Microstructural Characterization and Mechanical Properties of AA5083/Coal Composites Fabricated by Friction Stir Processing

Abstract

1. Introduction

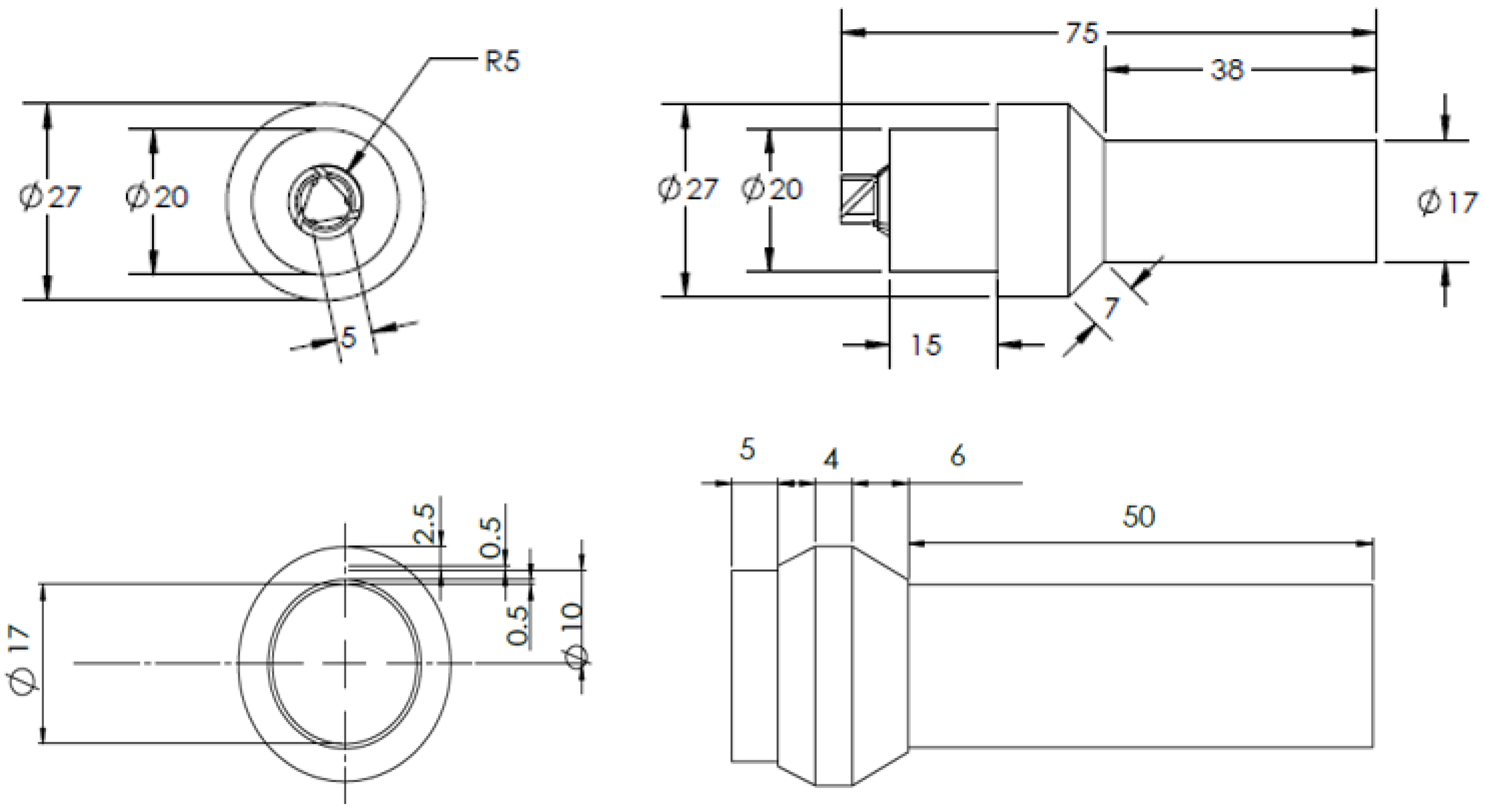

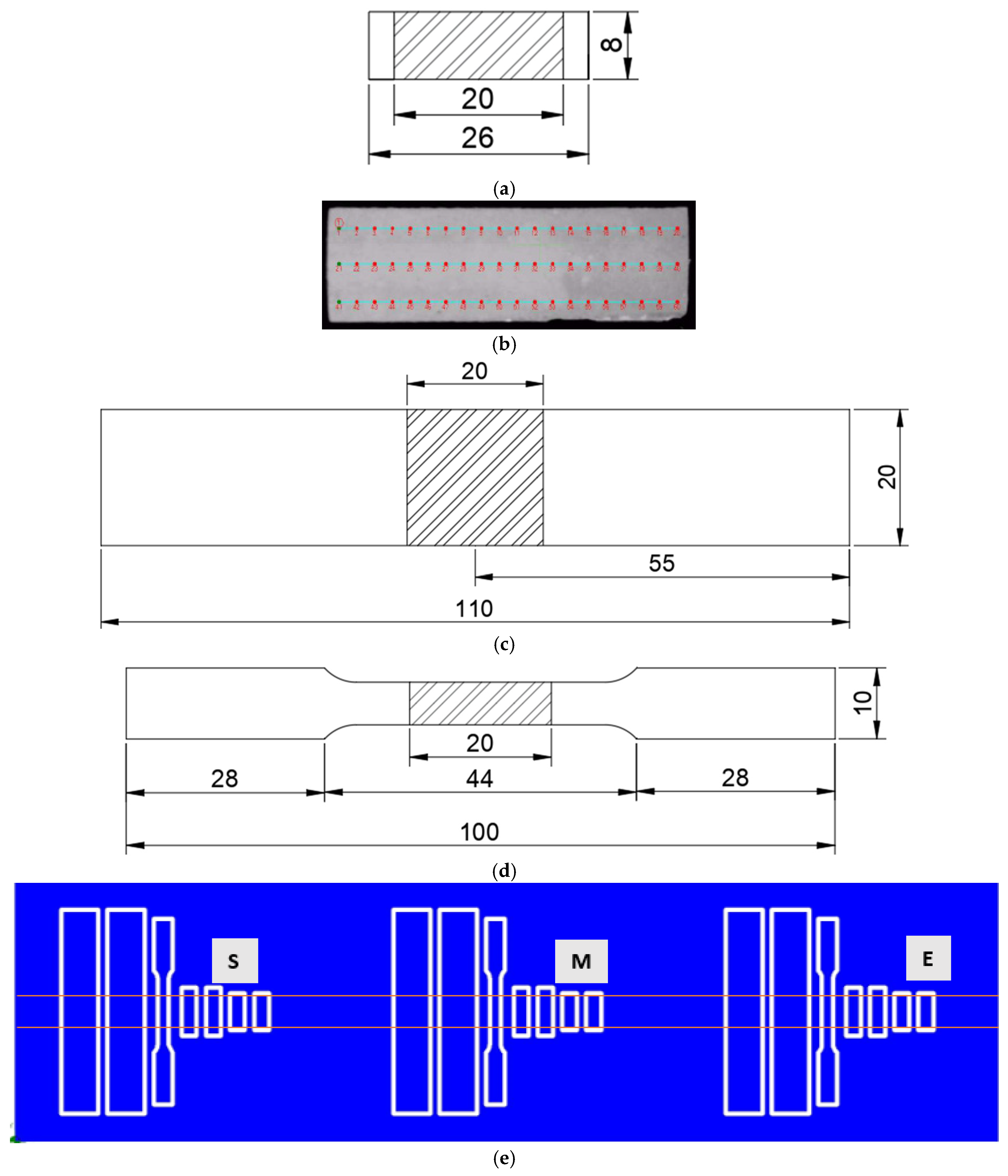

2. Experimental Procedure

3. Results and Discussion

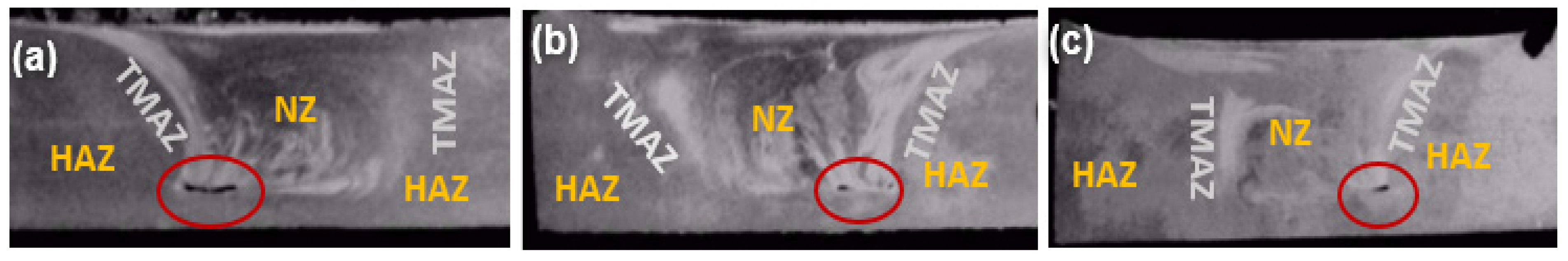

3.1. Macrostructural Analysis

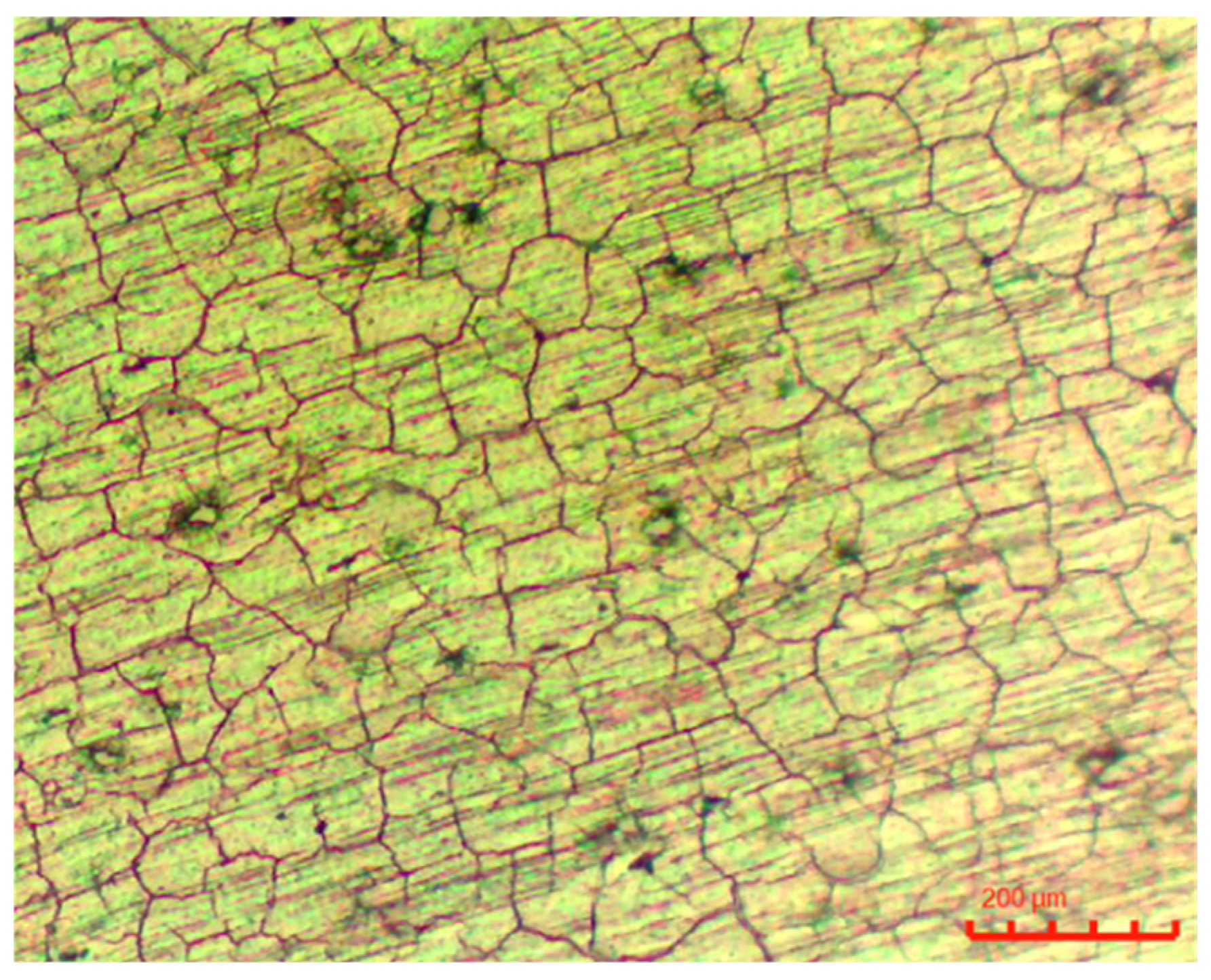

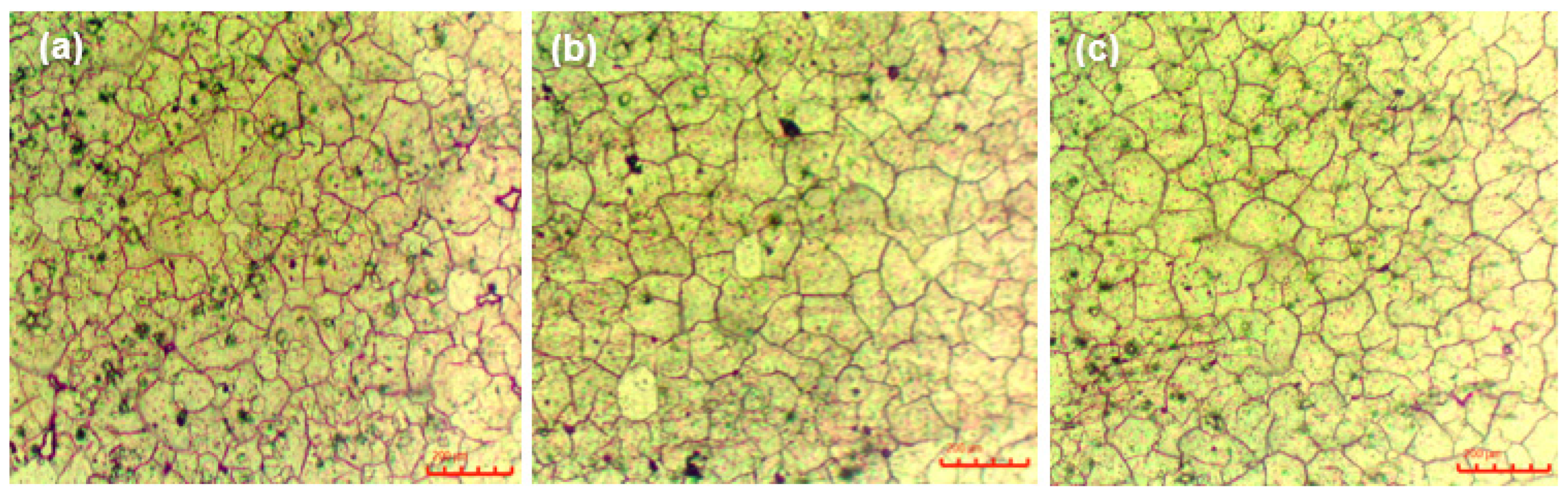

3.2. Microstructural Analysis

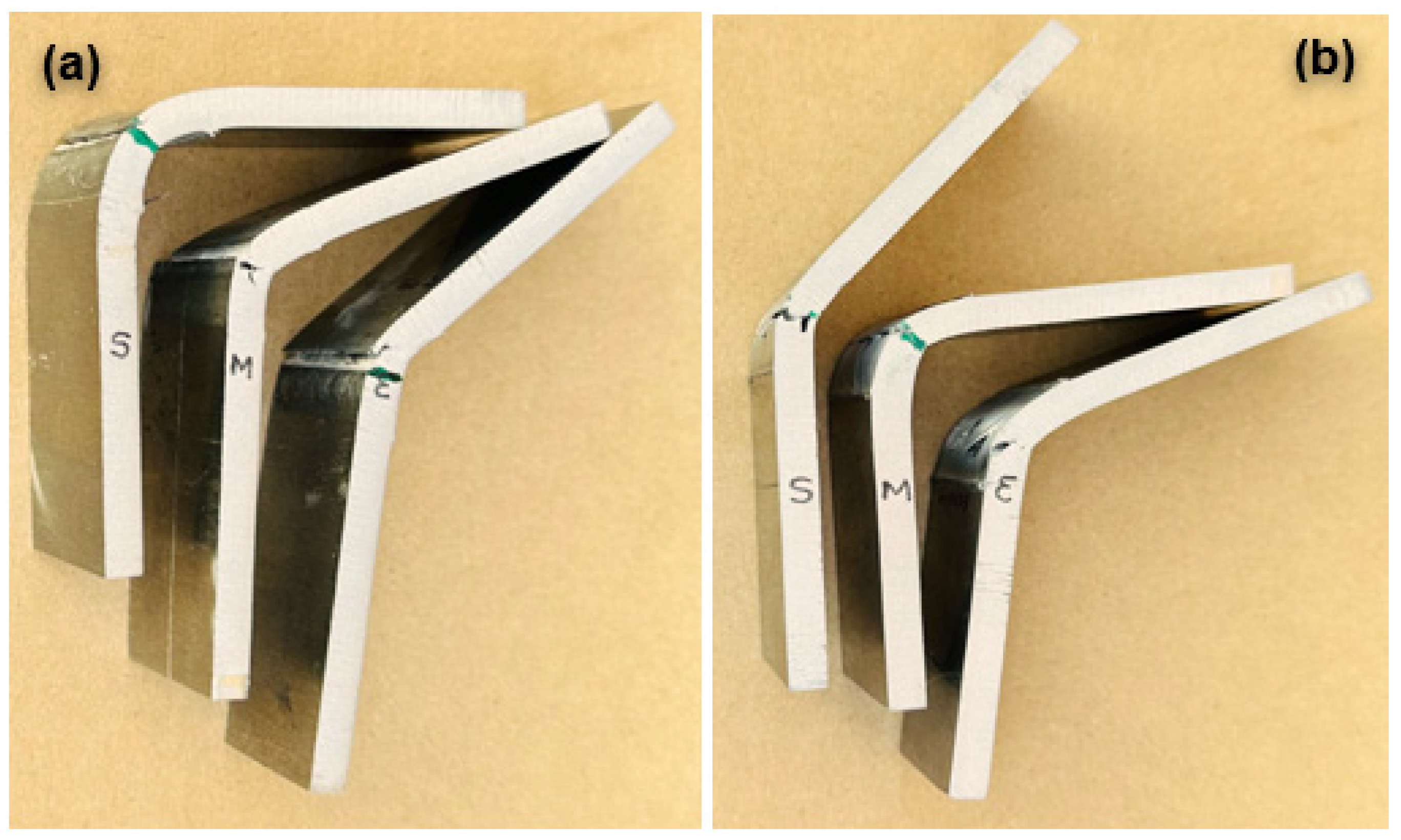

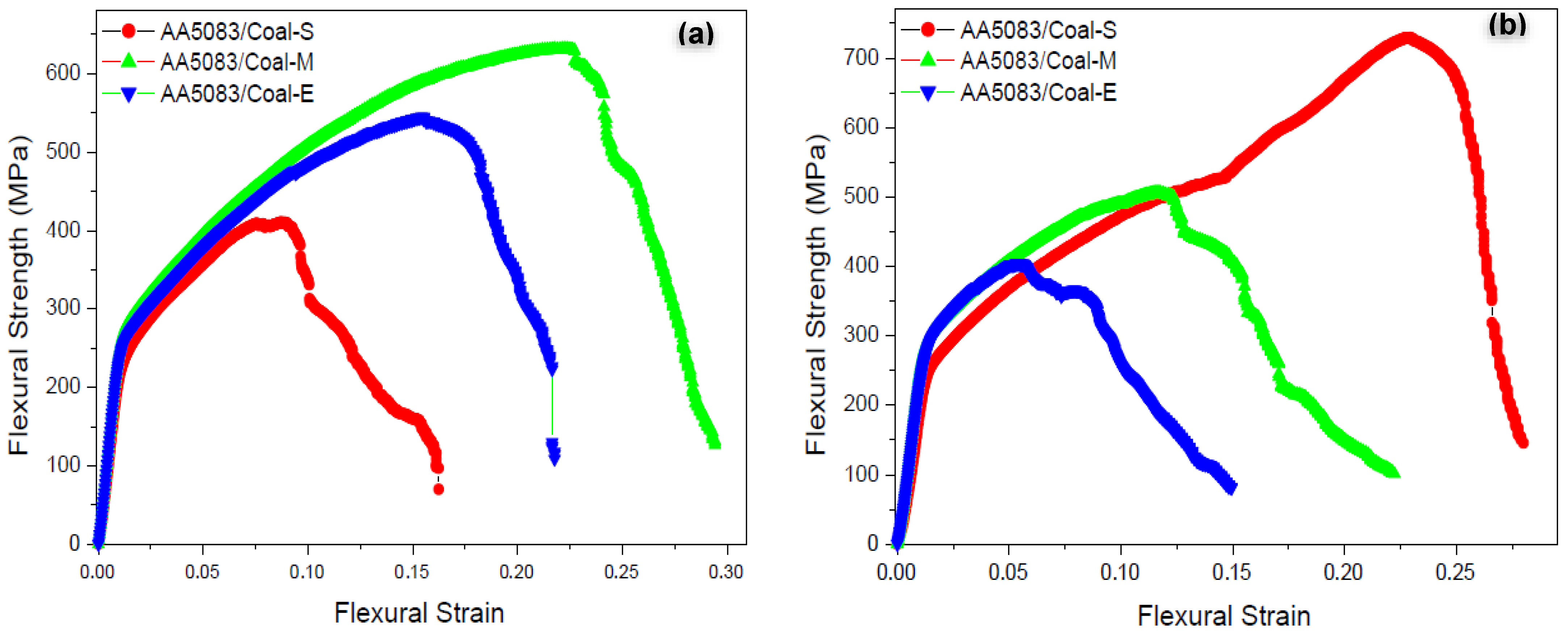

3.3. Flexural Properties

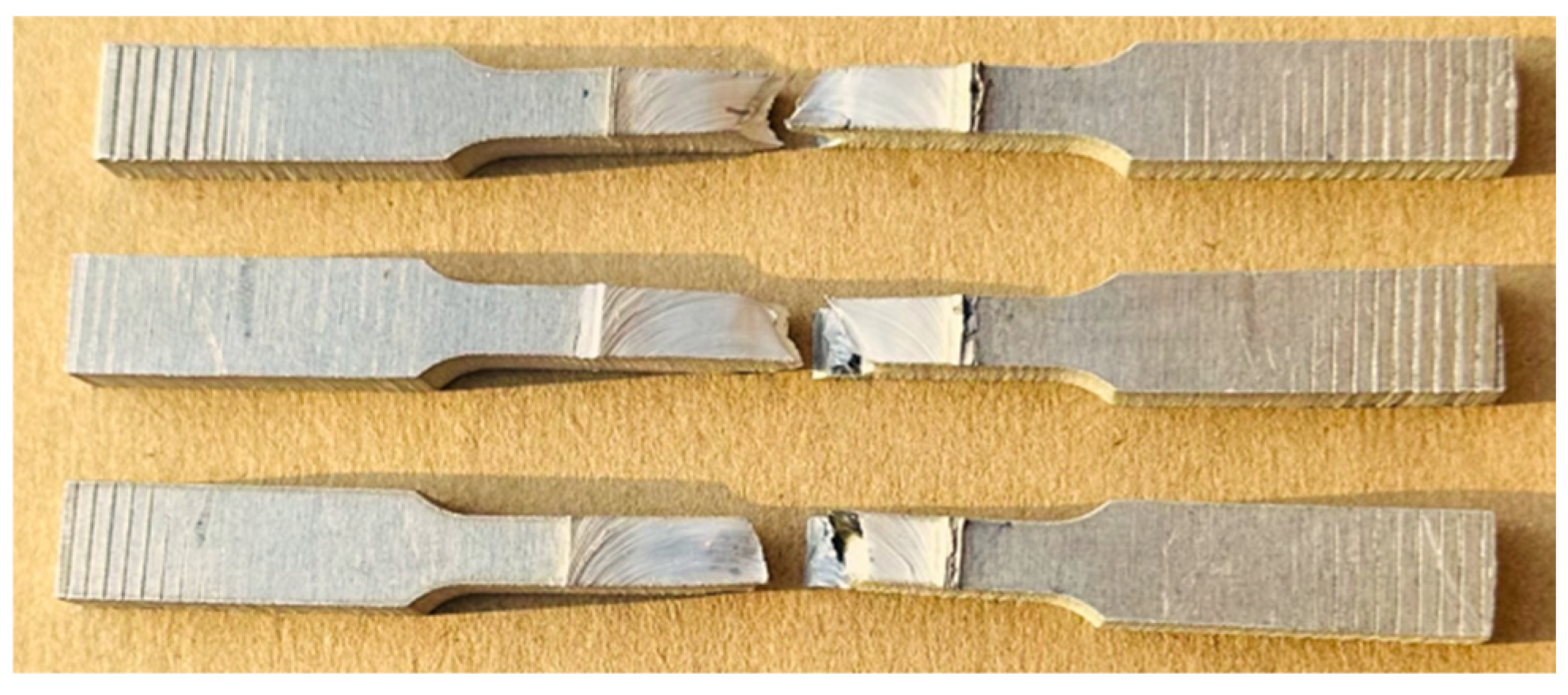

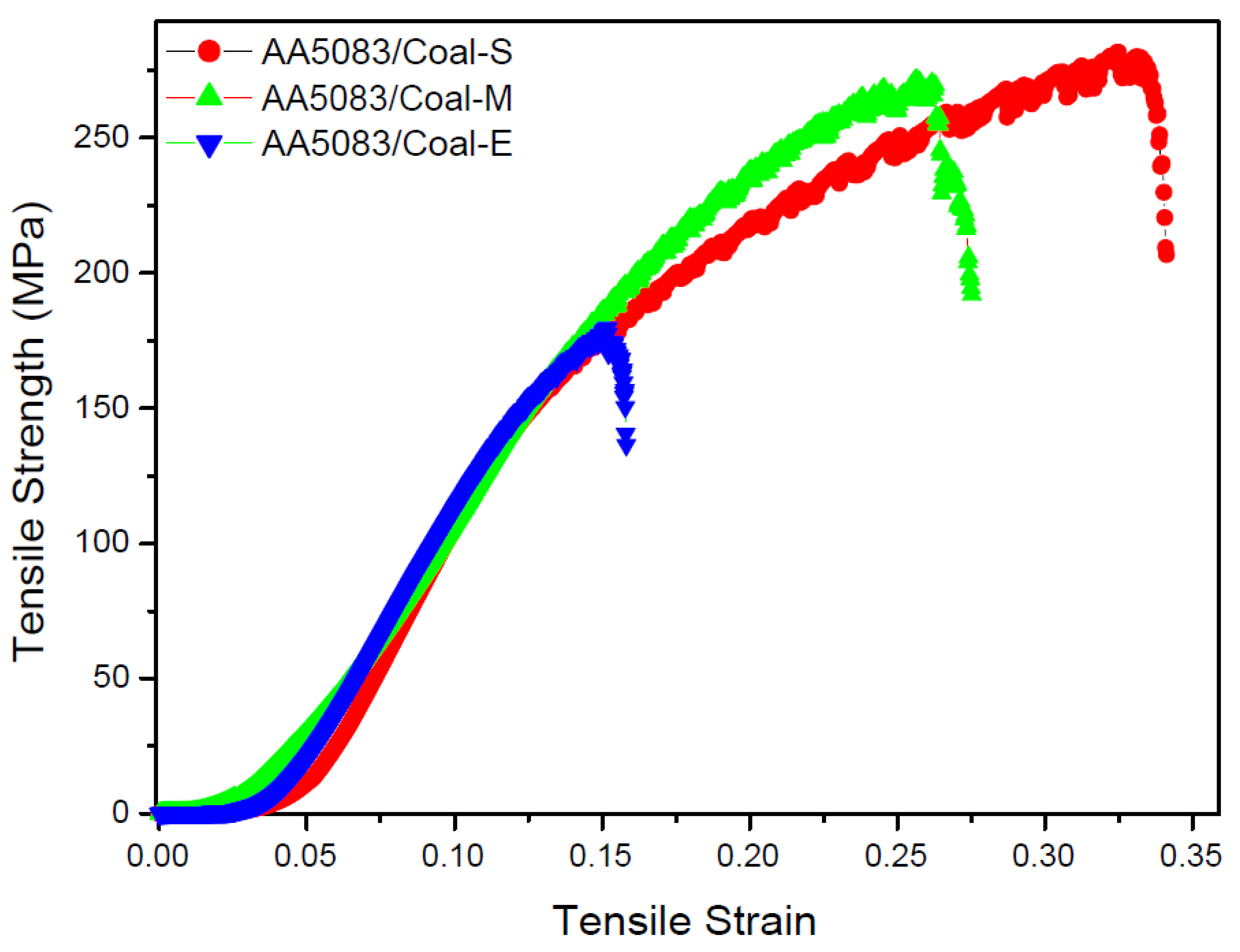

3.4. Tensile Properties

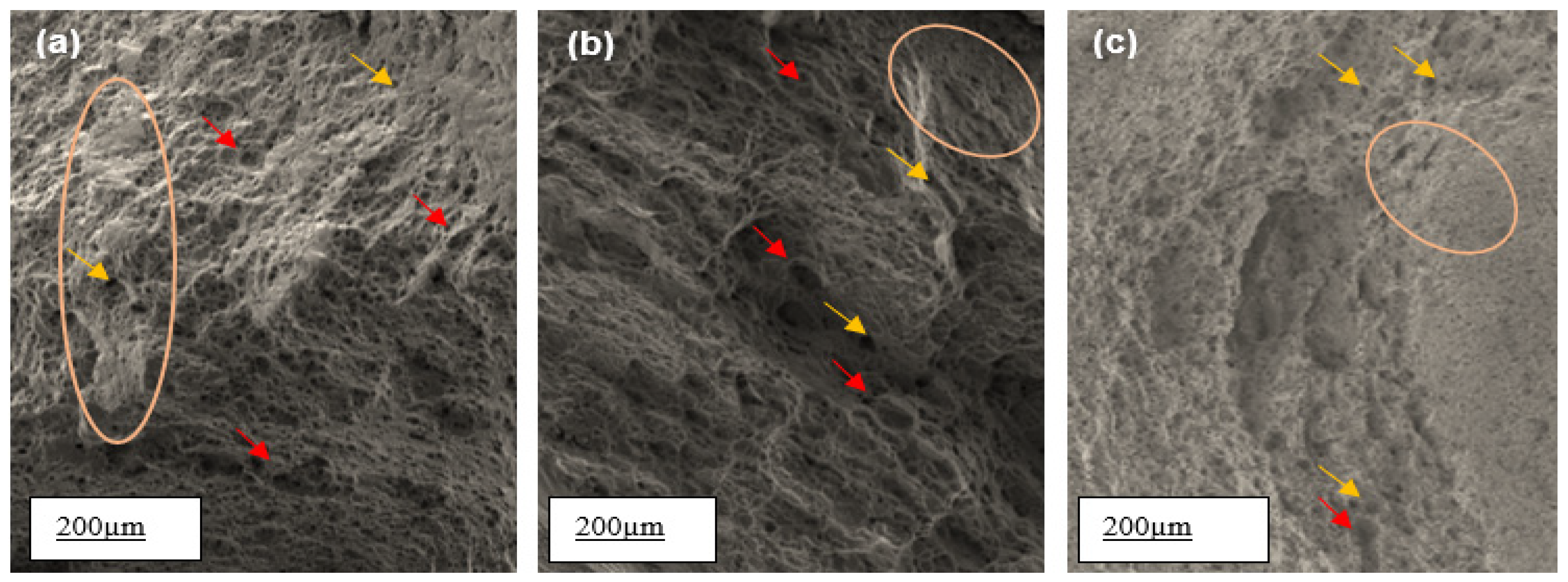

3.5. Fractography

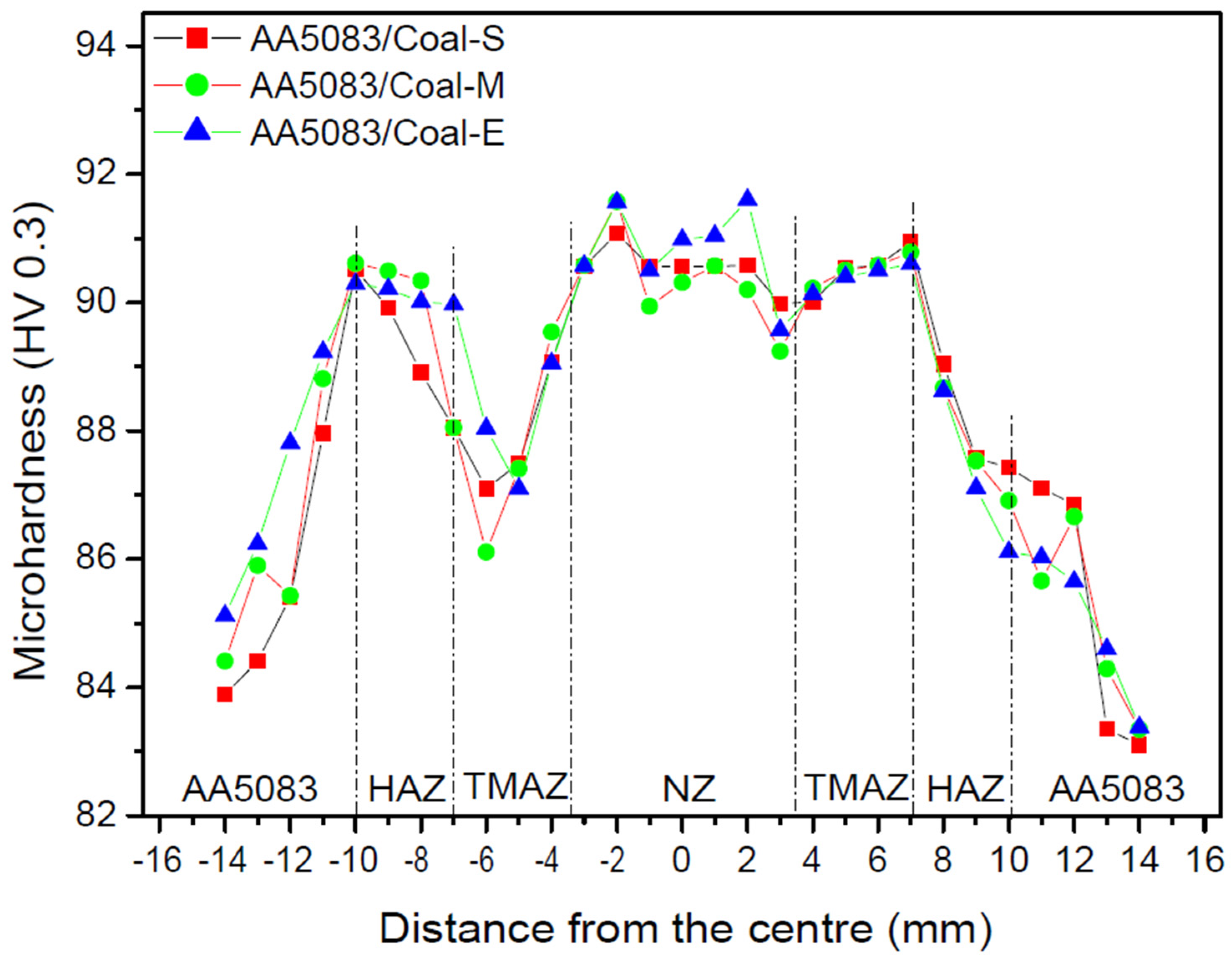

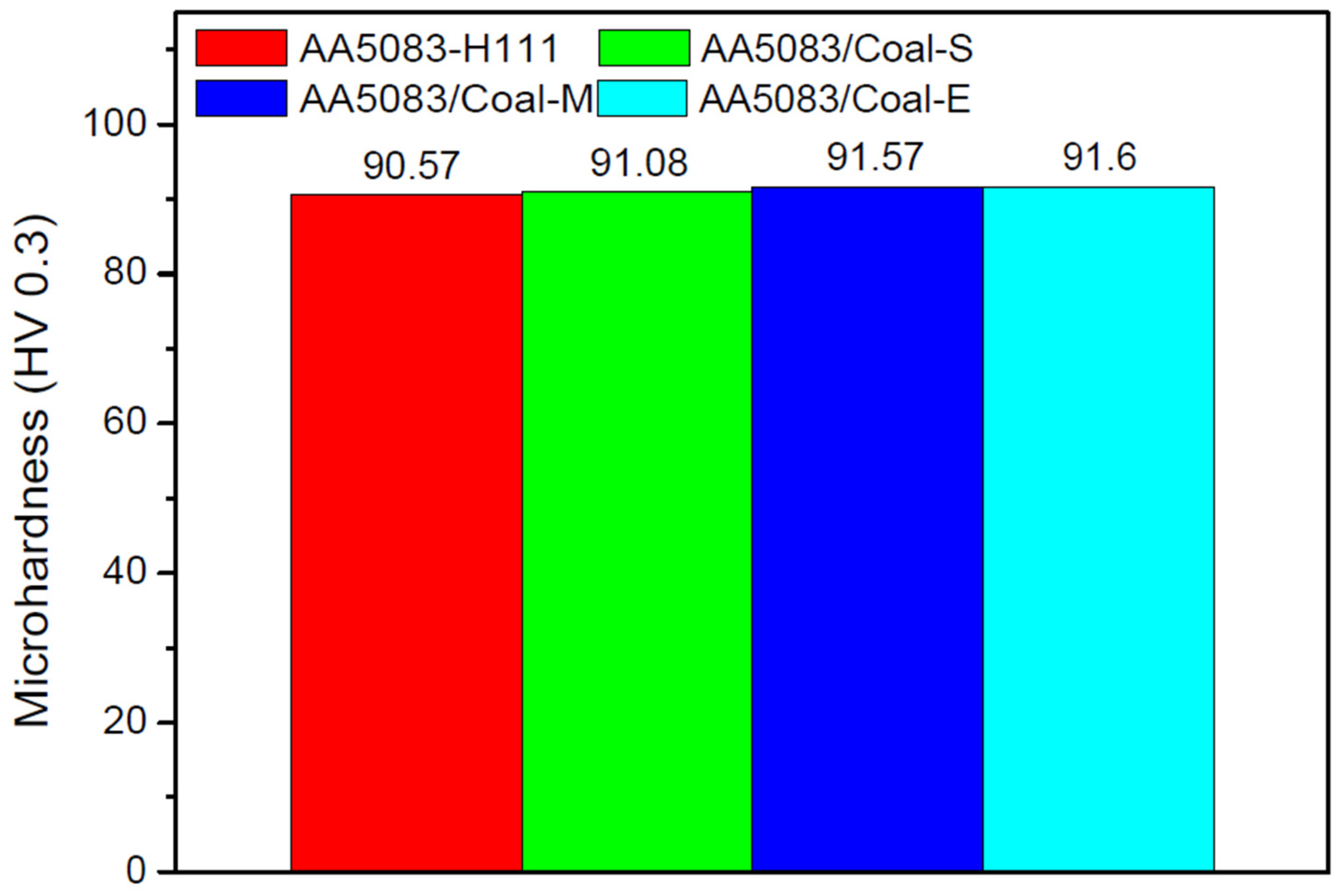

3.6. Microhardness

4. Conclusions

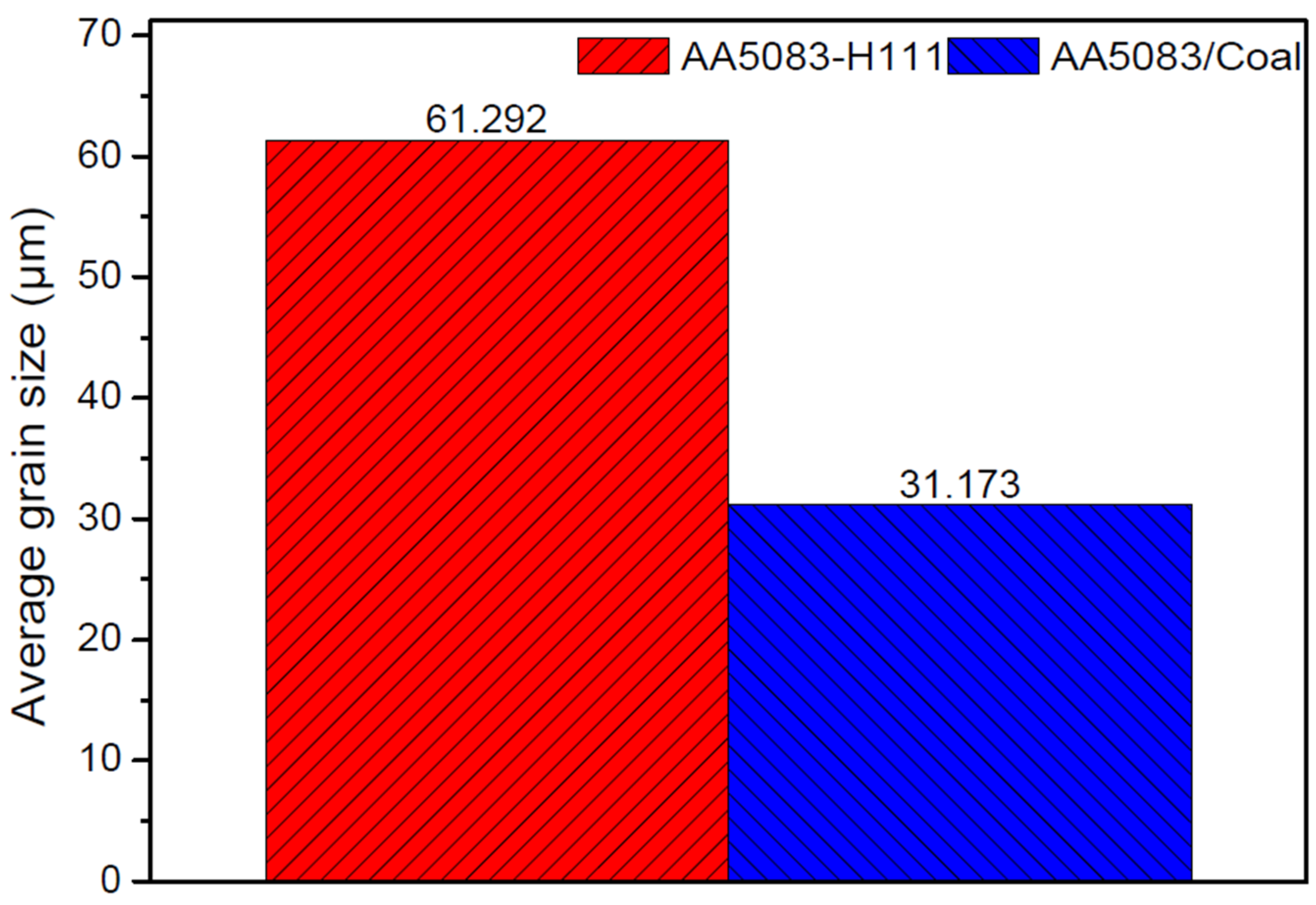

- Microstructure: FSP effectively induced dynamic recrystallization in the AA5083/coal composite joints, leading to significant grain refinement in the nugget zone due to dynamic recrystallization and coal particle presence. However, challenges remain in achieving uniform coal distribution, with agglomeration observed in some areas. The average grain size of the composite joints was 31.173 μm, representing a 50.86% reduction compared to the base material (61.292 µm).

- Tensile Properties: The AA5083/Coal composite achieved a maximum ultimate tensile strength (UTS) of 280 MPa and a corresponding tensile strain rate of 33.48%. This represents a 21.3% decrease compared to the base material’s UTS of 311 MPa. Despite this reduction, the composite’s tensile properties remain comparable to the base material. Overall, the tensile tests showed variations in strength across the joint, possibly due to inconsistent coal distribution and porosity.

- Hardness: The inclusion of coal particles increased the hardness of the composite substantially when compared to the base material. The average hardness of the AA5083/Coal composite joints was 91.42 HV, indicating a significant increase in hardness. A 50% reduction in grain size should, according to the Hall–Petch relationship, lead to a noticeable increase in hardness. The fact that the hardness only increased by roughly 1% (91.42 HV vs. 90.57 HV) suggests that other factors are counteracting the strengthening effect of grain refinement.

- Flexural Properties: Flexural strength was significantly higher in the composite, particularly in face specimens, indicating enhanced load-bearing capacity. The greatest UFS for face specimens was 747.53 MPa, whereas root specimens reached 631.95 MPa.

- Failure Mechanisms: Agglomeration of coal particles within the nugget zone was identified as a major contributor to strength reduction. Agglomerates acted as stress concentrators, initiating cracks and leading to premature failure. The composite’s mechanical properties were significantly reduced due to the non-uniform particle dispersion.

5. Limitations and Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rajan, T.P.D.; Pillai, R.M.; Pai, B.C. Reinforcement coatings and interfaces in aluminium metal matrix composites. J. Mater. Sci. 1998, 33, 3491–3503. [Google Scholar] [CrossRef]

- Shanavas, S.; Edwin Raja Dhas, J.; Murugan, N. Weldability of marine grade AA 5052 aluminum alloy by underwater friction stir welding. J. Adv. Manuf. Technol. 2018, 95, 4535–4546. [Google Scholar] [CrossRef]

- Abioye, T.E.; Mustar, N.; Zuhailawati, H.; Suhaina, I. Prediction of the tensile strength of aluminium alloy 5052-H32 fibre laser weldments using regression analysis. J. Adv. Manuf. Technol. 2019, 102, 1951–1962. [Google Scholar] [CrossRef]

- Gafur, M.A.; Abrar, R.; Soshi, S.S. Development and characterization of aluminium-based metal matrix composites. MSA 2023, 14, 1–19. [Google Scholar] [CrossRef]

- Dolatkhah, A.; Golbabaei, P.; Givi, M.B.; Molaiekiya, F. Investigating effects of process parameters on microstructural and mechanical properties of Al5052/SiC metal matrix composite fabricated via friction stir processing. Mater. Des. 2012, 37, 458–464. [Google Scholar] [CrossRef]

- Shahraki, S.; Khorasani, S.; Abdi Behnagh, R.; Fotouhi, Y.; Bisadi, H. Producing of AA5083/ZrO2 nanocomposite by friction stir processing (FSP). MMTB 2013, 44, 1546–1553. [Google Scholar] [CrossRef]

- Jain, V.K.S.; Muhammed, P.M.; Muthukumaran, S.; Babu, S.P. Microstructure, mechanical and sliding wear behavior of AA5083–B4C/SiC/TiC surface composites fabricated using friction stir processing. Trans. Indian Inst. Met. 2018, 71, 1519–1529. [Google Scholar] [CrossRef]

- Karmiris-Obratański, P.; Papantoniou, I.G.; Leszczyńska-Madej, B. Microstructure, mechanical and tribological properties of AA5083-TiO2 nanocomposite by multi-pass friction stir processing. ACME 2024, 24, 209. [Google Scholar] [CrossRef]

- Shukla, S.; Komarasamy, M.; Mishra, R.S. Grain size dependence of fatigue properties of friction stir processed ultrafine-grained Al-5024 alloy. Int. J. Fatigue 2018, 109, 1–9. [Google Scholar] [CrossRef]

- Ma, Z.Y. Friction stir processing technology: A review. MMTA 2008, 39, 642–658. [Google Scholar] [CrossRef]

- Bagheri, B.; Abdollahzadeh, A.; Sharifi, F.; Abbasi, M. The role of vibration and pass number on microstructure and mechanical properties of AZ91/SiC composite layer during friction stir processing. Proc. Inst. Mech. Eng. 2022, 236, 2312–2326. [Google Scholar] [CrossRef]

- Jain, V.K.; Yadav, M.K.; Saxena, A.; Siddiquee, A.N.; Khan, Z.A. Effect of tool rotational speed on microstructure and mechanical properties of friction stir processed AA5083/Fe-Al in-situ composite. Mater. Today 2021, 46, 6496–6500. [Google Scholar] [CrossRef]

- Schmidt, H.; Hattel, J.; Wert, J. An analytical model for the heat generation in friction stir welding. Model. Simul. Mater. Sci. Eng. 2003, 12, 143. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Akinlabi, E.T.; Mahamood, R.M.; Akinlabi, S.A.; Ogunmuyiwa, E. Processing parameters influence on wear resistance behaviour of friction stir processed Al-TiC composites. Adv. Mater. Sci. Eng. 2014, 2014, 724590. [Google Scholar] [CrossRef]

- Devaraju, A.; Kumar, A.; Kotiveerachari, B. Influence of rotational speed and reinforcements on wear and mechanical properties of aluminum hybrid composites via friction stir processing. Mater. Des. 2013, 45, 576–585. [Google Scholar] [CrossRef]

- Lee, C.J.; Huang, J.C.; Hsieh, P.J. Mg based nano-composites fabricated by friction stir processing. Scr. Mater. 2006, 54, 1415–1420. [Google Scholar] [CrossRef]

- Yuvaraj, N.; Aravindan, S. Fabrication of Al5083/B4C surface composite by friction stir processing and its tribological characterization. JMR&T 2015, 4, 398–410. [Google Scholar]

- Khan, M.; Rehman, A.; Aziz, T.; Shahzad, M.; Naveed, K.; Subhani, T. Effect of inter-cavity spacing in friction stir processed Al 5083 composites containing carbon nanotubes and boron carbide particles. J. Mater. Process. Technol. 2018, 253, 72–85. [Google Scholar] [CrossRef]

- Amra, M.; Ranjbar, K.; Hosseini, S.A. Microstructure and wear performance of Al5083/CeO2/SiC mono and hybrid surface composites fabricated by friction stir processing. TNMSC 2018, 28, 866–878. [Google Scholar] [CrossRef]

- Kaya, N.; Çetinkaya, C.; Karakoç, H.; Ada, H. Effect of process parameters of Al5083/SiC surface composites fabricated by FSP on microstructure, mechanical properties and wear behaviors. Mater. Chem. Phys. 2024, 315, 128991. [Google Scholar] [CrossRef]

- ASTM E112-12; Standard Test Methods for Determining Average Grain Size. ASTM International: West Conshohocken, PA, USA, 2012; pp. 1–27.

- ASTM E384-11; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2011; pp. 1–24.

- ASTM E290-14; Standard Test Methods for Bend Testing of Material for Ductility. ASTM International: West Conshohocken, PA, USA, 2011; pp. 1–24.

- ASTM E8M-04; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2004; pp. 1–24.

- Bharathikanna, R.; Elatharasan, G. An investigation on microstructures and mechanical properties of AA1050 in friction stir processing technique. ANAS 2017, 11, 316–322. [Google Scholar]

- Huang, G.; Wu, J.; Hou, W.; Shen, Y. Microstructure, mechanical properties and strengthening mechanism of titanium particle reinforced aluminum matrix composites produced by submerged friction stir processing. Mater. Sci. Eng. A 2018, 734, 353–363. [Google Scholar] [CrossRef]

- Agha Amini Fashami, H.; Bani Mostafa Arab, N.; Hoseinpour Gollo, M.; Nami, B. Numerical and experimental investigation of defects formation during friction stir processing on AZ91. SN Appl. Sci. 2021, 3, 1–13. [Google Scholar] [CrossRef]

- Khan, N.Z.; Siddiquee, A.N.; Khan, Z.A.; Shihab, S.K. Investigations on tunneling and kissing bond defects in FSW joints for dissimilar aluminum alloys. J. Alloys Compd. 2015, 648, 360–367. [Google Scholar] [CrossRef]

- Khan, M.; Rehman, A.; Aziz, T.; Naveed, K.; Ahmad, I.; Subhani, T. Cold formability of friction stir processed aluminium composites containing carbon nanotubes and boron carbide particles. Mater. Sci. Eng. A 2017, 701, 382–388. [Google Scholar] [CrossRef]

- Akbari, M.; Ezzati, M.; Asadi, P. Investigation of the effect of tool probe profile on reinforced particles distribution using experimental and CEL approaches. Int. J. Lightweight Mater. Manuf. 2022, 5, 213–223. [Google Scholar] [CrossRef]

- Azizieh, M.; Kokabi, A.H.; Abachi, P. Effect of rotational speed and probe profile on microstructure and hardness of AZ31/Al2O3 nanocomposites fabricated by friction stir processing. Mater. Des. 2011, 32, 2034–2041. [Google Scholar] [CrossRef]

- Xiong, Y.; Kong, D.; Wen, Z.; Wu, G.; Liu, Q. Analysis of coal face stability of lower coal seam under repeated mining in close coal seams group. Sci. Rep. 2022, 12, 509. [Google Scholar] [CrossRef]

- Kurt, A.; Uygur, I.; Cete, E. Surface modification of aluminium by friction stir processing. J. Mater. Process. Technol. 2011, 211, 313–317. [Google Scholar] [CrossRef]

- Takhakh, A.M. Formability of Friction Stir Welded and Processed AA 2024–O Aluminum Alloy Sheets. ANAS 2016, 11, 10. [Google Scholar]

- Sorger, G.; Sarikka, T.; Vilaça, P.; Santos, T.G. Effect of processing temperatures on the properties of a high-strength steel welded by FSW. Weld. World 2018, 62, 1173–1185. [Google Scholar] [CrossRef]

- Gupta, M.; Lai, M.O.; Soo, C.Y. Effect of type of processing on the microstructural features and mechanical properties of Al-Cu/SiC metal matrix composites. Mater. Sci. Eng. A 1996, 210, 114–122. [Google Scholar] [CrossRef]

- Flores, O.V.; Kennedy, C.; Murr, L.E.; Brown, D.; Pappu, S.; Nowak, B.M.; McClure, J.C. Microstructural issues in a friction-stir-welded aluminum alloy. Scr. Mater. 1998, 38, 703–708. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S.; Siddiquee, A.N.; Maheshwari, S. Investigation on the effects of silicon carbide and cooling medium during multi-pass FSP of Al-Mg/SiC surface composites. Silicon 2019, 11, 2149–2157. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S.; Maheshwari, S.; Siddiquee, A.N. Influence of multiple-passes on microstructure and mechanical properties of Al-Mg/SiC surface composites fabricated via underwater friction stir processing. MRX 2018, 5, 066511. [Google Scholar] [CrossRef]

- Ashraf, M.A.; Peng, W.; Zare, Y.; Rhee, K.Y. Effects of size and aggregation/agglomeration of nanoparticles on the interfacial/interphase properties and tensile strength of polymer nanocomposites. Nanoscale Res. Lett. 2018, 13, 1–7. [Google Scholar] [CrossRef]

- Bauri, R.; Yadav, D.; Kumar, C.S.; Balaji, B. Tungsten particle reinforced Al 5083 composite with high strength and ductility. Mater. Sci. Eng. A 2015, 620, 67–75. [Google Scholar] [CrossRef]

- Patel, M.; Jain, S.; Murugesan, J. Investigation of Mechanical Properties, Fretting Wear, and Corrosion Behaviour of AA6063/Si3N4 Nanocomposites Fabricated via Friction Stir Processing. Arab. J. Sci. Eng. 2024, 1–11. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Simchi, A.; Kokabi, A.; Nosko, M.; Švec, P. Strain rate sensitivity, work hardening, and fracture behavior of an Al-Mg TiO2 nanocomposite prepared by friction stir processing. MMTA 2014, 45, 4073–4088. [Google Scholar] [CrossRef]

- Karabacak, A.H.; Çanakçı, A.; Özkaya, S.; Tunç, S.A.; Güler, O.; Çelebi, M. Effect of AlCrCuFeNi high entropy alloy reinforcements with and without B4C on powder characteristic, mechanical and wear properties of AA5083 metal-metal composites. J. Alloys Compd. 2024, 1008, 176627. [Google Scholar] [CrossRef]

- Jha, K.K.; Kesharwani, R.; Imam, M. Microstructure, texture, and mechanical properties correlation of AA5083/AA6061/SiC composite fabricated by FSAM process. Mater. Chem. Phys. 2023, 296, 127210. [Google Scholar] [CrossRef]

- Li, Q.; Huang, G.; Cao, Y.; Zhang, C.; He, J.; Jiang, H.; Lin, L.; Liu, Q. Microstructure refinement, strengthening and ductilization mechanisms in Al–Mg–Mn–Er–Zr alloy with high Mn content by friction stir processing. Mater. Charact. 2022, 189, 111939. [Google Scholar] [CrossRef]

- Faraji, G.; Dastani, O.; Mousavi, S.A.A.A. Effect of process parameters on microstructure and micro-hardness of AZ91/Al2O3 surface composite produced by FSP. JMEP 2011, 20, 1583–1590. [Google Scholar] [CrossRef]

| BM | Cu | Cr | Fe | Mg | Mn | Si | Ti | Zn | Al |

|---|---|---|---|---|---|---|---|---|---|

| AA5083-H111 | 0.010 | 0.040 | 0.153 | 4.339 | 0.649 | 0.139 | 0.011 | 0.013 | Bal |

| Type | Tensile Strength (MPa) | Yield Strength (MPa) | PE (%) | Bending Test (MPa) | Hardness (HV) | Mean Grain Size (µm) |

|---|---|---|---|---|---|---|

| BM | 311 | 248.8 | 58.65 | 415.2 | 90.57 | 61.29 |

| Reinforcement | O | Br | C | Si |

|---|---|---|---|---|

| Coal | 5.4 | 1.3 | 91.7 | 1.6 |

| Rotational Speed (r/min) | Traverse Speed (mm per min) | Tilt Angle (°) | Axial Force (kN) | Vertical Force (kN) | Dwell Time (s) |

|---|---|---|---|---|---|

| 900 | 60 | 2 | 4 | 20 tan (2) = 0.698 | 20 |

| Shoulder Diameter | Probe Diameter | Pin Length | Plunge Depth |

|---|---|---|---|

| 20 mm | 7 mm | 5.8 | 5.8 |

| Type | Mean Grain Size (µm) | Standard Deviation (µm) |

|---|---|---|

| Base material | ||

| AA5083-H111 | 61.292 | 10.868 |

| AA5083/Coal composites joints | ||

| Start | 27.515 | 5.0464 |

| Middle | 32.203 | 4.8828 |

| End | 33.802 | 5.9413 |

| Type | Ultimate Flexural Strength (MPa) | Flexural Strain (%) |

|---|---|---|

| Base material | ||

| AA5083 | 415.2014 | 0.268235 |

| AA5083/Coal composite joints | ||

| Root specimens | ||

| S | 410.5972 | 0.087058 |

| M | 631.9514 | 0.222353 |

| E | 544.8264 | 0.155294 |

| Face specimens | ||

| S | 729.5833 | 0.229412 |

| M | 747.5278 | 0.228235 |

| E | 404.6944 | 0.054471 |

| Type | Ultimate Tensile Strength (MPa) | Yield Strength (MPa) @ 0.2% Offset | Strain Rate (%) | Fracture Location |

|---|---|---|---|---|

| Base material | ||||

| AA5083 | 311 | 248.8 | 58.65 | N/A |

| AA5083/Coal composite joints | ||||

| S | 280 | 225.6 | 33.48 | NZ |

| M | 272 | 217.6 | 25.64 | NZ |

| E | 180 | 144.0 | 15.17 | NZ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muribwathoho, O.; Msomi, V.; Mabuwa, S. Microstructural Characterization and Mechanical Properties of AA5083/Coal Composites Fabricated by Friction Stir Processing. Metals 2025, 15, 308. https://doi.org/10.3390/met15030308

Muribwathoho O, Msomi V, Mabuwa S. Microstructural Characterization and Mechanical Properties of AA5083/Coal Composites Fabricated by Friction Stir Processing. Metals. 2025; 15(3):308. https://doi.org/10.3390/met15030308

Chicago/Turabian StyleMuribwathoho, Oritonda, Velaphi Msomi, and Sipokazi Mabuwa. 2025. "Microstructural Characterization and Mechanical Properties of AA5083/Coal Composites Fabricated by Friction Stir Processing" Metals 15, no. 3: 308. https://doi.org/10.3390/met15030308

APA StyleMuribwathoho, O., Msomi, V., & Mabuwa, S. (2025). Microstructural Characterization and Mechanical Properties of AA5083/Coal Composites Fabricated by Friction Stir Processing. Metals, 15(3), 308. https://doi.org/10.3390/met15030308