Statistical Evaluation of the Mechanical Properties of Welded and Unwelded ASTM A706 Reinforcing Steel Bars of Different Commercial Brands

Abstract

1. Introduction

2. Materials and Methods

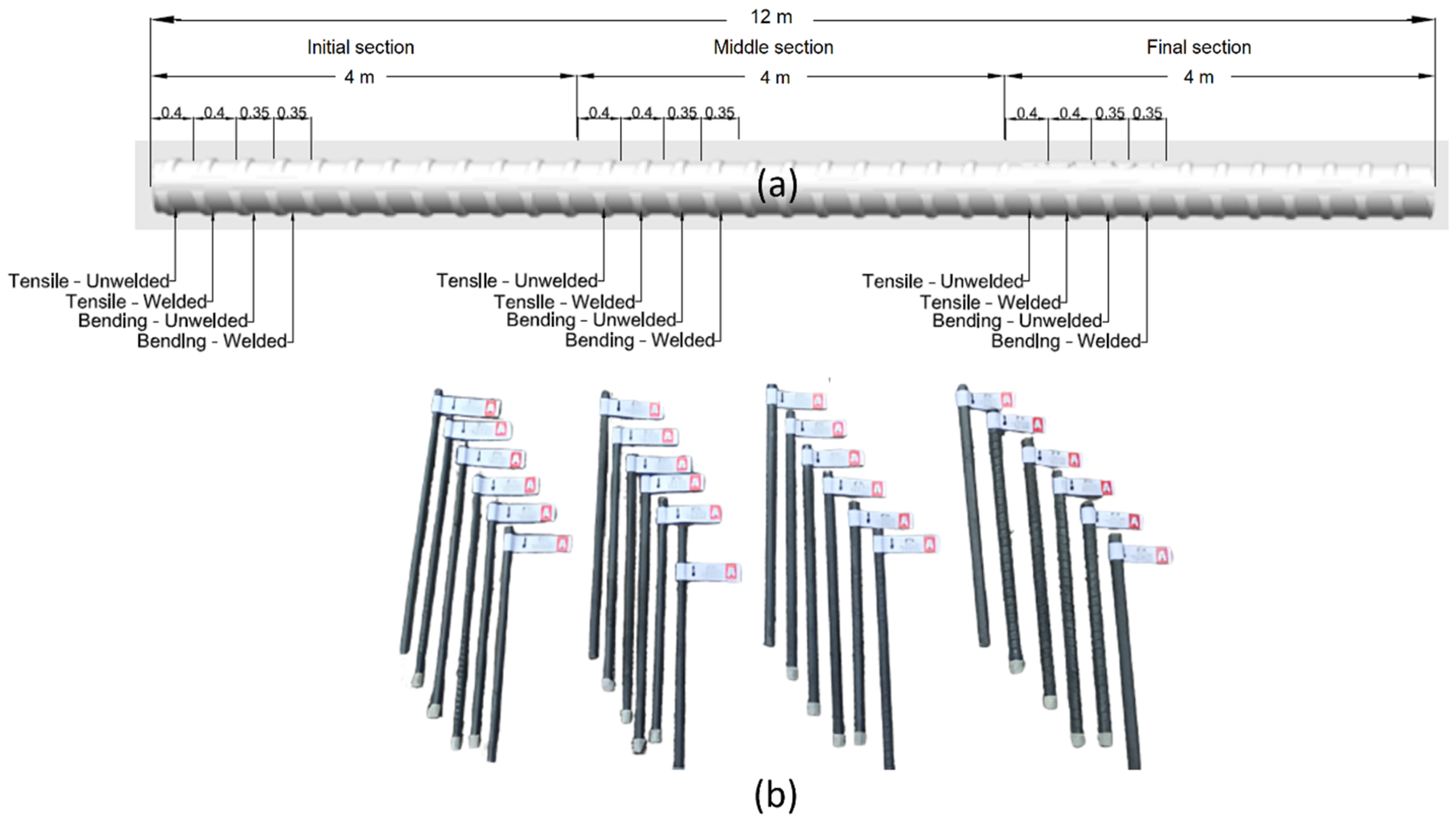

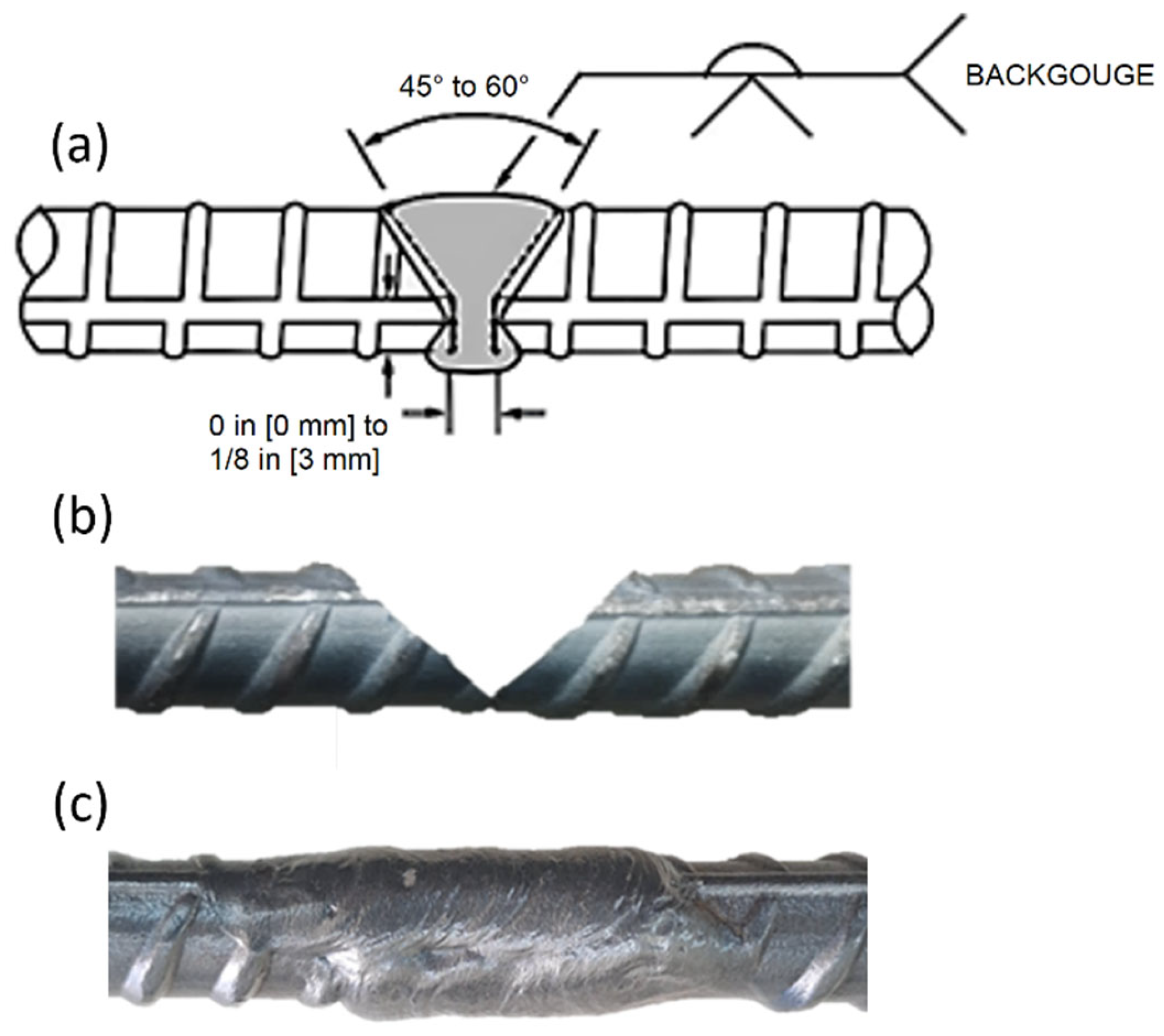

2.1. Material Preparation

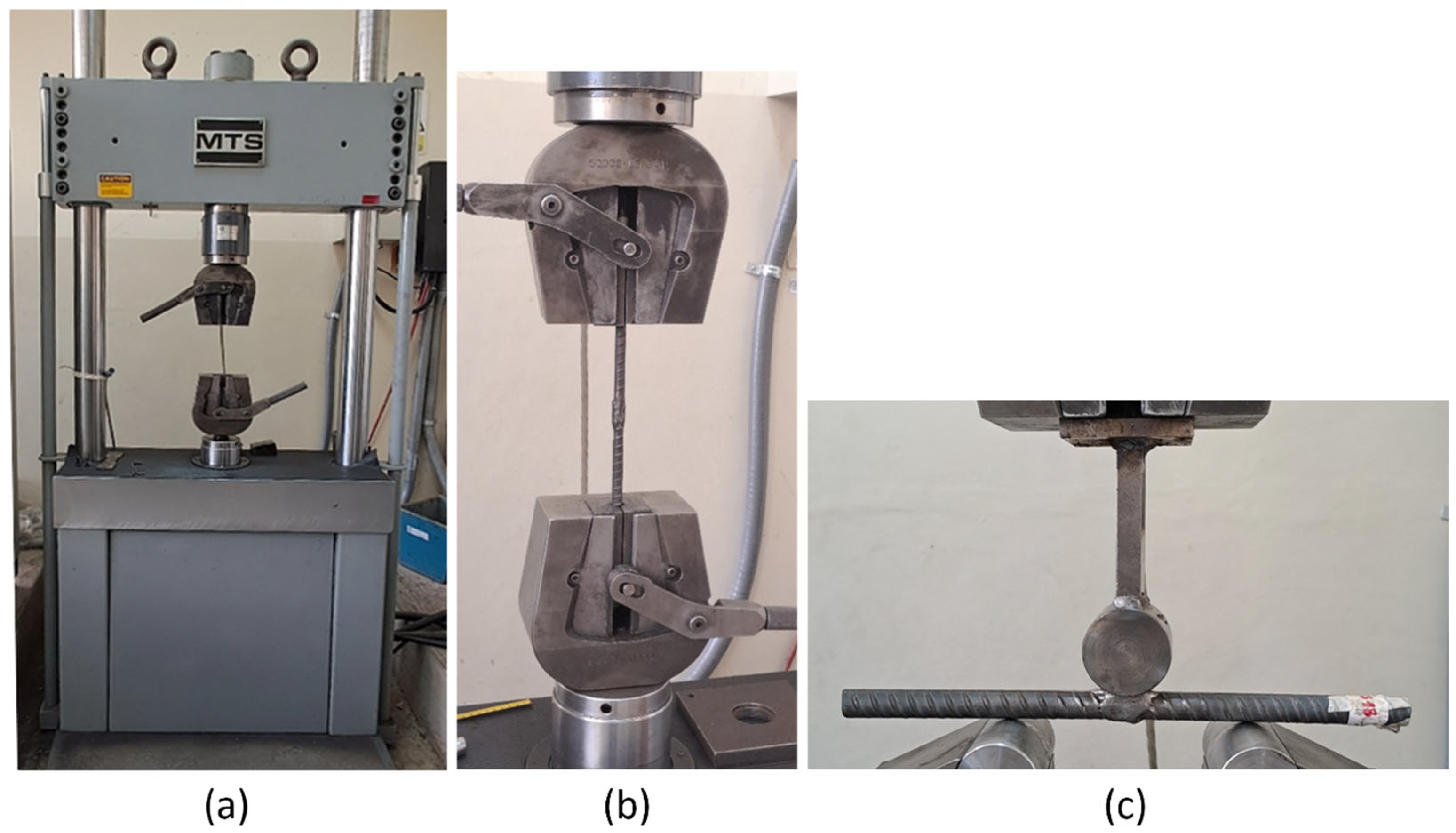

2.2. Mechanical Response

2.3. Statistical Evaluation

3. Results and Discussion

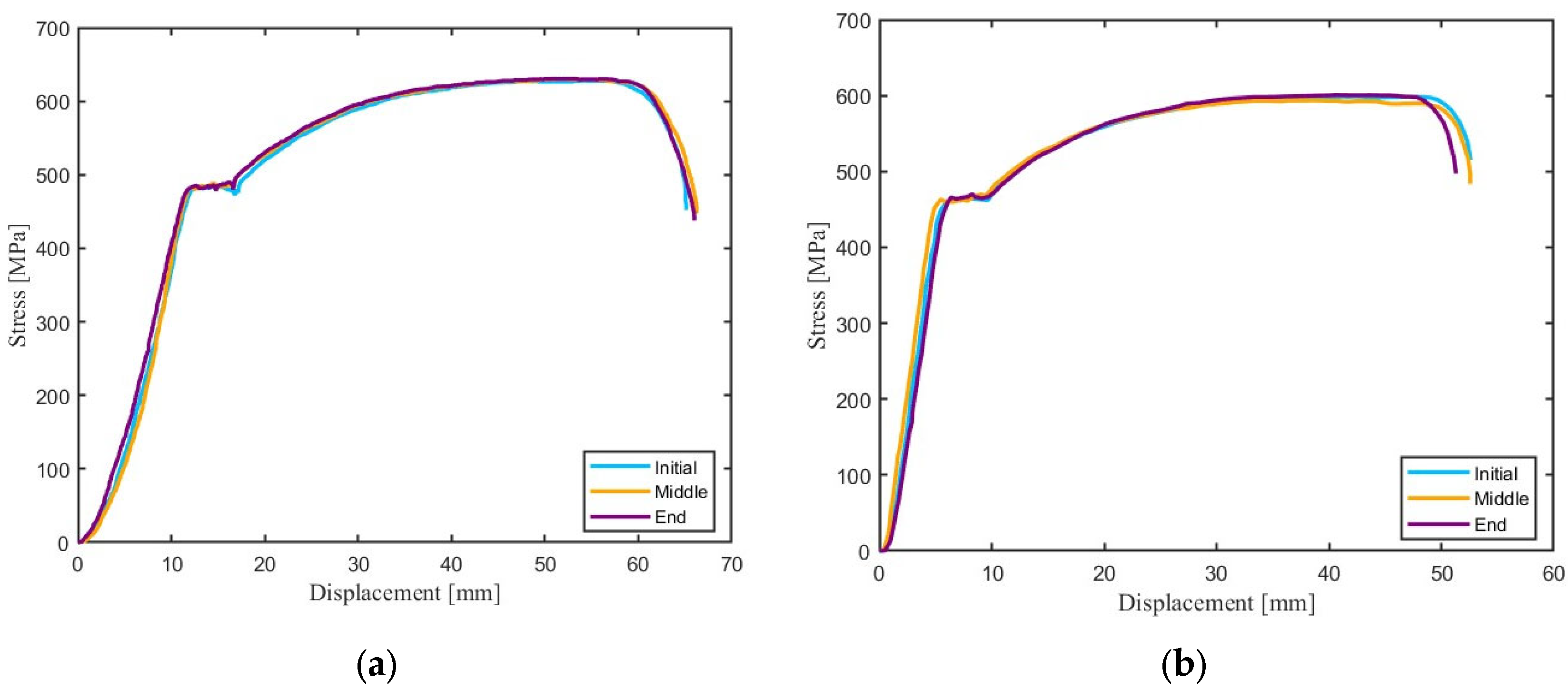

3.1. Tensile Test of Unwelded and Welded Reinforcing Steel Bars

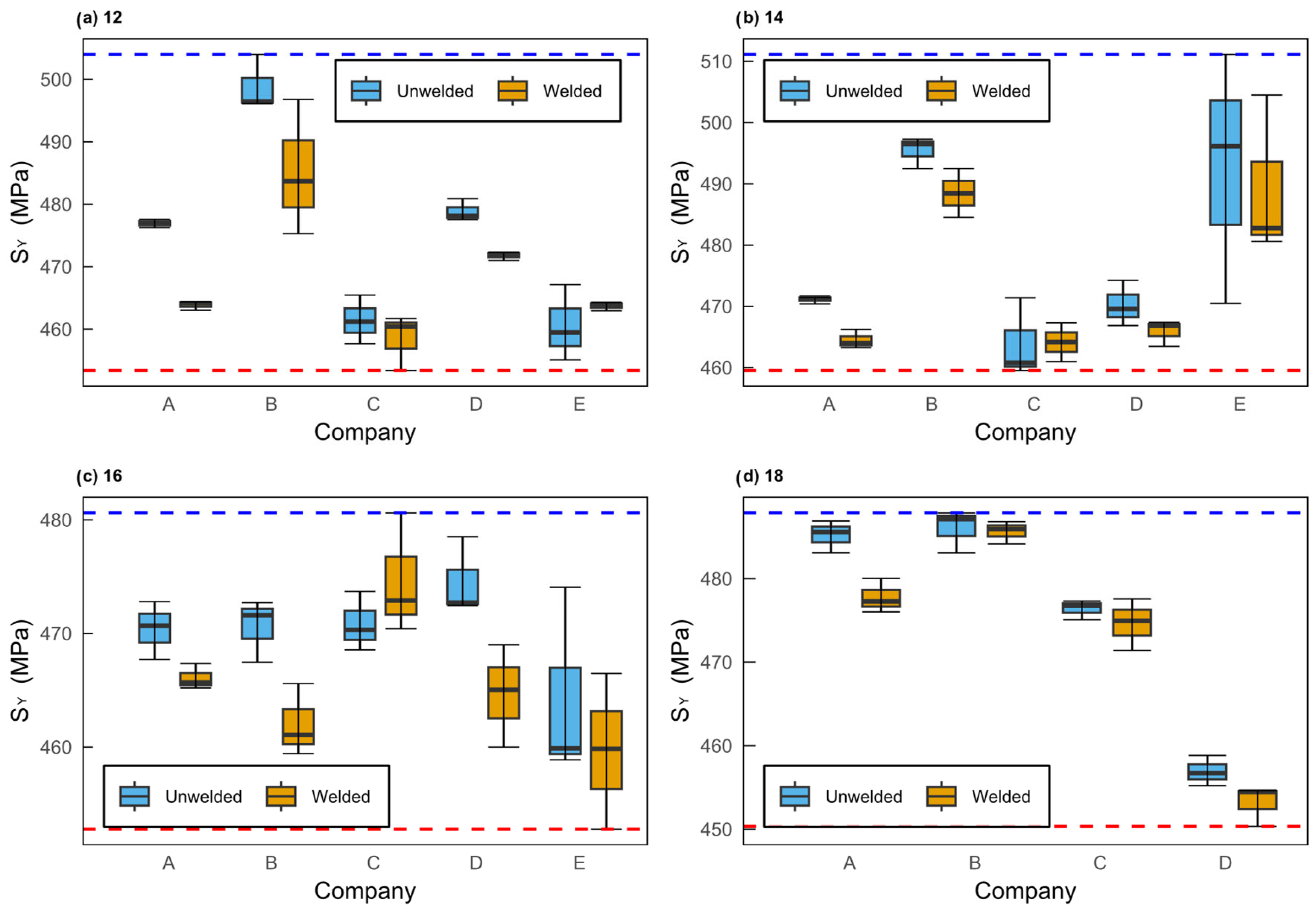

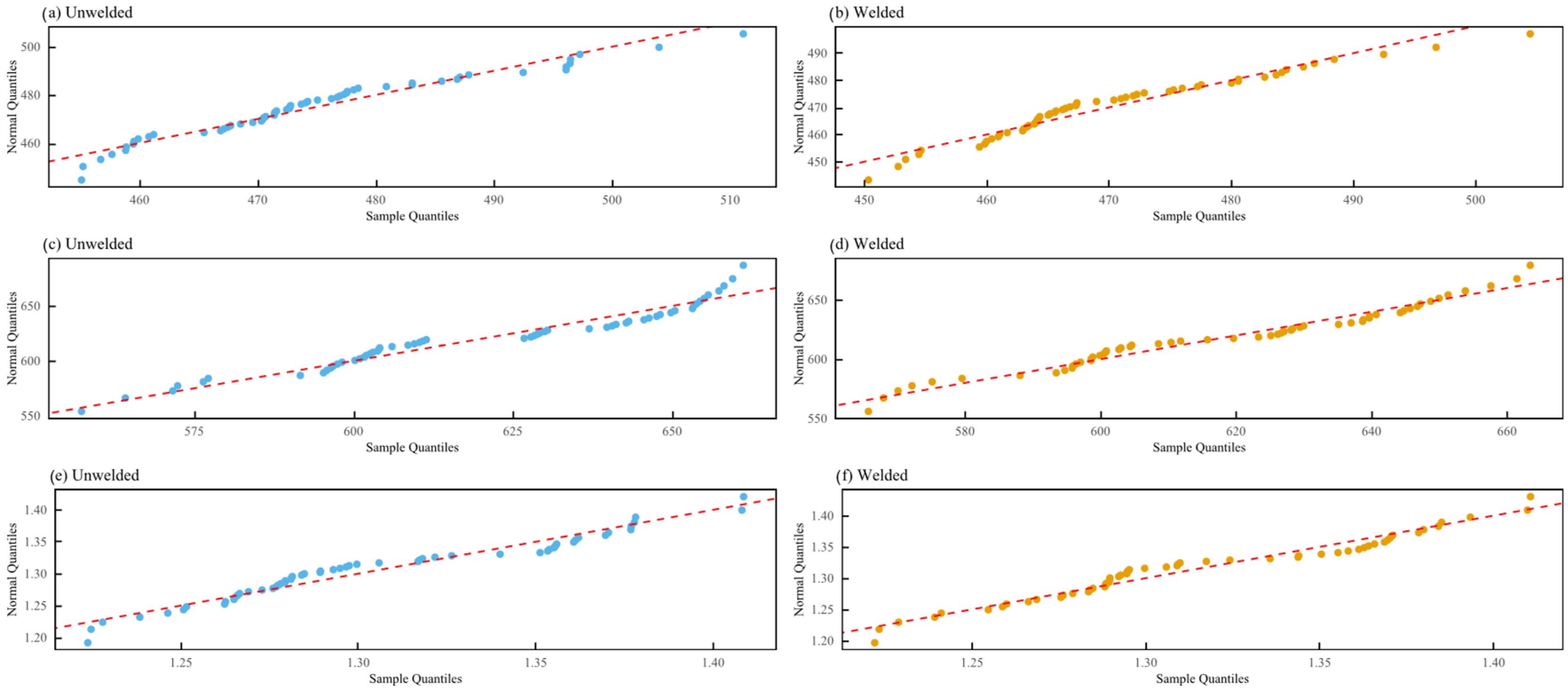

3.1.1. Yield Strength Response

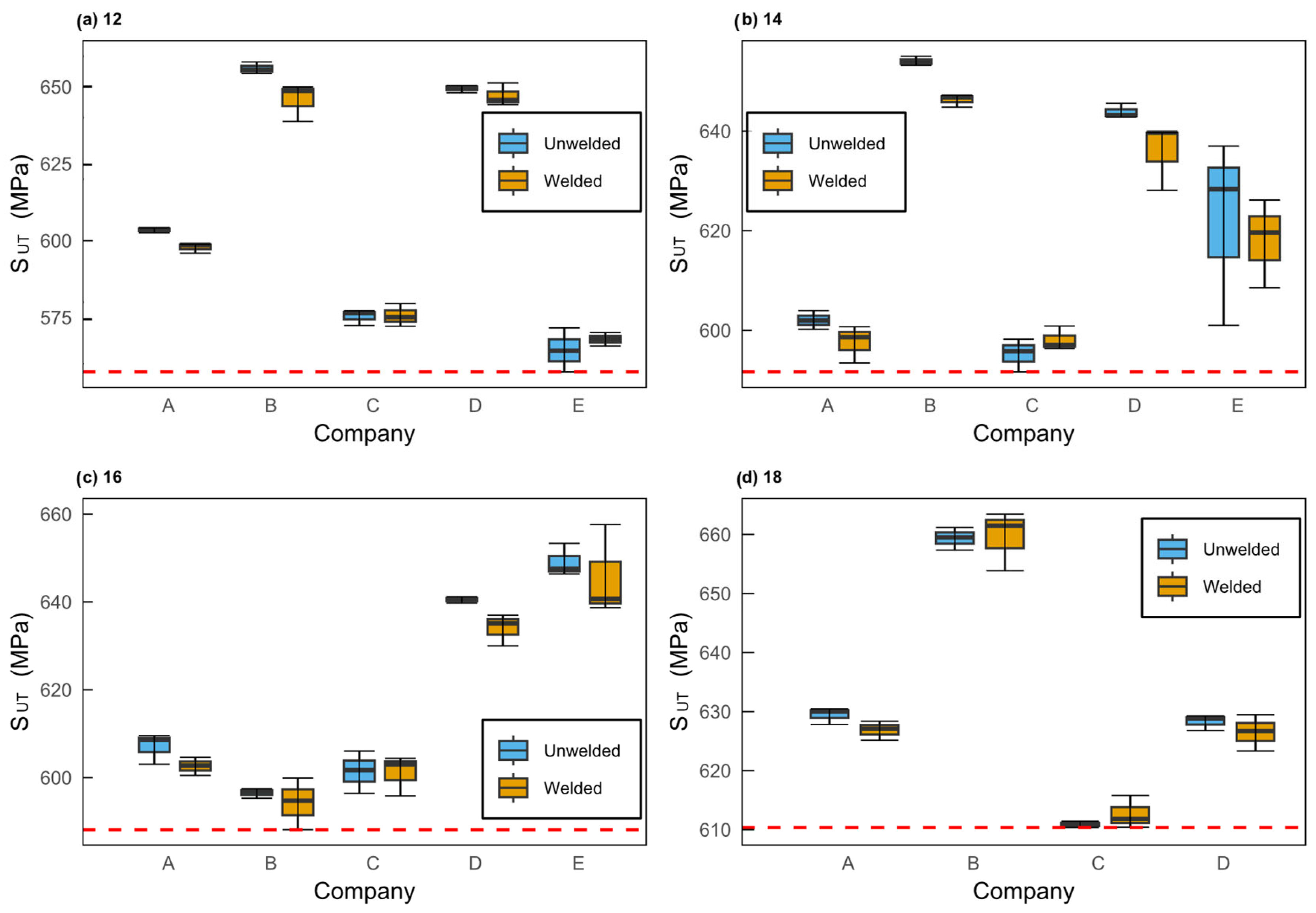

3.1.2. Ultimate Tensile Strength Response

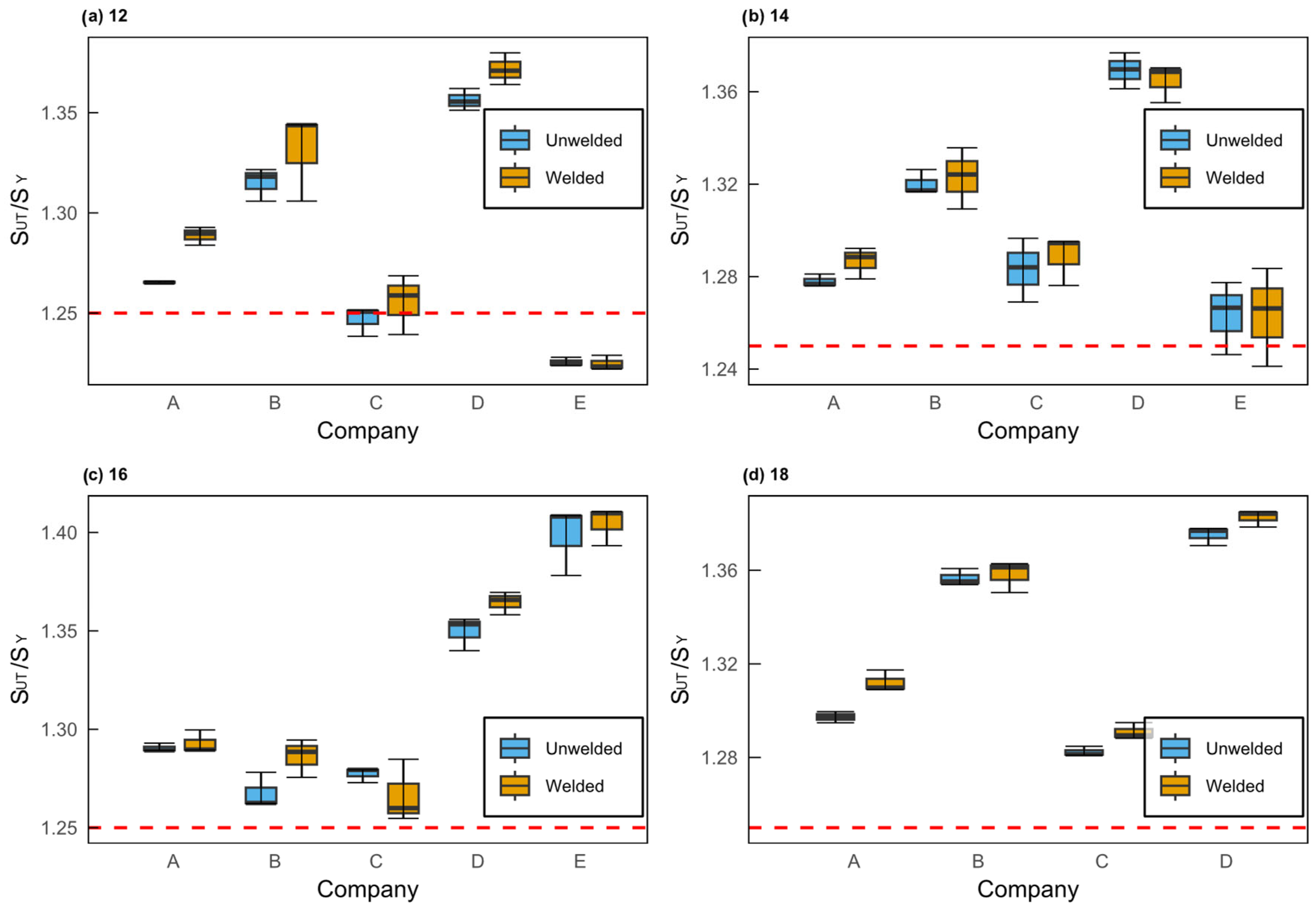

3.1.3. Ratio SUT/SY

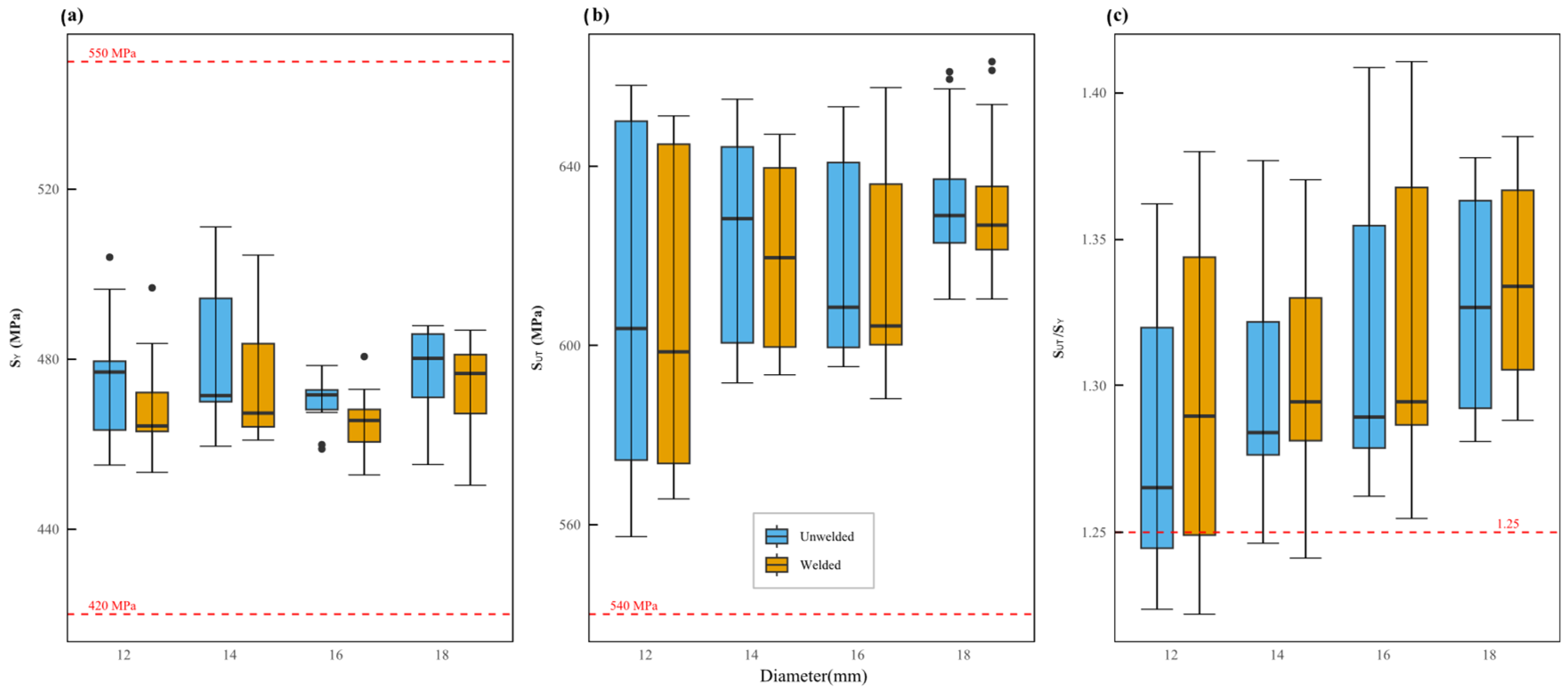

3.2. Analysis of Statistics Grouped by Diameter Without Considering Brands

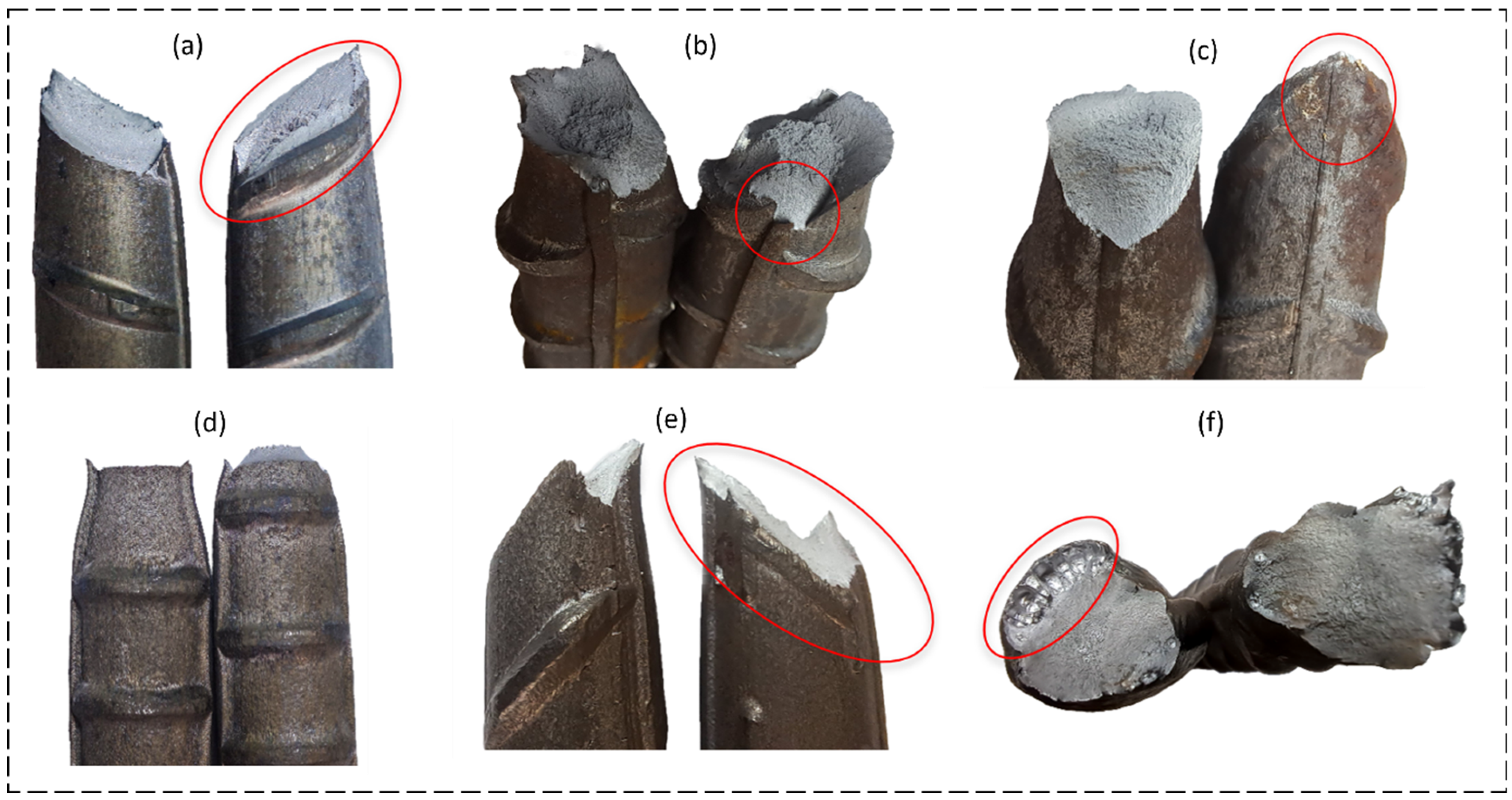

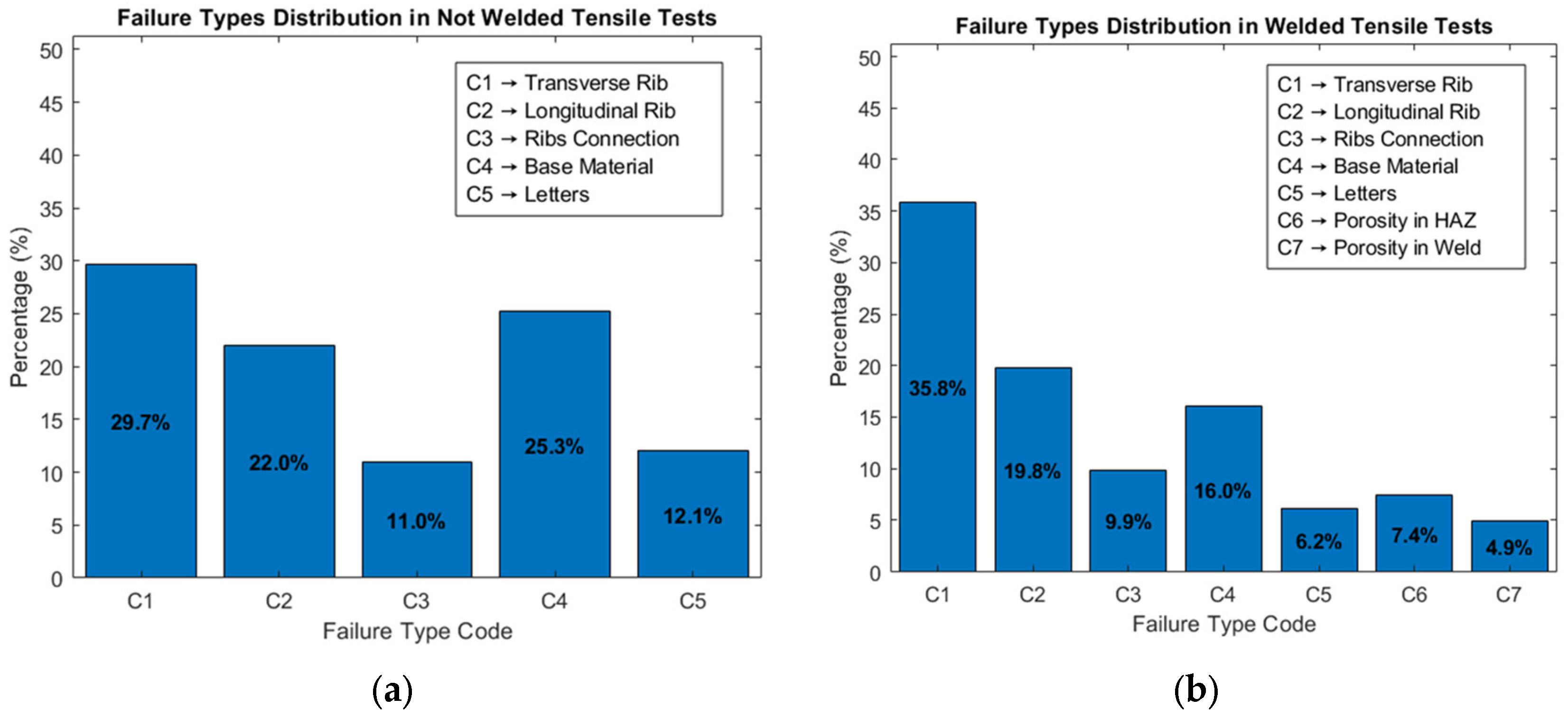

3.3. Analysis of the Fracture Zone

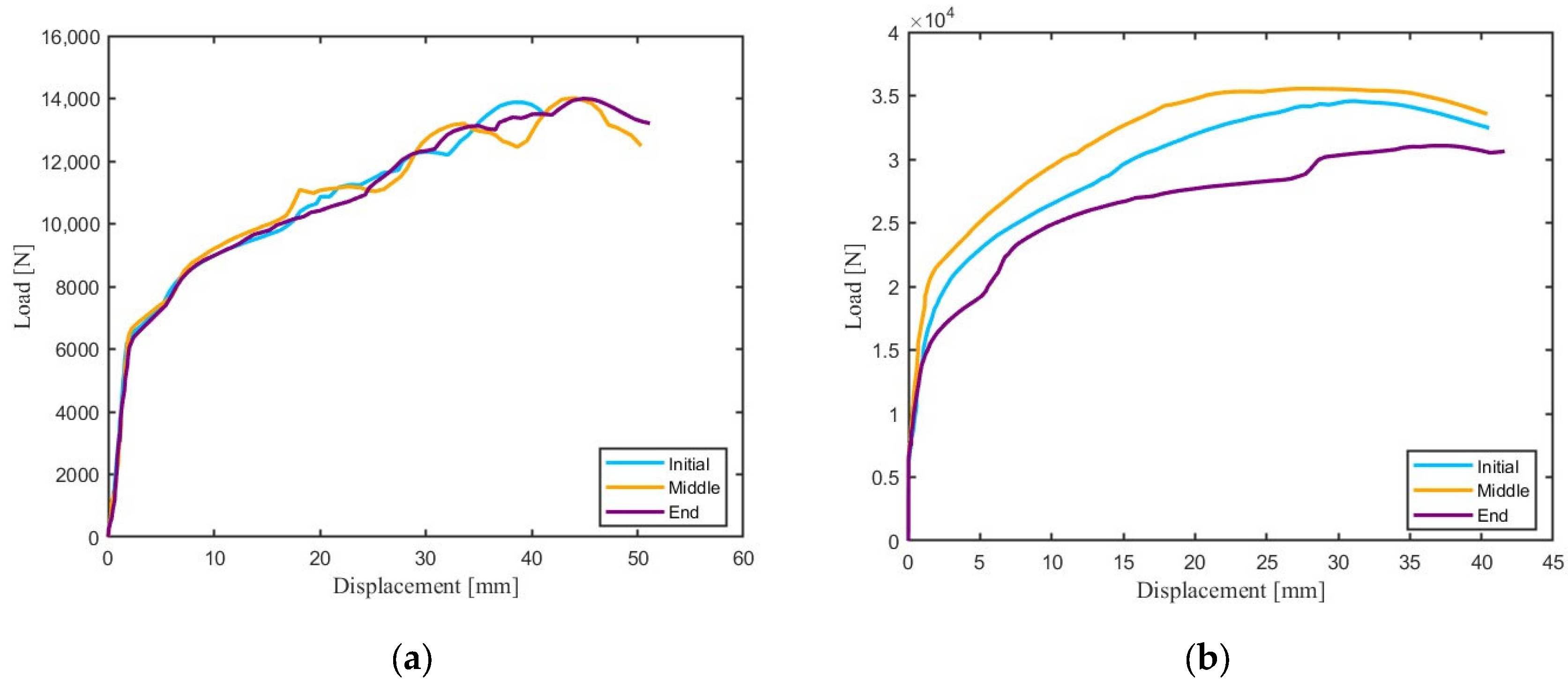

3.4. Bending Tests Response

4. Conclusions

- It was identified that the welding process generates a slight decrease in mechanical properties. Yield strength decreases from 475 to 470 MPa and ultimate tensile strength from 620 to 617 MPa, while the SUT/SY ratio is not altered. Despite the decrease in mechanical response, the welded specimens are within the restrictions established by ASTM A706/A706M.

- Bending tests revealed the influence of diameter on bending strength, as well as a marked difference in the performance of welded versus unwelded rods. The 57 unwelded specimens satisfactorily fulfilled the 180° bend without cracks. Meanwhile, in the welded specimens, only 3 out of 57 samples were able to reach the bending requirement; this shows that the welding process compromises the ductility of reinforcing steel bars.

- Statistical analysis of the tensile response on welded and unwelded reinforcing bars shows that both welded and unwelded bars meet the requirements of ASTM A706/A706M. Welding introduces a slight decrease in mechanical properties and increases dispersion in samples with diameters less than 14 mm, especially in the E manufacturer.

- For the larger-diameter bars (16 and 18 mm), a more homogeneous distribution in the mechanical response of the welded specimens is observed. This suggests that the effect of welding is more critical in smaller-diameter bars, since the reduction in the cross-sectional area can generate residual stresses affecting its strength, which may compromise its structural integrity.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Saleem, M.A.; Saleem, M.M.; Aziz, M.; Ahmed, T.; Aslam, F.; Mohamed, A. Statistical insight into the quality of reinforcing steel bars used in construction projects. Case Stud. Constr. Mater. 2024, 21, e03698. [Google Scholar] [CrossRef]

- Hojat Jalali, H.; Soltanabadi, R.; Abuhishmeh, K.; Soltanianfard, M.A.; Balderrama, J.A.; Correa, C.O.; Cornejo, J.S. High temperature effects on monotonic and low-cycle fatigue performance of different high strength rebars. Eng. Struct. 2025, 327, 119585. [Google Scholar] [CrossRef]

- Teran, J.; Arroyo-Olvera, M.; Mauricio, M.; Rendón, M.; López, M. Efecto de la soldadura en las propiedades mecánicas de dos tipos de acero de refuerzo. In Proceedings of the XXVIII Congreso Internacional Anual De La Somim, Bogotá, Colombia, 21–23 September 2022. [Google Scholar]

- Quiel, S.E.; Irwin, C.H.; Naito, C.J.; Vermaak, N. Mechanical Characterization of Normal and High-Strength Steel Bars in Reinforced Concrete Members under Fire. J. Struct. Eng. 2020, 146, 04020110. [Google Scholar] [CrossRef]

- Chen, W.; Zhen, H.; Liu, F.; Wu, B.; Li, H.; Wu, Z.; Huang, J.; Zhu, H.; Li, L.; Xiong, Z. Experimental and Theoretical Study on Tensile Mechanical Properties of GFRP–Steel Composite Bars. Buildings 2024, 14, 2513. [Google Scholar] [CrossRef]

- Abbas, S.; Hameed, R.; Nehdi, M.; Afzal, M.; Shaukat, S. Investigation of reinforcing steel rebar manufactured from local scrap at various finishing rolling temperature. Case Stud. Constr. Mater. 2023, 19, e02499. [Google Scholar] [CrossRef]

- Nair, S.A.O.; Mohandoss, P.; Ram, K.; Adnan, T.; Pillai, R.G. Mechanical characteristics of Quenched and Self-Tempered (QST or TMT) steel reinforcing bars used in concrete structures. Constr. Build. Mater. 2023, 363, 129761. [Google Scholar] [CrossRef]

- Dabiri, H.; Kheyroddin, A.; Dall’Asta, A. Splice methods used for reinforcement steel bars: A state-of-the-art review. Constr. Build. Mater. 2022, 320, 126198. [Google Scholar] [CrossRef]

- Carrillo, J.; Lozano, H.; Arteta, C. Mechanical properties of steel reinforcing bars for concrete structures in central Colombia. J. Build. Eng. 2021, 33, 101858. [Google Scholar] [CrossRef]

- Danso, H.; Sumaila, M. Experimental Investigation into Strength Properties of Ribbed Mild Steel Reinforcing Bars (RMSRBs) Produced by Local Companies in Ghana. Int. J. Eng. Mater. Manuf. 2024, 9, 41–51. [Google Scholar] [CrossRef]

- Liu, Y.; Miao, Z.; Yuan, H.; Geng, X.; Hogan, L.; Zhu, M. Experimental study of tensile behaviour of rebars with simulated pitting corrosion. Constr. Build. Mater. 2024, 445, 137952. [Google Scholar] [CrossRef]

- Abuhishmeh, K.; Hojat Jalali, H.; Ebrahimi, M.; Soltanianfard, M.A.; Correa, C.O.; Cornejo, J.S. Behavior of high strength reinforcing steel rebars after high temperature exposure: Tensile properties and bond behavior using pull-out and end beam tests. Eng. Struct. 2024, 305, 117730. [Google Scholar] [CrossRef]

- Aloisio, A.; Lavorato, D.; Xue, J.; Wu, J.; Rasulo, A.; Briseghella, B.; Nuti, C. The role of overstrength in welded joints for rebar substitution in damaged RC columns. Constr. Build. Mater. 2023, 409, 133952. [Google Scholar] [CrossRef]

- Schubnell, J.; Ladendorf, P.; Sarmast, A.; Farajian, M.; Knödel, P. Fatigue performance of high-and low-strength repaired welded steel joints. Metals 2021, 11, 293. [Google Scholar] [CrossRef]

- Carrillo, J.; Diaz, C.; Arteta, C.A. Tensile mechanical properties of the electro-welded wire meshes available in Bogotá Colombia. Constr. Build. Mater. 2019, 195, 352–362. [Google Scholar] [CrossRef]

- Cadoni, E.; Dotta, M.; Forni, D.; Tesio, N. High strain rate behaviour in tension of steel B500A reinforcing bar. Mater. Struct. Constr. 2015, 48, 1803–1813. [Google Scholar] [CrossRef]

- Abatta-Jácome, L.; Naranjo-Guatemala, C.; Naranjo-Torres, D.; Haro, E.E. Experimental Study of Low Cycle Fatigue in Welded Reinforcing Steel Bars ASTM A706 BT. In Communications in Computer and Information Science; Botto-Tobar, M., Zambrano Vizuete, M., Montes León, S., Torres-Carrión, P., Durakovic, B., Eds.; Springer Nature: Cham, Switzerland, 2023; pp. 3–15. [Google Scholar]

- Overby, D.; Kowalsky, M.; Seracino, R. Stress-strain response of A706 grade 80 reinforcing steel. Constr. Build. Mater. 2017, 145, 292–302. [Google Scholar] [CrossRef]

- Fernandez, I.; Bairán, J.M.; Marí, A.R. Corrosion effects on the mechanical properties of reinforcing steel bars. Fatigue and σ-ε behavior. Constr. Build. Mater. 2015, 101, 772–783. [Google Scholar] [CrossRef]

- Hassan, O.B.; Akin, O.O.; Lawan, A.; Amartey, Y.D. Mechanical and Chemical Properties of Reinforcement Bars Manufactured in Nigeria. Covenant J. Eng. Technol. 2021, 5, 56–68. [Google Scholar]

- Tristan, Y.; Taylor, S.; William, C.; Marc, M. Investigating the Mechanical Properties and Fracture Behavior of Welded-Wire Reinforcement. J. Mater. Civ. Eng. 2021, 33, 4021023. [Google Scholar] [CrossRef]

- Zhuang, Z.; Qian, X.; Zeng, L.; Lu, W.; Li, Z.; Xiang, Y. Response characterization on the microstructure, and mechanical and corrosion behavior of clad rebars of different weld materials. Case Stud. Constr. Mater. 2025, 22, e04316. [Google Scholar] [CrossRef]

- Bossio, A.; Lignola, G.P.; Prota, A. Theoretical effects of corrosion on lateral stress along reinforcement bars in concrete-NC-ND license. Procedia Struct. Integr. 2024, 64, 56–64. [Google Scholar] [CrossRef]

- AWS D1.4/D1.4M:2011; Structural Welding Code—Reinforcing Steel. American Welding Society: Miami, FL, USA, 2011.

- Sreeja, M.D. Behaviour of Steel Fibre Reinforced Concrete Beam under Cyclic Loading. IOSR J. Mech. Civ. Eng. 2013, 6, 1–4. [Google Scholar] [CrossRef]

- Leramo, R.O.; Adekoya, L.O.; Kilanko, O.; Oyedepo, S.O.; Eluwa, S.E.; Babalola, P.O.; Adeosun, S.O.; Leramo, N.T.; Aiyedun, P.O.; Ohunakin, O.S.; et al. A comparative analysis of the chemical composition and compliance level to established standards of concrete reinforcement steel rods rolled in Nigeria. Heliyon 2022, 8, e09597. [Google Scholar] [CrossRef]

- Loporcaro, G.; Cuevas, A.; Pampanin, S.; Kral, M.V. Strain-ageing effects on the residual low-cycle fatigue life of low-carbon steel reinforcement. Mater. Struct. Constr. 2022, 55, 35. [Google Scholar] [CrossRef]

- Shokrzadeh, M.; Nateghi-Alahi, F. Experimental study of seismic behavior and modification of the failure region of mechanical bar splices. Sharif Civ. Eng. J. 2025, 41, 84–97. [Google Scholar]

- Aiamsri, K.; Yaowarat, T.; Horpibulsuk, S.; Suddeepong, A.; Buritatum, A.; Hiranwatthana, K.; Nitichote, K. Bonding behavior of lap-spliced reinforcing bars embedded in ultra-high-performance concrete with steel fibers. Dev. Built Environ. 2024, 20, 100585. [Google Scholar] [CrossRef]

- Wu, D.; Ding, Y.; Su, J.; Li, Z.X.; Zong, L. Investigation on low-cycle fatigue performance of high-strength steel bars including the effect of inelastic buckling. Eng. Struct. 2022, 272, 114974. [Google Scholar] [CrossRef]

- Abatta-Jacome, L.; Caminos, L.; Gonzalez-Herrera, A.; Garcia-Manrique, J.M. Crack Growth Patterns of Aluminum Tubular Specimens Subjected to Cyclic Tensile Loads. Metals 2024, 14, 1094. [Google Scholar] [CrossRef]

- Richard, B.; Quiertant, M.; Bouteiller, V.; Delaplace, A.; Adelaide, L.; Ragueneau, F.; Cremona, C.; Richard, B.; Quiertant, M.; Bouteiller, V.; et al. Experimental and numerical analysis of corrosion-induced cover cracking in reinforced concrete sample. Comput. Concr. 2017, 18, 421–439. [Google Scholar] [CrossRef]

- Chen, J.; Agostini, F.; Shen, W.; Shao, J.; Bourbon, X.; Liu, S. Experimental and numerical studies of a reinforced concrete component subjected to corrosion. Mech. Res. Commun. 2023, 129, 104076. [Google Scholar] [CrossRef]

- Fröse, J.; Fischer, O. Influence of Rib Geometry on the Bond Strength of Reinforcing Steel in Coils. Lect. Notes Civ. Eng. 2023, 349 LNCE, 536–545. [Google Scholar] [CrossRef]

- Abubakar, M.; Abdulmajeed, I.S.A. Characterization, Mechanical Properties and Probabilistic Failure Analysis of Reinforcement Bars Produced from Scraps in Southern and Northern Region of Nigeria. J. Fail. Anal. Prev. 2023, 23, 1232–1241. [Google Scholar] [CrossRef]

- ISO 6892-1; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. International Organization for Standardization: Switzerland, Geneva, 2019.

- ISO 7438; Metallic materials—Bend Test. International Organization for Standardization: Switzerland, Geneva, 2020.

- ACI 318; Building Code Requirements for Structural Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2020.

- Fente, T.E.; Tsegaw, A.A.; Abebe, A.T.; Admasu, B.T. Investigating the quality of ethiopian steel reinforcing bars through comprehensive analysis. Heliyon 2024, 10, e31661. [Google Scholar] [CrossRef] [PubMed]

- INEN 2167-2020; Hot-Rolled Deformed and Plain Steel Bars, Weldable, Micro Alloyed or Quenched and Self-Tempered, For Reinforced concrete. Requirements; Servicio Ecuatoriano de Normalización: Quito, Ecuador, 2020.

- Mohd Razali, N.; Bee Wah, Y. Power comparisons of Shapiro-Wilk, Kolmogorov-Smirnov, Lilliefors and Anderson-Darling tests. J. Stat. Model. Anal. 2011, 2, 13–14. [Google Scholar]

- Assiamah, S.; Kankam, C.K.; Banini, E.K.; Agyeman, S.; Adinkrah-Appiah, K. Standardization Issues in Africa: Bayesian analysis of physicogeometrical and mechanical characteristics of rebars in Ghana’s construction industry. J. Build. Eng. 2023, 73, 106835. [Google Scholar] [CrossRef]

- ASTM A706/A706M; Standard Specification for Low-Alloy Steel Deformed and Plain Bars for Concrete Reinforcement. ASTM International: West Conshohocken, PA, USA, 2011.

- Barrionuevo, G.O.; Ramos-Grez, J.A.; Sánchez-Sánchez, X.; Zapata-Hidalgo, D.; Mullo, J.L.; Puma-Araujo, S.D. Influence of the Processing Parameters on the Microstructure and Mechanical Properties of 316L Stainless Steel Fabricated by Laser Powder Bed Fusion. J. Manuf. Mater. Process. 2024, 8, 35. [Google Scholar] [CrossRef]

- Vidal, J.G.; Barrionuevo, G.O.; Ramos-grez, J.A.; Vergara, J.; Mullo, J.L. Vibration-assisted laser welding: Frequency and amplitude vibration effect on the microhardness of A36 steel. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2022, 236, 2139–2149. [Google Scholar] [CrossRef]

- Ahmed, G. Mechanical Properties of Welded Deformed Reinforcing Steel Bars. ARO Sci. J. Koya Univ. 2015, 3, 28–39. [Google Scholar] [CrossRef]

- Barrionuevo, G.O.; Toapanta, M.; Mullo, J.L.; Camacho-Játiva, L. Recovery of Hydro Turbines: From Welding to Additive Manufacturing. In Solid State Phenomena; Trans Tech Publications Ltd.: Bäch, Switzerland, 2022; Volume 338, pp. 55–62. [Google Scholar] [CrossRef]

- Kumar, V.; Sharma, U.K.; Singh, B.; Bhargava, P. Effect of temperature on mechanical properties of pre-damaged steel reinforcing bars. Constr. Build. Mater. 2013, 46, 19–27. [Google Scholar] [CrossRef]

- Caprili, S.; Salvatore, W. Mechanical performance of steel reinforcing bars in uncorroded and corroded conditions. Data Br. 2018, 18, 1677–1695. [Google Scholar] [CrossRef]

- Weine, E.; McPeek, M.S.; Abney, M. Application of Equal Local Levels to Improve Q-Q Plot Testing Bands with R Package qqconf. J. Stat. Softw. 2023, 106, 1–31. [Google Scholar] [CrossRef]

- Yan, S.; Zheng, Y.L.; Yan, Z.W.; Zhang, Z.C. Influence of bending angles on initial damage and mechanical properties of bent rebars. Constr. Build. Mater. 2025, 499, 144124. [Google Scholar] [CrossRef]

- Yelek, İ.; Ardalı, R.; Yılmaz, İ. Fracture investigation of different welded steel beam-column connections under three-point bending test. J. Constr. Steel Res. 2021, 187, 106945. [Google Scholar] [CrossRef]

- Cho, S.; Lim, M.; Lee, C. Study on the bending and joint performances of reinforced concrete beams using high-strength rebars. Sustainability 2021, 13, 3482. [Google Scholar] [CrossRef]

- Amirtharaj, J.; Leema Rose, A. A state-of-the-art review on the Structural Behavior of concrete structures reinforced with various rebars as alternative to steel rebars. J. Build. Eng. 2025, 111, 113387. [Google Scholar] [CrossRef]

| Diameter (mm) | Calibrated Length (mm) |

|---|---|

| 12 | 60 |

| 14 | 70 |

| 16 | 80 |

| 18 | 90 |

| Diameter (mm) | Distance Between Supports (mm) |

|---|---|

| 12 | 66 |

| 14 | 77 |

| 16 | 88 |

| 18 | 117 |

| Diameter (mm) | Type | Company | SY (MPa) | SUT (MPa) | SUT/SY | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean | IQR | CV(%) | Mean | IQR | CV(%) | Mean | IQR | CV(%) | |||

| 12 | Unwelded | A | 476.940 | 0.669 | 0.140 | 603.512 | 0.780 | 0.136 | 1.265 | 0.000 | 0.040 |

| B | 498.853 | 3.937 | 0.893 | 656.060 | 1.885 | 0.292 | 1.315 | 0.008 | 0.629 | ||

| C | 461.440 | 3.899 | 0.846 | 575.356 | 2.406 | 0.449 | 1.247 | 0.007 | 0.591 | ||

| D | 478.853 | 1.682 | 0.375 | 649.461 | 1.154 | 0.184 | 1.356 | 0.005 | 0.402 | ||

| E | 460.566 | 6.021 | 1.323 | 564.399 | 7.157 | 1.268 | 1.225 | 0.002 | 0.180 | ||

| Mean value | 475.330 | 3.242 | 0.715 | 609.758 | 2.676 | 0.466 | 1.282 | 0.004 | 0.368 | ||

| Welded | A | 463.851 | 0.662 | 0.153 | 597.799 | 1.471 | 0.273 | 1.289 | 0.004 | 0.349 | |

| B | 485.261 | 10.741 | 2.231 | 645.840 | 5.603 | 0.951 | 1.331 | 0.019 | 1.647 | ||

| C | 458.497 | 4.158 | 0.977 | 575.640 | 3.696 | 0.646 | 1.256 | 0.015 | 1.188 | ||

| D | 471.768 | 0.655 | 0.145 | 647.098 | 3.528 | 0.575 | 1.372 | 0.008 | 0.579 | ||

| E | 463.721 | 0.666 | 0.148 | 567.956 | 2.185 | 0.385 | 1.225 | 0.003 | 0.299 | ||

| Mean value | 468.620 | 3.376 | 0.731 | 606.867 | 3.297 | 0.566 | 1.294 | 0.010 | 0.812 | ||

| 14 | Unwelded | A | 471.099 | 0.524 | 0.127 | 602.058 | 1.868 | 0.310 | 1.278 | 0.003 | 0.216 |

| B | 495.417 | 2.395 | 0.518 | 654.008 | 0.922 | 0.144 | 1.320 | 0.005 | 0.406 | ||

| C | 463.904 | 5.936 | 1.406 | 595.233 | 3.277 | 0.557 | 1.283 | 0.014 | 1.075 | ||

| D | 470.232 | 3.689 | 0.793 | 643.854 | 1.393 | 0.234 | 1.369 | 0.008 | 0.568 | ||

| E | 492.577 | 20.315 | 4.171 | 622.123 | 17.993 | 3.020 | 1.263 | 0.016 | 1.251 | ||

| Mean value | 478.646 | 6.572 | 1.403 | 623.455 | 5.090 | 0.853 | 1.303 | 0.009 | 0.703 | ||

| Welded | A | 464.503 | 1.483 | 0.332 | 597.612 | 3.628 | 0.625 | 1.287 | 0.007 | 0.529 | |

| B | 488.487 | 3.981 | 0.815 | 646.265 | 1.201 | 0.199 | 1.323 | 0.013 | 1.003 | ||

| C | 464.145 | 3.172 | 0.683 | 598.101 | 2.252 | 0.405 | 1.289 | 0.010 | 0.839 | ||

| D | 465.894 | 1.964 | 0.456 | 635.834 | 5.786 | 1.050 | 1.365 | 0.008 | 0.603 | ||

| E | 489.284 | 11.942 | 2.700 | 618.123 | 8.804 | 1.440 | 1.264 | 0.021 | 1.684 | ||

| Mean value | 474.462 | 4.508 | 0.997 | 619.187 | 4.334 | 0.744 | 1.305 | 0.012 | 0.932 | ||

| 16 | Unwelded | A | 470.395 | 2.542 | 0.543 | 607.052 | 3.257 | 0.578 | 1.291 | 0.002 | 0.164 |

| B | 470.589 | 2.624 | 0.588 | 596.535 | 1.089 | 0.187 | 1.268 | 0.008 | 0.716 | ||

| C | 470.857 | 2.568 | 0.554 | 601.399 | 4.819 | 0.803 | 1.277 | 0.003 | 0.295 | ||

| D | 474.560 | 3.027 | 0.721 | 640.521 | 0.715 | 0.112 | 1.350 | 0.008 | 0.634 | ||

| E | 464.276 | 7.594 | 1.829 | 649.103 | 3.482 | 0.573 | 1.398 | 0.015 | 1.247 | ||

| Mean value | 470.135 | 3.671 | 0.847 | 618.922 | 2.672 | 0.451 | 1.317 | 0.007 | 0.611 | ||

| Welded | A | 466.081 | 1.072 | 0.241 | 602.613 | 2.060 | 0.342 | 1.293 | 0.005 | 0.451 | |

| B | 462.026 | 3.080 | 0.690 | 594.265 | 5.886 | 0.993 | 1.286 | 0.009 | 0.753 | ||

| C | 474.643 | 5.098 | 1.120 | 601.083 | 4.280 | 0.765 | 1.266 | 0.015 | 1.269 | ||

| D | 464.681 | 4.500 | 0.971 | 634.048 | 3.500 | 0.572 | 1.365 | 0.006 | 0.424 | ||

| E | 459.698 | 6.852 | 1.491 | 645.677 | 9.471 | 1.611 | 1.405 | 0.009 | 0.695 | ||

| Mean value | 465.426 | 4.120 | 0.903 | 615.537 | 5.039 | 0.857 | 1.323 | 0.009 | 0.718 | ||

| 18 | Unwelded | A | 485.190 | 1.901 | 0.398 | 629.435 | 1.314 | 0.224 | 1.297 | 0.002 | 0.183 |

| B | 486.028 | 2.395 | 0.530 | 659.338 | 1.911 | 0.291 | 1.357 | 0.003 | 0.268 | ||

| C | 476.375 | 1.122 | 0.245 | 610.898 | 0.535 | 0.088 | 1.282 | 0.002 | 0.162 | ||

| D | 456.919 | 1.808 | 0.398 | 628.300 | 1.244 | 0.212 | 1.375 | 0.004 | 0.289 | ||

| Mean value | 476.128 | 1.806 | 0.393 | 631.993 | 1.251 | 0.203 | 1.328 | 0.003 | 0.226 | ||

| Welded | A | 477.773 | 2.012 | 0.431 | 626.871 | 1.608 | 0.258 | 1.312 | 0.004 | 0.353 | |

| B | 485.635 | 1.328 | 0.278 | 659.586 | 4.791 | 0.767 | 1.358 | 0.006 | 0.494 | ||

| C | 474.640 | 3.084 | 0.652 | 612.681 | 2.686 | 0.455 | 1.291 | 0.003 | 0.276 | ||

| D | 453.147 | 2.152 | 0.537 | 626.501 | 3.061 | 0.489 | 1.383 | 0.003 | 0.259 | ||

| Mean value | 472.799 | 2.144 | 0.475 | 631.410 | 3.037 | 0.492 | 1.336 | 0.004 | 0.345 | ||

| Diameter (mm) | Type | SY (MPa) | SUT (Mpa) | SUT/SY | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mean | IQR | CV(%) | Mean | IQR | CV(%) | Mean | IQR | CV(%) | ||

| 12 | Unwelded | 475.33 | 16.18 | 3.13 | 609.76 | 75.7 | 6.37 | 1.28 | 0.08 | 3.86 |

| Welded | 468.62 | 9.16 | 2.27 | 606.87 | 71.32 | 5.79 | 1.29 | 0.09 | 4.27 | |

| 14 | Unwelded | 478.65 | 24.31 | 3.27 | 623.46 | 43.77 | 3.97 | 1.3 | 0.05 | 3.1 |

| Welded | 474.46 | 19.56 | 2.82 | 619.19 | 40.01 | 3.36 | 1.31 | 0.05 | 2.92 | |

| 16 | Unwelded | 470.14 | 4.62 | 1.1 | 618.92 | 41.3 | 3.63 | 1.32 | 0.08 | 3.96 |

| Welded | 465.43 | 7.64 | 1.41 | 615.54 | 35.87 | 3.53 | 1.32 | 0.08 | 4.17 | |

| 18 | Unwelded | 476.13 | 14.9 | 2.59 | 631.99 | 14.23 | 2.88 | 1.33 | 0.07 | 3.07 |

| Welded | 472.8 | 13.86 | 2.69 | 631.41 | 14.11 | 2.89 | 1.34 | 0.06 | 2.85 | |

| Type | Property | N | Shapiro–Wilk Test | Anderson–Darling Test | Lilliefors Test | |||

|---|---|---|---|---|---|---|---|---|

| p-Value | Normal Shapiro–Wilk | p-Value | Normal AD | p-Value | Normal Lilliefors | |||

| Unwelded | SY | 57 | 0.0167 | No | 0.0156 | No | 0.0197 | No |

| SUT | 57 | 0.0049 | No | 0.0022 | No | 0.0311 | No | |

| SUT/SY | 57 | 0.0136 | No | 0.0024 | No | 0.0129 | No | |

| Welded | SY | 57 | 0.0151 | No | 0.0058 | No | 0.0010 | No |

| SUT | 57 | 0.0602 | Yes | 0.0415 | No | 0.0719 | Yes | |

| SUT/SY | 57 | 0.0315 | No | 0.0058 | No | 0.0018 | No | |

| Property | Mean Unwelded | Mean Welded | p-Value | Significant |

|---|---|---|---|---|

| SY | 475.0036778 | 470.1965191 | 0.0308 | Yes |

| SUT | 620.454977 | 617.5576235 | 0.3859 | No |

| SUT/SY | 1.306215944 | 1.313530136 | 0.2716 | No |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abatta-Jacome, L.; Rosero-Pazmiño, D.; Rosero-Vivas, J.; Chávez-Guerrero, B.F.; Barrionuevo, G.O. Statistical Evaluation of the Mechanical Properties of Welded and Unwelded ASTM A706 Reinforcing Steel Bars of Different Commercial Brands. Metals 2025, 15, 1307. https://doi.org/10.3390/met15121307

Abatta-Jacome L, Rosero-Pazmiño D, Rosero-Vivas J, Chávez-Guerrero BF, Barrionuevo GO. Statistical Evaluation of the Mechanical Properties of Welded and Unwelded ASTM A706 Reinforcing Steel Bars of Different Commercial Brands. Metals. 2025; 15(12):1307. https://doi.org/10.3390/met15121307

Chicago/Turabian StyleAbatta-Jacome, Lenin, Daniel Rosero-Pazmiño, Jeison Rosero-Vivas, Bryan Fernando Chávez-Guerrero, and Germán Omar Barrionuevo. 2025. "Statistical Evaluation of the Mechanical Properties of Welded and Unwelded ASTM A706 Reinforcing Steel Bars of Different Commercial Brands" Metals 15, no. 12: 1307. https://doi.org/10.3390/met15121307

APA StyleAbatta-Jacome, L., Rosero-Pazmiño, D., Rosero-Vivas, J., Chávez-Guerrero, B. F., & Barrionuevo, G. O. (2025). Statistical Evaluation of the Mechanical Properties of Welded and Unwelded ASTM A706 Reinforcing Steel Bars of Different Commercial Brands. Metals, 15(12), 1307. https://doi.org/10.3390/met15121307