Enhancing Automotive Valve Guide Tribomechanical Performance Through Alloy Optimization in Powder Metallurgy

Abstract

1. Introduction

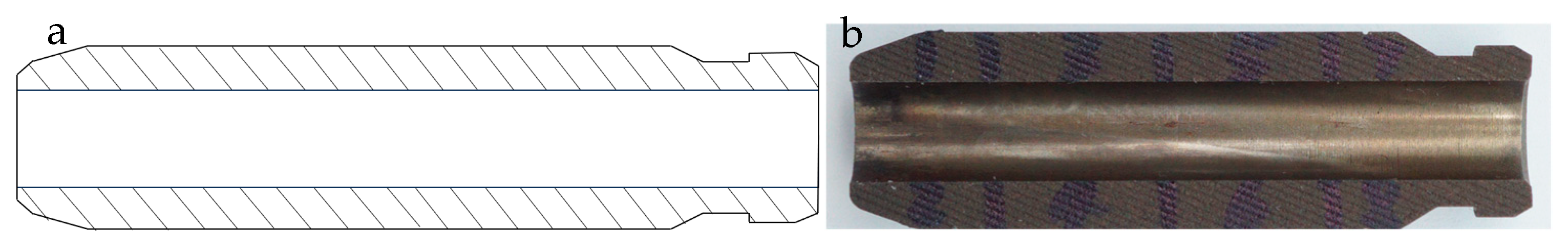

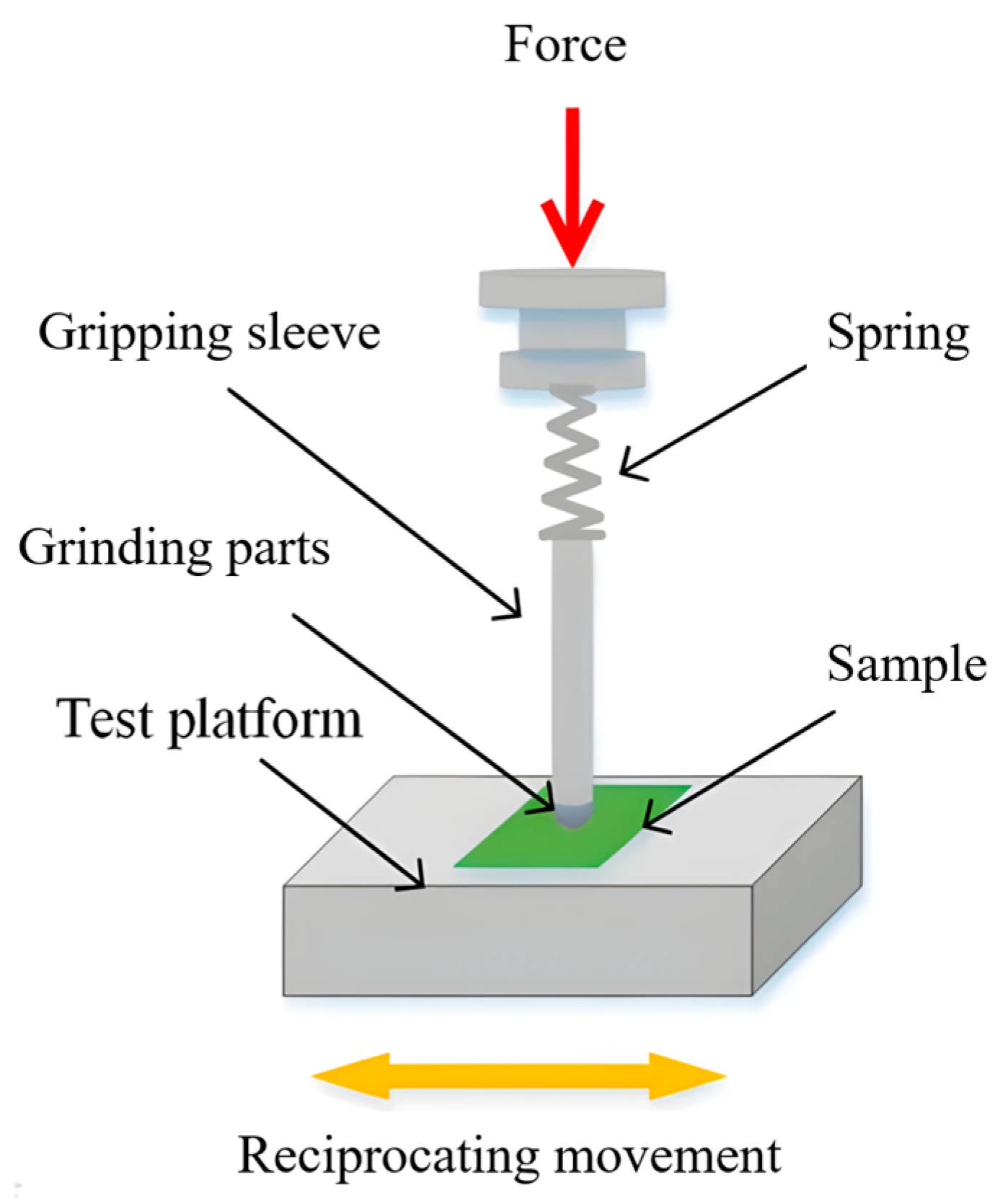

2. Materials and Methods

3. Results

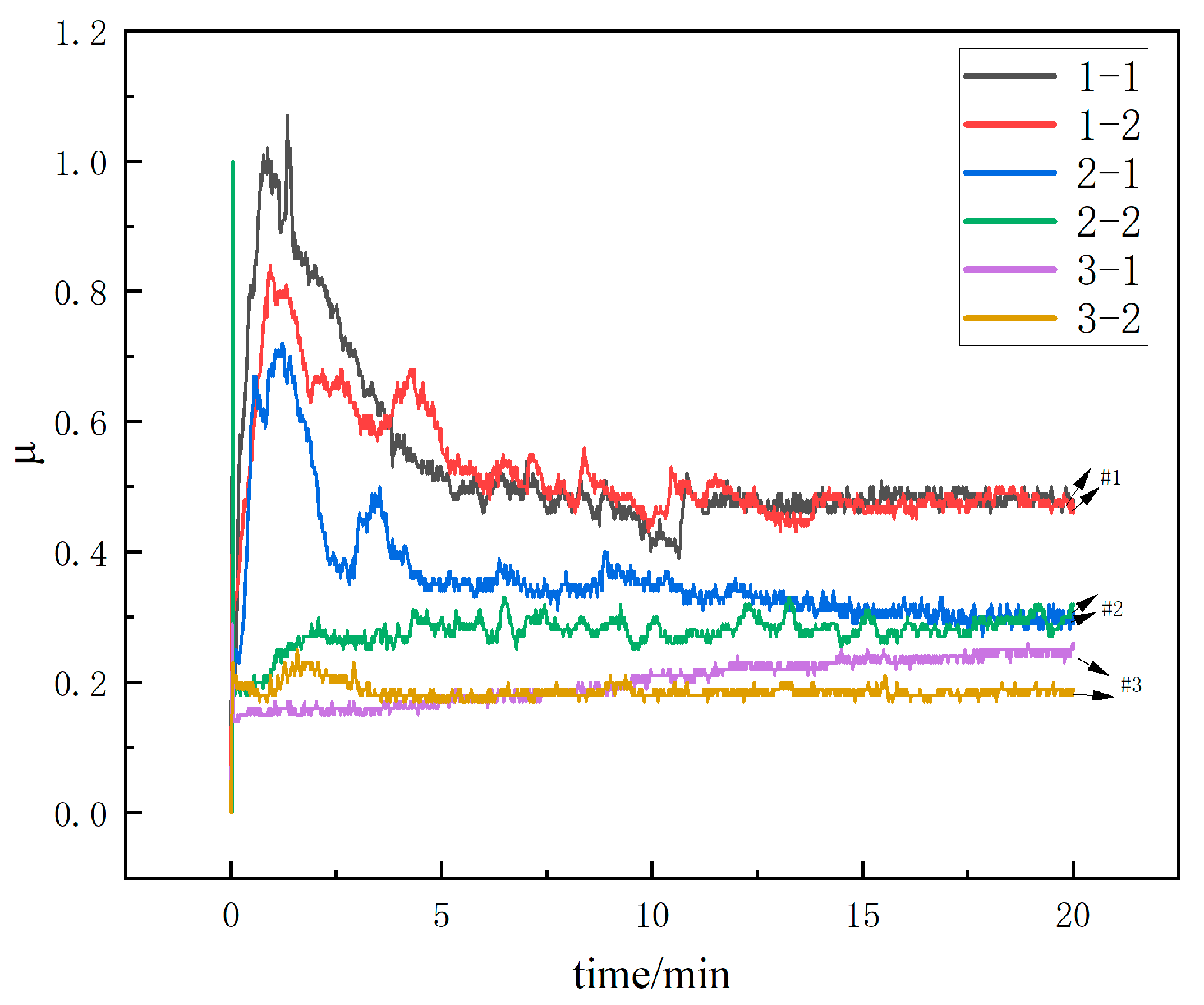

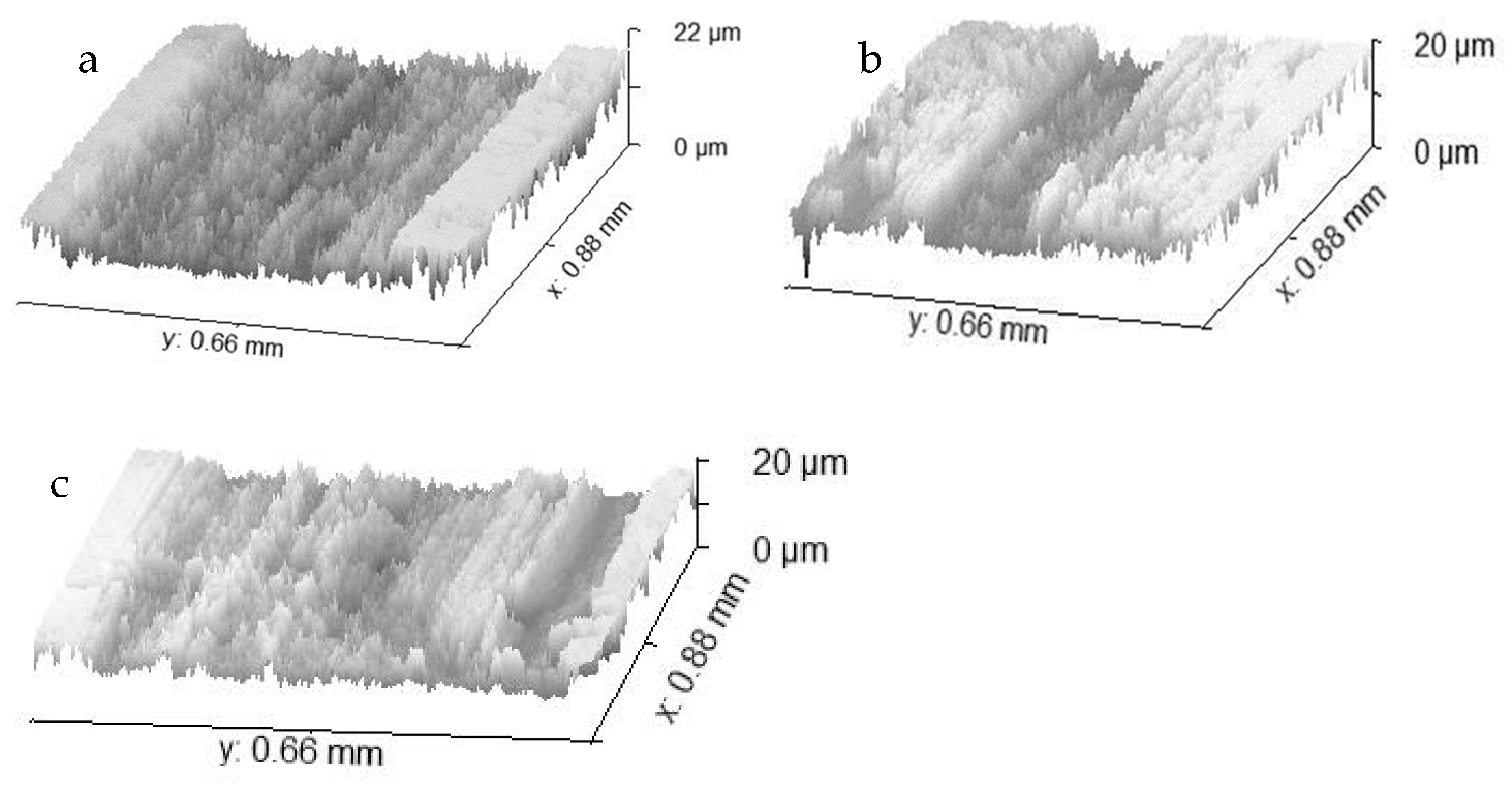

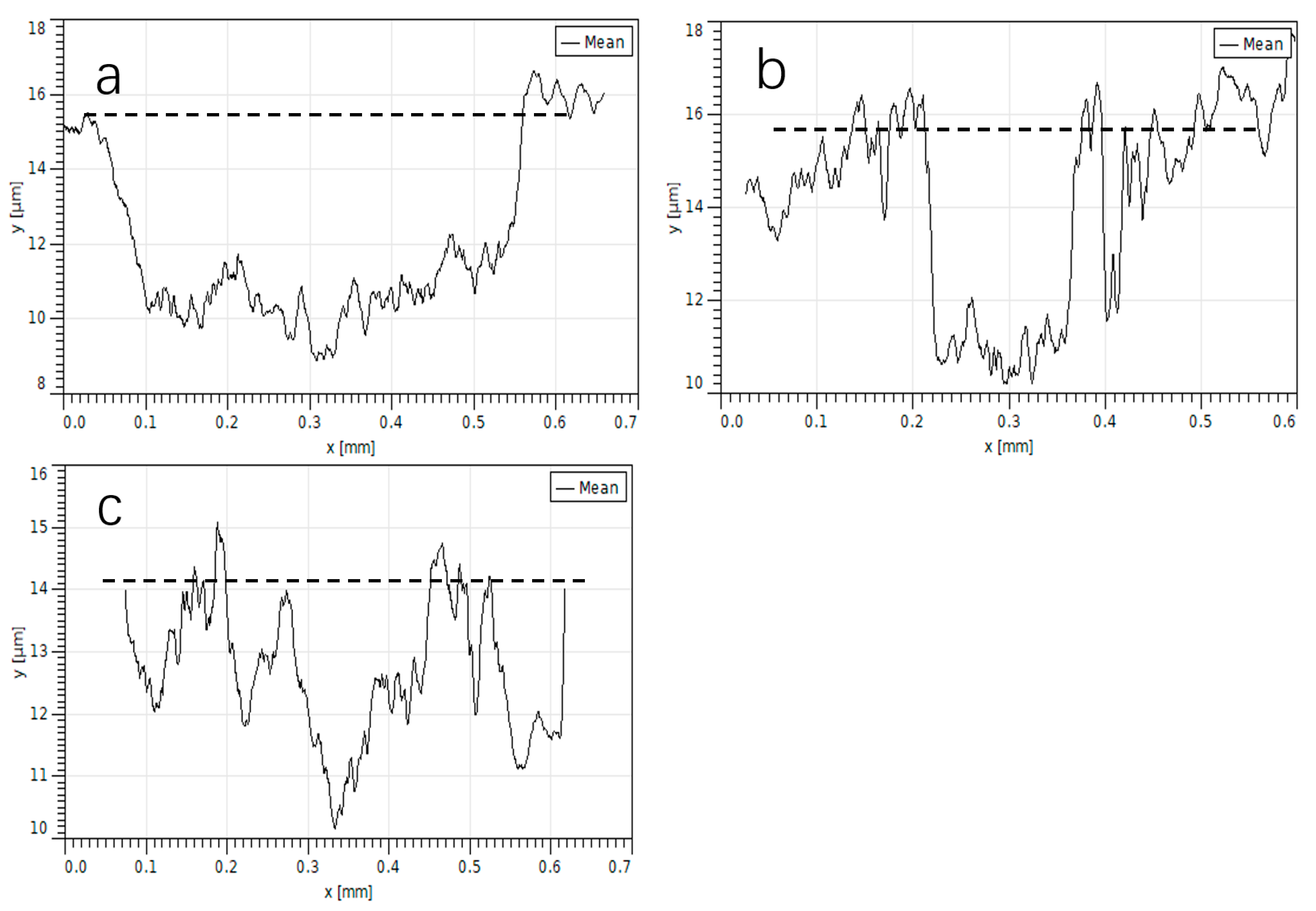

3.1. Tribological Performance and Dominant Wear Mechanisms

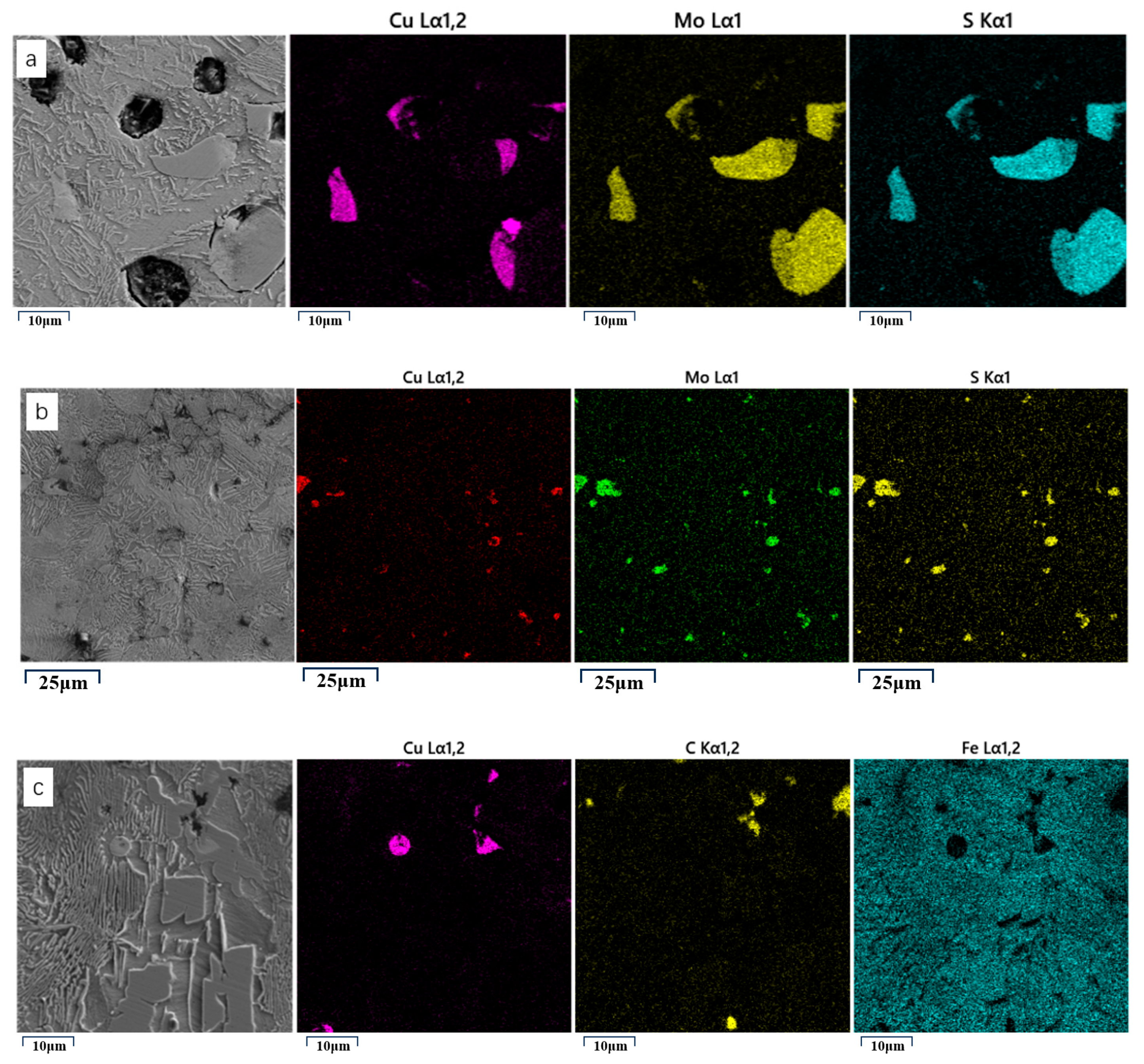

3.2. Spectroscopy Analysis

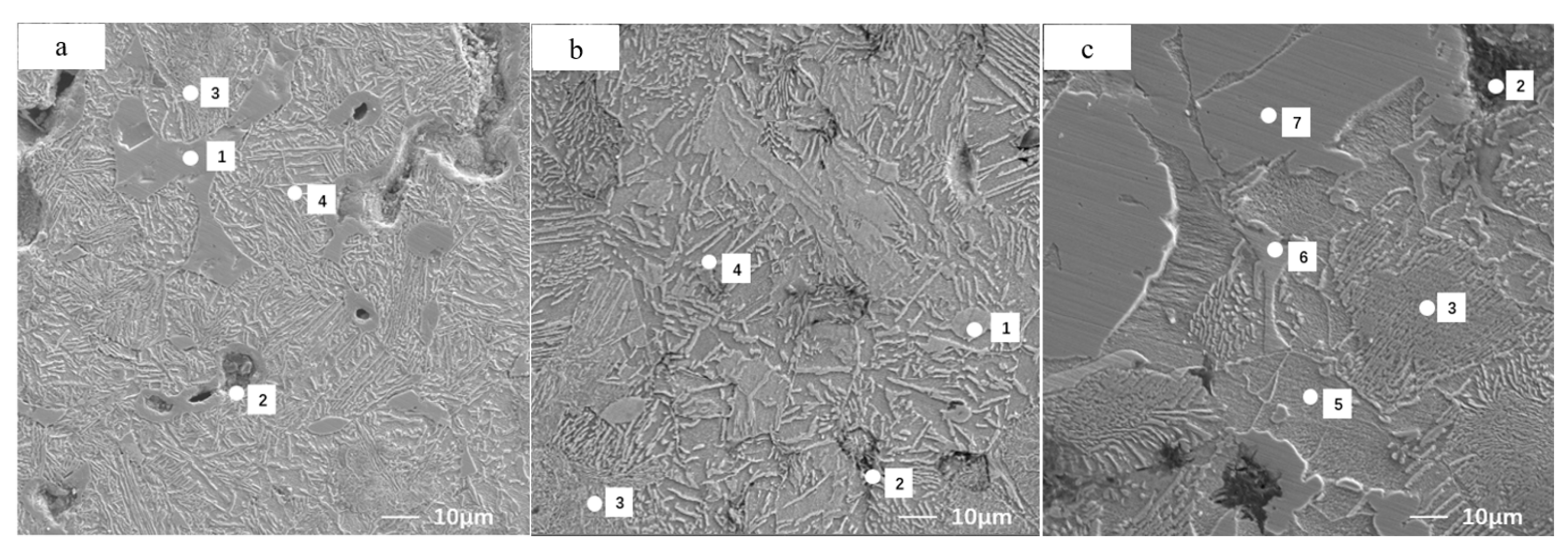

3.3. Microstructure Analysis

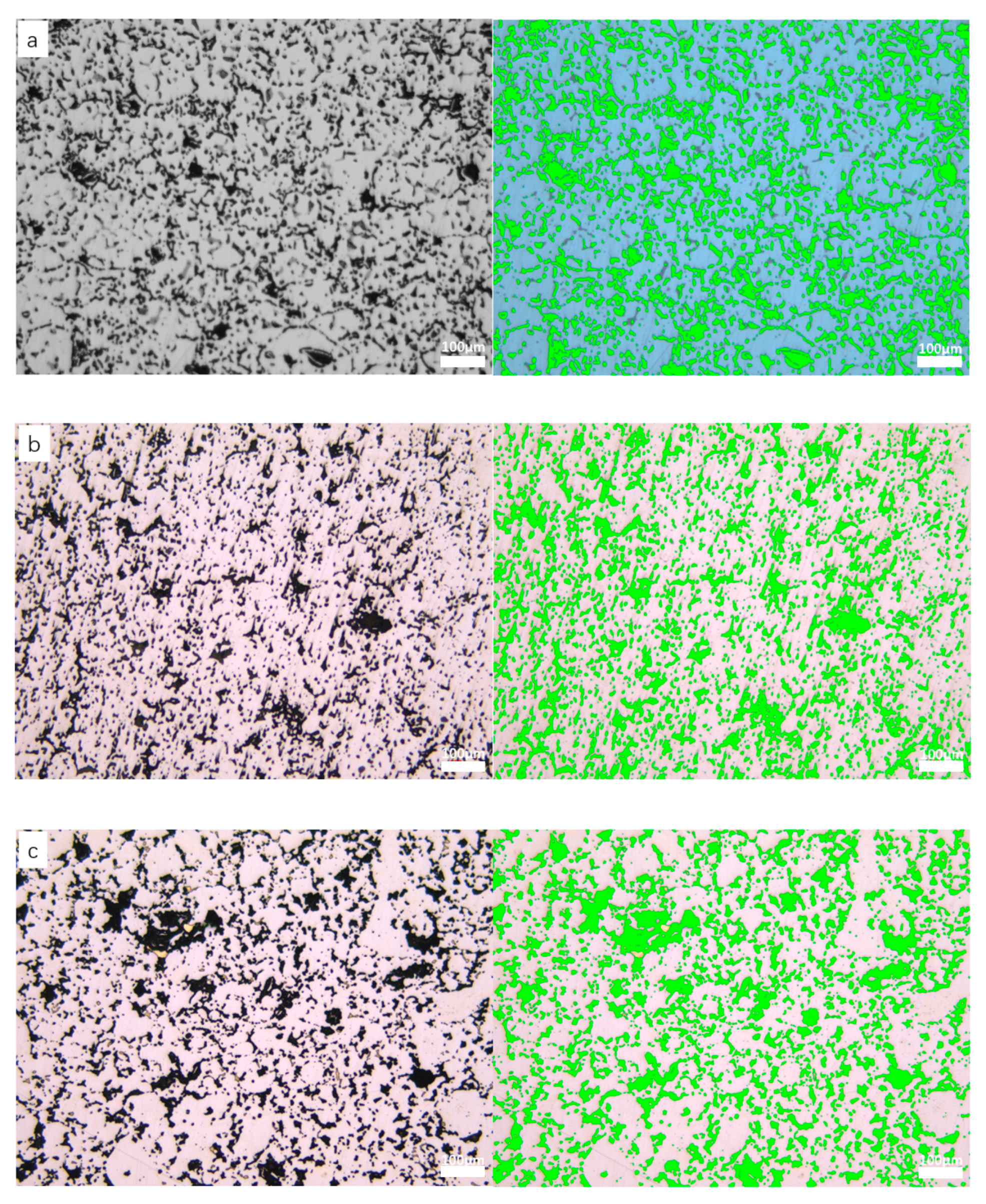

3.4. Porosity Analysis

4. Conclusions

- The influence of alloy elements on wear resistance: Research has found that adding MoS2 and Cu can improve the wear resistance of materials. MoS2 provides stable performance in harsh working environments due to its high temperature strength, hardness, and low density; Cu can not only promote the sintering process but can also improve the strength and wear resistance of materials through the formation of solid solutions. Sample 3 did not add MoS2, but it did add a large amount of Cu to improve its wear resistance, while Sample 1 added a large amount of MoS2; however, its wear resistance was worse than that of Sample 2 with a small amount of MoS2 added. Therefore, a reasonable adjustment of the types and contents of alloy elements is the key to improving the wear resist.

- The influence of microstructure on wear resistance: The microstructure of the three samples is mainly pearlite, and pores and alloy phases of MoS2 and Cu are added to improve the wear resistance of the materials. Comparing the three samples, it was found that the morphology of pearlite has a significant impact on the wear resistance of the material. Sample 3 had finer pearlite layers with better wear resistance, while Samples 1 and 2 had poorer wear resistance due to the addition of MoS2 causing their pearlite layers to widen. The large amount of MoS2 alloy phase in Sample 1 reduces the tightness of the material, making it easy to detach and form abrasive wear during friction, further exacerbating the wear of the material. Although there is not much difference in porosity among the three samples, the presence of pores still has a certain impact on the wear resistance of the material. Pores can store oil and provide lubrication, thereby improving the wear resistance of materials. However, high porosity may reduce material strength and rigidity, which is not conducive to improving wear resistance. Therefore, the porosity should be reasonably controlled in the manufacturing process of powder metallurgy valve guides.

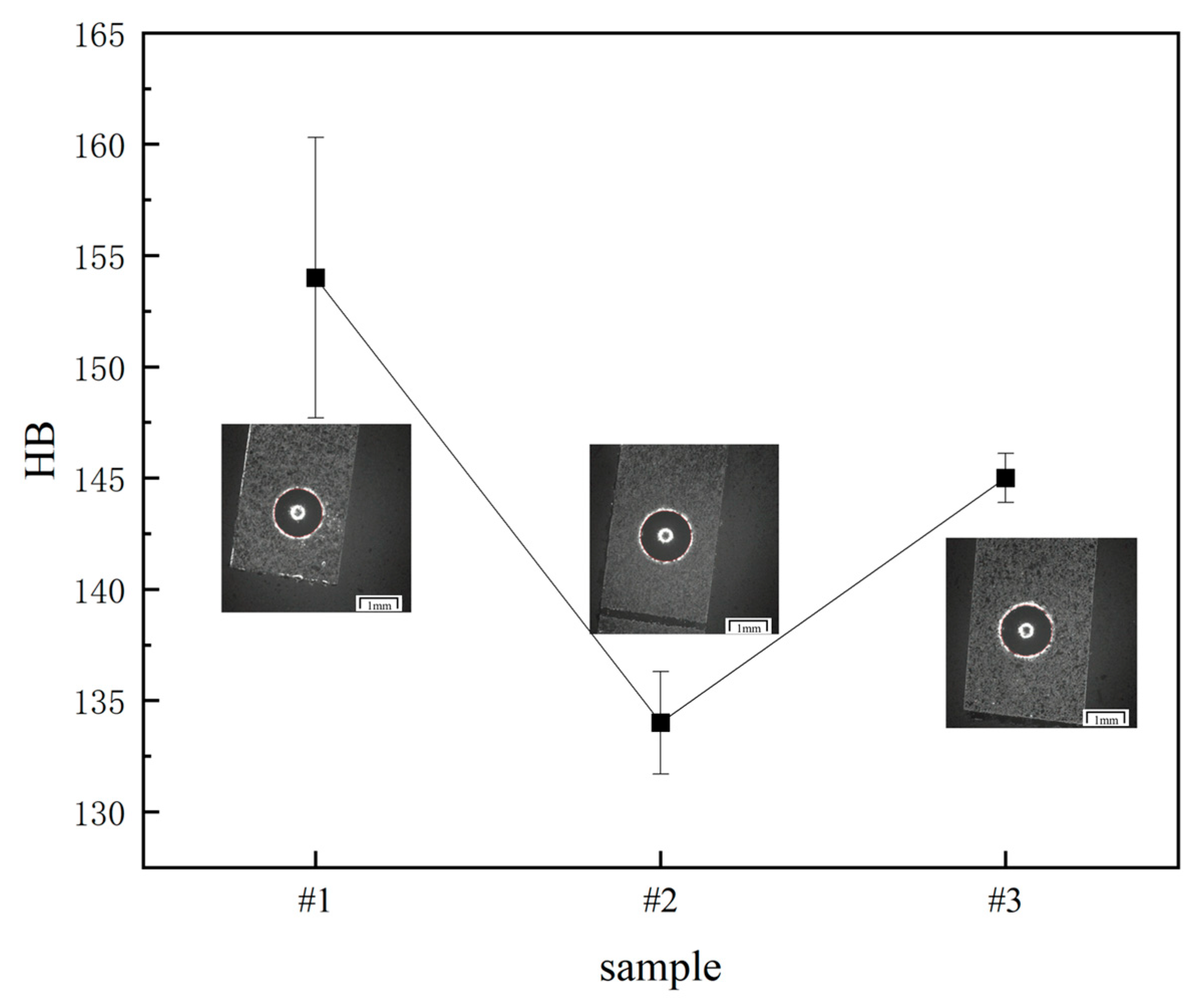

- Regarding the wear mechanisms of the alloys: Alloy 1 (high MoS2, low Cu) undergoes severe abrasive wear, as its coarse MoS2-rich phases and irregular pearlite easily detach during friction to form abrasive particles that scratch the surface, leading to the highest friction coefficient (0.5) and wear loss (2964 μm2). Alloy 2 (low MoS2, low Cu) experiences mild abrasive wear, where reduced MoS2 mitigates but does not eliminate phase coarsening, and low Cu provides limited lubrication, resulting in a moderate friction coefficient (0.3) and wear loss (1580 μm2). Alloy 3 (no Mo, high C-Cu) exhibits mild adhesive wear, with fine pearlite enhancing matrix hardness (145 HB) to resist scratching, Cu acting as a solid lubricant to reduce metal-to-metal contact, and pores (25.14% porosity) storing oil for further lubrication, thus achieving the lowest friction and wear.

- Based on the current research results, future work can focus on the following aspects: Further exploration of the influence of different alloy elements and their contents on the wear resistance of materials in order to find the best alloy element combination and content so as to maximize the wear resistance of materials. By adjusting the preparation process and heat treatment conditions, such as refining the pearlite layer and controlling the porosity and the distribution of alloy phase, the microstructure of the material can be optimized so as to improve the wear resistance and comprehensive properties of the material. The optimized material can then be applied to actual working conditions for long-term wear resistance testing and performance evaluation in order to verify its feasibility and reliability in practical applications.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ramakrishnan, P. Automotive applications of powder metallurgy. In Advances in Powder Metallurgy; Elsevier: Amsterdam, The Netherlands, 2013; pp. 493–519. [Google Scholar]

- Zhang, X.; Xuan, T.; Dai, Z.; Yuan, C. Analysis of Unbalanced Wear Failure of Exhaust Valve Ducts in Automotive Engines. Hot Process. Technol. 2016, 45, 255–258. [Google Scholar]

- Liu, J.; Xuan, T.; Dai, Z.; Yuan, C. Research on sintering temperature of iron-based powder metallurgy valve guide. Powder Metall. Ind. 2014, 24, 37–41. [Google Scholar]

- Li, X.; Fang, M.; Pei, X.; Hua, J. Research on Powder Metallurgy Valve Guide Materials. Automot. Parts 2022, 5, 30–35. [Google Scholar]

- Endoh, H.; Di, Y. Powder metallurgy valve guides for internal combustion engines. Automot. Engine 1982, 6, 50–55. [Google Scholar]

- Li, C. Research on Common Defects of Engine Valve Stem and Valve Guide. Agric. Dev. Equip. 2007, 8, 44. [Google Scholar]

- Qi, Y. Common damage forms and repairs of valves. Agric. Mach. Use Maint. 2013, 6, 72. [Google Scholar]

- Qu, S.; Xia, W.; Han, L. Wear and sealing characteristics of engine valve guide. Chin. J. Mech. Eng. 2005, 3, 18. [Google Scholar] [CrossRef]

- Fujiki, A. Present state and future prospects of powder metallurgy parts for automotive applications. Mater. Chem. Phys. 2001, 67, 298–306. [Google Scholar] [CrossRef]

- Lei, Q.; Chen, W.; Yan, J. Failure analysis and improvement application evaluation of a certain model of valve guide. Foreign Intern. Combust. Engines 2020, 3, 76–79. [Google Scholar]

- Zhong, W. Homemade Valve Guide for 280/285 Diesel Engine. Railw. Locomot. Electr. Veh. 2007, 5, 27–28+50. [Google Scholar]

- Chikahata, K.; Hayashi, K. Development of Sintered Valve Guide Material with Improved Machinability; SAE: Warrendale, PA, USA, 2002. [Google Scholar]

- Qian, Z.; Sheng, W. The influence of graphite content on the microstructure and properties of iron-based powder metallurgy oil containing friction reducing materials. Locomot. Roll. Stock. Technol. 2003, 4, 11–14. [Google Scholar]

- Lv, W.; Wang, T.; Hua, J. The effect of adding Cu3P on the microstructure and mechanical properties of iron-based powder metallurgy valve guide materials. Powder Metall. Ind. 2023, 33, 81–87. [Google Scholar]

- Peng, Y.; Wu, H.; Yi, J.; Li, L.; Liang, C. The Effect of C Content on the Properties of Fe-Cu-C Alloy. Met. Mater. Metall. Eng. 2007, 6, 15–18. [Google Scholar]

- Qin, Q.; Wang, T. Effect of mo content on the microstructure and properties of powder metallurgy iron based friction materials. J. Phys. Conf. Ser. 2024, 2760, 012071. [Google Scholar] [CrossRef]

- Feng, D.; Liu, W.; Xue, Q. The lubrication mechanism of cerium dithiomolybdate from room temperature to 600 °C. Mater. Sci. Eng. A 2002, 326, 195–201. [Google Scholar] [CrossRef]

- Yin, Y.; Jiao, M.; Yu, J.; Ma, S.; Xie, T.; Zheng, Z. The influence of carbon content and sulfurization treatment on the friction and wear properties of iron-based powder metallurgy materials. China Mech. Eng. 2006, 17, 5. [Google Scholar]

- Miao, J. The influence of carbon, copper, and nickel content on the properties and dimensional changes of iron-based powder metallurgy materials. Powder Metall. Ind. 2005, 15, 5. [Google Scholar]

- Sudha, G.T.; Stalin, B.; Ravichandran, M.; Balsubramanian, M. Mechanical Properties, Characterization and Wear Behavior of Powder Metallurgy Composites—A Review. Mater. Today Proc. 2020, 22, 2582–2596. [Google Scholar] [CrossRef]

- Chowdhury, M.A.; Khalil, M.K.; Nuruzzaman, D.M.; Rahaman, M.L. The effect of sliding speed and normal load on friction and wear property of aluminum. Int. J. Mech. Mechatron. Eng. 2011, 11, 53–57. [Google Scholar]

- Yu, C.; Chen, J.; Zhang, Q.; Li, W. Research progress on friction and wear properties of powder metallurgy brake pad. Adv. Mech. Eng. 2022, 14, 16878132221126854. [Google Scholar] [CrossRef]

- Xiong, X.; Chen, J.; Yao, P.; Li, J.; Huang, B. The influence of MoS2 on the sintering behavior and mechanical properties of iron-based friction materials. Powder Metall. Technol. 2006, 24, 182–186. [Google Scholar]

- Erden, M.A.; Yaşar, N.; Korkmaz, M.E.; Ayvacı, B.; Nimel Sworna Ross, K.; Mia, M. Investigation of microstructure, mechanical and machinability properties of Mo- added steel produced by powder metallurgy method. Int. J. Adv. Manuf. Technol. 2021, 114, 2811–2827. [Google Scholar] [CrossRef]

- Chen, J.; Yao, P.; Xiong, X.; Qiao, W. Study on the behavior of MoS2 during the sintering process of iron-based friction materials. Non Met. Miner. 2003, 26, 50–52. [Google Scholar]

- Yan, H.; Hu, W.; He, G. Analysis of contact stress on gear tooth surface considering surface roughness. Mech. Des. Res. 2012, 28, 5. [Google Scholar]

- Jiang, Z. A control method for porosity of powder metallurgy conduits for automobiles. In Proceedings of the 2017 National Powder Metallurgy Academic Conference, Las Vegas, NE, USA, 13–16 June 2017; Hong Kong Chinese Medicine Association, Education Research Foundation: Hong Kong, China, 2017. [Google Scholar]

- Zherdin, A.G.; Podrezov, Y.N.; Firstov, S.A.; Shytka, L.G. Effect of porosity on microplastic deformation of iron base powder materials. Sov. Powder Metall. Met. Ceram. 1989, 28, 579–584.5. [Google Scholar] [CrossRef]

- Park, J.; Lee, S.; Kang, S.; Jeon, J.; Lee, S.H.; Kim, H.K.; Choi, H. Complex effects of alloy composition and porosity on the phase transformations and mechanical properties of powder metallurgy steels. Powder Technol. Int. J. Sci. Technol. Wet Dry Part. Syst. 2015, 284, 459–466. [Google Scholar] [CrossRef]

- Mutlu, I.; Sugözü, İ.; Keskin, A. The effects of porosity in friction performance of brake pad using waste tire dust. Polímeros 2015, 25, 440–446. [Google Scholar] [CrossRef]

| Samples | C | Mo | Cu | S | Fe |

|---|---|---|---|---|---|

| #1 | 1.5 | 1.9 | 1.5 | 1.4 | 93.7 |

| #2 | 1.2 | 0.3 | 0.8 | 0.2 | 97.5 |

| #3 | 1.8 | 0 | 5 | 0.01 | 93.19 |

| Trademark | Sample 1 | Sample 2 | Sample 3 |

|---|---|---|---|

| Porosity/% | 23.74 | 22.99 | 25.14 |

| Sample | HIT (GPa)-MoS2 | HIT (MPa)-Black Porosity | HIT (GPa)-Matrix | HIT (GPa)-Cu | HIT (GPa)-Fe3C |

|---|---|---|---|---|---|

| #1 | 4.6 | 306 | 3.5 | ||

| #2 | 7.14 | 46.8 | 3.2 | ||

| #3 | 170.6 | 4.3 | 3.5 | 13.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, F.; Yan, Z.; Lu, G.; Liu, W.; Zhang, P.; Shen, G. Enhancing Automotive Valve Guide Tribomechanical Performance Through Alloy Optimization in Powder Metallurgy. Metals 2025, 15, 1301. https://doi.org/10.3390/met15121301

Guo F, Yan Z, Lu G, Liu W, Zhang P, Shen G. Enhancing Automotive Valve Guide Tribomechanical Performance Through Alloy Optimization in Powder Metallurgy. Metals. 2025; 15(12):1301. https://doi.org/10.3390/met15121301

Chicago/Turabian StyleGuo, Fujian, Zhongyuan Yan, Guangyi Lu, Wenle Liu, Pan Zhang, and Gengzhe Shen. 2025. "Enhancing Automotive Valve Guide Tribomechanical Performance Through Alloy Optimization in Powder Metallurgy" Metals 15, no. 12: 1301. https://doi.org/10.3390/met15121301

APA StyleGuo, F., Yan, Z., Lu, G., Liu, W., Zhang, P., & Shen, G. (2025). Enhancing Automotive Valve Guide Tribomechanical Performance Through Alloy Optimization in Powder Metallurgy. Metals, 15(12), 1301. https://doi.org/10.3390/met15121301