Abstract

Hydrogen-assisted fatigue cracking presents a critical challenge to the structural integrity of legacy carbon steel natural gas pipelines being repurposed for hydrogen transport, posing a major barrier to the deployment of hydrogen infrastructure. This study systematically evaluates the fatigue crack growth (FCG) behavior of API 5L X60 pipeline steel under varying hydrogen–natural gas (H2–NG) blending conditions to assess its suitability for long-term hydrogen service. Experiments are conducted using a custom-designed autoclave to replicate field-relevant environmental conditions. Gas mixtures range from 0% to 100% hydrogen by volume, with tests performed at a constant pressure of 6.9 MPa and a temperature of 25 °C. A fixed loading frequency of 8.8 Hz and load ratio (R) of 0.60 ± 0.1 are applied to simulate operational fatigue loading. The test matrix is designed to capture FCG behavior across a broad range of stress intensity factor values (ΔK), spanning from near-threshold to moderate levels consistent with real-world pipeline pressure fluctuations. The results demonstrate a clear correlation between increasing hydrogen concentration and elevated FCG rates. Notably, at 100% hydrogen, API X60 specimens exhibit crack propagation rates up to two orders of magnitude higher than those in 0% hydrogen (natural gas) conditions, particularly within the Paris regime. In the lower threshold region (ΔK ≈ 10 MPa·√m), the FCG rate (da/dN) increased nonlinearly with hydrogen concentration, indicating early crack activation and reduced crack initiation resistance. In the upper Paris regime (ΔK ≈ 20 MPa·√m), da/dNs remained significantly elevated but exhibited signs of saturation, suggesting a potential limiting effect of hydrogen concentration on crack propagation kinetics. Fatigue life declined substantially with hydrogen addition, decreasing by ~33% at 50% H2 and more than 55% in pure hydrogen. To complement the experimental investigation and enable predictive capability, a modular machine learning (ML) framework was developed and validated. The framework integrates sequential models for predicting hydrogen-induced reduction of area (RA), fracture toughness (FT), and FCG rate (da/dN), using CatBoost regression algorithms. This approach allows upstream degradation effects to be propagated through nested model layers, enhancing predictive accuracy. The ML models accurately captured nonlinear trends in fatigue behavior across varying hydrogen concentrations and environmental conditions, offering a transferable tool for integrity assessment of hydrogen-compatible pipeline steels. These findings confirm that even low-to-moderate hydrogen blends significantly reduce fatigue resistance, underscoring the importance of data-driven approaches in guiding material selection and infrastructure retrofitting for future hydrogen energy systems.

1. Introduction

The global transition toward low-carbon energy systems has positioned hydrogen as a critical energy carrier, prompting strategic interest in repurposing existing natural gas infrastructure for hydrogen transport. This repurposing offers clear economic and logistical advantages, especially for long-distance pipelines made of carbon steel. However, it also introduces a fundamental materials challenge: ensuring the structural integrity of pipeline steels exposed to hydrogen, either in pure form or as a hydrogen–natural gas (H2–NG) blend. The most insidious threat in this context is hydrogen embrittlement (HE), a phenomenon in which atomic hydrogen ingress degrades mechanical properties, including ductility, toughness, and fatigue resistance [1,2].

For pipelines operating under fluctuating pressures, typical of daily demand cycles, the most critical manifestation of HE is hydrogen-assisted FCG (HA-FCG). This process, which involves the acceleration of crack propagation due to hydrogen exposure, can dramatically shorten pipeline life, especially in materials with microstructural heterogeneities or service-induced defects [3]. Ferritic steels are particularly susceptible due to their body-centered cubic (BCC) crystal structure, which combines low hydrogen solubility with high diffusivity, enabling rapid hydrogen transport to high-stress regions such as crack tips [4].

HA-FCG is governed by a combination of chemical and mechanical processes. Molecular hydrogen (H2) at the steel surface dissociates into atomic hydrogen via chemisorption, which then diffuses into the steel matrix and accumulates at microstructural traps, including dislocations, grain boundaries, inclusions, and precipitate interfaces [5,6]. This trapping enhances local hydrogen concentration, promoting crack initiation and propagation. Two leading mechanisms explain these effects: Hydrogen-Enhanced Localized Plasticity (HELP), which reduces the resistance to dislocation motion [7,8], and Hydrogen-Enhanced De-cohesion (HEDE), which weakens atomic bonding at crack tips [9,10]. These processes operate synergistically to degrade fatigue performance, particularly under cyclic loading in gaseous environments [11].

Extensive research has been conducted on HE in pipeline steels under pure hydrogen or inert gas atmospheres. For example, San Marchi et al. [12] reported significantly accelerated crack growth and reduced FT in low-strength steels, such as API X60, when tested in high-purity hydrogen at pressures up to 21 MPa. Their findings emphasized the importance of realistic testing conditions for evaluating hydrogen degradation, noting that standard air-based fatigue protocols may significantly underestimate environmental damage. Xu [13] similarly highlighted the role of microstructure, hydrogen pressure, and alloying elements in determining susceptibility to HE, with particular attention to the influence of inclusion content and phase morphology in ferritic microstructures. More recent experimental studies have emphasized the operational relevance of hydrogen–natural gas blends. Faucon et al. [14] investigated FCG in X60 base and weld metals under blended hydrogen conditions (70–150 bar), finding that hydrogen accelerated fatigue crack propagation by a factor of four in base metal and up to eight in weldments. Notably, crack initiation was linked to micro-defects such as macro-pores, suggesting that surface quality and residual stress play important roles in HA-FCG. Achoui et al. [15] confirmed that microstructural heterogeneity, especially in the heat-affected zones (HAZ), results in significant variation in Paris law slope, with values increasing from ~4.3 in the base metal to ~5.8 in the HAZ, highlighting local accelerators of crack growth. Hopkin et al. [16] expanded these findings by testing vintage offshore X60 pipeline materials in hydrogen gas up to 172 bar using autoclave setups. Their results demonstrated a shift from classical Paris law behavior to time-dependent crack propagation at ΔK < 5 MPa√m, even under modest pressures. These observations challenge the conventional notion of a well-defined fatigue threshold in hydrogen environments and highlight the need for environment-specific fracture models.

To address these complexities, numerical modeling has become increasingly important. Nazar and Proverbio [17] employed phase-field finite element simulations to predict HA-FCG in X60, incorporating hydrogen diffusion, trap kinetics, and crack tip stress fields. Their work confirmed that hydrogen accelerates crack growth nonlinearly with pressure and that slow-frequency loading exacerbates embrittlement effects due to increased hydrogen uptake per cycle. These results align with prior studies that emphasize the coupling of hydrogen diffusion kinetics with mechanical loading to explain the acceleration of cracking.

Despite this progress, significant knowledge gaps remain. Most existing studies focus on either pure hydrogen or inert atmospheres, while few systematically investigate the effects of H2–NG blends, particularly at intermediate hydrogen concentrations relevant to near-future infrastructure repurposing. Moreover, the interplay between hydrogen concentration, loading frequency, and microstructural response across different fatigue regimes (e.g., near-threshold vs. Paris) remains poorly resolved. Importantly, existing standards, such as ASME B31.12 [18], do not yet provide clear fatigue-based guidance for mixed-gas conditions, resulting in uncertainties in fitness-for-service assessments.

Furthermore, experimental investigations remain resource-intensive. High-pressure hydrogen testing requires specialized autoclaves or sealed chambers, strict safety protocols, and prolonged test durations [19]. Reproducing real-world operating conditions, such as decades of cyclic exposure to moderate hydrogen blend concentrations, is especially challenging. This limitation creates a bottleneck in generating sufficient data for pipeline integrity assessments under evolving hydrogen energy strategies.

Despite recent advances in test setups—for example, hollow-cylinder specimens that can be pressurized internally with hydrogen—experimental approaches remain limited in their ability to explore the full matrix of service-relevant variables, such as blend composition, frequency, stress ratio, and heat treatment combinations [19]. Moreover, long-term pipeline behavior cannot be feasibly reproduced in laboratory settings. One study had to simulate over 100 years of service life using extreme hydrogen conditions, due to the impracticality of prolonged real-time testing [20]. In addition, the scarcity of field data from pipelines exposed to hydrogen blending further limits empirical calibration [21]. These constraints underscore the need for robust predictive tools that can extrapolate fatigue behavior across untested conditions using limited yet high-quality data.

To overcome these constraints, researchers have increasingly turned to machine learning approaches as a complementary predictive tool for material degradation. Ensemble models, such as CatBoost and XGBoost, have demonstrated strong performance in capturing complex, nonlinear dependencies between environmental conditions, material properties, and mechanical responses [22,23]. These models can be trained on limited, high-quality experimental datasets and subsequently used to predict FCG behavior under a broader range of operating conditions. Recent ML studies have predicted hydrogen-induced loss of RA [24], reduced fatigue life under hydrogen charging [25], and increased embrittlement susceptibility across various steel grades [26]. However, no existing ML model has been developed or validated specifically for predicting HA-FCG in API 5L X60 under H2–NG blend environments, a critical gap given the widespread use of X60 in legacy infrastructure.

To address this gap, the present study integrates controlled FCG experiments with ensemble ML modeling. The goal is to evaluate and predict the HA-FCG behavior in API 5L X60 pipeline steel. Experiments were conducted in gaseous environments with varied hydrogen–natural gas blend ratios at a fixed pressure of 6.9 MPa and a loading frequency of 8.8 Hz. Through systematic variation in hydrogen content and high-resolution tracking of crack length, we investigate the evolution of FCG rates across both the near-threshold and Paris regimes. In parallel, an ML model based on CatBoost was developed using experimental and literature data, enabling robust prediction of crack growth trends as a function of hydrogen concentration and stress intensity range. By coupling empirical and data-driven approaches, this study not only provides critical insight into hydrogen-induced fatigue in X60 but also delivers a validated predictive tool for assessing pipeline reliability under hydrogen blending conditions. These results support the development of safety standards and inform future efforts to repurpose natural gas pipelines for the transportation of hydrogen.

2. Methodology

2.1. Materials and Specimens

This study utilizes carbon steel pipeline segments, widely used in natural gas transmission, with a focus on API 5L Grade X60 steel. The material for the specimens originated from a field-extracted vintage pipe that had been in active service for more than 50 years. The pipe had an outer diameter of 42 inches and a wall thickness of 0.400 inches. A short nipple section was cut from the pipe and axially sectioned into a 12-inch-long segment for specimen preparation.

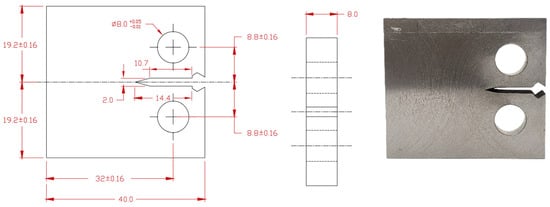

Using segmented samples, compact tension (CT) specimens were fabricated in accordance with ASTM E647–24 [27] to perform FCG experiments. The specimens were precisely machined from the longitudinal direction of the pipeline segments to align the crack propagation path with the pipe axis, as depicted in Figure 1. This orientation ensures that when a tensile load is applied in the transverse direction, crack advancement occurs parallel to the pipe’s longitudinal axis, thereby replicating service-relevant stress conditions experienced in pipeline operation.

Figure 1.

Schematic of the API 5L X60 pipeline segment showing the orientation of CT specimens extracted longitudinally for fatigue testing.

Figure 2 represents the schematic of the specimen with proper dimensions and the test-ready sample. All CT specimens were machined in accordance with the dimensional and geometric specifications outlined in ASTM E647–24 [27], which standardizes specimen configuration for valid FCG testing. The specimen width (W) was defined as the distance from the centerline of the loading holes (i.e., the load line) to the rear edge of the specimen and was precisely maintained at 32.0 mm. The overall thickness (B) was kept at 8.0 mm, satisfying the standard’s recommended range of W/20 ≤ B ≤ W/4, thereby promoting plane strain conditions around the crack tip. The specimen height was 38.4 mm, matching the standard 1.2 W requirement.

Figure 2.

Design and test-ready image of the CT specimen prepared per ASTM E647–24 [27], showing key dimensions and notch geometry for FCG testing.

Two 8.0 mm diameter loading holes (tolerance: +0.05 mm/–0.01 mm) were located at a vertical distance of 19.2 ± 0.16 mm above and below the crack line, yielding a total pin separation of 0.55 W, and ensuring symmetric load application. The center of each hole was positioned 32 ± 0.16 mm horizontally from the notch face, corresponding to 0.8 W, in alignment with standard specifications. The front notch was initiated 8.0 mm from the edge and shaped as a sharp 30° V-groove with a root width of 2.0 mm and side clearance of 3.2 mm. To ensure controlled crack initiation, the notch was further sharpened using electrical discharge machining (EDM), introducing a 60° tip and 120° flank geometry. The total notch extension reached 6.4 mm (from the load line), enabling stable fatigue crack propagation under cyclic loading.

Additional geometric considerations included dimensional offsets such as 4.8 mm wide transition zones and minor thickness variations near the crack tip ranging between 2.0 and 2.5 mm, which were introduced to promote uniform crack front development and minimize edge effects. The specimen’s side surfaces were machined to achieve a uniform surface roughness, enabling precise optical crack length measurements. The final specimen configuration was validated through dimensional inspection to confirm adherence to standard tolerances. This meticulous control of geometry and surface finish ensured that all CT specimens provided consistent and valid data on FCG behavior under hydrogen–natural gas exposure conditions, with minimal scatter due to machining variability.

To ensure precision and consistency in FCG measurements, all specimens underwent a standardized metallographic polishing procedure. This process produced a uniform surface finish, effectively minimizing surface irregularities that could otherwise influence crack initiation or growth behavior during testing. Following polishing, specimens were carefully degreased by immersing them in acetone to eliminate residual oils, machining fluids, and other contaminants that might compromise surface integrity. These meticulous preparation steps are critical for preserving specimen quality and ensuring the reliability of hydrogen-assisted FCG experiments. By rigorously controlling surface condition, dimensional precision, and material traceability, the testing protocol was designed to yield reproducible and accurate mechanical performance data for vintage pipeline steels subjected to hydrogen exposure. The chemical composition and tensile properties of the API 5L Grade X60 material used in this investigation were experimentally determined and are summarized in Table 1 and Table 2, respectively. The tensile tests were repeated three times, averaged, and performed in situ within the natural gas environment at 25 °C and 6.9 MPa, with a strain rate of 1.12 × 10−4 s−1. Strain measurement was achieved using a custom-built strain gauge system designed in-house in accordance with ASTM E399-22 [28] specifications, providing accuracy comparable to that of a conventional extensometer.

Table 1.

Chemical composition of API 5L Grade X60 steel (wt.%).

Table 2.

Tensile properties of API 5L X60 steel tested in NG.

2.2. Experimental Setup

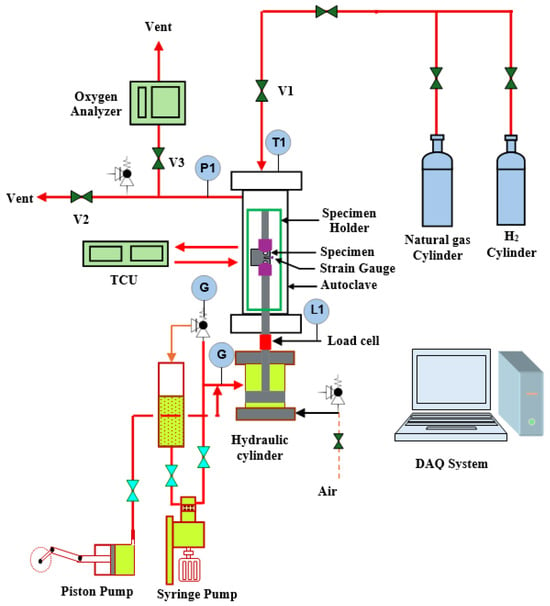

To simulate the environmental and loading conditions representative of hydrogen gas transmission pipelines, a custom-engineered autoclave system was developed to conduct in situ fatigue testing of pipeline-grade steels in high-purity hydrogen atmospheres (Figure 3). The autoclave had an internal volume of approximately 3.1 L and was constructed from corrosion-resistant materials to ensure compatibility with high-pressure hydrogen gas and long-duration testing. Its design supported flexibility in specimen geometries and mechanical mounting arrangements, allowing for varied loading configurations based on experimental requirements. Thermal control within the autoclave was a critical component of the testing environment. The vessel was equipped with an external jacket that enabled the circulation of glycol-based heat transfer fluid. This system was coupled with a high-capacity chiller and a 6-kilowatt electric heater, allowing for precise bidirectional temperature control, both heating and cooling, throughout the test duration. The outer aluminum housing of the autoclave was fabricated to enhance structural integrity and was thermally insulated using high-efficiency foam to minimize heat loss and maintain uniform temperature conditions inside the chamber. This configuration enabled the simulation of a broad spectrum of operational temperatures observed in hydrogen service environments.

Figure 3.

Schematic custom-built experimental test setup.

The gas delivery system was designed to accommodate multiple gases, including hydrogen and natural gas, each supplied from high-pressure storage cylinders. The hydrogen used in the experiments was industrial grade with a certified minimum purity of 99.95%. In contrast, the natural gas used for control testing contained approximately 85% methane, as specified by the supplier. Pressure regulation and gas flow were fully automated through a computerized control system, which governed valve actuation and maintained consistent gas supply and chamber pressure, thereby minimizing the risk of human error and ensuring repeatability across tests. Before initiating hydrogen charging, the autoclave underwent a thorough purging procedure to remove any remaining oxygen. During this process, an inline oxygen analyzer positioned at the outlet continuously measured the oxygen concentration in the exhaust stream.

The mechanical loading system was custom-designed to enable in situ fatigue testing of compact tension (CT) specimens within the high-pressure autoclave. The specimen inside the autoclave was connected to a hydraulic actuator positioned beneath the vessel through a pull rod that passed via a high-pressure sealing gland, ensuring load transfer without compromising chamber integrity. The actuator system employed a dual-pump configuration to reproduce stable cyclic loading conditions:

- Syringe Pump (Primary Unit): Maintained the mean (average) load on the specimen by regulating the baseline internal pressure within the actuator. This provided steady, long-term pressure control to establish Kmean.

- Piston Pump (Secondary Unit): Applied the cyclic component of the load. Operated in a single-acting mode with common suction and discharge, it precisely controlled the amplitude and frequency of cyclic loading, thereby defining ΔK.

The coordinated operation of these two pumps maintained the maximum and minimum stress intensity factors (Kmax and Kmin) with high stability. This configuration enabled reproducible cyclic loading representative of pipeline service conditions while ensuring compatibility with the pressurized autoclave environment.

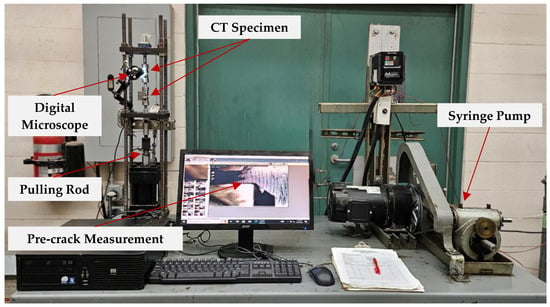

2.3. Fatigue Pre-Cracking

To facilitate controlled fatigue crack initiation, a dedicated pre-cracking setup was developed (Figure 4), which allows for the adjustment of load ratio and loading frequency. Fatigue pre-cracking was performed simultaneously on two CT specimens to reduce overall preparation time and ensure consistency between samples. Fatigue pre-cracking was carried out in air under ambient conditions using a sinusoidal cyclic load at R = 0.5 and f = 7.8 Hz. The final stress intensity factor range was ΔK = 9.2 MPa√m, corresponding to Kmax = 18.4 MPa√m. In accordance with ASTM E647-24 [27], the final Kmax used for pre-cracking did not exceed the initial Kmax applied in the subsequent fatigue crack-growth tests. Crack initiation and growth were monitored in real-time using a live Dino-lite optical microscope (ANMO ELECTRONICS CORPORATION, Taiwan, China), ensuring precise control over the crack length. Each specimen was pre-cracked to a target depth of 2.0 ± 0.1 mm, measured from the notch tip, to establish consistent initial crack fronts for subsequent testing. Specimens were pre-cracked, and an initial crack length (a0) of approximately 8 mm was measured from the load line (a0/W ≈ 0.25). The pre-cracked specimens were then subjected to fatigue testing under high-purity hydrogen environment conditions.

Figure 4.

Fatigue pre-cracking setup used for initiating cracks in CT specimens under ambient conditions.

2.4. Fatigue Crack Growth Test

Fatigue crack growth (FCG) experiments were conducted in accordance with ASTM E647-24 [27] using a sinusoidal waveform under constant load amplitude and a fixed loading frequency of 8.8 Hz. Load ratios (R = Kmin/Kmax) of 0.60 ± 0.12 were applied to simulate operational fatigue conditions typical of pipeline service. A constant Kmax with an incrementally increasing ΔK profile was employed to evaluate material behavior over a broad range of stress intensity factor amplitudes. All tests were performed at room temperature under varying gas environments, including high-purity hydrogen and hydrogen–natural gas mixtures. Each test was conducted at a single pressure condition (6.9 MPa) and at distinct R-ratios of 0.60 ± 0.10 (initial R ≈ 0.70 gives ΔK ≈ 5 MPa√m, and Kmax ≈ 18.4 MPa√m), with one CT specimen tested per condition. Although real-world pipeline systems typically operate under pressure fluctuation frequencies below 1 Hz, a test frequency of 8.8 Hz was selected to minimize experimental duration and eliminate the need for overnight operation, which was restricted due to safety protocols at the facility. This choice is supported by prior studies [22,29], indicating that hydrogen-assisted FCG rates (HA-FCGRs) do not exhibit significant sensitivity to test frequency within the range of 0.1 to 10 Hz. Therefore, the selected frequency is considered appropriate and efficient for this investigation. The fatigue testing procedure consisted of specimen preparation, autoclave conditioning, cyclic loading, and post-test analysis.

Specimen Preparation and Autoclave Conditioning

Before testing, pre-cracked specimens were degreased with acetone to remove surface contaminants. The specimen holder inside the autoclave was then elevated using a pneumatically actuated hydraulic cylinder (McMaster-Carr Item 1524N144, Elgin, IL, USA). Afterward, the specimen was positioned and fitted with a clip gauge. The holder components, including the top disk and thumbscrews, were assembled, and the cylinder was retracted to secure the specimen in place. The autoclave lid was sealed with screws, followed by the connection of gas inlet and outlet lines and the insertion of a thermocouple for temperature monitoring. Before hydrogen charging, the autoclave underwent a rigorous purging protocol to eliminate residual oxygen, which could adversely affect crack propagation and compromise the reliability of the fatigue test. The procedure began with evacuation using a high-capacity vacuum pump for approximately five minutes to remove ambient air, followed by four sequential gas exchange cycles through a bottom-directed inlet and top outlet to ensure efficient displacement of residual air. Oxygen concentration was continuously monitored with an inline analyzer until near-zero levels were achieved, establishing a contaminant-free environment.

Subsequently, the autoclave was pressurized stepwise, with gases introduced according to the principle of partial pressure to achieve the desired composition. For instance, in a 25% H2–75% NG mixture, hydrogen was first introduced to 25% of the target total pressure, followed by natural gas until the total pressure reached 6.9 MPa; the procedure was reversed for mixtures with higher hydrogen fractions. This approach ensured accurate control of molar fractions across all test environments. After the gas mixture was established, the specimen was subjected to hydrogen charging for approximately two hours. During this phase, temperature was controlled by a data acquisition system, while pressure was manually adjusted to maintain stable test conditions.

Fatigue testing commenced shortly after hydrogen pressurization, resulting in about two hours of pre-exposure before load cycling. Each specimen required approximately 4–12 h of active cycling to reach failure. However, when accounting for specimen preparation (mounting, autoclave assembly, purging, and pressurization), pre-exposure steps, and the restriction to daytime-only operation, the total duration for each experiment extended over 2–3 calendar days. Regarding hydrogen exposure, the overnight pauses in cyclic loading did not compromise the validity of the experimental results. Previous studies have demonstrated that in low-carbon steels, hydrogen diffusion and trapping rapidly reach saturation under high-pressure hydrogen environments, even in the absence of continuous mechanical loading [30]. More recent investigations have similarly confirmed that the ductility loss and embrittlement behavior of pipeline steels remain largely unaffected by variations in exposure time once near-saturation hydrogen levels are achieved [31]. Considering the small specimen thickness (B = 8 mm), the high diffusivity of hydrogen in ferritic steels, and the implemented pre-exposure protocol, equilibrium hydrogen concentrations were attained well before the initiation of cyclic loading. Consequently, the restriction to daytime-only operation did not influence the time-dependent hydrogen–material interactions pertinent to fatigue crack growth behavior.

Fatigue Loading and Crack Monitoring

During testing, the syringe pump was used to maintain the average static load on the specimen, while the programmable hydraulic piston pump controlled the minimum and maximum cyclic loads. Fatigue loading was applied for fixed intervals of 30 min at each Kmax, with corresponding ΔK and K values calculated based on specimen geometry, applied force, and compliance, as prescribed by ASTM E647-24 [27]. Crack propagation was monitored using a clip gauge mounted on each CT specimen in compliance with ASTM E399-22 [28]. The gauge incorporated hydrogen-compatible strain sensors and was connected to a high-pressure wire-sealed feedthrough on the autoclave lid, enabling real-time signal transmission under hazardous conditions. Analog signals were amplified and recorded using a data acquisition system. Following each fatigue interval, load–displacement data were analyzed to extract compliance gradients, which were used to estimate incremental crack length.

Post-Test Analysis

Upon completion of the fatigue loading protocol, specimens were fractured under monotonic loading to evaluate the final crack length. The fracture surfaces revealed distinct regions corresponding to fatigue crack growth in both air and hydrogen environments, as well as the final crack extension resulting from monotonic overload. The fractured CT specimens were retrieved from the autoclave, and the fractured surfaces were examined by scanning electron microscopy (SEM). The as-fractured surfaces were inspected without additional polishing or etching to preserve the original morphology produced during testing. Imaging was performed using a Thermo Fisher Scientific Quattro S (Thermo Fisher Scientific Brno s.r.o, Brno, Czech Republic) field-emission environmental SEM (FE-ESEM) operated in high-vacuum mode at an accelerating voltage of 30 kV. Representative regions near the fatigue crack propagation zone were captured at different magnifications. These fractographic observations enabled direct correlation between hydrogen concentration, fatigue crack growth behavior, and fracture surface morphology.

Pre-crack and final fatigue crack lengths were measured using an optical microscope, averaging seven measurements along the crack front. A linear correction was then applied to the calculated crack lengths to ensure alignment with physically measured positions. The crack growth rate (da/dN) was determined by fitting a four-parameter logistic model to the corrected crack length versus cycle data. Stress intensity factors were computed using standard expressions from ASTM E647-24 [27], based on the measured crack length-to-width ratio (a/W) and load amplitude (ΔP).

2.5. Test Matrix

To systematically evaluate the influence of hydrogen on FCG behavior, a structured test matrix was developed encompassing various gas compositions, as shown in Table 3. This matrix includes tests performed in pure hydrogen as well as in multiple hydrogen–natural gas mixtures, allowing for a comprehensive assessment of fracture behavior across a range of hydrogen exposure levels. All tests were conducted at a constant gas pressure of 6.9 MPa, with six mixture compositions consisting of 0%, 10%, 25%, 50%, 75%, and 100% hydrogen by volume. A control test was conducted in 100% natural gas at room temperature (77 °F), with zero hydrogen and oxygen content, serving as the baseline. This environment reflects typical operating conditions in conventional natural gas pipelines and serves as a reference point for isolating the effects of hydrogen. Establishing such a reference allows for consistent comparisons across all test cases, ensuring that any observed increases in da/dN can be directly attributed to the presence and concentration of hydrogen. By benchmarking performance under hydrogen-containing environments against this control, the contribution of HE to accelerated crack propagation can be quantitatively assessed. This methodology provides a reliable framework for identifying degradation mechanisms as the gas composition transitions from natural gas to hydrogen-enriched mixtures. To ensure reproducibility, the 100% natural gas and 10% hydrogen test conditions were each performed twice. The replicate results demonstrated consistent crack growth behavior, and the most representative dataset was reported in the present work.

Table 3.

Test matrix for FCG evaluation.

2.6. Microstructural Analysis: Specimen Preparation

Microstructural characterization was conducted on carefully sectioned CT specimens to ensure preservation of the original microstructure. Specimen extraction was performed with precision to avoid introducing thermal or mechanical distortion that could alter the microstructural features. The following sequential preparation protocol was employed to produce high-quality surfaces suitable for optical microscopy.

Grinding: Initial surface preparation involved mechanical grinding using silicon carbide (SiC) abrasive papers of progressively finer grit sizes. The grinding sequence began with coarse 360-grit paper, followed by 600, 800, 1000, and finally 1200-grit paper. Each grinding step was performed on an automated grinding machine operating at 120 revolutions per minute (rpm) for 10 min per stage. To ensure uniform material removal and minimize surface artifacts, the specimen was ground in a single direction for the first half of each step, and rotated 90 degrees for the remainder of the grinding duration.

Polishing: Following grinding, specimens underwent a three-stage polishing process, each stage lasting 10 min. The initial polishing step utilized a 3 µm polycrystalline diamond suspension in a glycol-based medium at a reduced speed of 100 rpm to enhance flatness and surface uniformity. Subsequent ultra-fine polishing steps utilized 1 µm and then 0.05 µm diamond suspensions under the same operating conditions. This progressive polishing protocol was designed to eliminate scratches and produce a mirror-like surface suitable for high-resolution imaging.

Etching and Sonication: Following polishing, chemical etching was carried out to reveal the microstructure of the API 5L X60 steel. A mixed-acid etchant was prepared by mixing 2 mL of Nitric Acid (HNO3) with 98 mL of Methanol (CH3OH). This etchant selectively attacked different microstructural constituents, including ferrite–pearlite interfaces, grain boundaries, and inclusions, providing strong phase contrast. The etchant was applied to the polished surface for a few seconds, after which the reaction was immediately quenched by rinsing the specimen with methanol.

To remove residual etchant and any particulate matter from the surface, the specimens were subsequently immersed in an ultrasonic bath containing methanol and subjected to sonication for 5–10 min. This non-invasive cleaning ensured a contaminant-free surface ideal for high-resolution imaging.

Post-Preparation Cleaning: Throughout the preparation process—after grinding, polishing, and etching—specimens were cleaned with acetone and dried using compressed air to eliminate any residual abrasives, chemical agents, or moisture. The entire procedure produced scratch-free, optically reflective surfaces with clearly visible microstructural features. Final imaging and evaluation were performed using a Keyence VHX-7000 ultra-microscope (Keyence Corporation, Osaka, Japan), enabling high-resolution visualization of grain structure, phase distribution, and micro-defects.

3. Experimental Results

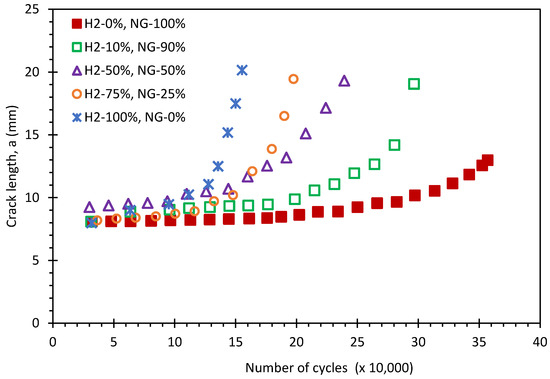

3.1. Crack Length Measurements

Figure 5 presents the relationship between crack length, measured using a strain gauge, and the number of loading cycles for X60 pipeline steel subjected to various hydrogen–natural gas (H2–NG) blending environments. Initially, crack growth was negligible, as evidenced by the minimal increase in crack length at low cycle counts. With increasing loading cycles, crack length progressively increased, reflecting the elevated stress intensity factor that promotes crack propagation. At higher cycle counts, a pronounced acceleration in crack growth was observed, particularly under hydrogen-containing environments, underscoring the significant role of hydrogen in enhancing fatigue crack growth rates.

Figure 5.

Measured fatigue crack length vs. loading cycles for X60 steel in various blended gas (H2–NG) environments at 6.9 MPa and ambient temperature.

3.2. Results of Microstructure Analysis

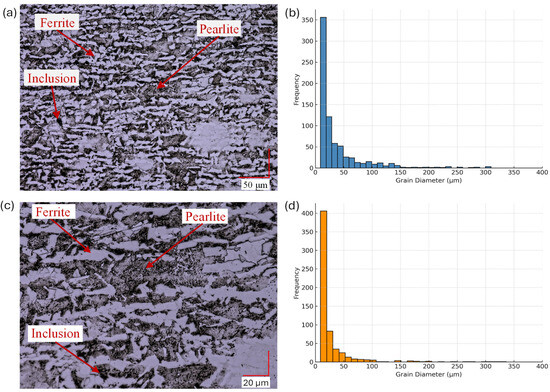

Optical micrographs obtained at 700× and 1500× magnifications, shown in Figure 6, respectively, reveal a distinct dual-phase microstructure in API 5L X60 pipeline steel, which is characteristic of low-carbon micro-alloyed steels [30]. This microstructure is predominantly composed of polygonal ferrite and lamellar pearlite, consistent with the typical microstructure of as-rolled or normalized X60 steel. Some inclusions were also observed, indicating the probable presence of manganese sulfides [31,32]. Ferrite, appearing as light-colored, equiaxed grains, is uniformly dispersed throughout the matrix. This phase, a body-centered cubic (BCC) iron, typically forms during the slow cooling of austenite through carbon diffusion and rejection. Interspersed within the ferritic matrix, pearlite is observed as darker, textured, and often elongated lamellar colonies. Pearlite is a composite microstructure consisting of alternating plates of ferrite and cementite (Fe3C), formed via the eutectoid decomposition of austenite upon cooling [33]. The presence of both phases is expected in hypo-eutectoid steels, such as X60.

Figure 6.

Microstructural characterization of API 5L X60 steel. (a,c) show optical micrographs obtained at 700× and 1500× magnifications, respectively. (b,d) present the corresponding grain size distribution histograms derived from quantitative image analysis.

Quantitative image analysis, as shown in Figure 6b,d, indicates an average grain diameter of approximately 4 µm at 700× magnification and 3.8 µm at 1500× magnification, indicative of a fine-grained microstructure. The grain size distribution at 700× is broader. At the same time, at 1500×, it is more concentrated within the 5–20 µm range, which is consistent with refined grain boundaries being more clearly resolved at higher magnification. These trends strongly support the inference of effective grain refinement achieved through thermomechanical controlled processing (TMCP).

Grain boundary overlays further illustrate the equiaxed morphology and size uniformity, indicative of metallurgical stability. Phase segmentation, performed via intensity-based thresholding, determined that ferrite occupies approximately 55–60% of the microstructural area, with pearlite comprising the remaining 40–45%. These proportions closely align with values reported in the literature for X60 steels, reflecting a favorable microstructural balance that underpins the mechanical performance expected of pipeline-grade materials. The observed uniform grain size distribution and consistent phase morphology across both magnifications suggest a homogeneous thermal history and processing regime. This contributes directly to the material’s optimal combination of high strength, good ductility, and enhanced FT, as fine grain size is known to simultaneously improve both strength and toughness by impeding dislocation movement [33,34].

4. Machine Learning Framework

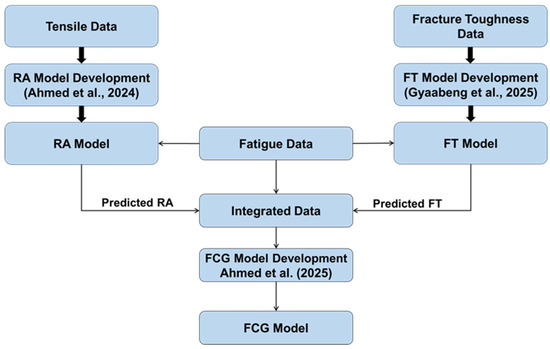

This study employs an ML framework to predict FCG rates in pipeline steels exposed to hydrogen–natural gas (H2–NG) environments. The framework integrates three sequential predictive models: (1) Reduction of Area (RA) prediction, (2) Fracture Toughness (FT) prediction, and (3) FCG rate (da/dN) prediction. Each model was developed or extended from prior work and adapted to generalize across various pipeline steels. The overall framework and model integration process are illustrated schematically in Figure 7.

Figure 7.

Workflow diagram of the integrated ML framework for FCG model development [23,24,35].

4.1. RA Prediction Model

The RA model, originally developed by Ahmed, Aldaw, Ahmed and Teodoriu [24], utilizes a CatBoost regressor to predict hydrogen-induced ductility loss, specifically the RA. The initial model was trained using tensile test data from 47 carbon and low-alloy steels under pressurized hydrogen gas. It is formulated using elemental composition, mechanical properties, and environmental parameters as input features. After developing the model, the predicted RA values are subsequently used as input features in the formulation of the fatigue model.

4.2. FT Prediction Model

To account for hydrogen-induced degradation, this study incorporates a model based on the work of Gyaabeng, Ahmed, Ahmed, Teodoriu and Devegowda [23], which originally used the k-nearest neighbors (KNN) algorithm to forecast FT of pipeline steels in hydrogen environments. In the present framework, this model was re-implemented and extended using the CatBoost algorithm and retrained with a broader dataset that includes various pipeline grades, alloying compositions, and exposure conditions. Inputs to the FT model include compositional elements, mechanical properties, hydrogen pressure, temperature, and oxygen content. The predicted FT value is integrated as an input feature in the fatigue model development.

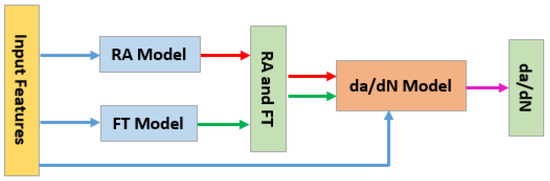

4.3. Fatigue Crack Growth Model

The fatigue crack growth (FCG) model, initially introduced by Ahmed et al. [35], was enhanced in the present study through the integration of both Predicted RA and FT as input features, as shown in Figure 8. These predicted RA and FT values represent hydrogen-degraded properties of the material. Combined with other input parameters such as the stress intensity factor range (ΔK), hydrogen partial pressure, frequency, load ratio, and elemental composition (including Ni, Cr, and Mo), the integrated model predicts the FCG rate (da/dN).

Figure 8.

Structure of integrated da/dN model.

This integrated modeling strategy enables the utilization of RA and FT models to capture the influence of material composition and properties, as well as environmental parameters, which are then propagated through the RA and FT predictions into the final fatigue model. By modularizing the prediction of hydrogen effects, the framework improves both interpretability and generalization compared to a conventional approach that does not incorporate these predicted parameters. The resulting integrated model is transferable and suitable for use across a variety of pipeline steels, not limited to X60.

During the development of all three models (RA, FT, and FCG), several ML algorithms were systematically evaluated. These included CatBoost, XGBoost, artificial neural networks (ANN), support vector machines (SVM), gradient boosting regressors, random forest (RF), k-nearest neighbors (KNN), and decision trees. Model selection was guided by cross-validated performance metrics, including the coefficient of determination (R2), root mean squared error (RMSE), mean squared error (MSE), mean absolute error (MAE), and feature importance rankings. CatBoost consistently exhibited the highest predictive accuracy and robustness across tasks and was therefore selected as the final algorithm for all three models.

The entire framework was implemented in Python using the CatBoostRegressor class. RA and FT values were first predicted from shared material and environmental input features and then incorporated into the fatigue model to generate da/dN predictions across a range of ΔK values and hydrogen partial pressures. This integrated approach supports material-specific fatigue life assessment under hydrogen exposure, allowing the development of a data-driven tool for evaluating steel performance in future hydrogen energy infrastructure.

5. Interpretation and Discussion

5.1. Effect of Hydrogen Concentration on FCG Behavior

Figure 5 illustrates the evolution of fatigue crack length as a function of the number of loading cycles for X60 pipeline steel subjected to various hydrogen–natural gas (H2–NG) blending environments. The specimens were tested under a constant gas pressure of 6.9 MPa and room temperature, with a cyclic loading frequency of 8.8 Hz. The results exhibit a clear trend: increasing hydrogen content in the gas mixture leads to accelerated crack propagation and reduced fatigue life.

In the baseline condition of 100% natural gas (H2-0%, NG-100%), the crack length increases gradually and remains relatively stable throughout most of the test duration. Significant acceleration is only observed after approximately 275,000 cycles, with the final crack length remaining within a moderate range (356,980 cycles). This behavior reflects the intrinsic fatigue resistance of X60 steel under inert gas conditions, where crack growth is primarily driven by cyclic plastic deformation, with minimal environmental degradation mechanisms.

The addition of 10% hydrogen (H2-10%, NG-90%) leads to a subtle but measurable change in crack propagation kinetics. While initial behavior closely follows that of the baseline, divergence emerges beyond ~200,000 cycles, with final failure occurring around 300,000 cycles. This suggests that even low hydrogen concentrations are sufficient to activate localized embrittlement mechanisms, such as hydrogen-enhanced localized plasticity (HELP) or early-stage decohesion. The curvature in this region’s crack growth trajectory reflects a gradual transition from mechanically dominated to environmentally assisted fatigue behavior.

At 50% hydrogen content, crack propagation accelerates markedly. The slope of the crack growth curve steepens significantly, with rapid growth initiating at just ~160,000 cycles and final failure occurring near 240,000 cycles. This early departure from stable growth indicates a substantial reduction in the effective fatigue threshold (ΔKth), likely due to increased hydrogen uptake and diffusion to the crack tip, which intensifies local slip activity and facilitates crack advance. Notably, the absence of a plateau or threshold region in the a–N curve under this condition suggests that hydrogen significantly suppresses crack closure effects and enhances FCG sensitivity [36].

At an intermediate blend of 75% hydrogen and 25% natural gas (H2-75%, NG-25%), the FCG behavior further confirms the concentration-dependent acceleration trend observed in hydrogen-rich conditions. In this scenario, significant crack propagation begins around 145,000 cycles, with final failure occurring before 200,000 cycles. The mid-life region of the crack growth curve exhibits a pronounced increase in slope, indicating an earlier transition to the Paris regime and a shortened stable growth phase. This response suggests intensified hydrogen activity at the crack tip due to greater hydrogen partial pressure and solubility, resulting in localized embrittlement and diminished resistance to fatigue cracking. Compared to the 50% H2 condition, the 75% mixture exhibits both earlier crack onset and a steeper propagation rate, indicating a nonlinear increase in damage severity with increasing hydrogen content.

The most aggressive behavior is observed under pure hydrogen (H2-100%, NG-0%), where crack acceleration begins before 90,000 cycles and catastrophic propagation is completed before 150,000 cycles. The lack of a prolonged stable crack growth regime highlights the dominant role of hydrogen-related damage processes in this condition, driven by the high diffusivity and solubility of hydrogen, which promotes interatomic de-cohesion and embrittlement at the crack tip. Moreover, the final crack length in this case exceeds that in all other environments, indicating more continuous and unimpeded crack advance. Overall, these findings demonstrate a clear inverse relationship between hydrogen concentration and fatigue life. The inflection points in the crack length–cycle curves progressively shift to earlier cycles with increasing hydrogen content, signaling a concentration-dependent reduction in ΔK and an earlier transition to the Paris regime. Quantitatively, the fatigue life is reduced by approximately 33% in the 50% H2 condition, around 45% in the 75% H2 blend, and more than 55% in pure hydrogen relative to the natural gas baseline. These results are consistent with established hydrogen-assisted cracking mechanisms (HEDE and HELP) and align with prior studies reporting elevated FCG rates in similar pressure and composition ranges [12,16]. These observations highlight the progressive reduction in fatigue life with increasing hydrogen concentration, as indicated by the shift in crack growth acceleration to earlier cycles. The a–N curves are thus used to illustrate differences in fatigue life and the onset of accelerated crack propagation. In contrast, quantitative crack growth rates (da/dN) are evaluated separately using fracture mechanics approaches.

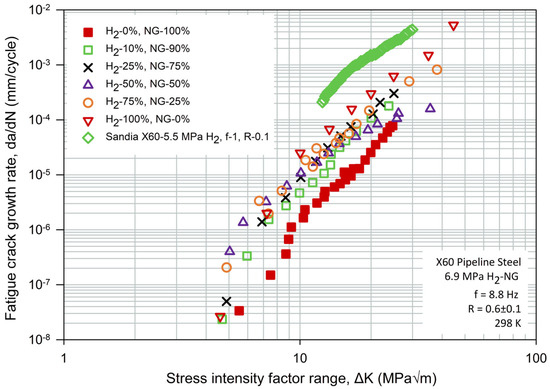

5.2. FCG Rate in Hydrogen–Natural Gas Blended Conditions

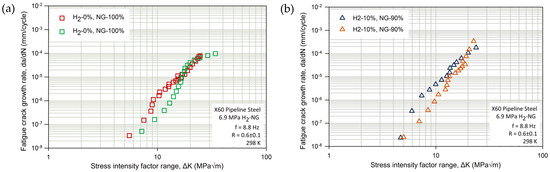

Figure 9 presents the da/dN as a function of the stress intensity factor range (ΔK) for API 5L X60 steel tested under various hydrogen–natural gas (H2–NG) environments at a constant pressure of 6.9 MPa and a frequency of 8.8 Hz. The results demonstrate a systematic increase in da/dN with rising hydrogen concentration, accompanied by distinct modifications in threshold behavior, Paris regime slope, and upper-growth characteristics, which collectively underscore the embrittling influence of hydrogen.

Figure 9.

FCG behavior of API 5L X60 steel under varying hydrogen–natural gas blending conditions.

In the baseline condition of 100% natural gas (H2-0%), the da/dN remains low across the tested ΔK range, with a well-defined threshold region around ΔK ≈ 10 MPa·√m and a gradual, stable transition into the Paris regime [37]. The da/dN curve for this condition exhibits the lowest slope, indicating that crack advance is governed by plasticity with minimal environmental influence. Introducing hydrogen at 10% causes a modest upward and leftward shift in the curve, initiating crack growth at slightly lower ΔK and increasing da/dN in the mid-Paris region. The 25% H2 blend exhibits a more pronounced departure from baseline behavior, with an earlier onset of propagation and a steeper curve, indicating increased hydrogen sensitivity and reduced resistance to fatigue cracking.

As the hydrogen content increases further to 50%, the crack growth accelerates significantly, and the threshold region becomes less distinct. The data show an earlier transition into the Paris regime and higher da/dN values across the spectrum. The 75% H2 blend continues this trend, with crack growth behavior closely approaching that of pure hydrogen, particularly in the upper Paris regime. This suggests a nonlinear acceleration in damage kinetics beyond 50% hydrogen, with potential saturation effects observed as the difference between 75% and 100% becomes narrower than between adjacent lower blends. The 100% H2 condition exhibits the most severe degradation, with crack propagation initiating at the lowest ΔK values (~8 MPa·√m) and continuing with the highest rates across the entire range. Additionally, there is an indication of saturation in da/dN at higher ΔK (>20 MPa·√m), possibly marking a transition toward cleavage-driven fracture or unstable crack front advance.

The Paris law slope (m) increases progressively with hydrogen content, rising from approximately 4.08 in pure natural gas to around 4.89–5.0 in 100% hydrogen, indicating a heightened sensitivity of FCG to loading amplitude [38,39]. The extracted Paris parameters are summarized in Table 4. The intermediate blends (10%, 25%, 50%) illustrate a transitional regime where ductile fatigue mechanisms coexist with hydrogen-assisted damage processes such as HELP and HEDE. These regimes are particularly relevant for hydrogen infrastructure, where blended gas mixtures are likely [40]. The monotonic degradation trend across the full concentration range implies that hydrogen thresholds for safe pipeline operation may occur well below saturation, especially given the steep increase in damage rate beyond 50% H2.

Table 4.

Paris law constants (C, m) for X60 steel in different H2/NG environments.

The microstructural features of API 5L X60 steel likely contribute to this behavior. The dual-phase structure, comprising polygonal ferrite and lamellar pearlite, offers distinct crack propagation pathways. Ferrite, being softer and more ductile, enables plastic deformation, while pearlite offers strength but may localize stress and facilitate de-cohesion. The fine-grain size (~5–20 μm), as observed in optical micrographs, enhances baseline fatigue resistance but also increases grain boundary density, creating diffusion and trapping sites for hydrogen. Furthermore, the presence of manganese sulfide (MnS) inclusions may exacerbate crack initiation under hydrogen exposure by serving as stress concentrators or de-cohesion initiators [41,42]. These combined features reduce the resistance to crack propagation and amplify the steel’s sensitivity to hydrogen-assisted fatigue.

Compared to literature data, particularly the work by San Marchi, Somerday, Nibur, Stalheim, Boggess, and Jansto [12], which was conducted under similar pressure but at a 1 Hz loading frequency, the present results show slightly lower da/dNs. This disparity is consistent with the known frequency dependence of HE; lower frequencies enable greater hydrogen ingress and localization at the crack tip. The 8.8 Hz frequency used in this study reduces dwell time at maximum load, thereby limiting the accumulation of hydrogen. As previously noted by Holbrook, Collings, Cialone and Drauglis [22], this frequency effect may make the present results conservative relative to field conditions, where loading cycles are typically much slower. The agreement in trend and Paris slope with Sadia et al. further validates the reproducibility of hydrogen-assisted fatigue acceleration in API X60 steels. These findings highlight the significance of blend ratio, loading frequency, and microstructural effects in determining long-term durability. The results offer a robust basis for fatigue life modeling, risk-informed integrity assessments, and the development of hydrogen-specific design criteria for pipeline systems.

5.3. Reproducibility of FCG Tests

Figure 10 shows the results of repeated FCG tests conducted under 100% natural gas (NG) and 10% hydrogen–90% NG mixture conditions. For both cases, the repeated experiments show a reasonable level of agreement between measurements. As seen in Figure 10a, the two tests conducted in 100% natural gas exhibit comparable crack growth rates at higher ΔK values, with some deviations in the mid-range of stress intensity, which diminishes as the ΔK reduces, as indicated by the converging trend of the two measurements. A similar trend is observed for the 10% H2 condition as illustrated in Figure 10b, where the two datasets converge at higher and lower ΔK values, with small offsets appearing in the intermediate regime. These slight differences can be attributed to experimental variability. One possible source is small variations in the load ratio, which may arise from changes in the viscosity of the hydraulic fluid during long-duration fatigue testing. Another important factor is the heterogeneous microstructure of vintage pipeline steels, which often contain inclusions, banding, and service-induced features due to prolonged field exposure. Such heterogeneity has been shown in the literature to cause measurable scatter in FCG behavior, even when tests were repeated under nominally identical conditions on the same alloy system [43,44]. Overall, the replicate results demonstrate consistent trends in FCG rates and fatigue life across both 100% NG and 10% H2–NG conditions, confirming that the observed crack growth behavior is reproducible within the expected variability for vintage pipeline steels. The close overlap of the replicate datasets supports the robustness of the reported findings.

Figure 10.

Replicate fatigue crack growth (FCG) tests for X60 pipeline steel in (a) 100% natural gas and (b) 10% H2–90% NG environments.

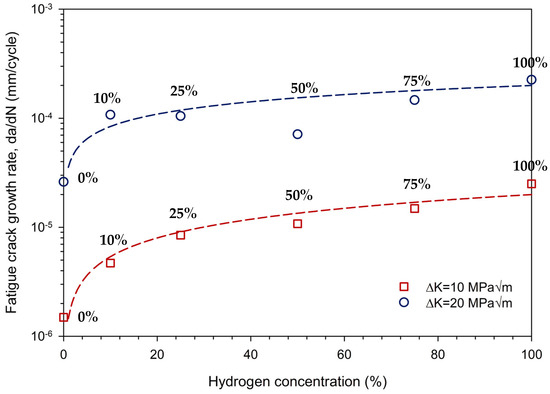

5.4. Effect of Hydrogen Concentration at Fixed Stress Intensity Levels

Figure 11 complements the ΔK-dependent analysis by presenting the variation in FCG rate (da/dN) as a function of hydrogen concentration at two fixed stress intensity factor ranges: ΔK = 10 MPa·√m (near-threshold) and ΔK = 20 MPa·√m (upper Paris regime). This composition-based perspective isolates the environmental influence on fatigue crack propagation, independent of changes in mechanical loading. It offers valuable insight into hydrogen-assisted cracking behavior across relevant service conditions.

Figure 11.

FCG rate (da/dN) as a function of hydrogen concentration at fixed stress intensity factor ranges (ΔK = 10 and 20 MPa·√m) for API 5L X60 steel.

In the lower threshold region (ΔK ≈ 10 MPa·√m), the FCG rate increases steeply and nonlinearly with hydrogen content. In pure natural gas (0% H2), da/dN remains low at approximately 1.49 × 10−6 mm/cycle, reflecting high resistance to fatigue crack propagation. However, the introduction of just 10% hydrogen leads to a more than threefold increase in da/dN, rising to approximately 4.69 × 10−6 mm/cycle. This marks a critical inflection point in the embrittlement response, where environmental effects begin to dominate crack growth behavior. With further increases in hydrogen content, da/dN continues to rise, reaching approximately 8.47 × 10−6 mm/cycle at 25% H2, 1.08 × 10−6 at 50%, 1.49 × 10−5 at 75%, and 2.50 × 10−5 at 100% H2. This represents a cumulative increase of nearly 17-fold, or approximately 1.22 orders of magnitude, from 0% to 100% hydrogen. Although the initial rise is sharp, particularly between 0% and 10% H2, subsequent increases occur more gradually, suggesting a saturation-like trend in the severity of embrittlement. This progression implies a continuous degradation of crack-tip shielding and increased environmental sensitivity, even at moderate hydrogen blends. These results demonstrate that even low-level hydrogen concentrations (as low as 10%) can substantially reduce near-threshold fatigue resistance, potentially accelerating premature transition into the Paris regime. Consequently, hydrogen content must be treated as a critical factor in pipeline design and fatigue life assessments, particularly under high-cycle or subcritical loading conditions.

In the upper Paris regime (ΔK ≈ 20 MPa·√m), da/dNs are intrinsically higher due to the elevated stress intensity factor. However, a distinct concentration-dependent response remains evident. From a baseline of approximately 2.61 × 10−5 mm/cycle in 0% H2, da/dN increases sharply to ~1.08 × 10−4 mm/cycle at 10% H2 and remains relatively stable at ~1.05 × 10−4 mm/cycle at 25% H2. Interestingly, a dip is observed at 50% H2 (~7.13 × 10−5 mm/cycle), which is followed by a renewed rise at 75% H2 (~1.47 × 10−4 mm/cycle) and peaks at ~2.25 × 10−4 mm/cycle in 100% H2. This non-monotonic yet overall increasing trend suggests that while hydrogen continues to promote crack propagation, saturation and trapping effects at intermediate blends may temporarily suppress da/dN before it increases again at higher concentrations. These findings reflect the dynamic interplay between hydrogen diffusion, trapping kinetics, and local plasticity around the crack tip under high ΔK conditions.

The nonlinear evolution of da/dN with hydrogen concentration is characteristic of HE mechanisms, such as Hydrogen-Enhanced Localized Plasticity (HELP) and Hydrogen-Enhanced Decohesion (HEDE) [45]. The acceleration of crack growth at low-to-moderate concentrations, coupled with the saturation behavior at higher blends, supports the notion of a threshold in hydrogen uptake or activity beyond which additional H2 has diminishing effects. Moreover, the fine ferrite–pearlite microstructure and manganese sulfide (MnS) inclusions in the X60 steel likely act as hydrogen traps and crack initiation points, especially at grain boundaries and phase interfaces, further contributing to the material’s embrittlement behavior [46]. The observed trends in both threshold and upper Paris regimes collectively highlight the importance of controlling hydrogen concentration in pipeline applications to mitigate fatigue degradation under cyclic loading.

5.5. SEM Fractography of Fracture Surfaces

Scanning electron microscopy (SEM) examination of the fracture surfaces of X60 specimens revealed a systematic transition in fracture morphology with increasing hydrogen concentration (0–100% H2, balance NG). Representative images are shown in Figure 12, captured at 2000× (0–10% H2) and 2500× (25–100% H2) magnification. In the baseline condition (0% H2, Figure 12a), the fracture surface presents leaf-like, torn-sheet morphology with a rough, irregular relief and pronounced tearing marks. These features reflect micro-void nucleation and coalescence at inclusions/phase interfaces; the resulting dimples are fine and closely packed, so they appear as overlapping “leaves” rather than deep, isolated cups. The absence of extended flat facets is consistent with ductile fracture under natural-gas (inert) conditions.

Figure 12.

SEM fractographs of X60 CT specimens tested under different hydrogen–natural gas (H2–NG) environments at 6.9 MPa and room temperature: (a) 0% H2, (b) 10% H2, (c) 25% H2, (d) 50% H2, (e) 75% H2, and (f) 100% H2.

At 10% H2 (Figure 12b), the fracture surface shows a noticeable reduction in roughness relative to the baseline natural gas condition. While ductile tearing and shallow dimples remain visible, they are less pronounced and appear shallower. In addition, the surface exhibits localized quasi-cleavage facets, which manifest as flatter, faceted regions interrupting the otherwise ductile morphology. This mixed appearance indicates the early onset of hydrogen-assisted fracture mechanisms, where hydrogen begins to suppress micro-void growth and promote localized brittle cracking. This trend becomes more pronounced at 25% H2 (Figure 12c), where the fracture surface reveals a mixed morphology. Ductile dimples are less prominent and confined to small, isolated regions. At the same time, the majority of the surface is occupied by quasi-cleavage facets, which appear as flat planes with step-like features and river markings. These features highlight the increasing influence of hydrogen in promoting brittle fracture, while ductile micro-void coalescence plays a progressively smaller role.

With further increase in hydrogen content to 50% (Figure 12d), the fracture surface is dominated by extended quasi-cleavage planes and step-like features. At the same time, ductile regions are scarce and confined to isolated patches. River-like markings and secondary facets indicate the advance of brittle cracks across ferrite–pearlite interfaces. At 75% H2 (Figure 12e), the fracture surface is dominated by broad quasi-cleavage facets with distinct step-terrace morphologies and sharp fracture steps. Multiple secondary cracks traverse these facets, reflecting unstable, brittle crack advance. The overall roughness is much lower than at lower hydrogen concentrations, and ductile dimples are nearly absent. This morphology demonstrates the overwhelming influence of HE, with fracture progressing primarily by cleavage-like mechanisms rather than plastic void coalescence.

The most severe changes occurred in the 100% H2 condition (Figure 12f), where the surface was almost entirely brittle in nature. Large, flat cleavage facets were fragmented into smaller planes, and intergranular cracking was apparent along grain boundaries. In contrast to the broad planes observed at 75% H2, the 100% H2 surface exhibited a more tortuous, discontinuous morphology with multiple ridges and crack bifurcations. The near-complete absence of ductile dimples and the presence of intergranular features confirm extensive HE under pure hydrogen exposure.

Taken together, these fractographic observations corroborate the FCG results, showing a progressive shift from ductile micro-void coalescence in natural gas to mixed-mode fracture at low-to-intermediate hydrogen concentrations, and ultimately to brittle, hydrogen-dominated fracture at high hydrogen contents. The morphological changes, shallower dimples, quasi-cleavage facets, step-like terraces, and intergranular cracking, provide direct microstructural evidence of the embrittlement processes that accelerate fatigue crack propagation in X60 steel under hydrogen–natural gas blending conditions.

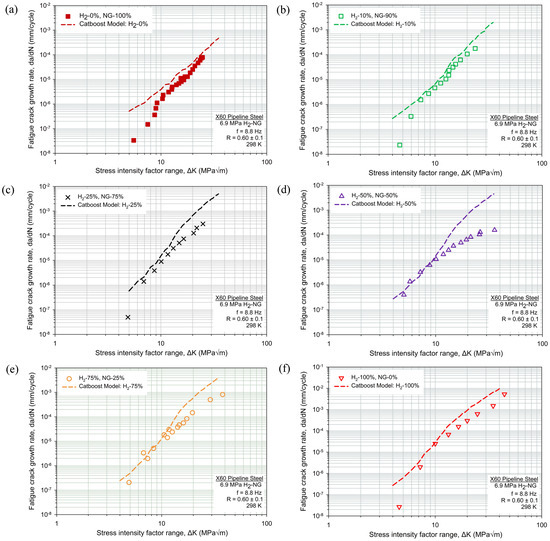

5.6. ML Model Evaluation

The performance of the CatBoost-based FCG rate model was validated against experimentally obtained da/dN–ΔK data for X60 steel under six hydrogen–natural gas (H2–NG) blend environments (0%, 10%, 25%, 50%, 75%, and 100% H2 at 6.9 MPa and 298 K). Figure 13 illustrates the model predictions against measured values, using identical input parameters for each case, including yield strength, chemical composition, test temperature, hydrogen partial pressure, and loading conditions (R = 0.60 ± 0.10, 8.8 Hz). The predicted curves accurately follow experimental trends, substantiating the generalizability and reliability of the ML framework.

Figure 13.

Comparison of CatBoost model predictions with measured da/dN vs. ΔK for X60 steel at 6.9 MPa and 298 K, and different hydrogen concentrations: (a) 0% H2, (b) 10% H2, (c) 25% H2, (d) 50% H2, (e) 75% H2, and (f) 100% H2.

In the absence of hydrogen, the predicted FCG rate curve aligns closely with the experimental data throughout the entire ΔK range (Figure 13a). The predicted da/dN curve closely follows the experimental trend with high precision, exhibiting only a slight underestimation in the near-threshold regime (ΔK ≲ 10 MPa· m^1/2). This deviation is attributed to intrinsic variability in crack closure behavior and microstructural effects that are challenging to capture near the threshold. Overall, this confirms the model’s robustness and establishes a reliable baseline for detecting hydrogen-induced degradation.

At 10% H2 (Figure 13b), the model effectively captures the early onset of hydrogen-enhanced crack propagation, especially in the Paris regime. The predicted curve mirrors the increase in da/dN with minimal deviation, demonstrating that the model is sensitive to minor changes in hydrogen activity. At 25% H2 (Figure 13c), the model continues to perform well, reproducing both the increased slope and magnitude of the da/dN response. A mild overprediction is observed at lower ΔK, possibly due to localized micro-void coalescence or hydrogen trapping. The predicted curve nonetheless captures the shift in fracture mode from ductile-dominated to a more brittle hydrogen-assisted mechanism. With further increase in hydrogen content to 50% H2 (Figure 13d), the model predicts a marked acceleration in da/dN. The predicted curve exhibits both a steepening slope and a reduction in the apparent threshold ΔKth, aligning closely with experimental observations. This response reflects the transition to embrittlement-driven mechanisms, consistent with increased hydrogen solubility and enhanced crack tip reactivity. At 75% H2 (Figure 13e), the model continues to accurately capture the general trend of the experimental data, particularly in the Paris and high-ΔK regions. However, slight underestimation is noted near the transition zone around ΔK ≈ 10 MPa√m. This could be attributed to stochastic effects in crack initiation or uneven hydrogen saturation at elevated concentrations.

In the most aggressive environment (Figure 13f), representing pure hydrogen exposure, the experimental data show a sharp rise in da/dN beginning at low ΔK, followed by a near-linear propagation with saturation beyond ΔK≈20 MPa√m. The CatBoost model successfully replicates this steep, monotonic increase, including the inflection point behavior—suggesting that it effectively captures the dominant crack propagation mechanism under extreme hydrogen activity, such as cleavage fracture or hydrogen-enhanced localized plasticity (HELP/HEDE).

Across all six hydrogen blend scenarios, the CatBoost model demonstrates high predictive fidelity and generalizability. The model not only captures the monotonic increase in FCG rate with rising hydrogen content, but also adapts to the nonlinearities and inflection zones that emerge due to changing failure mechanisms. Importantly, the integration of FT and RA predictions, derived from independent ML models, augments the model’s sensitivity to hydrogen-induced microstructural degradation. Minor deviations in the low ΔK regime, where variability in crack closure and hydrogen diffusion dominate, do not detract from the overall accuracy. These results validate the model as a powerful predictive tool for assessing hydrogen compatibility in pipeline steels, offering valuable insight for material screening, risk assessment, and design optimization in hydrogen-blended energy systems.

6. Conclusions

This study presents a detailed experimental investigation of fatigue crack growth (FCG) behavior in API 5L X60 pipeline steel exposed to hydrogen–natural gas (H2–NG) blended environments. Using a custom-designed autoclave system that replicates field-relevant loading and pressure conditions, crack propagation rates were systematically quantified across a full spectrum of hydrogen concentrations (0% to 100% H2) and stress intensity factor ranges (ΔK). In parallel, a CatBoost-based ML framework was developed using both experimental and literature data to predict FCG behavior as a function of hydrogen exposure, mechanical loading, and material properties. The following key conclusions are drawn:

- FCG rates increased significantly with hydrogen content, with the most severe degradation observed at 100% H2. At near-threshold conditions (ΔK ≈ 10 MPa·√m), da/dN increased by more than one order of magnitude, from 1.49 × 10−6 to 2.50 × 10−5 mm/cycle, as hydrogen concentration rose from 0% to 100%.

- The addition of only 10% hydrogen resulted in a more than threefold increase in da/dN at ΔK ≈ 10 MPa·√m, indicating a critical embrittlement threshold. Even modest hydrogen exposure can significantly compromise fatigue life, especially under high-cycle, near-threshold loading conditions.

- Increasing hydrogen concentration reduced the effective FCG threshold (ΔK_th), leading to an earlier onset of crack propagation and a steeper transition into the Paris regime. This effect was most pronounced between 10% and 50% H2 concentrations.

- Beyond 50% H2, the rate of increase in da/dN began to level off, especially at high ΔK, indicating a saturation effect in hydrogen damage kinetics, likely due to trap site saturation or rate-limited hydrogen diffusion.

- Hydrogen–natural gas mixtures, particularly at intermediate concentrations (25–75%), caused significant reductions in fatigue life, ranging from approximately 33% at 50% H2 to over 55% in 100% H2, relative to the natural gas baseline.

- The Paris law slope (m) increased with hydrogen content, rising from ~4.08 in pure natural gas to ~4.89–5.0 in 100% hydrogen, indicating heightened sensitivity of fatigue crack growth to loading amplitude and transition to hydrogen-assisted mechanisms.

- SEM fractography confirmed the transition from ductile microvoid coalescence in natural gas to brittle quasi-cleavage and intergranular fracture in hydrogen environments, directly supporting the observed acceleration in fatigue crack growth.

- Machine learning predictions corroborated experimental trends, with CatBoost-based models accurately capturing the nonlinear increase in da/dN as a function of ΔK and hydrogen content. The integration of predicted RA and FT enhanced the model’s performance in blended gas environments.

- Microstructural analysis revealed a dual-phase ferrite–pearlite structure with MnS inclusions, which likely acted as hydrogen traps and local stress concentrators, facilitating early crack initiation and enhancing FCG rates under hydrogen exposure.

Future research should extend this work by conducting fatigue crack growth tests at lower loading frequencies to better reflect field-relevant cyclic conditions in NG–H2 blending situations, examining weld zones and heat-affected regions where hydrogen effects are often more pronounced, exploring higher pressures and variable temperatures, and evaluating the influence of impurities such as O2 in the blended gas composition. Such efforts will broaden the applicability of the findings and provide deeper insight into the long-term integrity of repurposed pipelines for hydrogen transport.

Author Contributions

Conceptualization, R.A.; Methodology, N.A. and R.A.; Formal analysis, N.A.; Investigation, N.A., R.A., S.R., A.F.B.V. and C.T.; Data curation, N.A., S.R. and A.F.B.V.; Writing—original draft, N.A.; Writing—review and editing, R.A.; Supervision, R.A.; Project administration, R.A. and C.T.; Funding acquisition, R.A. and C.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Pipeline and Hazardous Materials Safety Administration (PHMSA) of the U.S. Department of Transportation under Competitive Academic Agreement Program Award No. 693JK32250004CAAP.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors also acknowledge the University of Oklahoma for institutional support. Microscopy analyses were performed at the Samuel Roberts Noble Microscopy Laboratory, a core facility supported by the Office of the Vice President for Research and Partnerships at the University of Oklahoma. We want to thank Williams Gas Pipeline Co. for providing the pipe materials used in preparing the specimens.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Dwivedi, S.K.; Vishwakarma, M. Hydrogen embrittlement in different materials: A review. Int. J. Hydrogen Energy 2018, 43, 21603–21616. [Google Scholar] [CrossRef]

- Lynch, S. Hydrogen embrittlement phenomena and mechanisms. Corros. Rev. 2012, 30, 105–123. [Google Scholar] [CrossRef]

- Ghosh, G.; Rostron, P.; Garg, R.; Panday, A. Hydrogen induced cracking of pipeline and pressure vessel steels: A review. Eng. Fract. Mech. 2018, 199, 609–618. [Google Scholar] [CrossRef]

- Völkl, J.; Alefeld, G. Hydrogen Diffusion in Metals. In Diffusion in Solids; Nowick, A.S., Burton, J.J., Eds.; Academic Press: Cambridge, MA, USA, 1975; pp. 231–302. [Google Scholar]

- Shanabarger, M.R. The isothermal kinetics of hydrogen adsorption onto iron films observed with the chemisorption-induced resistance change. Surf. Sci. 1985, 150, 451–479. [Google Scholar] [CrossRef]

- Martin, M.L.; Connolly, M.J.; DelRio, F.W.; Slifka, A.J. Hydrogen embrittlement in ferritic steels. Appl. Phys. Rev. 2020, 7, 041301. [Google Scholar] [CrossRef] [PubMed]

- Beachem, C.D. A new model for hydrogen-assisted cracking (hydrogen “embrittlement”). Metall. Trans. 1972, 3, 441–455. [Google Scholar] [CrossRef]

- Martin, M.L.; Dadfarnia, M.; Nagao, A.; Wang, S.; Sofronis, P. Enumeration of the hydrogen-enhanced localized plasticity mechanism for hydrogen embrittlement in structural materials. Acta Mater. 2019, 165, 734–750. [Google Scholar] [CrossRef]

- Pfeil, L.B.; Carpenter, H.C.H. The effect of occluded hydrogen on the tensile strength of iron. Proc. R. Soc. London. Ser. A Contain. Pap. A Math. Phys. Character 1926, 112, 182–195. [Google Scholar] [CrossRef]

- Troiano, A.R. The Role of Hydrogen and Other Interstitials in the Mechanical Behavior of Metals. Trans. ASM 1960, 52, 54–81. [Google Scholar] [CrossRef]

- Amaro, R.L.; Drexler, E.S.; Slifka, A.J. Fatigue crack growth modeling of pipeline steels in high pressure gaseous hydrogen. Int. J. Fatigue 2014, 62, 249–257. [Google Scholar] [CrossRef]

- San Marchi, C.; Somerday, B.P.; Nibur, K.A.; Stalheim, D.G.; Boggess, T.; Jansto, S. Fracture and Fatigue of Commercial Grade API Pipeline Steels in Gaseous Hydrogen. In Proceedings of the ASME 2010 Pressure Vessels and Piping Division/K-PVP Conference, Bellevue, WA, USA, 18–22 July 2010; pp. 939–948. [Google Scholar]

- Xu, K. Hydrogen embrittlement of carbon steels and their welds. In Gaseous Hydrogen Embrittlement of Materials in Energy Technologies; Gangloff, R.P., Somerday, B.P., Eds.; Woodhead Publishing: Cambridge, UK, 2012; Volume 2, pp. 526–561. [Google Scholar]

- Faucon, L.E.; Boot, T.; Riemslag, T.; Scott, S.P.; Liu, P.; Popovich, V. Hydrogen-Accelerated Fatigue of API X60 Pipeline Steel and Its Weld. Metals 2023, 13, 563. [Google Scholar] [CrossRef]

- Achoui, M.; Sebaa, F.; Bouchouicha, B. Influence of themo-mechanical treatments and microstructural state on the fatigue behaviour of a weald seam: Case of API X60 steel. Fract. Struct. Integr. 2021, 15, 365–375. [Google Scholar] [CrossRef]

- Hopkin, S.E.; Bezensek, B.; Martin, T.; Guijt, W. H2 Fracture and Fatigue Behaviour of a Vintage X60 Pipeline Material and Practical Implications for Reuse in H2 Service. In Proceedings of the 33rd International Ocean and Polar Engineering Conference, Ottawa, ON, Canada, 19–23 June 2023; p. ISOPE-I-23-446. [Google Scholar]

- Nazar, S.; Proverbio, E. Modeling of hydrogen-assisted fatigue crack growth in carbon steel pipelines. Int. J. Hydrogen Energy 2025, 138, 548–558. [Google Scholar] [CrossRef]

- ASME B31.12; Hydrogen Piping and Pipeline Code. ASME International: New York, NY, USA, 2023.

- Boot, T.; Riemslag, T.; Reinton, E.; Liu, P.; Walters, C.L.; Popovich, V. In-Situ Hollow Sample Setup Design for Mechanical Characterisation of Gaseous Hydrogen Embrittlement of Pipeline Steels and Welds. Metals 2021, 11, 1242. [Google Scholar] [CrossRef]

- Dadfarnia, M.; Sofronis, P.; Brouwer, J.; Sosa, S. Assessment of resistance to fatigue crack growth of natural gas line pipe steels carrying gas mixed with hydrogen. Int. J. Hydrogen Energy 2019, 44, 10808–10822. [Google Scholar] [CrossRef]

- Campari, A.; Vianello, C.; Ustolin, F.; Alvaro, A.; Paltrinieri, N. Machine learning-aided risk-based inspection strategy for hydrogen technologies. Process Saf. Environ. Prot. 2024, 191, 1239–1253. [Google Scholar] [CrossRef]

- Holbrook, J.H.; Collings, E.W.; Cialone, H.J.; Drauglis, E.J. Hydrogen Degradation of Pipeline Steels: Final Report; United States, 01 1986. Available online: https://www.osti.gov/servlets/purl/7122938/ (accessed on 12 May 2025).

- Gyaabeng, M.; Ahmed, R.; Ahmed, N.; Teodoriu, C.; Devegowda, D. Modeling the Impact of Hydrogen Embrittlement on the Fracture Toughness of Low-Carbon Steel Using a Machine Learning Approach. Metals 2025, 15, 588. [Google Scholar] [CrossRef]

- Ahmed, N.; Aldaw, M.; Ahmed, R.; Teodoriu, C. Modeling of necking area reduction of carbon steel in hydrogen environment using machine learning approach. Eng. Fail. Anal. 2024, 156, 107864. [Google Scholar] [CrossRef]

- Hu, Q.; Li, Y.; Cheng, Y.F. Distribution of hydrogen atoms at metallurgical microphases of X52 pipeline steel studied by scanning Kelvin probe force microscopy and finite element modelling. Surf. Sci. Technol. 2023, 1, 3. [Google Scholar] [CrossRef]

- Fan, X.; Mi, Z.; Yang, L.; Su, H. Application of DFT Simulation to the Investigation of Hydrogen Embrittlement Mechanism and Design of High Strength Low Alloy Steel. Materials 2023, 16, 152. [Google Scholar] [CrossRef]