Abstract

Under high fluence and a high repetition rate, femtosecond laser drilling still produces defects due to heat accumulation. In order to suppress these defects, this study conducted research on water-assisted femtosecond laser drilling. This study focused on the impact of two different water-assisted methods, static-water-based and flowing-water-based approaches, on the quality of microholes made using layer-by-layer helical drilling with a femtosecond laser in thermal-barrier-coated superalloys. Furthermore, the effects of single-pulse laser energy on the hole entrance/exit diameter, taper angle, sidewall morphology, sidewall roughness, and sidewall oxygen content in the two water environments were compared and analyzed. Water-based-assisted laser drilling is an auxiliary method where the lower surface of the workpiece is placed in water while the upper surface remains in the air. On the other hand, the water flows horizontally in the flowing-water-based method. The experimental results demonstrate that both static- and flowing-water-based methods can significantly improve the quality of femtosecond laser drilling. Notably, the improvement effect was more pronounced with the flowing-water-based method. At a laser pulse energy of 50 μJ, the hole taper angle in the flowing-water environment was reduced by 38.80% compared with that in the air. With flowing-water-based assistance, the hole sidewall roughness was lower and the melt was less. Flowing water was better at carrying away the debris and heat generated by processing. The oxygen content of the hole sidewalls decreased significantly in both kinds of water-assisted environments. The experimental results provide a valuable reference for optimizing water-assisted femtosecond laser drilling.

1. Introduction

Laser processing technology has been widely used in the agricultural engineering [1,2], precision manufacturing, optics, biomedical, and aerospace industries [3,4]. Aero-engine manufacturing technology serves as a crucial indicator of a country’s industrial capacity and level of application. Turbine blades, as fundamental components of aero-engines and gas turbines, endure cyclic alternating and dynamic loads, such as centrifugal force, aerodynamic force, and temperature stress, within a harsh working environment characterized by high temperatures, pressures, speeds, and gas corrosion. Thermal barrier coating (TBC) has the advantages of reducing the blade surface temperature, improving blade resistance to high-temperature oxidation corrosion, prolonging the blade service life, reducing engine fuel consumption, etc. It is one of three key technologies for turbine blades and is of equal importance to advanced high-temperature structural material technology and efficient cooling technology [5]. Due to the limited ability of TBC to isolate high temperatures, the structure is given a cooling gas film hole to increase the upper limit of the working temperature of the turbine blades. The cooling medium is introduced into the main airflow through the gas film hole, where it adheres to the blade wall under the pressure and friction of the gas flow within the turbine. This results in the formation of a low-temperature gas film that effectively isolates the high-temperature gas on the surface of the turbine blade while simultaneously removing a significant amount of thermal radiation [6]. Padture et al. [7] demonstrated that the application of TBC and thin-film cooling techniques enables an engine to operate at temperatures exceeding the melting temperature of the substrate.

The traditional methods for processing film-cooling holes include laser drilling, electro-hydraulic beam drilling, and EDM (Electrical Discharge Machining) drilling. Laser drilling has been more widely used because of its flexibility, but this material removal process produces significant thermal effects, resulting in delamination cracks, recast layers, and other defects [8,9]. Compared to conventional processing, femtosecond lasers minimize the thermal effects on almost all materials, making them advantageous for the complex hot end components of aero-engines, particularly turbine blades with thousands of film-cooling holes [10,11]. The utilization of femtosecond laser drilling technology addresses the challenges associated with significant thermal impacts, the formation of recasting layers, and the occurrence of micro-cracks in long-pulse laser drilling [12,13]. In order to process a deeper, larger-diameter hole and ensure processing efficiency, a high laser energy density is required. However, at high laser energy densities, especially with a high pulse repetition frequency, heat can accumulate, leading to thermal damage. Additionally, slag particle residue may appear on the sidewall of the hole, and micro-cracks and recast layers may also form [14,15]. Therefore, improving the quality of the hole sidewalls in laser drilling and reducing the thermal damage at high laser energy densities and high pulse repetition rates are urgent problems. In recent years, various assistance technologies have been applied to femtosecond laser drilling, including ultrasonic vibration assistance [16], magnetic assistance [17], and water assistance [18,19].

The water-assisted laser processing method, being an advanced manufacturing technique, can effectively mitigate or eliminate the aforementioned imperfections. Common water-assisted laser drilling processes include underwater-assisted laser drilling [18,20], water-jet-assisted laser drilling [21], and water-jet-guided laser drilling [22,23]. Zhang et al. [24] proposed a backwater-assisted laser processing method, which can reduce the taper angle of small holes and improve the holes’ roundness and consistency. The results demonstrate that, in comparison to direct laser drilling, the taper angle can be reduced by 6°, resulting in a 40~60% increase in processing efficiency and a significant reduction in deformation in the slag, hole wall recast layer, and filter. The laser drilling effect on copper, iron, stainless steel, and other metals with varying thicknesses in both air and water environments was compared by Lu et al. [25]. It was observed that the drilling efficiency was higher in water, leading to significant improvements in the surface morphology of the drilled holes. The intensity of the liquid jet pulse caused by the collapse of the cavitation bubble in the liquid on the material boundary was 12.5 times that of the laser ablation impact in air. Feng et al. [26] compared the drilling of zirconia holes using a picosecond laser in both water and air, and they also studied the influence of different laser parameters on hole quality. They found that the mechanism by which the zirconia phase transitioned from the tetragonal to monoclinic phase differed between air drilling and underwater drilling approaches, thus indicating minimal impact on the mechanical properties of the surrounding materials when drilled underwater. Liu et al. [27] drilled film-cooling holes into nickel-based single-crystal turbine blades using a 532 nm Nd: YVO4 nanosecond laser in a coaxial water-jet-assisted environment.

To conclude, in order to enhance the drilling quality, both domestic and international scholars have proposed water-assisted laser drilling methods. The results demonstrate that water-assisted femtosecond laser drilling can significantly improve the hole taper, thermal effect, micro-cracks, residual stress, recast layers, and other aspects. However, most studies have been on a single assistance method, and different methods have not been compared. The static-water-assisted mode has problems such as material slag and plasma pollution, which affects the surrounding water environment. Additionally, sewage spilling into orifices through capillary action will impact laser refraction and transmission. In order to further improve this phenomenon, a water-assisted femtosecond laser layer-by-layer helical drilling platform was constructed in this study. The effects of single-pulse energy on the hole diameter, taper, hole sidewall roughness, recast layer, and slag were analyzed. Femtosecond laser drilling experiments on superalloys with thermal barrier coatings were carried out in two different water-assisted modes, namely, static-water-based assistance and flowing-water-based assistance. The changes in hole quality with the two assistance methods were compared, and the influence mechanism was also analyzed. The results provide a theoretical basis for femtosecond laser drilling with flowing-water assistance, as well as technical support for the processing of holes in turbine blades with TBCs.

2. Experimental Setup and Procedure

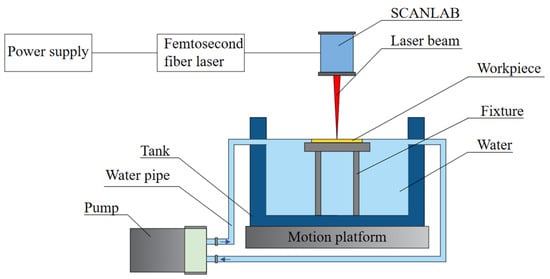

The flowing-water-based-assisted femtosecond laser layer-by-layer helical hole-drilling experimental platform built in this study is shown in Figure 1. The system primarily consists of a high-power femtosecond fiber laser processing center (Suzhou Delphi Laser Co., Ltd., Suzhou, China) and a flowing-water-based assistance device. The laser scanning path of helix layer-by-layer drilling can be achieved by controlling the optical module and operation platform in the machining center. One can switch between the static-water and flowing-water assistance modes by turning the external pump (Kamoer Fluid Technology Co., Ltd., Shanghai, China) on and off. The experiments mainly compared laser drilling conditions in the air, static-water, and flowing-water environments. The water surface should be as level as possible with the upper surface of the workpiece under both static- and flowing-water conditions, ensuring that, when a hole in the workpiece has just been drilled, the water medium can fully penetrate it through capillary action and laser shock to facilitate subsequent processing. However, it is important to keep the upper surface free from water, as excessive water has adverse effects on laser beam propagation (such as energy loss and changes in the beam propagation path). In this experiment, the flow rate of the water in the fixture was controlled by adjusting the flow rate of the water pump. It is difficult for flowing water to promote processing when the flow rate is too low. Conversely, when the flow rate is too high, the water may overflow onto the surface of the workpiece, affecting the processing. Through preliminary experiments, the flow rate of the pump was determined to be 0.042 L/s. At this flow rate, the water velocity was 1.48 m/s.

Figure 1.

Schematic diagram of the flowing-water-based-assisted femtosecond laser layer-by-layer helical trepanning system.

The ultra-high-performance fiber femtosecond laser used in this experiment was produced by Active Fiber Systems, and the five-axis dual-station precision machining tool control system used was manufactured by Delong Laser. The performance parameters of the femtosecond laser are shown in Table 1. Both the scanning galvanometer (SCANLAB GmbH, Puchheim, Germany, IntelliSCAN 14III) and the helical optical rotation module system were equipped in the optical path of the device. A scanning galvanometer module system was used in the experiment. The maximum scanning speed of this system is 2 m/s, and it can achieve a single maximum scanning area of 80 mm × 80 mm.

Table 1.

Femtosecond laser parameters.

The preparation of experimental samples was achieved in two steps. Initially, the metal substrate—which, in this experiment, was the GH4169 superalloy procured from Shanghai Nide Metal Co., Ltd. (Shanghai, China)—underwent processing. Subsequently, a coating was sprayed onto the processed substrate. Some of the primary chemical components of this superalloy are detailed in Table 2. A round metal rod was cut into the initial workpiece sample using the wire-cutting method with a certain grinding and polishing allowance. A metallographic sander with waterproof sandpaper was used to remove the scratches left by wire cutting until the sample thickness reached 1.4 mm. Subsequently, a TBC layer consisting of 8 wt.% yttria-stabilized zirconia (YSZ) with a thickness of 200 μm was deposited using atmospheric plasma spraying (APS); a bond coat layer (BC) was added between the TBC and the substrate [28]. The BC layer was made of modified aluminide coating (NiCoCrAlY) with a thickness of 100 μm. The sample was put into a beaker and washed for 5 min with an ultrasonic cleaning machine (the cleaning liquid used in this study was anhydrous ethanol) to remove surface debris and dirt. Next, the sample was removed, air-dried, and packaged and marked for later use.

Table 2.

Chemical composition of the nickel-based superalloy GH4169.

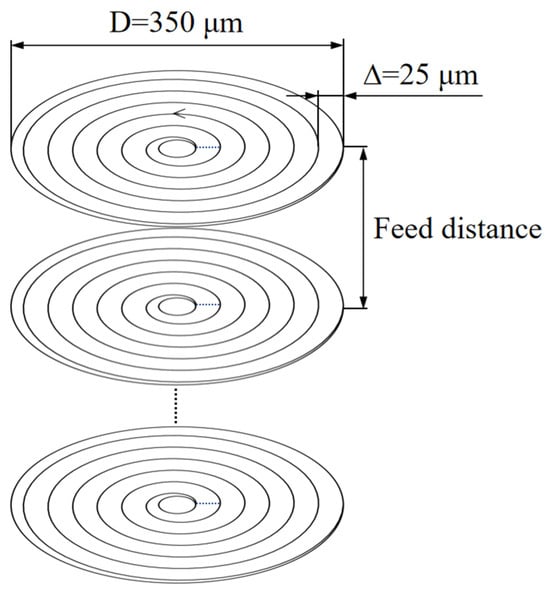

During the experiment, holes were first drilled in an air environment. Then, after adding the required amount of water (the water surface just reached the upper surface of the workpiece using ordinary pure water), holes were drilled again. Finally, a circulating pump was turned on to replenish the water level to the same level as that of the static-water-based medium, and then laser drilling was carried out. As shown in Figure 2, the scanning path of the laser on the workpiece was a spiral line with a pitch of 25 μm and a maximum radius of 350 μm. The laser beam moved along the spiral from the inside out. After processing one layer, the laser beam was fed downward to process the next layer until the end of the processing procedure, thus achieving the processing effect of layer-by-layer spirals. The feed distance and the number of downward feeds are presented in Table 3. The remaining specific process parameters are shown in Table 3. Holes with the same set of parameters were processed three times. The manufacturing time for each hole was approximately 120 s.

Figure 2.

Schematic diagram of the helical hole produced by femtosecond laser layer-by-layer drilling.

Table 3.

The specific parameters used in the experiment.

After the experiment, the samples underwent treatment and were subjected to a multi-step measurement analysis. Firstly, the sample was cleaned using an ultrasonic cleaning machine (Shenzhen Meiruigao Technology Co., Ltd., Shenzhen, China), the geometric morphology of the hole was observed and measured, and the taper angle was calculated. Then, the microhole cross-section was exposed by grinding and polishing. Ultrasonic cleaning of the sample should also be maintained during grinding and polishing to prevent abrasive particles and debris from blocking the microhole or scratching the sidewall. The hole cross-section and the morphology of the hole sidewall were observed using confocal microscopy (CLSM) (KEYENCE Corporation, Osaka, Japan), and the surface roughness of the sidewall was also characterized and measured. The quality of the hole sidewall was characterized using a variable vacuum tungsten filament scanning electron microscope (SEM) (Hitachi, Ltd., Tokyo, Japan). Finally, the element content in the sidewall of the hole was measured to analyze its oxidation.

3. Results and Discussion

3.1. Measurement and Analysis of Microhole Geometry

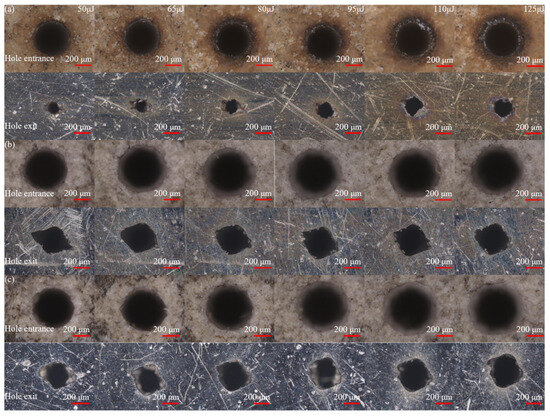

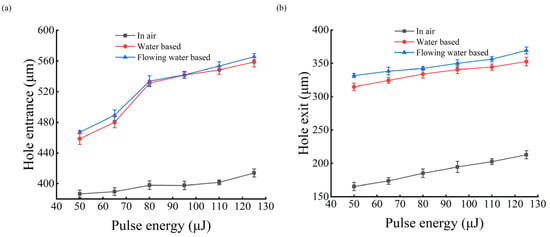

The entrance and exit morphologies of the holes fabricated by the femtosecond laser in air, static-water, and flowing-water environments are shown in Figure 3. The results indicate that the diameters of the hole entrances and exits all increased with static- and flowing-water-based assistance. Moreover, with the increase in the single-pulse energy of the laser, the diameters of the entrances and exits of the holes showed an increasing trend. The interaction between the femtosecond laser and materials was a complex process involving heating, melting, vaporization, particle ejection, and the growth and expansion of plasma [29]. During the initial stage of processing in an air environment, even the relatively low laser energy had already exceeded the ablation threshold of the material, thus allowing the material to be removed. As the processing continued, the deeper the hole became, the more severe the shielding effect of the plasma cloud generated inside the hole, thus resulting in insufficient laser energy, making it impossible to ensure the complete removal of the material within the irradiated area. With an increase in the drilling depth, the unremoved material gradually accumulated, ultimately leading to a decrease in the exit diameter and an increase in the taper angle. The increase in the single-pulse energy of the laser could effectively enhance the laser energy density in the middle and at the exit of the hole, making the processing more thorough. This was because, after the hole was drilled, the siphoning and oscillation effects of the laser caused water to enter the hole from the hole exit. At this time, part of the laser energy acted directly on the material, while a larger part was absorbed by the water to generate plasma [30,31]. Then, the thermal energy in the plasma diffused into the material, causing the material to be removed through melting and vaporization. Meanwhile, the interaction between the laser and water generated cavitation bubbles. When these bubbles collapsed and burst at the boundary of the hole wall, high-speed wall-directed liquid jets were produced [32]. This process could also effectively achieve the purpose of removing the material, thus improving the processing efficiency. It can be concluded from Figure 4 that the exit diameters of the microholes processed in the flowing-water environment were larger than those in the static-water environment. After water was included in the processing procedure, as hole drilling progressed, a large amount of processing debris accumulated at the hole exit and could not be discharged in a timely manner. Consequently, debris containing metal ions remained in the hole, reducing the absorption rate of laser energy. Additionally, due to a blocking effect, the density of cavitation bubbles and the laser-induced plasma plume increased, and the shielding effect on the laser became more pronounced, thus impeding the processing. However, the flowing-water environment enhanced the circulation of water inside the microholes, effectively washing away the debris and bubbles generated on the back of the workpiece and reducing the shielding effect on the laser. This enabled clean water to steadily enter the holes and participate in the removal of substances, which effectively improved the material removal rate at the hole’s exit position.

Figure 3.

The morphologies of the entrances and exits of the holes under different single-pulse energies: (a) in air; (b) static-water-based method; and (c) flowing-water-based method.

Figure 4.

The hole cross-section morphology using different single-pulse energies: (a) in air; (b) static-water-based method; and (c) flowing-water-based method.

It can be observed in Figure 3 that, in the air environment, molten materials accumulated at the hole entrance, and there was a considerable thermal effect phenomenon. Similarly, a pronounced heat-affected processing zone appeared at the hole exit. In contrast, this phenomenon was hardly seen in the static-water and flowing-water environments. With the increase in single-pulse energy, the thermal accumulation effect on the workpiece intensified rapidly, and the density of the plasma plume generated by the laser acting on the material also increased. Consequently, the volume of the molten material accumulating at the hole entrance in the air environment increased. In the water environment, the molten materials, plasma plumes, etc., generated after the material was removed rapidly cooled under the action of water, forming solid particles or ions in the solution. After the hole was drilled, the upward floating effect of the water effectively promoted the discharge of processing debris. After heating, water vapor drove the plasma plumes to float upward, and, at the same time, the high-speed water jets generated by the rupture of cavitation bubbles flushed the processing debris from the entrances and exits of the holes [33]. The cooling effect of water during processing could also effectively eliminate the influence of the thermal effect.

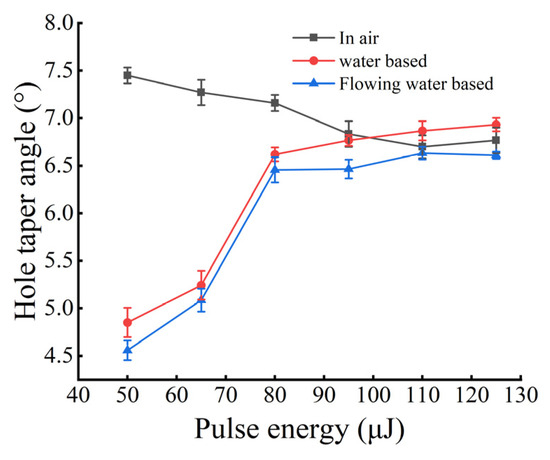

Figure 4 shows the cross-section morphology of the holes fabricated by the femtosecond laser under the air and two water-assisted conditions. After combining this information with that in Figure 5, it can be observed that the utilization of flowing-water-based assistance resulted in the highest rate of material removal from the hole and the smallest average taper angle. Conversely, when drilling in the air, the rate of material removal from the hole was at its lowest, and the average taper angle was at its highest. The hole taper angle is one of the inherent manufacturing problems associated with the laser drilling process, and it is influenced by many factors, such as the Gaussian distribution of laser energy and Fresnel reflection [34]. Moreover, in the drilling process, with the increasing depth of hole drilling, the hole cross-section area increased. In addition, the absorption and scattering of the laser energy by the hole increased, which reduced the energy at the bottom of the hole, and the ablation rate of the material gradually decreased. The large amount of plasma that was ejected during processing also hindered the ablation effect of the laser on the lower layer. This also caused differences in roundness and roughness on both sides of the hole. According to the polarization theory, a laser can be decomposed into p-light and s-light in the vertical vibration direction. With a change in the incident angle, the difference in the absorption rates of p-light and s-light by the material increases sharply [35,36]. During the laser drilling process, there was a gradual increase in the depth of the microhole, which led to an increase in the incidence angle of the laser relative to the sidewall, resulting in an uneven absorption of p-light and s-light by the material. This phenomenon eventually led to an irregular outlet shape and a poor microhole taper angle [35].

Figure 5.

The influence of the single-pulse laser energy on the hole taper angle.

Overall, the hole taper angles in static-water and flowing-water environments were smaller than those in the air environment, but they increased with the increase in single-pulse energy. After water was included in the machining process, it absorbed the laser energy to form high-temperature and high-pressure plasma, as well as cavitation bubbles. The plasma transmitted the energy to the material, and, with the assistance of shock waves, additional material was removed through melting and vaporization. Since the top of the initial through-hole was wide and the bottom was narrow, the compressed space enabled the plasma to generate a stronger impact, leading to a significant increase in the material removal rate near the exit of the microhole [37]. This phenomenon significantly reduced the taper angle of the hole. During the subsequent machining process, the exit of the hole enlarged and the taper decreased, which decreased the degree of aggregation of plasma and cavitation bubbles caused by the narrow bottom. Moreover, since the laser first contacted the liquid surface, which was closer to the entrance position of the hole, water was able to promote the removal of the material at the entrance of the hole to a greater extent. The data in Figure 6 also demonstrate this phenomenon. When the single-pulse energy was 50 μJ, compared with the machining data in the air environment, the diameter of the hole entrance in the static-water environment increased by 18.62%, while the diameter of the exit increased by 90.32%. When the single-pulse energy was increased to 125 μJ, the entrance and exit diameters in the static-water environment increased by 21.83% and 12.07%, respectively, compared with those at 50 μJ in the same environment. The overall situation in the flowing-water environment was similar to that in the static-water environment. Therefore, it could be concluded that the addition of the two water environments significantly increased the diameter of the hole exit, while the increase in single-pulse energy further enlarged the diameter of the hole entrance. As shown in Figure 6, the entrance diameters of the microholes machined in the flowing-water and static-water environments were similar. However, the exit diameters of the microholes in the flowing-water environment were larger. Therefore, the taper angles of the microholes in the flowing-water environment were smaller, and the material removal rate was higher.

Figure 6.

The influence of single-pulse laser energy on the hole diameter: (a) hole entrance; (b) hole exit.

Improvements in the hole diameter and taper when laser drilling under the two water environment conditions compared with those in air conditions at different single-pulse energies are shown in Table 4. Compared with the results under air conditions, the entrance diameter of the holes increased by 18.62% to 36.51%, the exit diameter increased by 65.57% to 90.32%, and the taper angle decreased by −2.51% to 34.89% when using laser drilling assisted by the static-water-based medium approach at different single-pulse energies; for laser drilling assisted by the flowing-water-based medium approach, the hole entrance diameter increased by 20.78% to 37.76%, the exit diameter increased by 73.40% to 100.60%, and the taper decreased by 1.00% to 38.80%.

Table 4.

Improvements in the microhole aperture and taper when using the two water-assisted modes and different single-pulse energies compared with those under air conditions. Unit: %.

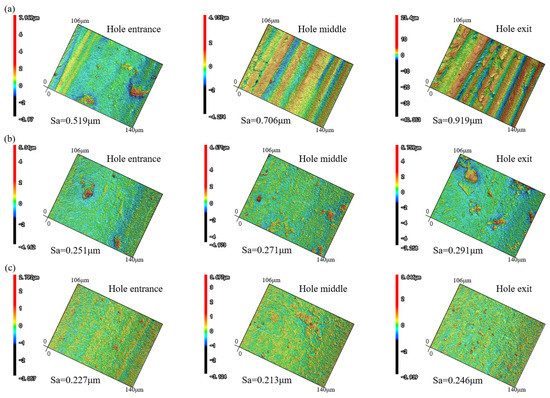

3.2. Measurement and Analysis of the Microhole Sidewall Quality

Figure 7 shows the 3D topography images of the sidewalls captured at the inlet, middle, and outlet of femtosecond-laser-drilled holes under the air and two water-assisted conditions when the single-pulse energy of the laser was 125 μJ. Under static-water-based and air conditions, the roughness of the hole sidewalls increased as the depth of the measurement position increased. In the air, gullies in the same direction as the laser irradiation could be seen on the hole walls. This was due to the unevenness of material directly processed by the laser along the same path, as well as redeposition. However, in the water environment, the water absorbed the laser energy, generating plasma and cavitation bubbles, which then acted on the material to achieve the removal effect, thus improving this phenomenon. Overall, the quality of the sidewalls of the holes with static-water assistance was better than that under air conditions, but there were still more redeposited melts at the outlet. When laser drilling was assisted by flowing water, the quality of the sidewalls of the holes was the best. Moreover, the roughness values of the sidewalls in different regions of the holes did not fluctuate much, and the overall morphology was relatively smooth.

Figure 7.

CLSM images of the 3D morphologies of hole sidewalls at different positions when the single-pulse laser energy was 125 μJ: (a) in air; (b) Static-water-based method; (c) flowing-water-based method.

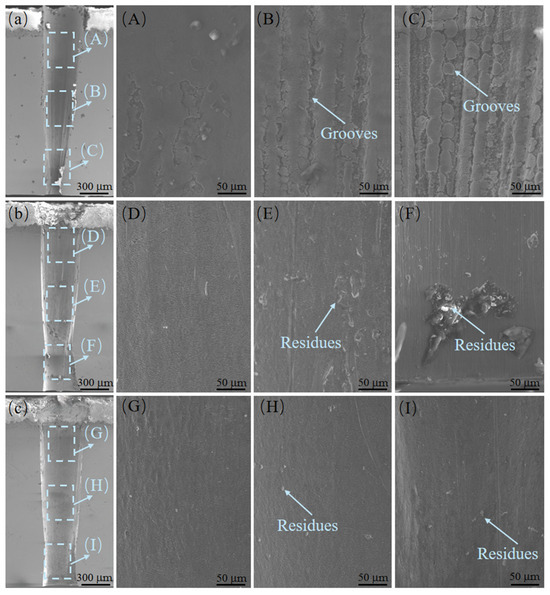

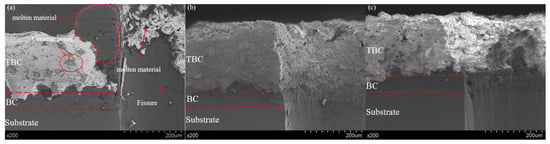

Figure 8 shows the SEM images of the cross-sections of the femtosecond-laser-drilled holes under the air and two water-assisted conditions when the single-pulse energy of the laser was 125 μJ. It can be seen that, in the air environment, there were grooves on the sidewalls of the holes. In the static-water environment, there were small amounts of residue at the middle and outlet of the holes. However, in the flowing-water environment, the holes were generally smooth and free of residues.

Figure 8.

SEM observations of the hole cross-section when the single-pulse laser energy was 125 μJ: (a) in air (A-Top, B-Middle, C-Bottom); (b) static-water-based method (D-Top, E-Middle, F-Bottom); (c) flowing-water-based method (G-Top, H-Middle, I-Bottom).

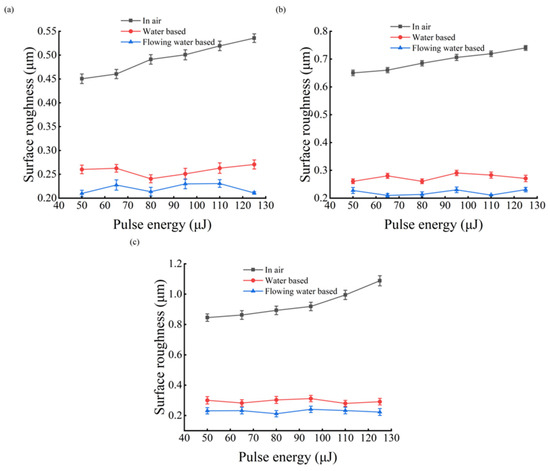

Figure 9 shows the variation curves of the roughness values in the different regions of the microhole sidewalls with the increase in the single-pulse energy of the laser in the two water environment conditions and in air. The results show that, with the increase in single-pulse energy, the roughness value of the sidewalls in air continually increased; meanwhile, in the two water environments, the roughness of the sidewalls changed little, and the values were relatively low. When a high-power laser beam penetrated the water and was focused on the target, a small portion of the material melted, vaporized, and became ionized, forming high-temperature and high-pressure plasma on the surface of the target [19]. The plasma expanded, creating a recoil pressure on the surface of the sample, which led to the removal of the material. Due to the pressure under the liquid, the recoil force and expansion pressure of the plasma increased. The intensity of the plasma-induced shock in the liquid region was four times higher than that in air, and the duration of the shock wave was two to three times longer [38]. Meanwhile, the increase in the recoil pressure promoted the removal of the materials generated during processing, and the formation of remelted substances inside the holes was reduced [39]. In addition, the laser induced the formation of cavitation bubbles in water [40]. When these bubbles burst near the surface of the sample, a high-speed liquid jet was generated [41], which exerted a strong impact on the sample. The intensity of this pulse was 5.2 to 12.4 times that of the laser ablation impact in air [39]. The cavitation effect caused by the collapse of bubbles removed the materials on the sidewalls more evenly, making the overall morphology smoother. In contrast, the roughness of the hole sidewalls in the flowing-water environment was generally lower than that in the static-water environment. This was because the flowing water was better at carrying away the debris generated during processing and reducing heat accumulation.

Figure 9.

The influence of the single-pulse laser energy on the hole sidewall roughness: (a) hole entrance; (b) hole middle; and (c) hole exit.

The improvements in the roughness of the sidewalls of the holes drilled by the laser in the two water environments and in air at different single-pulse energies are shown in Table 5. In comparison with air conditions, at different single-pulse energies, the roughness at the entrance of the hole sidewall in the static-water-assisted laser drilling environment was reduced by 42.19% to 50.98%, the roughness in the middle was decreased by 57.55% to 63.38%, and the roughness at the exit was diminished by 64.47% to 73.26%; with the flowing-water-assisted laser drilling approach, the roughness of the hole sidewall was reduced by 50.54% to 60.61% at the entrance, by 64.99% to 70.67% in the middle, and by 72.63% to 79.51% at the exit.

Table 5.

The improvements in the hole sidewall roughness using the two water-assisted methods and different pulse energies compared with air conditions. Unit: %.

Figure 10 shows SEM images of the sidewalls at the entrances of holes created using the two water-assisted methods and in air when the single-pulse energy of the laser was 125 μJ. Due to the high infrared reflectivity of the TBC, part of the laser energy was reflected, reducing the effective energy input of the laser to the material. Therefore, a longer processing time was required. The low thermal conductivity of the TBC makes it difficult for the heat generated by laser action to conduct and diffuse, resulting in high temperature accumulation in the coating surface and near-surface areas, thus leading to excessive ablation of the coating. As can be seen from Figure 10, in air, the TBC layer experienced excessive ablation due to heat accumulation. The inner wall of the hole was covered by the molten material generated during processing, and the molten material accumulated to a certain height at the coating position of the hole exit. In the working environment, the accumulation of molten material will change the shape and size of the air film hole exit, altering the direction and velocity distribution of the cooling air flow when it exits. The originally designed uniform air film-cooling flow field was thus disrupted, causing uneven coverage of the cooling air flow in some areas and reducing the cooling efficiency. The composition and thermal expansion coefficient of the molten material were different from those of the thermal barrier coating. Thermal stress was generated between them during the temperature change process. This thermal stress weakened the bonding force between the molten material and the thermal barrier coating, as well as that between the thermal barrier coating and the substrate. In these two water environments, the demarcation lines of the TBC, the BC, and the metal substrate could be clearly seen on the sidewall of the hole, and molten substances were not observed (which was basically the same as the situation at the unperforated positions). However, the sidewall of the hole that was created under air conditions was covered by the molten substances generated during the processing, and the molten substances piled up to a certain height above the hole exit. Moreover, the TBC layer also suffered excessive ablation that was larger than the hole diameter due to heat accumulation. This is because, after the hole was drilled, water participated in the processing, thus removing the plasma and molten substances generated during the processing. Meanwhile, it also played a cooling role, removing the residual heat from the processing and avoiding the excessive ablation of the TBC layer.

Figure 10.

SEM images of the sidewall of the hole entrance in different environments with a single-pulse laser energy of 125 μJ: (a) in air; (b) static-water-based method; (c) flowing-water-based method.

3.3. Sidewall Oxidation of the Microhole

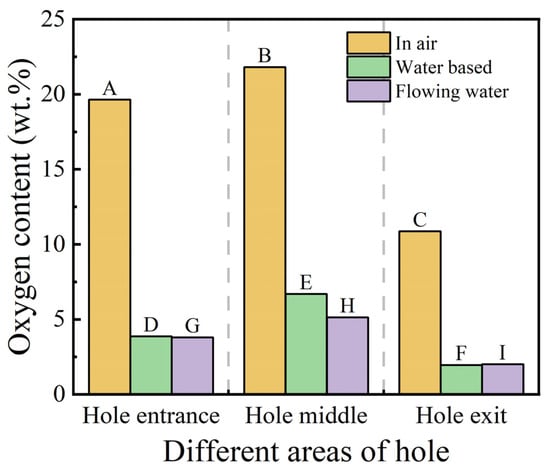

The oxidation state of the materials at different positions on the sidewall of the hole was further observed through elemental analysis, as shown in Figure 8. The comparison of the oxygen content on the sidewall of the hole at different positions is shown in Figure 11. In the air environment, the oxygen content was the highest at the middle position of the hole, followed by that at the entrance of the hole and then at the exit of the hole. This was because when the single-pulse energy of the laser increased, the heat accumulation during processing intensified, and the high-temperature and molten materials underwent oxidation reactions with the oxygen in the air. The metal on the inner wall of the hole combined with oxygen to form metal oxides. Due to the relatively large ratio of the hole depth to the diameter, the heat at the middle position of the hole was not easily dissipated during processing. Therefore, its oxidation rate was relatively high. Meanwhile, the oxygen content at the middle position of the hole was the highest since the molten substances generated during processing at the middle position of the hole were more difficult to remove. During the whole processing procedure, compared with the position at the hole exit, the energy at the hole entrance was higher and the contact time with the laser was longer. Therefore, the degree of oxidation at the hole entrance was higher.

Figure 11.

The oxygen element wt.% (A–I) at the different positions shown in Figure 8.

In the static-water and flowing-water environments, when the single-pulse energy of the laser increased, under the influence of heat accumulation, the temperature of the sidewall of the hole gradually rose, and an oxidation reaction occurred with the dissolved oxygen in the water. Similar to the situation in air, the heat accumulation at the middle position of the hole was greater than that at the entrance of the hole, which was, in turn, greater than that at the exit of the hole. Therefore, the oxygen content also corresponded with heat accumulation. However, since the content of dissolved oxygen in water was far less than that in air, the change in the source of oxygen elements made the oxygen content of materials in the water environment far less than that of materials in the air. The cooling effect of the water medium alleviated the heat accumulation during the machining process, reducing the temperature of the material. Meanwhile, it carried away the machining debris, leaving only a small amount of molten matter on the sidewalls of the holes. These two factors also improved the oxidation situation of the material on the sidewalls of the holes. As shown in Figure 11, at the middle position of the hole, the oxygen content of the material in the flowing-water environment was lower than that in the static-water environment.

3.4. Theoretical Analysis

In air, when a laser irradiates the surface of a thermal barrier coating, the atoms and molecules in the material, under the influence of a strong laser field, absorb multiple photons simultaneously. This causes electrons to transition from low energy levels to high energy levels and, in some cases, to even break free from the constraints of atoms and molecules, forming free electrons. These free electrons collide with surrounding atoms or molecules, causing further ionization. A chain reaction, known as avalanche ionization, occurs, generating high-density plasma in a short period. Under the action of high-temperature and high-pressure plasma, the material transforms directly from a solid state to a gaseous state, or a plasma state, and it is removed in the form of eruptions or vaporization. As the processing progresses and the hole deepens, the molten material accumulates above the hole opening and the plasma cloud impedes the propagation of laser energy. This leads to incomplete material removal, increasing the taper of the hole. Molten material that is not promptly discharged from the hole adheres to the inner wall of the hole, increasing the surface roughness.

During water-based-assisted laser drilling, right after the hole is created, water enters the hole along with the oscillation of the high-frequency laser beam. Cavitation occurs in the water under the action of the laser. When the cavitation bubbles collapse, they generate local high-temperature, high-pressure micro-jets. These micro-jets and high pressure further impact the inner wall of the hole, assisting in material removal. When the pulsed laser irradiates the material surface, strong pressure waves and shock waves are generated in the water medium and act on the inner wall of the hole. Furthermore, when the stress exceeds the material’s limit, the material is removed. The relatively high specific heat capacity and thermal conductivity of the water medium cause the melted material to cool and solidify rapidly, suppressing the formation of a recast layer and the adhesion of molten substances, which improves the quality and performance of the inner wall of the hole. However, as the hole deepens, the bubbles and debris generated during processing accumulate in the hole, inhibiting the propagation of laser energy to some extent. Flowing water can promptly carry away the molten material and debris generated by the interaction between the laser and the material, preventing these substances from accumulating at the hole entrance or re-attaching to the hole wall. This enables the laser to continuously act on the material, reducing the energy loss caused by obstacles such as slag, thereby improving the material removal efficiency. At the same time, the flowing water also carries away excessive cavitation bubbles and plasma, reducing their shielding effect on the laser.

4. Conclusions

In this study, experimental research was conducted on the effects of two water-assisted femtosecond laser drilling methods, namely, static-water-based and flowing-water-based methods. The geometric morphology of microholes and the quality of hole sidewalls using different single-pulse laser energies were analyzed, thus providing a new process for water-assisted femtosecond laser drilling. The following conclusions can be drawn:

- 1.

- Compared with air conditions, both water-based assistance methods can significantly increase the diameters of the hole entrances and exits that are produced by femtosecond laser drilling of a superalloy with a thermal barrier coating, reduce the taper of the holes, and improve the quality of microhole sidewalls. However, the overall quality of the microholes in the flowing-water environment was better.

- 2.

- Both water-assisted methods increased the material removal rate in the femtosecond laser hole-drilling process. The proportion of the increase was even greater in the flowing-water-based method. When the pulse repetition frequency was 150 kHz and the single-pulse energy was 50 μJ, the hole taper angle was reduced by 38.80% compared with that produced under air conditions.

- 3.

- The sidewall roughness of the microholes continually increased under air conditions as the single-pulse energy of the femtosecond laser increased. However, there were no significant changes under the two water-assisted conditions, and the overall roughness was reduced. The sidewalls were even smoother under flowing-water conditions. Compared with the air conditions, when the single-pulse energy reached 125 μJ, the flowing-water-based method reduced the sidewall roughness at the exit of the microholes by 79.51%.

- 4.

- Under air conditions, a large amount of molten matter adhered to the sidewalls of the holes and accumulated at the hole entrance positions. Under static-water condition, a small amount of granular molten matter adhered to the exit positions of the holes. However, there was no obvious molten matter on the sidewalls of the holes under flowing-water conditions. The oxygen content on the sidewalls of the holes was significantly reduced in both water environments compared with air conditions.

- 5.

- Flowing-water-assisted femtosecond laser hole drilling is applicable to the processing of film-cooling holes in aero-engine turbine blades, semiconductors, etc. When processing microholes with a high aspect ratio, this method can be used to reduce the taper angle of the microholes, improve processing efficiency, and enhance the quality of the microhole sidewalls.

Author Contributions

Conceptualization, N.R., H.Z. and K.X.; methodology, N.R., J.Z., H.Z. and K.X.; validation, N.R., J.Z., Z.L. and K.X.; formal analysis, Z.L. and D.Q.; investigation, J.Z., Z.L. and D.Q.; resources, N.R., H.Z. and K.X.; data curation, N.R., J.Z., Z.L. and D.Q.; writing—original draft preparation, J.Z., Z.L. and D.Q.; writing—review and editing, N.R., H.Z. and K.X.; supervision, K.X.; project administration, N.R., H.Z. and K.X.; funding acquisition, K.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (grant number 52205469).

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding authors.

Conflicts of Interest

Author Kaibo Xia was employed by Jiangsu university and a postdoctoral fellow at the company Suzhou Delphi Laser Co., Ltd., Suzhou, China. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Chen, H.; Geng, D.C.; Chen, T.; Lu, D.L.; Chen, B. Second-derivative laser-induced fluorescence spectroscopy combined with chemometrics for authentication of the adulteration of camellia oil. CyTA-J. Food 2018, 16, 747–754. [Google Scholar] [CrossRef]

- Feng, J.S.; Zhang, R.; Dabbour, M.; Mintah, B.K.; Gao, X.L.; He, R.H.; Ma, H.L. Enhancing acid production of Acetobacter pasteurianus by laser and intense pulsed light mutagenesis and its molecular mechanism based on transcriptomic analysis. LWT-Food Sci. Technol. 2023, 182, 114803. [Google Scholar] [CrossRef]

- Xia, K.B.; Yang, H.Y.; Ren, N.F.; Di, J.K.; Han, Q. Effects of water temperature on femtosecond laser layered-ring trepanning in superalloy with water-based assistance. Opt. Laser Technol. 2024, 170, 110311. [Google Scholar] [CrossRef]

- Bai, J.W.; Zhang, L.; Cai, J.R.; Wang, Y.C.; Tian, X.Y. Laser light backscattering image to predict moisture content of mango slices with different ripeness during drying process. J. Food Process Eng. 2021, 44, e13900. [Google Scholar] [CrossRef]

- Wei, S.B.; Lu, F.; He, L.M.; Xu, Z.H. Progress in processing techniques and ceramic materials of thermal barrier coatings. Therm. Spray Technol. 2013, 5, 31–37. [Google Scholar]

- Ning, M.; Zhu, H.R.; Qiu, Y.; Xu, D.C.; Liu, S.L. Review of aero turbine blade cooling technologies. Gas Turbine Technol. 2005, 18, 25–33. [Google Scholar]

- Padture, N.P.; Gell, M.; Jordan, E.H. Thermal Barrier Coatings for Gas-Turbine Engine Applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef]

- Beck, T. Laser drilling in gas turbine blades: Shaping of holes in ceramic and metallic coatings. Laser Tech. J. 2011, 8, 40–43. [Google Scholar] [CrossRef]

- Fan, Z.J.; Dong, X.; Wang, K.D.; Duan, W.Q.; Wang, R.J.; Mei, X.S.; Wang, W.J.; Cui, J.L.; Yuan, X.; Xu, C.Y. Effect of drilling allowance on TBC delamination, spatter and re-melted cracks characteristics in laser drilling of TBC coated superalloys. Int. J. Mach. Tools Manuf. 2016, 106, 1–10. [Google Scholar] [CrossRef]

- Feng, Q.; Picard, Y.N.; Liu, H.; Yalisove, S.M.; Mourou, G.; Pollock, T.M. Femtosecond laser micromachining of a single-crystal superalloy. Scr. Mater. 2005, 53, 511–516. [Google Scholar] [CrossRef]

- Feng, Q.; Picard, Y.N.; McDonald, J.P.; van Rompay, P.A.; Yalisove, S.M.; Pollock, T.M. Femtosecond laser machining of single-crystal superalloys through thermal barrier coatings. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2006, 430, 203–207. [Google Scholar] [CrossRef]

- Du, Y.; Zhao, K.; Zhu, Z.; Wang, J.; Deng, W.; Liang, X. Research and application of ultrafast laser precision manufacturing technology. Laser Infrared 2020, 50, 1419–1425. [Google Scholar]

- Wang, L.; Yang, H.Y.; Ren, N.F.; Wu, Z.T.; Xia, K.B. Experimental Characterization of Laser Trepanned Microholes in Superalloy GH4220 with Water-Based Assistance. Micromachines 2022, 13, 2249. [Google Scholar] [CrossRef]

- Sun, J.L.; Sun, H.L.; Yue, D.M.; Yang, X. Research on laser machining of microholes in superalloy with thermal barrier coating. Laser Infrared 2021, 51, 1259–1271. [Google Scholar]

- Yu, Y.Q.; Zhou, L.C.; Cai, Z.B.; He, W.F. DD6 single-crystal superalloy with thermal barrier coating in femtosecond laser percussion drilling. Opt. Laser Technol. 2021, 133, 106555. [Google Scholar] [CrossRef]

- Liu, B.; Dai, Y.T.; Yin, G.L.; Li, T. Exploration on ultrasonic vibration aided femtosecond laser machining process of fiber optic materials. Chin. J. Laser 2016, 43, 0303005. [Google Scholar]

- Xia, K.B.; Ren, N.F.; Lin, Q.; Li, T.; Gao, F.Q.; Yang, H.Y.; Song, S.W. Experimental investigation of femtosecond laser through-hole drilling of stainless steel with and without transverse magnetic assistance. Appl. Opt. 2021, 60, 1399–1410. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.J.; Song, H.W.; Liao, K.; Mei, X.S. Water-assisted femtosecond laser drilling of 4H-SiC to eliminate cracks and surface material shedding. Int. J. Adv. Manuf. Technol. 2021, 112, 553–562. [Google Scholar] [CrossRef]

- Behera, R.R.; Sankar, M.R. State of the art on Under Liquid Laser Beam Machining. Mater. Today Proc. 2015, 2, 1731–1740. [Google Scholar] [CrossRef]

- Tsai, C.H.; Li, C.C. Investigation of underwater laser drilling for brittle substrates. J. Mater. Process. Technol. 2009, 209, 2838–2846. [Google Scholar] [CrossRef]

- Nikolic, V.; Petkovic, D.; Lazov, L.; Milovancevic, M. Selection of the most influential factors on the water-jet assisted underwater laser process by adaptive neuro-fuzzy technique. Infrared Phys. Technol. 2016, 77, 45–50. [Google Scholar] [CrossRef]

- Zhang, Y.N.; Qiao, H.C.; Zhao, J.B.; Cao, Z.H. Research on water jet-guided laser micro-hole machining of 6061 aluminum alloy. Int. J. Adv. Manuf. Technol. 2022, 118, 1–13. [Google Scholar] [CrossRef]

- Liu, Q.; Zhao, Y.G.; Meng, J.B.; Wang, K.; Zhao, G.Y.; Li, L.; Zheng, Z.L.; Liu, G.X.; Cao, C.; Dai, D. Research on the Removal Mechanism of Resin-Based Coatings by Water Jet-Guided Quasi-Continuous Laser Cleaning. Appl. Sci. 2022, 12, 5450. [Google Scholar] [CrossRef]

- Zhang, X.S.; Zhang, Z.Y.; Zhu, H.; Li, S.W.; Wang, Y.F.; Xu, K.; Chu, S.L.; Huang, J.J. Mass Fabrication of Microholes in Aviation Kerosene Filters Using the Back-water-assisted Picosecond Laser Drilling Technique. Lasers Eng. 2022, 52, 37–54. [Google Scholar]

- Lu, J.; Xu, R.Q.; Chen, X.; Shen, Z.H.; Ni, X.W.; Zhang, S.Y.; Gao, C.M. Mechanisms of laser drilling of metal plates underwater. J. Appl. Phys. 2004, 95, 3890–3894. [Google Scholar] [CrossRef]

- Feng, D.C.; Shen, H. Hole quality control in underwater drilling of yttria-stabilized zirconia using a picosecond laser. Opt. Laser Technol. 2019, 113, 141–149. [Google Scholar] [CrossRef]

- Liu, Y.Z. Coaxial waterjet-assisted laser drilling of film cooling holes in turbine blades. Int. J. Mach. Tools Manuf. 2020, 150, 103510. [Google Scholar] [CrossRef]

- Kaplan, M.; Uyaner, M.; Avcu, E.; Avcu, Y.Y.; Karaoglanli, A.C. Solid particle erosion behavior of thermal barrier coatings produced by atmospheric plasma spray technique. Mech. Adv. Mater. Struc. 2019, 26, 1606–1612. [Google Scholar] [CrossRef]

- Li, Q.; Yang, L.J.; Hou, C.J.; Adeyemi, O.; Chen, C.Y.; Wang, Y. Surface ablation properties and morphology evolution of K24 nickel based superalloy with femtosecond laser percussion drilling. Opt. Lasers Eng. 2019, 114, 22–30. [Google Scholar] [CrossRef]

- Wang, X.S.; Huang, Y.K.; Wang, X.W.; Xu, B.; Feng, J.; Shen, B. Experimental investigation and optimization of laser induced plasma micromachining using flowing water. Opt. Laser Technol. 2020, 126, 106067. [Google Scholar] [CrossRef]

- Saxena, I.; Ehmann, K.; Cao, J. High throughput microfabrication using laser induced plasma in saline aqueous medium. J. Mater. Process. Technol. 2015, 217, 77–87. [Google Scholar] [CrossRef]

- Vogel, A.; Lauterborn, W. Time-resolved particle image velocimetry used in the investigation of cavitation bubble dynamics. Appl. Opt. 1988, 27, 1869–1876. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.; Zhang, Z.Y.; Xu, J.L.; Xu, K.; Ren, Y.P. An experimental study of micro-machining of hydroxyapatite using an ultrashort picosecond laser. Precis. Eng. J. Int. Soc. Precis. Eng. Nanotechnol. 2018, 54, 154–162. [Google Scholar] [CrossRef]

- Shen, Q.; Wang, T.; Song, Q.; Ye, F.; Li, H.; Fu, M.W. Unraveling of the laser drilling of carbon/carbon composites: Ablation mechanisms, shape evolution, and damage evaluation. Int. J. Mach. Tools Manuf. 2023, 184, 103978. [Google Scholar]

- Weber, R.; Michalowski, A.; Abdou-Ahmed, M.; Onuseit, V.; Rominger, V.; Kraus, M.; Graf, T. Effects of radial and tangential polarization in laser material processing. Phys. Procedia 2011, 12, 21–30. [Google Scholar] [CrossRef]

- Krishnan, V.; Tan, B. Generation of radially polarized beam for laser micromachining. J. Laser Micro/Nanoeng. 2012, 7, 274–278. [Google Scholar]

- Zhang, H.; Mao, Y.; Kang, M.; Ma, C.; Li, H.; Zhang, Y.; Wang, X. Fabrication of high aspect ratio micro-holes on 304 stainless steel via backside-water-assisted laser drilling. Opt. Lasers Eng. 2023, 162, 107426. [Google Scholar] [CrossRef]

- Mak, G.Y.; Lam, E.Y.; Choi, H. Liquid-immersion laser micromachining of GaN grown on sapphire. Appl. Phys. A 2011, 102, 441–447. [Google Scholar] [CrossRef]

- Hong, M.; Koh, M.; Zhu, S.; Lu, Y.; Chong, T. Steam-assisted laser ablation and its signal diagnostics. Appl. Surf. Sci. 2002, 197, 911–914. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Z.; Zhang, G.; Wang, B.; Zhang, W. Study on immersion waterjet assisted laser micromachining process. J. Mater. Process. Technol. 2018, 262, 290–298. [Google Scholar] [CrossRef]

- Zhang, D.; Ranjan, B.; Tanaka, T.; Sugioka, K. Underwater persistent bubble-assisted femtosecond laser ablation for hierarchical micro/nanostructuring. Int. J. Extreme Manuf. 2020, 2, 015001. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).