High Strength–Ductility Synergy of As-Cast B2-Containing AlNbTaTiZr Refractory High-Entropy Alloy Under Intermediate and Dynamic Strain Rates

Abstract

1. Introduction

2. Materials Details

2.1. Fabrication Process

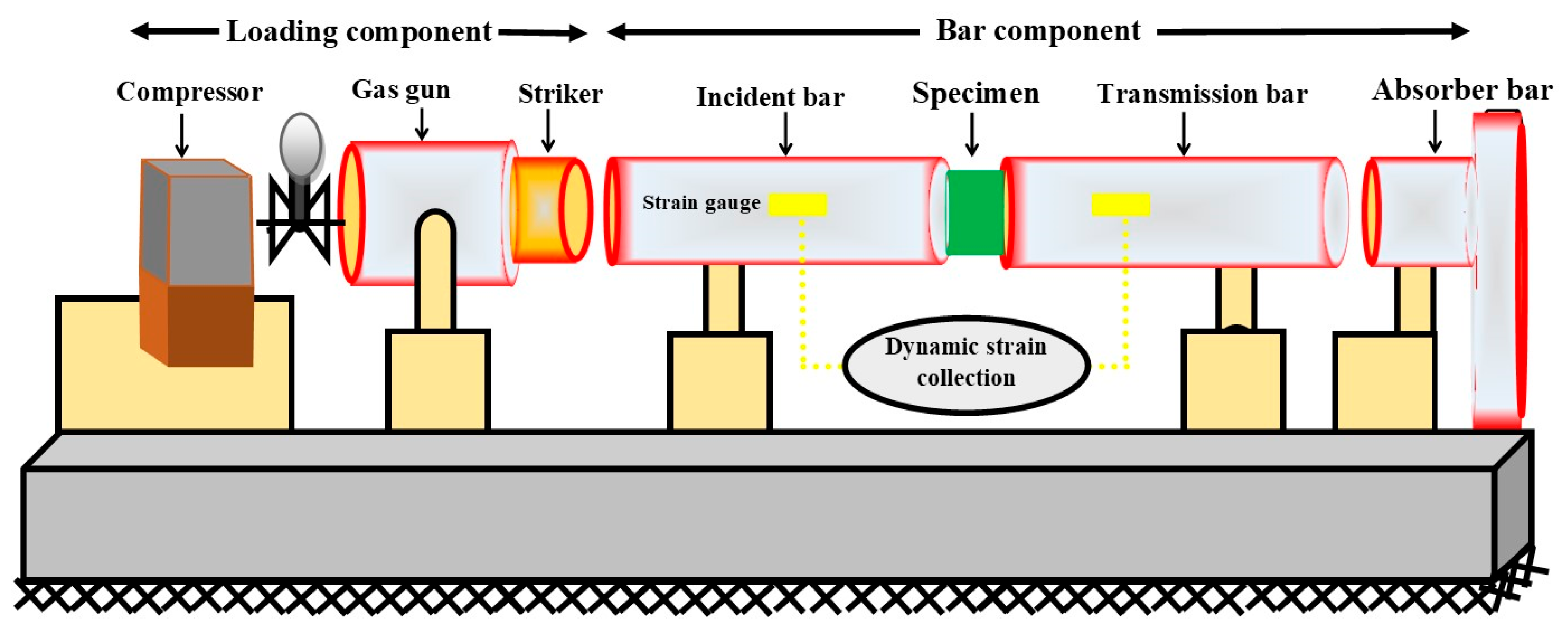

2.2. Quasi-Static and Dynamic-Compression Testing

2.3. Materials Characterization After Intermediate and High Strain-Rate Compression

3. Results

3.1. Stress–Strain Curves at Intermediate Strain Rates

3.2. Stress–Strain Curve Under Dynamic Compression

4. Deformation Behavior

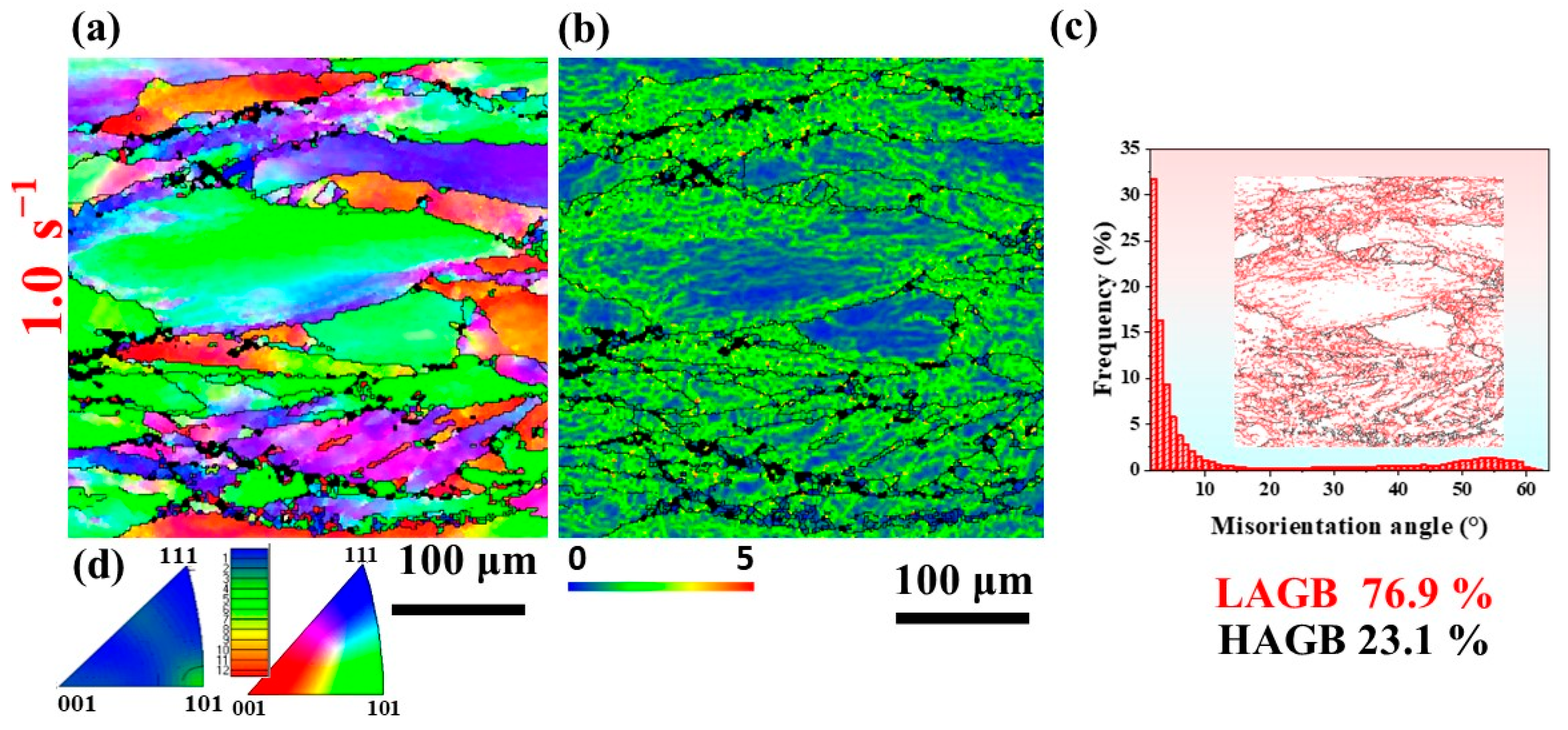

4.1. Effect of Intermediate Strain Rate Deformation on Microstructure

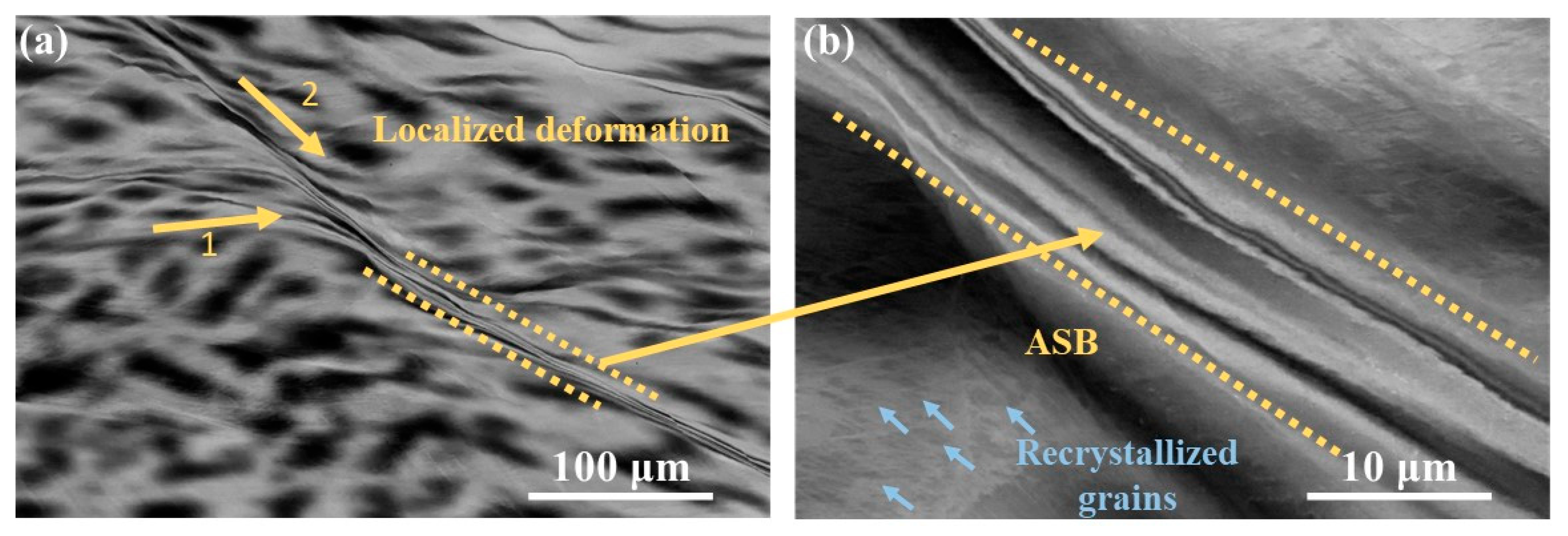

4.2. Effect of High-Strain-Rate Deformation on Microstructure

5. Conclusions

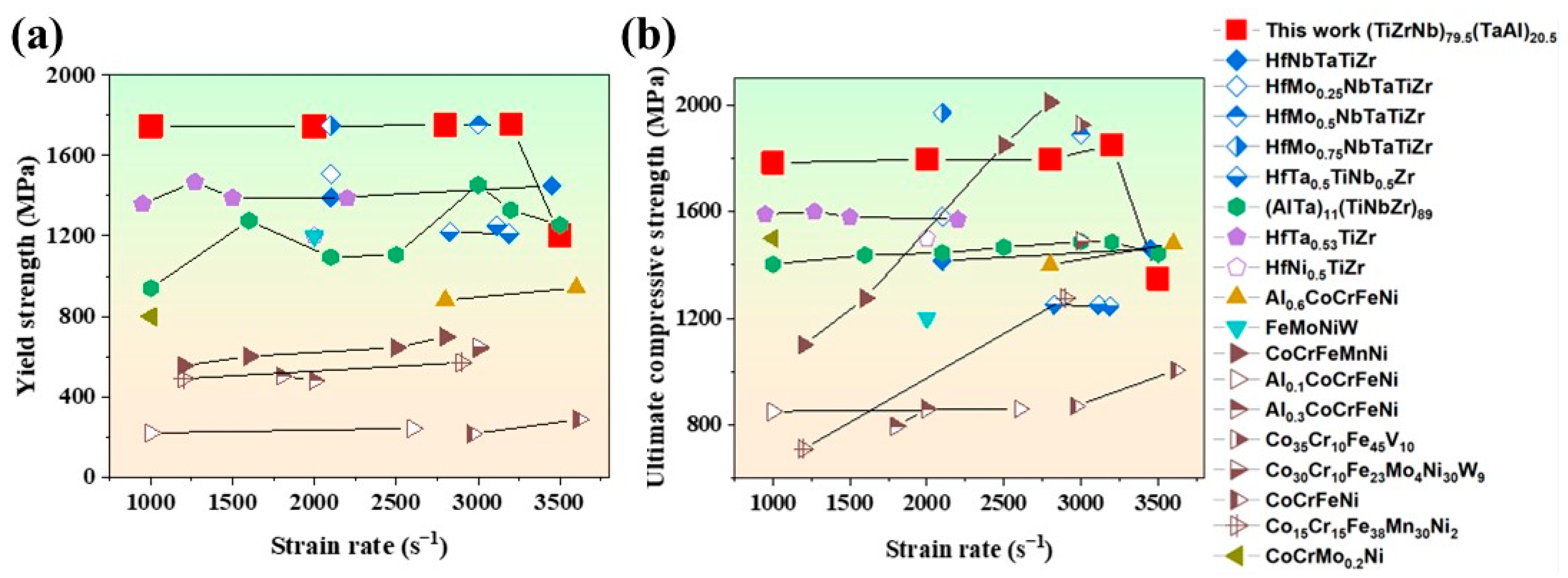

- The room-temperature compressive mechanical behavior and deformation mechanism of as-cast (TiZrNb)79.5(TaAl)20.5 RHEA is studied over intermediate and dynamic strain rates. The RHEA exhibits remarkable mechanical performance under intermediate strain rates (1.0 × 10−1, 1.0 s−1) with exceptional YS (~1437 MPa) and fracture strain (>90%). The RHEA also maintained excellent balance between strength and ductility during the entire plastic deformation.

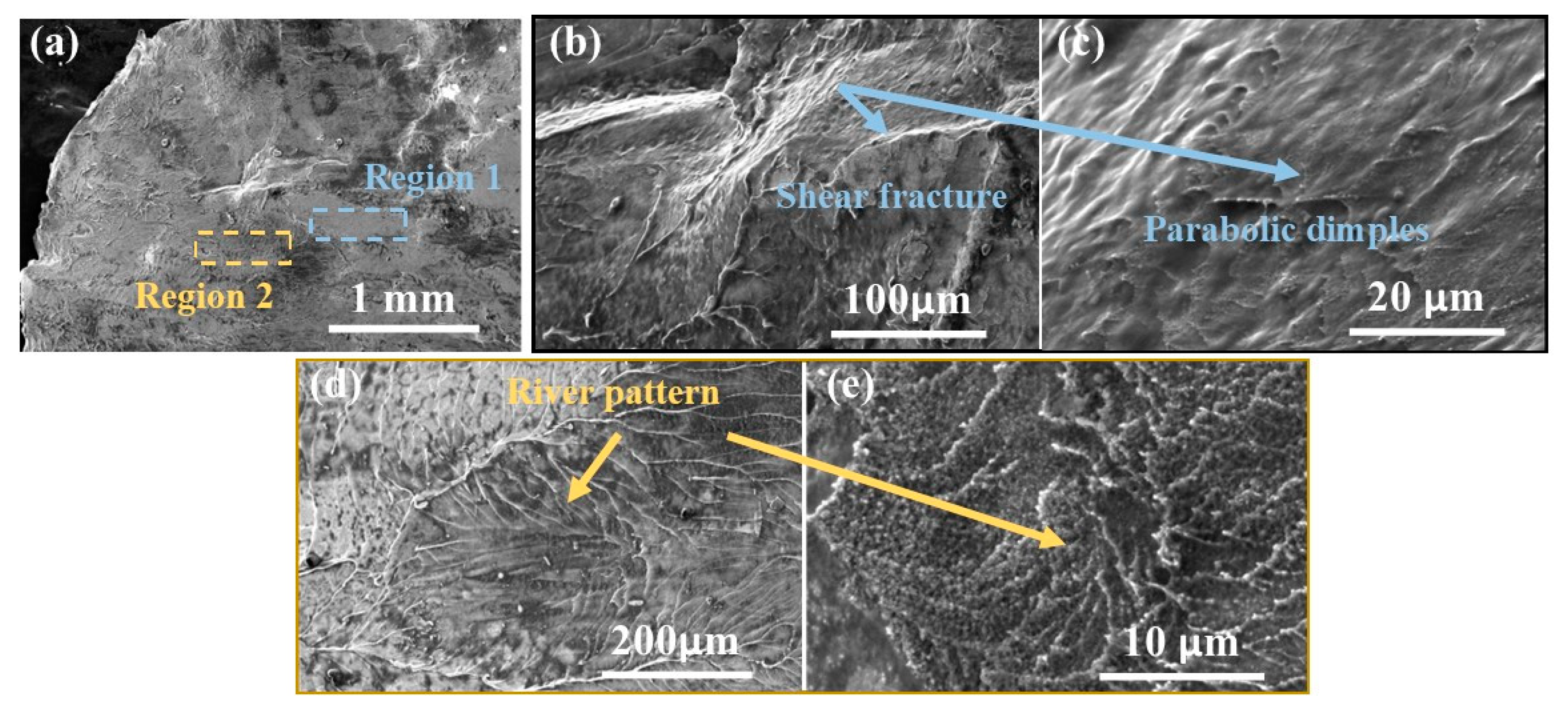

- Under dynamic strain rates (1.0 × 103, 1.5 × 103, 2.0 × 103 s−1, 2.8 × 103, 3.2 × 103, and 3.5 × 103), the RHEA demonstrates an increase in YS of around ~350 MPa compared with compression at intermediate strain rates. Further, the RHEA demonstrates a mixed ductile–brittle fracture mechanism, evident from the presence of dimples, which indicate good plasticity, while the observed river patterns suggest brittle fracture.

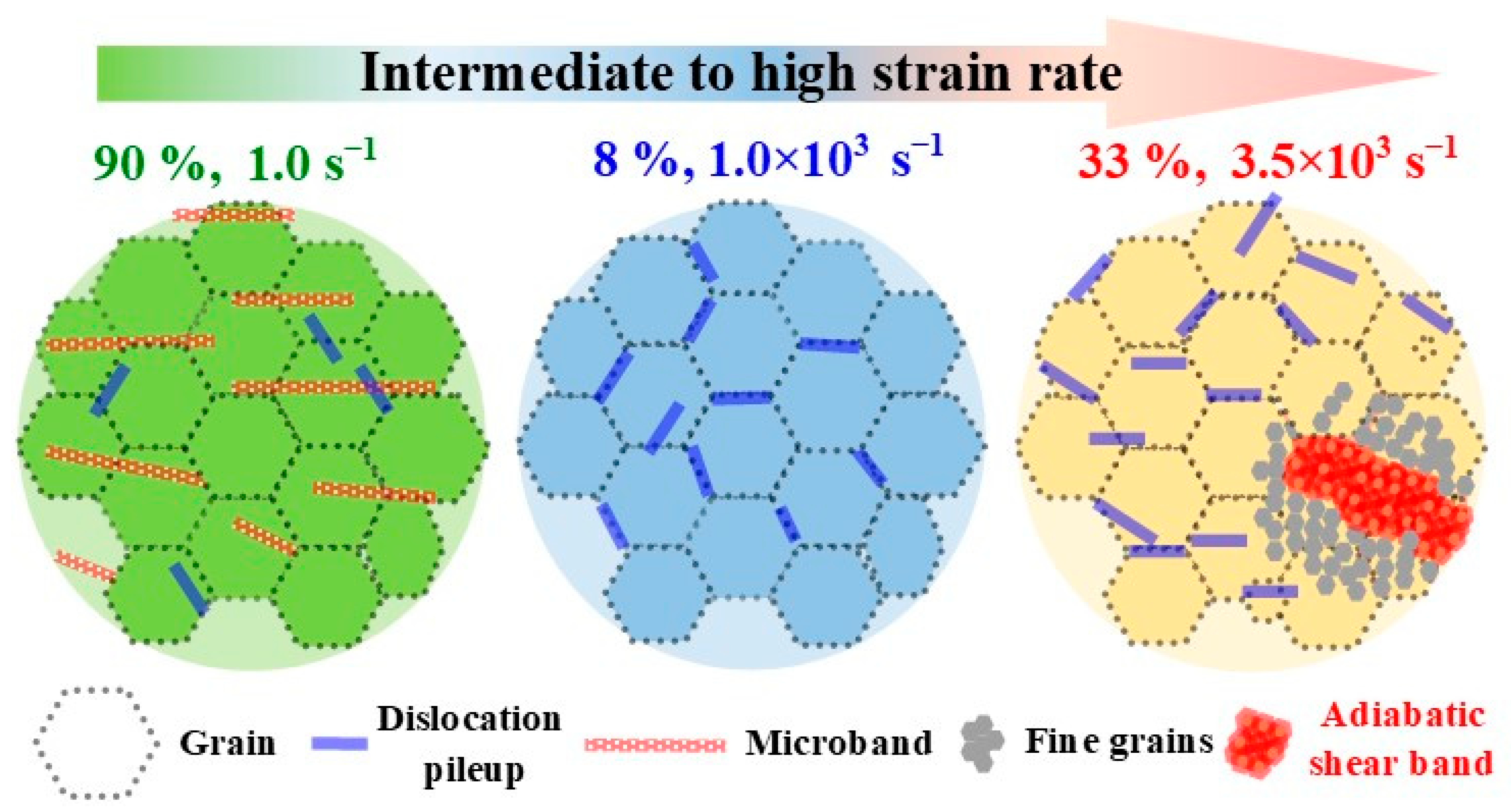

- The analyses of deformed specimens over intermediate strain rates show the presence of multiple delocalized dislocation bands causing large plasticity, whereas under dynamic loading, the deformed microstructure changes from the formation of dislocation cells that coalesce into microbands and, finally, to adiabatic shear bands after experiencing thermal instability.

- The excellent strength–ductility synergy and low SRS highlight the alloy’s robust performance under diverse loading conditions. The RHEA shows great potential for room-temperature processing and anti-penetration applications.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dirras, G.; Couque, H.; Lilensten, L.; Heczel, A.; Tingaud, D.; Couzinié, J.P.; Perrière, L.; Gubicza, J.; Guillot, I. Mechanical behavior and microstructure of Ti20Hf20Zr20Ta20Nb20 high-entropy alloy loaded under quasi-static and dynamic compression conditions. Mater. Charact. 2016, 111, 106–113. [Google Scholar] [CrossRef]

- Meyers, M.A. Dynamic Deformation and Waves. In Dynamic Behavior of Materials; John Wiley & Sons: Hoboken, NJ, USA, 1994; pp. 1–22. [Google Scholar]

- Wasley, R.J.; Miklowitz, J. Stress Wave Propagation in Solids. Phys. Today 1974, 27, 85–87. [Google Scholar] [CrossRef]

- Jiang, W.; Gao, X.; Guo, Y.; Chen, X.; Zhao, Y. Dynamic impact behavior and deformation mechanisms of Cr26Mn20Fe20Co20Ni14 high-entropy alloy. Mater. Sci. Eng. A 2021, 824, 141858. [Google Scholar] [CrossRef]

- Wang, C.T.; He, Y.; Guo, Z.; Huang, X.; Chen, Y.; Zhang, H.; He, Y. Strain Rate Effects on the Mechanical Properties of an AlCoCrFeNi High-Entropy Alloy. Met. Mater. Int. 2021, 27, 2310–2318. [Google Scholar] [CrossRef]

- Khan, M.A.; Brechtl, J.; Hamza, M.; Feng, C.; Mansoor, A.; Jabar, B.; Liaw, P.K.; Afifi, M.A. Influence of high-strain-rate compression and subsequent heat treatment on (TiNbZr)89(AlTa)11 refractory high-entropy alloys: Dynamic-mechanical behavior and microstructural changes. Mater. Des. 2024, 243, 113062. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Scott, J.M.; Miracle, D.B. Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys. Intermetallics 2011, 19, 698–706. [Google Scholar] [CrossRef]

- Feng, R.; Feng, B.J.; Gao, M.C.G.; Zhang, C.; Neuefeind, J.C.; Poplawsky, J.D.; Ren, Y.; An, K.; Widom, M.; Liaw, P.K. Superior High-Temperature Strength in a Supersaturated Refractory High-Entropy Alloy. Adv Mater 2021, 33, 2102401. [Google Scholar] [CrossRef]

- Hua, X.-J.; Hu, P.; Xing, H.-R.; Han, J.-Y.; Ge, S.-W.; Li, S.-L.; He, C.-J.; Wang, K.-S.; Cui, C.-J. Development and Property Tuning of Refractory High-Entropy Alloys: A Review. Acta Metall. Sin. (Engl. Lett.) 2022, 35, 1231–1265. [Google Scholar] [CrossRef]

- Chen, J.; Zhou, X.; Wang, W.; Liu, B.; Lv, Y.; Yang, W.; Xu, D.; Liu, Y. A review on fundamental of high entropy alloys with promising high–temperature properties. J. Alloys Compd. 2018, 760, 15–30. [Google Scholar] [CrossRef]

- Yurchenko, N.; Stepanov, N.; Zherebtsov, S.; Tikhonovsky, M.; Salishchev, G. Structure and mechanical properties of B2 ordered refractory AlNbTiVZrx (x = 0–1.5) high-entropy alloys. Mater. Sci. Eng. A 2017, 704, 82–90. [Google Scholar] [CrossRef]

- Lai, W.; Vogel, F.; Zhao, X.; Wang, B.; Yi, Y.; You, D.; Tong, X.; Li, W.; Yu, X.; Wang, X. Design of BCC refractory multi-principal element alloys with superior mechanical properties. Mater. Res. Lett. 2022, 10, 133–140. [Google Scholar] [CrossRef]

- Soni, V.; Senkov, O.N.; Gwalani, B.; Miracle, D.B.; Banerjee, R. Microstructural Design for Improving Ductility of An Initially Brittle Refractory High Entropy Alloy. Sci. Rep. 2018, 8, 8816. [Google Scholar] [CrossRef] [PubMed]

- Senkov, O.N.; Senkova, S.V.; Woodward, C.; Miracle, D.B. Low-density, refractory multi-principal element alloys of the Cr–Nb–Ti–V–Zr system: Microstructure and phase analysis. Acta Mater. 2013, 61, 1545–1557. [Google Scholar] [CrossRef]

- Xu, Z.Q.; Ma, Z.L.; Wang, M.; Chen, Y.W.; Tan, Y.D.; Cheng, X.W. Design of novel low-density refractory high entropy alloys for high-temperature applications. Mater. Sci. Eng. A 2019, 755, 318–322. [Google Scholar] [CrossRef]

- Senkov, O.N.; Couzinie, J.-P.; Rao, S.I.; Soni, V.; Banerjee, R. Temperature dependent deformation behavior and strengthening mechanisms in a low density refractory high entropy alloy Al10Nb15Ta5Ti30Zr40. Materialia 2020, 9, 100627. [Google Scholar] [CrossRef]

- Cui, J.; Chen, S.; Zhang, Y.; Qi, Z.; Dou, B.; Liu, F.; Wang, B.; Sun, S.; Cai, H.; Wang, L.; et al. Effect of B2 nanoprecipitates on mechanical behavior of TiZrNbVAl lightweight high entropy alloys upon dynamic loading. J. Alloys Compd. 2024, 1002, 175311. [Google Scholar] [CrossRef]

- Naseer, H.; Wang, Y.; Bao, J.; Khan, M.A.; Afifi, M.A. Designing a novel low-density, high-strength Al12Nb25.5Ta8.5Ti27.5Zr26.5 refractory high-entropy alloy for medium-temperature applications. Mater. Charact. 2025, 219, 114602. [Google Scholar] [CrossRef]

- Naseer, H.; Wang, Y.; Khan, M.A.; Afifi, M.A. Development of Low-Density AlNbTaTiZr Refractory High-Entropy-Intermetallic-Alloy: Microstructural Evolution, Mechanical Properties, and High-Temperature Deformation. J. Alloys Compd. 2024, 1010, 178102. [Google Scholar] [CrossRef]

- Hu, M.-L.; Song, W.-D.; Duan, D.-B.; Wu, Y. Dynamic behavior and microstructure characterization of TaNbHfZrTi high-entropy alloy at a wide range of strain rates and temperatures Int. J. Mech. Sci. 2020, 182, 105738. [Google Scholar] [CrossRef]

- Ren, K.; Liu, H.; Chen, R.; Tang, Y.; Guo, B.; Li, S.; Wang, J.; Wang, R.; Lu, F. Compression properties and impact energy release characteristics of TiZrNbV high-entropy alloy. Mater. Sci. Eng. A 2021, 827, 142074. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, Z.; Yang, H.J.; Qiao, J.W.; Wang, Z.H.; Wu, Y.C. Ultra-high strain-rate strengthening in ductile refractory high entropy alloys upon dynamic loading. Intermetallics 2020, 121, 106699. [Google Scholar] [CrossRef]

- Companhoni, M.V.P.; Gonçalves, A.-m.B.; Ferrante, M.; Sordi, V.; Pinto, A.L. ACOM/TEM and EBSD Microstructure Characterization of ECAE-Processed Zirconium. Metals 2024, 14, 624. [Google Scholar] [CrossRef]

- Tang, Y.; Wang, R.; Xiao, B.; Zhang, Z.; Li, S.; Qiao, J.; Bai, S.; Zhang, Y.; Liaw, P.K. A review on the dynamic-mechanical behaviors of high-entropy alloys. Prog. Mater. Sci. 2023, 135, 101090. [Google Scholar] [CrossRef]

- Wang, R.; Duan, D.; Tang, Y.; Lei, Z.; Li, S.; Chen, R.; Ma, C.; Wu, Y.; Bai, S.; Lu, Z. Evading dynamic strength and ductility trade-off in a high-entropy alloy via local chemical ordering. Nat. Commun. Mater. 2023, 4, 25. [Google Scholar] [CrossRef]

- Schuster, B.E.; Ligda, J.P.; Pan, Z.L.; Wei, Q. Nanocrystalline refractory metals for extreme condition applications. JOM 2011, 63, 27–31. [Google Scholar] [CrossRef]

- Zhong, X.; Zhang, Q.; Xie, J.; Wu, M.; Jiang, F.; Yan, Y.; Wang, Z. Mechanical properties and microstructure of the Al0.3CoCrFeNiTi0.3 high entropy alloy under dynamic compression. Mater. Sci. Eng. A 2021, 812, 141147. [Google Scholar] [CrossRef]

- Park, J.M.; Moon, J.; Bae, J.W.; Jang, M.J.; Park, J.; Lee, S.; Kim, H.S. Strain rate effects of dynamic compressive deformation on mechanical properties and microstructure of CoCrFeMnNi high-entropy alloy. Mater. Sci. Eng. A 2018, 719, 155–163. [Google Scholar] [CrossRef]

- Kumar, N.; Ying, Q.; Nie, X.; Mishra, R.S.; Tang, Z.; Liaw, P.K.; Brennan, R.E.; Doherty, K.J.; Cho, K.C. High strain-rate compressive deformation behavior of the Al0.1CrFeCoNi high entropy alloy. Mater. Des. 2015, 86, 598–602. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Y.; Cheng, X.; Wu, C.; Cheng, B.; Xu, Z. The Microstructure and Mechanical Properties of Refractory High-Entropy Alloys with High Plasticity. Materials 2018, 11, 208. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, H.; Tang, Y.; Zhu, L.a.; Ye, Y.; Li, S.; Bai, S. Microstructure, mechanical properties and energetic characteristics of a novel high-entropy alloy HfZrTiTa0.53. Mater. Des. 2017, 133, 435–443. [Google Scholar] [CrossRef]

- Chen, J.; Chen, C.; Guo, K.; Chang, M.; Wang, R.; Han, Y.; Cheng, C.; Tang, E. Dynamic mechanical properties and ignition behavior of TiZrHfX0.5 high-entropy alloys associated with temperature, trace element and strain rate. J. Alloys Compd. 2023, 933, 167798. [Google Scholar] [CrossRef]

- Wang, L.; Qiao, J.W.; Ma, S.G.; Jiao, Z.M.; Zhang, T.W.; Chen, G.; Zhao, D.; Zhang, Y.; Wang, Z.H. Mechanical response and deformation behavior of Al0.6CoCrFeNi high-entropy alloys upon dynamic loading. Mater. Sci. Eng. A 2018, 727, 208–213. [Google Scholar] [CrossRef]

- Liu, X.-F.; Tian, Z.-L.; Zhang, X.-F.; Chen, H.-H.; Liu, T.-W.; Chen, Y.; Wang, Y.-J.; Dai, L.-H. “Self-sharpening” tungsten high-entropy alloy. Acta Mater. 2020, 186, 257–266. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, S.; Diao, H.; Liaw, P.K.; Meyers, M.A. High-velocity deformation of Al(0.3)CoCrFeNi high-entropy alloy: Remarkable resistance to shear failure. Sci. Rep. 2017, 7, 42742. [Google Scholar] [CrossRef]

- Song, H.; Kim, D.G.; Kim, D.W.; Jo, M.C.; Jo, Y.H.; Kim, W.; Kim, H.S.; Lee, B.J.; Lee, S. Effects of strain rate on room- and cryogenic-temperature compressive properties in metastable V10Cr10Fe45Co35 high-entropy alloy. Sci. Rep. 2019, 9, 6163. [Google Scholar] [CrossRef]

- Liu, X.; Wu, Y.; Wang, Y.; Chen, J.; Bai, R.; Gao, L.; Xu, Z.; Wang, W.Y.; Tan, C.; Hui, X. Enhanced dynamic deformability and strengthening effect via twinning and microbanding in high density NiCoFeCrMoW high-entropy alloys. J. Mater. Sci. Technol. 2022, 127, 164–176. [Google Scholar] [CrossRef]

- Zhang, T.W.; Ma, S.G.; Zhao, D.; Wu, Y.C.; Zhang, Y.; Wang, Z.H.; Qiao, J.W. Simultaneous enhancement of strength and ductility in a NiCoCrFe high-entropy alloy upon dynamic tension: Micromechanism and constitutive modeling. Int. J. Plast. 2020, 124, 226–246. [Google Scholar] [CrossRef]

- Xu, J.; Liang, L.; Tong, W.; Wang, H.J.; Tian, J.; Peng, L.M. Role of strain rate in phase stability and deformation mechanism of non-equiatomic Fe38-xMn30Co15Cr15Ni2Gdx high-entropy alloy. Mater. Charact. 2022, 194, 112356. [Google Scholar] [CrossRef]

- Li, N.; Chen, W.; He, J.; Gu, J.; Wang, Z.; Li, Y.; Song, M. Dynamic deformation behavior and microstructure evolution of CoCrNiMox medium entropy alloys. Mater. Sci. Eng. A 2021, 827, 142048. [Google Scholar] [CrossRef]

- Gwalani, B.; Gangireddy, S.; Zheng, Y.; Soni, V.; Mishra, R.S.; Banerjee, R. Influence of ordered L1(2) precipitation on strain-rate dependent mechanical behavior in a eutectic high entropy alloy. Sci. Rep. 2019, 9, 6371. [Google Scholar] [CrossRef]

- Wang, Y.; Hamza, A.; Ma, E. Temperature-dependent strain rate sensitivity and activation volume of nanocrystalline Ni. Acta Mater. 2006, 54, 2715–2726. [Google Scholar] [CrossRef]

- Senkov, O.N.; Scott, J.M.; Senkova, S.V.; Miracle, D.B.; Woodward, C.F. Microstructure and room temperature properties of a high-entropy TaNbHfZrTi alloy. J. Alloys Compd. 2011, 509, 6043–6048. [Google Scholar] [CrossRef]

| Elements | Al | Nb | Ta | Ti | Zr |

|---|---|---|---|---|---|

| Atomic % | 23 | 25.5 | 8.5 | 27.5 | 26.5 |

| Sr# | Strain Rate (s−1) | Yield Strength (MPa) | UCS (MPa) | Peak Strain (mm/mm) |

|---|---|---|---|---|

| 1 | 1.0 × 10−1 | 1351 ± 4.2 | 1552 ± 5.8 | 0.91 ± 0.001 |

| 2 | 1.0 | 1437 ± 5.4 | 1476 ± 6.7 | 0.91 ± 0.001 |

| 3 | 1.0 × 103 | 1759 ± 8.7 | 1788 ± 9.3 | 0.10 ± 0.001 |

| 4 | 2.0 × 103 | 1766 ± 11.1 | 1788 ± 10.8 | 0.17 ± 0.002 |

| 5 | 2.8 × 103 | 1778 ± 8.6 | 1796 ± 9.4 | 0.22 ± 0.001 |

| 6 | 3.2 × 103 | 1797 ± 10.7 | 1811 ± 12.1 | 0.26 ± 0.002 |

| 7 | 3.5 × 103 | 1201 ± 13.7 | 1348 ± 11.7 | 0.33 ± 0.004 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naseer, H.; Wang, Y.; Khan, M.A.; Brechtl, J.; Afifi, M.A. High Strength–Ductility Synergy of As-Cast B2-Containing AlNbTaTiZr Refractory High-Entropy Alloy Under Intermediate and Dynamic Strain Rates. Metals 2025, 15, 249. https://doi.org/10.3390/met15030249

Naseer H, Wang Y, Khan MA, Brechtl J, Afifi MA. High Strength–Ductility Synergy of As-Cast B2-Containing AlNbTaTiZr Refractory High-Entropy Alloy Under Intermediate and Dynamic Strain Rates. Metals. 2025; 15(3):249. https://doi.org/10.3390/met15030249

Chicago/Turabian StyleNaseer, Hashim, Yangwei Wang, Muhammad Abubaker Khan, Jamieson Brechtl, and Mohamed A. Afifi. 2025. "High Strength–Ductility Synergy of As-Cast B2-Containing AlNbTaTiZr Refractory High-Entropy Alloy Under Intermediate and Dynamic Strain Rates" Metals 15, no. 3: 249. https://doi.org/10.3390/met15030249

APA StyleNaseer, H., Wang, Y., Khan, M. A., Brechtl, J., & Afifi, M. A. (2025). High Strength–Ductility Synergy of As-Cast B2-Containing AlNbTaTiZr Refractory High-Entropy Alloy Under Intermediate and Dynamic Strain Rates. Metals, 15(3), 249. https://doi.org/10.3390/met15030249