Development of Novel Mg-Al-Mn-Based Alloys with High-Strength and Ductility via Co-Addition of Ce and Ca

Abstract

1. Introduction

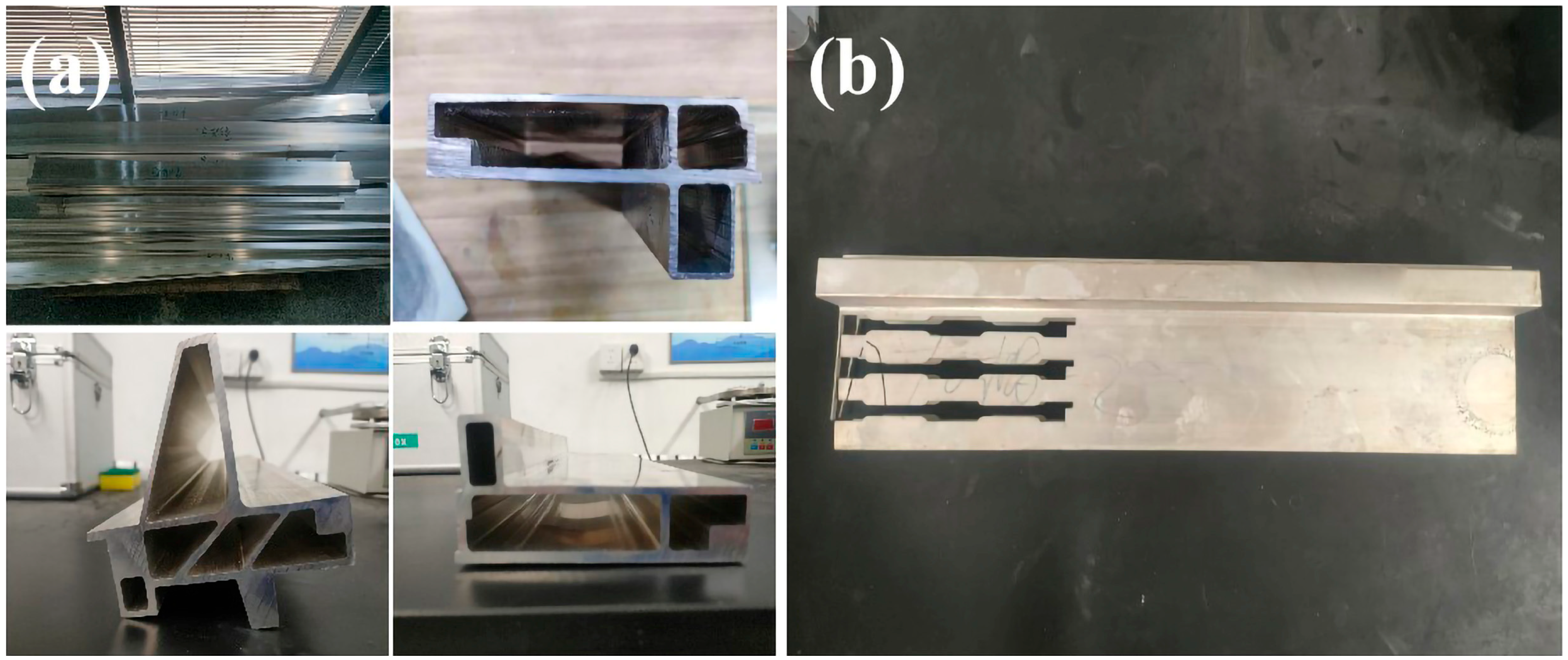

2. Materials and Methods

3. Results

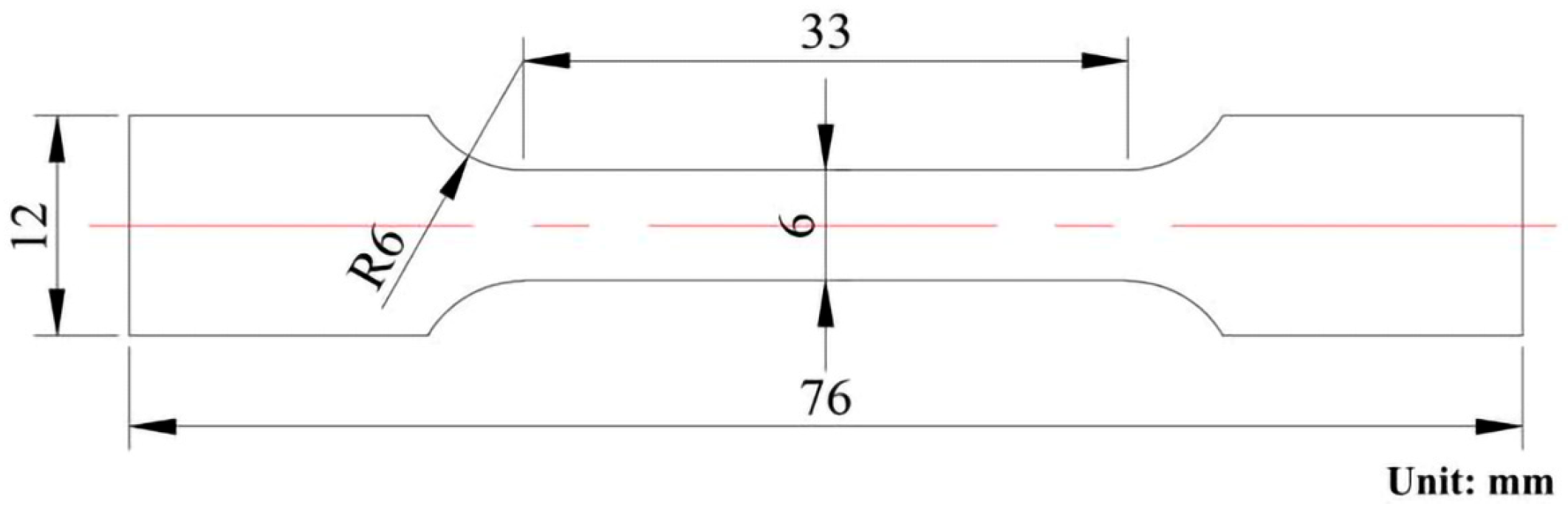

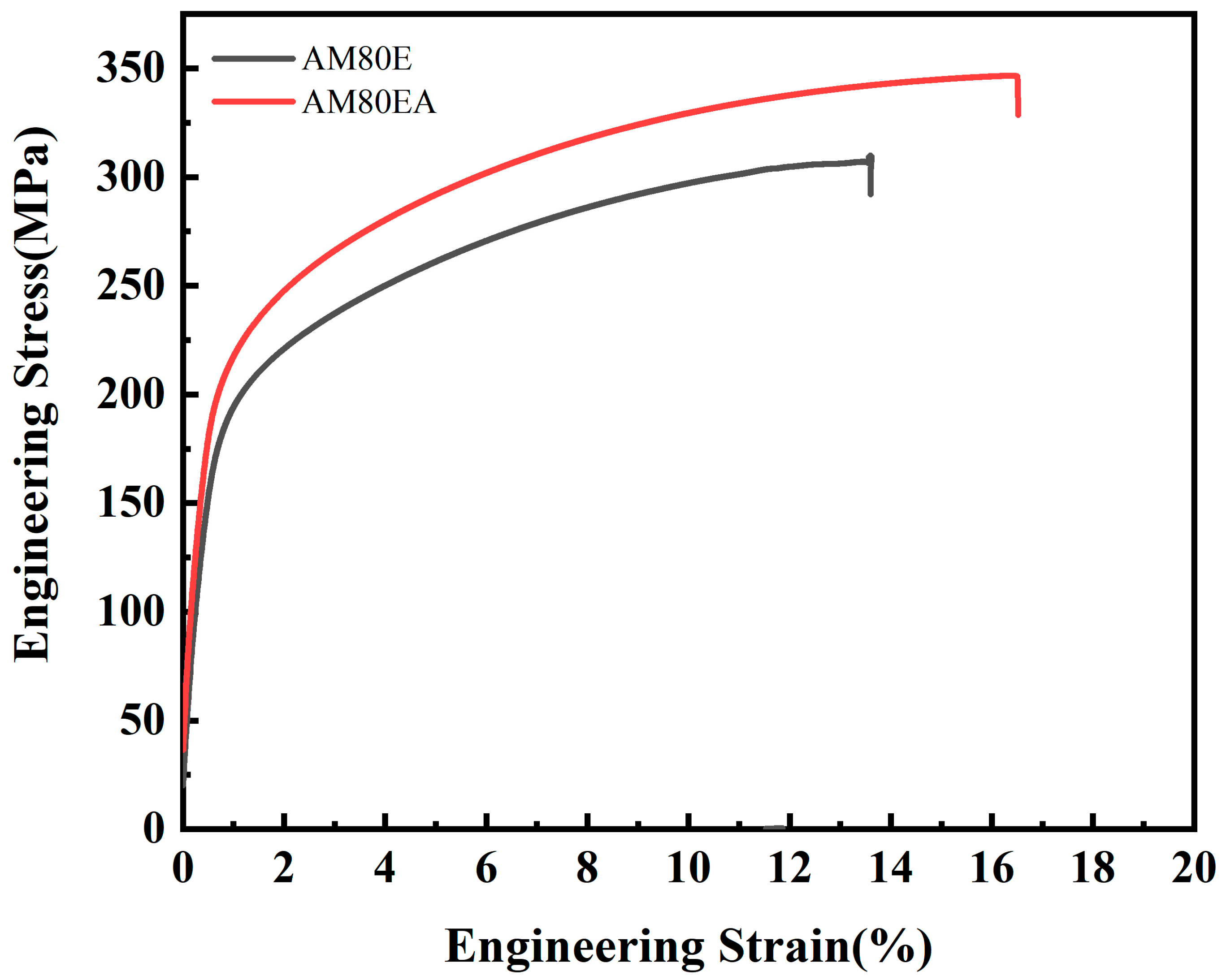

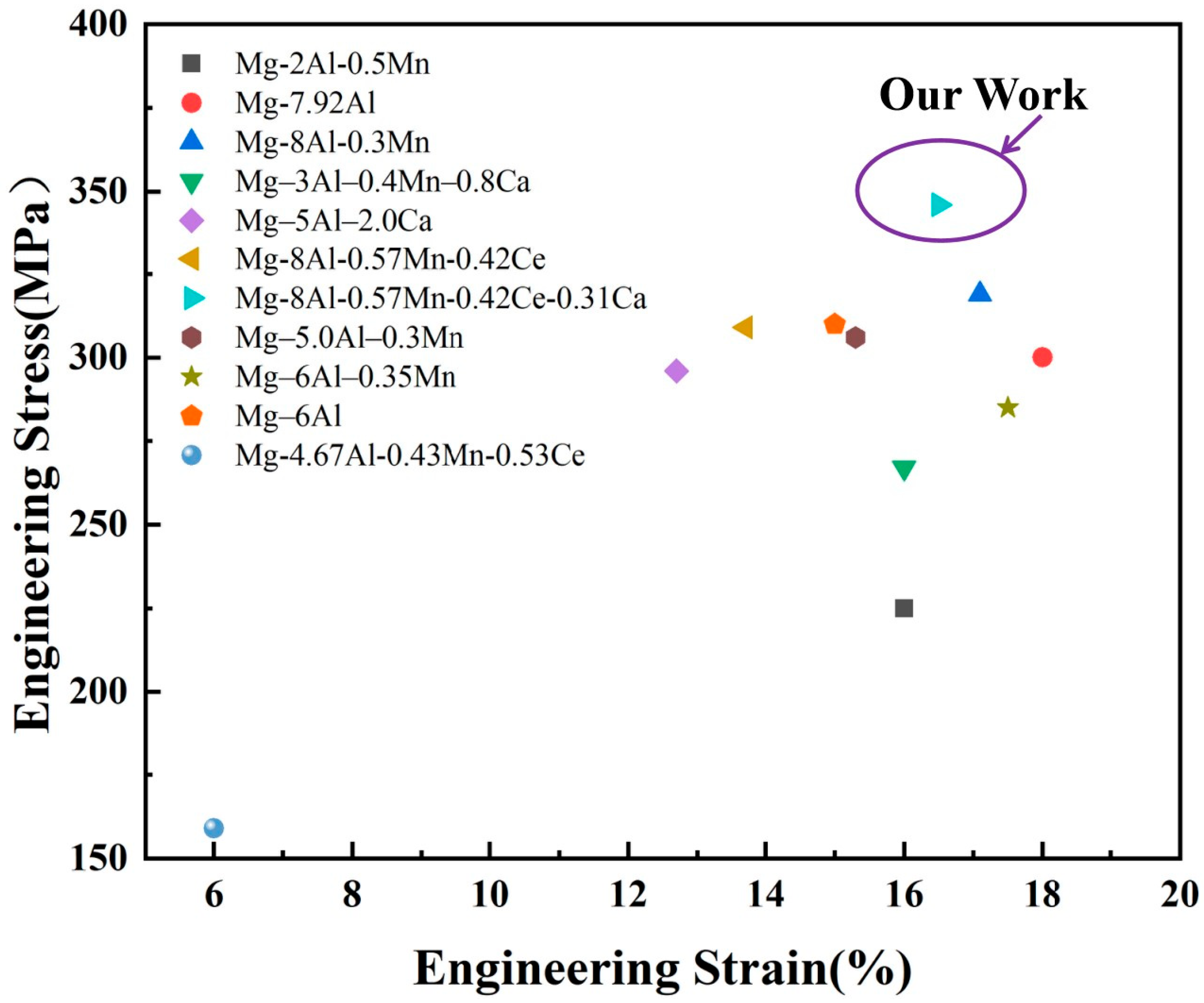

3.1. Mechanical Properties of As-Extruded Mg Alloys

3.2. Microstructures of As-Extruded Mg Alloys

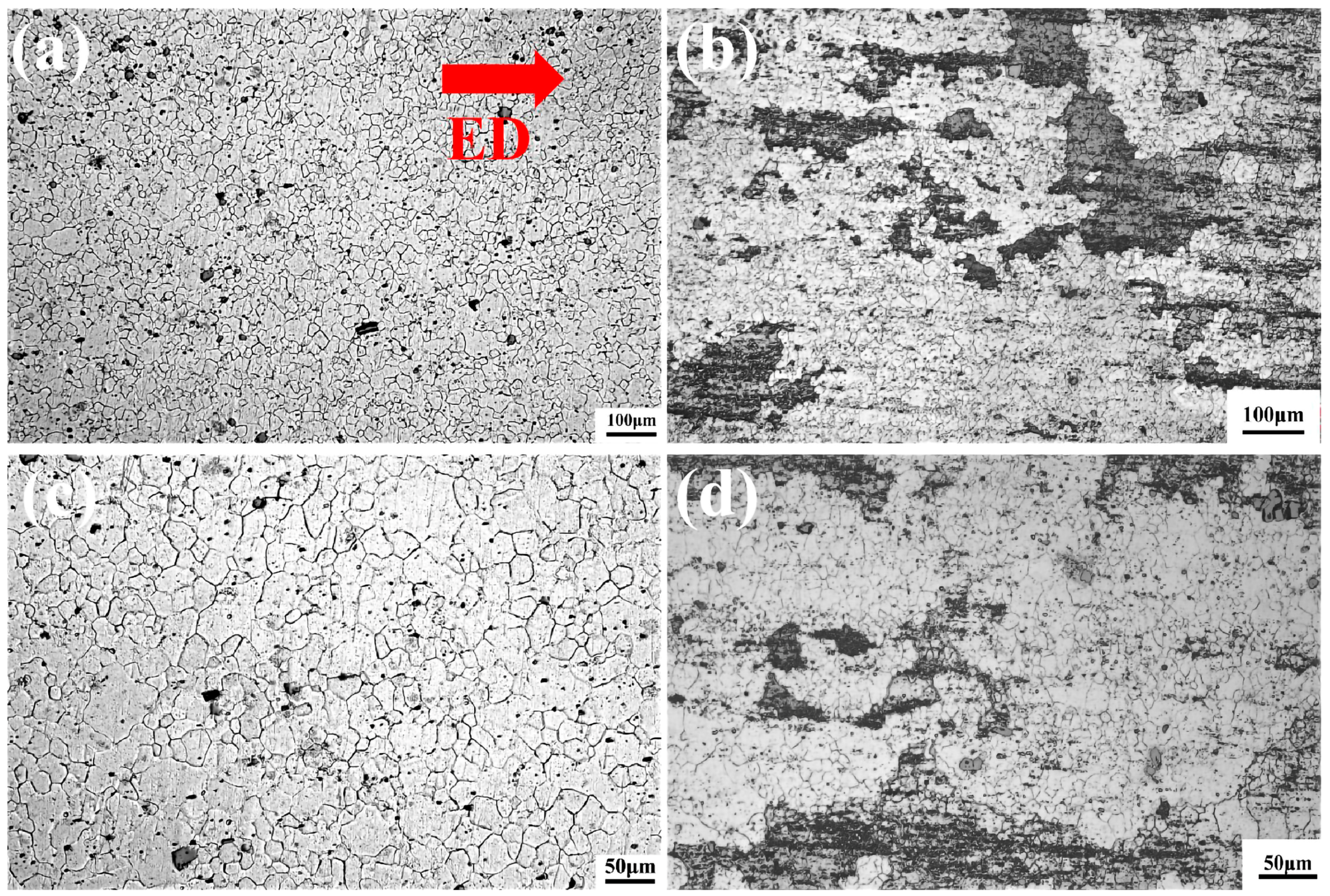

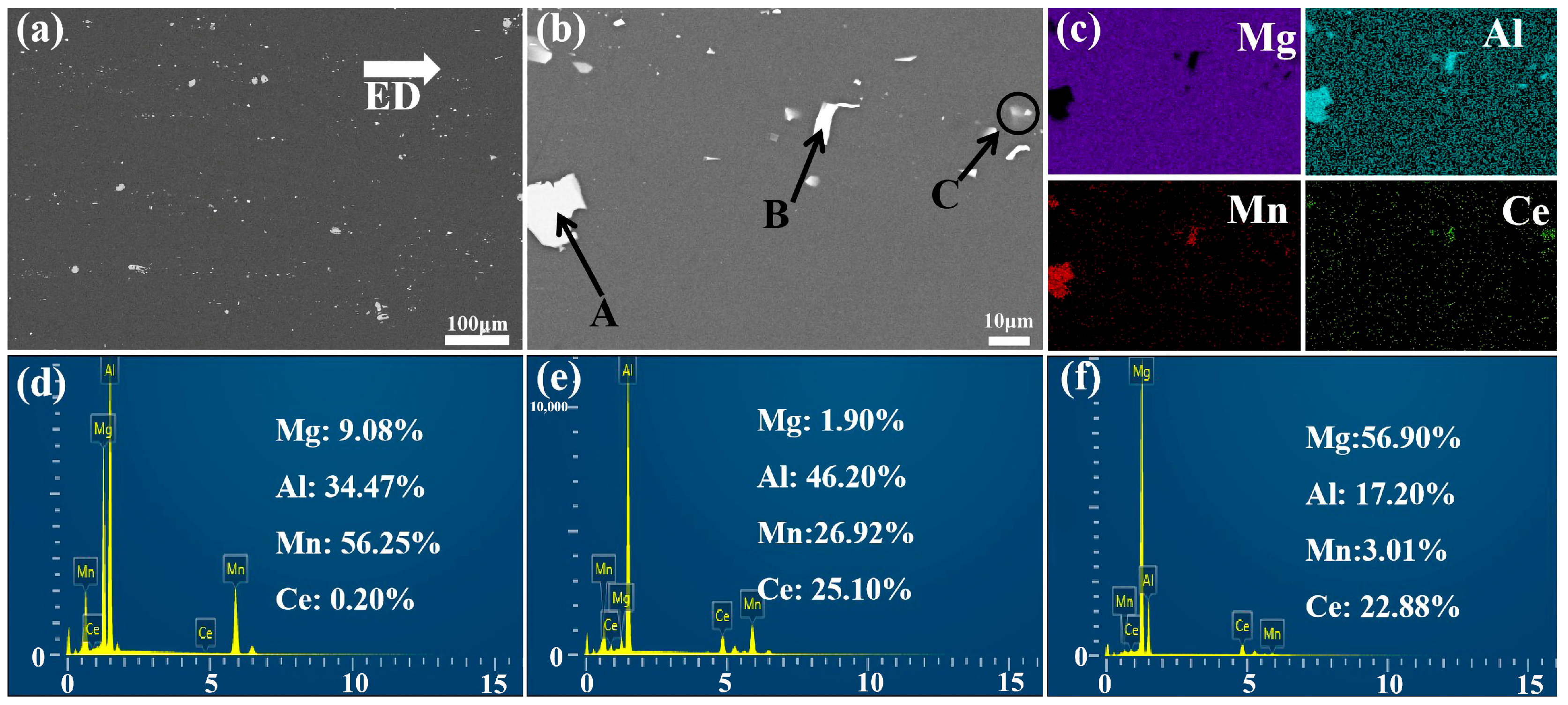

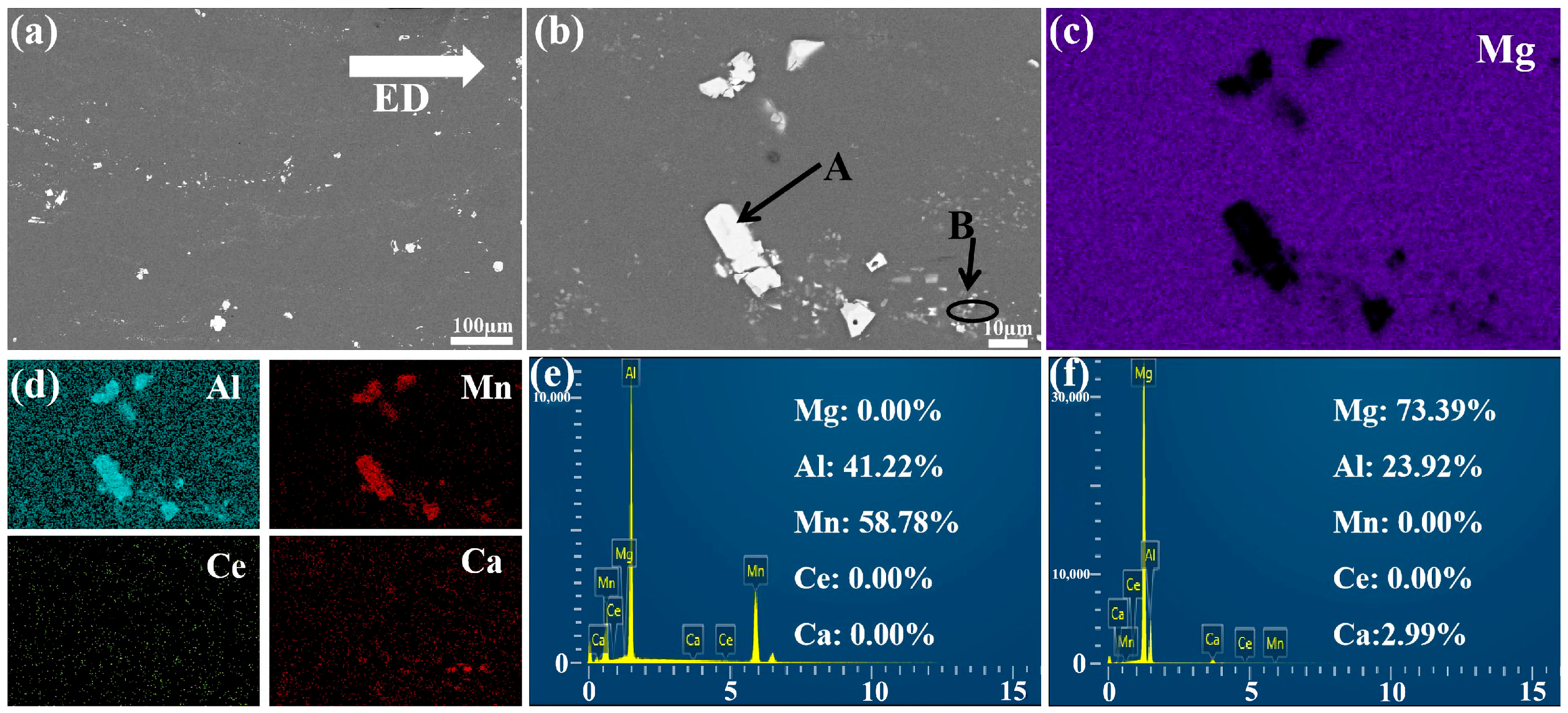

3.2.1. OM and SEM Images of As-Extruded Mg Alloys

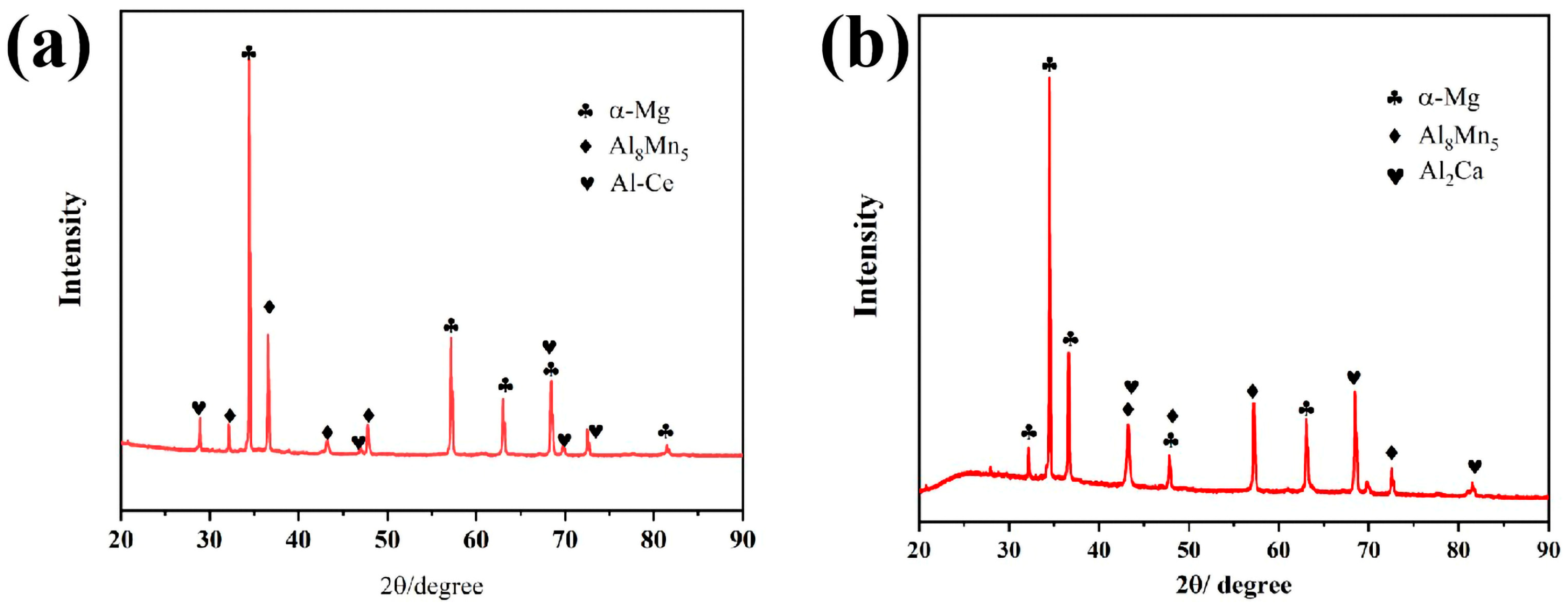

3.2.2. XRD Results of As-Extruded Alloys

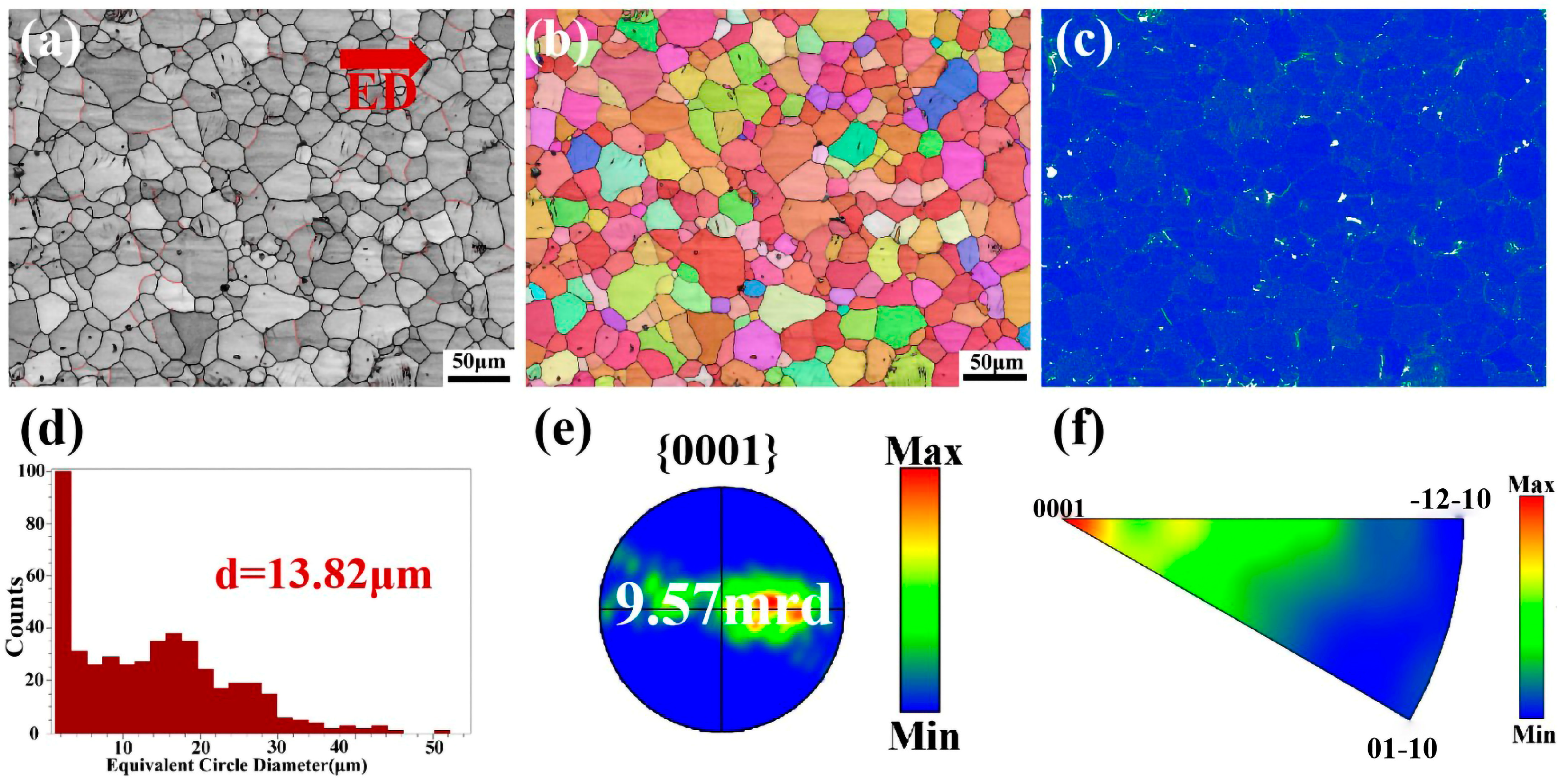

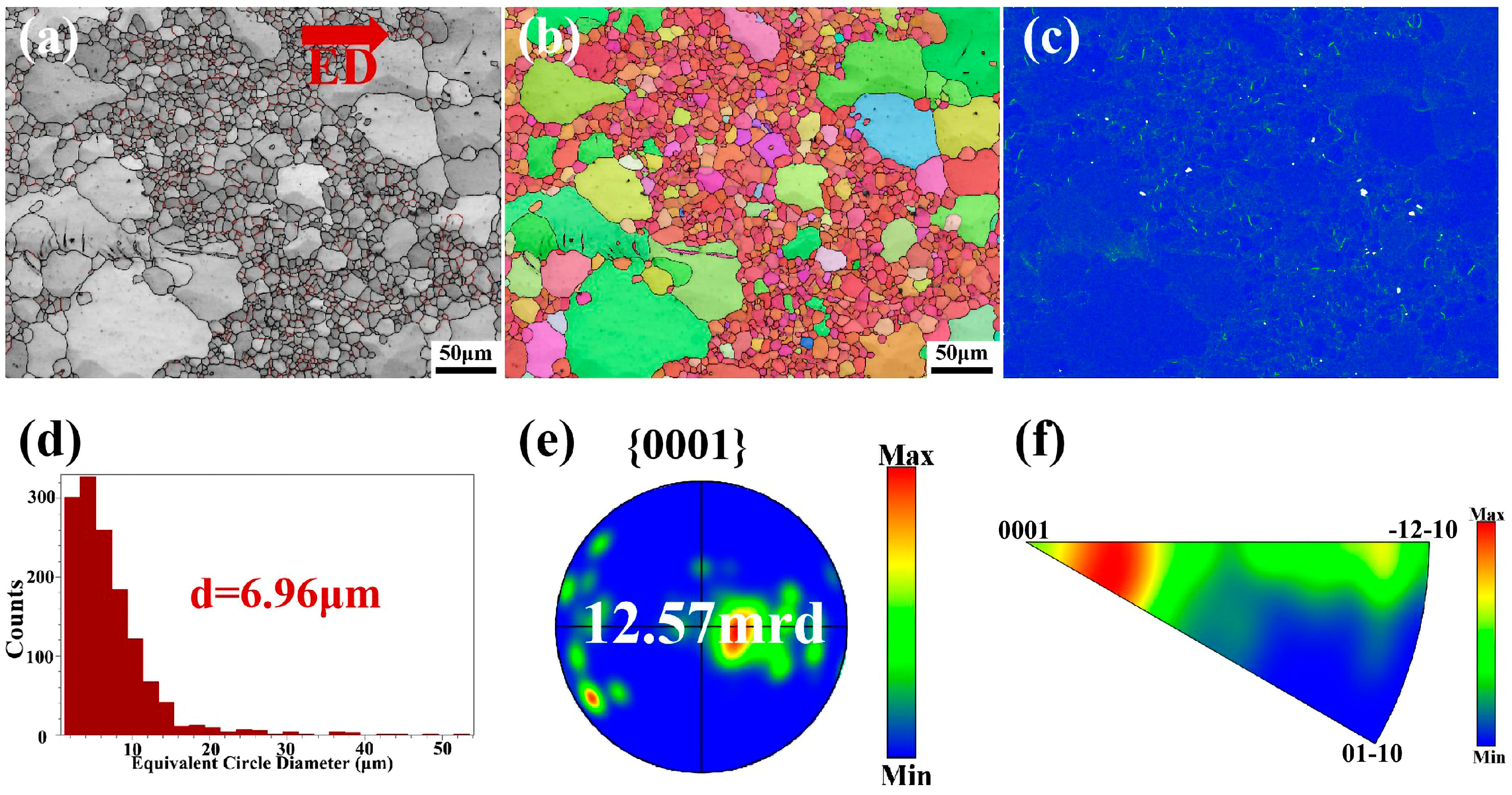

3.2.3. EBSD Results of As-Extruded Alloys

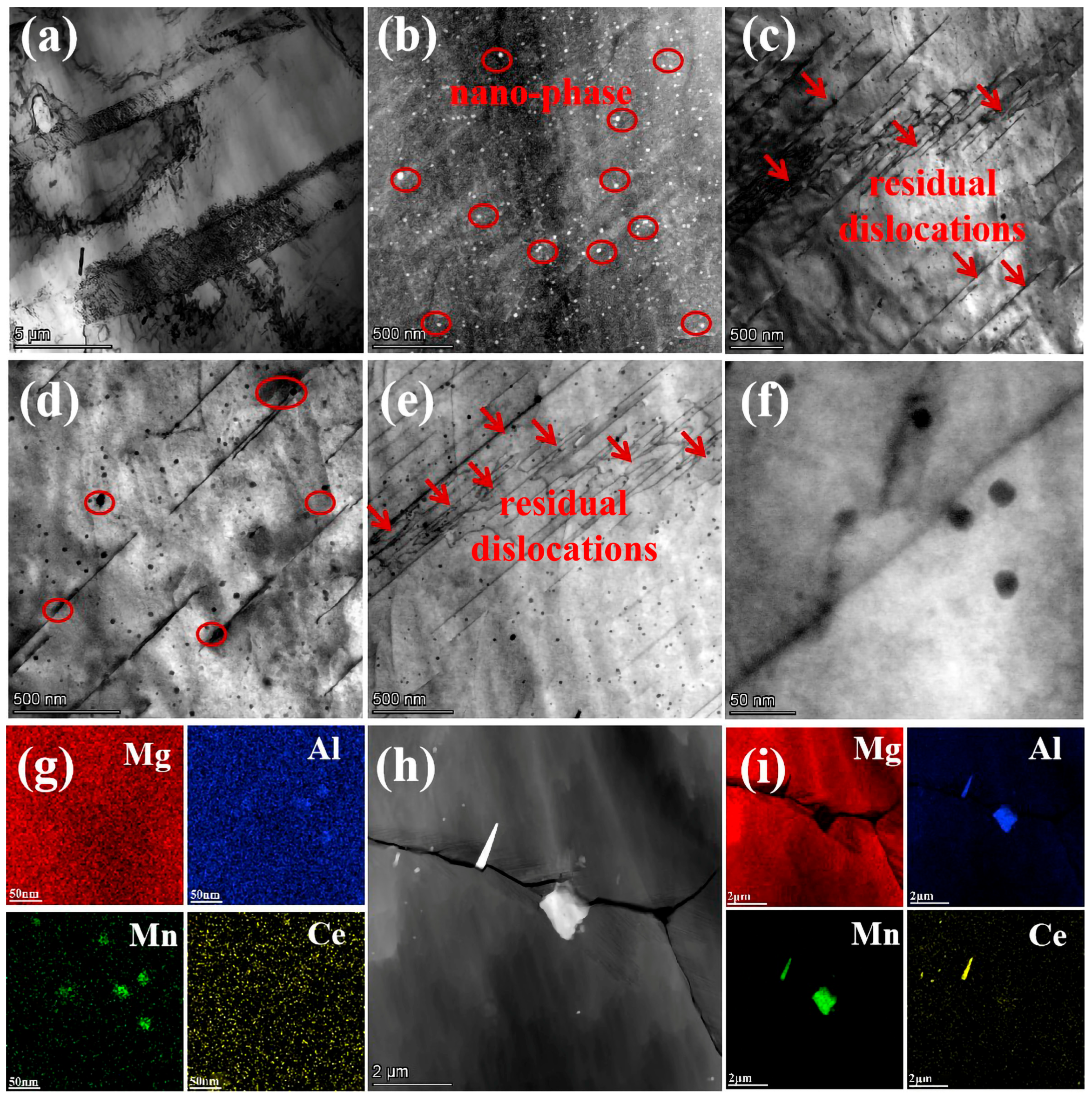

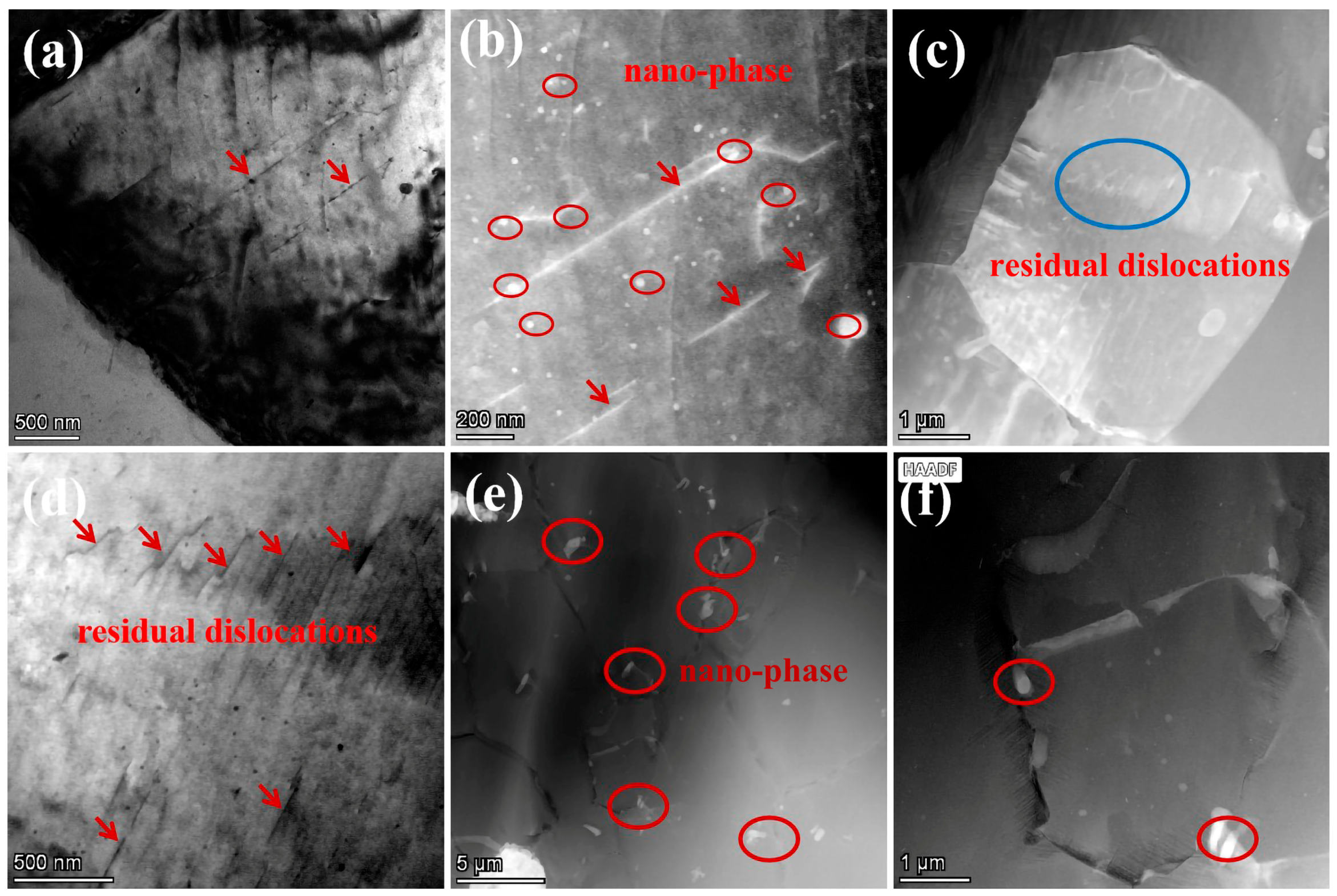

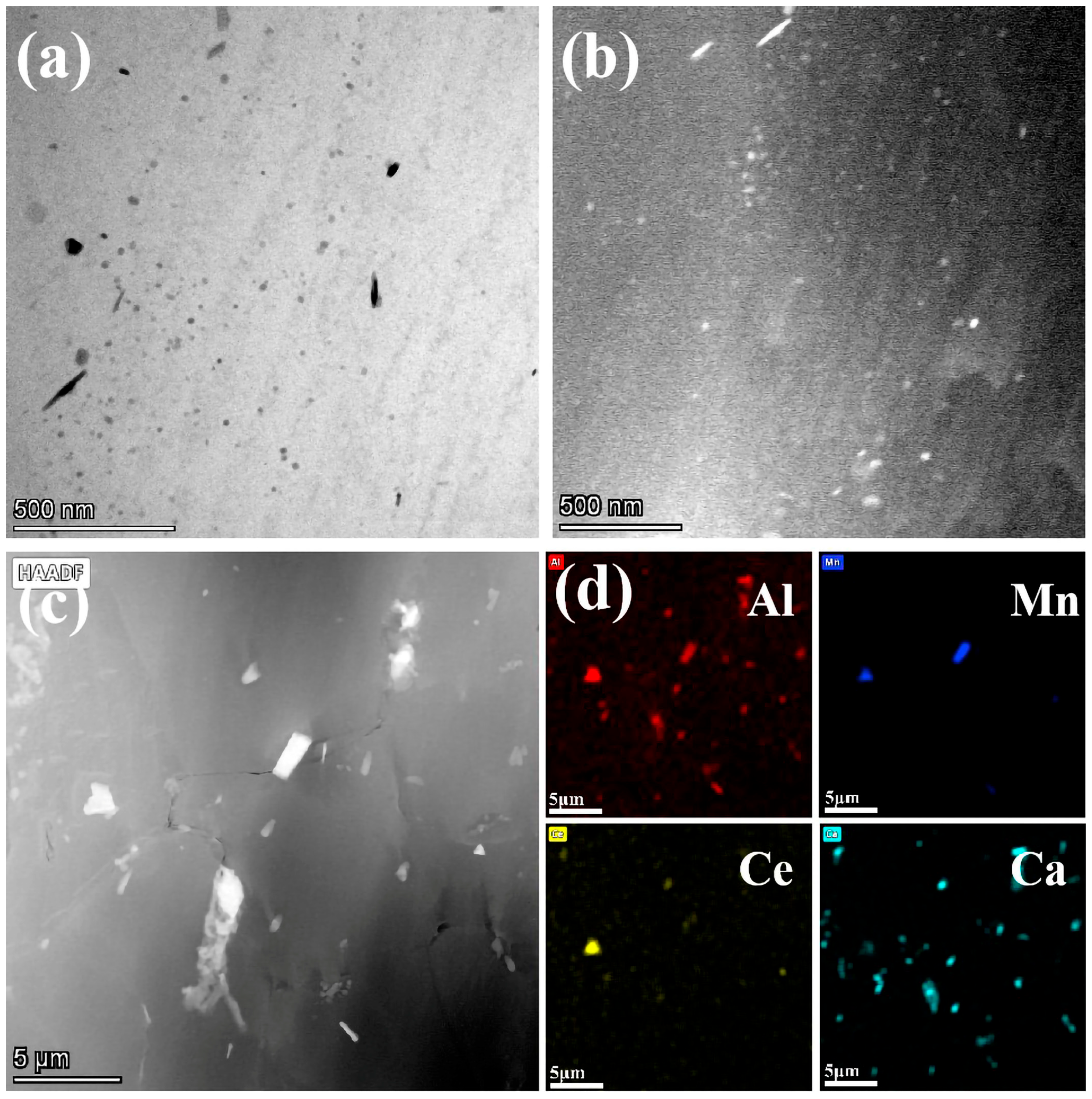

3.2.4. TEM Analysis of As-Extruded Alloys

4. Discussion

5. Conclusions

- (1)

- Through the composition design, high quality Mg-8Al-0.57Mn-0.42Ce-(0.31Ca) alloy profiles were successfully prepared, and a high YS of 190 MPa, UTS of 346 MPa, and high EL of 16% were achieved.

- (2)

- Due to the precipitation of high-density micro-nano second phases in the extruded alloy profile, the AM80EA alloy obtains a finer grain size (average grain size of 6.96 μm), as compared with that of the AM80E alloy. Therefore, the precipitation strengthening and grain refinement strengthening together contribute to the high YS of the AM80EA alloy.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AM80E | Mg-8al-0.57mn-0.42ce |

| AM80EA | Mg-8al-0.57mn-0.42ce-0.31ca |

| YS | Yield strength |

| UTS | Ultimate tensile strength |

| EL | Elongation |

| RE | Rare-earth |

| LRE | Light rare-earth |

| Ce | Cerium |

| Sm | Samarium |

| LAGBs | Low-angle grain boundaries |

| ED | Extrusion direction |

| OM | Optical microscopy |

| SEM | Scanning electron microscopy |

| EBSD | Electron backscatter diffraction |

| TEM | Transmission electron microscopy |

References

- Emadi, P.; Andilab, B.; Ravindran, C. Engineering lightweight aluminum and magnesium alloys for a sustainable future. J. Indian Inst. Sci. 2022, 102, 405–420. [Google Scholar]

- Li, Y.Q.; Li, F.; Kang, F.W.; Du, H.Q.; Chen, Z.Y. Recent research and advances in extrusion forming of magnesium alloys: A review. J. Alloys Compd. 2023, 953, 170080. [Google Scholar]

- Liu, B.; Yang, J.; Zhang, X.; Yang, Q.; Zhang, J.; Li, X. Development and application of magnesium alloy parts for automotive OEMs: A review. J. Magnes. Alloy. 2023, 11, 15–47. [Google Scholar] [CrossRef]

- Song, J.; She, J.; Chen, D.; Pan, F. Latest research advances on magnesium and magnesium alloys worldwide. J. Magnes. Alloy. 2020, 8, 1–41. [Google Scholar] [CrossRef]

- Jiang, H.; Yang, B.; Wu, Y.; Peng, B.; He, M. Deformation Behaviors and Microstructure Evolution of Mg-Zn-Y-Zr Alloys During Hot Compression Process. Metals 2024, 14, 1332. [Google Scholar] [CrossRef]

- Su, N.; Wu, Q.; Ding, C.; Wu, Y.; Peng, L. Effect of Y and Gd solutes on grain refinement of the as-extruded Mg-Gd (-Y)-Zn-Mn alloys. J. Alloys Compd. 2023, 968, 171804. [Google Scholar]

- Zheng, Z.; Dong, Z.; Jiang, B.; Cheng, Y.; Zhang, A.; Song, J.; Li, T.; Pan, F. Evolution of strength with rare-earth content in highly-alloyed Mg-Gd-Y alloys. Scr. Mater. 2024, 238, 115772. [Google Scholar]

- Che, C.; Cai, Z.; Cheng, L.; Meng, F.; Yang, Z. The Microstructures and Tensile Properties of As-Extruded Mg–4Sm–xZn–0.5Zr (x = 0, 1, 2, 3, 4 wt%) Alloys. Metals 2017, 7, 281. [Google Scholar]

- Gensch, F.; Gall, S.; Lechner, S.; Fahrenson, C.; Mueller, S. Microstructural Stability of Extruded Mg-Mn-Ce Hollow Profiles with Weld Seams. Metals 2021, 11, 547. [Google Scholar] [CrossRef]

- Mao, H.; Bai, X.; Wang, Y.; Xu, H.; Hou, J.; Wei, L.; Misra, R.D.K. Microstructures and High-Temperature Properties of Sm-Modified Mg-4Al-4RE Alloy. Metals 2022, 12, 135. [Google Scholar] [CrossRef]

- Li, J.; Xie, D.; Zeng, Z.; Song, B.; Xie, H.; Pei, R.; Pan, H.; Ren, Y.; Qin, G. Mechanistic investigation on Ce addition in tuning recrystallization behavior and mechanical property of Mg alloy. J. Mater. Sci. Technol. 2023, 132, 1–17. [Google Scholar] [CrossRef]

- Xie, D.; Pan, H.; Pan, Z.; Fu, T.; Zeng, Z.; Xie, H.; Ren, Y.; Tang, W.; Qin, G. Achieving outstanding heat-resistant properties in Mg alloy via constructing stable solute-network. Mater. Res. Lett. 2023, 11, 374–382. [Google Scholar] [CrossRef]

- Kondori, B.; Mahmudi, R. Effect of Ca additions on the microstructure, thermal stability and mechanical properties of a cast AM60 magnesium alloy. Mater. Sci. Eng. A 2010, 527, 2014–2021. [Google Scholar]

- Zha, M.; Wang, S.C.; Jia, H.L.; Yang, Y.; Ma, P.K.; Wang, H.Y. Effect of minor Ca addition on microstructure and mechanical properties of a low-alloyed Mg–Al–Zn–Sn alloy. Mater. Sci. Eng. A 2023, 862, 144457. [Google Scholar]

- Zhang, W.; Shen, Z.; Pan, H.; Wang, T.; Fu, T.; Xie, D.; Tang, A.; Teng, C.; Wu, L.; Qin, G. Enhancing strength and irradiation tolerance of Mg alloy via co-addition of Mn and Ca elements. J. Mater. Sci. Technol. 2025, 216, 38–51. [Google Scholar]

- Pan, H.; Qin, G.; Xu, M.; Fu, H.; Ren, Y.; Pan, F.; Gao, Z.; Zhao, C.; Yang, Q.; She, J.; et al. Enhancing mechanical properties of Mg–Sn alloys by combining addition of Ca and Zn. Mater. Des. 2015, 83, 736–744. [Google Scholar]

- Zhang, J.; Peng, P.; Yang, Q.; Luo, A.A. Bimodal grain structure formation and strengthening mechanisms in Mg-Mn-Al-Ca extrusion alloys. J. Magnes. Alloy. 2023, 11, 4407–4419. [Google Scholar]

- Akbaripanah, F.; Fereshteh-Saniee, F.; Mahmudi, R.; Kim, H. Microstructural homogeneity, texture, tensile and shear behavior of AM60 magnesium alloy produced by extrusion and equal channel angular pressing. Mater. Des. 2013, 43, 31–39. [Google Scholar] [CrossRef]

- Cheng, R.; Li, M.; Du, S.; Pan, H.; Liu, Y.; Gao, M.; Zhang, X.; Huang, Q.; Yang, C.; Ma, L.; et al. Effects of single-pass large-strain rolling on microstructure and mechanical properties of Mg-Al-Ca alloy sheet. Mater. Sci. Eng. A 2020, 786, 139332. [Google Scholar] [CrossRef]

- Huang, W.; Chen, J.; Jiang, Z.; Xiong, X.; Qiu, W.; Chen, J.; Ren, X.; Lu, L. Influence of Ca Content on Microstructure and Mechanical Properties of Extruded Mg–Al–Ca–Mn Alloys. Acta Metall. Sin. 2022, 36, 426–438. [Google Scholar] [CrossRef]

- Huang, X.; Suzuki, K.; Chino, Y.; Mabuchi, M. Influence of aluminum content on the texture and sheet formability of AM series magnesium alloys. Mater. Sci. Eng. A 2015, 633, 144–153. [Google Scholar] [CrossRef]

- Mert, F.; Akar, N.; Kilicli, V. Influence of Cerium Addition on Microstructure, Mechanical Properties, and Dry Sliding Wear Behavior of AM50 Magnesium Alloy. Int. J. Met. 2024. [Google Scholar] [CrossRef]

- Nakata, T.; Xu, C.; Ajima, R.; Shimizu, K.; Hanaki, S.; Sasaki, T.; Ma, L.; Hono, K.; Kamado, S. Strong and ductile age-hardening Mg-Al-Ca-Mn alloy that can be extruded as fast as aluminum alloys. Acta Mater. 2017, 130, 261–270. [Google Scholar] [CrossRef]

- Park, S.H.; Kim, S.-H.; Kim, Y.M.; You, B.S. Improving mechanical properties of extruded Mg–Al alloy with a bimodal grain structure through alloying addition. J. Alloys Compd. 2015, 646, 932–936. [Google Scholar] [CrossRef]

- Razzaghi, M.; Mirzadeh, H.; Emamy, M. Mechanical properties of Mg-Al-Mn magnesium alloys with low Al content in the as-cast and extruded conditions. Mater. Res. Express 2019, 6, 106521. [Google Scholar] [CrossRef]

- Zhang, L.; Deng, K.-K.; Nie, K.-B.; Xu, F.-J.; Su, K.; Liang, W. Microstructures and mechanical properties of Mg–Al–Ca alloys affected by Ca/Al ratio. Mater. Sci. Eng. A 2015, 636, 279–288. [Google Scholar] [CrossRef]

- Gao, W.; Wang, X.; Lin, Y.; Wang, X.; Liu, D.; Sun, X. Achieving ultra-high strength and ductility in a rare-earth-free magnesium alloy via precisely controlled secondary hot extrusion process with an extremely low extrusion speed. J. Magnes. Alloy. 2024, 12, 5216–5230. [Google Scholar] [CrossRef]

- Luo, Y.-X.; Dong, B.-X.; Yang, H.-Y.; Qiu, F.; Yan, B.-C.; Shu, S.-L.; Jiang, Q.-C.; Shi, F.-J. Research progress on nanoparticles reinforced magnesium alloys. J. Mater. Res. Technol. 2024, 30, 5166–5191. [Google Scholar] [CrossRef]

- Chen, Q.; Chen, R.; Su, J.; He, Q.; Tan, B.; Xu, C.; Huang, X.; Dai, Q.; Lu, J. The mechanisms of grain growth of Mg alloys: A review. J. Magnes. Alloy. 2022, 10, 2384–2397. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, J.; Wang, J.; Li, Z.; Xie, J.; Liu, S.; Guan, K.; Wu, R. Toward the development of Mg alloys with simultaneously improved strength and ductili-ty by refining grain size via the deformation process. Int. J. Miner. Metall. Mater. 2021, 28, 30–45. [Google Scholar] [CrossRef]

- Yu, H.; Xin, Y.; Wang, M.; Liu, Q. Hall-Petch relationship in Mg alloys: A review. J. Mater. Sci. Technol. 2018, 34, 248–256. [Google Scholar]

- He, S.-h.; Wang, C.; Sun, C.; Zhang, Y.; Yan, K.; Jiang, J.-h.; Bai, J.; Xue, F.; Liu, H. Corrosion properties of ECAP-processed Mg–Al–Ca–Mn alloys with separate Al2Ca and Mg2Ca phases. Trans. Nonferrous Met. Soc. China 2022, 32, 2527–2540. [Google Scholar]

- Luo, S.; Wang, L.; Wang, J.; Zhu, G.; Zeng, X. Micro-compression of Al2Ca particles in a Mg-Al-Ca alloy. Materialia 2022, 21, 101300. [Google Scholar]

- Zhan, H.; Zhang, J.; Miao, J.; Wang, C.; Zeng, G.; Wang, J.; Luo, A.A. A low-cost Mg–Al–Mn–Zn alloy for automotive road wheel applications. Mater. Sci. Eng. A 2024, 897, 146321. [Google Scholar]

| Samples | Alloy Composition, wt.% | Extrusion Temperature, °C | Extrusion Rate, mm/s |

|---|---|---|---|

| AM80E | Mg-8Al-0.57Mn-0.42Ce | 375–385 | 0.6 |

| AM80EA | Mg-8Al-0.57Mn-0.42Ce-0.31Ca | 375–385 | 0.6 |

| Samples | YS/MPa | UTS/MPa | EL/% |

|---|---|---|---|

| AM80E | 174 ± 3 | 309 ± 2 | 13.7 ± 0.5 |

| AM80EA | 190 ± 5 | 346 ± 5 | 16.5 ± 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, W.; Li, S.; Pan, H.; Zhang, Y.; Pan, Z.; Wang, S.; Ren, Y.; Qin, G. Development of Novel Mg-Al-Mn-Based Alloys with High-Strength and Ductility via Co-Addition of Ce and Ca. Metals 2025, 15, 361. https://doi.org/10.3390/met15040361

Liu W, Li S, Pan H, Zhang Y, Pan Z, Wang S, Ren Y, Qin G. Development of Novel Mg-Al-Mn-Based Alloys with High-Strength and Ductility via Co-Addition of Ce and Ca. Metals. 2025; 15(4):361. https://doi.org/10.3390/met15040361

Chicago/Turabian StyleLiu, Wei, Shuo Li, Hucheng Pan, Yuan Zhang, Zhen Pan, Sen Wang, Yuping Ren, and Gaowu Qin. 2025. "Development of Novel Mg-Al-Mn-Based Alloys with High-Strength and Ductility via Co-Addition of Ce and Ca" Metals 15, no. 4: 361. https://doi.org/10.3390/met15040361

APA StyleLiu, W., Li, S., Pan, H., Zhang, Y., Pan, Z., Wang, S., Ren, Y., & Qin, G. (2025). Development of Novel Mg-Al-Mn-Based Alloys with High-Strength and Ductility via Co-Addition of Ce and Ca. Metals, 15(4), 361. https://doi.org/10.3390/met15040361