The Influence of a Constant Magnetic Field on a Vertical Combined Magnetic Field in Magneto-Optical Imaging

Abstract

1. Introduction

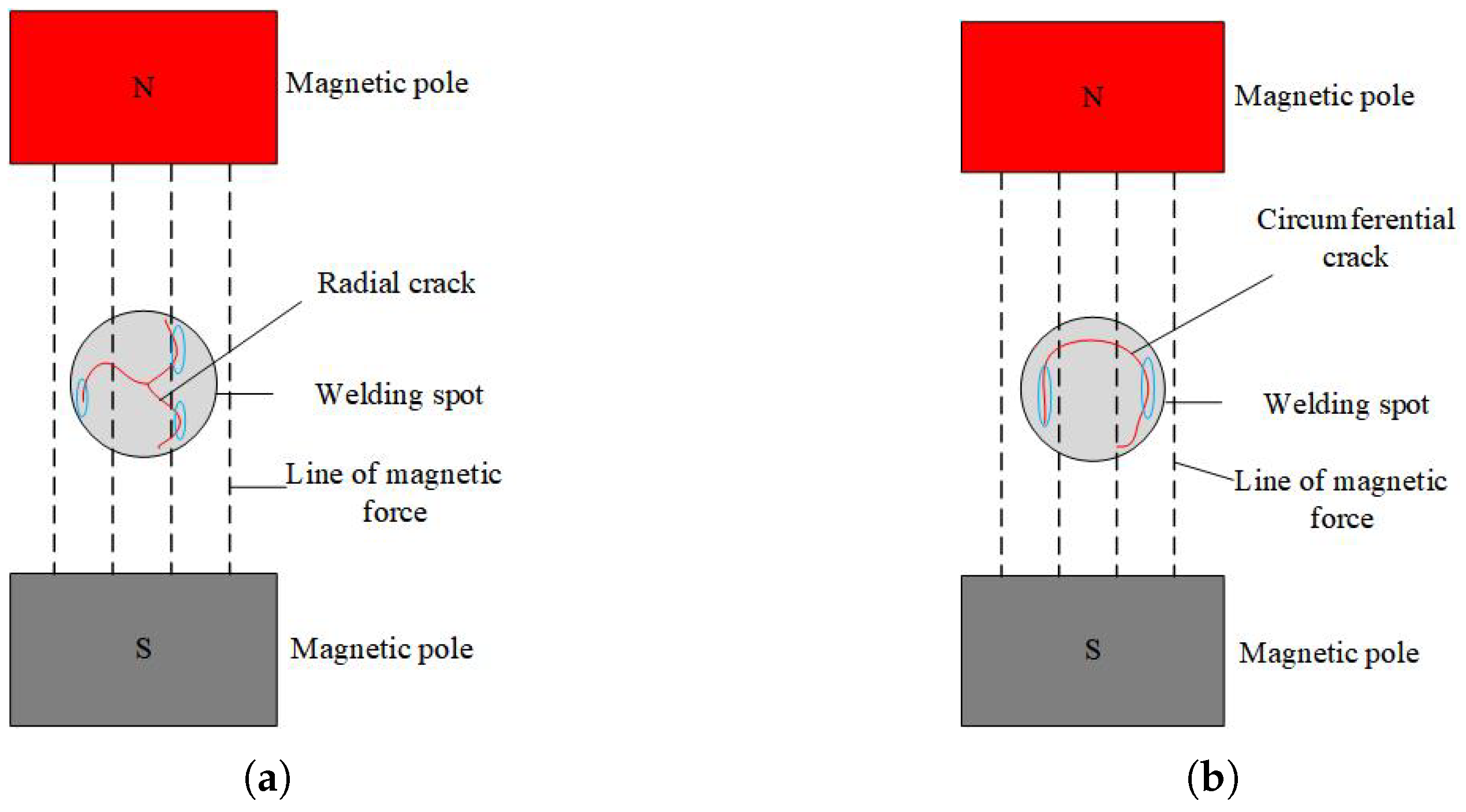

2. Simulation Analysis of Welding Defects

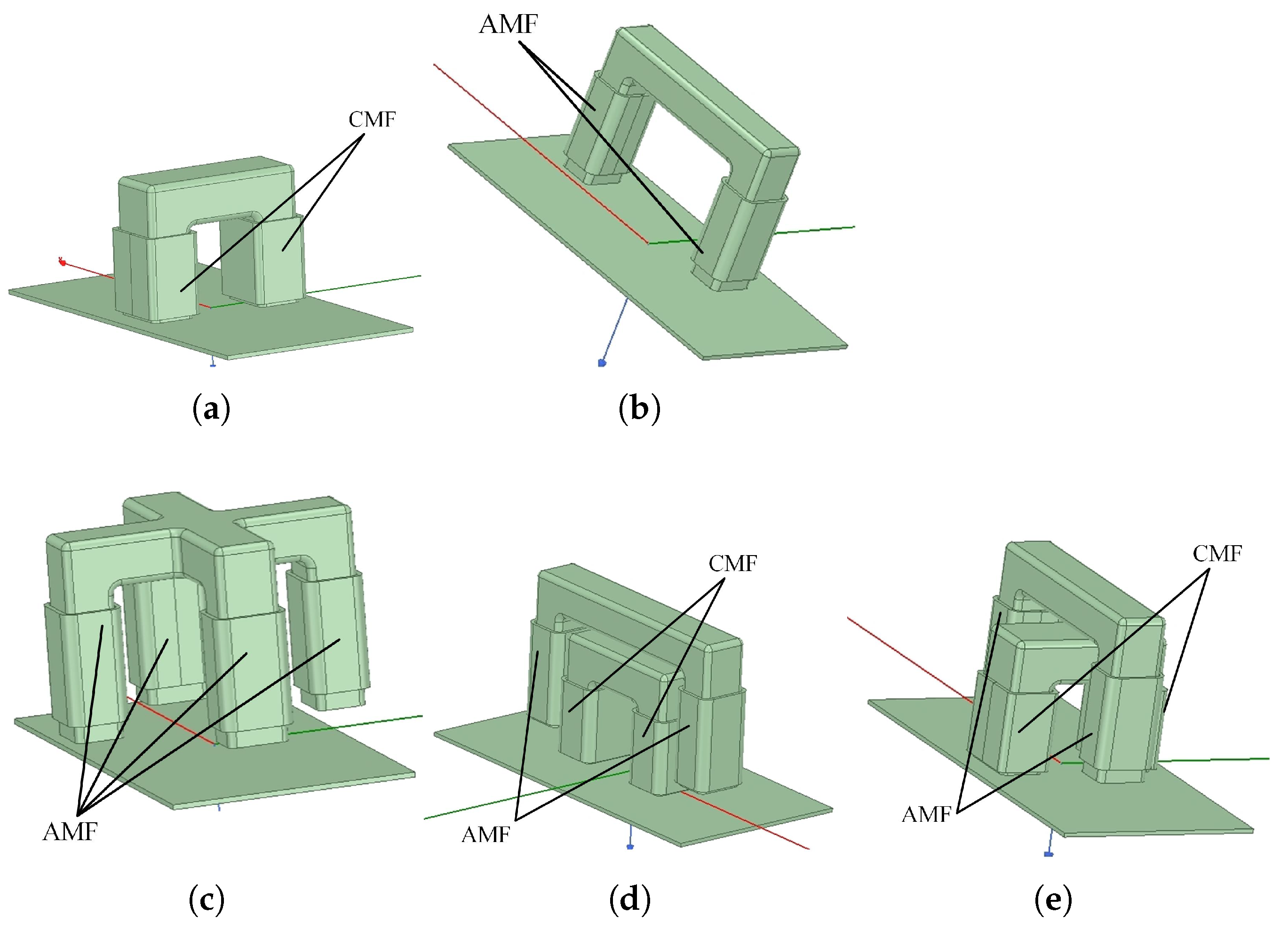

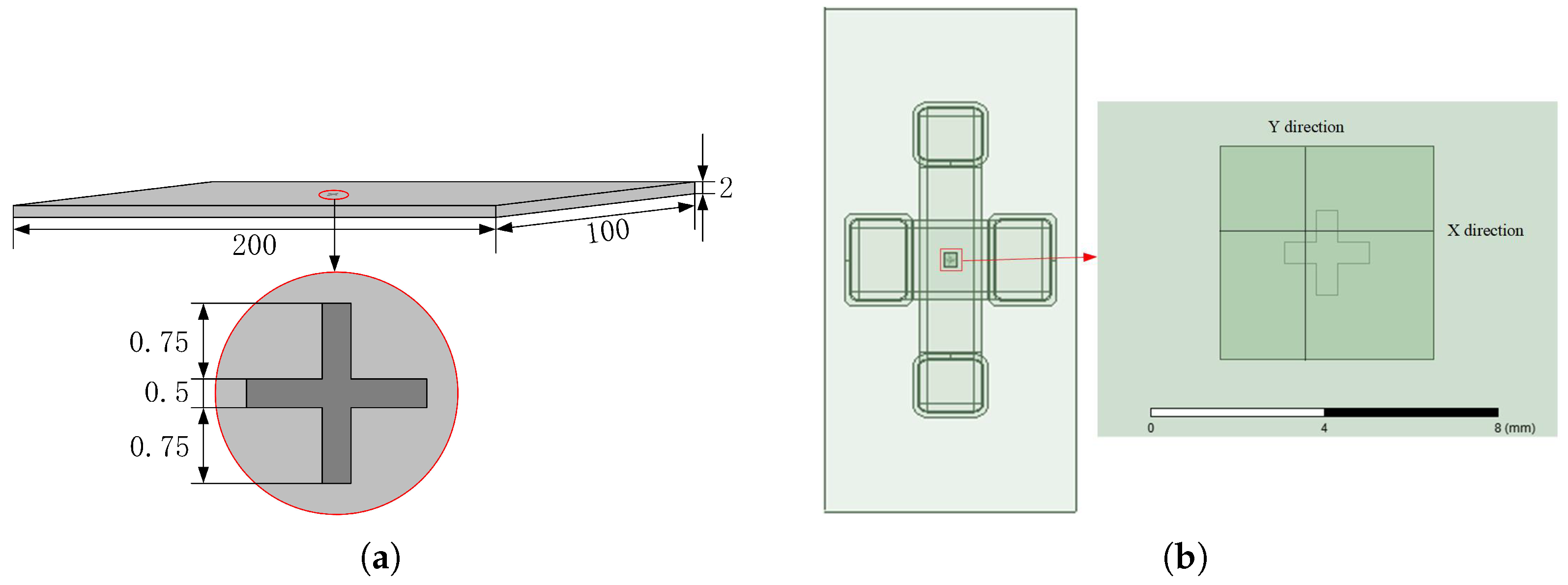

2.1. Establishment of Magnetic Field Simulation Models

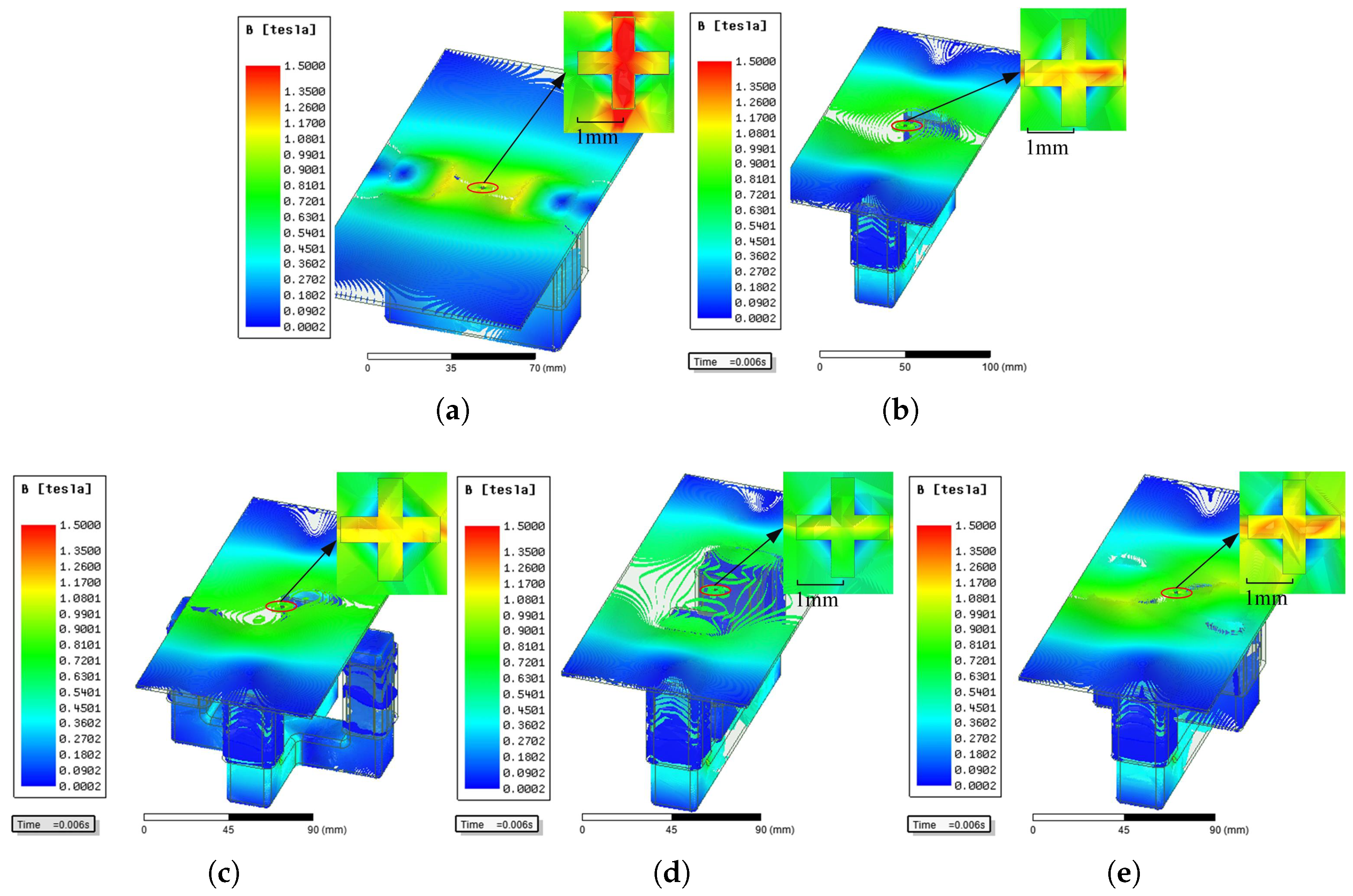

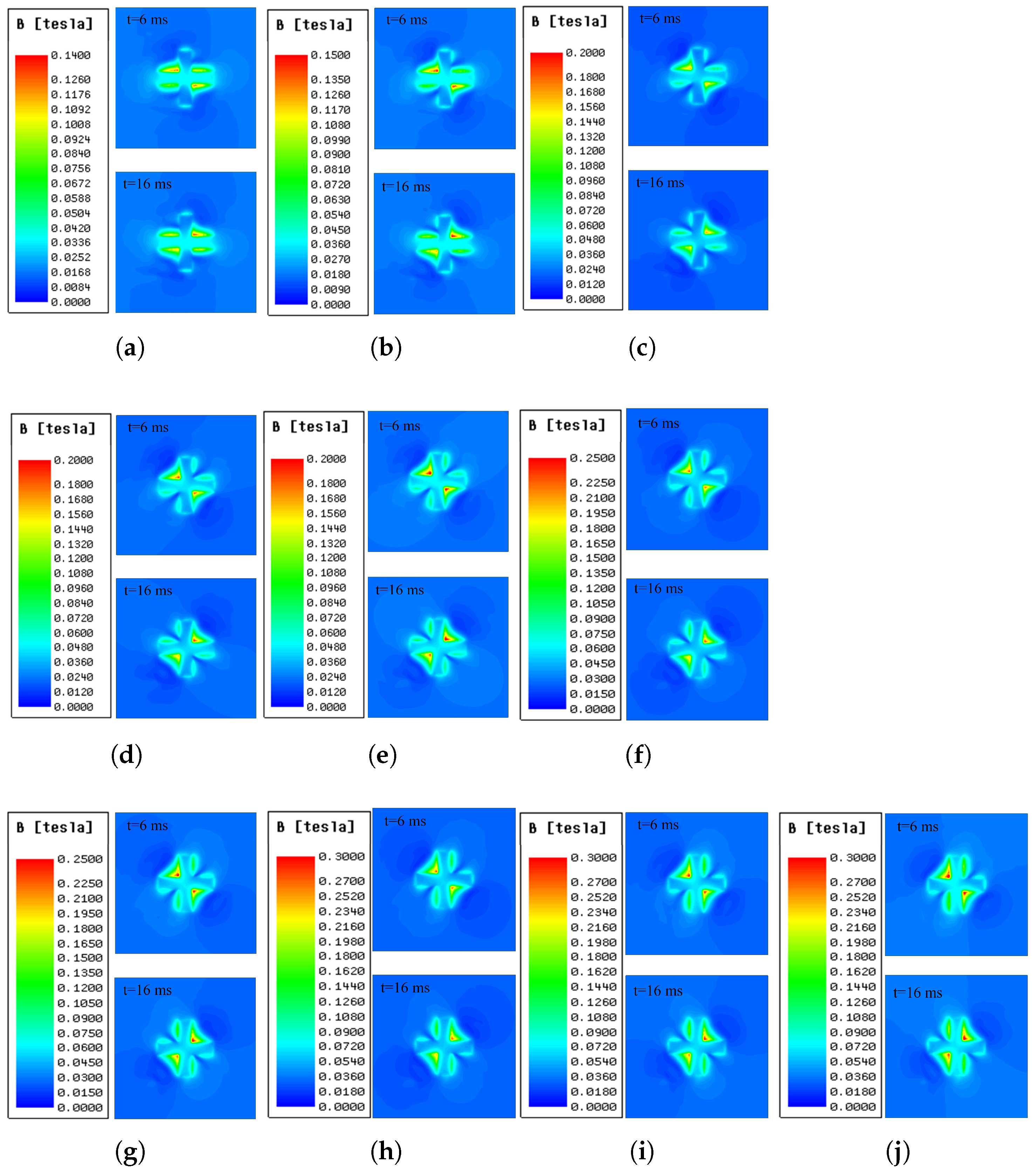

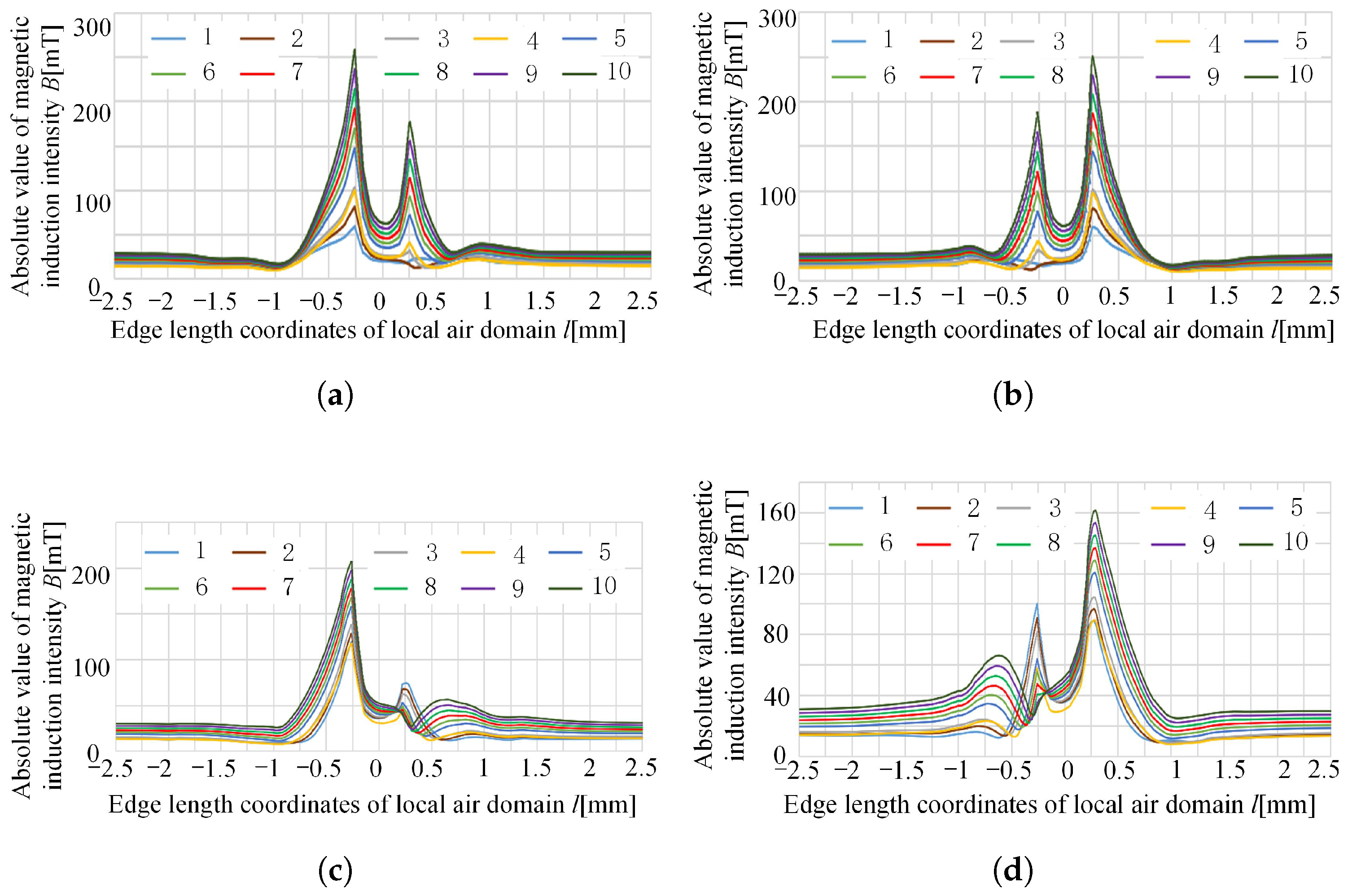

2.2. The Influence of CMF on the Characteristics of a Defect Leakage Magnetic Field

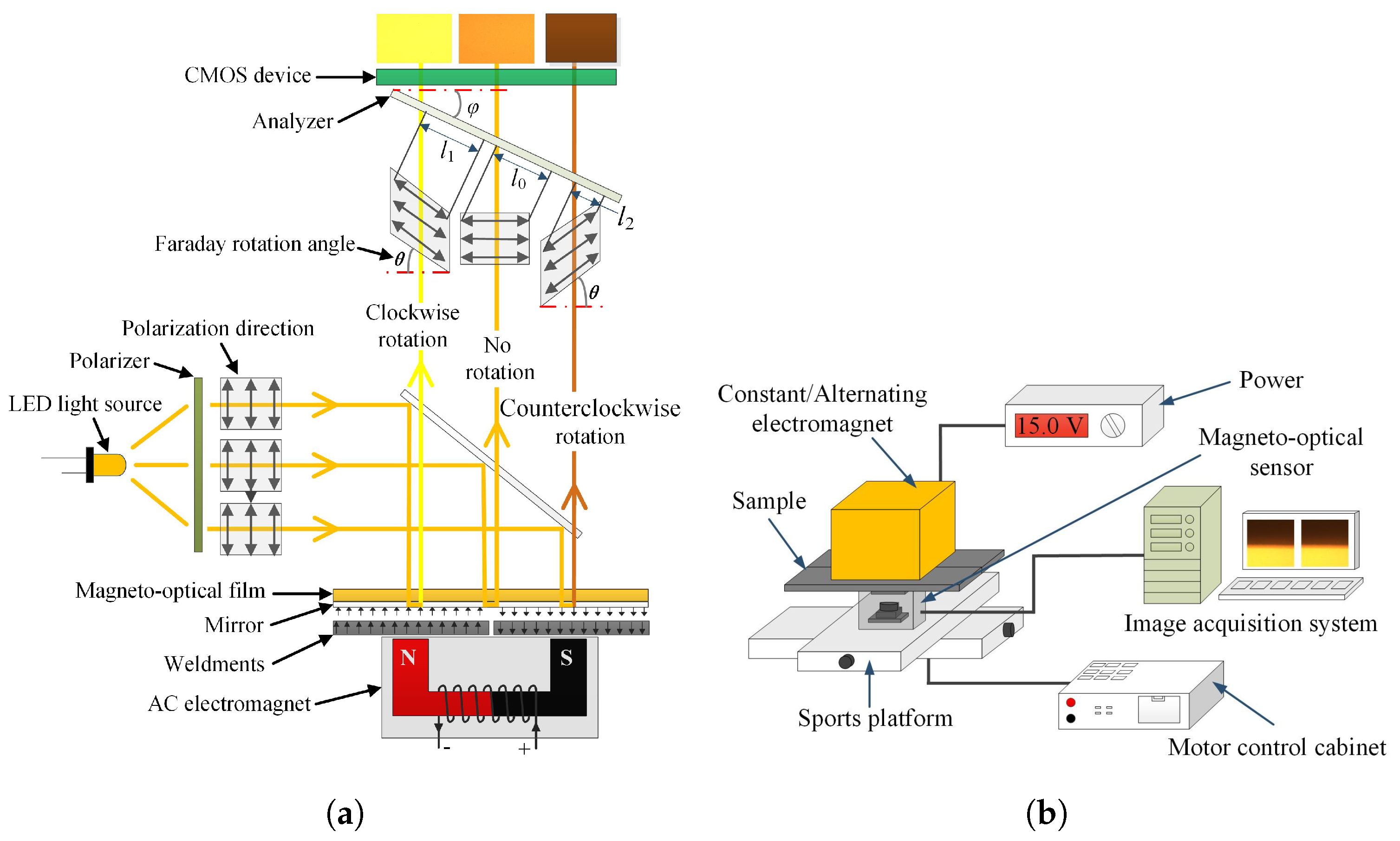

3. Magneto-Optical Imaging Under VCMF

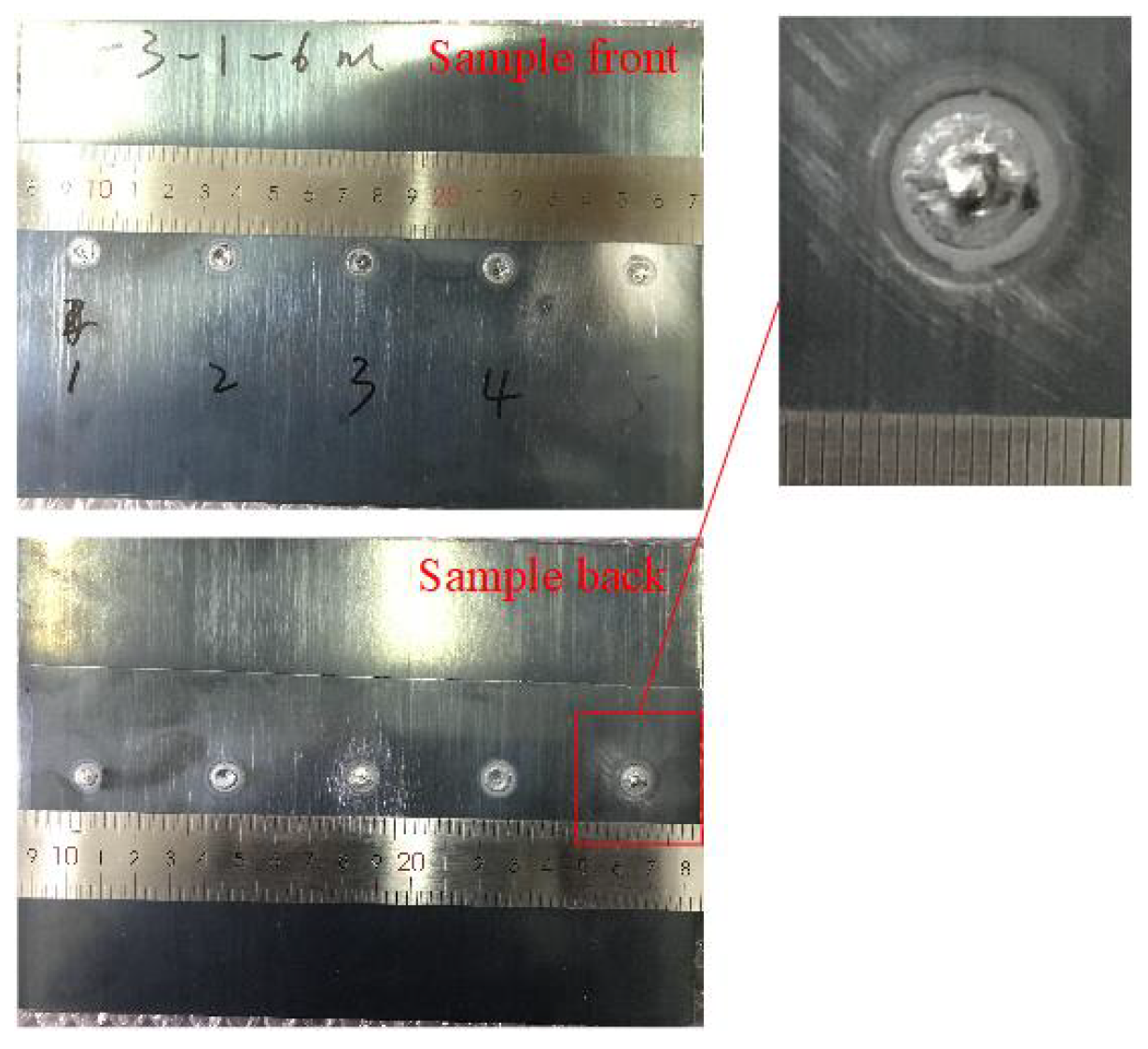

3.1. Magneto-Optical Imaging Testing Under VCMF

3.2. The Influence of the CMF on Magneto-Optical Imaging

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, J.; Li, C.; Wu, X.J.; Palade, V.; Fang, W. An Effective Method of Weld Defect Detection and Classification Based on Machine Vision. IEEE Trans. Ind. Inform. 2019, 15, 6322–6333. [Google Scholar] [CrossRef]

- Liu, T.; Zheng, P.; Bao, J.; Chen, H. A state-of-the-art survey of welding radiographic image analysis: Challenges, technologies and applications. Measurement 2023, 214, 112821. [Google Scholar] [CrossRef]

- Liu, W.; Shan, S.; Chen, H.; Wang, R.; Sun, J.; Zhou, Z. X-ray weld defect detection based on AF-RCNN. Weld. World 2022, 66, 1165–1177. [Google Scholar] [CrossRef]

- Górka, J.; Jamrozik, W. Enhancement of Imperfection Detection Capabilities in TIG Welding of the Infrared Monitoring System. Metals 2021, 11, 1624. [Google Scholar] [CrossRef]

- Sun, H.; Ramuhalli, P.; Jacob, R.E. Machine learning for ultrasonic nondestructive examination of welding defects: A systematic review. Ultrasonics 2023, 127, 106854. [Google Scholar] [CrossRef] [PubMed]

- Honarvar, F.; Varvani-Farahani, A. A review of ultrasonic testing applications in additive manufacturing: Defect evaluation, material characterization, and process control. Ultrasonics 2020, 108, 106227. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Wu, C.; Padhy, G.; Ding, W. Application of ultrasonic vibrations in welding and metal processing: A status review. J. Manuf. Process. 2017, 26, 295–322. [Google Scholar] [CrossRef]

- Gholizadeh, S. A review of non-destructive testing methods of composite materials. Procedia Struct. Integr. 2016, 1, 50–57. [Google Scholar] [CrossRef]

- Fitzpatrick, G.L.; Thome, D.K.; Skaugset, R.L.; Shih, E.Y.; Shih, W.C. Magneto-optic/eddy current imaging of aging aircraft: A new NDI technique. Mater. Eval. 1993, 51, 1402–1407. Available online: https://www.osti.gov/biblio/5044997 (accessed on 9 February 2025).

- Gao, X.; Mo, L.; You, D.; Li, Z. Tight butt joint weld detection based on optical flow and particle filtering of magneto-optical imaging. Mech. Syst. Signal Process. 2017, 96, 16–30. [Google Scholar]

- Gao, X.; Lan, C.; You, D.; Li, G.; Zhang, N. Weldment nondestructive testing using magneto-optical imaging induced by alternating magnetic field. J. Nondestruct. Eval. 2017, 36, 55. [Google Scholar] [CrossRef]

- Li, D.; Han, Z.; Zhao, P.; Dong, Z.; Zhao, S.; Zhu, R.; Li, F.; Yang, Y.; Lin, X. Laser welding by focusing multi-laser beams. Opt. Express 2024, 32, 23147–23160. [Google Scholar] [CrossRef] [PubMed]

- Alghannam, E.; Lu, H.; Ma, M.; Cheng, Q.; Gonzalez, A.A.; Zang, Y.; Li, S. A Novel Method of Using Vision System and Fuzzy Logic for Quality Estimation of Resistance Spot Welding. Symmetry 2019, 11, 990. [Google Scholar] [CrossRef]

- Xu, H.; Yan, Z.; Ji, B.; Huang, P.; Cheng, J.; Wu, X. Defect detection in welding radiographic images based on semantic segmentation methods. Measurement 2022, 188, 110569. [Google Scholar] [CrossRef]

- Naddaf-Sh, M.M.; Naddaf-Sh, S.; Zargarzadeh, H.; Zahiri, S.M.; Dalton, M.; Elpers, G.; Kashani, A.R. Defect detection and classification in welding using deep learning and digital radiography. In Fault Diagnosis and Prognosis Techniques for Complex Engineering Systems; Elsevier: Amsterdam, The Netherlands, 2021; pp. 327–352. [Google Scholar] [CrossRef]

- Sazonova, S.A.; Nikolenko, S.D.; Osipov, A.A.; Zyazina, T.V.; Venevitin, A.A. Weld defects and automation of methods for their detection. J. Phys. Conf. Ser. 2021, 1889, 022078. [Google Scholar] [CrossRef]

- Tsukada, K.; Miyake, K.; Harada, D.; Sakai, K.; Kiwa, T. Magnetic nondestructive test for resistance spot welds using magnetic flux penetration and eddy current methods. J. Nondestruct. Eval. 2013, 32, 286–293. [Google Scholar] [CrossRef]

- Zhao, D.; Ivanov, M.; Wang, Y.; Du, W. Welding quality evaluation of resistance spot welding based on a hybrid approach. J. Intell. Manuf. 2021, 32, 1819–1832. [Google Scholar] [CrossRef]

- Ma, N.; Gao, X.; Wang, C.; Zhang, Y. Optimization of Magneto-Optical Imaging Visualization of Micro-Defects Under Combined Magnetic Field Based on Dynamic Permeability. IEEE Trans. Instrum. Meas. 2021, 70, 1–9. [Google Scholar]

- Xu, Z.; Zha, X.; Chen, H.; Sun, Y.; Long, M. A simulation study for locating defects in tubes using the weak MFL signal based on the multi-channel correlation technique. Insight-Non-Destr. Test. Cond. Monit. 2015, 57, 518–527. [Google Scholar] [CrossRef]

- Zheng, X.; Zhu, S.; Zhang, X.; Shen, B. Compressing magnetic field into a high-intensity electromagnetic field with a relativistic flying mirror. Opt. Express 2021, 29, 41121–41131. [Google Scholar] [CrossRef]

| Serial Number of VCMF | AMF I[A] | CMF I[A] |

|---|---|---|

| 1 | 100sin(100t) | 2 |

| 2 | 4 | |

| 3 | 6 | |

| 4 | 8 | |

| 5 | 10 | |

| 6 | 12 | |

| 7 | 14 | |

| 8 | 16 | |

| 9 | 18 | |

| 10 | 20 |

| NMF | Excitation Voltage | Magneto-Optical Imaging | |||

|---|---|---|---|---|---|

| CMF [V] | AMF [V] | F1 | F2 | F3 | |

| 1 | 1 | - |  | ||

| 2 | 1.5 | - |  | ||

| 3 | 2 | - |  | ||

| 4 | - | 15 |  |  |  |

| 5 | - | 35 |  |  |  |

| 6 | 1 | 15 |  |  |  |

| 7 | 1.5 | 15 |  |  |  |

| 8 | 2 | 15 |  |  |  |

| 9 | 1.5 | 35 |  |  |  |

| NMF | Excitation Voltage | Magneto-Optical Imaging | |||

|---|---|---|---|---|---|

| CMF [V] | AMF [V] | F1 | F2 | F3 | |

| 1 | 1 | - | 9.71 | ||

| 2 | 1.5 | - | 12.39 | ||

| 3 | 2 | - | 24.98 | ||

| 4 | - | 15 | 17.62 | 19.69 | 13.10 |

| 5 | - | 35 | 27.18 | 19.38 | 19.78 |

| 6 | 1 | 15 | 17.77 | 13.24 | 12.14 |

| 7 | 1.5 | 15 | 15.51 | 28.34 | 20.50 |

| 8 | 2 | 15 | 17.95 | 30.47 | 23.15 |

| 9 | 1.5 | 35 | 18.70 | 40.18 | 32.10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, N.; Gao, X.; Zhang, Y.; Gu, S.; Liu, J. The Influence of a Constant Magnetic Field on a Vertical Combined Magnetic Field in Magneto-Optical Imaging. Metals 2025, 15, 340. https://doi.org/10.3390/met15040340

Ma N, Gao X, Zhang Y, Gu S, Liu J. The Influence of a Constant Magnetic Field on a Vertical Combined Magnetic Field in Magneto-Optical Imaging. Metals. 2025; 15(4):340. https://doi.org/10.3390/met15040340

Chicago/Turabian StyleMa, Nvjie, Xiangdong Gao, Yanxi Zhang, Shichao Gu, and Jinyang Liu. 2025. "The Influence of a Constant Magnetic Field on a Vertical Combined Magnetic Field in Magneto-Optical Imaging" Metals 15, no. 4: 340. https://doi.org/10.3390/met15040340

APA StyleMa, N., Gao, X., Zhang, Y., Gu, S., & Liu, J. (2025). The Influence of a Constant Magnetic Field on a Vertical Combined Magnetic Field in Magneto-Optical Imaging. Metals, 15(4), 340. https://doi.org/10.3390/met15040340