Microstructure and Mechanical Properties of Inconel 718 Alloy Fabricated Using Wire Feeding Oscillated Double-Pulsed GTA-AM

Abstract

1. Introduction

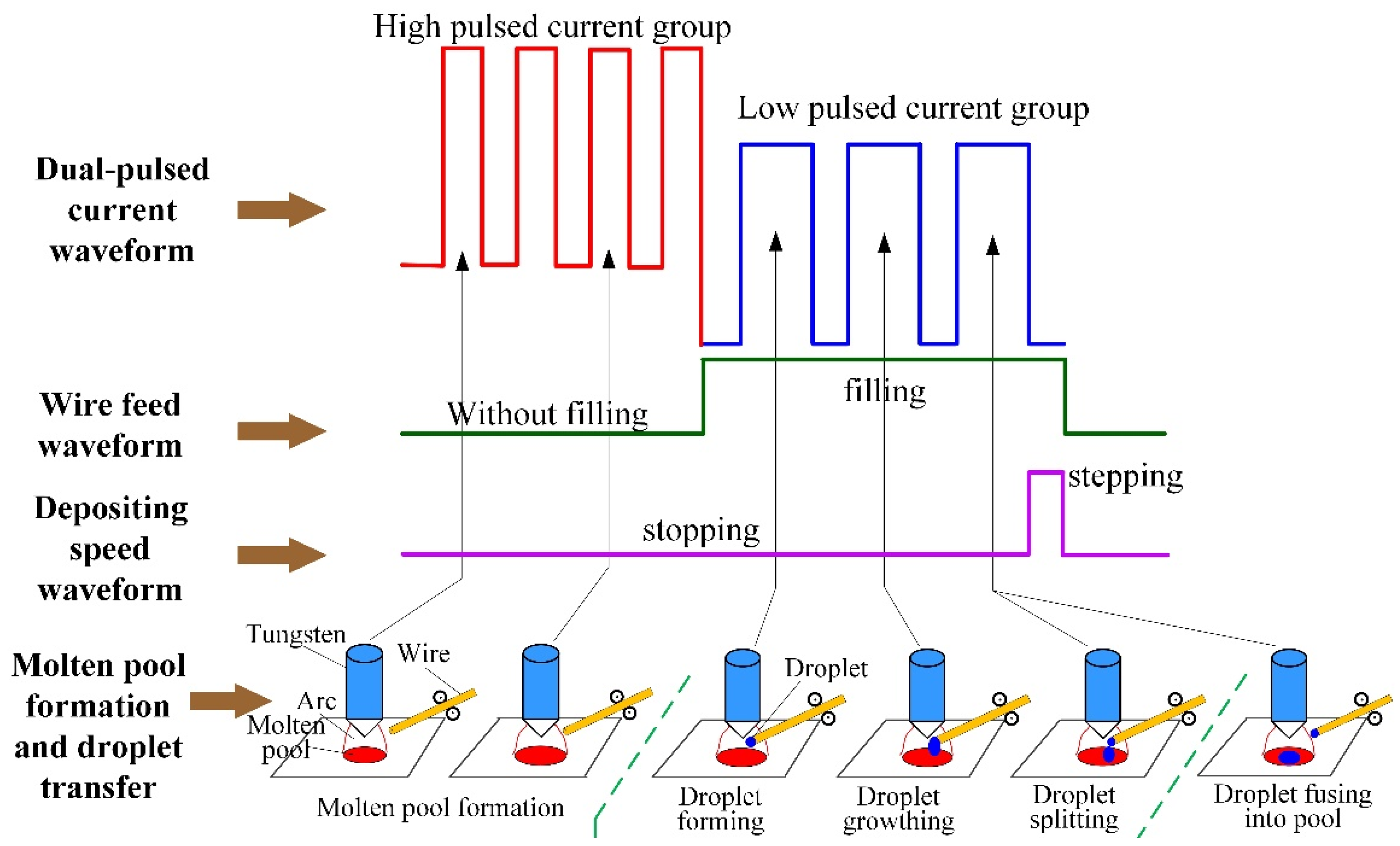

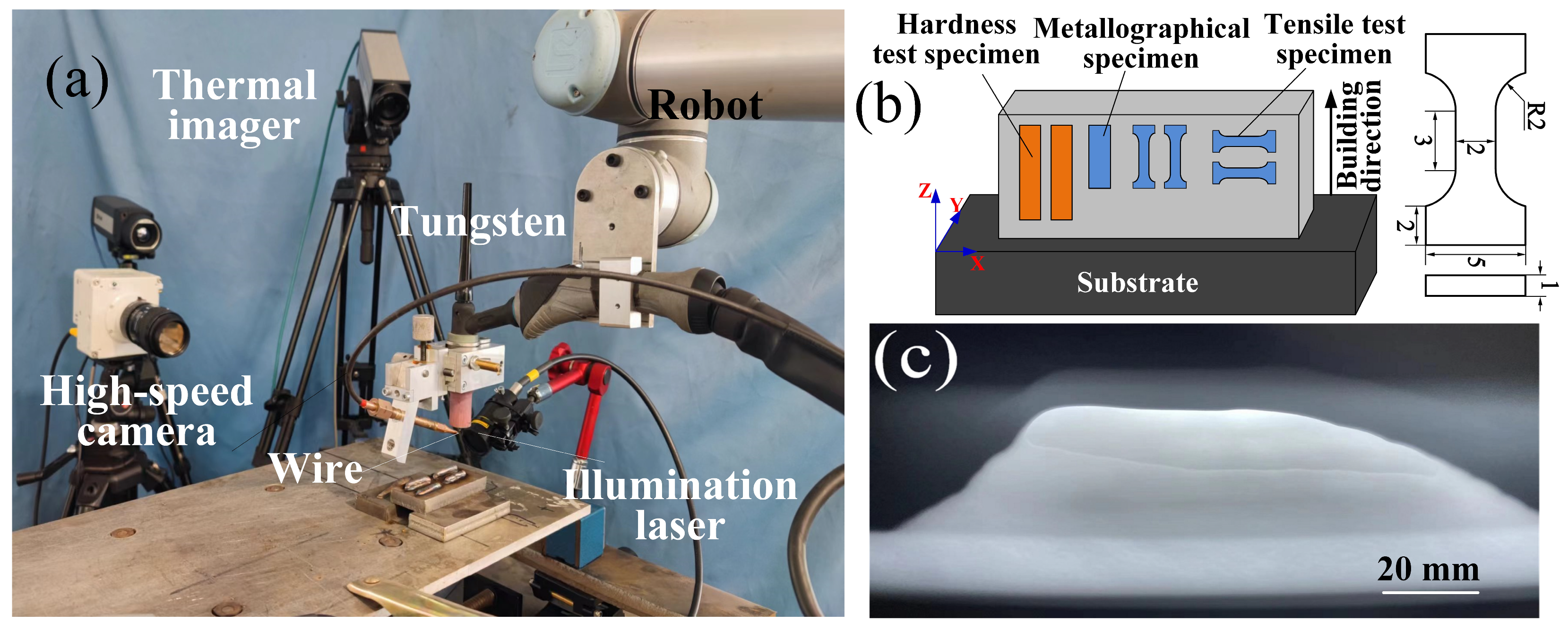

2. Materials and Methods

3. Results and Discussions

3.1. Microstructure of the Wire Feeding Oscillated Double-Pulsed GTA-AM Components

3.2. Mechanical Properties of the Wire Feeding Oscillated Double-Pulsed GTA-AM Parts

4. Conclusions

- The developed wire feeding oscillated DP-GTA-AM technique successfully fabricates crack-free IN718 components with controlled microstructural gradation: columnar grains (bottom) → cellular dendrites (mid-section) → equiaxed grains (top).

- Key frequency-dependent phase optimization indicates that raised pulse frequencies (120 → 160 Hz) reduce Laves phase content by 23% with improved distribution homogeneity, and the average grain size decreases 9.6% (68.3 → 61.76 μm), accompanied by 28% reduction in secondary dendrite arm spacing (10.77 → 8.5 μm).

- Crystallographic optimization demonstrates that the <001> texture intensity declines by 34% (28.32 → 19.45), coupled with 18% lower Schmid factor deviation, synergistically enhancing isotropic mechanical performance.

- The tensile strength and microhardness on the horizontal and the vertical direction show consistent values, reaching 830 MPa and 235 HV1.0, respectively. This reduction in property anisotropy enhances overall component performance. Fracture morphology predominantly exhibited a quasi-cleavage pattern.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sujan, G.K.; Li, H.; Pan, Z. Microstructural characterization and oxidation performance of solution-annealed and precipitation hardened wire-arc additively manufactured Inconel 718 superalloys. Addit. Manuf. 2022, 51, 102602. [Google Scholar] [CrossRef]

- Hao, Z.; He, Z.; Nie, Z. Effects of residual Laves phase on microstructural evolution and mechanical properties of wire arc additive manufactured GH4169 Ni-based superalloy. Mater. Sci. Eng. A 2024, 914, 147175. [Google Scholar] [CrossRef]

- Hosseini, E.; Popovich, V. A review of mechanical properties of additively manufactured Inconel 718. Addit. Manuf. 2019, 30, 100877. [Google Scholar] [CrossRef]

- Dhinakaran, V.; Ajith, J.; Fahmidha, A. Wire Arc Additive Manufacturing (WAAM) process of nickel based superalloys—A review. Mater. Today. Process. 2020, 21, 920–925. [Google Scholar] [CrossRef]

- Sun, P.; Yan, N.; Wei, S. Microstructural evolution and strengthening mechanisms of Inconel 718 alloy with different W addition fabricated by laser cladding. Mater. Sci. Eng. A 2023, 868, 144535. [Google Scholar] [CrossRef]

- Ansari, M.; Jabari, E.; Toyserkani, E. Opportunities and challenges in additive manufacturing of functionally graded metallic materials via powder-fed laser directed energy deposition: A review. J. Mater. Process. Technol. 2021, 294, 117117. [Google Scholar] [CrossRef]

- Kanishka, K.; Acherjee, B. A systematic review of additive manufacturing-based remanufacturing techniques for component repair and restoration. J. Manuf. Process. 2023, 89, 220–283. [Google Scholar] [CrossRef]

- Nurhudan, A.; Supriadi, S.; Humana, Y. Additive manufacturing of metallic based on extrusion process: A review. J. Manuf. Process. 2021, 66, 228–237. [Google Scholar] [CrossRef]

- Lupo, M.; Ajabshir, S.Z.; Sofia, D. Experimental metrics of the powder layer quality in the selective laser sintering process. Powder Technol. 2023, 419, 118346. [Google Scholar] [CrossRef]

- Singh, V.K.; Sahoo, D.; Amirthalingam, M. Dissolution of the Laves phase andδ-precipitate formation mechanism in additively manufactured Inconel 718 during post printing heat treatments. Addit. Manuf. 2024, 81, 104021. [Google Scholar]

- Kindermann, R.M.; Roy, M.J.; Morana, R. Effects of microstructural heterogeneity and structural defects on the mechanical behaviour of wire + arc additively manufactured Inconel 718 components. Mater. Sci. Eng. A 2022, 839, 142826. [Google Scholar] [CrossRef]

- Sandeep, K.J.; Teja, P.J.; Choudhary, A.K. Development of correlation between temperature, liquid life span, molten pool, and porosity during Wire Arc Additive Manufacturing: A finite element approach. CIRP J. Manuf. Sci. Tec. 2022, 38, 274–287. [Google Scholar] [CrossRef]

- Kindermann, R.M.; Roy, M.J.; Morana, R. Wire-arc directed energy deposition of Inconel 718: Effects of heat input and build interruptions on mechanical performance. Addit. Manuf. 2023, 76, 103765. [Google Scholar] [CrossRef]

- Bhuvanesh, K.M.; Sathiya, P.; Senthil, S.M. A critical review of wire arc additive manufacturing of nickel-based alloys: Principles, process parameters, microstructure, mechanical properties, heat treatment effects, and defects. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 164. [Google Scholar] [CrossRef]

- Rao, S.; Reddy, G.; Kamaraj, M. Grain refinement through arc manipulation techniques in Al–Cu alloy GTA welds. Mater. Sci. Eng. A 2005, 404, 227–234. [Google Scholar] [CrossRef]

- Fang, Y.; Kim, M.; Zhang, Y. A new grain refinement route for duplex stainless steels: Micro-duplex stainless steel matrix composites processed by laser powder bed fusion. Mater. Sci. Eng. A 2023, 881, 145351. [Google Scholar] [CrossRef]

- Qian, X.; Dong, Z.; Jiang, B. The improved mechanical properties of Mg–Zn-Nd alloy with Ca addition via grain refinement and nano precipitates. Mater. Sci. Eng. A 2023, 887, 145729. [Google Scholar] [CrossRef]

- Wainwright, J.; Williams, S.; Ding, J. Refinement of Ti-6Al-4V prior-βgrain structure in the as-deposited condition via process control during wire-direct energy deposition. Addit. Manuf. 2023, 74, 103712. [Google Scholar]

- Tan, Y.; Fang, H.; Liu, Y. Regulating the macro/microstructure and mechanical properties of Ti2AlN/Ti46Al4Nb1Mo composites via ultrasonic treatment. Mater. Sci. Eng. A 2022, 841, 143013. [Google Scholar] [CrossRef]

- Villaret, V.; Deschaux-Beaume, F.; Bordreuil, C. A solidification model for the columnar to equiaxed transition in welding of a Cr-Mo ferritic stainless steel with Ti as inoculant. J. Mater. Process. Technol. 2016, 233, 115–124. [Google Scholar] [CrossRef]

- Fan, W.; Bai, Y.; Zuo, G. The control of NbB2 particles in Al-NbB2 master alloy and its effect on grain refinement of AZ 91 magnesium alloy. Mater. Sci. Eng. A 2022, 854, 143808. [Google Scholar] [CrossRef]

- Chen, Z.; Kang, H.; Fan, G. Grain refinement of hypoeutectic Al-Si alloys with B. Acta Mater. 2016, 120, 168–178. [Google Scholar] [CrossRef]

- Xu, S.; Zhang, H.; Xiao, N. Mechanisms of macrozone elimination and grain refinement of nearαTi alloy via the spheroidization of the widmannstätten structure. Acta Mater. 2023, 260, 119339. [Google Scholar] [CrossRef]

- Wang, E.; Gao, T.; Nie, J. Grain refinement limit and mechanical properties of 6063 alloy inoculated by Al–Ti–C (B) master alloys. J. Alloys Compd. 2014, 594, 7–11. [Google Scholar] [CrossRef]

- Ng, C.; Bermingham, M.; Yuan, L. Towardsβ-fleck defect free additively manufactured titanium alloys by promoting the columnar to equiaxed transition and grain refinement. Acta Mater. 2022, 224, 117511. [Google Scholar] [CrossRef]

- Wu, D.; Ma, S.; Jing, T. Revealing the mechanism of grain refinement and anti Si-poisoning induced by (Nb, Ti)B2 with a sandwich-like structure. Acta Mater. 2021, 219, 117265. [Google Scholar] [CrossRef]

- Liu, K.; Yan, Z.; Wang, F. Microstructure, texture and mechanical properties of Inconel GH4169 superalloy fabricated by wire arc additive manufacturing with arc oscillation. J. Alloys Compd. 2023, 952, 170070. [Google Scholar] [CrossRef]

- Yuan, T.; Luo, Z.; Kou, S. Grain refining of magnesium welds by arc oscillation. Acta Mater. 2016, 116, 166–176. [Google Scholar] [CrossRef]

- Zhuo, Y.; Yang, C.; Fan, C. Grain refinement of wire arc additive manufactured titanium alloy by the combined method of boron addition and low-frequency pulse arc. Mater. Sci. Eng. A 2020, 805, 140557. [Google Scholar] [CrossRef]

- Ke, W.; Oliveira, J.; Cong, B.Q. Multi-layer deposition mechanism in ultra-high-frequency pulsed wire arc additive manufacturing (WAAM) of NiTi shape memory alloys. Addit. Manuf. 2022, 50, 102513. [Google Scholar] [CrossRef]

- Chen, Z.; Soh, G.S. Microstructure and mechanical properties of Wire Arc Additive Manufactured (WAAM) Inconel 718 parts via post heat treatments. Mater. Today Process. 2022, 70, 567–573. [Google Scholar] [CrossRef]

- Xu, X.; Ganguly, S.; Ding, J. Enhancing mechanical properties of wire+ arc additively manufactured INCONEL 718 superalloy through in-process thermomechanical processing. Mater. Design 2018, 160, 1042–1051. [Google Scholar] [CrossRef]

- Standard Test Method for Microindentation Hardness of Materials. Available online: https://tajhizkala.ir/doc/ASTM/ASTM%20E384__09.pdf (accessed on 15 January 2025).

- Standard Test Methods for Tension Testing of Metallic Materials. Available online: https://www.astm.org/e0008_e0008m-21.html (accessed on 15 January 2025).

- Su, G.X.; Shi, Y.; Li, G.; Zhang, G.; Xu, Y.W. Improving the deposition efficiency and mechanical properties of additive manufactured Inconel 625 through hot wire laser metal deposition. J. Mater. Process. Technol. 2023, 322, 118175. [Google Scholar] [CrossRef]

| C | Cr | Ni | S | Mn | Si | Nb | Mo |

|---|---|---|---|---|---|---|---|

| <0.08 | 16–18 | 50–55 | ≤0.015 | ≤0.35 | ≤0.35 | 4.75–5.50 | 2.80–3.30 |

| Co | P | Mg | B | Al | Ti | Cu | Fe |

| ≤1.00 | 0.015 | 0.01 | <0.006 | 0.2–0.8 | 0.65–1.15 | ≤0.30 | Bal. |

| Deposition Processing Parameters | Value | |

|---|---|---|

| High-pulse current group | Base current (A) | 100 |

| Peak current (A) | 120 | |

| Frequency (Hz) | 160 | |

| Duty cycle (%) | 50 | |

| Low-pulse current group | Base current (A) | 70 |

| Peak current (A) | 90 | |

| Frequency (Hz) | 20 | |

| Duty cycle (%) | 50 | |

| Moving speed (m/min) | 1.7 | |

| Moving frequency (Hz) | 10 | |

| Moving step-length (m) | 0.011 | |

| Wire feeding speed (m/min) | 1 | |

| Wire feeding frequency (Hz) | 10 | |

| Wire feeding step length (mm) | 6 | |

| Feeding angle (°) | 35 | |

| Arc length (mm) | 3 | |

| Cooling time of each layer (s) | 43 | |

| Pulse Frequency | Key Parameters of Microstructure | ||||

|---|---|---|---|---|---|

| Morphology | Secondary Dendrite Arm Space | Grain Size | Standard Deviation | Orientation Density | |

| 120 Hz | spindly dendrite | 10.77 μm | 68.3 μm | 121.62 μm | 28.32 |

| 160 Hz | short cellular crystals | 8.5 μm | 61.7 μm | 144.39 μm | 19.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Zhang, C.; Shi, Y.; Fan, D. Microstructure and Mechanical Properties of Inconel 718 Alloy Fabricated Using Wire Feeding Oscillated Double-Pulsed GTA-AM. Metals 2025, 15, 248. https://doi.org/10.3390/met15030248

Zhang G, Zhang C, Shi Y, Fan D. Microstructure and Mechanical Properties of Inconel 718 Alloy Fabricated Using Wire Feeding Oscillated Double-Pulsed GTA-AM. Metals. 2025; 15(3):248. https://doi.org/10.3390/met15030248

Chicago/Turabian StyleZhang, Gang, Cheng Zhang, Yu Shi, and Ding Fan. 2025. "Microstructure and Mechanical Properties of Inconel 718 Alloy Fabricated Using Wire Feeding Oscillated Double-Pulsed GTA-AM" Metals 15, no. 3: 248. https://doi.org/10.3390/met15030248

APA StyleZhang, G., Zhang, C., Shi, Y., & Fan, D. (2025). Microstructure and Mechanical Properties of Inconel 718 Alloy Fabricated Using Wire Feeding Oscillated Double-Pulsed GTA-AM. Metals, 15(3), 248. https://doi.org/10.3390/met15030248