Advances in Microstructural Evolution and Mechanical Properties of Magnesium Alloys Under Shear Deformation

Abstract

1. Introduction

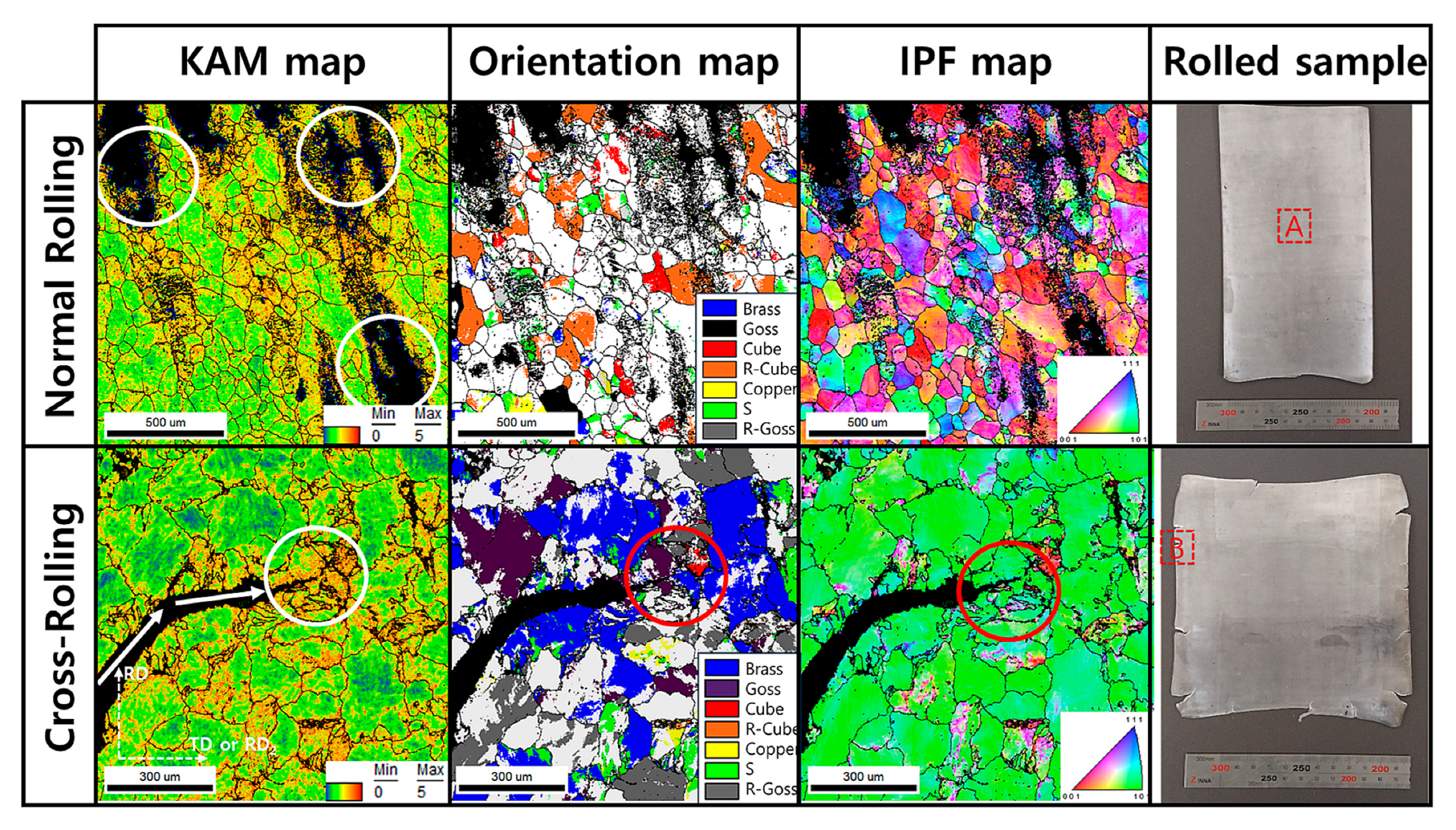

2. Effects of Shear Deformation on the Microstructure of Mg Alloys

2.1. Formation and Evolution Mechanisms of Shear Bands

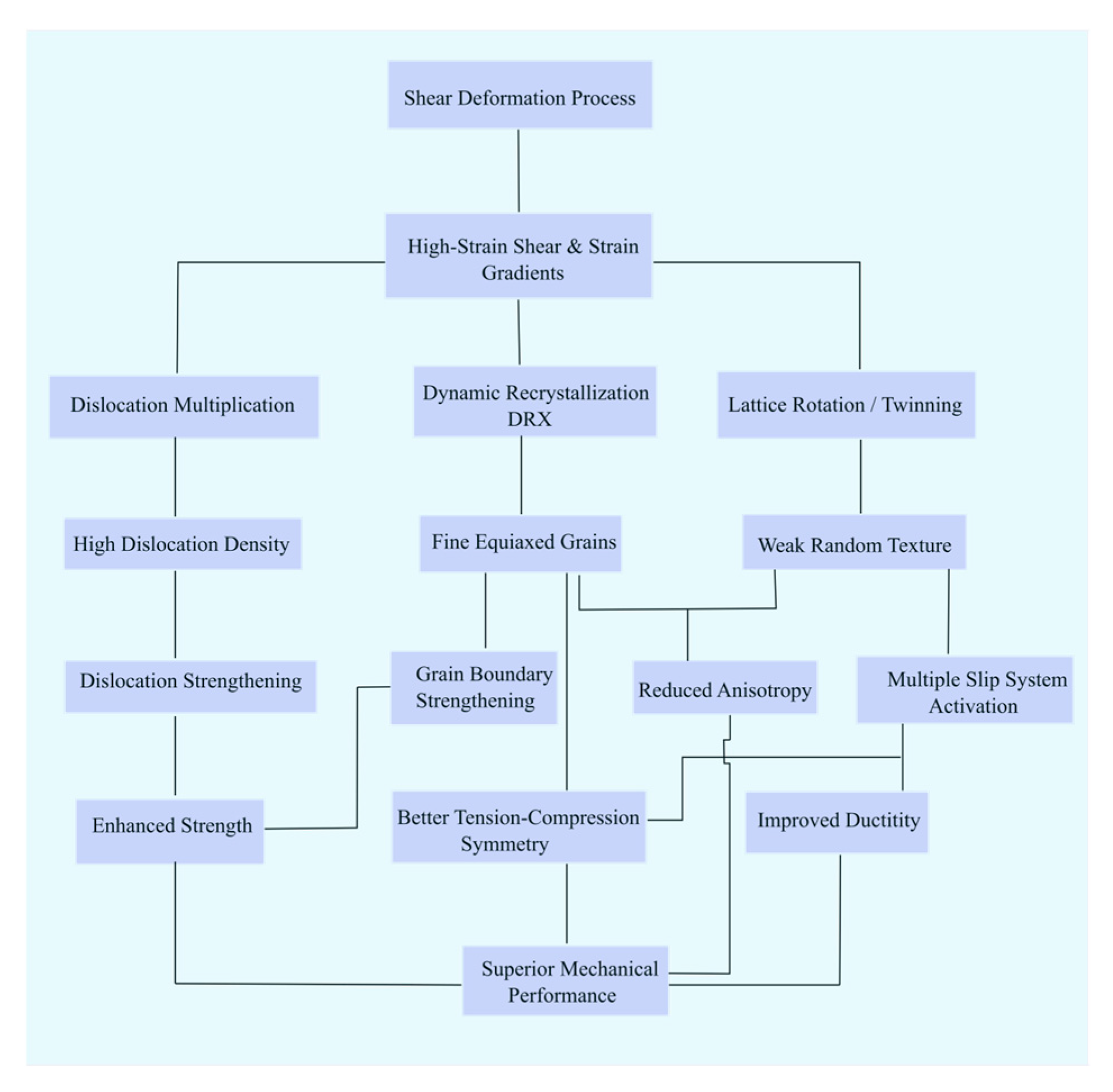

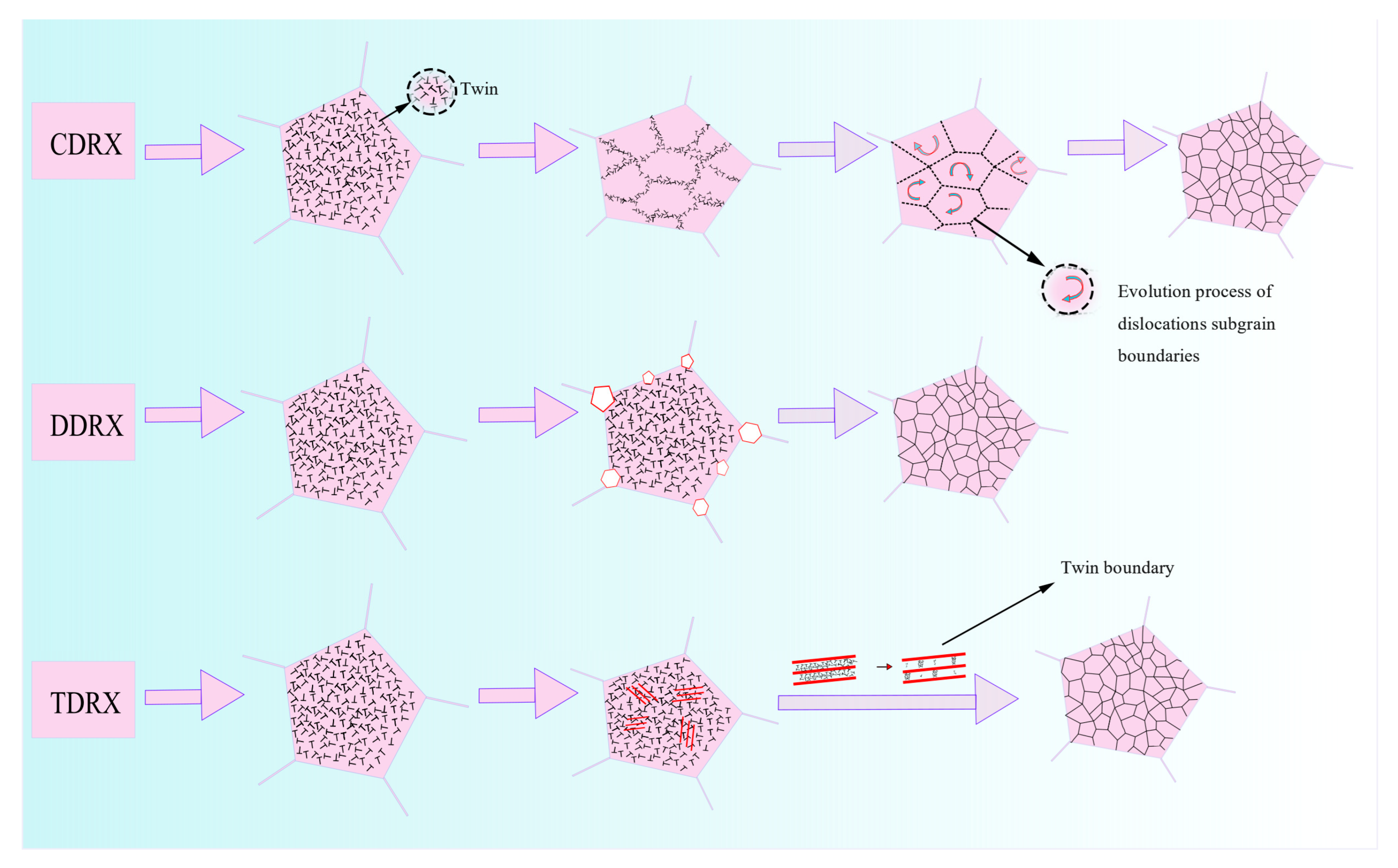

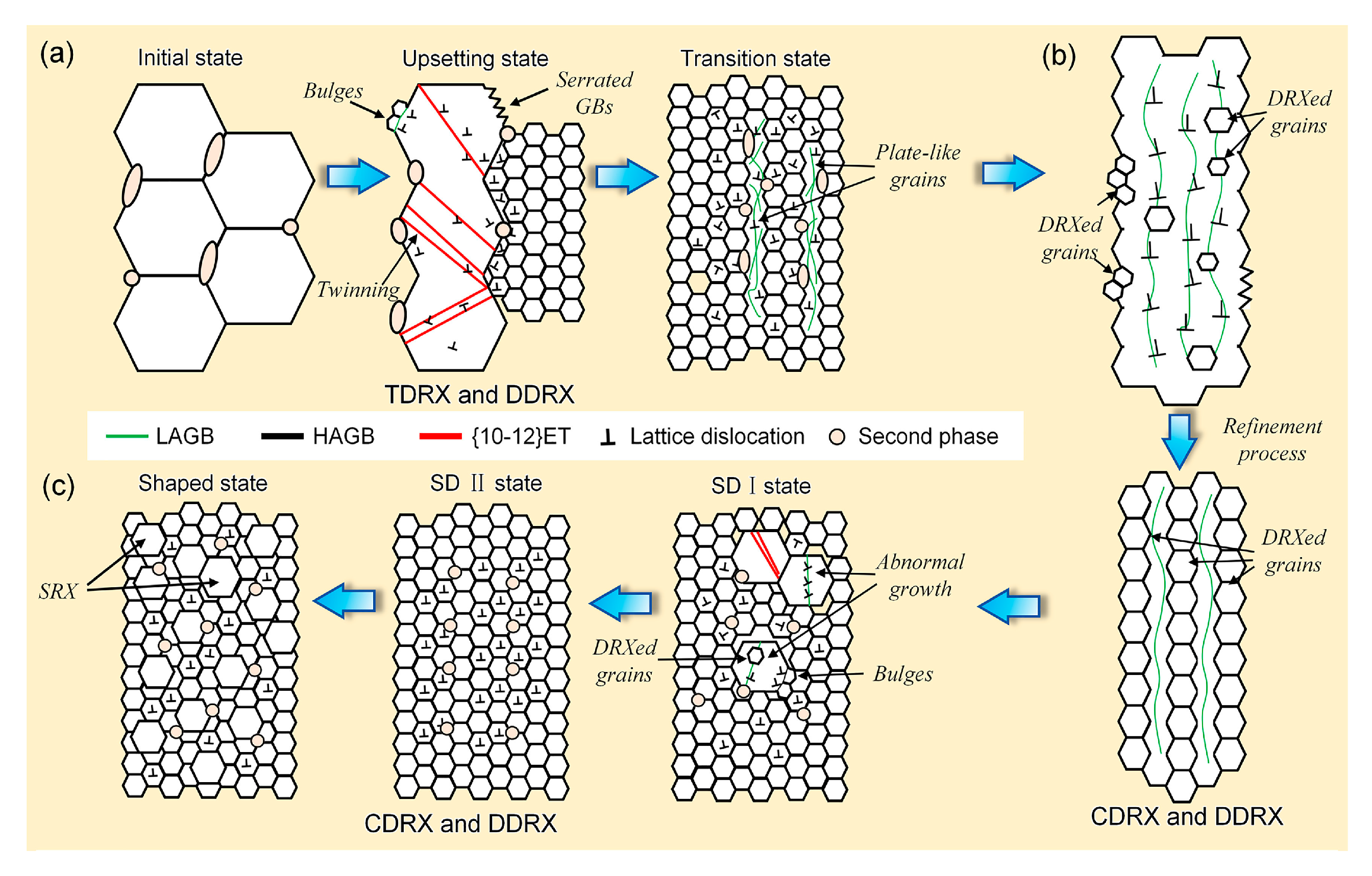

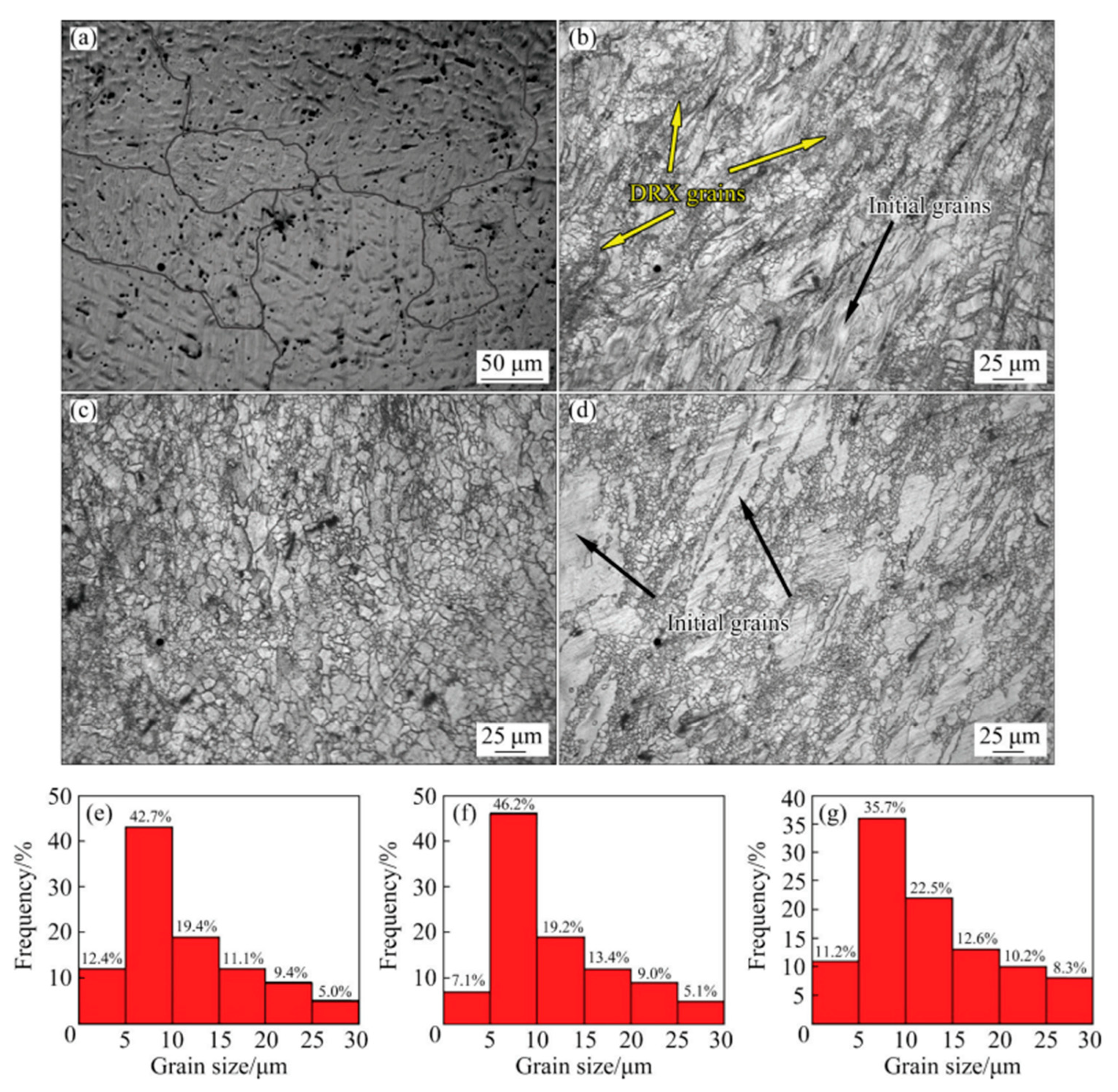

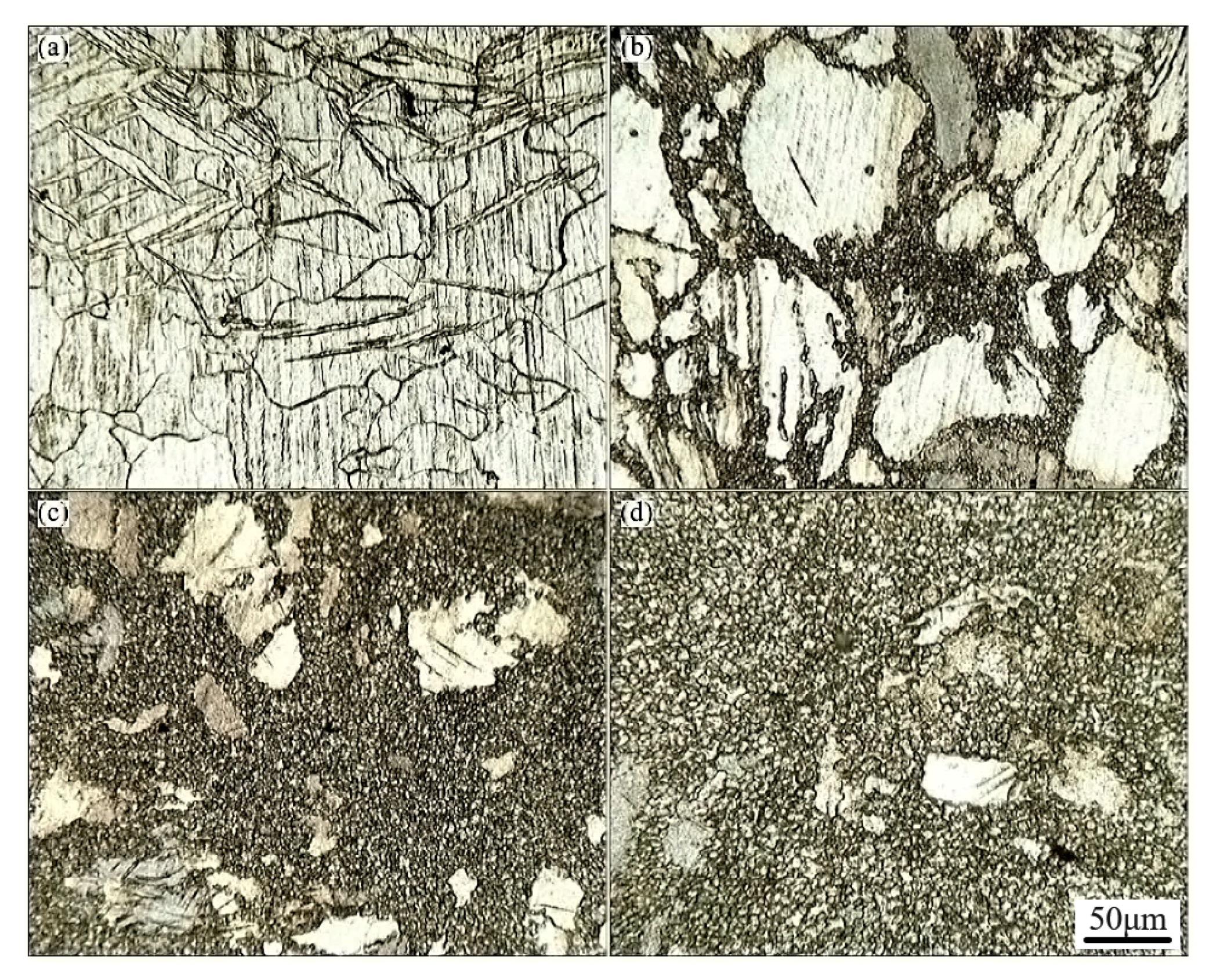

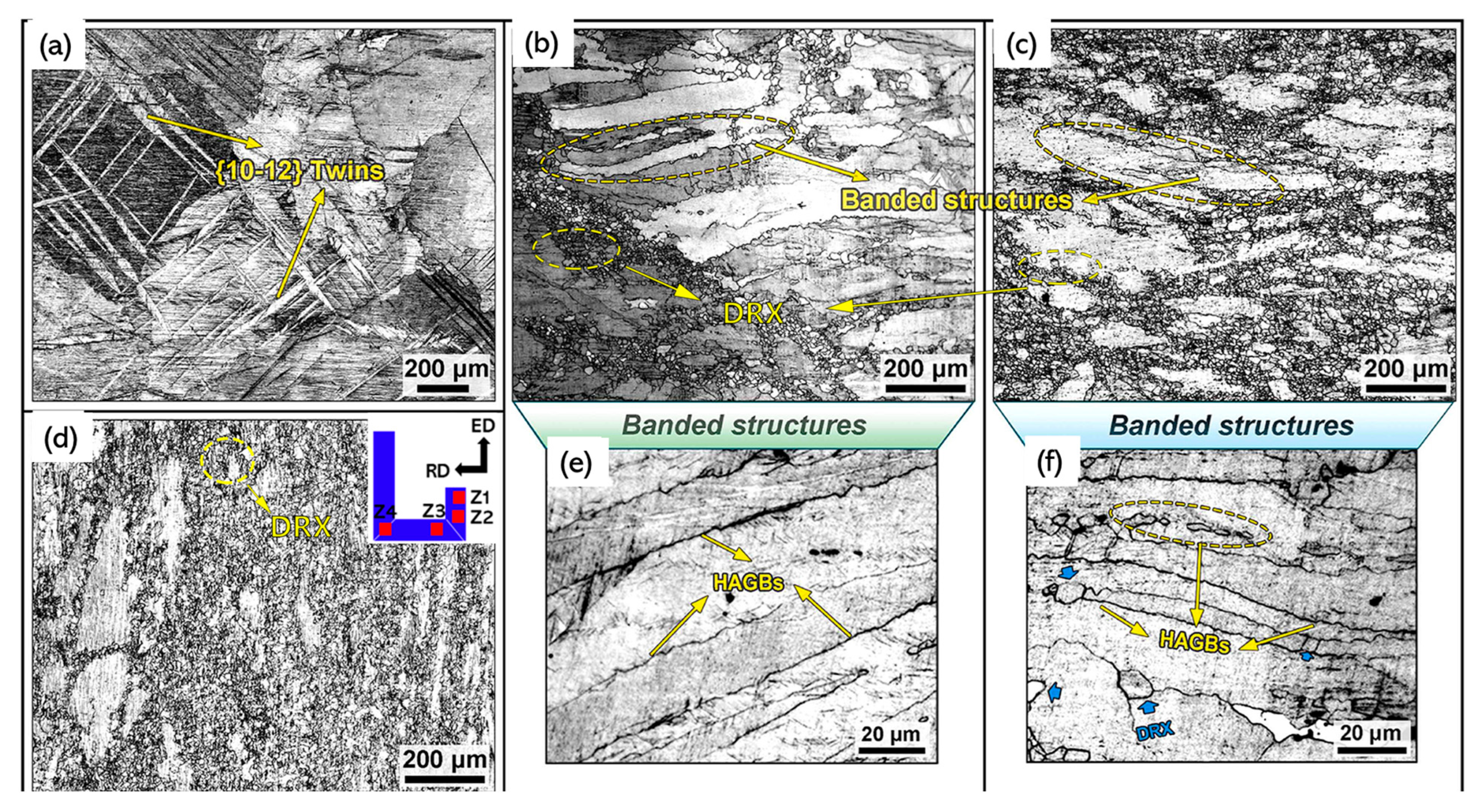

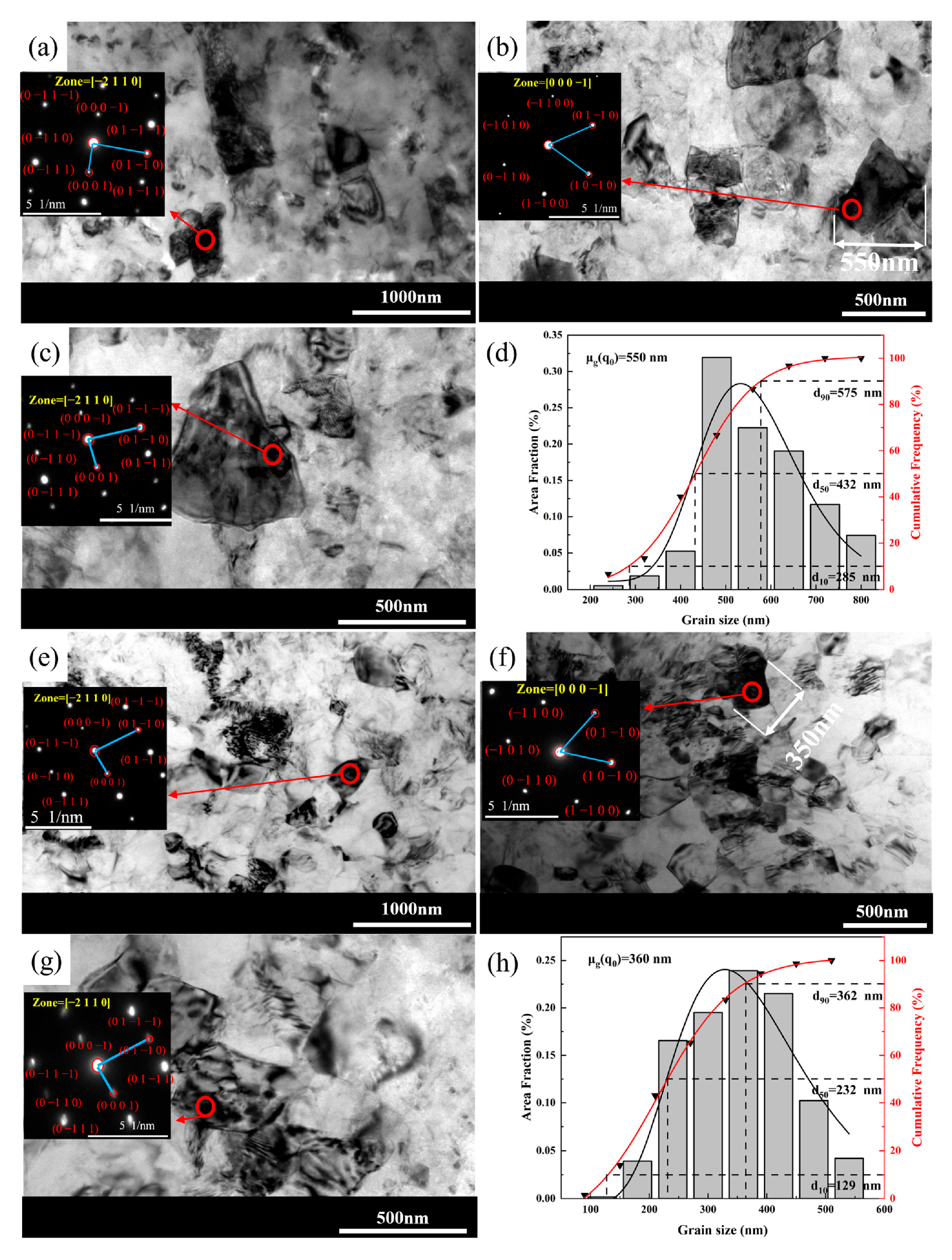

2.2. DRX Behavior and Grain Refinement

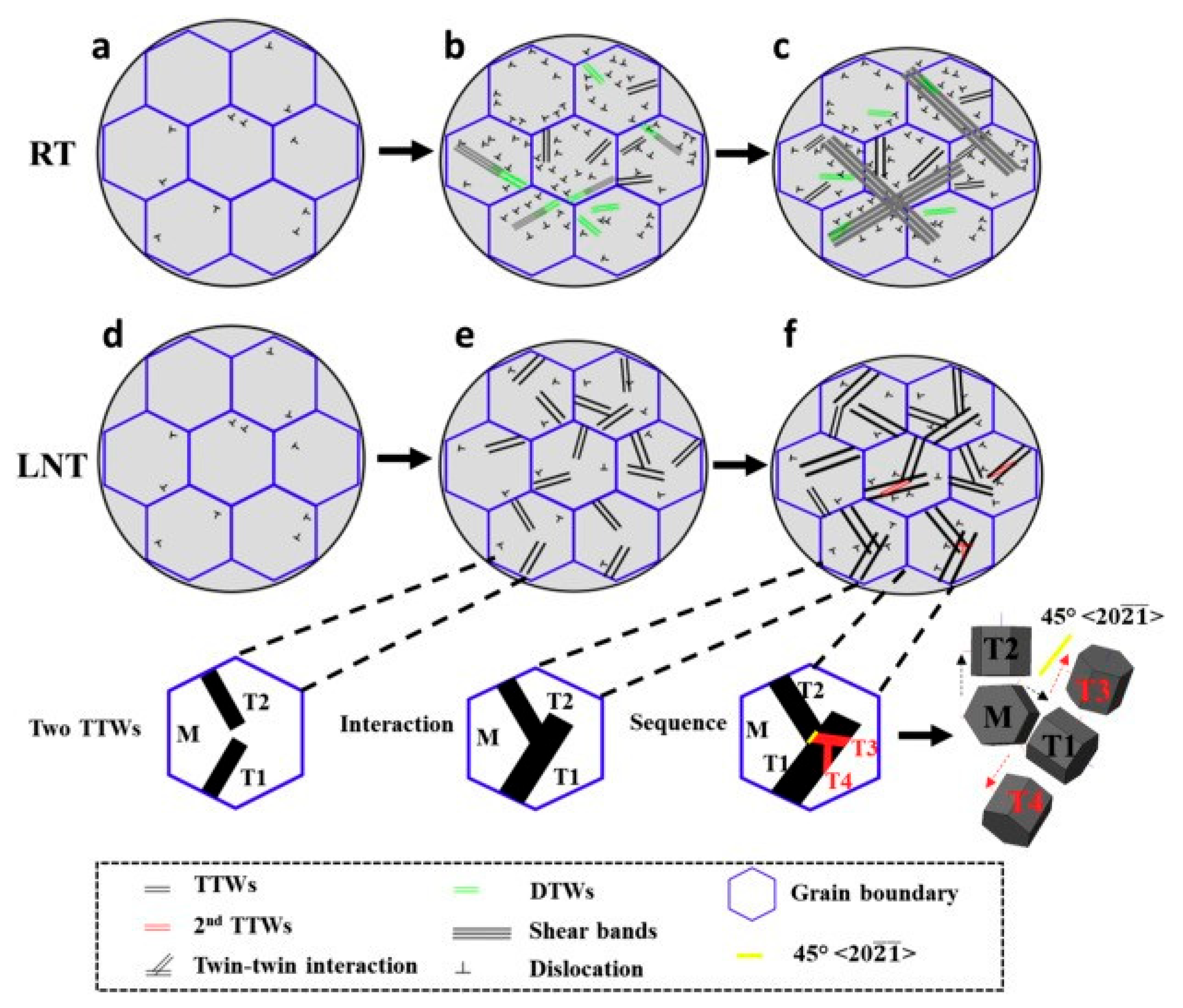

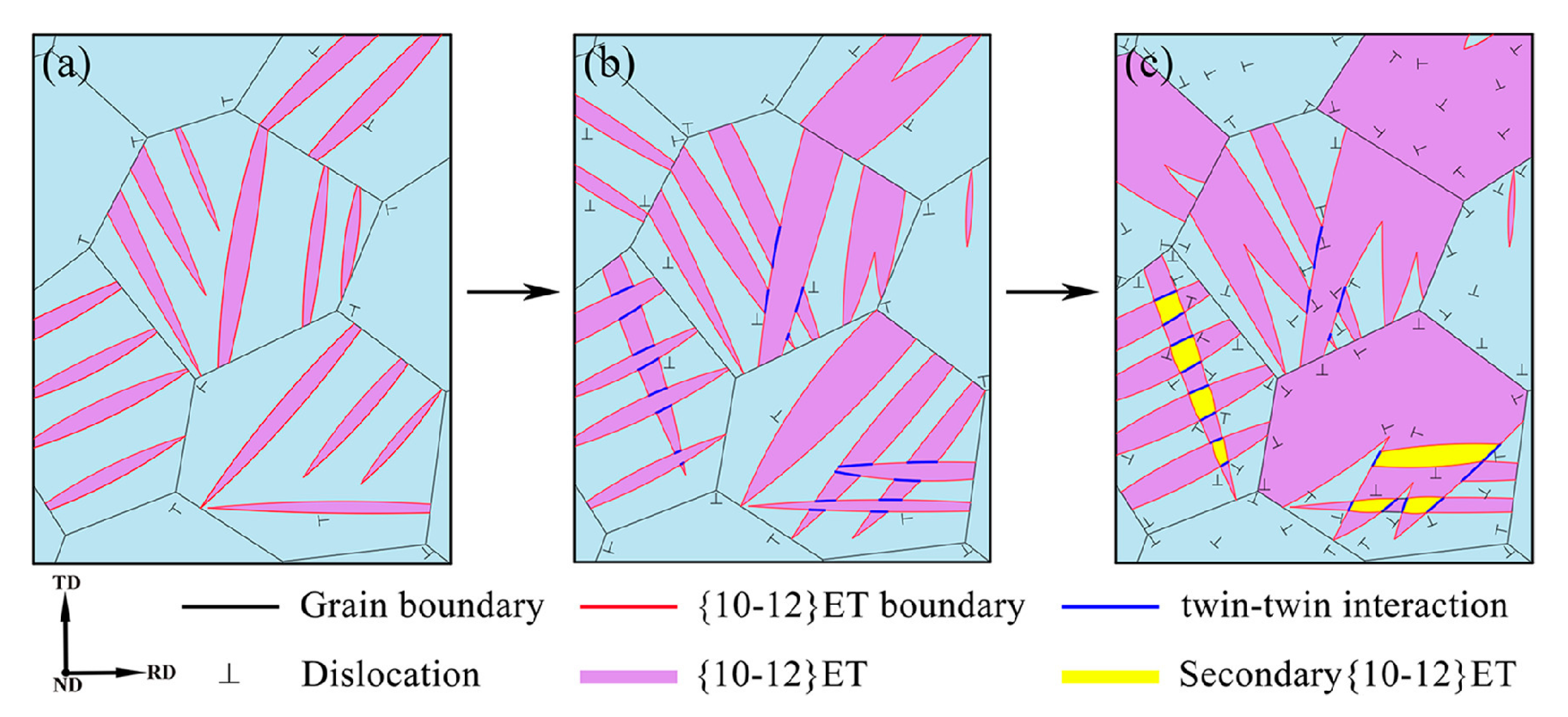

2.3. Microstructural Evolution Induced by Twinning

2.4. Distribution Behavior of Second Phases and Precipitates

2.5. Summary and Synthesis

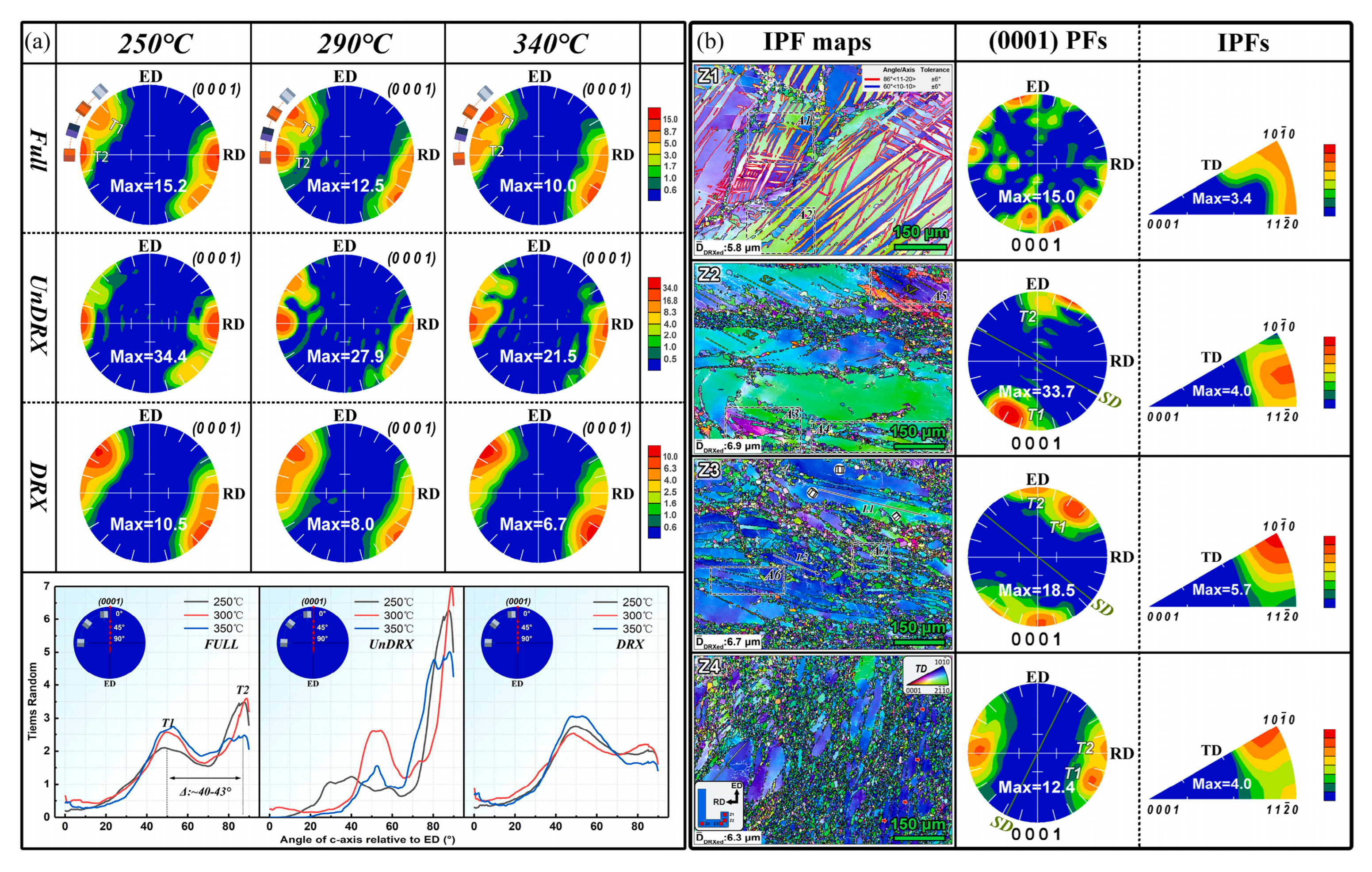

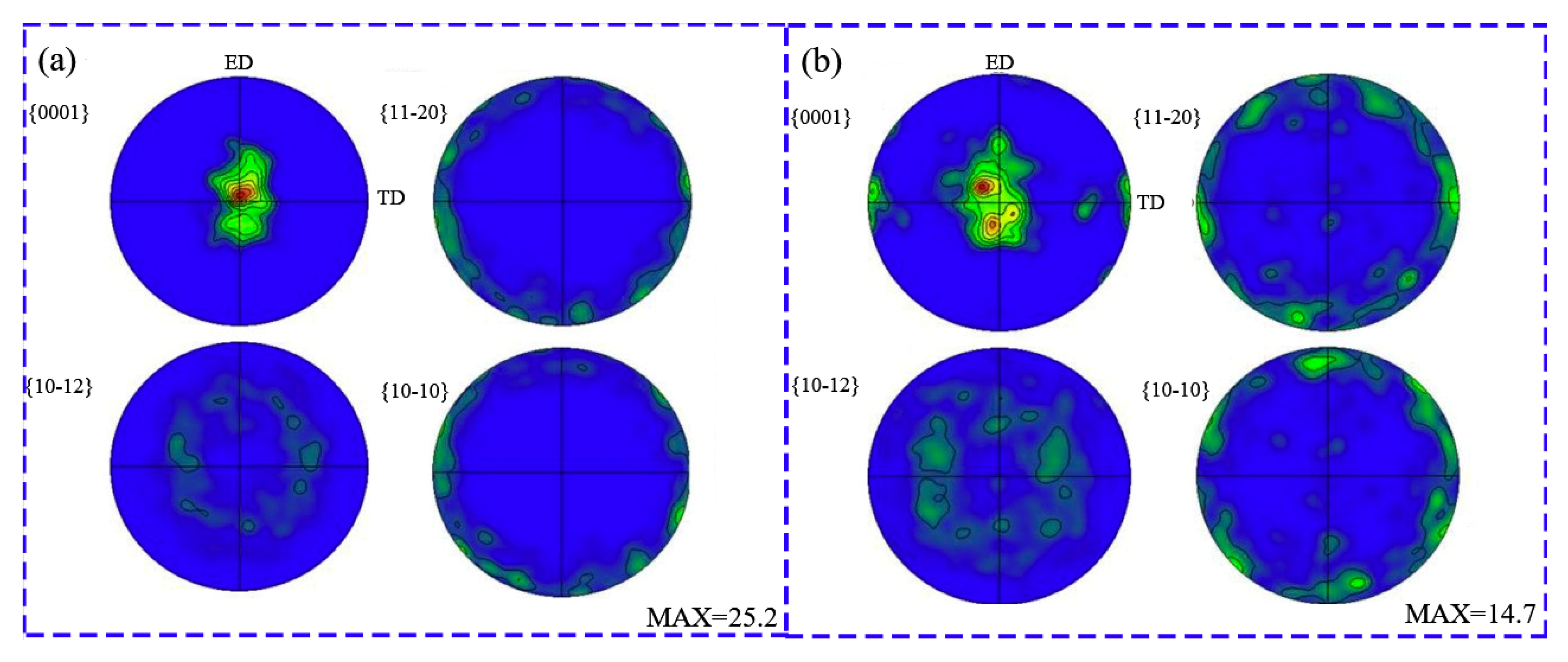

3. Effect of Shear Deformation on Texture Evolution

3.1. Subsection Mechanisms of Weakening in Basal Plane Texture

3.2. Texture Formation and Evolution of Bimodal Textures

3.3. Relationship Between Crystal Orientation Rearrangement and Shear Direction

3.4. Summary and Synthesis

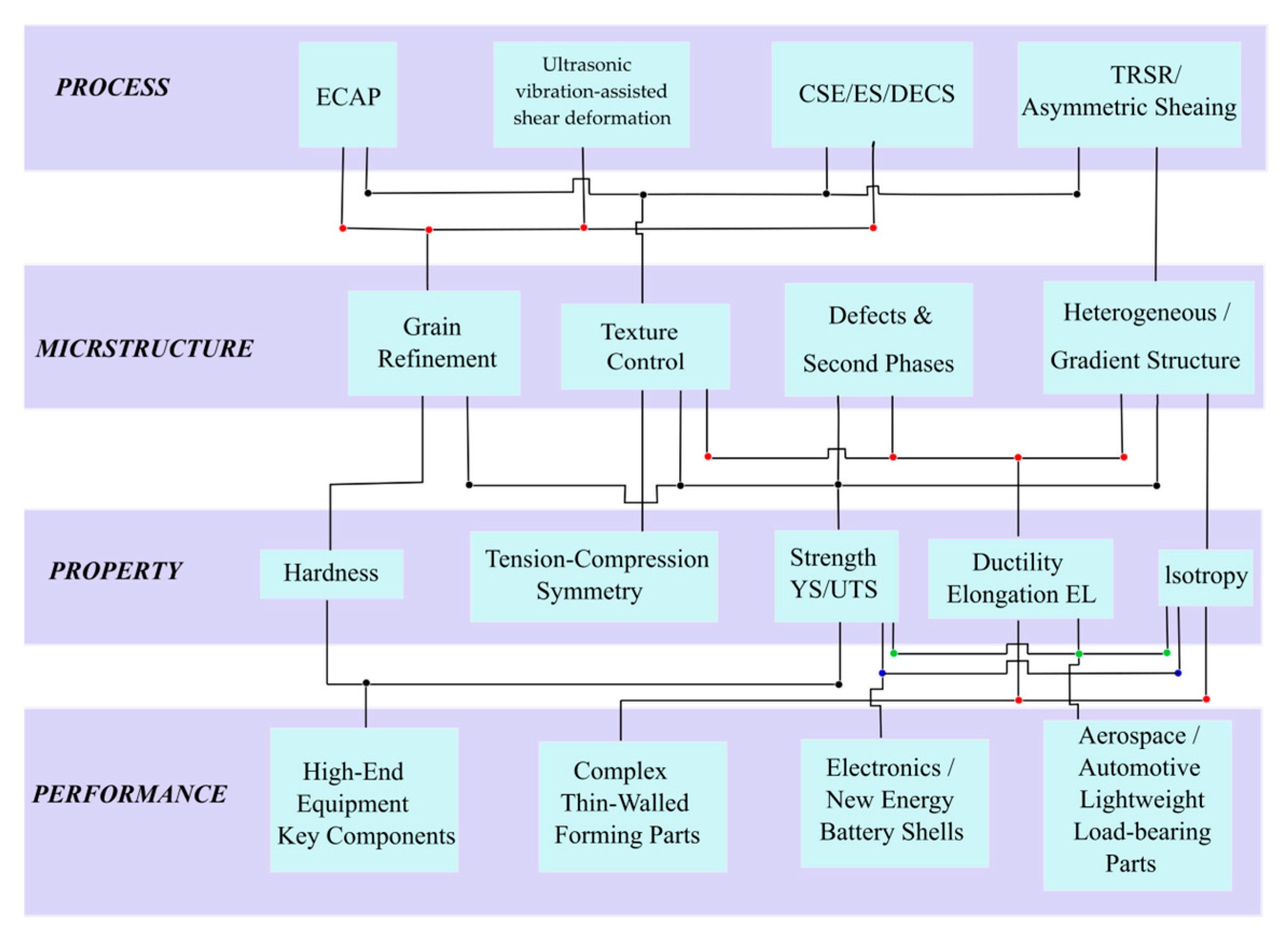

4. Shear Deformation Processes and Their Recent Technological Advances

4.1. Shear Deformation via ECAP

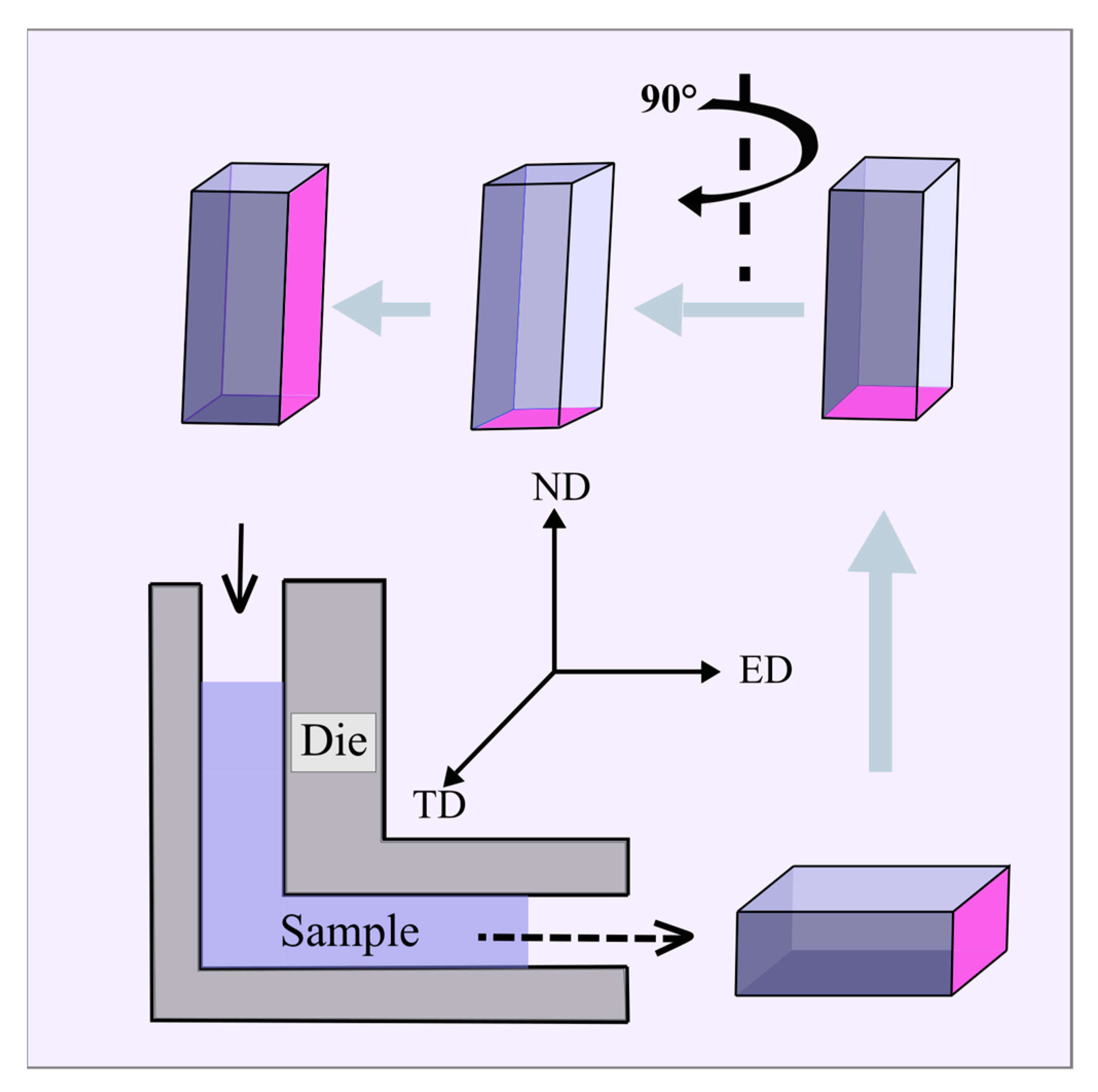

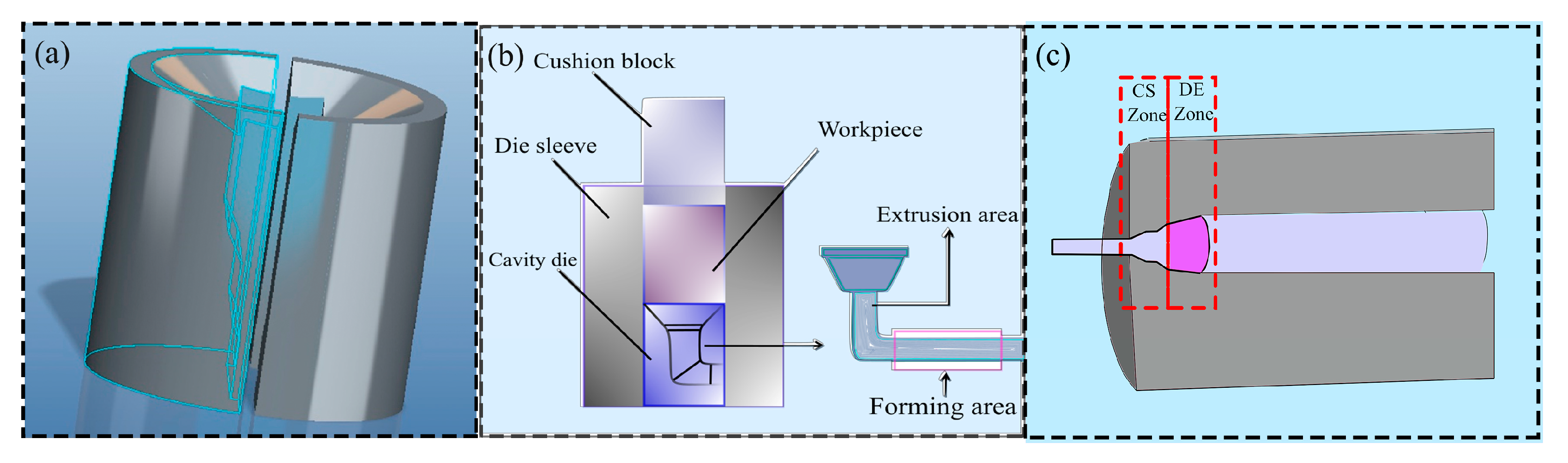

4.2. CSE and Advanced Composite Processing Techniques

4.3. Ultrasonic Vibration–Assisted Shear Deformation

4.4. Shear–Induced Evolution of Microstructural Gradient Architectures

5. Effects of Shear Deformation on Mechanical Properties

5.1. Strength Enhancement Mechanisms Through Grain Refinement and Dislocation Hardening

5.2. Improvement in Ductility and Formability

5.3. Mitigation of Tensile–Compressive Strength Asymmetry

5.4. Summary and Synthesis

6. Defect Evolution and Regulation Under Severe Shear Deformation

6.1. Void Nucleation, Growth, and Closure

6.2. Shear–Specific Crack Initiation and Propagation

6.3. Residual Stress Distribution and Regulation

6.4. Summary and Synthesis

7. Summary and Outlook

7.1. Summary

- (1)

- Shear deformation effectively promotes processes such as CDRX, DDRX, and TDRX. This results in marked refinement of coarse grains to the micron or even sub–micron scale, providing a key route to grain refinement strengthening.

- (2)

- Shear deformation effectively mitigates the undesirable strong basal texture in Mg alloys. Through activating {10–12} tensile twinning and non–basal slip, as well as fostering random orientations in recrystallized grains, it induces a bimodal texture or tilts the basal plane. In turn, this notably diminishes mechanical anisotropy and enhances the material’s formability.

- (3)

- Intense shear strain fragments, refines, and uniformly distributes second–phase particles. This not only enhances strength via dispersion strengthening but also leverages the Zener pinning effect to stabilize the fine–grained structure. Furthermore, these particles serve as nucleation sites for recrystallization, thereby further refining the microstructure.

- (4)

- Shear deformation processes enable the construction of surface–to–core gradient structures or recrystallized/UDRX heterostructures. These engineered microstructures facilitate the simultaneous improvement of strength and ductility via their synergistic actions.

- (5)

- Optimizing thermomechanical processes regulates metallic materials’ internal voids, shear–induced cracks, and residual stress, and these integrated defect control measures facilitate the synchronous enhancement of mechanical properties and service reliability of magnesium alloys via synergistic regulation.

7.2. Outlook

- (1)

- Future research should prioritize investigating shear deformation processes coupled with multiple physical fields, including thermodynamics, mechanics, acoustics, and electromagnetism. Leveraging the synergistic effects of acoustic field–induced texture refinement, thermal field–driven microstructural homogenization, and electric field–enhanced regulation, texture asymmetry and stress concentration during shear processing can be effectively mitigated.

- (2)

- Furthermore, in situ characterization techniques enable real–time tracking of dynamic interactions between dislocations, twinning, and recrystallization during shear deformation. Coupled with multi–scale simulations–including crystal plasticity finite element (CPFE) and phase–field methods–this integrated approach quantitatively uncovers the intrinsic physical mechanisms underlying shear deformation–induced microstructural evolution and performance enhancement, spanning atomic, dislocation, and macroscopic scales.

- (3)

- For novel high–strength–high–ductility and multi–functional Mg alloys, customized shear deformation paths and parameters are critical to tapping their full potential. Notably, precisely controlling the interactions among LPSO phases, NM particles, and the shear strain field facilitates significant performance breakthroughs.

- (4)

- Current research primarily centers on static mechanical properties; future efforts should prioritize investigations into the service performance of shear–processed Mg alloys, including dynamic mechanical properties, fatigue resistance, corrosion resistance, and wear resistance. Efforts should also advance the scaling of processes from laboratory to pilot to industrial demonstration, establish a comprehensive “process–microstructure–properties–service behavior” database and corresponding control criteria, and deliver reliable material solutions for critical high–end equipment components.

- (5)

- The future development of Mg–based high–entropy alloys should center on developing shear deformation processes tailored for multi–principal element systems. By regulating shear parameters, processing inhomogeneity stemming from atomic size mismatch in these alloys can be mitigated, thus further improving the stability of the amorphous phase.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Luo, A.A. Magnesium casting technology for structural applications. J. Magnes. Alloys 2013, 1, 2–22. [Google Scholar] [CrossRef]

- Doty, H.W.; El–Hadad, S.; Samuel, E.; Sumel, A.M.; Samuel, F.H. The Influence of Rare Earth Metals on the Microstructure and Mechanical Properties of 220 and 356.1 Alloys for Automotive Industry. Materials 2025, 18, 941. [Google Scholar] [CrossRef] [PubMed]

- Luo, A.A.; Sachdev, A.K. Applications of magnesium alloys in automotive engineering. In Advances in Wrought Magnesium Alloys; Elsevier: Amsterdam, The Netherlands, 2012; pp. 393–426. [Google Scholar] [CrossRef]

- Frank, C. (Ed.) . Magnesium Alloys—Properties in Solid and Liquid States; InTech Ebooks: Rijeka, Croatia, 2014. [Google Scholar] [CrossRef]

- Jia, L.; Zhang, Z.M.; Xue, Y.; Sun, J.X.; Mao, F.L.; Xu, B.H. The twinning and DRX mechanisms of AZ31 Mg alloy by comparing compressive/shear/compressive–shear deformation. J. Alloys Compd. 2025, 1030, 180736. [Google Scholar] [CrossRef]

- Tian, Y.; Hu, H.J.; Zhao, H.; Zhang, W.; Liang, P.C.; Jiang, B.; Zhang, D.F. extrusion−shear−expanding process for manufacturing AZ31 magnesium alloy tube. Trans. Nonferrous Met. Soc. China 2022, 32, 2569–2577. [Google Scholar] [CrossRef]

- Zhang, K.; Zheng, J.H.; Huang, Y.; Catalin, P.; Jiang, J. Evolution of twinning and shear bands in magnesium alloys during rolling at room and cryogenic temperature. Mater. Des. 2020, 193, 108793. [Google Scholar] [CrossRef]

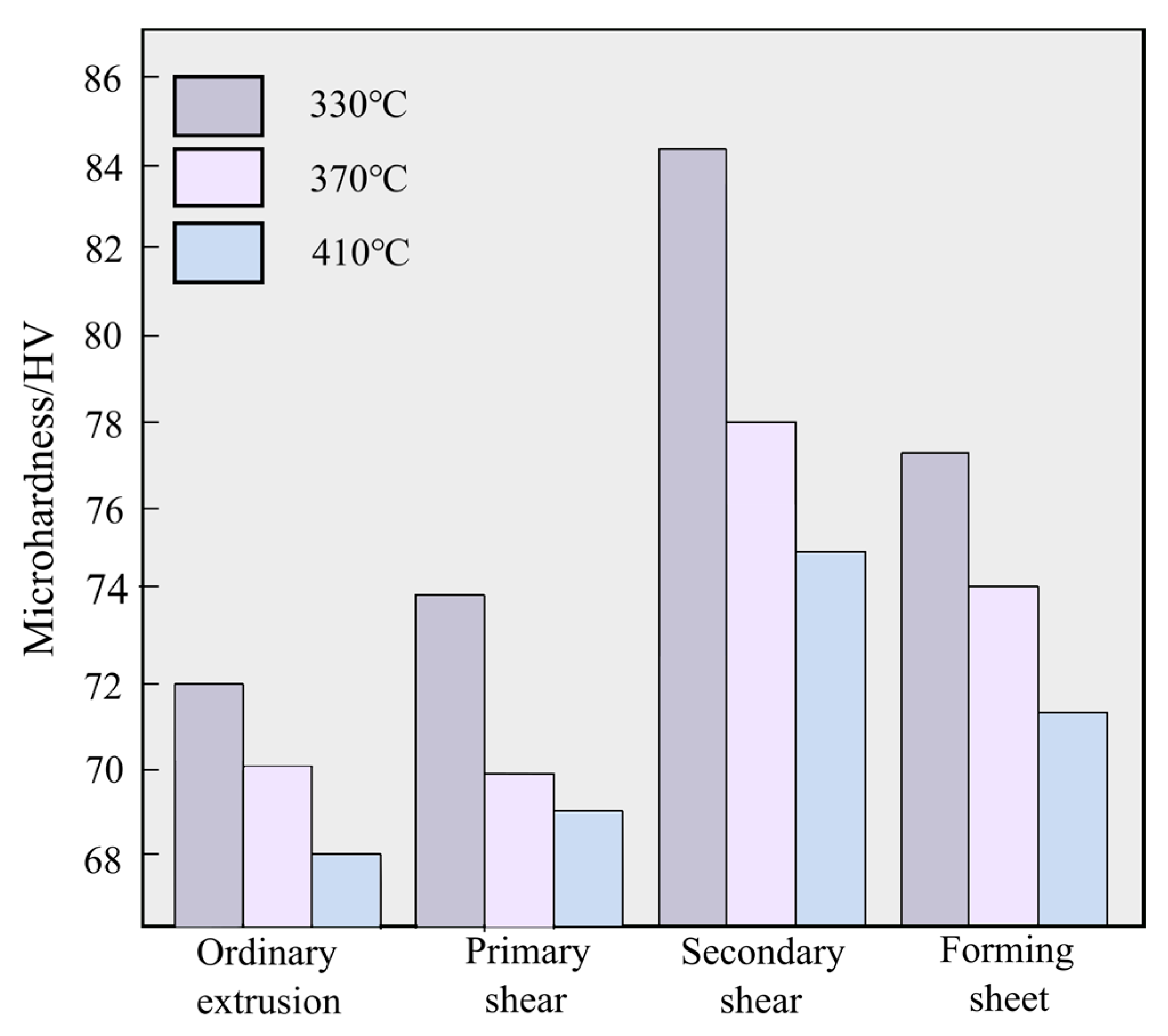

- Yang, Q.S.; Jiang, B.; Pan, H.C.; Jiang, Z.T.; Dai, J.H.; Wang, L.Y.; Pan, F.S. Influence of different extrusion processes on mechanical properties of magnesium alloy. J. Magnes. Alloys 2014, 2, 220–224. [Google Scholar] [CrossRef]

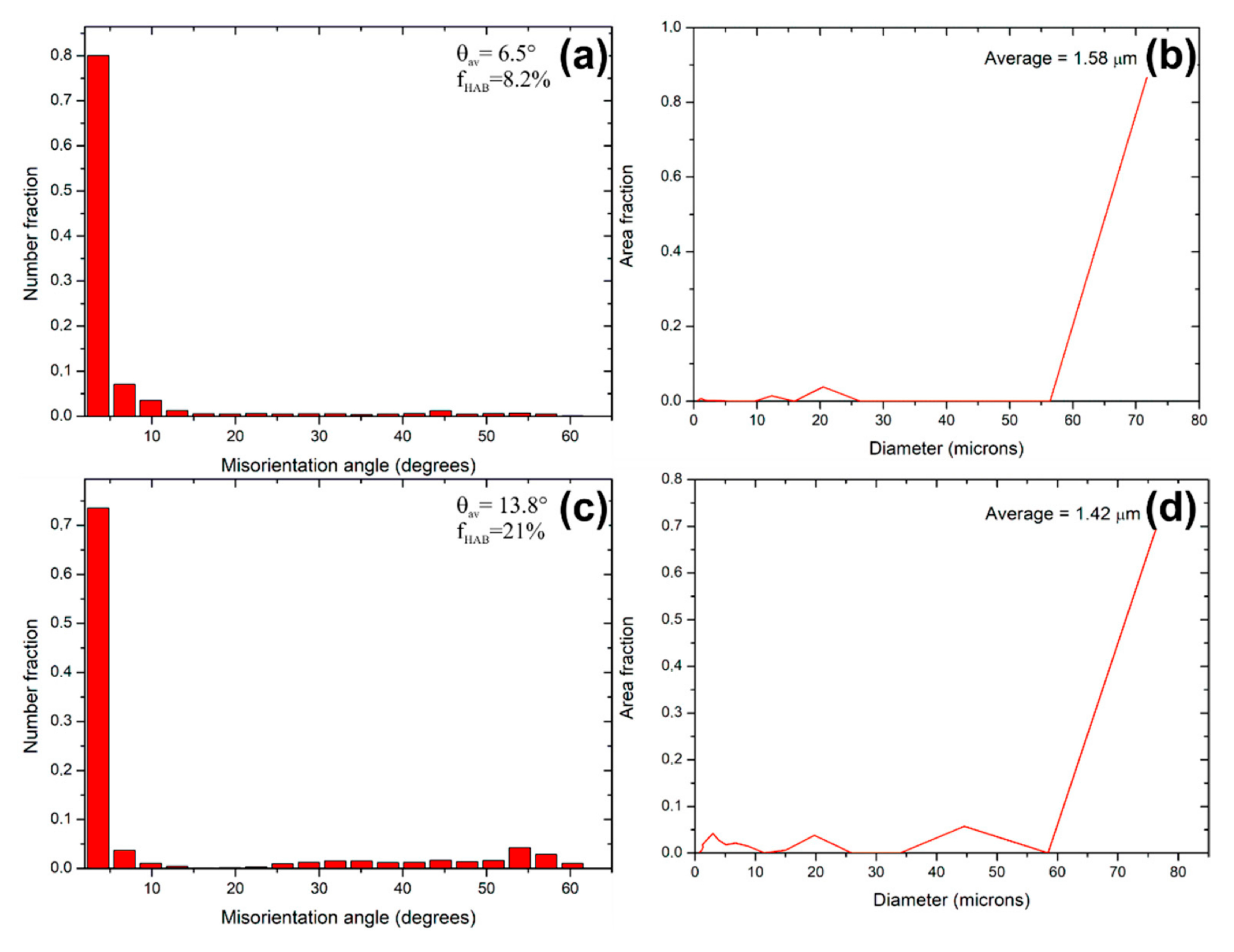

- Li, S.S.; Zhao, X.; Wang, X.D.; Mu, X.M.; Yan, F.F. Understanding the mechanism of bimodal texture evolution and DRX behavior of AZ31 magnesium alloy during shear deformation. J. Alloys Compd. 2024, 1005, 176102. [Google Scholar] [CrossRef]

- Guo, W.R.; Zhou, L.; Mao, P.L.; Wang, Z.; Wang, F.; Wei, Z.Q. Effect of strain on the adiabatic shear behaviour of AZ31 magnesium alloy. Mater. Sci. Technol. 2024, 41, 221–232. [Google Scholar] [CrossRef]

- Yang, M.M.; Yan, Y.L.; Geng, S.N.; Zhang, P.F. Deformation Localization and Crack Propagation in AZ31 Magnesium Alloy. Hot Work. Technol. 2022, 22, 126–129. [Google Scholar] [CrossRef]

- Francis, T.; Hanson, D.S.; Solomon, B.–Y. Susceptibility of adiabatic shear band formation in AZ31B magnesium alloy during high strain rate impact. Int. J. Adv. Manuf. Technol. 2023, 128, 2161–2174. [Google Scholar] [CrossRef]

- Liu, X.Y.; Mao, P.L.; Wu, X.X.; Zhou, L.; Wang, Z.; Liu, Z.; Wang, F. Effect of Grain Size on Adiabatic Shear Sensitivity of AZ31 Magnesium Alloys. J. Mater. Eng. Perform. 2023, 33, 398–409. [Google Scholar] [CrossRef]

- Zhang, Q.H.; Zhang, X.H.; Yang, X.J.; Huang, M. The Strain Heterogeneity and Microstructural Shear Bands in AZ31B Magnesium Alloy. Appl. Sci. 2025, 15, 1571. [Google Scholar] [CrossRef]

- Malik, A.; Nazeer, F.; Naqvi, S.Z.H.; Long, J.Y.; Li, C.; Yang, Z.; Huang, Y.W. Microstructure feathers and ASB susceptibility under dynamic compression and its correlation with the ballistic impact of Mg alloys. J. Mater. Res. Technol. 2021, 16, 801–813. [Google Scholar] [CrossRef]

- Feng, X.Y.; Wang, L.F.; Chen, X.; Deng, K.K.; Wang, X.; Deng, L.W.; Wang, H.X.; Quan, H.; Xing, B.; Shin, K.S. Recent plastic technologies development of basal texture control to improve the property of wrought Mg Alloys—A review. J. Mater. Res. Technol. 2024, 34, 1165–1190. [Google Scholar] [CrossRef]

- Yuqing, E.; Mao, P.L.; Liu, X.Y.; Wu, X.X.; Wang, F.; Wang, Z.; Zhou, L.; Liu, Z. Adiabatic shear behaviour of AZ31 alloy with different grain size under high–strain–rate. Mater. Sci. Technol. 2022, 38, 1070–1080. [Google Scholar] [CrossRef]

- Karantza, K.D.; Manolakos, D.E. A Review on the Adiabatic Shear Banding Mechanism in Metals and Alloys Considering Microstructural Characteristics, Morphology and Fracture. Metals 2023, 13, 1988. [Google Scholar] [CrossRef]

- Che, B.; Lu, L.W.; Xiang, Y.; Ma, M.; Luo, J. Grain Refinement Mechanism of AZ31 Magnesium Alloy by Expansion–Continuous Shear Deformation. Chin. J. Nonferrous Met. 2021, 12, 49–61. [Google Scholar]

- Mo, Y.; Jiang, F.L.; Xu, H.; Tang, J.; Fu, D.F.; Zhang, H.; Teng, J. Deformation mechanisms and microstructural characteristics of AZ61 magnesium alloys processed by a continuous expansion extrusion approach. J. Magnes. Alloys 2022, 12, 2826–2846. [Google Scholar] [CrossRef]

- Xie, W.Z.; Wang, W.K.; Kang, T.T.; Zhang, W.X.; Liu, H.; Wang, S.H.; Liu, Y.X.; Chen, W.Z.; Zhang, W.C.; Zhou, S.J. Significant improvement of bending properties for WE43 magnesium alloys under the coupling effects of weak basal texture and high deformation temperature. J. Mater. Res. Technol. 2024, 29, 4702–4713. [Google Scholar] [CrossRef]

- Zheng, T.X.; Hu, Y.B.; Zhang, C.; Zhao, T.S.; Jiang, B.; Pan, F.S.; Tian, A.T. Uncovering of the formation of rare earth texture and pseudo fiber bimodal microstructure in the high ductility Mg–2Gd–0.4Zr alloy during extrusion. J. Mater. Sci. Technol. 2024, 172, 166–184. [Google Scholar] [CrossRef]

- Karami, M.; Mahmudi, R. Work hardening behavior of the extruded and equal–channel angularly pressed Mg–Li–Zn alloys under tensile and shear deformation modes. Mater. Sci. Eng. A–Struct. Mater. Prop. Microstruct. Process. 2021, 607, 512–520. [Google Scholar] [CrossRef]

- Li, Y.; Hou, P.J.; Wu, Z.G.; Feng, Z.L.; Ren, Y.; Choo, H. Dynamic recrystallization of a wrought magnesium alloy: Grain size and texture maps and their application for mechanical behavior predictions. Mater. Des. 2021, 202, 109562. [Google Scholar] [CrossRef]

- Guo, F.; Jiang, L.Y.; Ma, Y.L.; Liu, L.; Zhang, Z.; Yang, M.B.; Zhang, D.F.; Fan, F.S. Strengthening a dual–phase Mg–Li alloy by strain–induced phase transformation at room temperature. Scr. Mater. 2020, 179, 16–19. [Google Scholar] [CrossRef]

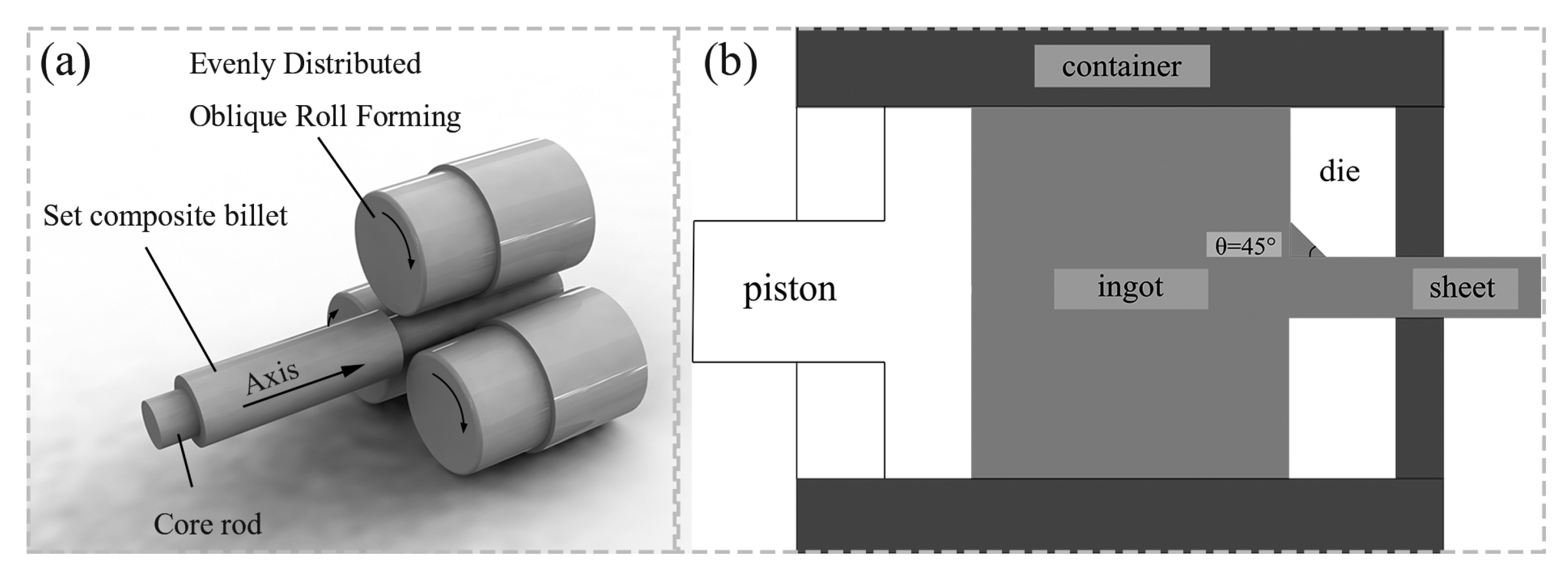

- Zhang, W.; Zeng, C.W.; Zhao, H.; Hu, H.J.; Zhang, D.F.; Hong, R.; Yuan, T.; Sun, Z.W.; Peng, W. Achieved strength–ductility simultaneous enhancement of AZ31 magnesium alloy square tube through a novel tube continuous expanding shear extrusion processing. J. Magnes. Alloys 2024, 13, 2390–2415. [Google Scholar] [CrossRef]

- Guo, J.T.; Guo, S.L.; Shen, Y.Z.; Li, D.F. Hot Deformation Behavior and Microstructural Evolution Based on the Processing Map of Dual–Phase Mg–Li Based Alloy. Materials 2022, 15, 1022. [Google Scholar] [CrossRef]

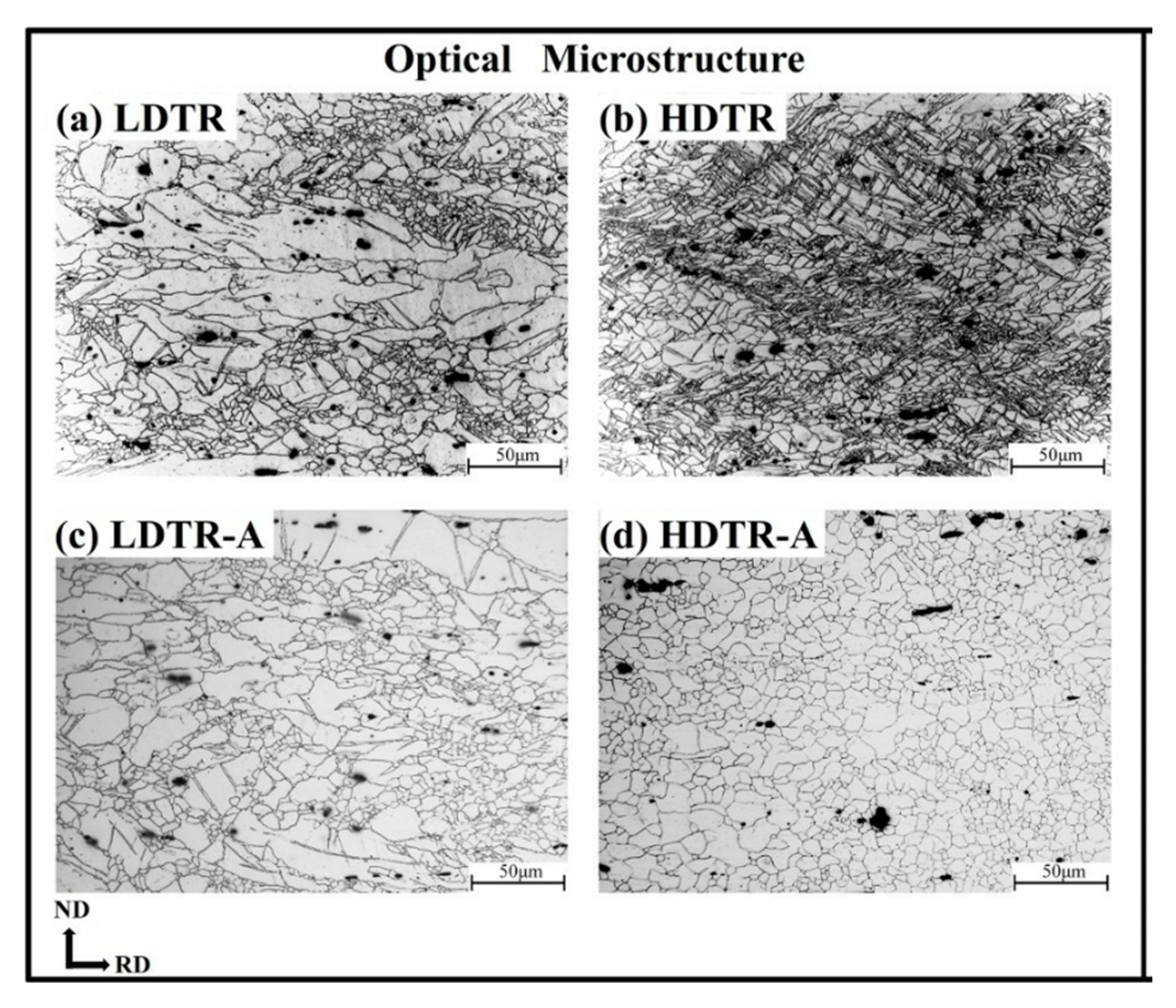

- Zhang, X.; Xu, Y.; Li, W.; Yan, Z.; Hu, P.; Liu, X. Microstructure Characterization and Mechanical Properties of an AM60B Magnesium Alloy Sheet Prepared by the Double–Pass High Strain Rate Rolling with Gradient Cooling. Adv. Eng. Mater. 2020, 23, 2000625. [Google Scholar] [CrossRef]

- Liu, Z.; Zheng, J.; Zhang, Z.M.; Xue, Y. High elongation heterostructure rare earth magnesium alloy based on rotating backward extrusion process. J. Mater. Res. Technol. 2024, 30, 6108–6122. [Google Scholar] [CrossRef]

- Fan, Y.T.; Lu, L.W.; Liu, J.B.; Ma, M.; Huang, W.Y.; Wu, R.Z. Effect of deformation temperature on microstructure and texture of AZ31 magnesium alloy processed by new plastic deformation method. Trans. Nonferrous Met. Soc. China 2024, 34, 2138–2152. [Google Scholar] [CrossRef]

- Yue, Y.; Wang, J.; Nie, J.F. Twin–solute, twin–dislocation and twin–twin interactions in magnesium. J. Magnes. Alloys 2023, 11, 3427–3462. [Google Scholar] [CrossRef]

- Zhang, S.Z.; Hu, L.; Ruan, Y.T.; Zhou, T.; Chhen, Q.; Zhou, Y.; Shi, L.X.; Li, M.A.; Yang, M.B.; Jiang, S.Y. Influence of bimodal non–basal texture on microstructure characteristics, texture evolution and deformation mechanisms of AZ31 magnesium alloy sheet rolled at liquid–nitrogen temperature. J. Magnes. Alloys 2022, 11, 2600–2609. [Google Scholar] [CrossRef]

- Sahoo, S.K.; Toth, L.S.; Biswas, S. An analytical model to predict strain–hardening behaviour and twin volume fraction in a profoundly twinning magnesium alloy. Int. J. Plast. 2019, 119, 273–290. [Google Scholar] [CrossRef]

- He, J.J.; Wu, L.S. Deformation Microstructure Evolution Mechanism of Extruded AZ31 Magnesium Alloy. Trans. Mater. Heat Treat. 2017, 38, 47–53. [Google Scholar] [CrossRef]

- Chen, H.C.; Shao, C.W.; Wang, L.J.; Chen, H.; Zou, Y. A quasi–in–situ EBSD study on mechanical response and twin variant selection of a hot–rolled AZ31 magnesium alloy. J. Magnes. Alloys 2025, 13, 1549–1560. [Google Scholar] [CrossRef]

- Fakhar, N.; Sabbaghian, M. Hot shear deformation constitutive analysis of fine–grained ZK60 Mg alloy sheet fabricated via dual equal channel lateral extrusion and sheet extrusion. Trans. Nonferrous Met. Soc. China 2022, 32, 2541–2556. [Google Scholar] [CrossRef]

- Zhou, B.X.; Wang, Z.L.; Zheng, H.; Jiang, M.X.; Li, A.; Huang, H.; Zeng, H.; Wang, D.L.; Yuan, G.Y. Microstructure and mechanical properties of Mg–Nd–Zn–Zr alloy rod prepared by eccentric extrusion. J. Alloys Compd. 2025, 1036, 181651. [Google Scholar] [CrossRef]

- Sharma, P.; Gandhi, P.M.; Chintersingh, K.L.; Schoenitz, M.; Dreizin, E.L.; Liou, S.C.; Balasubramanian, G. Accelerated intermetallic phase amorphization in a Mg–based high–entropy alloy powder. J. Magnes. Alloys 2024, 12, 1792–1798. [Google Scholar] [CrossRef]

- Zheng, Y.Q.; Zhang, Y.; Liu, Y.; Tian, Y.Q.; Zheng, X.P.; Chen, L.S. Research Progress on Microstructure Evolution and Strengthening–Toughening Mechanism of Mg Alloys by Extrusion. Materials 2023, 16, 3791. [Google Scholar] [CrossRef]

- Catorceno, L.L.C.; Abreu, H.F.G.; Padilha, A.F. Effects of cold and warm cross–rolling on microstructure and texture evolution of AZ31B magnesium alloy sheet. J. Magnes. Alloys 2018, 6, 121–133. [Google Scholar] [CrossRef]

- Wu, G.Q.; Yu, J.M.; Jia, L.C.; Xu, W.L.; Dong, B.B.; Zhang, Z.M.; Hao, B.Y. Microstructure and Texture Evolution of Mg–Gd–Y–Zr Alloy during Reciprocating Upsetting–Extrusion. Materials 2020, 13, 4932. [Google Scholar] [CrossRef]

- Zhang, D.F.; Liu, J.H.; Hu, H.J. Microstructure and Texture Evolution of AZ31 Magnesium Alloy Processed by Extrusion–Shear Deformation. J. Mater. Eng. 2010, 7, 28–32. [Google Scholar]

- Sun, D.C.; Chen, S.F.; Song, G.S.; Zhang, S.H.; Song, H.W. Research Progress on Shear–Induced Texture Weakening and Performance Enhancement of Magnesium Alloy Thin Sheets. Rare Met. Mater. Eng. 2024, 53, 882–893. [Google Scholar]

- Wu, Z.H.; Gu, W.Q.; Yu, Y.F.; Lian, Y.; Li, Y. Factors Influencing and Improvement Measures for the Room Temperature Formability of Magnesium Alloy Sheets. Hot Work. Technol. 2015, 17, 14–17. [Google Scholar] [CrossRef]

- Li, L.; Hu, X. Enhancing the Stampability of Automotive Magnesium Alloy Sheets through Texture Weakening. Hot Work. Technol. 2017, 21, 113–115. [Google Scholar] [CrossRef]

- Wu, Y.Z.; Deng, B.; Ye, T.; Nie, Z.C.; Liu, X. Fabrication of Strong and Ductile AZ31 Magnesium Alloy Using High Strain Rate Multiple Forging in a Wide Temperature Range. Metals 2020, 10, 729. [Google Scholar] [CrossRef]

- Kumar, S.; Panchal, M.; Gandi, A.N.; Kaushik, L.; Choi, S.H.; Singh, J. Investigation of tensile twinning on texture and microstructure evolution of Mg–3Al–1Zn–1Ca alloy under in–plane shear deformation. J. Magnes. Alloys 2025, 13, 1815–1828. [Google Scholar] [CrossRef]

- Fan, J.J.; Lv, H.H.; Zhang, Y.G.; Liang, W. On the Anisotropy of Mechanical Properties in AZ31 Magnesium Alloy Sheet with a Bimodal Texture. J. Precis. Form. Eng. 2023, 8, 16–24. [Google Scholar]

- Li, P.Y.; Wang, G.X.; Ye, L.; Guan, S.K.; Wang, J.F. Bimodal grain structure and balanced mechanical properties of cryo–rolled Mg–Zn–Y alloy via twinning–induced recrystallization. Mater. Lett. 2024, 369, 136756. [Google Scholar] [CrossRef]

- Lu, P.B.; Wang, L.F.; Pan, X.H.; Huang, G.S.; Zhang, Q.; Zhang, H.; Zheng, L.W.; Lu, L.W.; Wang, H.X.; Jiang, S.Y.; et al. Unveiling the ductility enhancement mechanisms in AZ31 magnesium alloy achieved via shear strain–assisted twin orientation regulation. J. Alloys Compd. 2023, 948, 169698. [Google Scholar] [CrossRef]

- Liu, Y.F.; Lu, D.L.; Wu, G.Q.; Zhang, Z.M.; Huang, H.G.; Li, L.L.; Feng, Y.; Yu, J.M. Deformation mechanism and hardening behavior of gradient heterostructured magnesium alloys prepared by severe shear deformation. J. Alloys Compd. 2024, 985, 174099. [Google Scholar] [CrossRef]

- Wu, B.L. Research Overview of Crystal Orientation and Deformation Behavior Mechanisms in Magnesium Alloys. J. Shenyang Aerosp. Univ. 2015, 6, 3–29. [Google Scholar]

- Liu, Y.J.; Zhang, H.Z.; He, Y.P.; Dong, Z.M.; Jiang, H.L.; Shen, Z.H. A Study of Microstructure Evolution for Mg Alloy Subjecting to Multi–Pass Equal Channel Angular Extrusion. Trans. Indian Inst. Met. 2023, 76, 165–173. [Google Scholar] [CrossRef]

- Zha, M.; Wang, C.X.; Jin, Z.Z.; Jia, H.L.; Xu, H.; Zhang, P.Y.; Huang, Y.; Ma, P.K.; Wang, H.Y. Tailoring Mechanical Properties of Mg–Al–Zn–Sn–Mn Alloy by Multipass Equal Channel Angular Pressing. Adv. Eng. Mater. 2020, 23, 2000790. [Google Scholar] [CrossRef]

- Xu, J.H.; Gong, X.Y.; Zhao, W.Y.; Sun, S.; Shan, G.B.; Liu, H.; Song, D. Achieving Superplasticity in Ultrafine–Grained Mg–9Li Alloy via Dual–Phase Microstructure Optimization. Metals 2025, 15, 533. [Google Scholar] [CrossRef]

- Mueller, K.; Mueller, S. Severe plastic deformation of the magnesium alloy AZ31. J. Mater. Process. Technol. 2007, 187, 775–779. [Google Scholar] [CrossRef]

- Luo, P.; Xia, J.C.; Hu, Q.D.; Wang, X.Y. Study on the Fabrication of Ultrafine–Grained Cast Magnesium Alloy via Equal–Channel Angular Pressing (ECAP). Rare Met. Mater. Eng. 2005, 9, 152–155. [Google Scholar]

- Huang, H.; Liu, H.; Wang, C.; Sun, J.P.; Bai, J.; Xue, F.; Jiang, J.H.; Ma, A.B. Potential of multi–pass ECAP on improving the mechanical properties of a high–calcium–content Mg–Al–Ca–Mn alloy. J. Magnes. Alloys 2019, 7, 617–627. [Google Scholar] [CrossRef]

- Zhang, W.; Hu, H.J.; Gan, S.L.; Zhao, H.; Sun, Z.W.; Yuan, T.; Li, Y.; Ou, Z.W. Microstructural characterization and mechanical behavior of Mg–AZ31B/Al 6063 bimetallic sheets produced by combining continuous shear deformation with direct extrusion. Mater. Today Commun. 2023, 37, 107164. [Google Scholar] [CrossRef]

- He, J.Z.; Wang, L.F.; Wu, H.H.; Li, Y.Q.; Xia, Y.Q.; Xia, D.B.; Wang, H.X.; Zhou, X.Y.; Zhang, Q.; Yang, Q.S.; et al. A novel continues multi–shear extrusion process on the microstructure and mechanical property evolution of AZ31 magnesium alloys. J. Mater. Res. Technol.–JmrT 2023, 28, 176–198. [Google Scholar] [CrossRef]

- Gan, S.L.; Hu, H.G.; Zhang, H.L.; Yuan, T.; Zeng, C.W. Numerical and Experimental Investigation of AZ31 Magnesium Alloy Sheet Formed by Continuous Extrusion–Shear. Chin. J. Nonferrous Met. 2021, 12, 89–100. [Google Scholar]

- Piao, N.Y.; Shi, F.J.; Zhang, W.B.; Zou, N.K.; Yang, F.; Wang, J.H.; Guo, Y.H.; Lu, S.; Wang, L.G. Unveiling the microstructure evolution and deformation mechanisms of micro–alloying Mg–1.5Zn–0.5Zr–0.5Sr alloy via extrusion–shearing. J. Mater. Res. Technol. 2024, 29, 213–224. [Google Scholar] [CrossRef]

- Snopiński, P.; Donič, T.; Tański, T.; Matus, K.; Hadzima, B.; Bastovansky, R. Ultrasound Effect on the Microstructure and Hardness of AlMg3 Alloy under Upsetting. Materials 2021, 14, 1010. [Google Scholar] [CrossRef]

- Su, C.J.; Xu, T.T.; Zhang, K.; Luo, S.M.; Wang, Q. Plastic deformation of magnesium alloy with different forming parameters during ultrasonic vibration–assisted single–point incremental forming. Rare Met. 2018, 41, 3878–3886. [Google Scholar] [CrossRef]

- Ma, Y.J.; Ding, Y.T.; Gao, Y.B.; Chen, J.J.; Wang, X.M. Gradient Nanotwinned Structure and Its Formation Mechanism in Inconel 625 Alloy Produced by Surface Mechanical Grinding Treatment. Met. Mater. Int. 2022, 29, 1454–1468. [Google Scholar] [CrossRef]

- Chang, L.L.; Wang, Y.N.; Zhao, X. Modeling of severe deformation and mechanical properties in Mg–3Al–1Zn alloy through asymmetric hot–extrusion. Trans. Nonferrous Met. Soc. China 2008, 18, S257–S262. [Google Scholar] [CrossRef]

- Wang, B.N.; Wang, F.; Wang, Z.; Liu, Z.; Mao, P.L. Fabrication of fine–grained, high strength and toughness Mg alloy by extrusion–shearing process. Trans. Nonferrous Met. Soc. China 2021, 31, 666–678. [Google Scholar] [CrossRef]

- Zhang, W.; Peng, W.; Hu, H.G.; Sun, Z.W.; Zeng, C.W.; Yuan, T.; Ou, Z.W. Deformation behaviour, microstructure evolution and dynamic recrystallization mechanism of AZ31 magnesium alloy under co–extruded by Mg–Al composite billet. Mater. Today Commun. 2023, 37, 107435. [Google Scholar] [CrossRef]

- Luan, S.Y.; Chen, L.J.; Zhang, L.; Xue, Y.J.; Wang, J.H.; Jin, P.P. The strength contribution via heterostructure in a mg–Gd–Zn–Mn alloy. Mater. Charact. 2024, 214, 114119. [Google Scholar] [CrossRef]

- Wang, C.Z.; Liu, Z.; Cai, Z.H. AZ31 magnesium alloy sheet with high ductility and low anisotropy achieved by a novel asymmetrical angular rolling process. J. Magnes. Alloys 2025, 9, 25. [Google Scholar] [CrossRef]

- Peng, R.Z.; Xu, C.; Li, Y.; Zhong, S.X.; Cao, X.; Ding, Y.F. Multiple–twinning induced recrystallization and texture optimization in a differential–temperature–rolled AZ31B magnesium alloy with excellent ductility. Mater. Res. Lett. 2022, 10, 318–326. [Google Scholar] [CrossRef]

- Li, L.H.; Liu, W.H.; Qi, F.G.; Wu, D.; Zhang, Z.Q. Effects of deformation twins on microstructure evolution, mechanical properties and corrosion behaviors in magnesium alloys—A review. J. Magnes. Nd Alloys 2022, 10, 2334–2353. [Google Scholar] [CrossRef]

- Yang, Q.S.; Jiang, B.; Song, B.; Yu, D.L.; Chai, S.S.; Zhang, J.Y.; Pan, F.S. Mechanical behavior and microstructure evolution for extruded AZ31 sheet under side direction strain. Prog. Nat. Sci. Mater. Int. 2020, 30, 270–277. [Google Scholar] [CrossRef]

- Lim, S.S.; Hong, J.P.; Kim, M.; Park, Y.C.; Lee, S.M.; Cho, D.Y.; Cho, C.H. Study on Rolling Defects of Al–Mg Alloys with High Mg Content in Normal Rolling and Cross–Rolling Processes. Materials 2023, 16, 6260. [Google Scholar] [CrossRef]

- Emil, C.; Calin, D.M.; Bjørn, H.; Odd, S.H.; Randi, H. Nano–scale characterisation of sheared β” precipitates in a deformed Al–Mg–Si alloy. Sci. Rep. 2019, 9, 17446. [Google Scholar]

- Huang, X.T.; Chen, Y.P.; Wang, J.J.; Lu, G.; Wang, W.X.; Yao, Z.; Zhao, S.X.; Liu, Y.J.; Li, Q. High–resolution reconstruction–based investigation of multi–scale lamellar microstructures by coupled crystal plasticity and in–situ experiment. Scr. Mater. 2023, 241, 115896. [Google Scholar] [CrossRef]

- Zeng, X.; Yi, S.B.; Cristea, D. Deformation Mechanisms of Magnesium Alloys with Rare–Earth and Zinc Additions under Plane Strain Compression. Materials 2023, 17, 33. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Kochmann Dennis, M. Atomistic insight into three–dimensional twin embryo growth in Mg alloys. J. Mater. Sci. 2023, 58, 3972–3995. [Google Scholar] [CrossRef]

- Zhou, J.X.; Luo, X.J.; Yang, H.; Gao, Y.Y.; Xie, W.L.; Dong, Z.H.; Jiang, B.; Pan, F.S. Interfacial segregation enables exceptional high–temperature thermal stability in magnesium alloy. Vacuum 2025, 238, 114311. [Google Scholar] [CrossRef]

| (MPa) | (MPa) | |||||||

| Mode | AR Type | Pt | AR–SA Type | 3PT–SA Type | AR Type | Pt | AR–SA Type | 3PT–SA Type |

| plinth | 45 | 21 | 58 | 52 | 0 | 0 | 0 | 0 |

| prism | 110 | 70 | 128 | 130 | 43 | 30 | 30 | 50 |

| pyramid | 170 | 190 | 170 | 170 | 85 | 85 | 85 | 85 |

| {1012} twin | 28 | 19 | 75 | 65 | 0 | 0 | 0 | 0 |

| {1011} twin | 250 | 250 | 250 | 250 | 20 | 20 | 20 | 20 |

| (MPa) | (MPa) | |||||||

| Mode | AR Type | Pt | AR–SA Type | 3PT–SA Type | AR Type | Pt | AR–SA Type | 3PT–SA Type |

| plinth | 220 | 220 | 220 | 180 | 140 | 140 | 140 | 140 |

| prism | 500 | 0 | 217 | 80 | 0 | 1700 | 20 | 40 |

| pyramid | 550 | 550 | 220 | 550 | 100 | 100 | 100 | 100 |

| {1012} twin | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| {1011} twin | 300 | 300 | 300 | 300 | 10 | 10 | 10 | 10 |

| SPD Technique | Types | Processing Parameters | Mechanical Properties | Grain Size/μm | Texture Intensity | ||||

|---|---|---|---|---|---|---|---|---|---|

| Extrusion Speed | Extrusion Temperatures | YS/MPa | UST/MPa | EL/% | Before | After | |||

| ECAP | Mg–3.7Al–0.7Zn–0.8Sn–0.4Mn | 225 | 312 | 31.9 | |||||

| Mg–9Li | – | 373 K | 23.6 | 14.3 | 98.4 | 0.36 | – | – | |

| AZ31 | 370 °C | – | 250 | 9.4 | 4 | 5.06 | 1.92 | ||

| CES | AZ31 | 0.1 mm/s | 340 °C | 225.2 | 305.8 | 20.17 | 16.12 | 25.77 | 10.7 |

| ES | Mg–1.5Zn–0.5Zr–0.5Sr | 2 mm/s | 200 °C | 206 | 254 | 21.4 | 2.63 | 48.5 | 6.3 |

| DECS | Mg–AZ31B/Al6030 | 3 mm/s | 330 °C | – | 251.4 | 23.5% | 5.09 | – | 16.97 |

| Process | Key Advantages | Key Limitations/Challenges | Scalability & Industrial Potential |

|---|---|---|---|

| ECAP |

|

| Primarily a laboratory–scale tool for fundamental research and high–value, small components. Continuous variants (like Conform–ECAP) are emerging but not yet mature for Mg alloys. |

| CES& Derivatives (ES, DE–CS) |

|

| Shows the greatest immediate potential for scaling to industrial production of extruded Mg profiles and sheets, particularly for automotive applications. |

| Ultrasonic Vibration–Assisted Shearing |

|

| Highly promising for niche, high–precision forming operations (e.g., micro–forming, incremental forming) rather than bulk material production. |

| TRSR & Asymmetric Shearing |

|

| TRSR is already an industrial process for steels and Ti alloys; adaptation for Mg alloys is feasible for sheet and plate production. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Xue, Y.; Yan, Z. Advances in Microstructural Evolution and Mechanical Properties of Magnesium Alloys Under Shear Deformation. Metals 2025, 15, 1304. https://doi.org/10.3390/met15121304

Liu Y, Xue Y, Yan Z. Advances in Microstructural Evolution and Mechanical Properties of Magnesium Alloys Under Shear Deformation. Metals. 2025; 15(12):1304. https://doi.org/10.3390/met15121304

Chicago/Turabian StyleLiu, Yaqing, Yong Xue, and Zhaoming Yan. 2025. "Advances in Microstructural Evolution and Mechanical Properties of Magnesium Alloys Under Shear Deformation" Metals 15, no. 12: 1304. https://doi.org/10.3390/met15121304

APA StyleLiu, Y., Xue, Y., & Yan, Z. (2025). Advances in Microstructural Evolution and Mechanical Properties of Magnesium Alloys Under Shear Deformation. Metals, 15(12), 1304. https://doi.org/10.3390/met15121304