Optimizing FSP Parameters for AA5083/SiC Composites: A Comparative Analysis of Taguchi and Regression

Abstract

1. Introduction

2. Experimental Procedure

2.1. Material Used

2.2. Parameter Selection for Fabrication of AMMCs

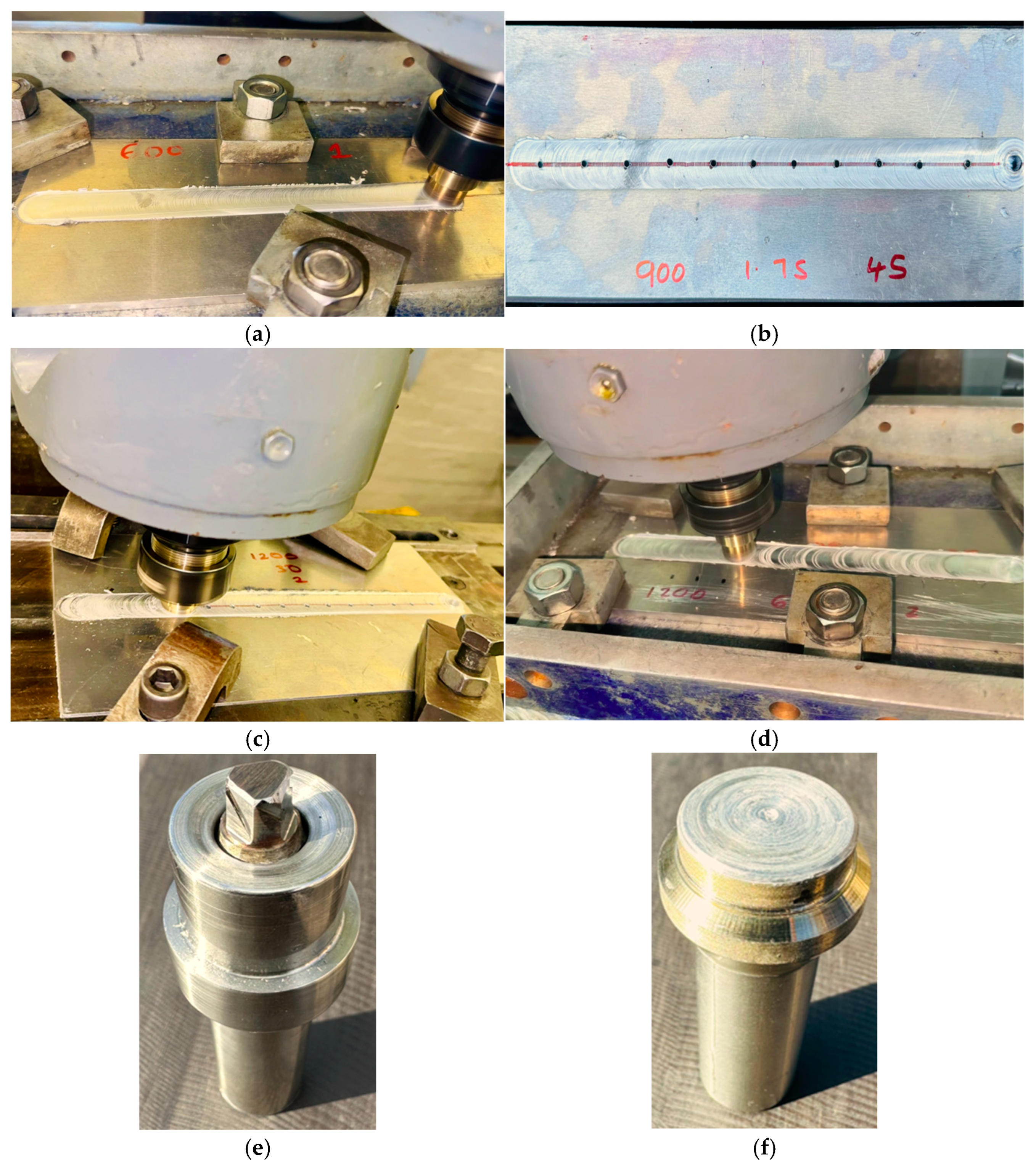

2.3. Fabrication of AMMCs

3. Results and Discussion

3.1. Mechanical Properties

3.1.1. Hardness

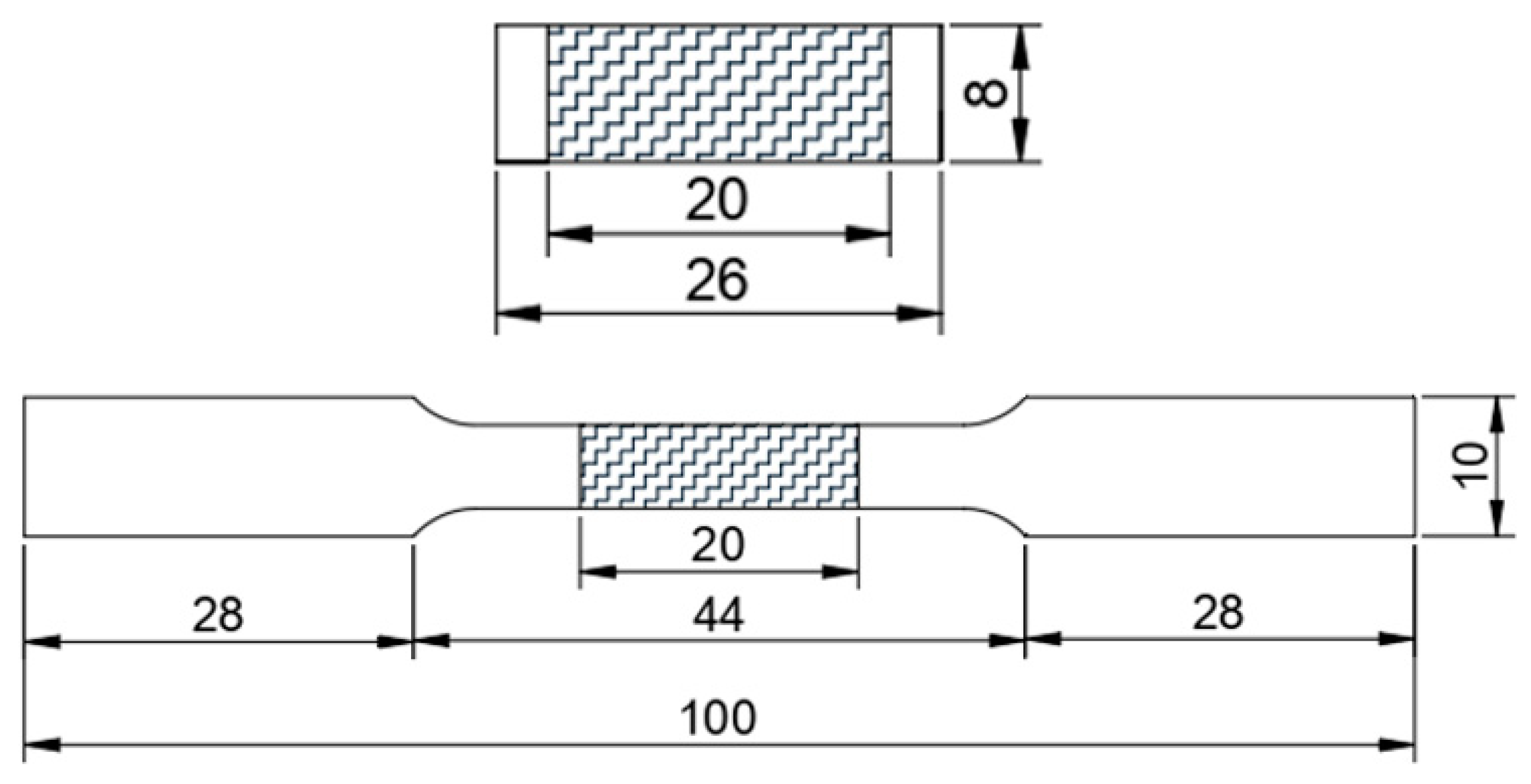

3.1.2. Tensile Strength

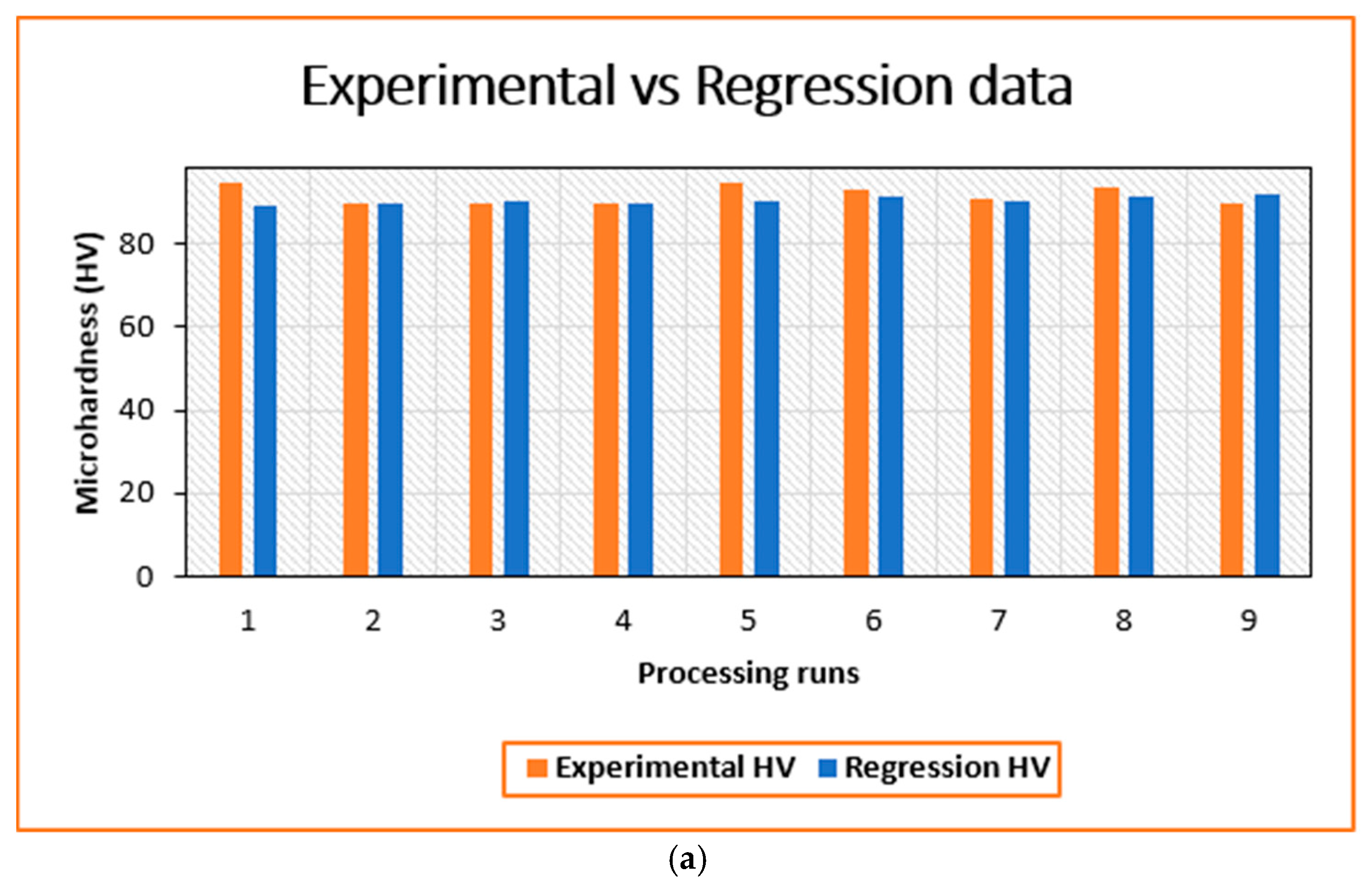

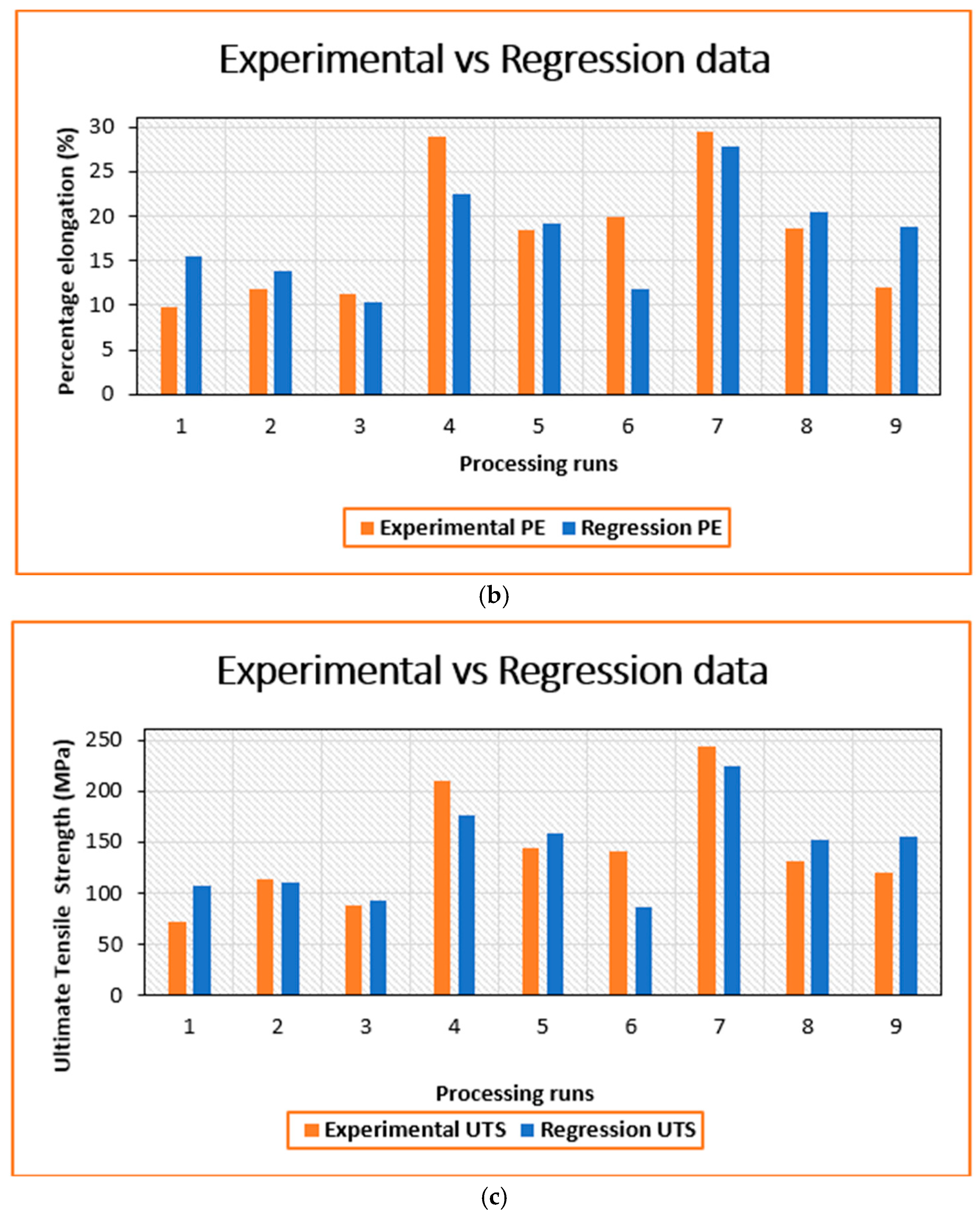

3.1.3. Comparison Plots of Regression-Predicted Values and Investigational Values

Alignment with Physical Expectations

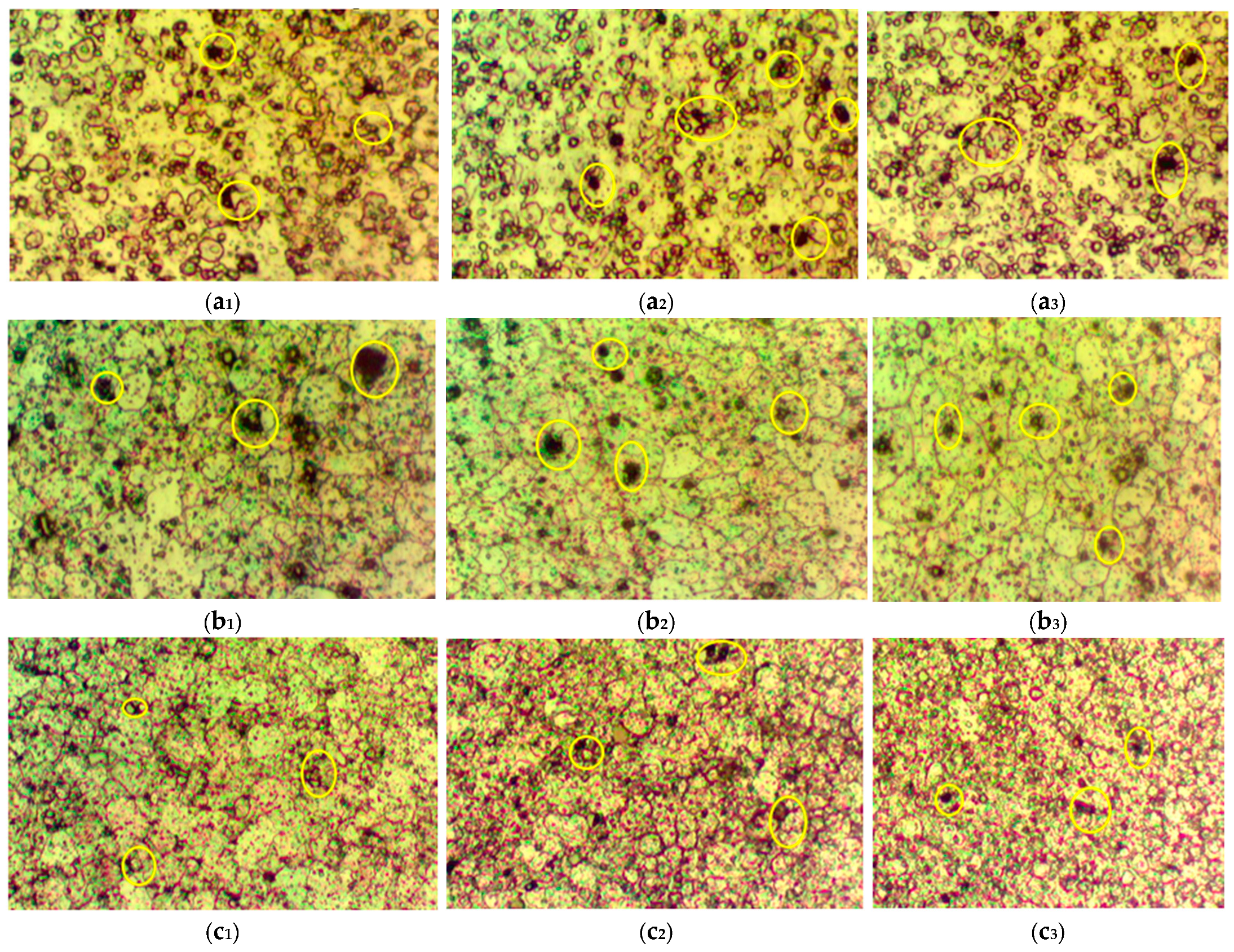

3.2. Microstructural Analysis

3.3. Interpretation of Experimental Results

3.3.1. Signal-to-Noise (S/N) Ratio Analysis

3.3.2. Determining Optimum Process Parameters and Ranking of Critical Factors

3.3.3. Analysis of Variance (ANOVA)

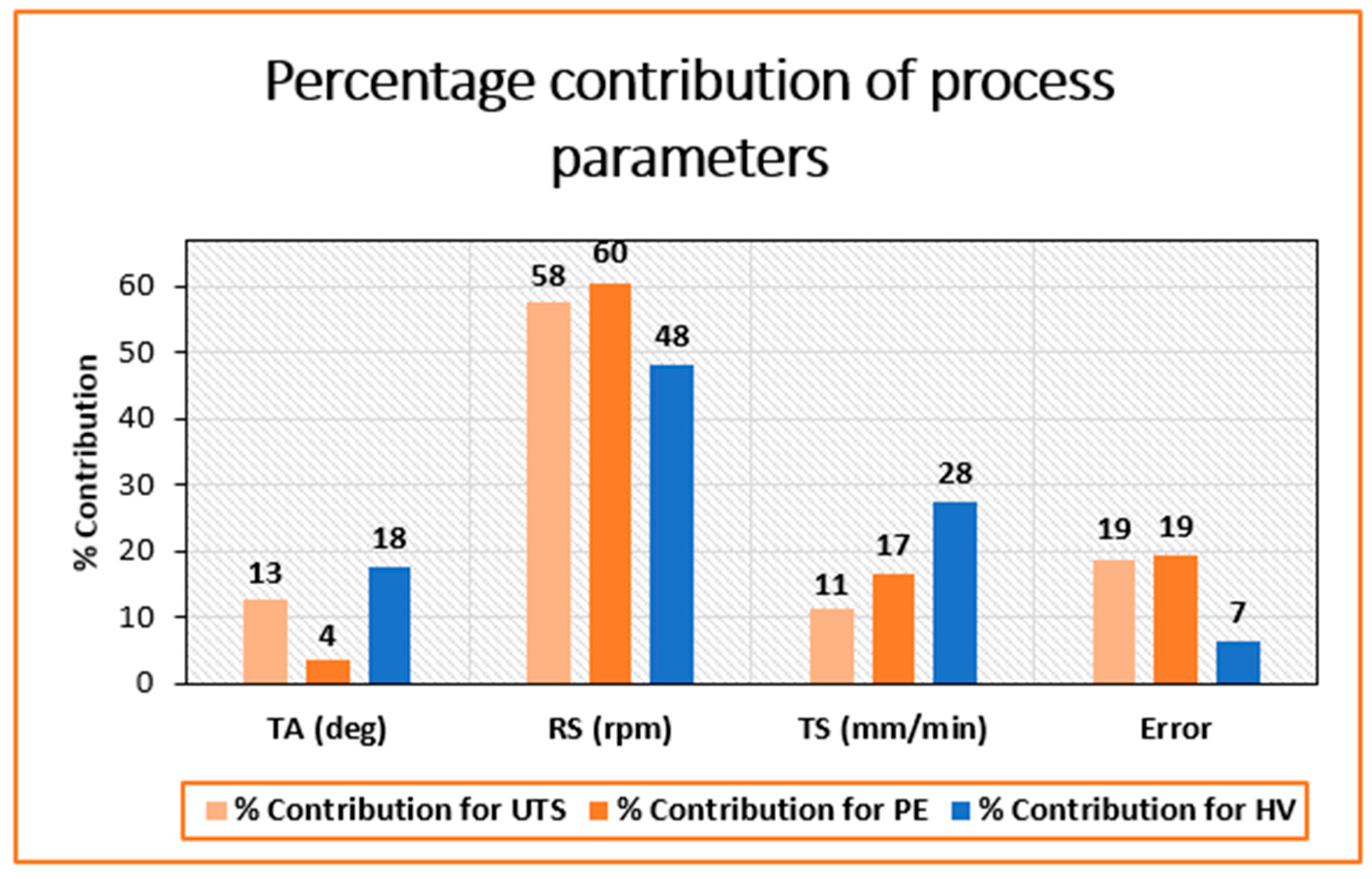

Interpretation of ANOVA Data

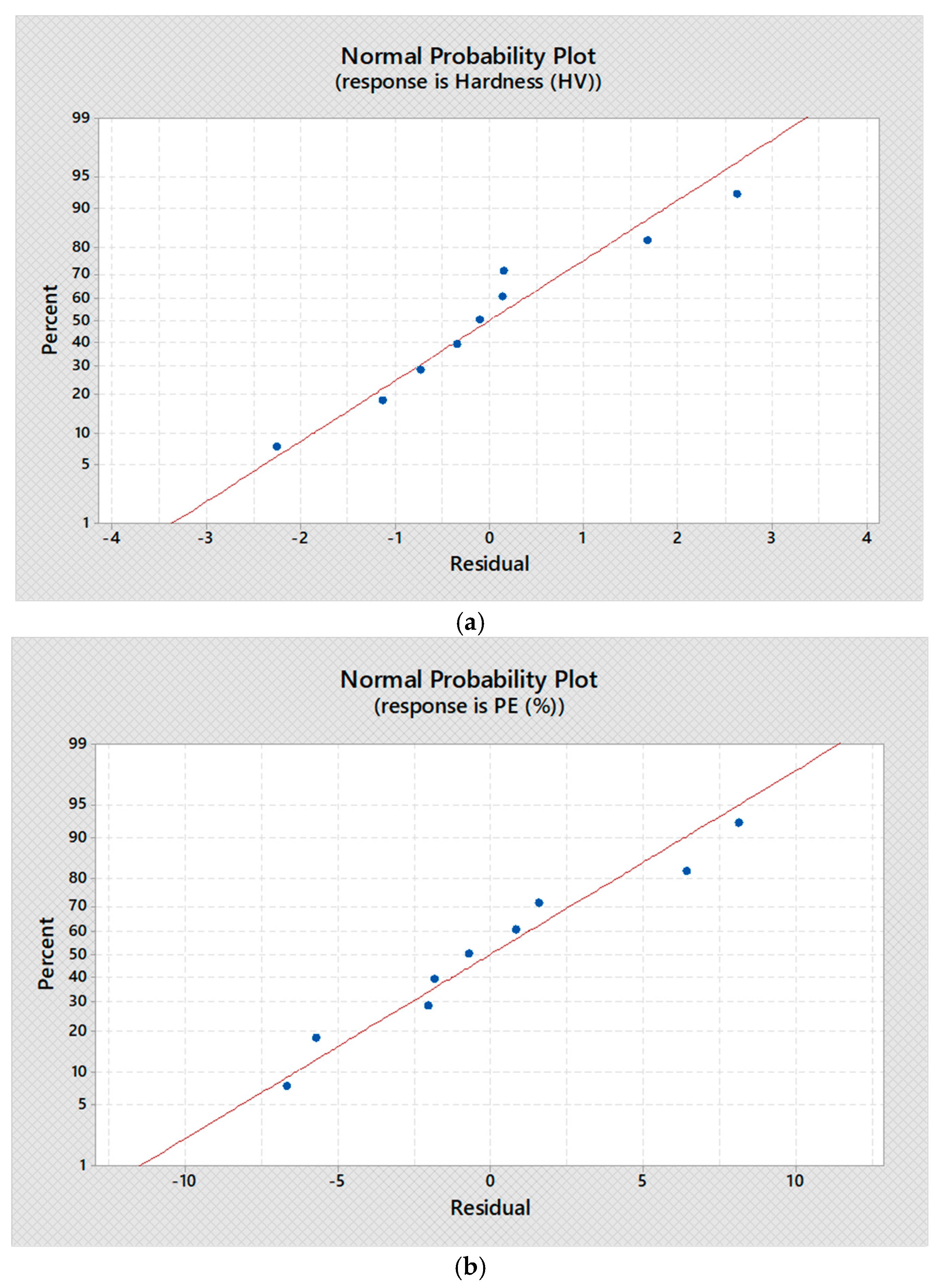

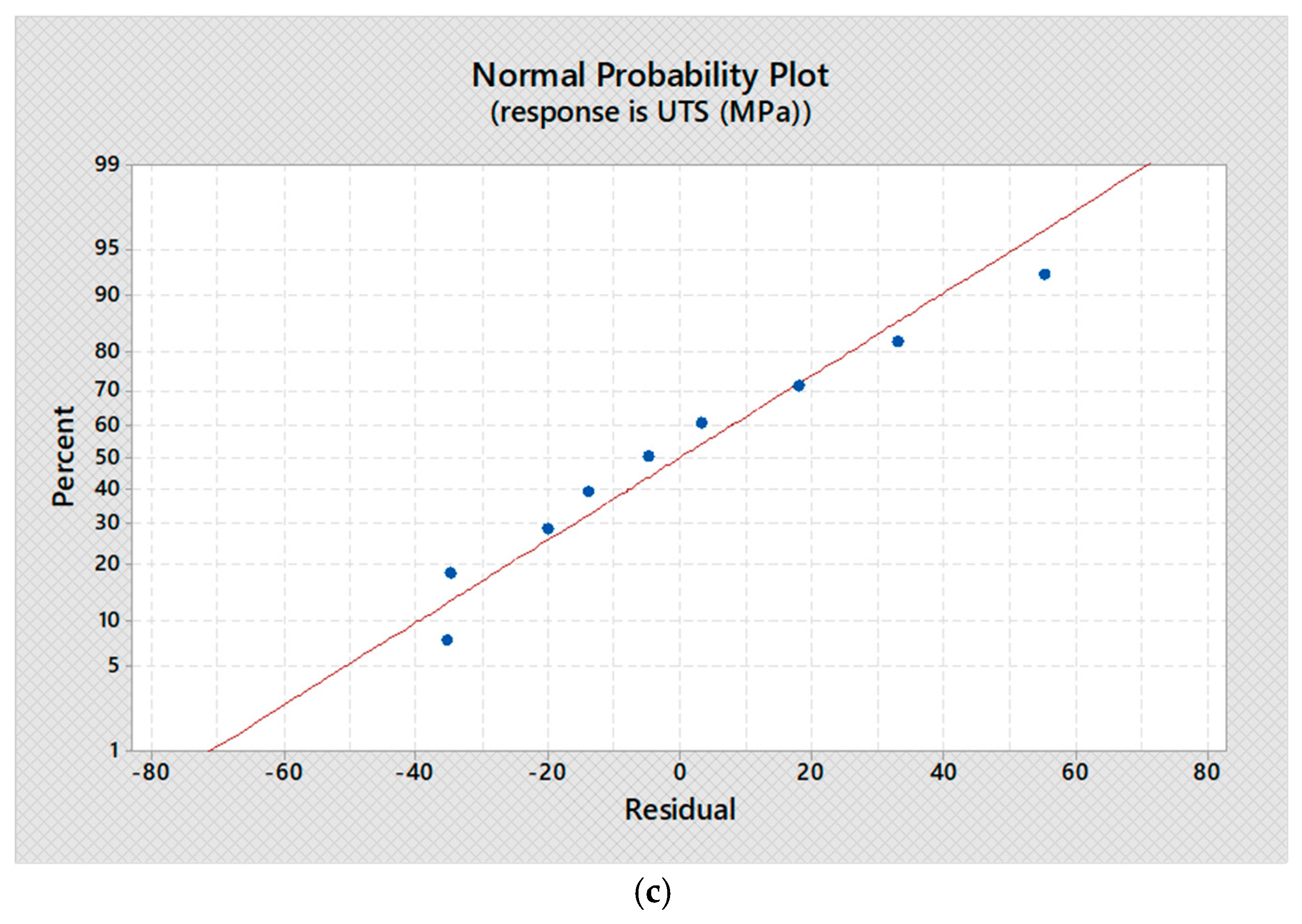

Normal Probability Plot

3.4. Confirmation Test

4. Conclusions

- The ultimate tensile strength of 311 MPa for the base AA5083 material was higher than the greatest experimental tensile strength of 243 MPa for the AA5083/SiC composite. The inclusion of reinforcing silicon carbide particle powder reduced the composite’s ductility, even though it showed other mechanical properties that were higher than those of the base material, and this was due to particle agglomeration.

- The base material AA5083’s hardness of 93.07 HV was surpassed by the experimental microhardness of the AA5083/SiC composite, which maxed at 94.80 HV. By adding reinforcements, the composite’s hardness increased above that of the base material. Grain refinement, particle dispersion, intermetallic particle fracture, and recrystallization are some of the factors that are attributed to the increase.

- According to the investigation, when the AA5083/silicon carbide composite joints were operated at 900 rev/min, 45 mm per minute traverse speed, and a tilt angle of 2 degrees, the greatest microhardness (MH) was generated. However, to maximize both ultimate tensile strength (UTS) and percentage elongation (PE), a slightly lower traverse speed of 30 mm per minute at the same rotational speed and tilt angle is needed.

- According to the ANOVA results of the S/N ratio shown in the crosstab, rotational speed significantly affects UTS, PE, and MH, contributing 58%, 60%, and 48% of the total. These results show that tool rotation speed has a major effect on output responses.

- The experimental design and the range of parameters utilized in this study may limit the generalizability of the developed regression models. However, despite these limitations, the models still provide valuable predictive estimations. Future studies should investigate adding interaction factors to the regression models to better understand the complex relationships between FSP parameters and mechanical properties. Additionally, more sophisticated regression techniques, such as response surface methodology, could be employed to provide more comprehensive and accurate predictions.

5. Limitations of the Study

6. Future Prospects

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Idusuyi, N.; Olayinka, J.I. Dry sliding wear characteristics of aluminium metal matrix composites: A brief overview. J. Mater. Res. Technol. 2019, 8, 3338–3346. [Google Scholar] [CrossRef]

- Senthilkumar, M.; Saravanan, S.D.; Shankar, S. Dry sliding wear and friction behavior of aluminum–rice husk ash composite using Taguchi’s technique. J. Compos. Mater. 2015, 49, 2241–2250. [Google Scholar] [CrossRef]

- Reeb, A.; Walter, V.; Schulze, V.; Weidenmann, K.A. Characterization of a hybrid Al2O3–aluminum matrix composite manufactured via composite extrusion. J. Compos. Mater. 2016, 50, 1099–1108. [Google Scholar] [CrossRef]

- Mistry, J.M.; Gohil, P.P. An overview of diversified reinforcement on aluminum metal matrix composites: Tribological aspects. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2017, 231, 399–421. [Google Scholar] [CrossRef]

- Nathan, S.R.; Suganeswaran, K.; Kumar, S.; Thangavel, P.; Gobinath, V.K. Investigations on microstructure, thermo-mechanical and tribological behavior of graphene oxide reinforced AA7075 surface composites developed via friction stir processing. J. Manuf. Process. 2023, 90, 139–150. [Google Scholar] [CrossRef]

- Gan, W.Y.; Zheng, Z.; Zhang, H.; Tao, P. Evolution of microstructure and hardness of aluminum after friction stir processing. Trans. Nonferrous Met. Soc. China 2014, 24, 975–981. [Google Scholar] [CrossRef]

- Sohn, Y.H.; Patterson, T.; Hofmeister, C.; Kammerer, C.; Mohr, W.; Van Den Bergh, M.; Shaeffer, M.; Seaman, J.; Cho, K. Tailoring microstructure and properties of hierarchical aluminum metal matrix composites through friction stir processing. JOM 2012, 64, 234–238. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Xiao, B.L.; Wang, W.G.; Ma, Z.Y. Singly dispersed carbon nanotube/aluminum composites fabricated by powder metallurgy combined with friction stir processing. Carbon 2012, 50, 1843–1852. [Google Scholar] [CrossRef]

- El Rayes, M.M.; El Danaf, E.A.; Soliman, M.S. High-temperature deformation and enhanced ductility of friction stir processed-7010 Aluminum Alloy. Mater. Des. 2011, 32, 1916–1922. [Google Scholar] [CrossRef]

- Pradeep, S.; Pancholi, V. Effect of microstructural inhomogeneity on superplastic behaviour of multipass friction stir processed aluminium alloy. Mater. Sci. Eng. A 2013, 561, 78–87. [Google Scholar] [CrossRef]

- Borrego, L.P.; Costa, J.D.; Jesus, J.S.; Loureiro, A.R.; Ferreira, J.M. Fatigue life improvement by friction stir processing of 5083 aluminium alloy MIG butt welds. Theor. Appl. Fract. Mech. 2014, 70, 68–74. [Google Scholar] [CrossRef]

- Costa, J.D.M.; Jesus, J.S.; Loureiro, A.; Ferreira, J.A.M.; Borrego, L.P. Fatigue life improvement of mig welded aluminium T-joints by friction stir processing. Int. J. Fatigue. 2014, 61, 244–254. [Google Scholar] [CrossRef]

- Karthikeyan, L.; Senthilkumar, V.S.; Padmanabhan, K.A. On the role of process variables in the friction stir processing of cast aluminum A319 alloy. Mater. Des. 2010, 31, 761–771. [Google Scholar] [CrossRef]

- Mahmoud, T.S. Surface modification of A390 hypereutectic Al–Si cast alloys using friction stir processing. Surf. Coat. Technol. 2013, 228, 209–220. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y.; Charit, I. Friction stir processing: A novel technique for fabrication of surface composite. Mater. Sci. Eng. A 2003, 341, 307–310. [Google Scholar] [CrossRef]

- Dinaharan, I.; Murugan, N.; Thangarasu, A. Development of empirical relationships for prediction of mechanical and wear properties of AA6082 aluminum matrix composites produced using friction stir processing. Eng. Sci. Technol. Int. J. 2016, 19, 1132–1144. [Google Scholar] [CrossRef]

- Narimani, M.; Lotfi, B.; Sadeghian, Z. Evaluation of the microstructure and wear behaviour of AA6063-B4C/TiB2 mono and hybrid composite layers produced by friction stir processing. Surf. Coat. Technol. 2016, 285, 1–10. [Google Scholar] [CrossRef]

- Selvakumar, S.; Dinaharan, I.; Palanivel, R.; Babu, B.G. Characterization of molybdenum particles reinforced Al6082 aluminum matrix composites with improved ductility produced using friction stir processing. Mater. Charact. 2017, 125, 13–22. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Gerlich, A.P.; Simchi, A.; Kokabi, A.H. Hot deformation behavior of an aluminum-matrix hybrid nanocomposite fabricated by friction stir processing. Mater. Sci. Eng. A 2015, 626, 458–466. [Google Scholar] [CrossRef]

- Adel Mehraban, F.; Karimzadeh, F.; Abbasi, M.H. Development of surface nanocomposite based on Al-Ni-O ternary system on Al6061 alloy by friction-stir processing and evaluation of its properties. JOM 2015, 67, 998–1006. [Google Scholar] [CrossRef]

- Yadav, D.; Bauri, R. Friction stir processing of Al-TiB 2 in situ composite: Effect on particle distribution, microstructure and properties. J. Mater. Eng. Perform. 2015, 24, 1116–1124. [Google Scholar] [CrossRef]

- Chen, Z.; Li, J.; Borbely, A.; Ji, G.; Zhong, S.Y.; Wu, Y.; Wang, M.L.; Wang, H.W. The effects of nanosized particles on microstructural evolution of an in-situ TiB2/6063Al composite produced by friction stir processing. Mater. Des. 2015, 88, 999–1007. [Google Scholar] [CrossRef]

- Rajan, H.M.; Dinaharan, I.; Ramabalan, S.; Akinlabi, E.T. Influence of friction stir processing on microstructure and properties of AA7075/TiB2 in situ composite. J. Alloys Compd. 2016, 657, 250–260. [Google Scholar] [CrossRef]

- Hangai, Y.; Nakano, Y.; Utsunomiya, T.; Kuwazuru, O.; Yoshikawa, N. Drop weight impact behavior of Al-Si-Cu alloy foam-filled thin-walled steel pipe fabricated by friction stir back extrusion. J. Mater. Eng. Perform. 2017, 26, 894–900. [Google Scholar] [CrossRef]

- Zangabad, P.S.; Khodabakhshi, F.; Simchi, A.; Kokabi, A.H. Fatigue fracture of friction-stir processed Al–Al3Ti–MgO hybrid nanocomposites. Int. J. Fatigue. 2016, 87, 266–278. [Google Scholar] [CrossRef]

- Saini, N.; Dwivedi, D.K.; Jain, P.K.; Singh, H. Surface modification of cast Al-17% Si alloys using friction stir processing. Procedia Eng. 2015, 100, 1522–1531. [Google Scholar] [CrossRef]

- Dolatkhah, A.; Golbabaei, P.; Givi, M.B.; Molaiekiya, F. Investigating effects of process parameters on microstructural and mechanical properties of Al5052/SiC metal matrix composite fabricated via friction stir processing. Mater. Des. 2012, 37, 458–464. [Google Scholar] [CrossRef]

- Prabhakar, D.A.P.; Shettigar, A.K.; Herbert, M.A.; GC, M.P.; Pimenov, D.Y.; Giasin, K.; Prakash, C. A comprehensive review of friction stir techniques in structural materials and alloys: Challenges and trends. J. Mater. Res. Technol. 2022, 20, 3025–3060. [Google Scholar] [CrossRef]

- Yang, Z.; Fan, J.; Liu, Y.; Nie, J.; Yang, Z.; Kang, Y. Strengthening and weakening effects of particles on strength and ductility of SiC particle reinforced Al-Cu-Mg alloys matrix composites. Materials 2021, 14, 1219. [Google Scholar] [CrossRef]

- Ye, J.; Chen, X.; Luo, H.; Zhao, J.; Li, J.; Tan, J.; Yang, H.; Feng, B.; Zheng, K.; Pan, F. Microstructure, mechanical properties and wear resistance of Ti particles reinforced AZ31 magnesium matrix composites. J. Magnes. Alloy. 2022, 10, 2266–2279. [Google Scholar] [CrossRef]

- Kumaravel, S.; Suresh, P. Optimization of friction stir processing parameters to improve mechanical properties and microstructure of Al5083 aluminum alloy reinforced with AlCoCrFeNiSi high-entropy alloy. Phys. Scr. 2024, 99, 105903. [Google Scholar]

- Hang, Z.Y.; Jones, M.E.; Brady, G.W.; Griffiths, R.J.; Garcia, D.; Rauch, H.A.; Cox, C.D.; Hardwick, N. Non-beam-based metal additive manufacturing enabled by additive friction stir deposition. Scr. Mater. 2018, 153, 122–130. [Google Scholar]

- Mohan, R.; Jayadeep, U.B.; Manu, R. CFD modelling of ultra-high rotational speed micro friction stir welding. J. Manuf. Process. 2021, 64, 1377–1386. [Google Scholar] [CrossRef]

- Rana, H.; Badheka, V. Influence of friction stir processing conditions on the manufacturing of Al-Mg-Zn-Cu alloy/boron carbide surface composite. J. Mater. Process. Technol. 2018, 255, 795–807. [Google Scholar] [CrossRef]

- Wang, L.; Jin, J.; Cao, J.; Yang, P.; Peng, Q. Interaction of edge dislocations with graphene nanosheets in graphene/Fe composites. Crystals 2018, 8, 160. [Google Scholar] [CrossRef]

- Zhang, Z.; Urbassek, H.M. Dislocation-based strengthening mechanisms in metal-matrix nanocomposites: A molecular dynamics study of the influence of reinforcement shape in the Al-Si system. Comput. Mater. Sci. 2018, 145, 109–115. [Google Scholar] [CrossRef]

- Mukherjee, I.; Ray, P.K. A review of optimization techniques in metal cutting processes. CAIE 2006, 50, 15–34. [Google Scholar] [CrossRef]

- Besharati-Givi, M.K.; Asadi, P. Advances in Friction-Stir Welding and Processing; Woodhead Publishing: Sawston, UK; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Siddiquee, A.N.; Pandey, S. Experimental investigation on deformation and wear of WC tool during friction stir welding (FSW) of stainless steel. Int. J. Adv. Manuf. Technol. 2014, 73, 479–486. [Google Scholar] [CrossRef]

- Siddiquee, A.N.; Khan, N.Z. Friction stir welding of austenitic stainless steel: A study on microstructure and effect of parameters on tensile strength. Mater. Today 2015, 2, 1388–1397. [Google Scholar] [CrossRef]

- Zass, K.; Mabuwa, S.; Msomi, V. Introduction of Coal Reinforcing Particles on the Dissimilar FSW AA608/AA5083 Joint via Friction Stir Processing. Metals 2023, 13, 1981. [Google Scholar] [CrossRef]

- ASTM E8M-04; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2004; pp. 1–24.

- ASTM E384-11; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2011; pp. 1–24. Available online: https://www.astm.org/Standards/E384.htm (accessed on 10 January 2025).

- Li, Q.; Huang, G.; Cao, Y.; Zhang, C.; He, J.; Jiang, H.; Lin, L.; Liu, Q. Microstructure refinement, strengthening and ductilization mechanisms in Al–Mg–Mn–Er–Zr alloy with high Mn content by friction stir processing. Mater. Charact. 2022, 189, 111939. [Google Scholar] [CrossRef]

- Amra, M.; Ranjbar, K.; Hosseini, S.A. Microstructure and wear performance of Al5083/CeO2/SiC mono and hybrid surface composites fabricated by friction stir processing. Trans. Nonferrous Met. Soc. China 2018, 28, 866–878. [Google Scholar] [CrossRef]

- Faraji, G.; Dastani, O.; Mousavi, S.A.A.A. Effect of process parameters on microstructure and micro-hardness of AZ91/Al2O3 surface composite produced by FSP. J. Mater. Eng. Perform. 2011, 20, 1583–1590. [Google Scholar] [CrossRef]

- Ayvaz, S.I.; Arslan, D.; Ayvaz, M. Investigation of mechanical and tribological behavior of SiC and B4C reinforced Al-Zn-Mg-Si-Cu alloy matrix surface composites fabricated via friction stir processing. Mater. Today Commun. 2022, 31, 103419. [Google Scholar] [CrossRef]

- Yuvaraj, N.; Aravindan, S. Fabrication of Al5083/B4C surface composite by friction stir processing and its tribological characterization. J. Mater. Res. Technol. 2015, 4, 398–410. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S.; Maheshwari, S.; Siddiquee, A.N. Influence of multiple-passes on microstructure and mechanical properties of Al-Mg/SiC surface composites fabricated via underwater friction stir processing. Mater. Res. Express. 2018, 5, 066511. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S.; Siddiquee, A.N.; Maheshwari, S. Investigation on the effects of silicon carbide and cooling medium during multi-pass FSP of Al-Mg/SiC surface composites. Silicon 2019, 11, 2149–2157. [Google Scholar] [CrossRef]

- Bharathikanna, R.; Elatharasan, G. An investigation on microstructures and mechanical properties of AA1050 in friction stir processing technique. Adv. Nat. Appl. Sci. 2017, 11, 316–322. [Google Scholar]

- Huang, G.; Wu, J.; Hou, W.; Shen, Y. Microstructure, mechanical properties and strengthening mechanism of titanium particle reinforced aluminum matrix composites produced by submerged friction stir processing. Mater. Sci. Eng. A 2018, 734, 353–363. [Google Scholar] [CrossRef]

- Agha Amini Fashami, H.; Bani Mostafa Arab, N.; Hoseinpour Gollo, M.; Nami, B. Numerical and experimental investigation of defects formation during friction stir processing on AZ91. SN Appl. Sci. 2021, 3, 108. [Google Scholar] [CrossRef]

- Habibnia, M.; Shakeri, M.; Nourouzi, S.; Givi, M.B. Microstructural and mechanical properties of friction stir welded 5050 Al alloy and 304 stainless steel plates. Int. J. Adv. Manuf. Technol. 2015, 76, 819–829. [Google Scholar] [CrossRef]

- Zandsalimi, S.; Heidarzadeh, A.; Saeid, T. Dissimilar friction-stir welding of 430 stainless steel and 6061 aluminum alloy: Microstructure and mechanical properties of the joints. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 233, 1791–1801. [Google Scholar] [CrossRef]

- Akbari, M.; Ezzati, M.; Asadi, P. Investigation of the effect of tool probe profile on reinforced particles distribution using experimental and CEL approaches. Int. J. Lightweight Mater. Manuf. 2022, 5, 213–223. [Google Scholar] [CrossRef]

- Hamilton, C.; Kopyściański, M.; Senkov, O.; Dymek, S. A coupled thermal/material flow model of friction stir welding applied to Sc-modified aluminum alloys. Metall. Mater. Trans. A 2013, 44, 1730–1740. [Google Scholar] [CrossRef]

- Hamilton, C.; Węglowski, M.S.; Dymek, S. A simulation of friction-stir processing for temperature and material flow. Metall. Mater. Trans. B 2015, 46, 1409–1418. [Google Scholar] [CrossRef]

- Khan, N.Z.; Siddiquee, A.N.; Khan, Z.A.; Shihab, S.K. Investigations on tunneling and kissing bond defects in FSW joints for dissimilar aluminum alloys. J. Alloys Compd. 2015, 648, 360–367. [Google Scholar] [CrossRef]

- Bozkurt, Y. The optimization of friction stir welding process parameters to achieve maximum tensile strength in polyethylene sheets. Mater. Des. 2012, 35, 440–445. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S.; Maheshwari, S.; Siddiquee, A.N. Optimisation of friction stir processing parameters to fabricate AA6063/SiC surface composites using Taguchi technique. Int. J. Mater. Prod. Technol. 2019, 58, 16–31. [Google Scholar] [CrossRef]

- Ahmadkhaniha, D.; Sohi, M.H.; Zarei-Hanzaki, A.; Bayazid, S.M.; Saba, M. Taguchi optimization of process parameters in friction stir processing of pure Mg. J. Magnes. Alloy. 2015, 3, 168–172. [Google Scholar] [CrossRef]

- Jain, V.K.; Yadav, M.K.; Siddiquee, A.N.; Khan, Z.A. Optimization of friction stir processing parameters for enhanced microhardness of AA5083/Al-Fe in-situ composites via Taguchi technique. Mater. Sci. Eng. Appl. 2021, 1, 55–61. [Google Scholar] [CrossRef]

- Kolli, M.; Naresh, D.S.; Devaraju, A.; Satyanarayana, K. Investigation of mechanical properties in friction stir processing parameters of Cu-TiB2 composite using Taguchi approach. Int. J. Interact. Des. Manuf. 2023, 19, 153–164. [Google Scholar] [CrossRef]

- Muthukrishnan, N.; Davim, J.P. Optimization of machining parameters of Al/SiC-MMC with ANOVA and ANN analysis. J. Mater. Process. Technol. 2009, 209, 225–232. [Google Scholar] [CrossRef]

- Chanakyan, C.; Sivasankar, S.; Meignanamoorthy, M.; Ravichandran, M.; Mohanavel, V.; Alfarraj, S.; Almoallim, H.S.; Manikandan, V.; Isaac JoshuaRamesh Lalvani, J. Optimization of FSP process parameters on AA5052 employing the S/N ratio and ANOVA method. Adv. Mater. Sci. Eng. 2021, 2021, 6450251. [Google Scholar] [CrossRef]

- Syed, K.; Ali, M.A.; Reddy, K.P.K.; Rao, B.N. Analyzing the Influence of Tool Profile on Friction Stir Process with Taguchi Optimization and Tungsten Nano Powder. Int. J. Veh. Struct. Syst. 2023, 15, 802–807. [Google Scholar]

- Butola, R.; Ranganath, M.S.; Murtaza, Q. Fabrication and optimization of AA7075 matrix surface composites using Taguchi technique via friction stir processing (FSP). Eng. Res. Express 2019, 1, 025015. [Google Scholar] [CrossRef]

- Salehi, M.; Saadatmand, M.; Mohandesi, J.A. Optimization of process parameters for producing AA6061/SiC nanocomposites by friction stir processing. Trans. Nonferrous Met. Soc. China 2012, 22, 1055–1063. [Google Scholar] [CrossRef]

- Puviyarasan, M.; Kumar, V.S. Optimization of friction stir process parameters in fabricating AA6061/SiCp composites. Procedia Eng. 2012, 38, 1094–1103. [Google Scholar] [CrossRef]

- Ross, P.J. Taguchi Techniques for Quality Engineering: Loss Function, Orthogonal Experiments, Parameter and Tolerance Design; McGraw-Hill: New York, NY, USA, 1998; pp. 1–279. [Google Scholar]

- Akinlabi, E.T.; Mahamood, R.M.; Akinlabi, S.A.; Ogunmuyiwa, E. Processing parameters influence on wear resistance behaviour of friction stir processed Al-TiC composites. Adv. Mater. Sci. Eng. 2014, 2014, 724590. [Google Scholar] [CrossRef]

- Swain, P.K.; Mohapatra, K.D.; Das, R.; Sahoo, A.K.; Panda, A. Experimental investigation into characterization and machining of Al+ SiCp nano-composites using coated carbide tool. Mech. Ind. 2020, 21, 307. [Google Scholar] [CrossRef]

- Gunasekaran, J.; Sevvel, P.; Roy, J.V.; Sivaramakrishnan, A. Analysis of sensitivity and formulation of empirical relationship between parameters of FSW process and tensile strength of AZ80A Mg alloy joints. Mater. Res. Express 2023, 10, 056513. [Google Scholar] [CrossRef]

- Gunasekaran, J.; Sevvel, P.; John Solomon, I.; Vasanthe Roy, J. Multi objective optimization of parameters during FSW of AZ80A-AZ31B Mg alloys using grey relational analysis. J. Mech. Sci. Technol. 2024, 38, 4971–4982. [Google Scholar] [CrossRef]

- Adiga, K.; Herbert, M.A.; Rao, S.S.; Shettigar, A.K. Optimization of process parameters for friction stir processing (FSP) of AA8090/boron carbide surface composites. Weld. World 2024, 68, 2683–2700. [Google Scholar] [CrossRef]

- Muribwathoho, O.; Msomi, V.; Mabuwa, S. An Analysis Comparing the Taguchi Method for Optimizing the Process Param-eters of AA5083/Silicon Carbide and AA5083/Coal Composites That Are Fabricated via Friction Stir Processing. Appl. Sci. 2024, 14, 9616. [Google Scholar] [CrossRef]

| Mechanical Properties | |

|---|---|

| Ultimate Tensile Strength | 311 MPa |

| Percentage Elongation | 58.65% |

| Microhardness | 93.07 HV |

| Process Parameters | Factor Symbol | Unit | Level of Parameters | ||

|---|---|---|---|---|---|

| 1 | 2 | 3 | |||

| Traverse speed | (TS) | [mm per min] | 30 | 45 | 60 |

| Rotational speed | (RS) | [rev/min] | 600 | 900 | 1200 |

| Tilt angle | (TA) | [°] | 1 | 1.75 | 2 |

| No of Experiments | Tilt Angle [°] | Rotational Speed [rev/min] | Traverse Speed [mm per min] |

|---|---|---|---|

| 1. | 1 | 600 | 30 |

| 2. | 1.75 | 600 | 45 |

| 3. | 2 | 600 | 60 |

| 4. | 1.75 | 900 | 30 |

| 5. | 2 | 900 | 45 |

| 6. | 1 | 900 | 60 |

| 7. | 2 | 1200 | 30 |

| 8. | 1 | 1200 | 45 |

| 9. | 1.75 | 1200 | 60 |

| Trial No. | UTS (MPa) | YS (MPa) | PE (%) | MH (HV) |

|---|---|---|---|---|

| 1. | 71.5 | 57.20 | 9.88 | 94.78 |

| 2. | 114 | 91.20 | 11.75 | 89.57 |

| 3. | 88 | 70.40 | 11.23 | 89.57 |

| 4. | 210 | 168.0 | 29 | 89.39 |

| 5. | 145 | 116.0 | 18.45 | 94.80 |

| 6. | 141 | 112.8 | 19.9 | 92.95 |

| 7. | 243 | 194.4 | 29.5 | 90.56 |

| 8. | 132 | 105.6 | 18.7 | 93.65 |

| 9. | 121 | 96.80 | 12.08 | 89.56 |

| TA (°) | TS (mm per min) | RS (rev/min) | UTS (MPa) | Fits UTS | % Error | PE (%) | Fits PE | % Error | MH (HV) | Fits HV | % Error |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 30 | 600 | 71.5 | 106.929 | 49.6 | 9.88 | 15.5965 | 57.9 | 94.78 | 89.1813 | 5.90 |

| 1.75 | 45 | 600 | 114 | 110.865 | 2.75 | 11.75 | 13.7938 | 17.4 | 89.57 | 89.6832 | 0.13 |

| 2 | 60 | 600 | 88 | 92.788 | 5.44 | 11.23 | 10.3963 | 7.43 | 89.57 | 90.3038 | 0.82 |

| 1.75 | 30 | 900 | 210 | 177.032 | 15.7 | 29 | 22.5588 | 22.2 | 89.39 | 89.7349 | 0.39 |

| 2 | 45 | 900 | 145 | 158.955 | 9.59 | 18.45 | 19.1613 | 3.85 | 94.80 | 90.3555 | 4.69 |

| 1 | 60 | 900 | 141 | 85.846 | 39.1 | 19.9 | 11.7765 | 40.8 | 92.95 | 91.2729 | 1.81 |

| 2 | 30 | 1200 | 243 | 225.122 | 7.37 | 29.5 | 27.9263 | 5.33 | 90.56 | 90.4072 | 0.17 |

| 1 | 45 | 1200 | 132 | 152.013 | 15.1 | 18.7 | 20.5415 | 9.87 | 93.65 | 91.3246 | 2.48 |

| 1.75 | 60 | 1200 | 121 | 155.949 | 28.8 | 12.08 | 18.7388 | 55.2 | 89.56 | 91.8265 | 2.53 |

| TA (°) | RS (rev/min) | TS (mm per min) | MH (HV) | S/N Ratio (HV) | UTS (MPa) | S/N Ratio (UTS) | PE (%) | S/N Ratio (PE) |

|---|---|---|---|---|---|---|---|---|

| 1 | 600 | 30 | 88.05 | 38.895 | 71.5 | 37.086 | 9.88 | 19.895 |

| 1.75 | 600 | 45 | 89.57 | 39.043 | 114 | 41.138 | 11.75 | 21.401 |

| 2 | 600 | 60 | 89.57 | 39.043 | 88 | 38.889 | 11.23 | 21.008 |

| 1.75 | 900 | 30 | 89.39 | 39.026 | 210 | 46.444 | 29.00 | 29.248 |

| 2 | 900 | 45 | 92.98 | 39.368 | 145 | 43.227 | 18.45 | 25.319 |

| 1 | 900 | 60 | 92.95 | 39.365 | 141 | 42.984 | 19.90 | 25.977 |

| 2 | 1200 | 30 | 90.56 | 39.139 | 243 | 47.712 | 29.50 | 29.396 |

| 1 | 1200 | 45 | 91.46 | 39.225 | 132 | 42.412 | 18.70 | 25.437 |

| 1.75 | 1200 | 60 | 89.56 | 39.042 | 121 | 41.656 | 12.08 | 21.641 |

| Level | Tilt Angle (°) | Rotational Speed (rev/min) | Traverse Speed (mm per min) |

|---|---|---|---|

| For UTS | |||

| S/N ratio | |||

| 1 | 40.83 | 39.04 | 43.75 |

| 2 | 43.08 | 44.22 | 42.26 |

| 3 | 43.28 | 43.93 | 41.18 |

| Delta | 2.450 | 5.180 | 2.570 |

| Rank | 3 | 1 | 2 |

| Means | |||

| 1 | 114.83 | 91.17 | 174.83 |

| 2 | 148.33 | 165.34 | 130.33 |

| 3 | 158.67 | 165.33 | 116.67 |

| Delta | 43.830 | 74.170 | 58.170 |

| Rank | 3 | 1 | 2 |

| For PE | |||

| S/N ratio | |||

| 1 | 23.77 | 20.77 | 26.18 |

| 2 | 24.10 | 26.85 | 24.05 |

| 3 | 25.24 | 25.49 | 22.88 |

| Delta | 1.470 | 6.080 | 3.300 |

| Rank | 3 | 1 | 2 |

| Means | |||

| 1 | 16.16 | 10.95 | 22.79 |

| 2 | 17.61 | 22.45 | 16.30 |

| 3 | 19.73 | 20.09 | 14.40 |

| Delta | 3.570 | 11.50 | 8.390 |

| Rank | 3 | 1 | 2 |

| For HV | |||

| S/N ratio | |||

| 1 | 39.16 | 38.99 | 39.02 |

| 2 | 39.04 | 39.25 | 39.21 |

| 3 | 39.18 | 39.14 | 39.15 |

| Delta | 0.150 | 0.260 | 0.190 |

| Rank | 3 | 1 | 2 |

| Means | |||

| 1 | 90.82 | 89.06 | 89.33 |

| 2 | 89.51 | 91.77 | 91.34 |

| 3 | 91.04 | 90.53 | 90.69 |

| Delta | 1.530 | 2.710 | 2.000 |

| Rank | 3 | 1 | 2 |

| Source | Degree of Freedom (DF) | Seq SS | Adj SS | Adj MS | F-Value | p-Value | % Contribution |

|---|---|---|---|---|---|---|---|

| S/N ratio | |||||||

| TA (°) | 2 | 11.110 | 11.108 | 5.5540 | 0.68 | 0.596 | 12.581 |

| RS (rev/min) | 2 | 50.823 | 50.823 | 25.411 | 3.10 | 0.244 | 57.552 |

| TS (mm per min) | 2 | 9.9970 | 9.9970 | 4.9990 | 0.61 | 0.621 | 11.321 |

| Error | 2 | 16.379 | 16.379 | 8.1900 | 18.548 | ||

| Total | 8 | 88.308 | |||||

| Means | |||||||

| TA (°) | 2 | 3150 | 3150 | 1575 | 0.73 | 0.579 | 13.109 |

| RS (rev/min) | 2 | 11001 | 11001 | 5501 | 2.54 | 0.282 | 45.782 |

| TS (mm per min) | 2 | 5550 | 5550 | 2775 | 1.28 | 0.438 | 23.097 |

| Error | 2 | 4327 | 4327 | 2163 | 18.007 | ||

| Total | 8 | 24029 |

| Source | Degree of Freedom (DF) | Seq SS | Adj SS | Adj MS | F-Value | p-Value | % Contribution |

|---|---|---|---|---|---|---|---|

| S/N ratio | |||||||

| TA (°) | 2 | 3.5830 | 3.5830 | 1.7910 | 0.18 | 0.846 | 3.5378 |

| RS (rev/min) | 2 | 61.127 | 61.127 | 30.563 | 3.10 | 0.244 | 60.357 |

| TS (mm per min) | 2 | 16.831 | 16.831 | 8.4160 | 0.85 | 0.540 | 16.619 |

| Error | 2 | 19.734 | 19.734 | 9.8670 | 19.486 | ||

| Total | 8 | 101.275 | |||||

| Means | |||||||

| TA (°) | 2 | 19.300 | 19.300 | 9.6520 | 0.22 | 0.817 | 4.3549 |

| RS (rev/min) | 2 | 221.27 | 221.27 | 110.633 | 2.56 | 0.281 | 49.928 |

| TS (mm per min) | 2 | 116.15 | 116.15 | 58.0760 | 1.34 | 0.427 | 26.208 |

| Error | 2 | 86.450 | 86.450 | 43.2260 | 19.507 | ||

| Total | 8 | 443.18 |

| Source | Degree of Freedom (DF) | Seq SS | Adj SS | Adj MS | F-Value | p-Value | % Contribution |

|---|---|---|---|---|---|---|---|

| S/N ratio | |||||||

| TA (°) | 2 | 0.03729 | 0.03729 | 0.018644 | 2.73 | 0.268 | 17.778 |

| RS (rev/min) | 2 | 0.10103 | 0.10103 | 0.050514 | 7.39 | 0.119 | 48.167 |

| TS (mm per min) | 2 | 0.05777 | 0.05777 | 0.028885 | 4.23 | 0.191 | 27.542 |

| Error | 2 | 0.01367 | 0.01367 | 0.006833 | 6.5173 | ||

| Total | 8 | 0.20975 | |||||

| Means | |||||||

| TA (°) | 2 | 4.1130 | 4.1130 | 2.0563 | 2.78 | 0.264 | 17.955 |

| RS (rev/min) | 2 | 11.040 | 11.040 | 5.5198 | 7.47 | 0.118 | 48.195 |

| TS (mm per min) | 2 | 6.2770 | 6.2770 | 3.1384 | 4.25 | 0.191 | 27.402 |

| Error | 2 | 1.4780 | 1.4780 | 0.7391 | 6.4522 | ||

| Total | 8 | 22.907 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muribwathoho, O.; Msomi, V.; Mabuwa, S. Optimizing FSP Parameters for AA5083/SiC Composites: A Comparative Analysis of Taguchi and Regression. Metals 2025, 15, 280. https://doi.org/10.3390/met15030280

Muribwathoho O, Msomi V, Mabuwa S. Optimizing FSP Parameters for AA5083/SiC Composites: A Comparative Analysis of Taguchi and Regression. Metals. 2025; 15(3):280. https://doi.org/10.3390/met15030280

Chicago/Turabian StyleMuribwathoho, Oritonda, Velaphi Msomi, and Sipokazi Mabuwa. 2025. "Optimizing FSP Parameters for AA5083/SiC Composites: A Comparative Analysis of Taguchi and Regression" Metals 15, no. 3: 280. https://doi.org/10.3390/met15030280

APA StyleMuribwathoho, O., Msomi, V., & Mabuwa, S. (2025). Optimizing FSP Parameters for AA5083/SiC Composites: A Comparative Analysis of Taguchi and Regression. Metals, 15(3), 280. https://doi.org/10.3390/met15030280