Hot-Deformed Microstructure and Texture of Ti-62222 Alloy

Abstract

1. Introduction

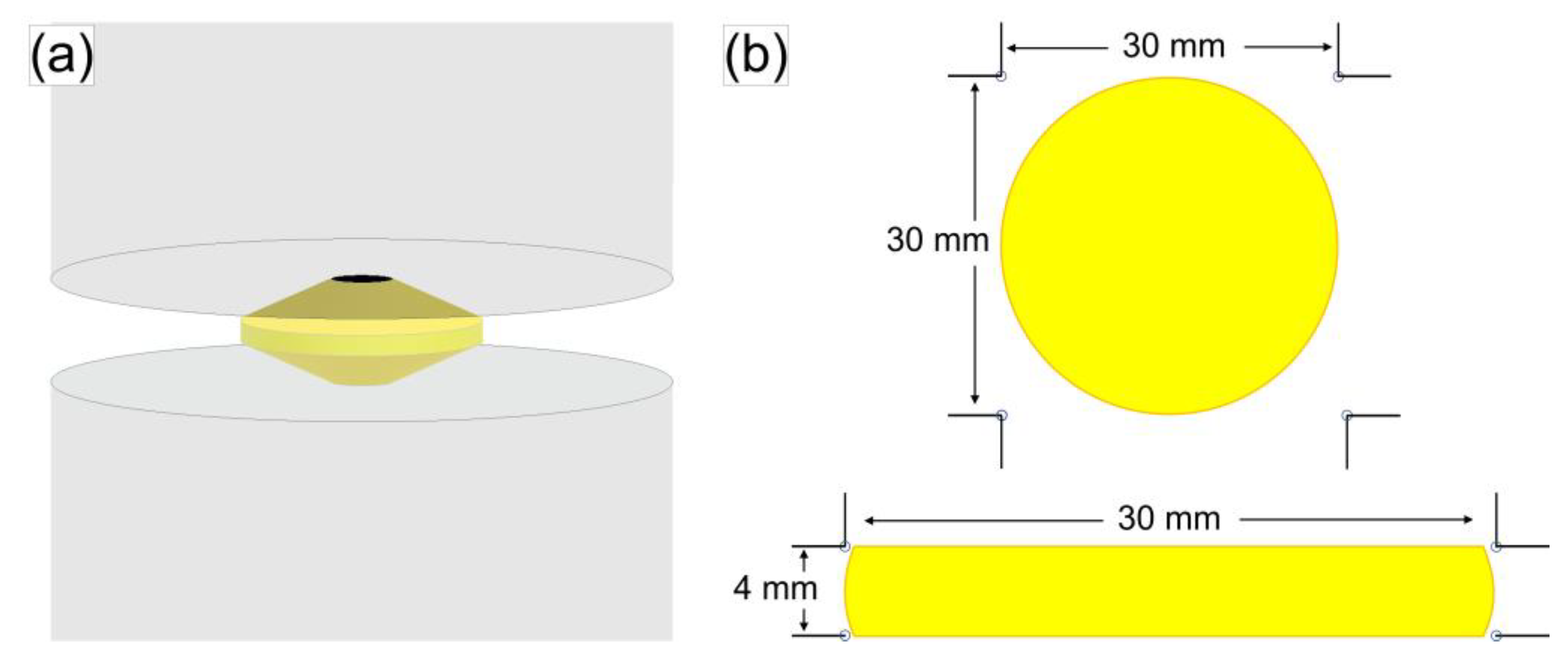

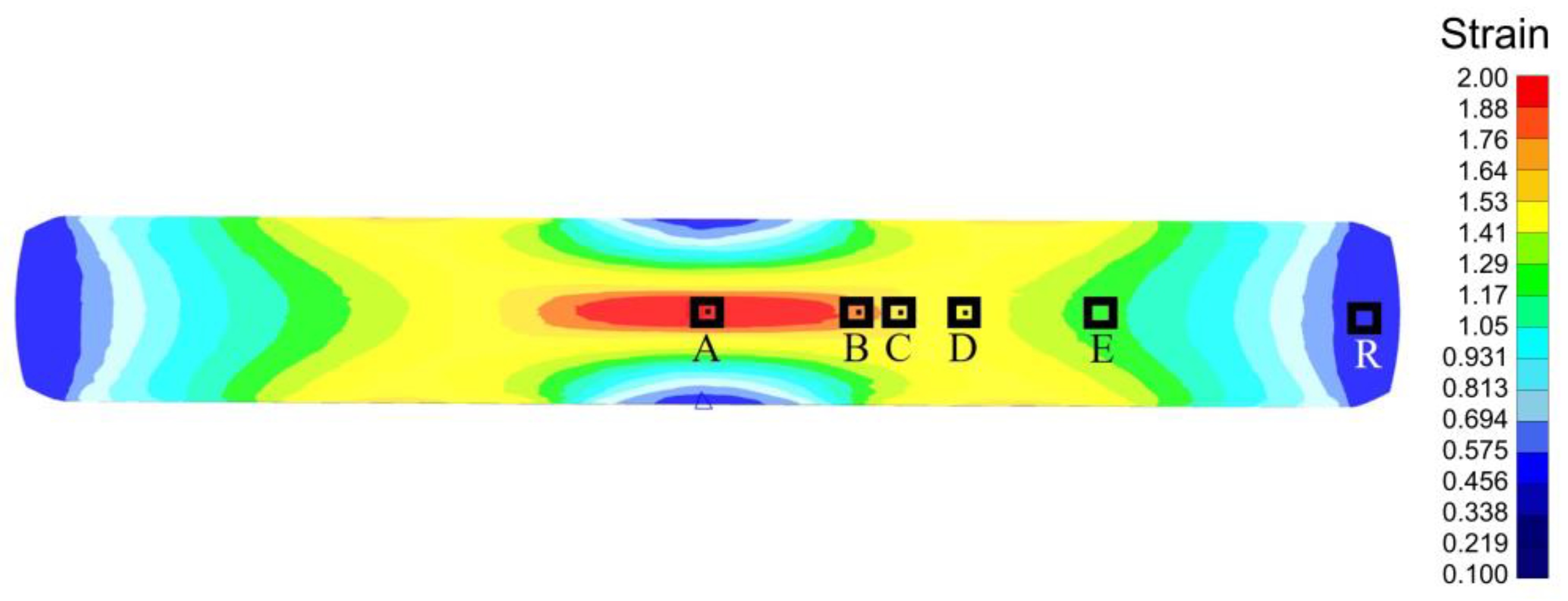

2. Materials and Methods

3. Results and Discussion

4. Conclusions

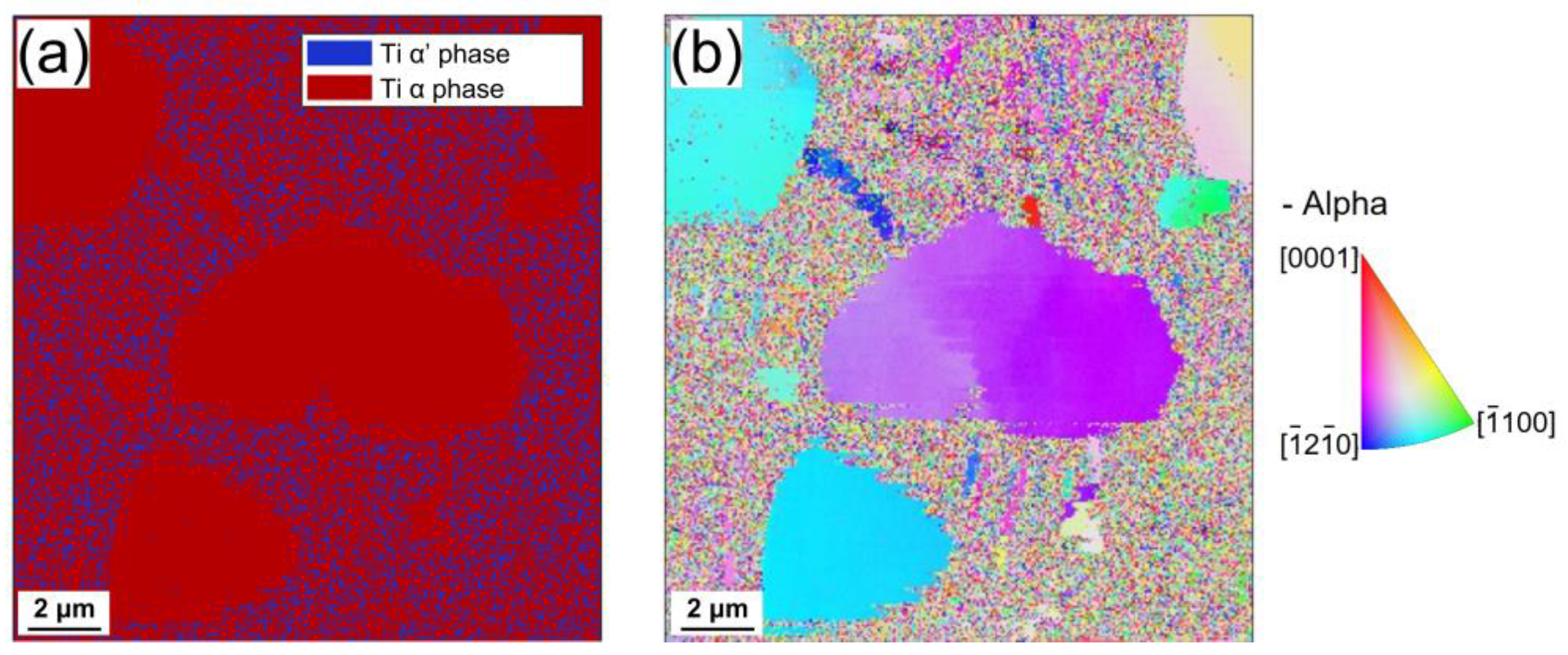

- During high-temperature compressive deformation, the thermally stable Ti β phase formed as primary grains. During cooling, Ti α+β phases developed around the primary β grains, followed by a diffusion-free transformation of the Ti β phase into the Ti α’ phase. This phenomenon resulted in regions containing a mixture of Ti α and Ti α’ phases in the hot-forged Ti-62222. The dynamic recrystallization of the Ti α phase is not observed during the hot forging process up to a strain of 2 mm/mm. It is inferred that much higher deformation is required for the dynamic recrystallization of Ti-62222 to occur during the hot deformation process, owing to the higher thermal stability of the α phase of this alloy in comparison to Ti-6Al-4V.

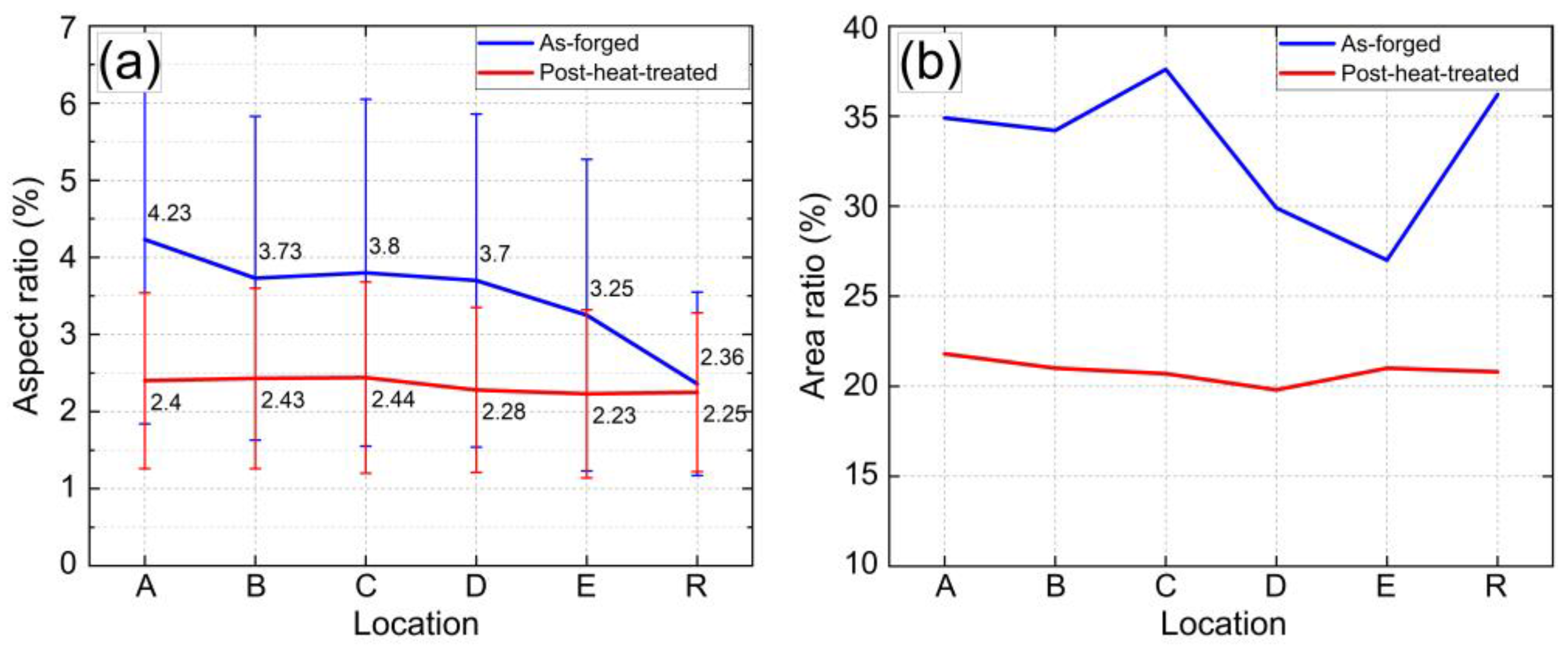

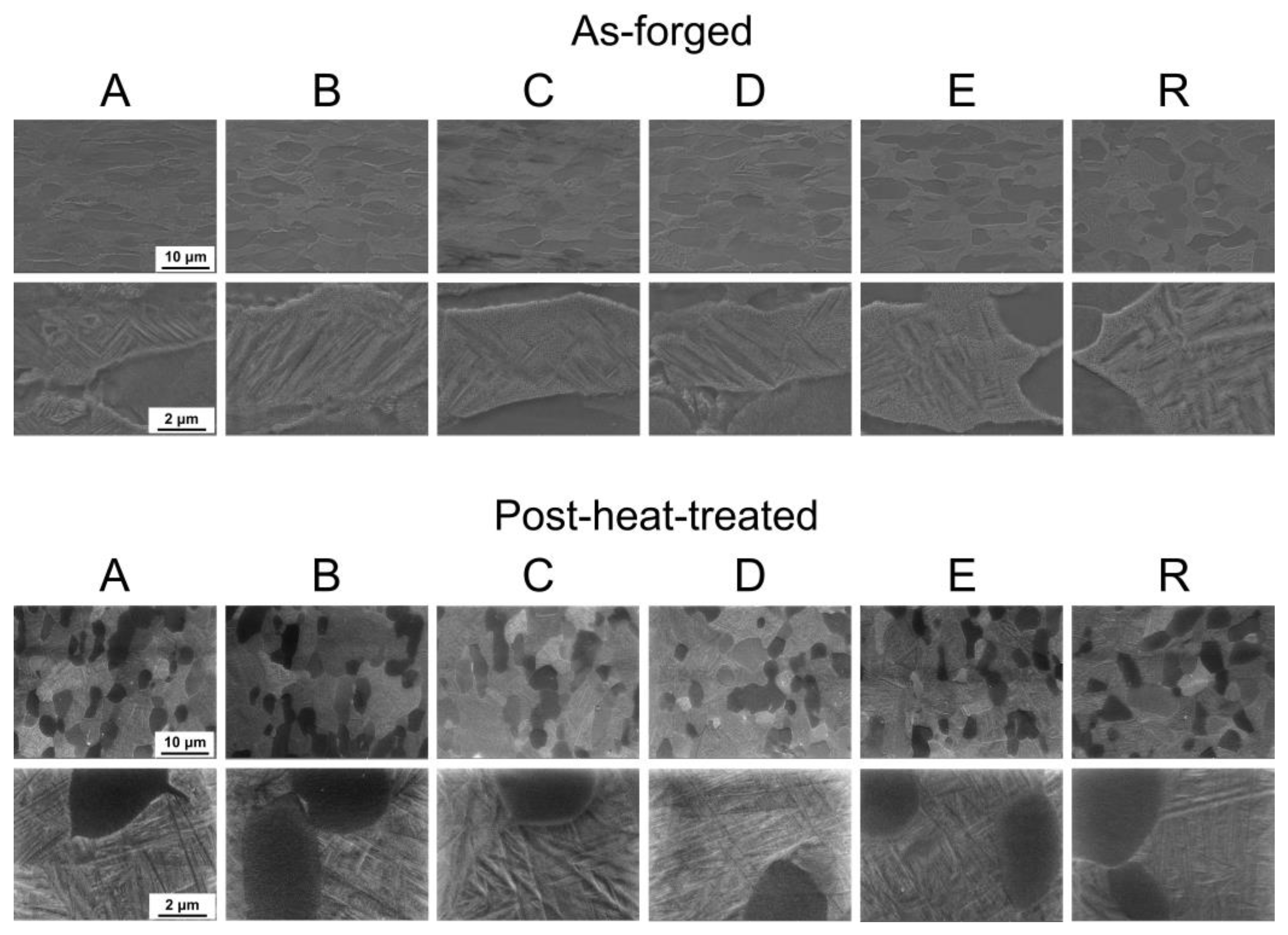

- Both as-forged and post-heat-treated specimens exhibited spheroidal primary Ti α phase and acicular Ti α’ phase. The primary Ti α phase exhibited grain elongation, which became more pronounced with increasing strain levels. In contrast, the acicular Ti α’ phase showed no significant changes in size or morphology regardless of strain level. Spheroidization of the primary α phase occurred after the STA heat treatment.

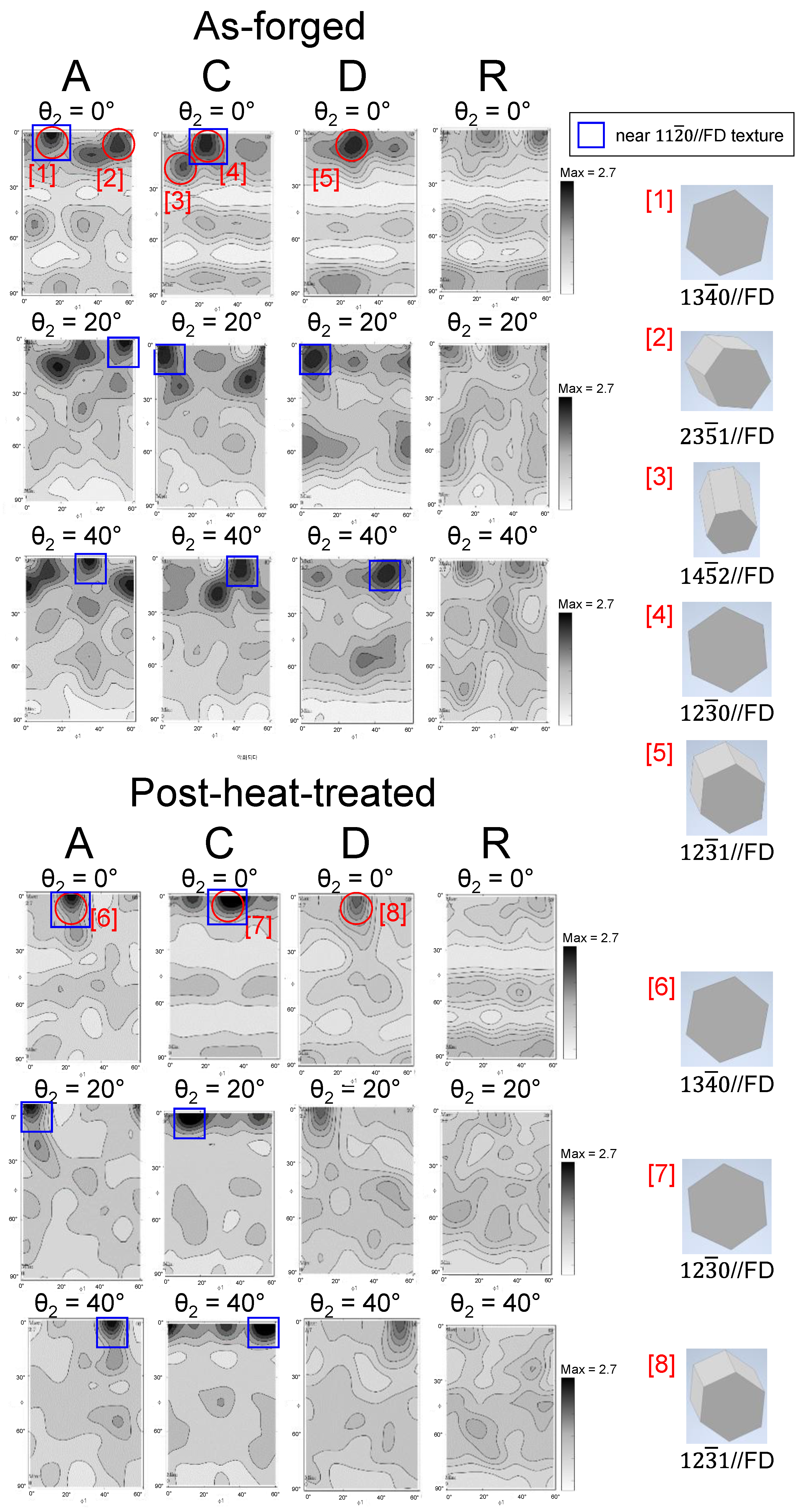

- Texture analysis established that the strong textures formed during deformation weakened after heat treatment. Particularly, the ()//FD, ()//FD, and ()//FD textures were preserved, whereas the ()//FD and ()//FD textures disappeared after the heat treatment. The development of a near ()//FD texture along the direction perpendicular to the forging direction confirms the considerable influence of hot deformation on texture orientation.

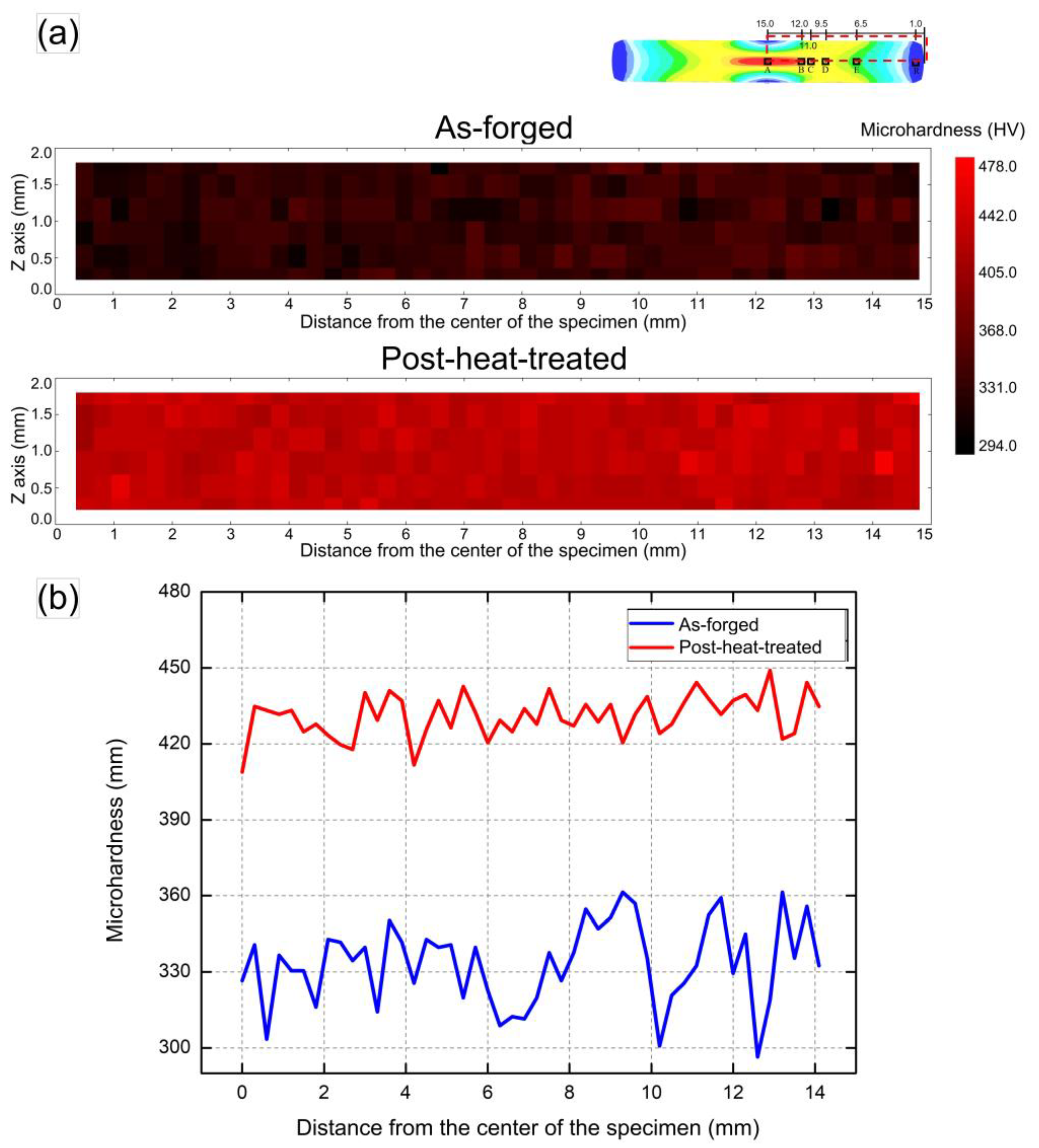

- The microhardness measurement results indicated that strain had no significant effect on the microhardness of either the as-forged or the post-heat-treated specimens. In contrast, the post-heat-treated specimen exhibited higher average microhardness; this can be attributed to the aging process during STA.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Collings, E.W. Physical Metallurgy of Titanium Alloys; Metallurgiya: Moscow, Russia, 1988. [Google Scholar]

- Lin, J.; Ozan, S.; Li, Y.; Ping, D.; Tong, X.; Li, G.; Wen, C. Novel Ti-Ta-Hf-Zr Alloys with Promising Mechanical Properties for Prospective Stent Applications. Sci. Rep. 2016, 6, 37901. [Google Scholar] [CrossRef]

- Gao, K.; Zhang, Y.; Yi, J.; Dong, F.; Chen, P. Overview of Surface Modification Techniques for Titanium Alloys in Modern Material Science: A Comprehensive Analysis. Coatings 2024, 14, 148. [Google Scholar] [CrossRef]

- Yang, X.; Lin, B.; Zhang, H.; Tang, J.; Zhou, T.; Wang, Y.; Zheng, H.; Kuang, Y. Influence of Stress on the Corrosion Behavior of Ti Alloys: A Review. J. Alloys Compd. 2024, 985, 173346. [Google Scholar] [CrossRef]

- Semenova, I.P.; Polyakov, A.V.; Dong, Y.; Sun, Z.; Alexandrov, I. V Microstructure and Mechanical Properties of Titanium Alloys Produced by Additive Technologies: New Approaches and Promising Areas of Research. Metals 2024, 14, 966. [Google Scholar] [CrossRef]

- Guo, S.; Meng, Q.; Zhao, X.; Wei, Q.; Xu, H. Design and Fabrication of a Metastable β-Type Titanium Alloy with Ultralow Elastic Modulus and High Strength. Sci. Rep. 2015, 5, 14688. [Google Scholar] [CrossRef]

- Shell, E.B.; Semiatin, S.L. Effect of Initial Microstructure on Plastic Flow and Dynamic Globularization during Hot Working of Ti-6Al-4V. Metall. Mater. Trans. A 1999, 30, 3219–3229. [Google Scholar] [CrossRef]

- Devaraj, A.; Joshi, V.V.; Srivastava, A.; Manandhar, S.; Moxson, V.; Duz, V.A.; Lavender, C. A Low-Cost Hierarchical Nanostructured Beta-Titanium Alloy with High Strength. Nat. Commun. 2016, 7, 11176. [Google Scholar] [CrossRef]

- Lin, N.; Zhang, H.; Zou, J.; Tang, B. Recent Developments in Improving Tribological Performance of TC4 Titanium Alloy via Double Glow Plasma Surface Alloying in China: A Literature Review. Rev. Adv. Mater. Sci. 2014, 38, 61–74. [Google Scholar]

- Jin, H.X.; Wei, K.X.; Li, J.M.; Zhou, J.Y.; Peng, W.J. Research Development of Titanium Alloy in Aerospace Industry. Chin. J. Nonferrous Met. 2015, 25, 280–292. [Google Scholar]

- Beese, A.M.; Carroll, B.E. Review of Mechanical Properties of Ti-6Al-4V Made by Laser-Based Additive Manufacturing Using Powder Feedstock. JOM 2016, 68, 724–734. [Google Scholar] [CrossRef]

- Disegi, J.A.; Roach, M.D.; McMillan, R.D.; Shultzabarger, B.T. Alpha plus Beta Annealed and Aged Ti-15 Mo Alloy for High Strength Implant Applications. J. Biomed. Mater. Res. Part B Appl. Biomater. 2017, 105, 2010–2018. [Google Scholar] [CrossRef]

- Cai, J.M.; Mi, G.B.; Gao, F.; Huang, H.; Cao, J.X.; Huang, X.; Cao, C.X. Research and Development of Some Advanced High Temperature Titanium Alloys for Aero-Engine. J. Mater. Eng. 2016, 44, 1–10. [Google Scholar]

- Zhang, S.; Lin, Y.C.; He, D.-G.; Jiang, Y.-Q.; Zhang, H.-J.; Zeng, N.-F.; Wu, G.-C.; Naseri, M. Correlation between Plastic Deformation Mechanism and Texture Evolution of a near β-Ti Alloy Deformed in β Region. Intermetallics 2024, 170, 108333. [Google Scholar] [CrossRef]

- Tong, Y.; Hua, K.; Sun, L.; Xie, H.; Zhao, M.; Zhou, L.; Wu, H.; Wang, H. Effect of Rolling-Texture Intensity on Fretting Damage and Subsurface Deformation Behavior in a High-Strength Titanium Alloy. J. Mater. Sci. Technol. 2024, 196, 200–214. [Google Scholar] [CrossRef]

- Sun, T.; Deng, Y.; Liu, W.; Teng, H.; Wang, R.; Sun, C.; Deng, H.; Zhou, J. Substructure and Texture Evolution of a Novel Near-α Titanium Alloy with Bimodal Microstructure during Hot Compression in A+β Phase Region. J. Alloys Compd. 2024, 996, 174869. [Google Scholar] [CrossRef]

- Fan, J.; Zhao, D.; Chen, Z.; Zhang, Z.; Wang, J.; Tang, B.; Chen, Z.; Wang, Q.; Kou, H.; Li, J. Tailoring Texture in a Near-α Titanium Alloy: Insights from Strain Paths and Cooling Rate Influences. J. Mater. Res. Technol. 2024, 30, 1388–1402. [Google Scholar] [CrossRef]

- Wang, W.; Chen, C.; Zhao, R.; Gludovatz, B.; Lu, X.; Zhang, K.; Shuai, S.; Hu, T.; Xu, S.; Wang, J.; et al. A Laser Additive Manufactured Metastable Ti-10V-2Fe-3Al β-Titanium Alloy: Microstructure, Mechanical Properties, and Deformation Mechanisms. Mater. Sci. Eng. A 2024, 890, 145863. [Google Scholar] [CrossRef]

- Skvortsova, S.V.; Ilyin, A.A. Mechanisms of Phase and Structural Transformations and Texture Formation in Titanium Alloy Sheet Semiproducts. Russ. Metall. 2007, 2007, 355–363. [Google Scholar] [CrossRef]

- Obasi, G.C.; Birosca, S.; Leo Prakash, D.G.; Quinta da Fonseca, J.; Preuss, M. The Influence of Rolling Temperature on Texture Evolution and Variant Selection during A→β→α Phase Transformation in Ti–6Al–4V. Acta Mater. 2012, 60, 6013–6024. [Google Scholar] [CrossRef]

- Semiatin, S.L. An Overview of the Thermomechanical Processing of α/β Titanium Alloys: Current Status and Future Research Opportunities. Metall. Mater. Trans. A 2020, 51, 2593–2625. [Google Scholar] [CrossRef]

- Kobryn, P.A.; Semiatin, S.L. Microstructure and Texture Evolution during Solidification Processing of Ti–6Al–4V. J. Mater. Process. Technol. 2003, 135, 330–339. [Google Scholar] [CrossRef]

- Peters, M.; Gysler, A.; Lütjering, G. Influence of Texture on Fatigue Properties of Ti-6Al-4V. Metall. Mater. Trans. A 1984, 15, 1597–1605. [Google Scholar] [CrossRef]

- Evans, D.J.; Broderick, T.F.; Woodhouse, J.B.; Hoenigman, J.R. The Role of Intermetallic Precipitates in Ti-62222S. Mater. Sci. Eng. A 1996, 213, 37–44. [Google Scholar] [CrossRef]

- Eylon, D.; Seagle, S.R. Titanium’99, Science and Technology. In Proceedings of the Ninth World Concerence on Titanium, Central Research Institute of Structural Materials (CRISM), Saint-Petersburg, Russia, 7–11 June 1999; pp. 866–875. [Google Scholar]

- Semiatin, S.L.; Seetharaman, V.; Weiss, I. The Thermomechanical Processing of Alpha/Beta Titanium Alloys. JOM 1997, 49, 33–39. [Google Scholar] [CrossRef]

- Yang, L.; Yang, Y. Deformed Microstructure and Texture of Ti6Al4V Alloy. Trans. Nonferrous Met. Soc. China 2014, 24, 3103–3110. [Google Scholar] [CrossRef]

- Warchomicka, F.; Poletti, C.; Stockinger, M.; Henke, T. Microstructure Evolution during Hot Deformation of Ti-6Al-4V Double Cone Specimens. Int. J. Mater. Form. 2010, 3, 215–218. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Qu, S.J.; Feng, A.H.; Shen, J.; Chen, D.L. Hot Deformation Behavior of Ti-6Al-4V Alloy: Effect of Initial Microstructure. J. Alloys Compd. 2017, 718, 170–181. [Google Scholar] [CrossRef]

- Lee, S.W.; Lee, H.J.; Kim, J.H.; Park, C.H.; Hong, J.-K.; Yeom, J.-T. Effect of Prior β Grain Size on the Martensitic Transformation of Titanium Alloys. Mater. Charact. 2021, 182, 111525. [Google Scholar] [CrossRef]

- Zhang, X.D.; Bonniwell, P.; Fraser, H.L.; Baeslack III, W.A.; Evans, D.J.; Ginter, T.; Bayha, T.; Cornell, B. Effect of Heat Treatment and Silicon Addition on the Microstructure Development of Ti–6Al–2Cr–2Mo–2Sn–2Zr Alloy. Mater. Sci. Eng. A 2003, 343, 210–226. [Google Scholar] [CrossRef]

- Wood, J.R.; Russo, P.A.; Welter, M.F.; Crist, E.M. Thermomechanical Processing and Heat Treatment of Ti–6Al–2Sn–2Zr–2Cr–2Mo–Si for Structural Applications. Mater. Sci. Eng. A 1998, 243, 109–118. [Google Scholar] [CrossRef]

- Gupta, A.; Khatirkar, R.; Singh, J. A Review of Microstructure and Texture Evolution during Plastic Deformation and Heat Treatment of β-Ti Alloys. J. Alloys Compd. 2022, 899, 163242. [Google Scholar] [CrossRef]

- Pinke, P.; Caplovic, L.; Kovacs, T. The Influence of Heat Treatment on the Microstructure of the Casted Ti6Al4V Titanium Alloy. Slovak Univ. Technol. Bratislava. Web 2011, 11. Available online: https://www.kfki.hu/anyagokvilaga/tartalom/2007/oktober/Pinke_2.pdf (accessed on 21 February 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, C.; Jo, H.; Kim, J.H.; Yeom, J.; Kang, N.; Lee, W. Hot-Deformed Microstructure and Texture of Ti-62222 Alloy. Metals 2025, 15, 244. https://doi.org/10.3390/met15030244

Park C, Jo H, Kim JH, Yeom J, Kang N, Lee W. Hot-Deformed Microstructure and Texture of Ti-62222 Alloy. Metals. 2025; 15(3):244. https://doi.org/10.3390/met15030244

Chicago/Turabian StylePark, Chanho, Haeju Jo, Jae H. Kim, Jongtaek Yeom, Namhyun Kang, and Wookjin Lee. 2025. "Hot-Deformed Microstructure and Texture of Ti-62222 Alloy" Metals 15, no. 3: 244. https://doi.org/10.3390/met15030244

APA StylePark, C., Jo, H., Kim, J. H., Yeom, J., Kang, N., & Lee, W. (2025). Hot-Deformed Microstructure and Texture of Ti-62222 Alloy. Metals, 15(3), 244. https://doi.org/10.3390/met15030244