven to significantly reduce temperature rise without sacrificing forming efficiency. Deng et al. [19] discovered that a slow-rising and fast-falling current waveform could change the direction of the Lorentz force, enabling an attractive electromagnetic forming. Based on this, Xiong et al. [20] developed a double-circuit system to produce an approximate current waveform, thus realizing an attractive tube forming. Ouyang et al. [21] proposed a new circuit consisting of an additional inductive load and a crowbar circuit for attractive tube forming, where the inductive load can slow down the rise of the current, while the crowbar circuit can accelerate the decay of the current.

2. Principle and Method

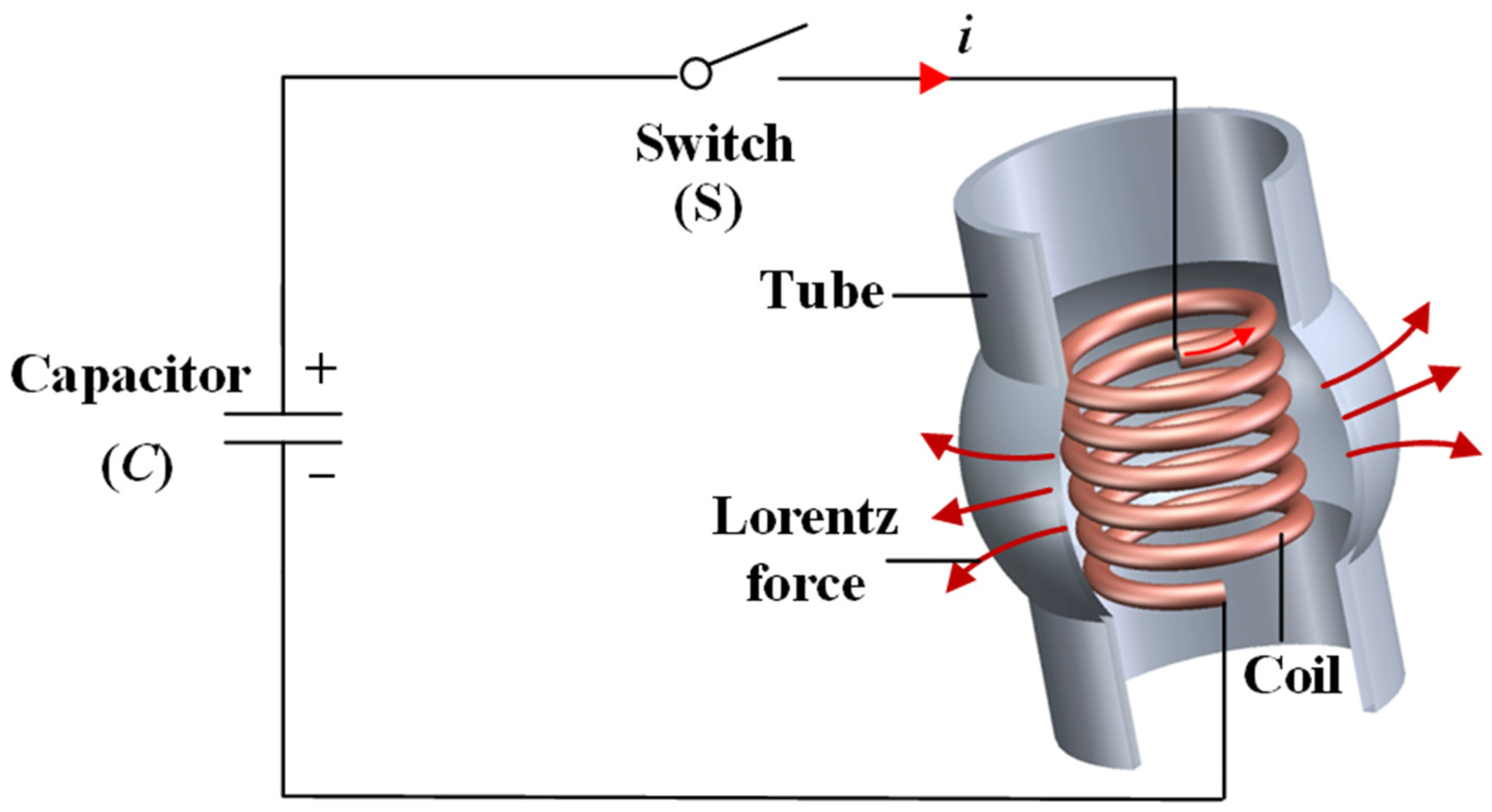

2.1. Principle

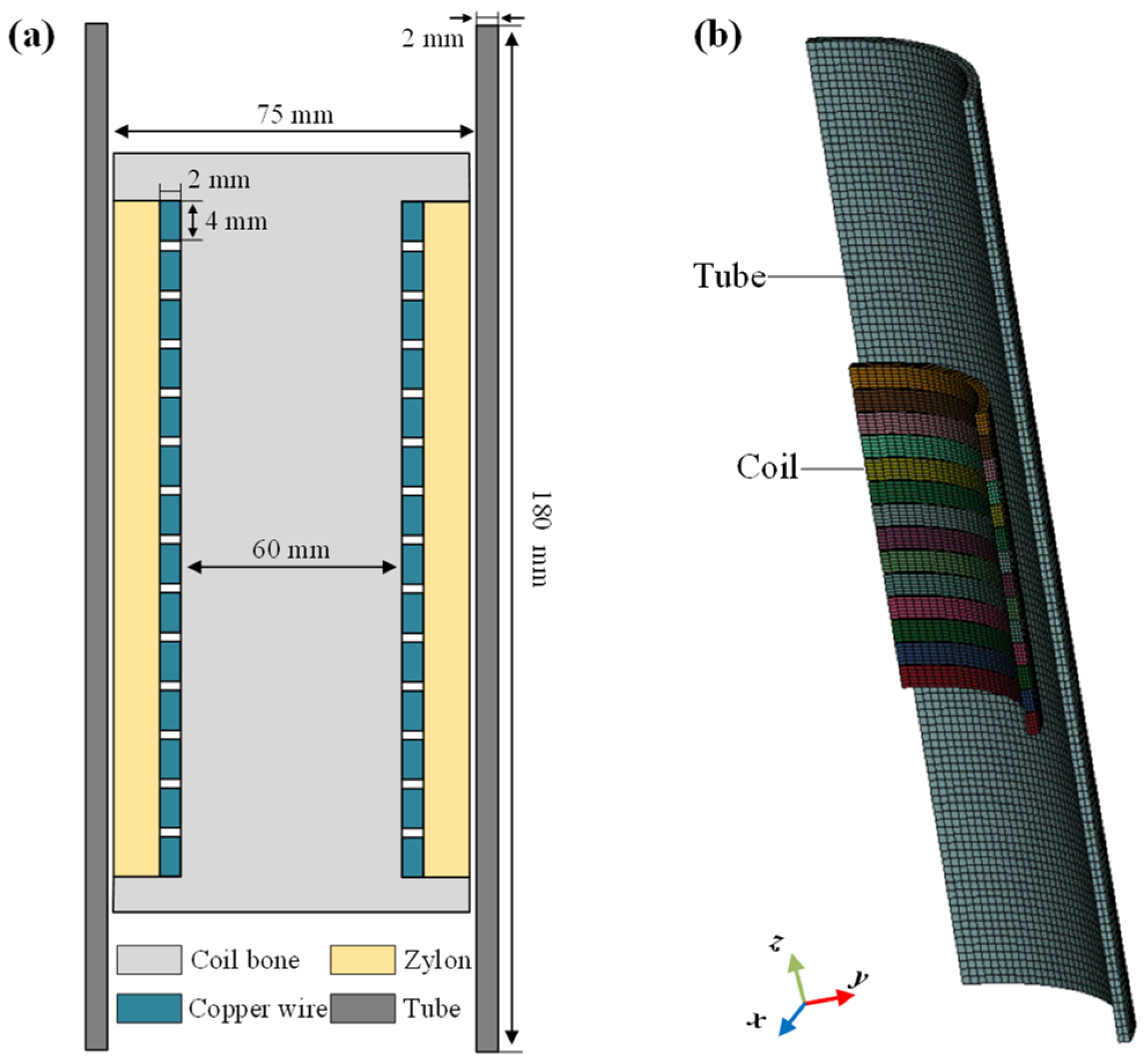

2.2. Numerical Method

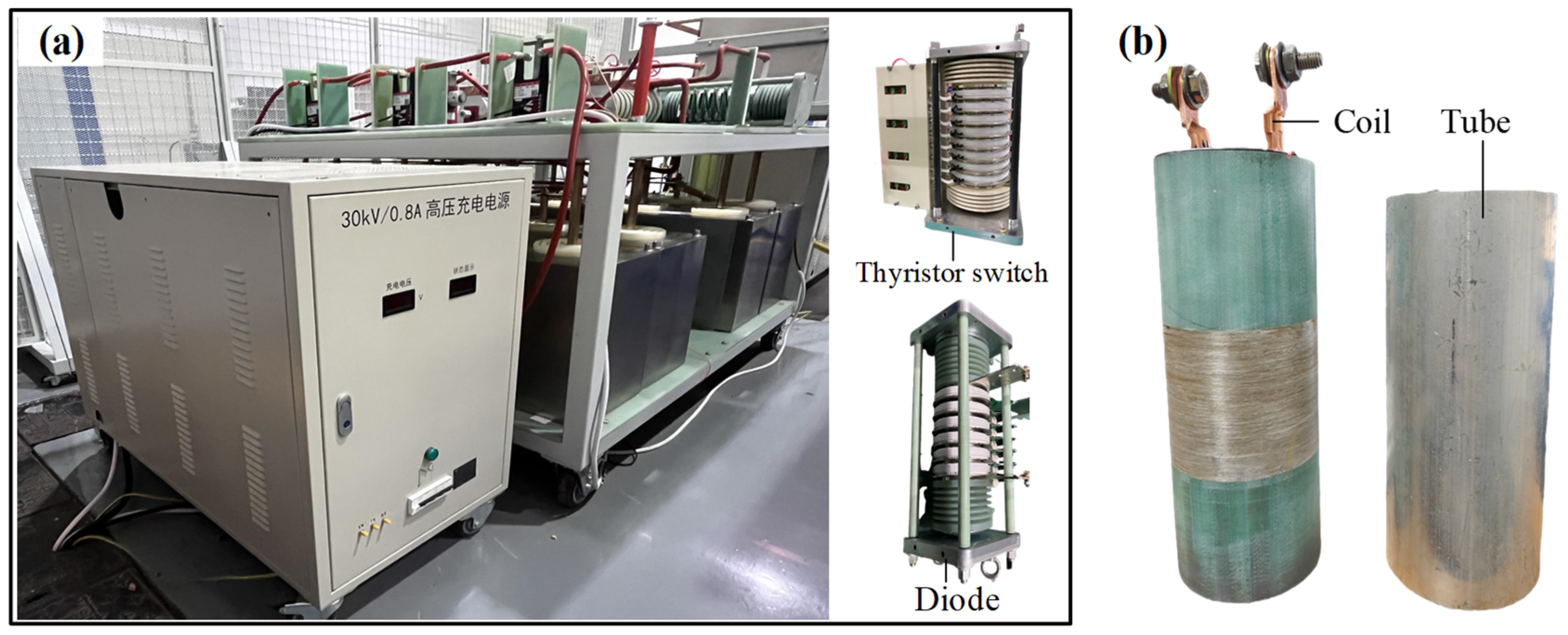

2.3. Experimental Setup

3. Result and Discussion

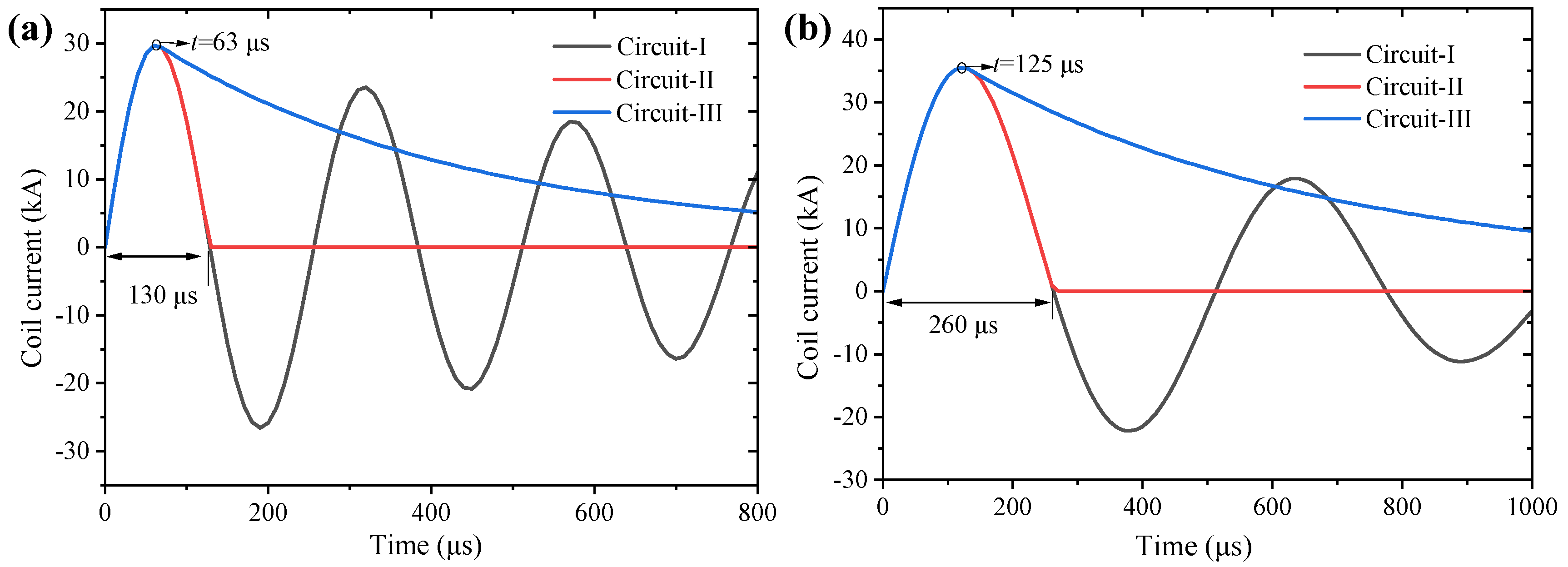

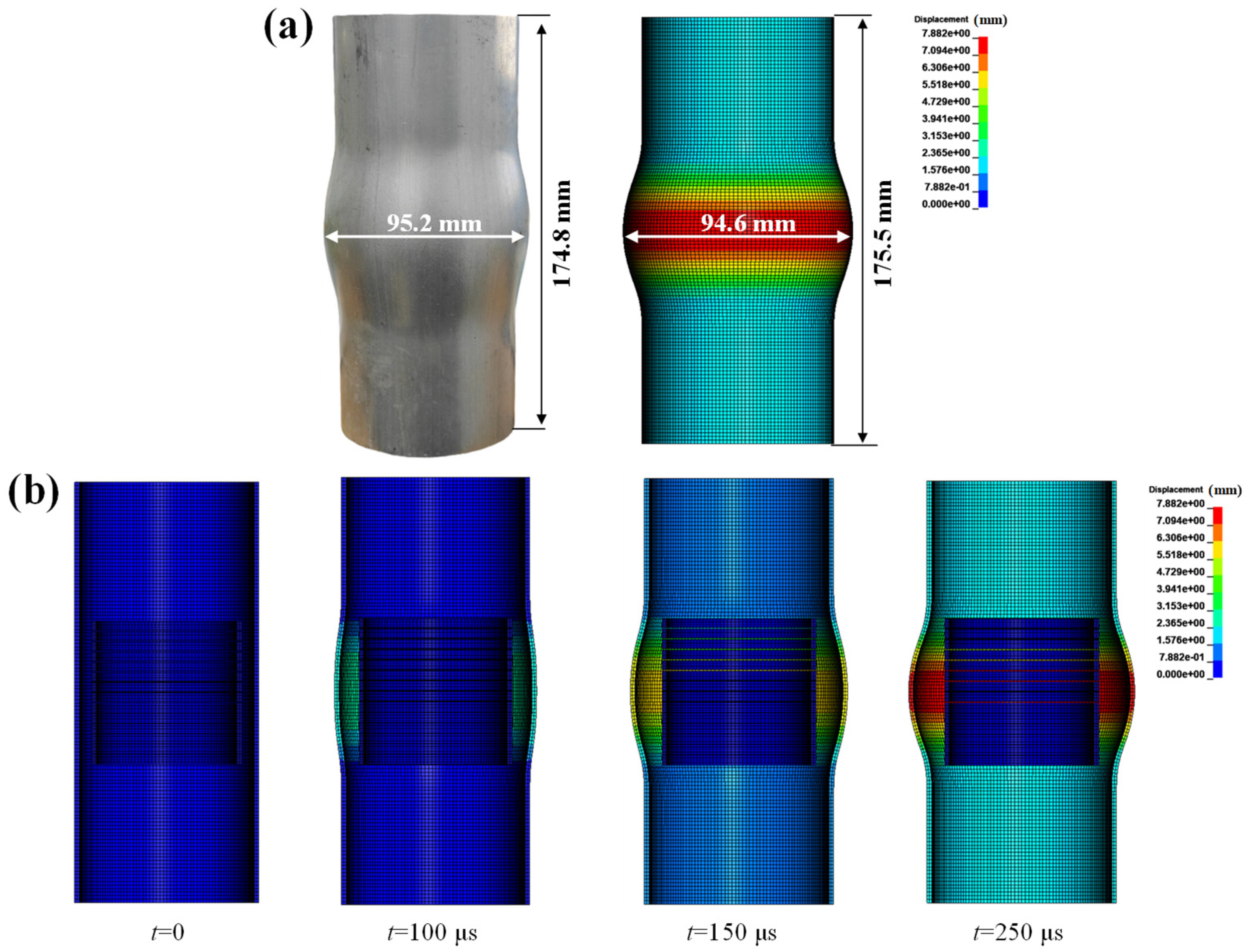

3.1. Current Realization and Model Verification

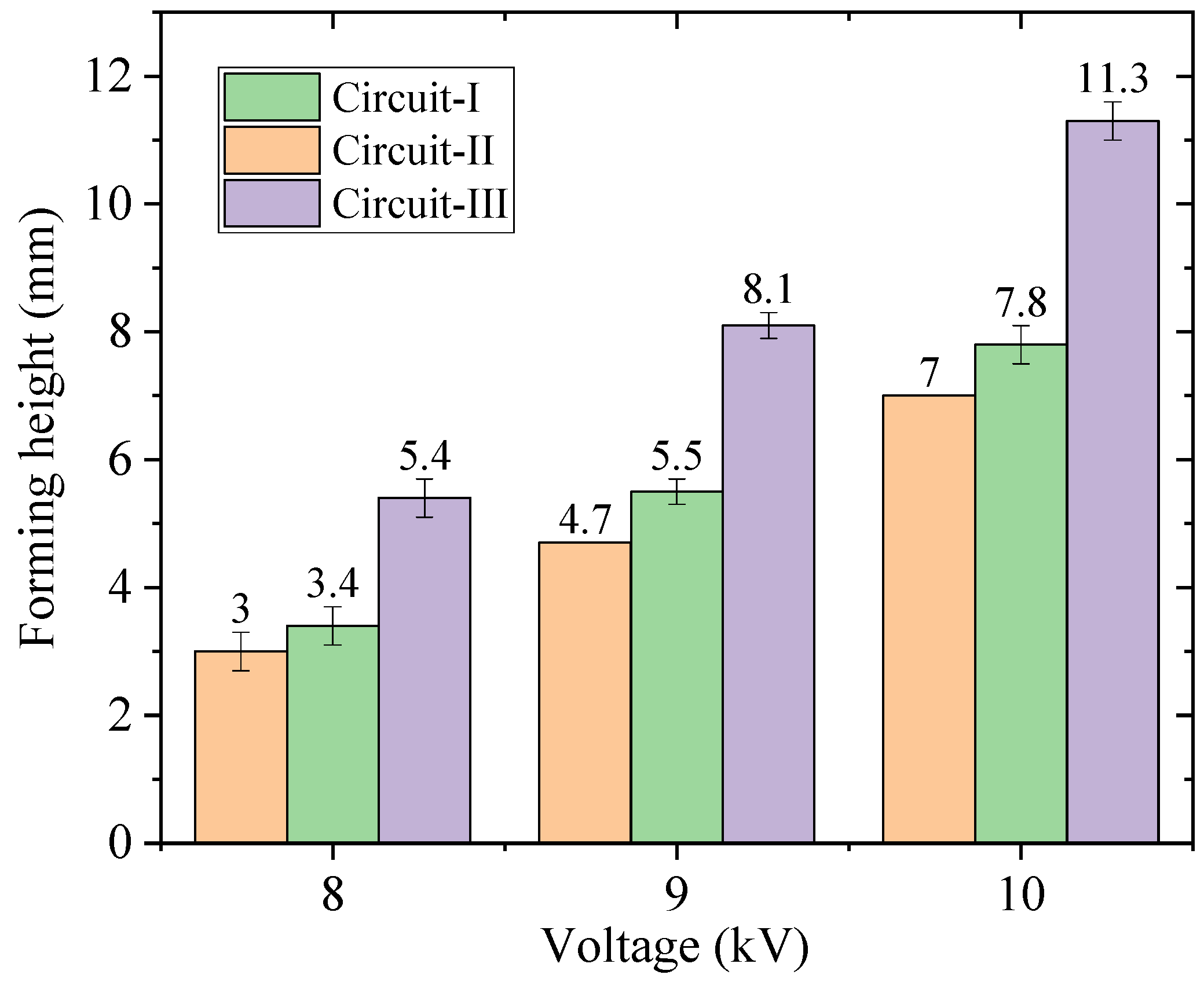

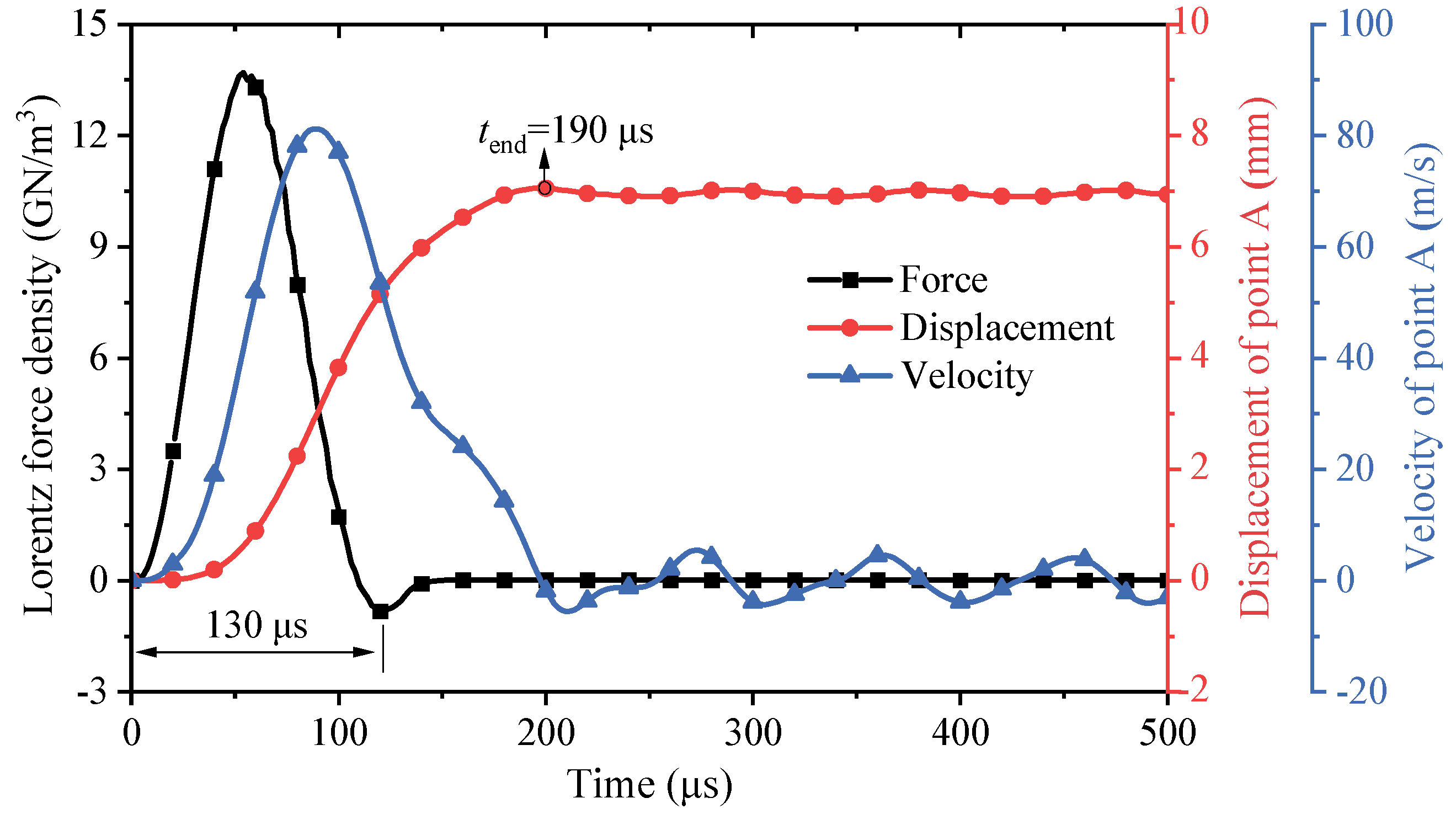

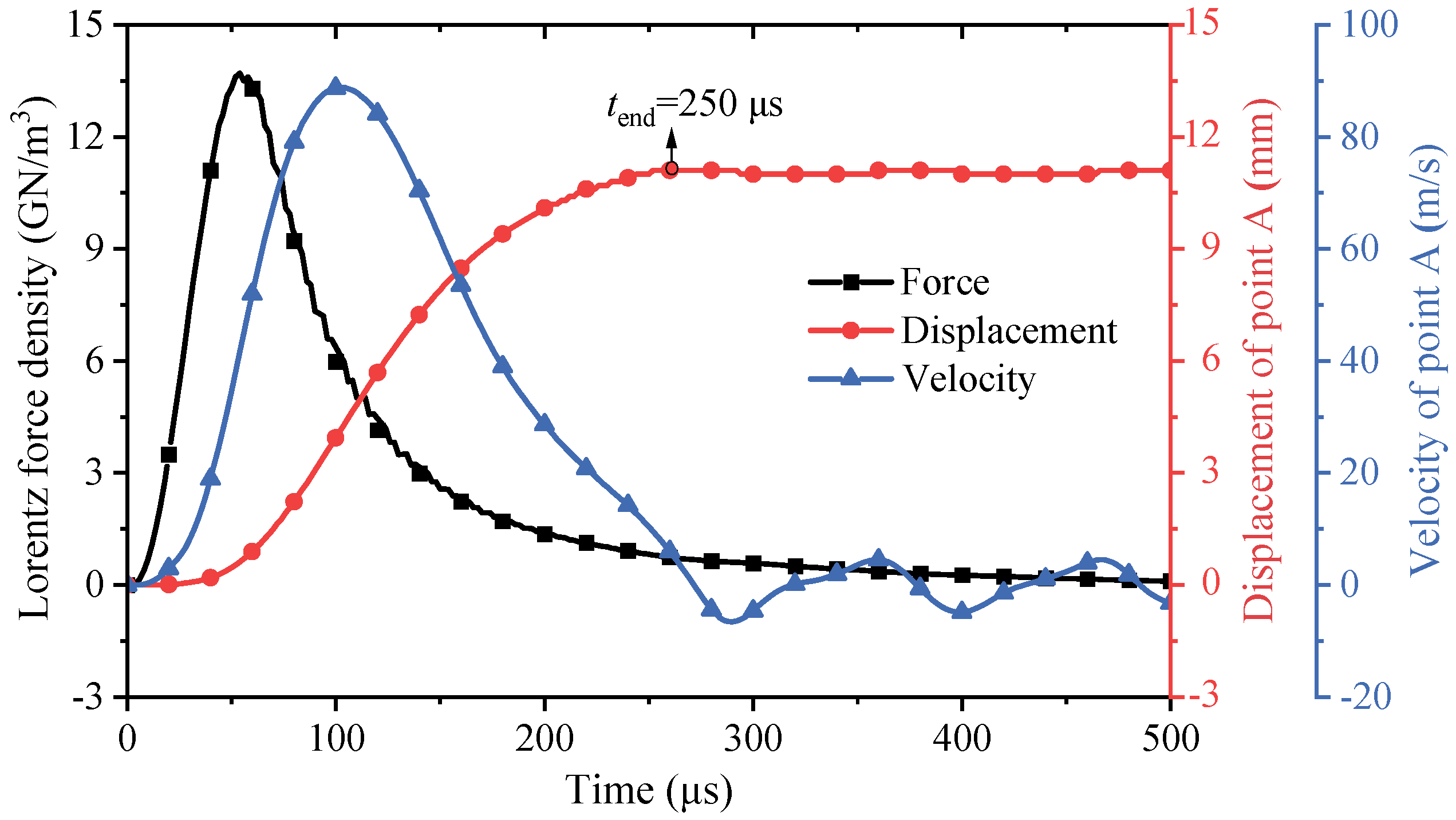

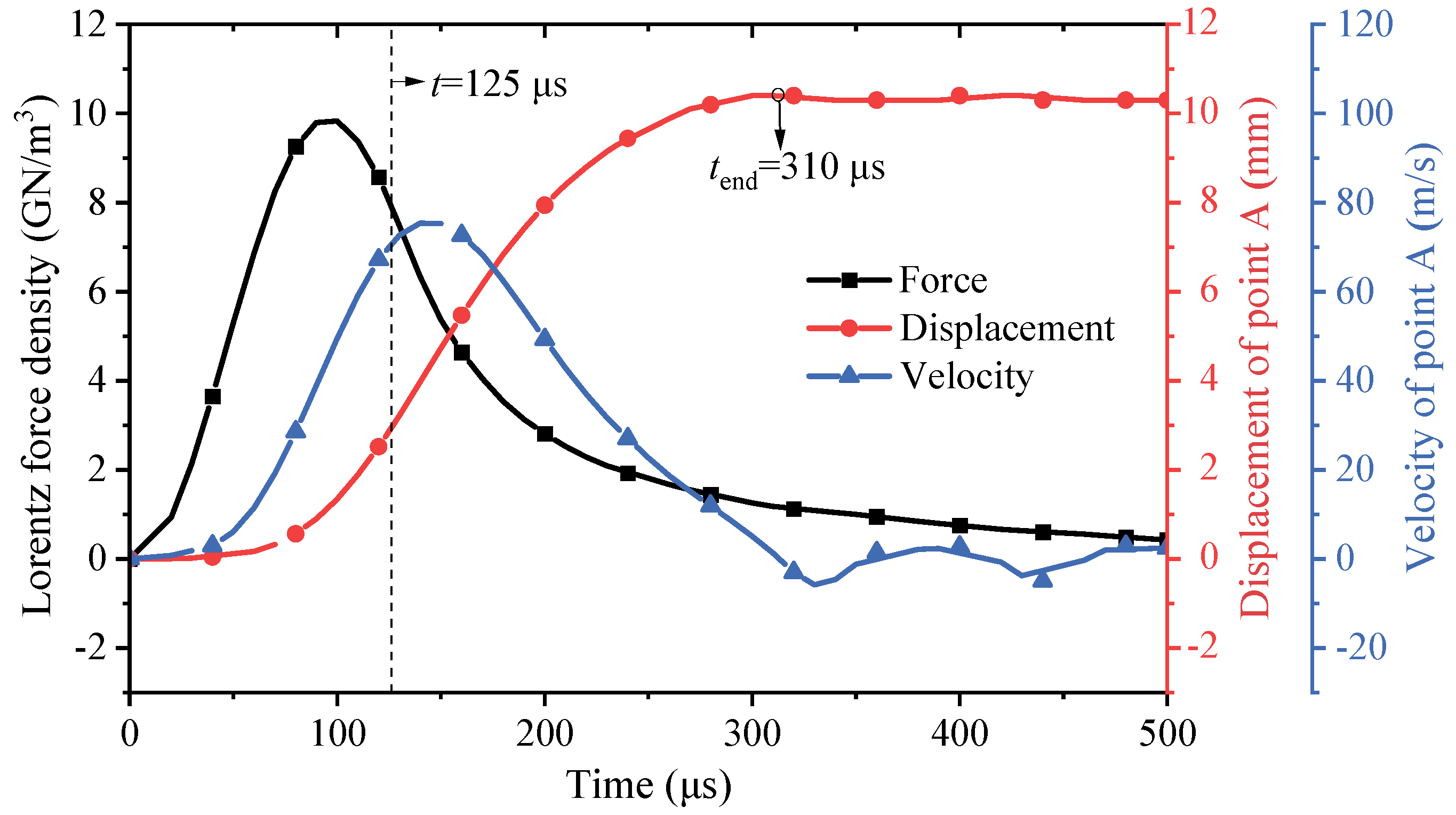

3.2. Deformation Analysis Under a High-Frequency Current

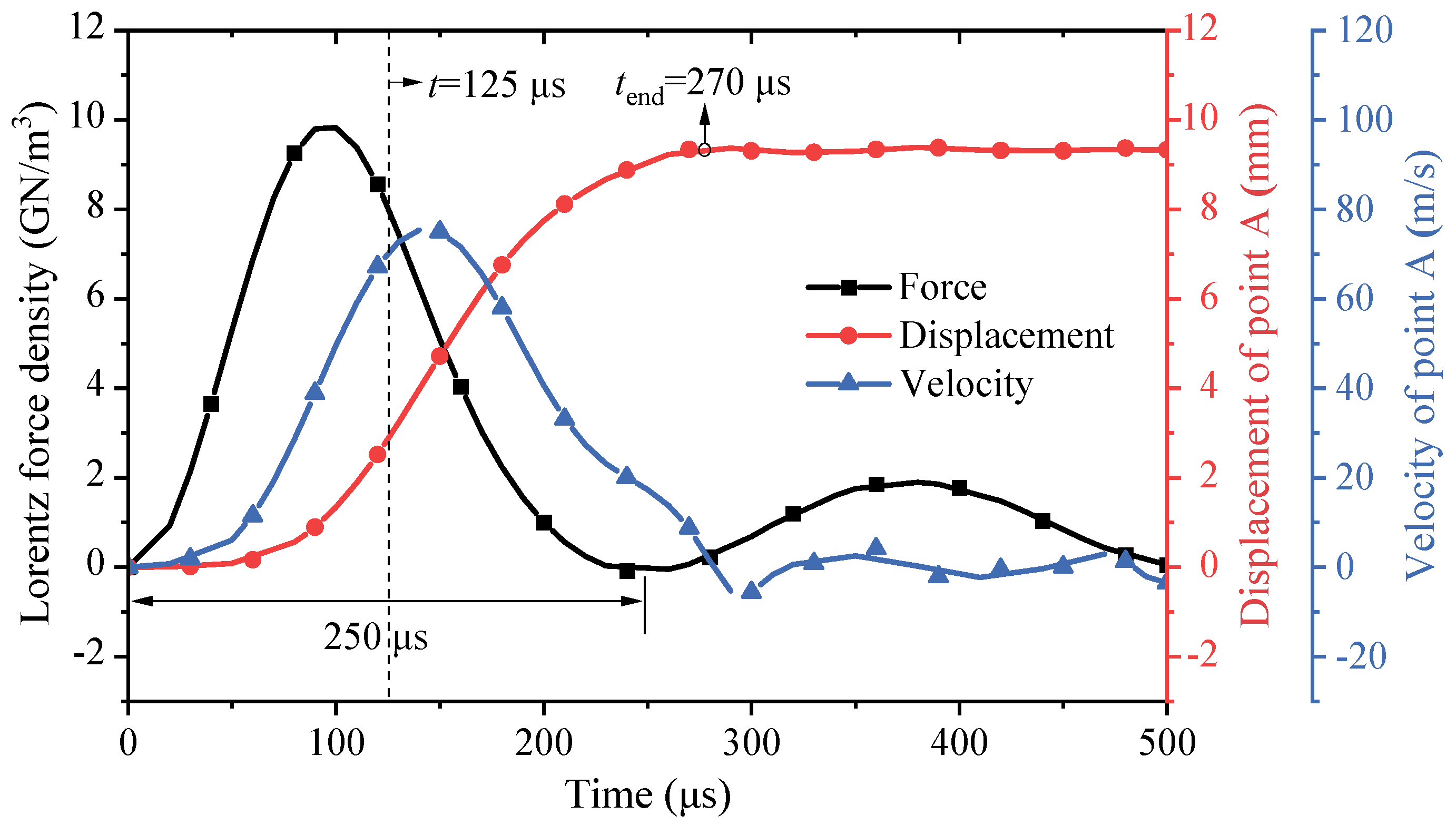

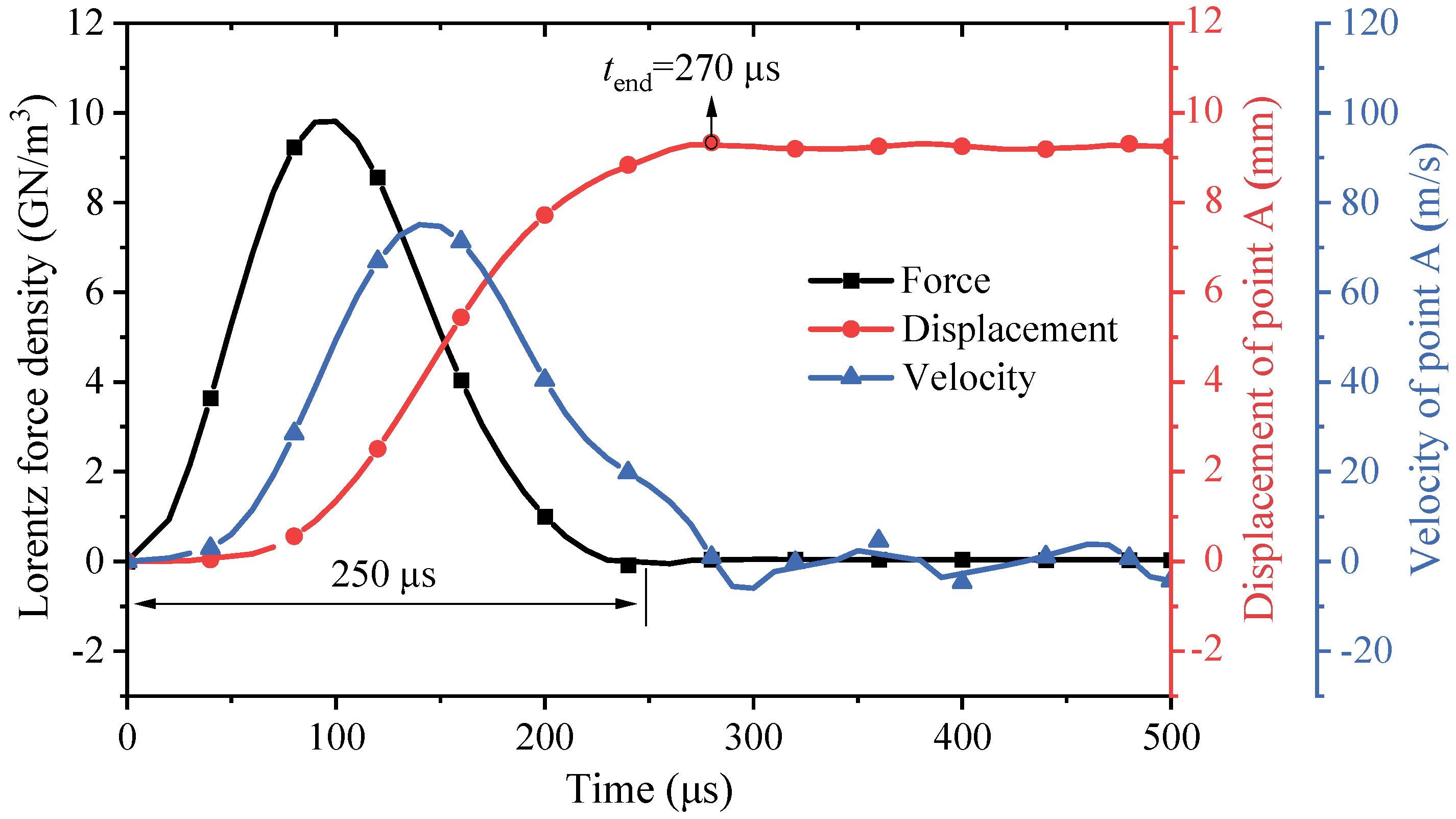

3.3. Deformation Analysis Under a Low-Frequency Current

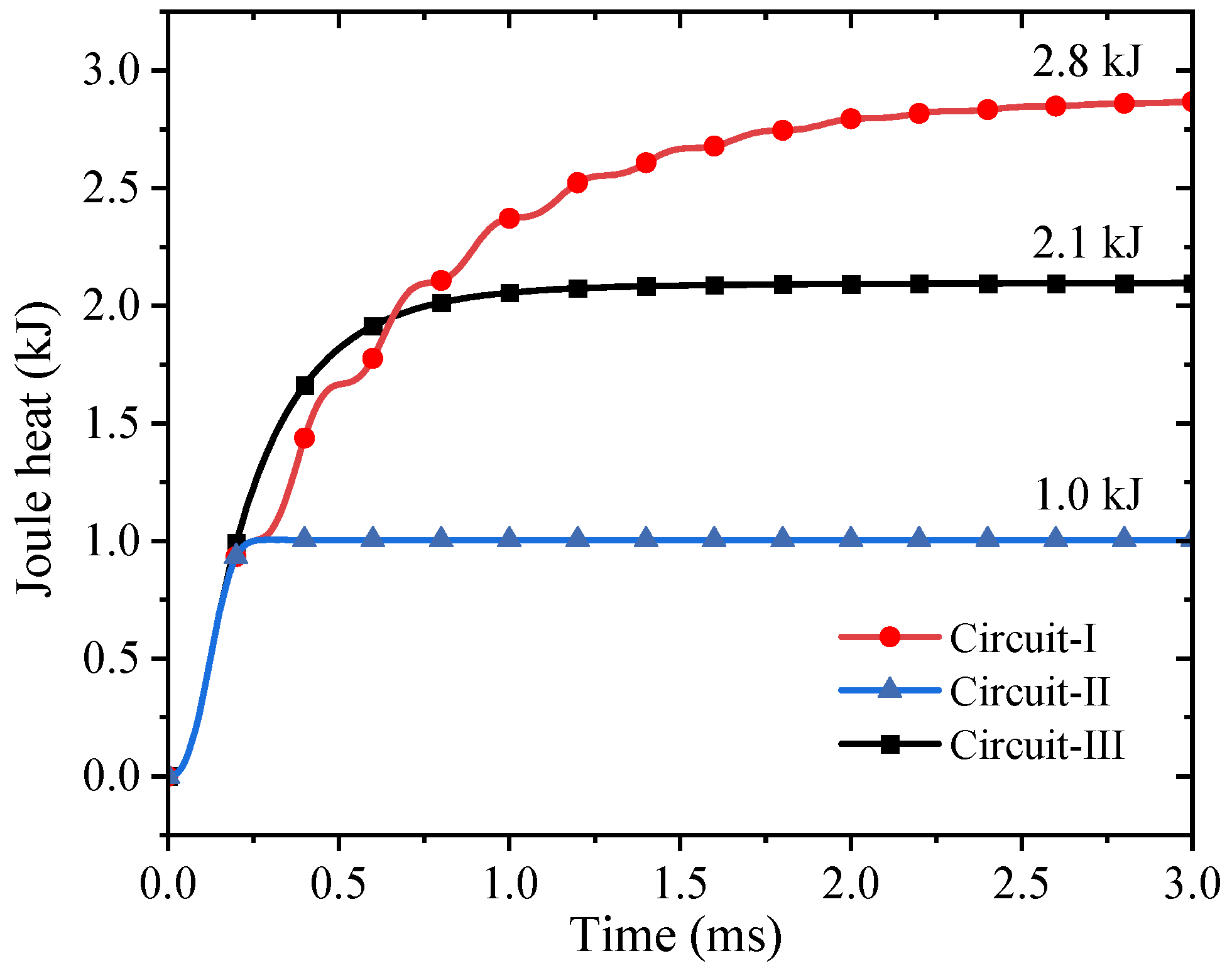

3.4. Effect of Current Waveform on Coil Performance

4. Conclusions

- (1)

- It is demonstrated that at high-frequency discharge, a current having a slow decay rate can improve the forming efficiency. This is because the tube is not deformed until the current has decayed, which allows the subsequent Lorentz force to be strong to promote forming.

- (2)

- It is demonstrated that at low-frequency discharge, the current waveform has little effect on forming efficiency. This is because the tube has already been deformed before the current decays, which weakens the following induced Lorentz force.

- (3)

- It is found that a current having a slow decay rate is highly recommended in high-frequency discharge since it can increase the forming efficiency as well as reduce the temperature rise of the coil, while a current having a half-wave is favorable for low-frequency discharge since it can significantly reduce the coil temperature.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Psyk, V.; Risch, D.; Kinsey, B.L.; Tekkaya, A.E.; Kleiner, M. Electromagnetic Forming—A Review. J. Mater. Process. Technol. 2011, 211, 787–829. [Google Scholar] [CrossRef]

- Gayakwad, D.; Dargar, M.K.; Sharma, P.K.; Purohit, R.; Rana, R.S. A review on electromagnetic forming process. Procedia Mater. Sci. 2014, 6, 520–527. [Google Scholar] [CrossRef]

- Zhu, X.; Xu, X.; Zhang, W.; Du, L.; Shao, Z.; Lai, Z.; Han, X.; Li, L.; Cao, Q.; Ouyang, S. Electro-magnetic Shielding Forming: A Facile Approach for Lorentz Force Regulation and its Application in Tube Forming. J. Mater. Process. Technol. 2025, 338, 118795. [Google Scholar] [CrossRef]

- Li, X.; Tang, X.; Li, M.; Liu, Q.; Tuo, Z.; Cao, Q.; Li, L. Relaxation of Residual Stress in Aluminum Alloy Rings by Pulsed High Magnetic Field: Relieving Mechanisms and Performance Evaluation. J. Mater. Process. Technol. 2025, 338, 118778. [Google Scholar] [CrossRef]

- Su, H.; Huang, L.; Li, J.; Xiao, W.; Zhu, H.; Feng, F.; Li, H.; Yan, S. Formability of AA 2219-O Sheet under Quasi-Static, Electromagnetic Dynamic, and Mechanical Dynamic Tensile Loadings. J. Mater. Sci. Technol. 2021, 70, 125–135. [Google Scholar] [CrossRef]

- Zhang, L.; Cui, X.; Deng, Q.; Yan, Z.; Ye, S. Comparison of the Deformation Behavior of Circular Hole-Flanging Obtained by Electromagnetic Forming and Stamping. Int. J. Adv. Manuf. Technol. 2022, 121, 171–183. [Google Scholar] [CrossRef]

- Jin, Y.; Yu, H. Enhanced Formability and Hardness of AA2195-T6 during Electromagnetic Forming. J. Alloys Compd. 2022, 890, 161891. [Google Scholar] [CrossRef]

- Lin, Y.; Cui, X.; Chen, K.; Xiao, A.; Yan, Z. Forming Limit and Mechanical Properties of 2024-O Aluminum Alloy Under Electromagnetic Forming. Met. Mater.-Int. 2022, 28, 2472–2482. [Google Scholar]

- Cui, X.; Zhang, Z.; Yu, H.; Xiao, X.; Cheng, Y. Springback Calibration of a U-Shaped Electromagnet-ic Impulse Forming Process. Metals 2019, 9, 603. [Google Scholar] [CrossRef]

- Soni, M.; Ahmed, M.; Panthi, S.K.; Kumar, S. Effect of Coil Design Parameters on Performance of Electromagnetic Forming Process. Mater. Manuf. Process. 2022, 37, 64–80. [Google Scholar] [CrossRef]

- Paese, E.; Rosa, P.A.R.; Geier, M.; Homrich, R.P.; Rossi, R. An Analysis of Electromagnetic Sheet Metal Forming Process. AMM 2014, 526, 9–14. [Google Scholar] [CrossRef]

- Ouyang, S.; Wang, C.; Li, C.; Li, X.; Lai, Z.; Peng, T.; Han, X.; Cao, Q.; Li, L. Improving the Uni-formity and Controllability of Tube Deformation via a Three-Coil Forming System. Int. J. Adv. Manuf. Technol. 2021, 114, 1533–1544. [Google Scholar] [CrossRef]

- Yu, H.; Li, C. Effects of Current Frequency on Electromagnetic Tube Compression. J. Mater. Process. Technol. 2009, 209, 1053–1059. [Google Scholar] [CrossRef]

- Dond, S.; Choudhary, H.; Dikshit, B.; Kolge, T.; Sharma, A. Current Frequency Effect on Electro-magnetic Tube Expansion. Proc. Inst. Mech. Eng. Part C-J. Eng. Mech. Eng. Sci. 2020, 234, 4636–4644. [Google Scholar] [CrossRef]

- Cao, Q.; Han, X.; Lai, Z.; Zhang, B.; Zhou, Z.; Qiu, L.; Li, L. Effects of Current Frequency on Electromagnetic Sheet Metal Forming Process. IEEE Trans. Appl. Supercond. 2014, 24, 3700104. [Google Scholar] [CrossRef]

- Cui, X.; Mo, J.; Li, J.; Huang, L.; Zhu, Y.; Li, Z.W.; Zhong, K. Effect of Second Current Pulse and Different Algorithms on Simulation Accuracy for Electromagnetic Sheet Forming. Int. J. Adv. Manuf. Technol. 2013, 68, 1137–1146. [Google Scholar] [CrossRef]

- Qiu, L.; Wang, C.; Abu-Siada, A.; Xiong, Q.; Zhang, W.; Wang, B.; Yi, N.; Li, Y.; Cao, Q. Coil Tem-perature Rise and Workpiece Forming Efficiency of Electromagnetic Forming Based on Half-Wave Current Method. IEEE Access 2020, 8, 9371–9379. [Google Scholar] [CrossRef]

- Cao, Q.; Han, X.; Lai, Z.; Xiong, Q.; Zhang, X.; Chen, Q.; Xiao, H.; Li, L. Analysis and Reduction of Coil Temperature Rise in Electromagnetic Forming. J. Mater. Process. Technol. 2015, 225, 185–194. [Google Scholar] [CrossRef]

- Deng, J.; Li, C.; Zhao, Z.; Tu, F.; Yu, H. Numerical Simulation of Magnetic Flux and Force in Elec-tromagnetic Forming with Attractive Force. J. Mater. Process. Technol. 2007, 184, 190–194. [Google Scholar] [CrossRef]

- Xiong, Q.; Tang, H.; Wang, M.; Huang, H.; Qiu, L.; Yu, K.; Chen, Q. Design and Implementation of Tube Bulging by an Attractive Electromagnetic Force. J. Mater. Process. Technol. 2019, 273, 116240. [Google Scholar] [CrossRef]

- Ouyang, S.; Du, L.; Li, C.; Li, X.; Wu, Z.; Lai, Z.; Han, X.; Cao, Q.; Li, L. Electromagnetic Attractive Forming of Aluminum Alloy Tubes Utilizing a Dual-Frequency Current: New Circuit Design and Forming Process Analysis. J. Mater. Process. Technol. 2023, 318, 118006. [Google Scholar] [CrossRef]

- Li, J.; Qiu, W.; Huang, L.; Su, H.; Tao, H.; Li, P. Gradient Electromagnetic Forming (GEMF): A New Forming Approach for Variable-Diameter Tubes by Use of Sectional Coil. Int. J. Mach. Tools Manuf. 2018, 135, 65–77. [Google Scholar] [CrossRef]

- Mamalis, A.G.; Manolakos, D.E.; Kladas, A.G.; Koumoutsos, A.K. Electromagnetic Forming Tools and Processing Conditions: Numerical Simulation. Mater. Manuf. Process. 2006, 21, 411–423. [Google Scholar] [CrossRef]

| Parameters | Materials | |

|---|---|---|

| Tube (AA6061-O) | Coil (Copper) | |

| Density (kg/m3) | 2.7 × 103 | 8.9 × 103 |

| Elastic modulus (GPa) | 68.8 | 126 |

| Poisson ratio | 0.33 | 0.34 |

| Yield strength (MPa) | 55.2 | 100 |

| Electrical resistivity (Ω × m) | 3.66 × 10−8 | 1.66 × 10−8 |

| Discharge Parameters | Symbol/Unit | Value |

|---|---|---|

| Discharge voltage | U0kV | 0~30 |

| Capacitance | C/μF | 160~640 |

| Coil resistance | Rc/mΩ | 9 |

| Coil inductance | Lc/μH | 10 |

| Crowbar resistance | Rd/mΩ | 0~1000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, F.; Xu, X.; Wang, Y.; Yu, Z.; Jiang, C. Investigation of the Effect of Coil Current Waveform on Electromagnetic Tube Forming. Metals 2025, 15, 367. https://doi.org/10.3390/met15040367

Deng F, Xu X, Wang Y, Yu Z, Jiang C. Investigation of the Effect of Coil Current Waveform on Electromagnetic Tube Forming. Metals. 2025; 15(4):367. https://doi.org/10.3390/met15040367

Chicago/Turabian StyleDeng, Fangxiong, Xiaofei Xu, Yang Wang, Zhiyong Yu, and Can Jiang. 2025. "Investigation of the Effect of Coil Current Waveform on Electromagnetic Tube Forming" Metals 15, no. 4: 367. https://doi.org/10.3390/met15040367

APA StyleDeng, F., Xu, X., Wang, Y., Yu, Z., & Jiang, C. (2025). Investigation of the Effect of Coil Current Waveform on Electromagnetic Tube Forming. Metals, 15(4), 367. https://doi.org/10.3390/met15040367