Effect of Solution and Aging Treatment on the Microstructure and Properties of LAZ931 Mg-Li Alloy by Friction Stir Processing

Abstract

1. Introduction

2. Materials and Methods

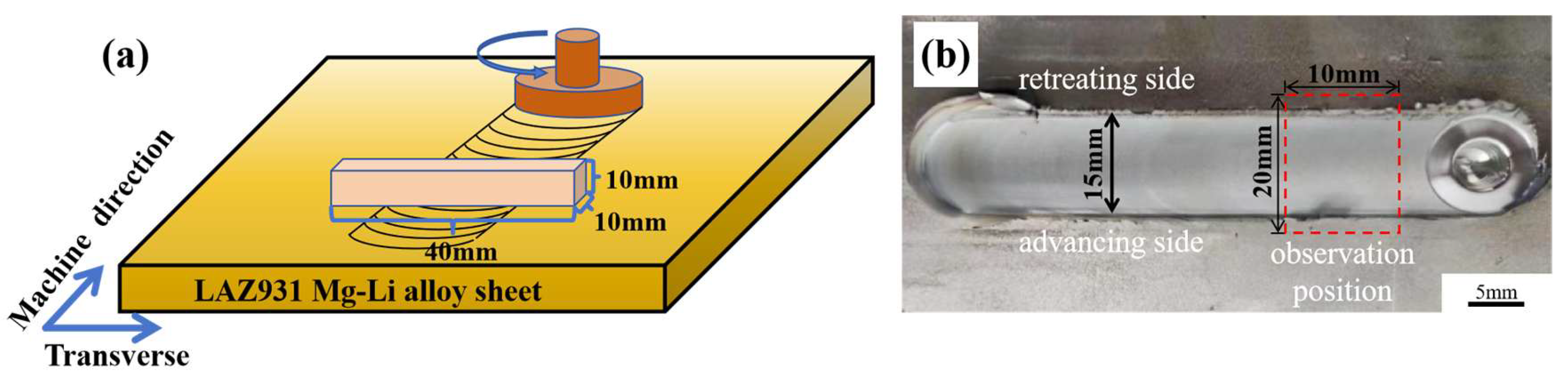

2.1. FSPed LAZ931 Mg-Li Alloy and T6 Heat Treatment

2.2. Performance Characterization

3. Results and Discussion

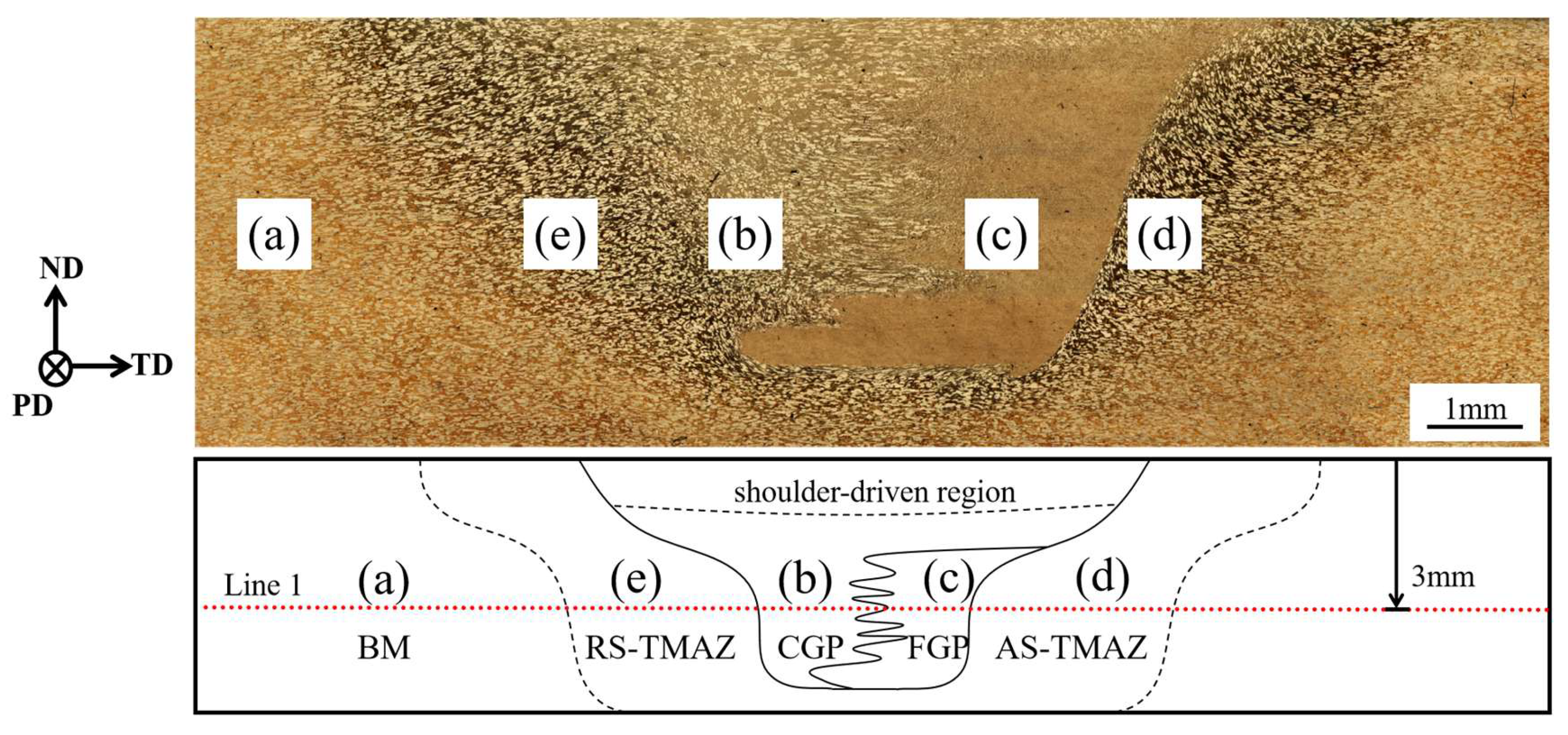

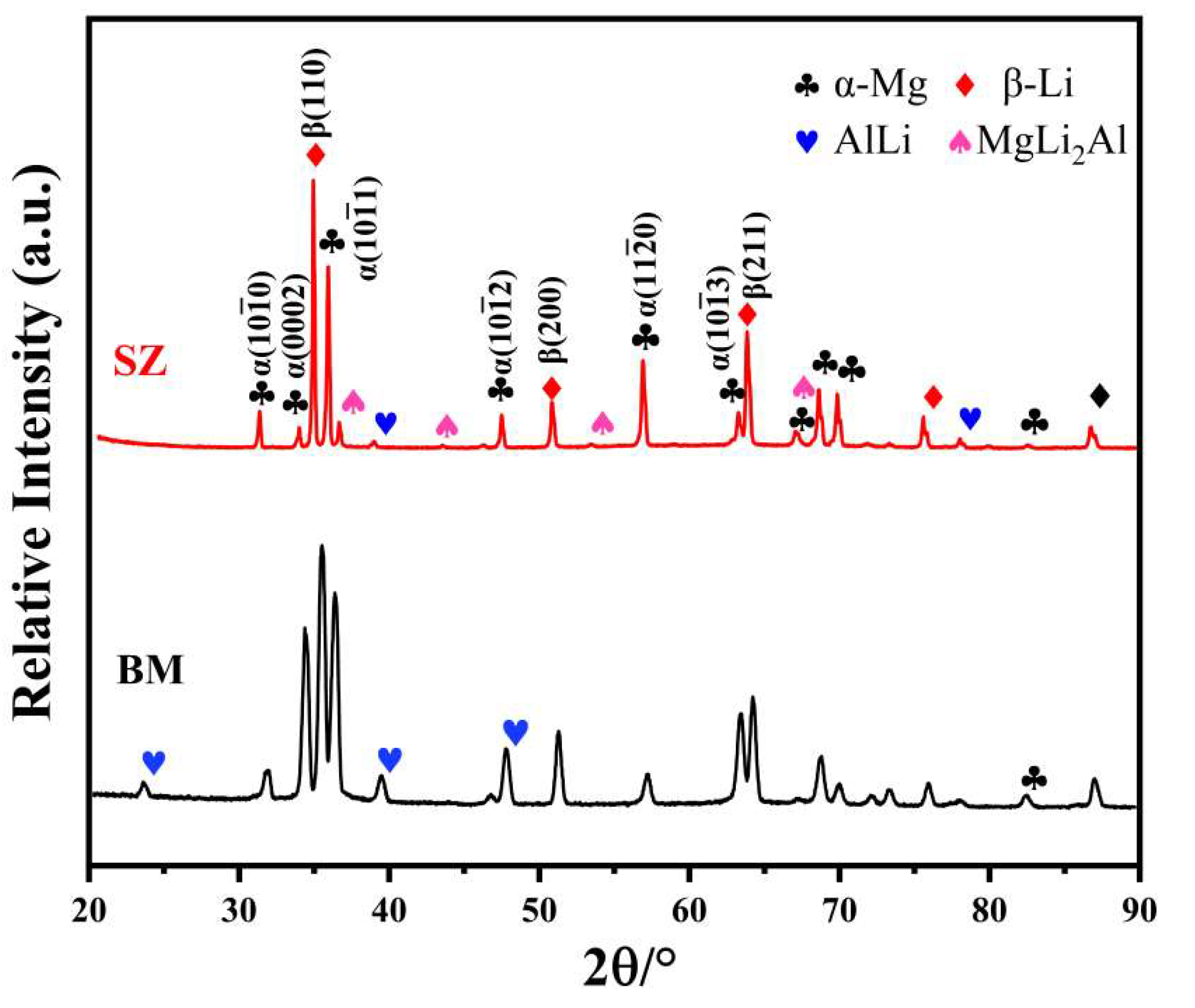

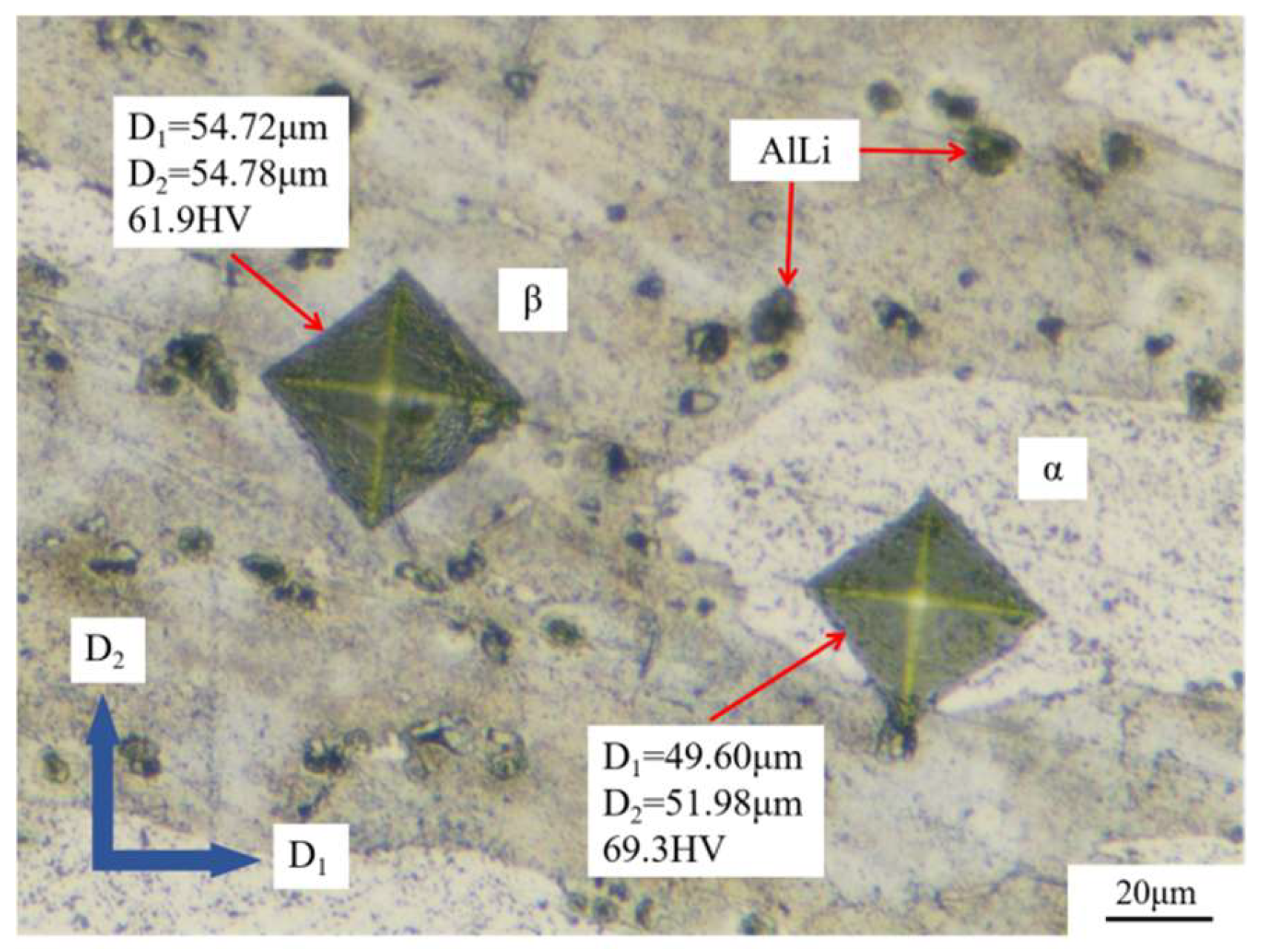

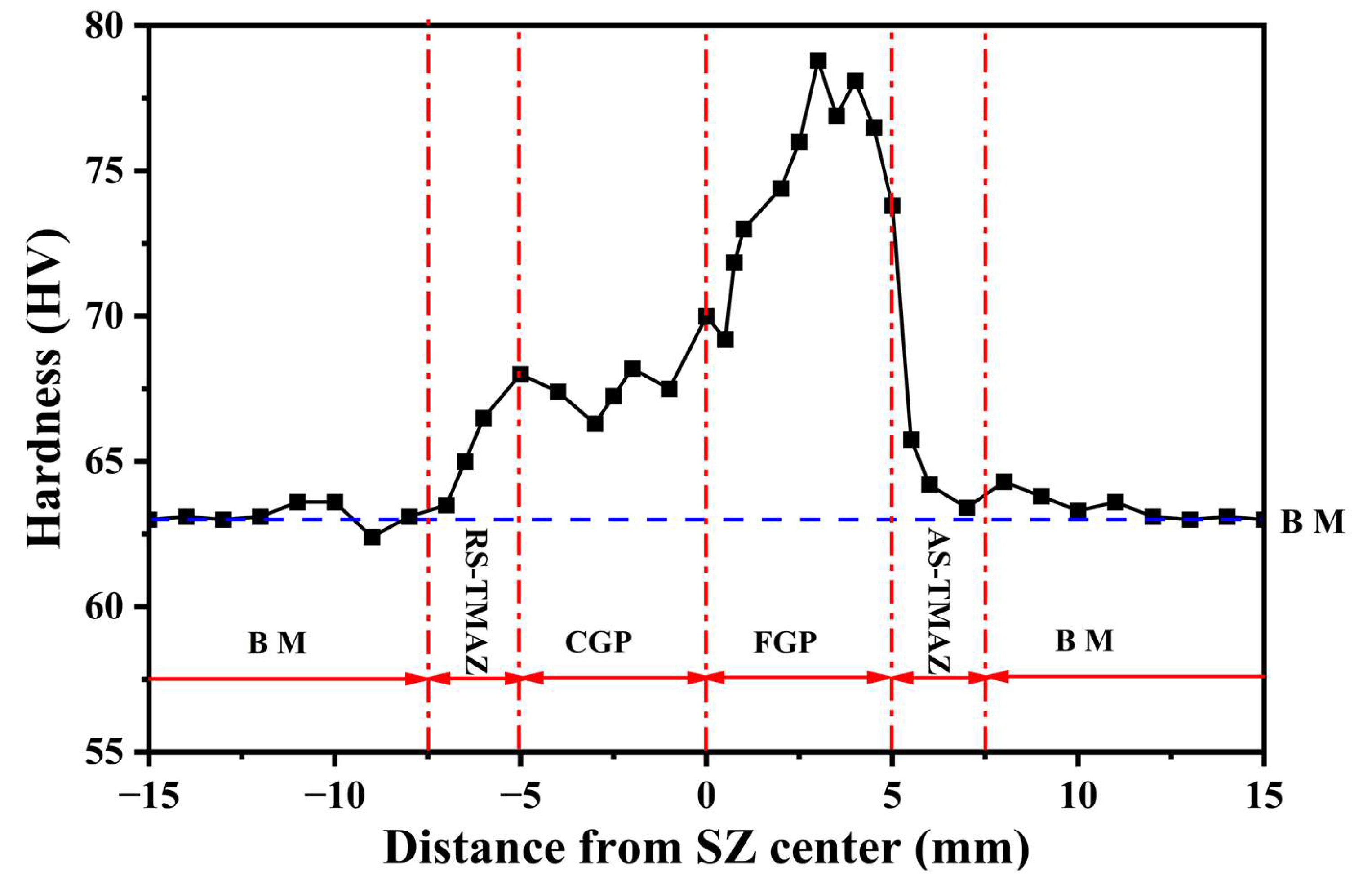

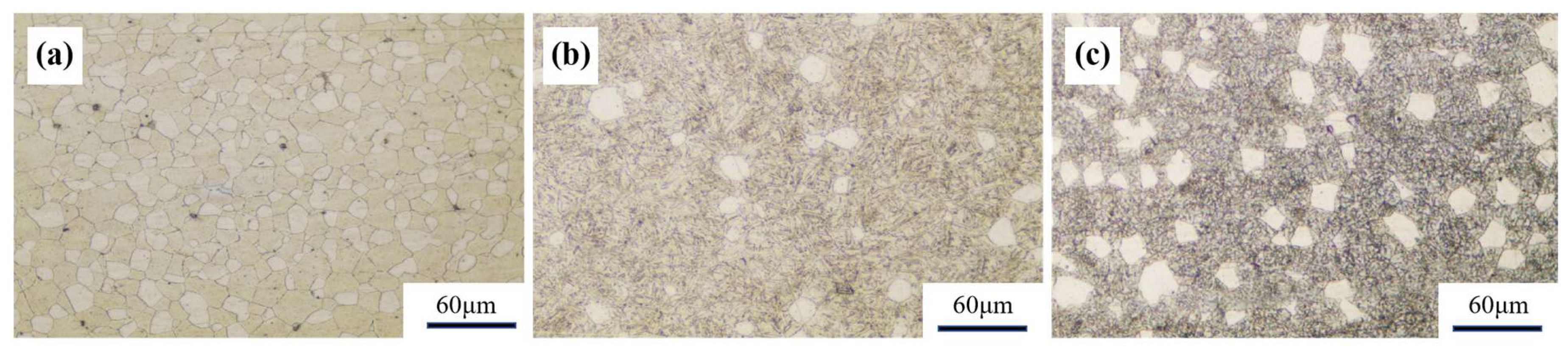

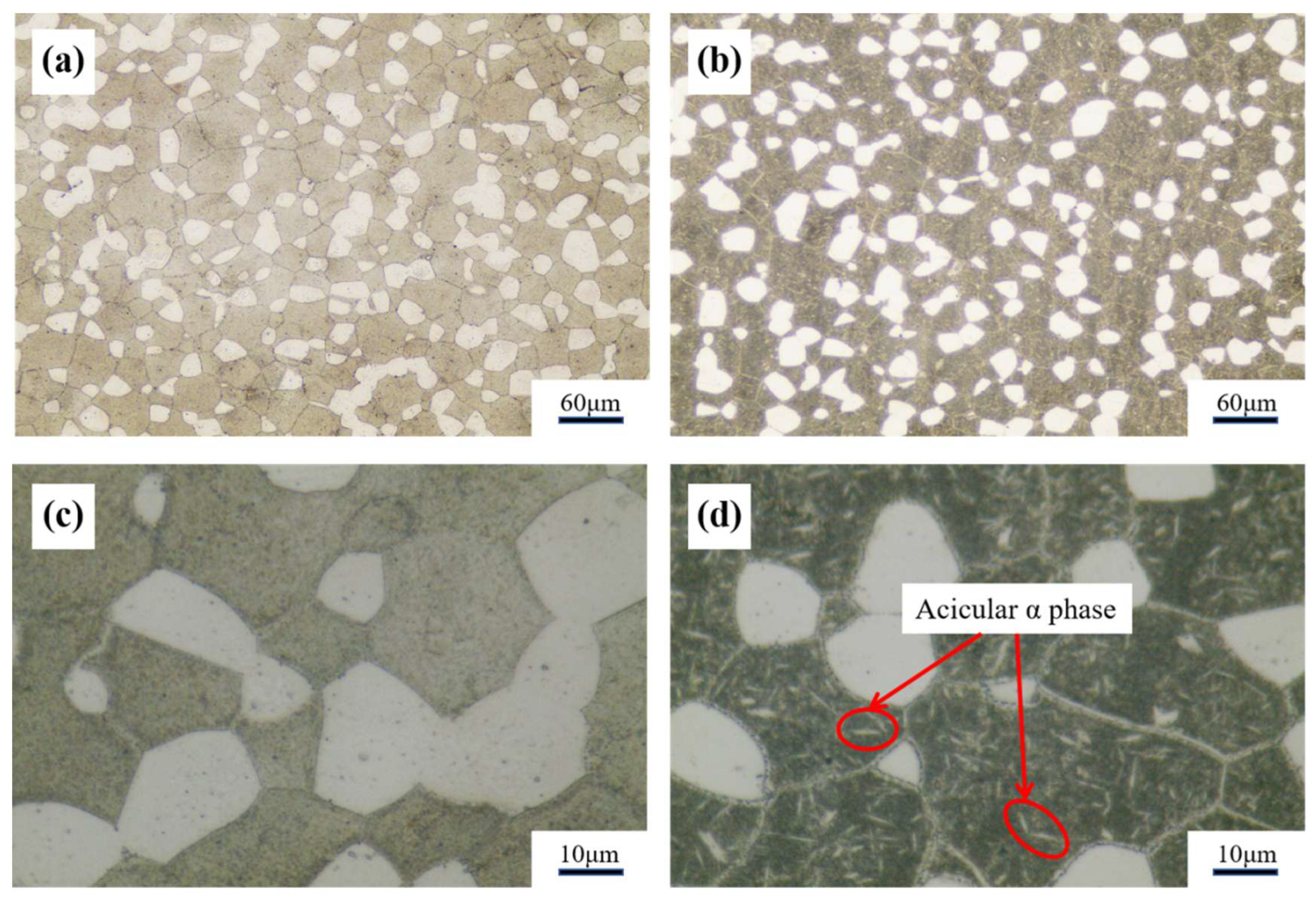

3.1. Microstructural Analysis of the BM and SZ

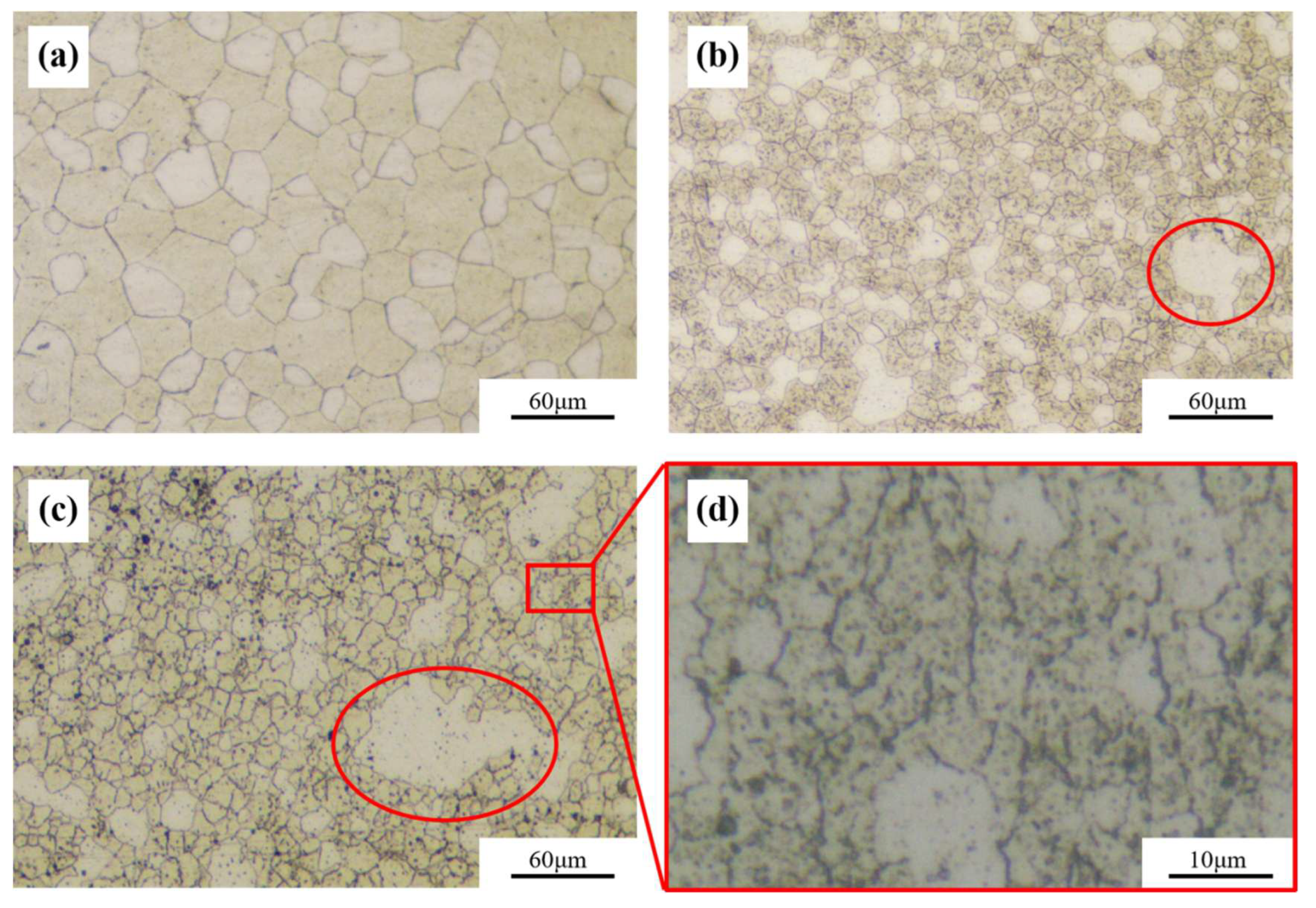

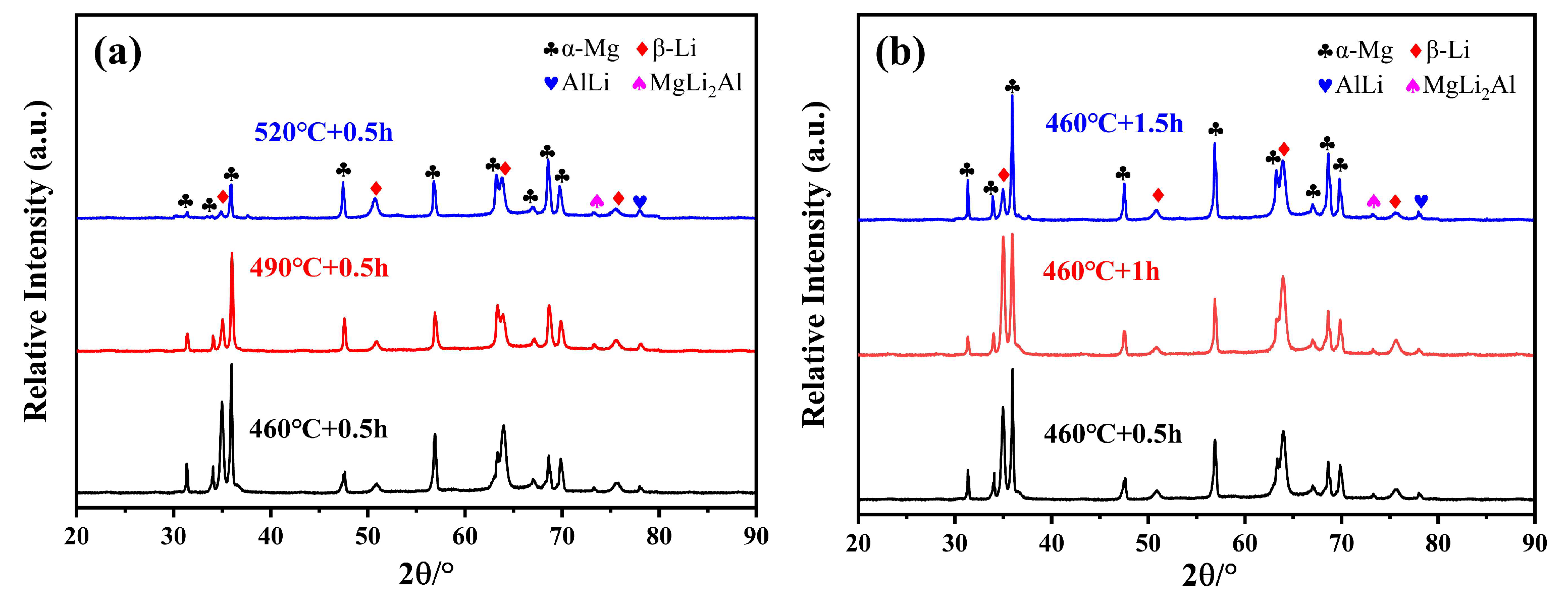

3.2. Effect of Heat Treatment on the Microstructure and Properties of the SZ

3.3. Effect of Artificial Aging on the Microstructure and Properties of the SZ

4. Conclusions

- (1)

- The hot-rolled LAZ931 Mg-Li alloy manifests a dual-phase microstructure comprising α-Mg and β-Li matrices with dispersed AlLi intermetallic particulates. The BM exhibits an average microhardness of 63.7 HV, with phase-specific values of 69.3 HV (α-phase) and 61.9 HV (β-phase), correlating with their respective crystallographic packing densities. FSP enhances the composite hardness to 67.1 HV through synergistic grain refinement (10–20 μm equiaxed grains) and strain-induced strengthening mechanisms.

- (2)

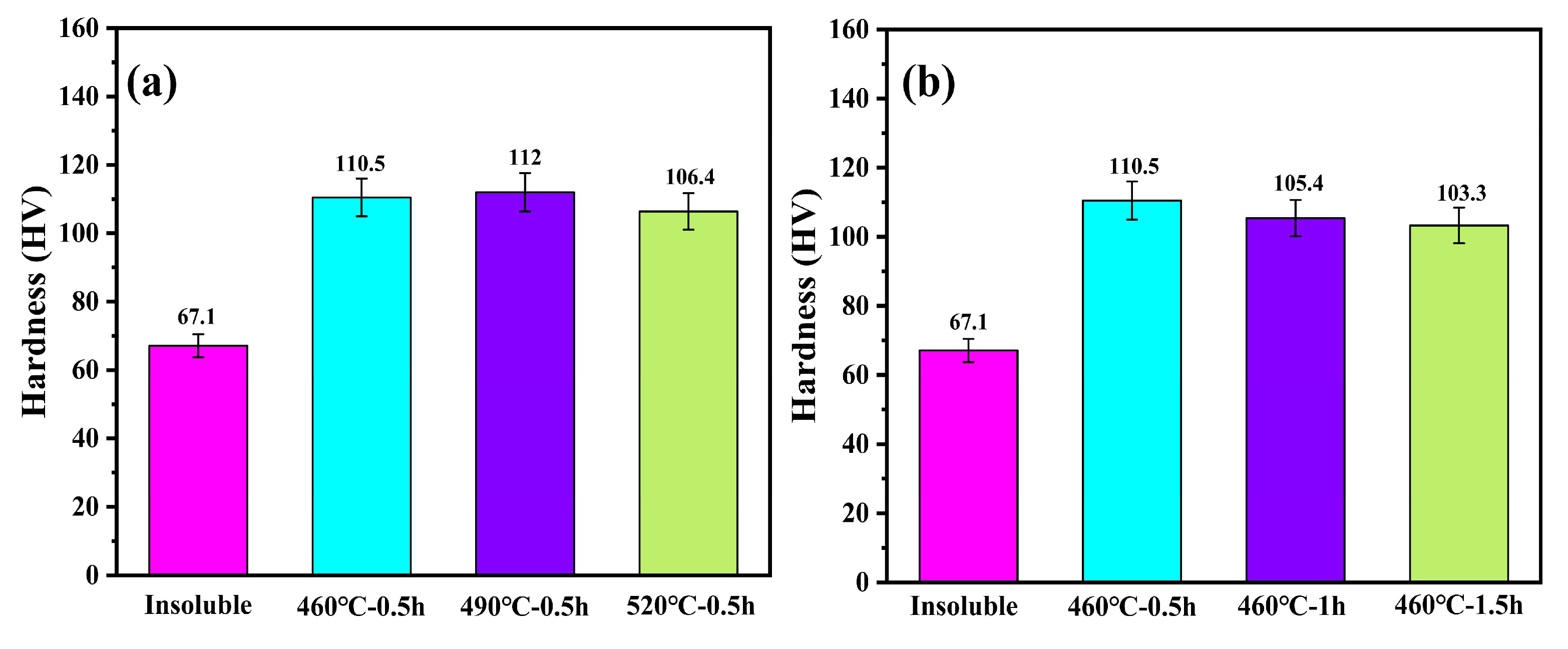

- Isothermal solution treatment at 460 °C for 0.5 h achieves near-complete dissolution of secondary phases, yielding a homogenized microstructure with a hardness of 110.5 HV. Peak hardness (112 HV) occurs at 490 °C, concomitant with nanoscale precipitate formation. Elevated temperatures induce deleterious grain coarsening and incipient melting, resulting in mechanical degradation. Microstructural optimization is attained at 460 °C, balancing dissolution kinetics and precipitate suppression.

- (3)

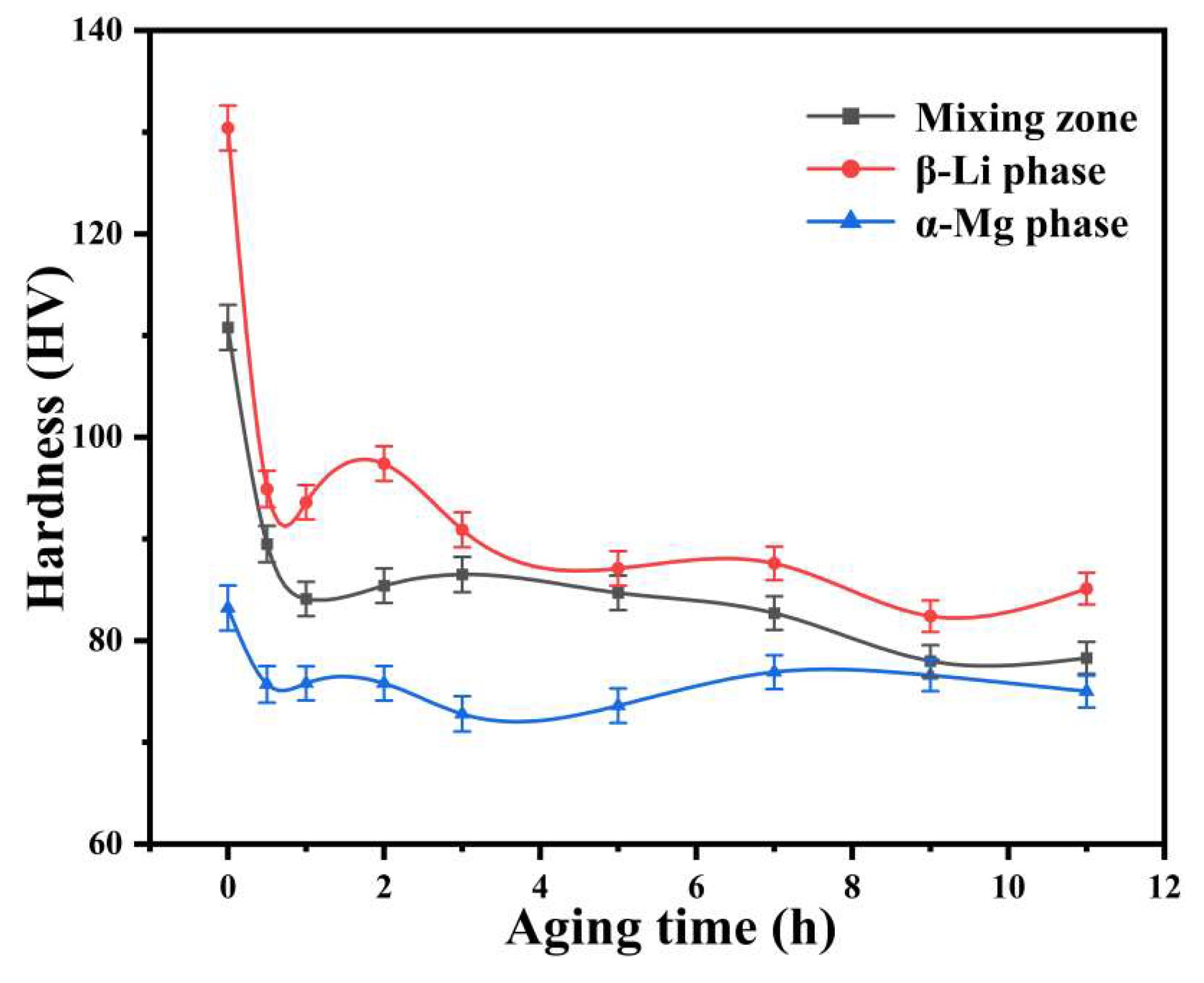

- Artificial aging at 125 °C demonstrates suboptimal strengthening efficacy, with aged hardness values consistently below solution-treated benchmarks. A transient hardness maximum of 86.5 HV is achieved after 3 h, followed by progressive softening attributable to over-aging phenomena—specifically, the transformation of metastable zones into coarse equilibrium precipitates with reduced strengthening contributions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tian, G.; Wang, J.; Wang, S.; Xue, C.; Yang, X.; Su, H. An ultra-light Mg-Li alloy with exceptional elastic modulus, high strength, and corrosion-resistance. Mater. Today Commun. 2023, 35, 105623. [Google Scholar] [CrossRef]

- Wang, G.; Song, D.; Li, C.; Klu, E.E.; Qiao, Y.; Sun, J.; Jiang, J.; Ma, A. Developing Improved Mechanical Property and Corrosion Resistance of Mg-9Li Alloy via Solid-Solution Treatment. Metals 2019, 9, 920. [Google Scholar] [CrossRef]

- Gao, S.; Zhao, H.; Li, G.; Ma, L.; Zhou, L.; Zeng, R.; Li, D. Microstructure, properties and natural ageing behavior of friction stir welded dual-phase Mg-Li alloy. J. Mater. Process. Technol. 2024, 324, 118252. [Google Scholar] [CrossRef]

- Liu, D.; Zong, X.; Xue, P.; Zhang, Y.; Zhou, H.; Gao, Z.; Wang, R.; Lu, B. Comprehensive study on the differences in microstructure and mechanical properties of Mg-Li alloy fabricated by additive manufacturing, casting, and rolling. J. Mater. Res. Technol. 2024, 31, 4128–4138. [Google Scholar] [CrossRef]

- Cui, S.; Cao, W.; Zhang, Q.; Wang, L.; Sun, Y.; Guan, S. Material Flow and Microstructural Evolution in Friction Stir Welding of LAZ931 Duplex Mg-Li Alloys. Metals 2024, 14, 1305. [Google Scholar] [CrossRef]

- Zhou, Z.; Ouyang, Y.; Guo, E.; Li, B.; Qiu, R.; Kang, H.; Chen, Z.; Wang, T. Biomimetic super-hydrophobic matrix constructed on a buffer aluminum layer: A compositing coating for Mg-Li alloy corrosion inhibition. Colloid. Surface. A. 2023, 676, 132268. [Google Scholar] [CrossRef]

- Mou, F.; Wang, Z.; Zeng, H.; Ma, Y.; Guo, F.; Chai, L.; She, Z.; Zhang, L. Fabricating a corrosion-protective Li2CO3/Mg(OH)2 composite film on LA141 magnesium-lithium alloy by hydrothermal method. Surf. Coat. Tech. 2023, 472, 129939. [Google Scholar] [CrossRef]

- Liu, S.; Qian, X.; Zou, Y. Role of heat treatment temperatures on mechanical properties and corrosion resistance properties of Mg-10.16Li-8.14Al-1.46Er alloy. Res. Appl. Mater. Sci. 2022, 3, 2. [Google Scholar] [CrossRef]

- Lin, H.; Wu, R.S.; Fei, P.; Leng, Z.; Guo, X.H.; Zhang, J.; Liu, B.; Zhang, M. The solution and aging behavior of Mg-8Li-3Al-xCe (x=0, 1.0) alloys. Kovove Mater. 2016, 52, 47–55. [Google Scholar] [CrossRef][Green Version]

- Li, Y.; Lu, Z.; Liu, S.; Li, D.; Zou, Y. Effect of Heat Treatment on Low-Cycle Fatigue Performance of LZ91 Mg–Li Alloy. Adv. Eng. Mater. 2021, 23, 2100281. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, B.; Wu, R.; Zhou, Y.; Wu, Q. Nanocrystalline strengthened Mg-Li alloy with a bcc structure prepared via heat treatment and rolling. Mater. Lett. 2022, 312, 131680. [Google Scholar] [CrossRef]

- Pahlavani, M.; Marzbanrad, J.; Rahmatabadi, D.; Hashemi, R.; Bayati, A. A comprehensive study on the effect of heat treatment on the fracture behaviors and structural properties of Mg-Li alloys using RSM. Mater. Res. 2019, 6, 076554. [Google Scholar] [CrossRef]

- Li, Y.; Liu, J.W.; Dai, M.H.; Zhang, Y.; Yao, J. Constitutive model and microstructure evolution of LZ91 magnesium lithium alloy during hot deformation. Trans. Mater. Heat. Treat. 2021, 42, 167–174. [Google Scholar]

- Zhu, Y.; Chen, G.; Zhou, Y.; Shi, Q.; Zhou, M. Achieving synergistic strength-ductility-corrosion optimization in Mg-Li-Al-Zn alloy via cross-pass friction stir processing. J. Alloys Compd. 2023, 959, 170581. [Google Scholar] [CrossRef]

- Li, B.; Sun, X.; Chen, H.; Yang, Y.; Luo, Q.; Yang, X.; Chen, Y.; Wei, G.; Li, Q.; Pan, F. Enhancing Mg-Li alloy hydrogen storage kinetics by adding molecular sieve via friction stir processing. J. Mater. Sci. Technol. 2024, 180, 45–54. [Google Scholar] [CrossRef]

- Cao, F.; Xiang, C.; Kong, S.; Guo, N.; Shang, H. Room Temperature Strengthening and High-Temperature Super plasticity of Mg-Li-Al-Sr-Y Alloy Fabricated by Asymmetric Rolling and Friction Stir Processing. Materials 2023, 16, 2345. [Google Scholar] [CrossRef]

- Hu, K.; Guan, Y.; Zhai, J.; Li, Y.; Chen, F.; Liu, Y.; Lin, J. Effect on microstructure and properties of LA103Z Mg-Li alloy plate by multi-pass friction stir processing. J. Mater. Res. Technol. 2022, 20, 3985–3994. [Google Scholar] [CrossRef]

- Xu, L.; Wang, J.; Wu, R.; Zhang, C.; Wu, H.; Hou, L.; Zhang, J. High specific strength MWCNTs/Mg-14Li-1Al composite prepared by electrophoretic deposition, friction stir processing and cold rolling. T. Nonferr. Metal. Soc. 2022, 32, 3914–3925. [Google Scholar] [CrossRef]

- Li, Y.; Guan, Y.; Liu, Y.; Zhai, J.; Hu, K.; Lin, J. Effect of processing parameters on the microstructure and tensile properties of a dual-phase Mg-Li alloy during friction stir processing. J. Mater. Res. Technol. 2022, 17, 2714–2724. [Google Scholar] [CrossRef]

- Li, Y.; Guan, Y.; Liu, Y.; Zhai, J.; Hu, K.; Lin, J. Microstructure and tensile properties of the friction stir processed LA103Z alloy. Mater. Charact. 2023, 196, 112616. [Google Scholar] [CrossRef]

- Song, W.; Wu, Z.; He, S.; Liu, J.; Yang, G.; Liu, Y.; Jin, H.; He, Y.; Heng, Z. Effects of Friction Stir Processing on the Microstructure and Mechanical Properties of an Ultralight Mg-Li Alloy. Crystals 2024, 14, 64. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhou, M.; Geng, Y.; Zhang, S.; Xin, T.; Chen, G.; Zhou, Y.; Zhou, X.; Wu, R.; Shi, Q. Microstructural evolution and its influence on mechanical and corrosion behaviors in a high-Al/Zn containing duplex Mg-Li alloy after friction stir processing. J. Mater. Sci. Technol. 2024, 184, 245–255. [Google Scholar] [CrossRef]

- Zheng, D.; Ma, H.; Fu, H.; Zeng, L.; Li, C.; Liu, Q.; Peng, F.; Lv, T.; Zhu, S.; Jiang, Y. Effect of solid solution treatment on biomedical Mg-Li alloy with high Zn content. Mater. Lett. 2024, 363, 136309. [Google Scholar] [CrossRef]

- Wang, J.; Sun, D.; Wu, R.; Du, C.; Yang, Z.; Zhang, J.; Hou, L. A good balance between mechanical properties and electromagnetic shielding effectiveness in Mg-9Li-3Al-1Zn alloy. Mater. Charact. 2022, 188, 111888. [Google Scholar] [CrossRef]

- Su, H.; Wang, J.; Li, Y.; Xue, C.; Tian, G.; Wang, S.; Yang, X.; Li, Q.; Yang, Z.; Dou, R. Effective strategies for improving the mechanical stability of aged Mg-Li alloys. Mater. Des. 2024, 244, 113180. [Google Scholar] [CrossRef]

- Peng, X.; Liu, W.; Wu, G.; Ji, H.; Ding, W. Plastic deformation and heat treatment of Mg-Li alloys: A review. J. Mater. Sci. Technol. 2022, 99, 193–206. [Google Scholar] [CrossRef]

- Ji, H.; Peng, X.; Zhang, X.; Liu, W.; Wu, G.; Zhang, L.; Ding, W. Balance of mechanical properties of Mg-8Li-3Al-2Zn-0.5Y alloy by solution and low-temperature aging treatment. J. Alloys Compd. 2019, 791, 655–664. [Google Scholar] [CrossRef]

- Zhang, Q.; Xie, H.; Huang, L.; Wang, L.; Sun, Y.; Guan, S. Microstructure and Mechanical Properties of Friction Stir Welded LAZ931 Duplex Mg-Li Alloy Plates. J. Mater. Eng. Perform. 2024, 33, 12171–12180. [Google Scholar] [CrossRef]

- Ding, Z.; Li, Z.; Li, H.; Chen, Y. Microstructure of Mg solid solution layer during multi-pass FSP of Mg/Al Composite Plates. Vacuum 2020, 172, 109078. [Google Scholar] [CrossRef]

- Maurya, R.; Mittal, D.; Balani, K. Effect of heat-treatment on microstructure, mechanical and tribological properties of Mg-Li-Al based alloy. J. Mater. Res. Technol. 2020, 9, 4749–4762. [Google Scholar] [CrossRef]

- Peng, P.; Yan, X.; Zheng, W.; Xu, Y.; Zhang, X.; Ma, Z.; Zhang, H. Microstructure and mechanical properties of heat-treated Mg-6.2Li-3.5Al-3Y alloy. Mater. Sci. Eng. A 2022, 857, 144039. [Google Scholar] [CrossRef]

- Jiang, L.; Bai, Y.; Jiang, W.; Guo, F.; Huang, W.; Wang, F.; Chai, L.; Chen, X.; Xu, A. Obtaining ultra-fine and uniform two-phase structures: Evolution of morphology and phase redistribution in a dual-phase Mg–Li alloy during submerged friction stir processing. Mater. Sci. Eng. A 2024, 895, 146238. [Google Scholar] [CrossRef]

- Hou, Y.; Liu, C.; Zhang, B.; Wei, L.; Dai, H.; Ma, Z. Mechanical properties and corrosion resistance of the fine grain structure of Al-Zn-Mg-Sc alloys fabricated by friction stir processing and post-heat treatment. Mater. Sci. Eng. A 2020, 785, 139393. [Google Scholar] [CrossRef]

- Zeng, Z.; Zhou, M.; Esmaily, M.; Zhu, Y.; Choudhary, S.; Griffith, J.C.; Ma, J.; Hora, Y.; Chen, Y.; Gullino, A.; et al. Corrosion resistant and high-strength dual-phase Mg-Li-Al-Zn alloy by friction stir processing. Commun. Mater. 2022, 3, 18. [Google Scholar] [CrossRef]

- Ji, H.; Wu, G.; Liu, W.; Zhang, X.; Zhang, L.; Wang, M. Origin of the age-hardening and age-softening response in Mg-Li-Zn based alloys. Acta Mater. 2022, 226, 117673. [Google Scholar] [CrossRef]

- Chi, Y.; Zheng, M.; Xu, C.; Du, Y.; Qiao, X.; Wu, K.; Liu, X.; Wang, G.; Lv, X. Effect of ageing treatment on the microstructure, texture and mechanical properties of extruded Mg-8.2Gd-3.8Y-1Zn-0.4Zr (wt%) alloy. Mater. Sci. Eng. A 2013, 565, 112–117. [Google Scholar] [CrossRef]

- Liu, L.; Wu, G. Effects of Nd/YAl2 on aging behavior of Mg-8Li-3Al-RE alloys. Mater. Today Commun. 2023, 38, 107922. [Google Scholar] [CrossRef]

- Cain, T.; Labukas, J. The development of β phase Mg-Li alloys for ultralight corrosion resistant applications. NPJ Mater. Degrad. 2020, 4, 17. [Google Scholar] [CrossRef]

| Alloy Composition | Li | Al | Zn | Mn | Si | Mg |

|---|---|---|---|---|---|---|

| Content (wt.%) | 8.90 | 3.15 | 0.90 | 0.02 | 0.02 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, Z.; Xu, S.; Wang, Z.; Sun, Y. Effect of Solution and Aging Treatment on the Microstructure and Properties of LAZ931 Mg-Li Alloy by Friction Stir Processing. Metals 2025, 15, 314. https://doi.org/10.3390/met15030314

Fang Z, Xu S, Wang Z, Sun Y. Effect of Solution and Aging Treatment on the Microstructure and Properties of LAZ931 Mg-Li Alloy by Friction Stir Processing. Metals. 2025; 15(3):314. https://doi.org/10.3390/met15030314

Chicago/Turabian StyleFang, Zhe, Shuaiwei Xu, Zhixin Wang, and Yufeng Sun. 2025. "Effect of Solution and Aging Treatment on the Microstructure and Properties of LAZ931 Mg-Li Alloy by Friction Stir Processing" Metals 15, no. 3: 314. https://doi.org/10.3390/met15030314

APA StyleFang, Z., Xu, S., Wang, Z., & Sun, Y. (2025). Effect of Solution and Aging Treatment on the Microstructure and Properties of LAZ931 Mg-Li Alloy by Friction Stir Processing. Metals, 15(3), 314. https://doi.org/10.3390/met15030314