Optimization of Microstructure and Mechanical Properties in Al-Zn-Mg-Cu Alloys Through Multiple Remelting and Heat Treatment Cycles

Abstract

1. Introduction

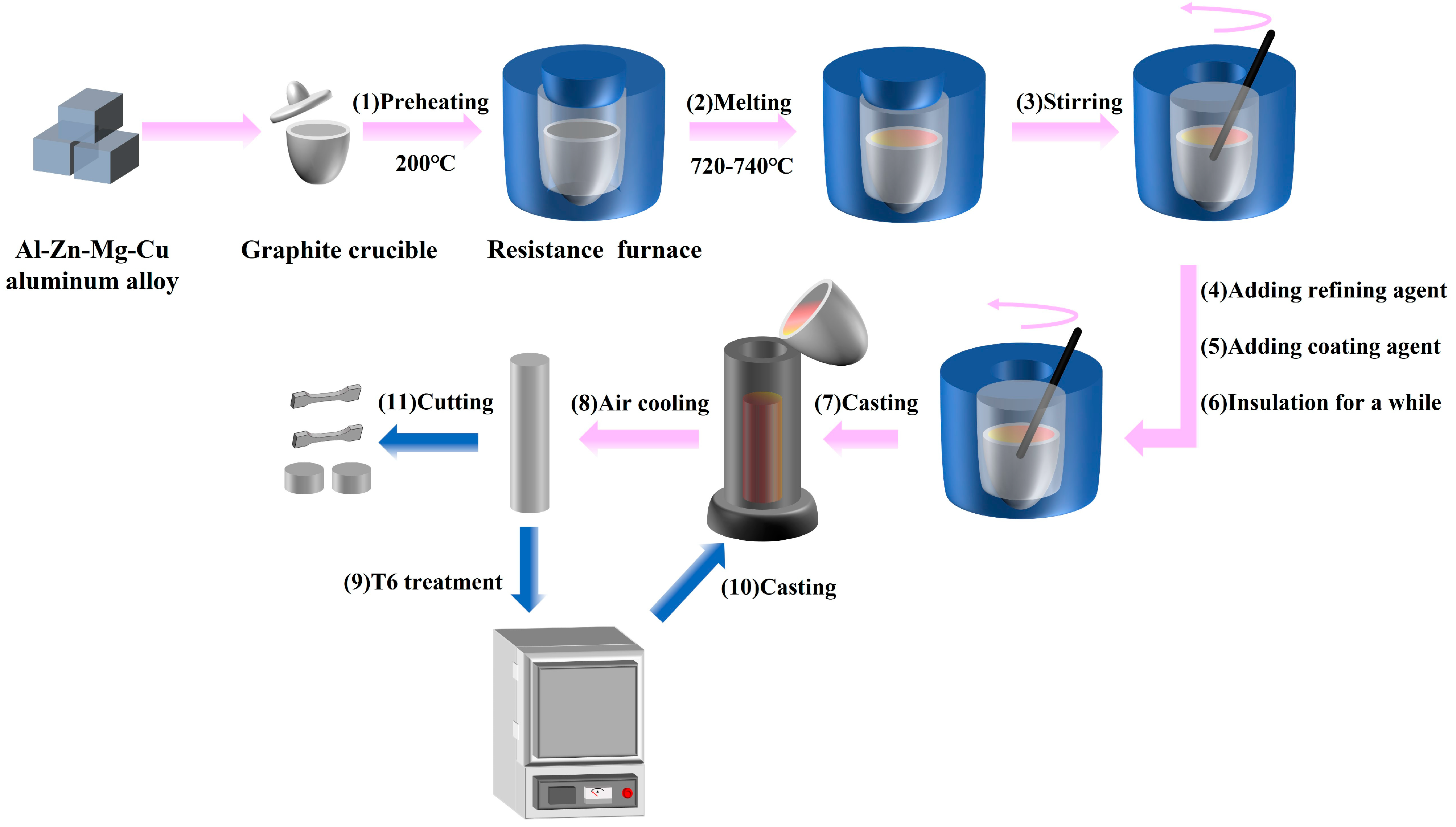

2. Materials and Methods

3. Results and Discussion

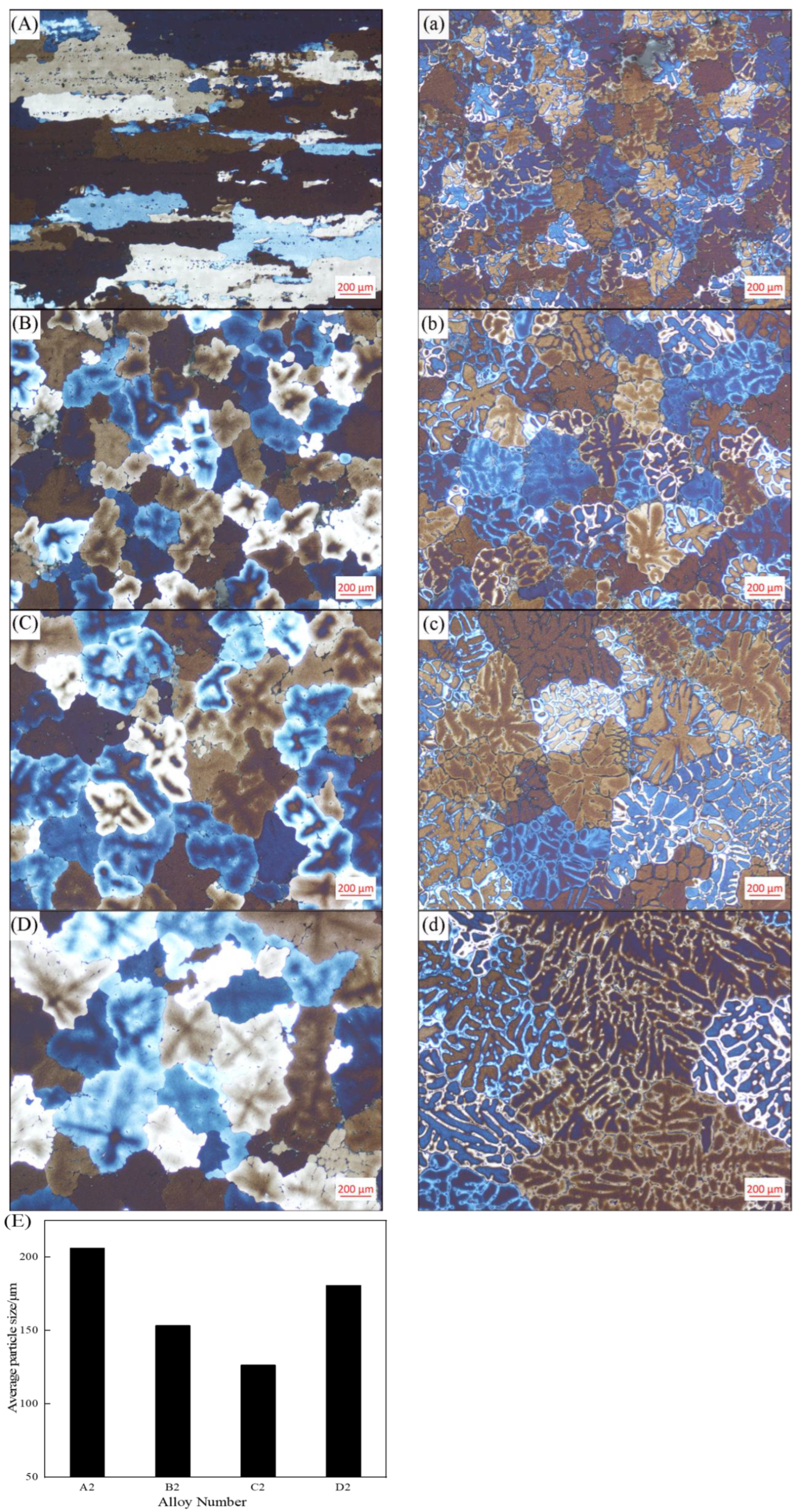

3.1. Grain Structure Evolution

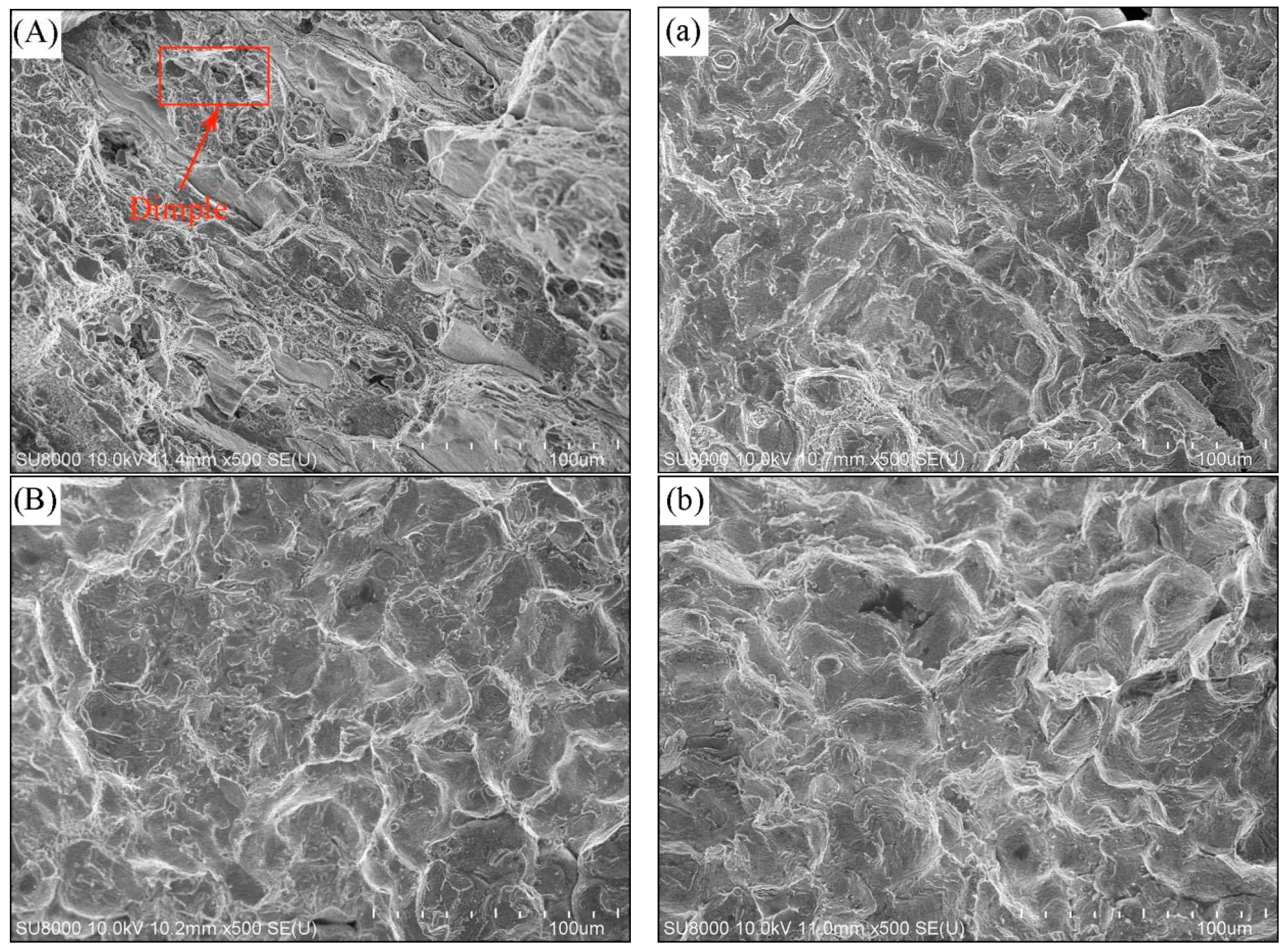

3.2. Impact on Mechanical Properties

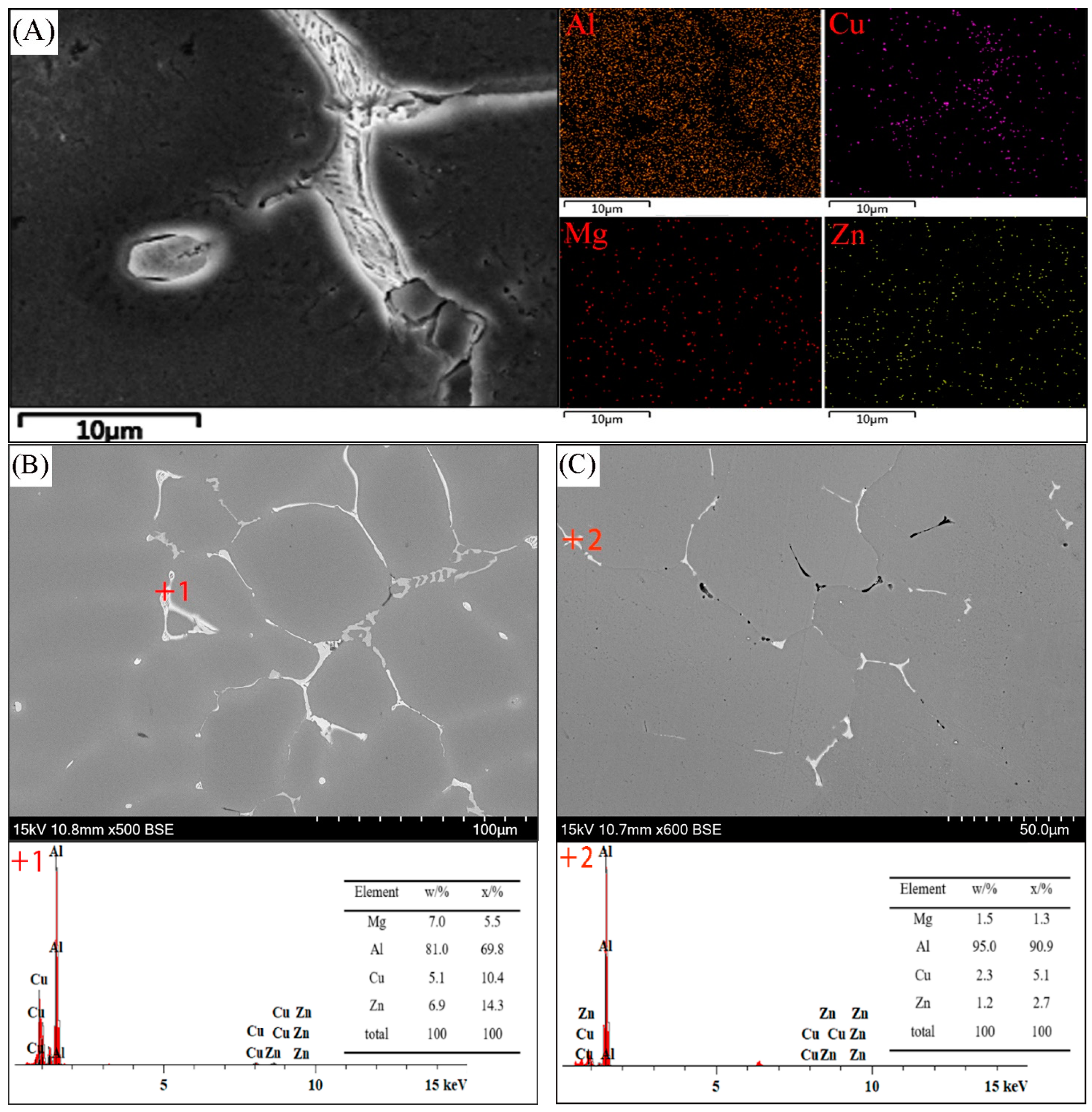

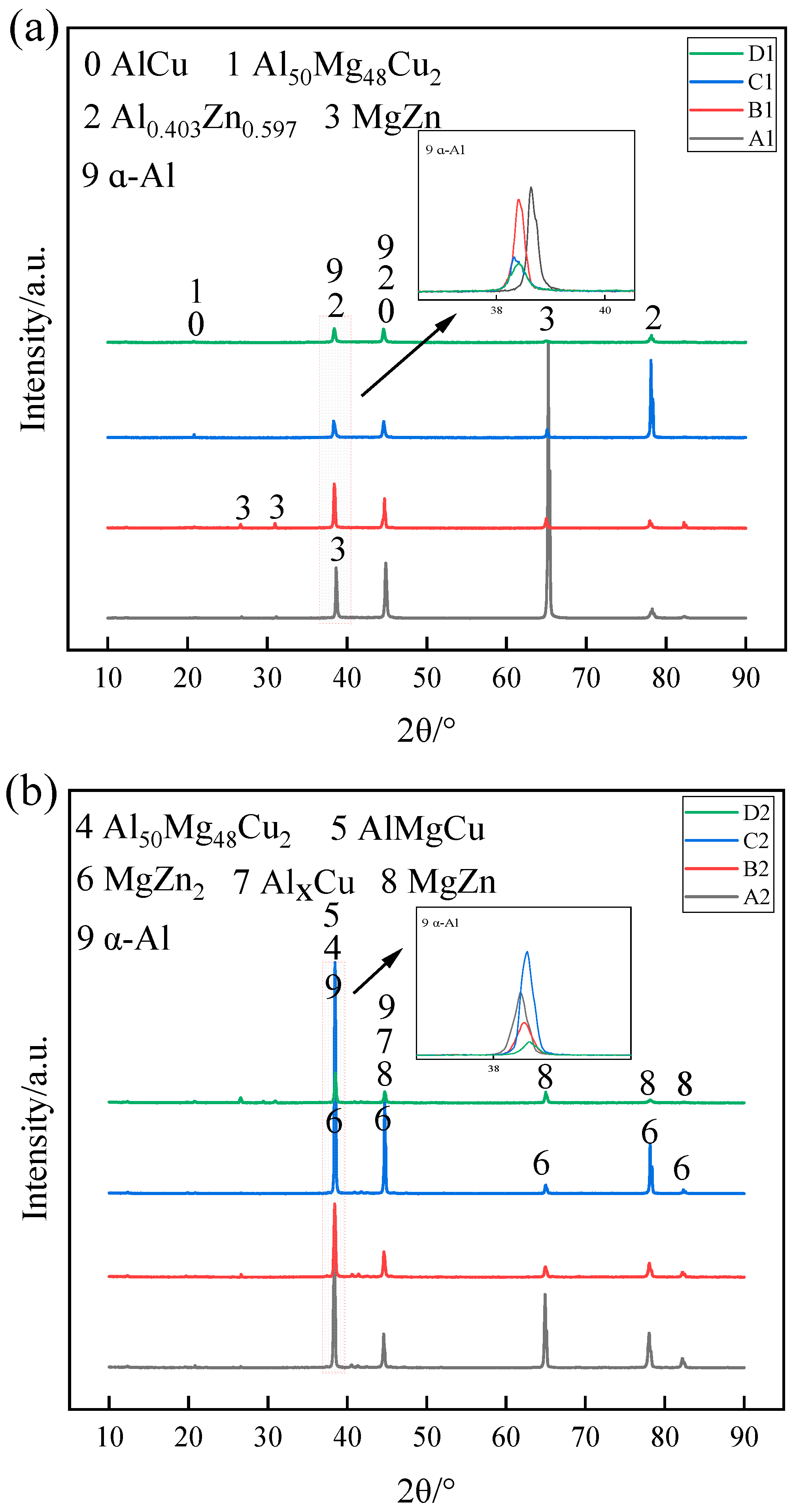

3.3. Microstructure and Precipitation Phases

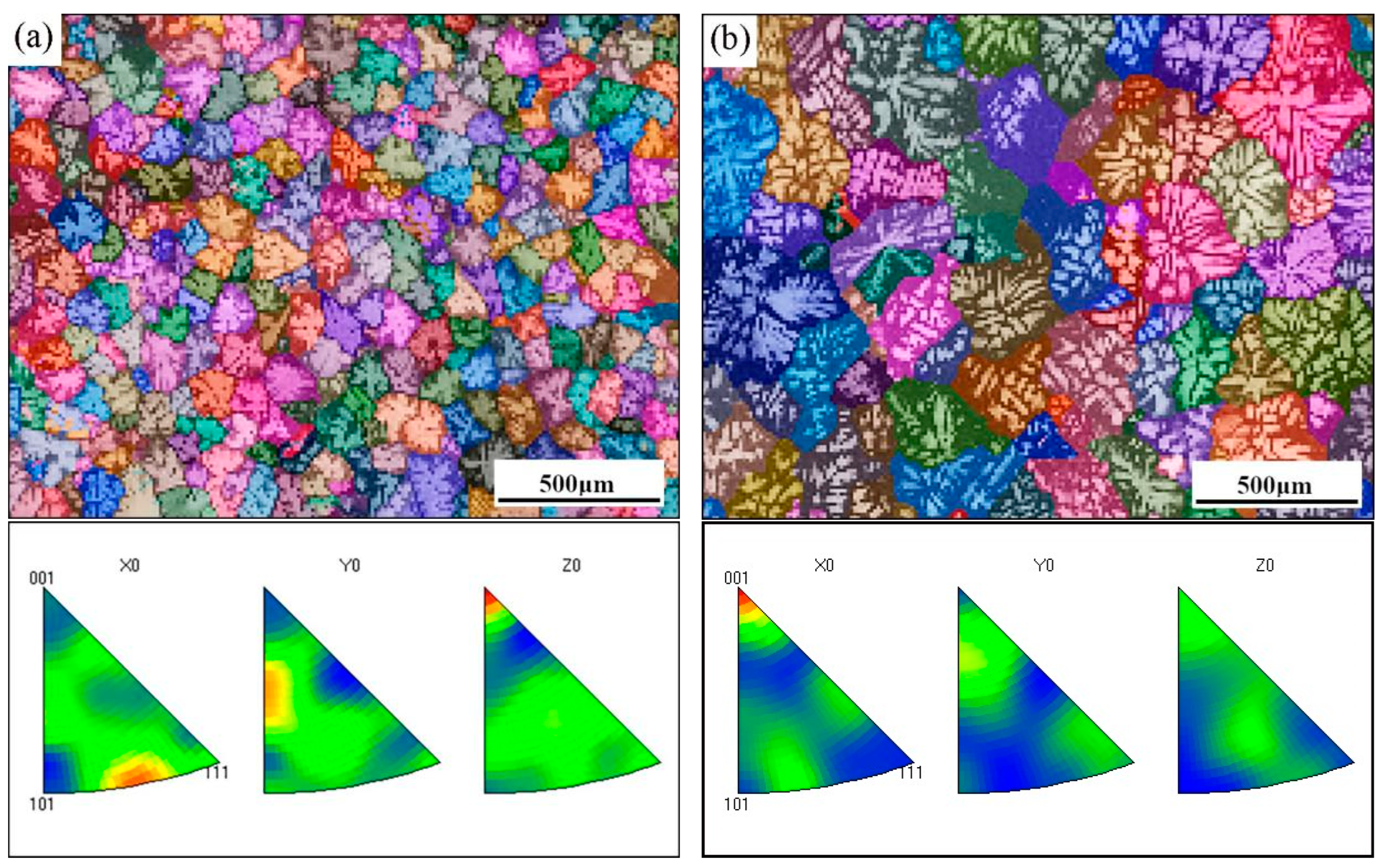

3.4. Phase Composition and Grain Structure

4. Conclusions

- (1)

- The properties of the alloy were studied after multiple heat treatment and four times remelting. It can be seen from the metallographic structure that under the same conditions, the grain size becomes smaller and smaller and the dendrites are developed during remelting, that is, the grains are refined during the remelting process. With the increase in the number of remelting times, the alloy underwent different structural changes due to the recovery, recrystallization and grain growth during the remelting process, and the mechanical properties of the alloy were improved. Under the state of remelting, the alloy demonstrates an initial increase followed by a decrease in both fracture strength and yield strength. Comparative analysis reveals that, relative to the A2 sample, the ultimate tensile strength undergoes a significant enhancement of 88.7%, rising from 115.4 MPa to 217.7 MPa. Similarly, the yield strength increases by 84.5%, from 115.1 MPa to 212.5 MPa. However, at the fourth remelting iteration, both tensile and yield strengths undergo a notable decrease, with ultimate tensile strength dropping to 147.2 MPa and yield strength to 147.5 MPa. The yield strength (YS, σ0.2) and ultimate tensile strength (UTS) are the parameters obtained when the strain rate is 1 mm/min.

- (2)

- Under the same conditions, it is found that the fracture strength and yield strength of the alloy without remelting are better than those in the melting state. With the increase in remelting times, α-Al dendrites and MgZn2 phase continue to maintain favorable grain shape and size, and their mechanical properties are still high. However, due to the continuous transformation of the alloy phase during remelting, the morphology and size of α-Al dendrites and MgZn2 phase begin to deteriorate, leading to the decrease in mechanical properties.

- (3)

- Upon successive remelting, the MgZn2 phase within the alloy undergoes a transformation to MgZn, which, along with AlxCu, exhibits a more favorable morphology relative to MgZn2. With each iteration of heat treatment, the MgZn2 phase that precipitates become increasingly coherent with the aluminum matrix, with a diminutive size correlating positively with strengthening effects.

- (4)

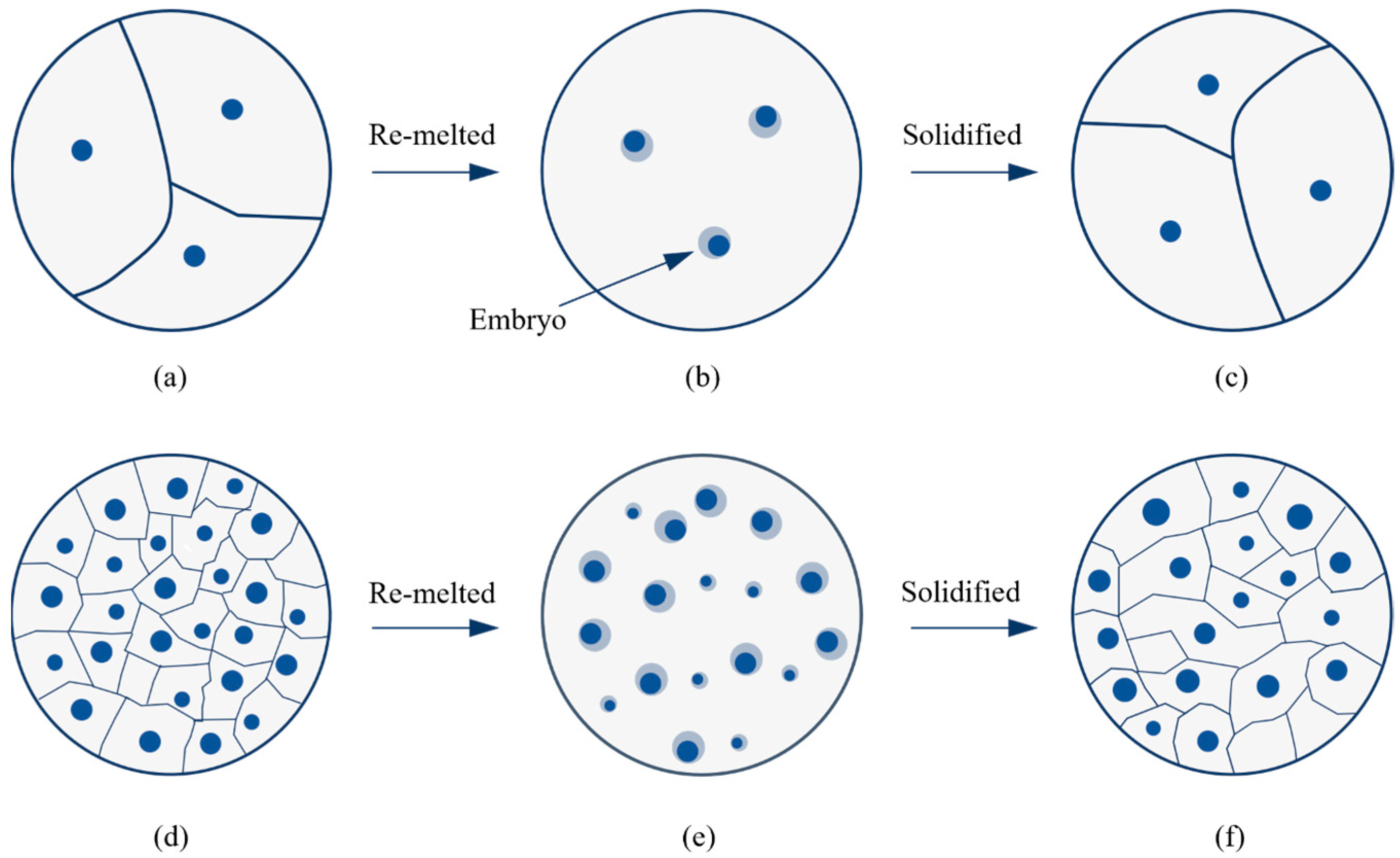

- In the context of the remelting process, there is a progressive ordering of atomic groups within the melt, which augments the population of potential nucleation embryos. This ordering leads to a refinement of the grain structure, which is maintained even post-remelting. In contrast, an initial coarser grain structure in the casting implies a scarcity of ordered atomic groups within the aluminum alloy melt subsequent to remelting. This deficiency in ordered atomic groups correlates with a diminished number of nucleation embryos, perpetuating the coarser grain structure through the remelting process. These findings underscore the complex interplay between thermal treatments, melt composition, and the resultant grain structure in the 7075 aluminum alloy, emphasizing the significance of these factors in dictating material properties.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, H.; Xie, Y.; Tang, P.; Tang, Z.; Liao, C.; Pang, R. Demystifying the Influence of Scrap to Raw Material Ratio on Microstructural and Mechanical Properties of the Secondary 7075 Aluminum Alloy. Mater. Lett. 2025, 382, 137847. [Google Scholar] [CrossRef]

- Alatorre, N.; Ambriz, R.R.; Noureddine, B.; Amrouche, A.; Talha, A.; Jaramillo, D. Tensile Properties and Fusion Zone Hardening for GMAW and MIEA Welds of a 7075-T651 Aluminum Alloy. Acta Metall. Sin. (Engl. Lett.) 2014, 27, 694–704. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Umer, R.; Khan, K.A. Review of recent trends and developments in aluminium 7075 alloy and its metal matrix composites (MMCs) for aircraft applications. Results Eng. 2023, 20, 100372. [Google Scholar] [CrossRef]

- Zhou, B.; Liu, B.; Zhang, S.; Lin, R.; Jiang, Y.; Lan, X. Microstructure evolution of Secondary 7075 aluminum alloy and its mechanical and corrosion properties. J. Alloys Compd. 2021, 879, 160379. [Google Scholar] [CrossRef]

- Miller, W.S.; Zhuang, L.; Bottema, J.; Wittebrood, A.J.; De Smet, P.; Haszler, A.; Vieregge, A. Recent development in aluminium alloys for the automotive industry. Mater. Sci. Eng. A 2000, 280, 37–49. [Google Scholar] [CrossRef]

- Damgaard, A.; Larsen, A.W.; Christensen, T.H. Recycling of metals: Accounting of greenhouse gases and global warming contributions. Waste Manag. Res. 2009, 27, 773–780. [Google Scholar] [CrossRef] [PubMed]

- Muñiz-Lerma, J.A.; Paliwal, M.; Jung, I.-H.; Brochu, M. Fractional Crystallization Model of Multicomponent Aluminum Alloys: A Case Study of Aircraft Recycling. Metall. Mater. Trans. B 2017, 48, 1024–1034. [Google Scholar] [CrossRef]

- Lin, R.; Liu, B.; Zhang, J.; Zhang, S. Microstructure evolution and properties of 7075 aluminum alloy Secondary from scrap aircraft aluminum alloys. J. Mater. Res. Technol. 2022, 19, 354–367. [Google Scholar] [CrossRef]

- Wang, P.; Lei, H.; Zhu, X.; Chen, H.; Fang, D. Investigation on the mechanical properties of epoxy resin with void defects using digital image correlation and image-based finite element method. Polym. Test. 2018, 72, 223–231. [Google Scholar] [CrossRef]

- Barot, R.P.; Sutaria, M.P. Effect of multiple remelting on behaviour of AlSi5Cu3 Aluminium alloy. Mater. Today Proc. 2022, 62, 4046–4051. [Google Scholar] [CrossRef]

- Liu, T.; Hu, M.; Li, X.; Piao, J. Synthesis of Al-5Ti-1B-1Ce alloy from remelted chips and its refinement effect. Mater. Lett. 2023, 349, 134798. [Google Scholar] [CrossRef]

- Matejka, M.; Bolibruchová, D.; Kuriš, M. Crystallization of the Structural Components of Multiple Remelted AlSi9Cu3 Alloy. Arch. Foundry Eng. 2020, 20, 41–45. [Google Scholar] [CrossRef]

- Rometsch, P.A.; Zhang, Y.; Knight, S. Heat treatment of 7xxx series aluminium alloys—Some recent developments. Trans. Nonferrous Met. Soc. China 2014, 24, 2003–2017. [Google Scholar] [CrossRef]

- Choi, J.-Y.; Moon, J.; Jang, J.-H.; Lee, T.-H.; Hong, H.-U.; Kim, H.C.; Kang, N.H.; Shin, J.-H.; Lee, C.-H. Enhancement of mechanical properties by repeated heat treatment in reduced activation ferritic/martensitic steel with Ta and Ti. J. Nucl. Mater. 2021, 557, 153321. [Google Scholar] [CrossRef]

- Zhao, A.; Hu, S.; Chen, S.; Zhang, Y.; Zhao, H.; Zhang, Y. Effect of repeated solution aging treatment on microstructure and mechanical properties of TB15 titanium alloy. Heat Treat. Met. 2022, 47, 91–94. [Google Scholar] [CrossRef]

- Yang, Y.; Xie, Y.; Tang, P.; Lu, J. Mechanism of Fe-rich phase supercooling induced by CDS process to regulating microstructure and strengthen properties of Al-Si-Fe alloy. J. Alloys Compd. 2024, 1007, 176462. [Google Scholar] [CrossRef]

- Barot, R.P.; Sutaria, M.P. Microstructural and mechanical characteristics of AlSi5Cu3 aluminum alloy cast in metal mold and sand mold. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- ASTM E8M-2004; Standard Test Methods for Tension Testing of Metallic Materials, American Society for Materials and Testing. ASTM: West Conshohocken, PA, USA, 2004.

- Oh, J.; Park, H.D.; Gwak, M.; Lee, J.; Son, S.; Amanov, A.; Kim, H.S.; Seol, J.B.; Sung, H.; Kim, J.G. Mechanical property enhancement in gradient structured aluminum alloy by ultrasonic nanocrystalline surface modification. Mater. Sci. Eng. A 2021, 812, 141101. [Google Scholar] [CrossRef]

- Liao, W.; Zhang, C.; Qiang, H.; Song, W.; Ren, H. Effect and Mechanism of Solidified Microstructure on Deformation Behavior, Mechanical Properties, and Residual Stress of Cu-Ni-Si Alloy. Materials 2022, 15, 8724. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.Q.; Li, W.; Zheng, X.P.; Song, J.Y.; Wei, Y.L.; Chen, L.S. Study on Carbide precipitation Behavior and Microstructure Properties of two-phase zone Annealing hot rolled Medium Manganese Steel. Mater. Rev. 2019, 33, 2765–2770. [Google Scholar] [CrossRef]

- Wang, X.; Rong, Q.; Shi, Z.; Li, Y.; Cao, J.; Chen, B.; Lin, J. Investigation of stress effect on creep, precipitation and dislocation evolution of Al–Li alloy during creep age forming. Mater. Sci. Eng. A 2022, 836, 142723. [Google Scholar] [CrossRef]

- Andani, M.T.; Lakshmanan, A.; Sundararaghavan, V.; Allison, J.; Misra, A. Estimation of micro-Hall-Petch coefficients for prismatic slip system in Mg-4Al as a function of grain boundary parameters. Acta Mater. 2022, 226, 117956. [Google Scholar] [CrossRef]

| Alloys | Elements (wt.%) | |||||||

|---|---|---|---|---|---|---|---|---|

| Al | Zn | Mg | Cu | Cr | Fe | Si | Mn | |

| A1 | 89.66 | 5.58 | 2.61 | 1.40 | 0.03 | 0.18 | 0.08 | 0.15 |

| A2 | 89.36 | 5.87 | 2.48 | 1.50 | 0.02 | 0.18 | 0.09 | 0.13 |

| B1 | 89.37 | 5.85 | 2.48 | 1.56 | 0.02 | 0.18 | 0.09 | 0.13 |

| B2 | 89.06 | 6.12 | 2.43 | 1.66 | 0.02 | 0.20 | 0.09 | 0.13 |

| C1 | 90.04 | 5.87 | 1.83 | 1.49 | 0.02 | 0.18 | 0.08 | 0.14 |

| C2 | 89.94 | 6.01 | 1.78 | 1.55 | 0.02 | 0.20 | 0.09 | 0.14 |

| D1 | 90.40 | 5.73 | 1.70 | 1.46 | 0.02 | 0.18 | 0.08 | 0.14 |

| D2 | 90.67 | 5.93 | 1.20 | 1.48 | 0.02 | 0.21 | 0.09 | 0.14 |

| Step | T6 Heat Treatment | Multiple Remelting + Repeated T6 | Remelting Cycles |

|---|---|---|---|

| A1 | 470 °C × 1 h + 120 °C × 24 h | 1st T6 (Rolled condition) | 0 |

| A2 | 470 °C × 1 h + 120 °C × 24 h | Sample A (T6 + remelting) | 1 |

| B1 | 470 °C × 1 h + 120 °C × 24 h | Sample A2 (T6) | 1 |

| B2 | 470 °C × 1 h + 120 °C × 24 h | Sample B (T6 + remelting) | 2 |

| C1 | 470 °C × 1 h + 120 °C × 24 h | Sample B2 (T6) | 2 |

| C2 | 470 °C × 1 h + 120 °C × 24 h | Sample C (T6 + remelting) | 3 |

| D1 | 470 °C × 1 h + 120 °C × 24 h | Sample C2 (T6) | 3 |

| D2 | 470 °C × 1 h + 120 °C × 24 h | Sample D (T6 + remelting) | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, P.; Pang, R.; Chen, H.; Ren, Y.; Tan, J. Optimization of Microstructure and Mechanical Properties in Al-Zn-Mg-Cu Alloys Through Multiple Remelting and Heat Treatment Cycles. Metals 2025, 15, 234. https://doi.org/10.3390/met15030234

Tang P, Pang R, Chen H, Ren Y, Tan J. Optimization of Microstructure and Mechanical Properties in Al-Zn-Mg-Cu Alloys Through Multiple Remelting and Heat Treatment Cycles. Metals. 2025; 15(3):234. https://doi.org/10.3390/met15030234

Chicago/Turabian StyleTang, Peng, Ronghui Pang, Hanbing Chen, Yulong Ren, and Jun Tan. 2025. "Optimization of Microstructure and Mechanical Properties in Al-Zn-Mg-Cu Alloys Through Multiple Remelting and Heat Treatment Cycles" Metals 15, no. 3: 234. https://doi.org/10.3390/met15030234

APA StyleTang, P., Pang, R., Chen, H., Ren, Y., & Tan, J. (2025). Optimization of Microstructure and Mechanical Properties in Al-Zn-Mg-Cu Alloys Through Multiple Remelting and Heat Treatment Cycles. Metals, 15(3), 234. https://doi.org/10.3390/met15030234