With the intensification of global climate change, industries worldwide are actively seeking low-carbon technologies to reduce their CO2 emissions and achieve carbon neutrality in their processes. The development of such technologies has become a central focus in both environmental and policy agendas. In the steelmaking industry, blast furnaces constitute a primary source of CO2 emissions. Therefore, innovative technologies that can substantially reduce the carbon emissions produced during blast furnace ironmaking are critical for promoting environmental sustainability and enabling a low-carbon transition in the steel sector.

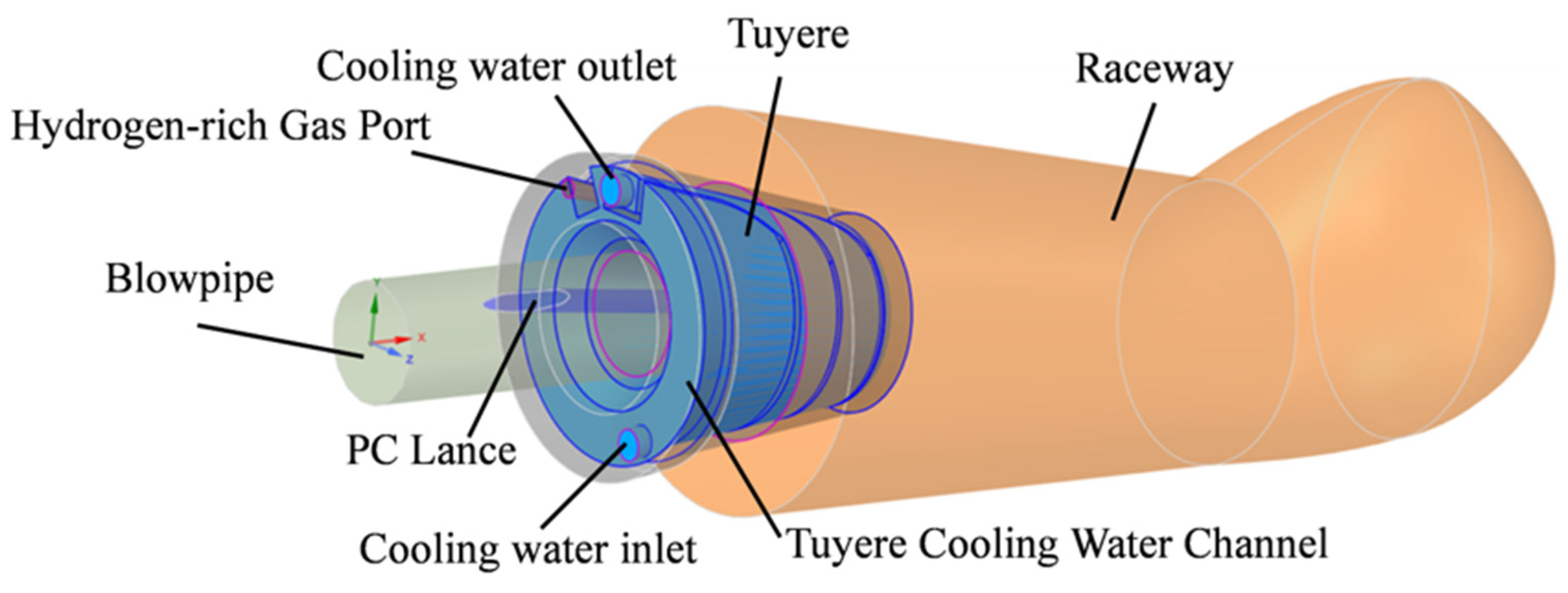

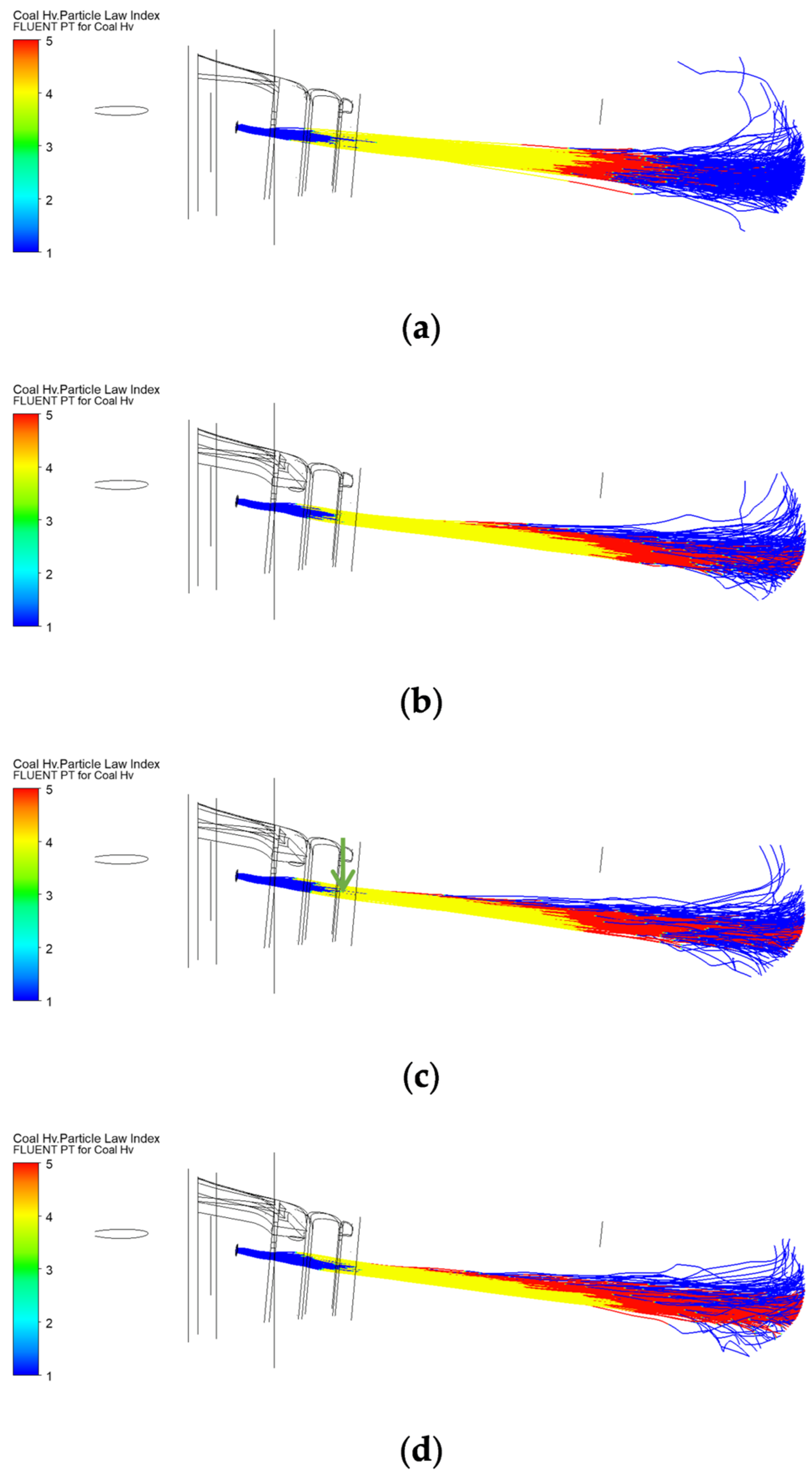

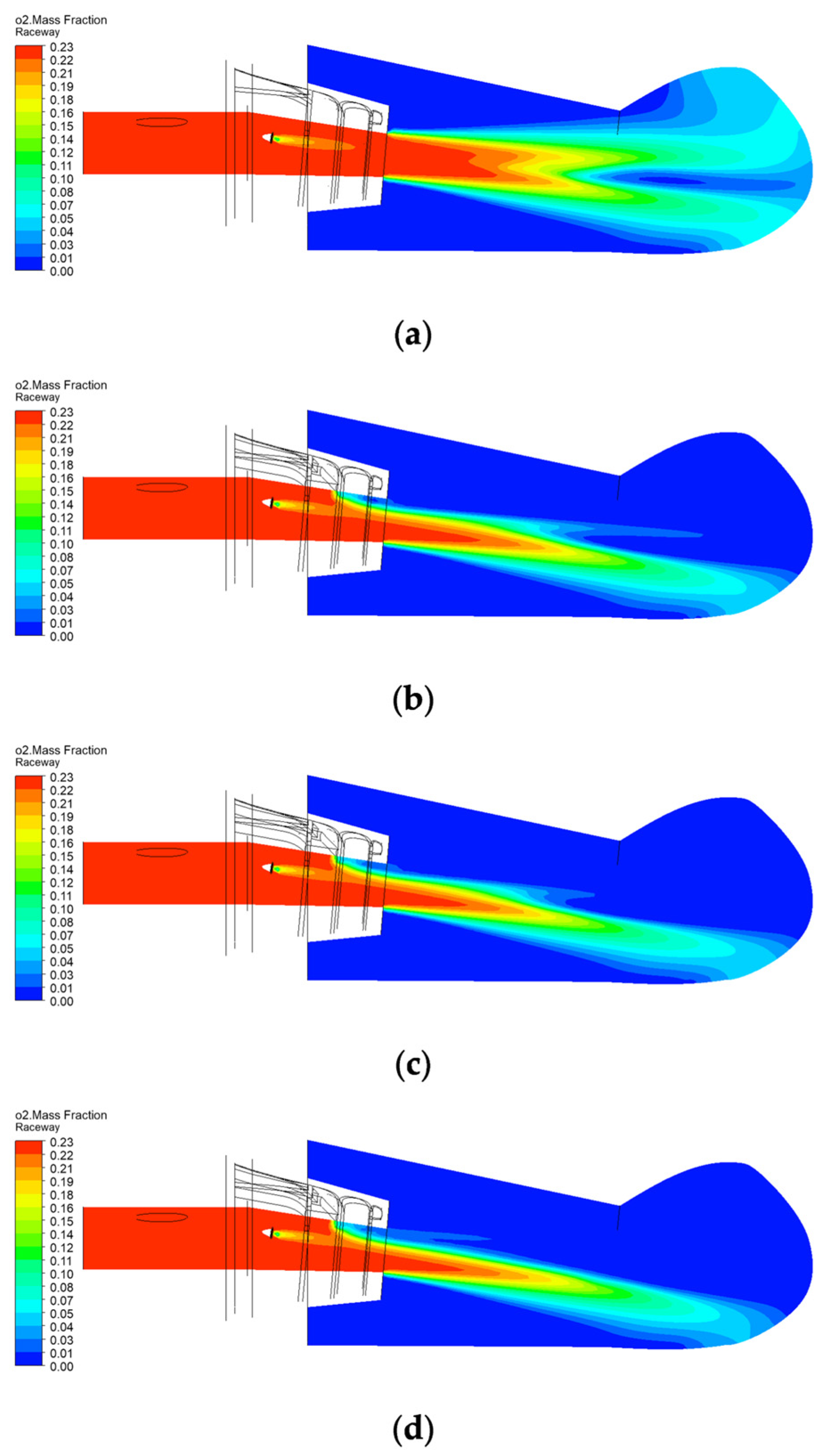

Blast furnace ironmaking is a continuous process in which iron ore is reduced and melted. This process is primarily driven by the combustion of coke, which results in the production of CO as the primary reducing agent. Solid raw materials such as iron ore and coke are charged from the top of the furnace and form an alternating layered structure as they descend. During the descent of the raw materials, the iron ore gradually reacts with the reducing gases and eventually melts into hot metal. The thermal energy and reducing atmosphere within the furnace are mainly provided by a hot blast injected laterally through the blowpipe and tuyere into the coke bed. This high-velocity gas stream generates a cavity known as the raceway in front of the tuyere. Intense combustion occurs between the hot blast and coke, resulting in the production of CO2. This CO2 then reacts with coke at a temperature of approximately 2000 °C to form CO, thereby maintaining the reducing environment. In addition, auxiliary fuel injection techniques are commonly applied in modern blast furnaces. Pulverized coal (PC) injection is a widely adopted auxiliary fuel injection method. In this method, PC is delivered to the blast furnace through a lance to supply the furnace with supplementary thermal energy and reducing gases. This method enables the partial replacement of coke, effectively reducing ironmaking costs and improving combustion efficiency.

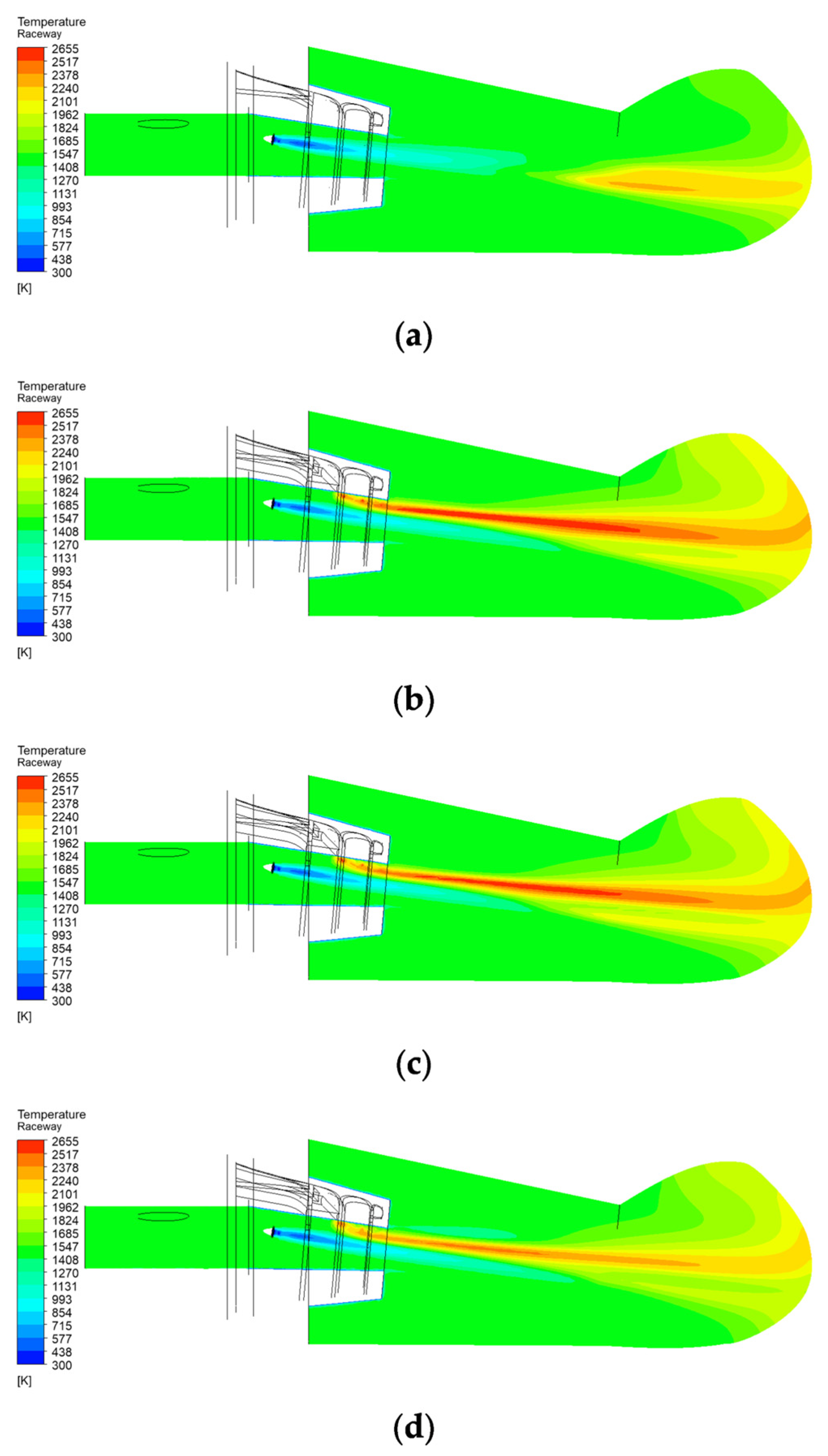

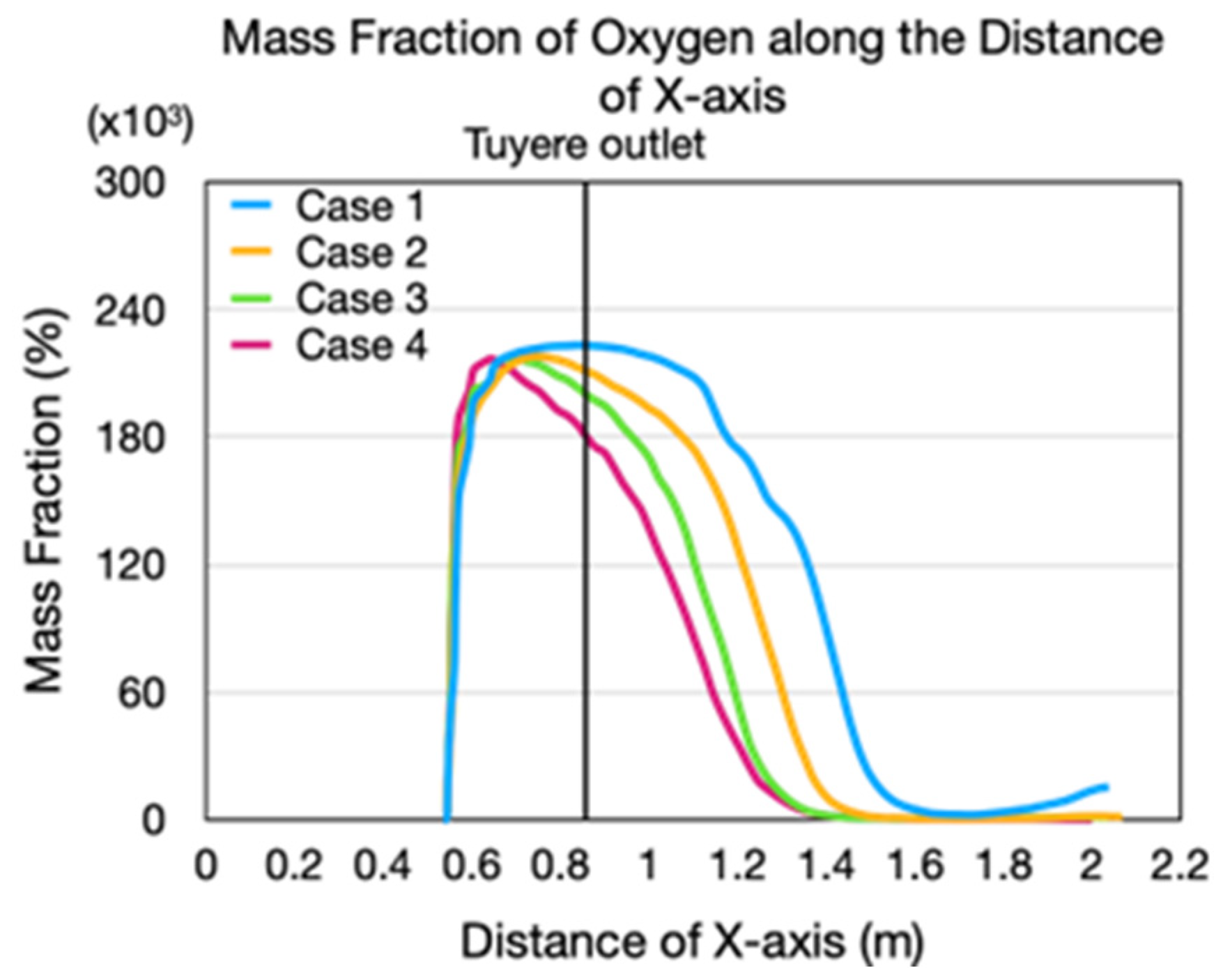

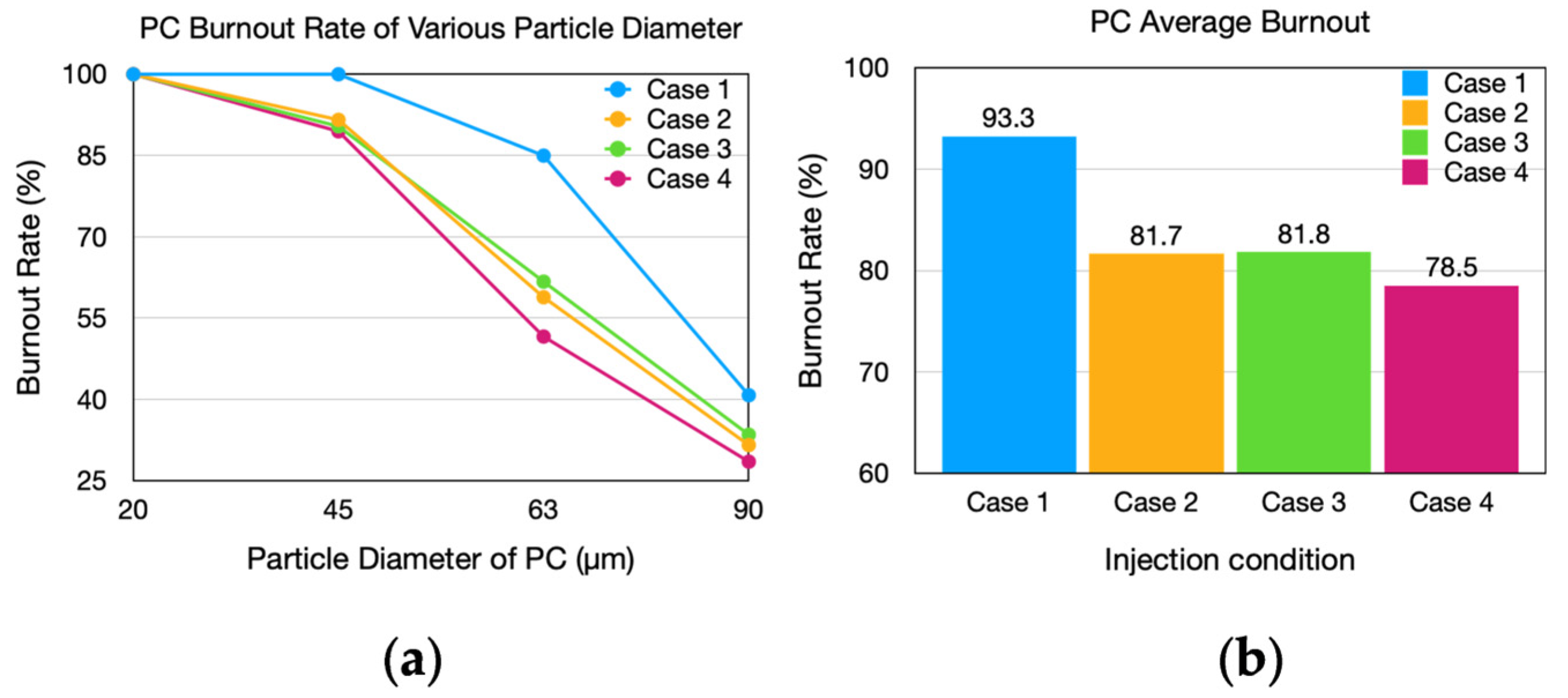

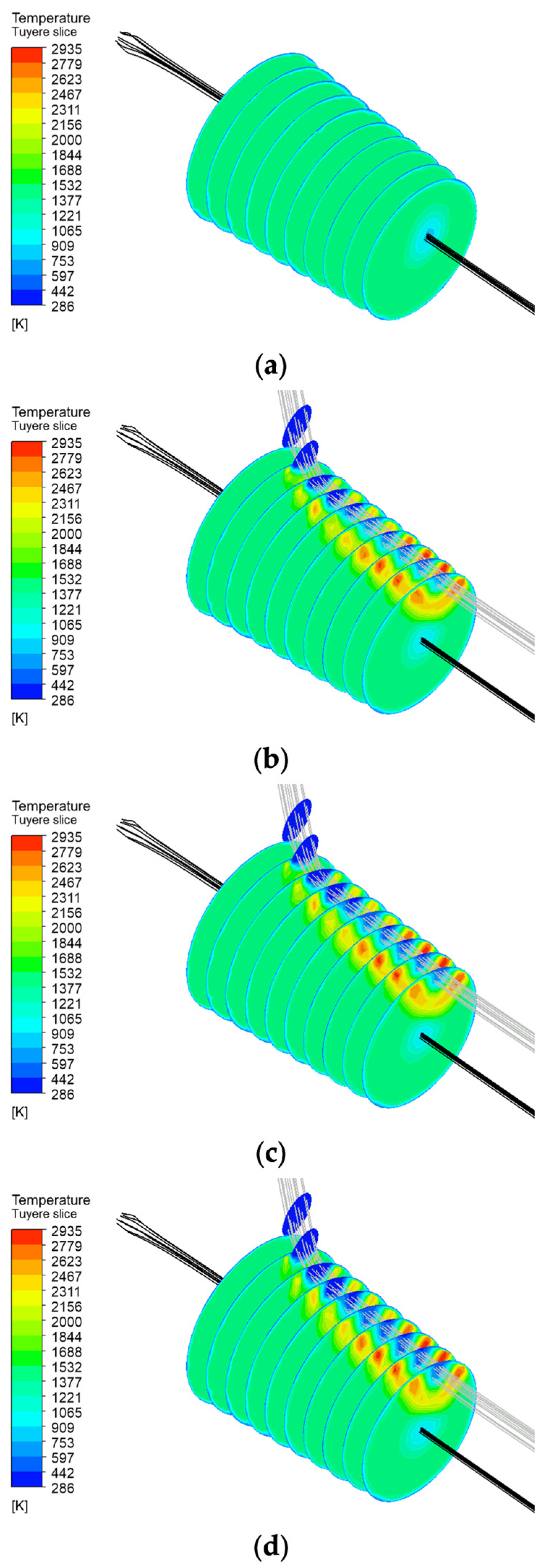

Temperatures in the lower part of a blast furnace are extremely high. Hence, conducting direct measurements and analysis by using experimental tools in this region is highly challenging. Computational fluid dynamics (CFD) is an effective and practical simulation tool for clearly understanding the combustion behaviors of PC and HRG in the raceway and for evaluating the thermal load on the tuyere. CFD simulations facilitate predictions of changes in flow, combustion behavior, heat transfer, and tuyere temperature under different fuel injection conditions, such as changes in the mass flow rates of HRG and PC, adjustments to the oxygen enrichment level in the hot blast, and the injection of different types of HRG (e.g., natural gas, COG, or hydrogen-enriched gases). These predictions offer useful technical support for improving blast furnace operation and encouraging the use of low-carbon fuels.

Several research groups have conducted CFD simulations to investigate how HRG injection affects combustion in blast furnaces. For example, Yeh et al. [

3] performed a three-dimensional simulation to examine the flow and combustion behaviors during the simultaneous injection of PC and blast furnace gas (BFG) into the blowpipe–tuyere–raceway area. They explored the effects of different lance designs, BFG types, and BFG flow rates on pressure drop and combustion performance. Their results revealed that BFG mixed with oxygen in the tuyere and formed a premixed flame, which caused earlier ignition and led to an increase in pressure and turbulence in this area. In addition, when more BFG was added, oxygen was consumed more quickly, which further slowed down PC combustion and reduced burnout. Zhang et al. [

4] conducted a three-dimensional numerical simulation to examine the influence of the coinjection of NG and PC on the combustion zone in a blast furnace. Their findings indicated that NG–PC coinjection increased the local temperature near the tuyere. As the NG injection rate was increased from 0 to 34.5 m

3/t, the burnout rate of PC decreased from 68.11% to 64.12%, primarily because of the higher oxygen consumption during hydrogen combustion, which prevented the complete burnout of char. Moreover, they observed that NG combustion increased the hydrogen concentration and decreased the CO content in the gas phase, thereby contributing to a potential reduction in CO

2 emissions. In a follow-up study, Zhang et al. [

5] explored the effects of different HRGs, namely H

2, NG, COG, and recycled top gas, on the combustion zone in a blast furnace. Their findings revealed that among the considered HRGs, COG caused the earliest ignition, with the ignition occurring closest to the tuyere. Furthermore, it offered a more balanced CO/H

2 ratio than did the other HRGs, which helped maintain a more stable reducing gas composition. They concluded that optimizing the ratio and injection method of HRGs can enhance furnace performance and support carbon reduction efforts. Liu et al. [

1] conducted a simulation study on the coinjection of H

2 and PC, reporting that when the H

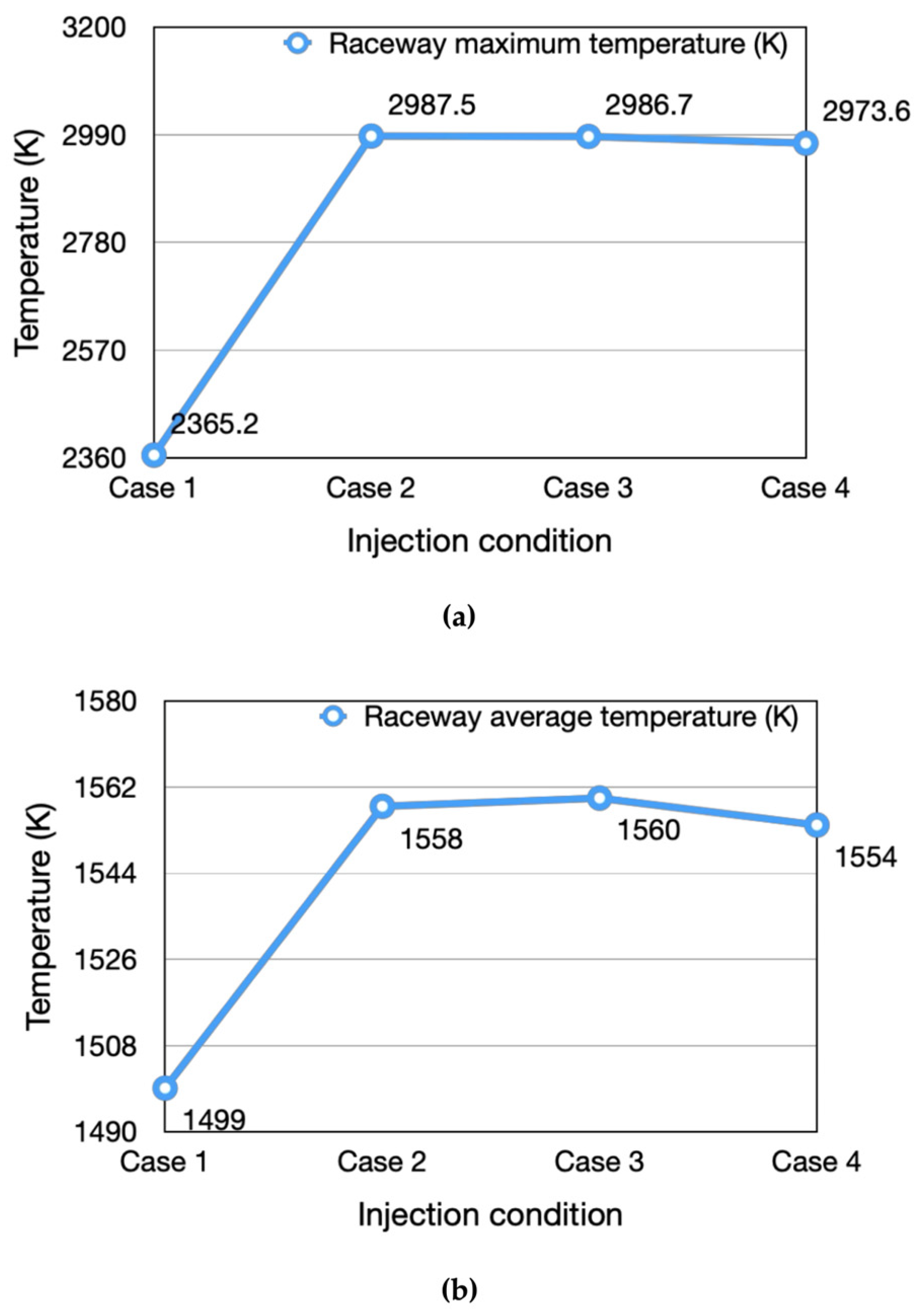

2 injection rate reached 4000 Nm

3/h, the average temperature in the raceway increased from 2003 to 2042 K. As the H

2 injection rate was further increased, the concentration of reducing gases (H

2 + CO) in the raceway increased, contributing to a reduction in CO

2 emissions from the blast furnace. However, Li et al. observed that excessive hydrogen injection reduced the combustion zone temperature and affected combustion stability. Okosun et al. [

6] investigated the coinjection of NG and PC. They noted that NG combustion occurred near the tuyere wall, which increased the local temperature. Consequently, some PC remained unburned within the raceway, potentially increasing the resistance of the coke bed. In addition, using NG as the carrier gas instead of nitrogen considerably accelerated the devolatilization of PC, thereby enhancing combustion kinetics. However, excessive NG injection could cause pressure fluctuations, which may negatively affect the operational stability of a furnace. Ren et al. [

7] explored the effects of varying hydrogen content levels on the combustion zone in a blast furnace. Their results indicated that increasing the hydrogen content from 20% to 80% raised the PC burnout rate from 83.2% to 86.8%. Hydrogen combustion accelerated volatile release from PC, advanced the ignition point, and considerably altered the CO/H

2 ratio. Specifically, the inlet CO/H

2 molar ratio varied from 8:2 to 2:8, leading to corresponding outlet ratios of 54:46 and 24:76. The highest reduction efficiency was achieved at 80% hydrogen content (CO/H

2 = 2:8), resulting in a PC burnout rate of 86.8%. They also revealed that hydrogen injection enhanced the water–gas reaction (C + H

2O → CO + H

2) within the combustion zone, leading to increased H

2O generation and reduced CO

2 formation, which in turn altered the composition of the reducing gases. Additionally, higher hydrogen content levels resulted in a slight decrease in the peak temperature in the raceway, suggesting that excessive hydrogen may have a negative effect on combustion stability.

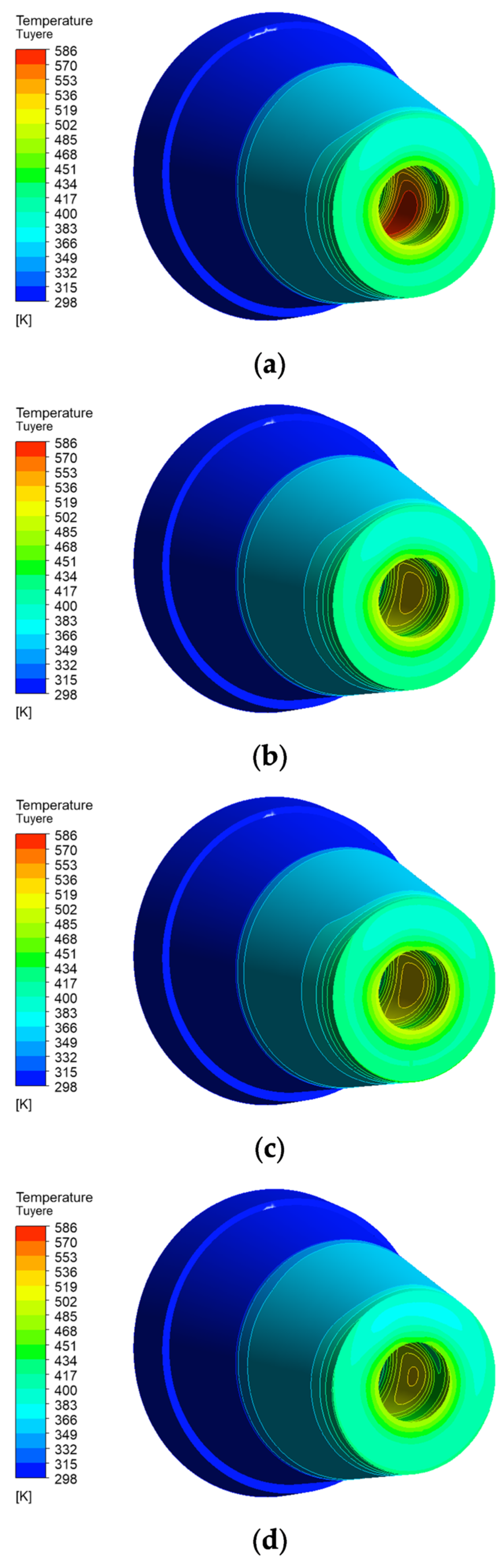

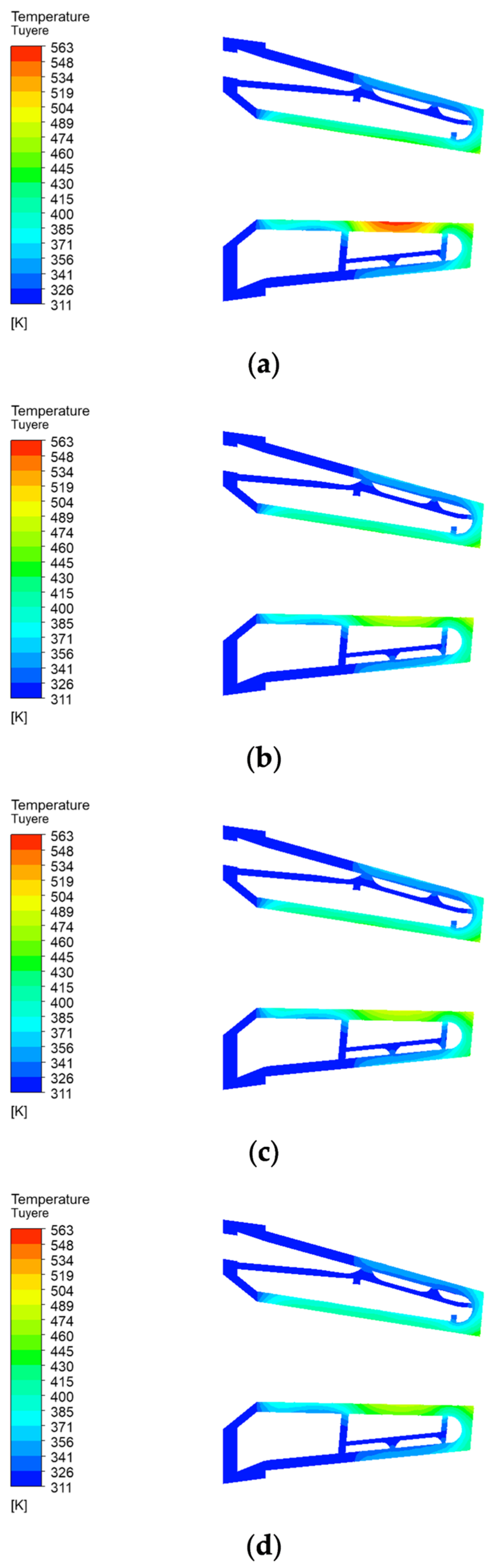

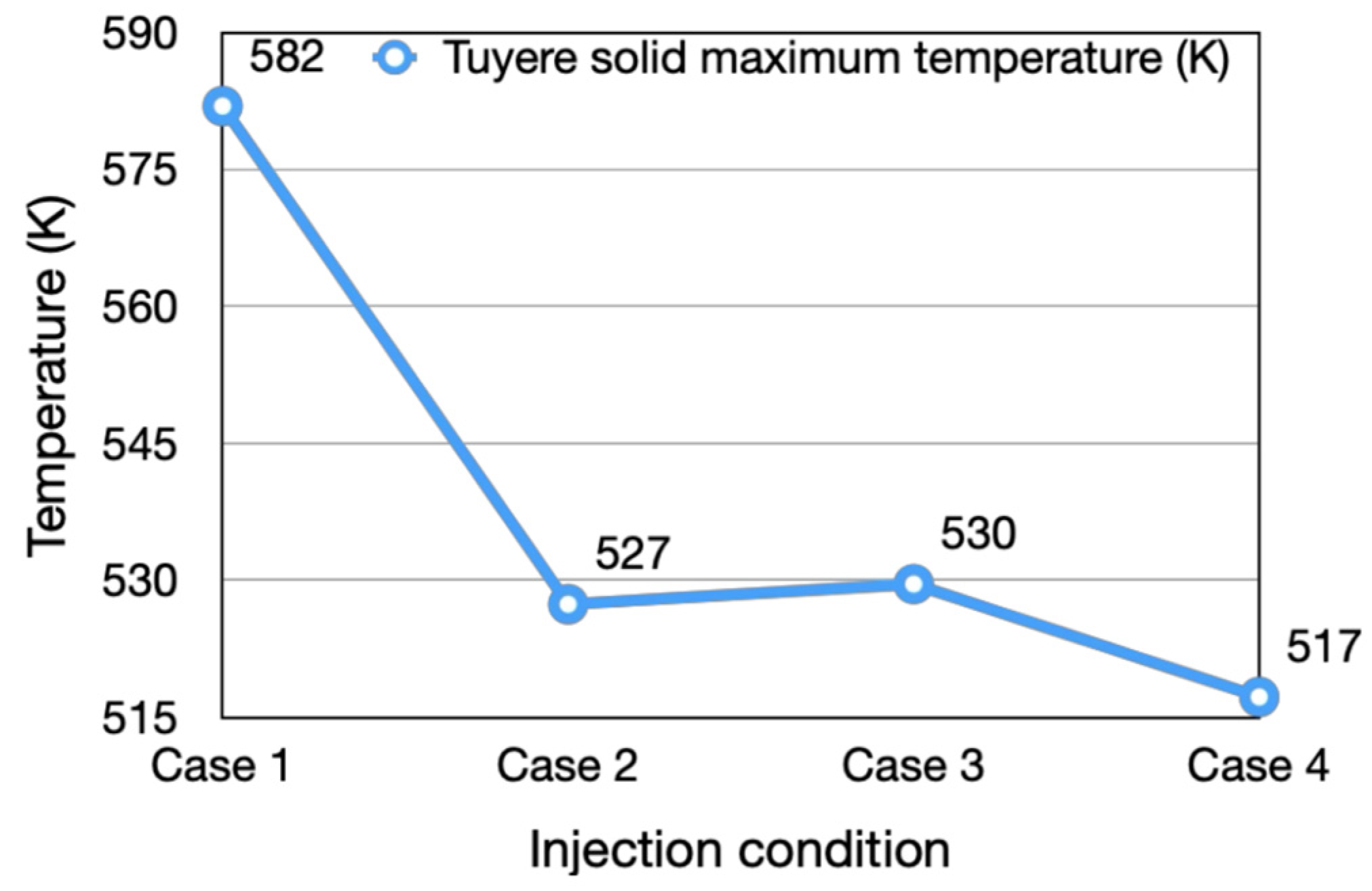

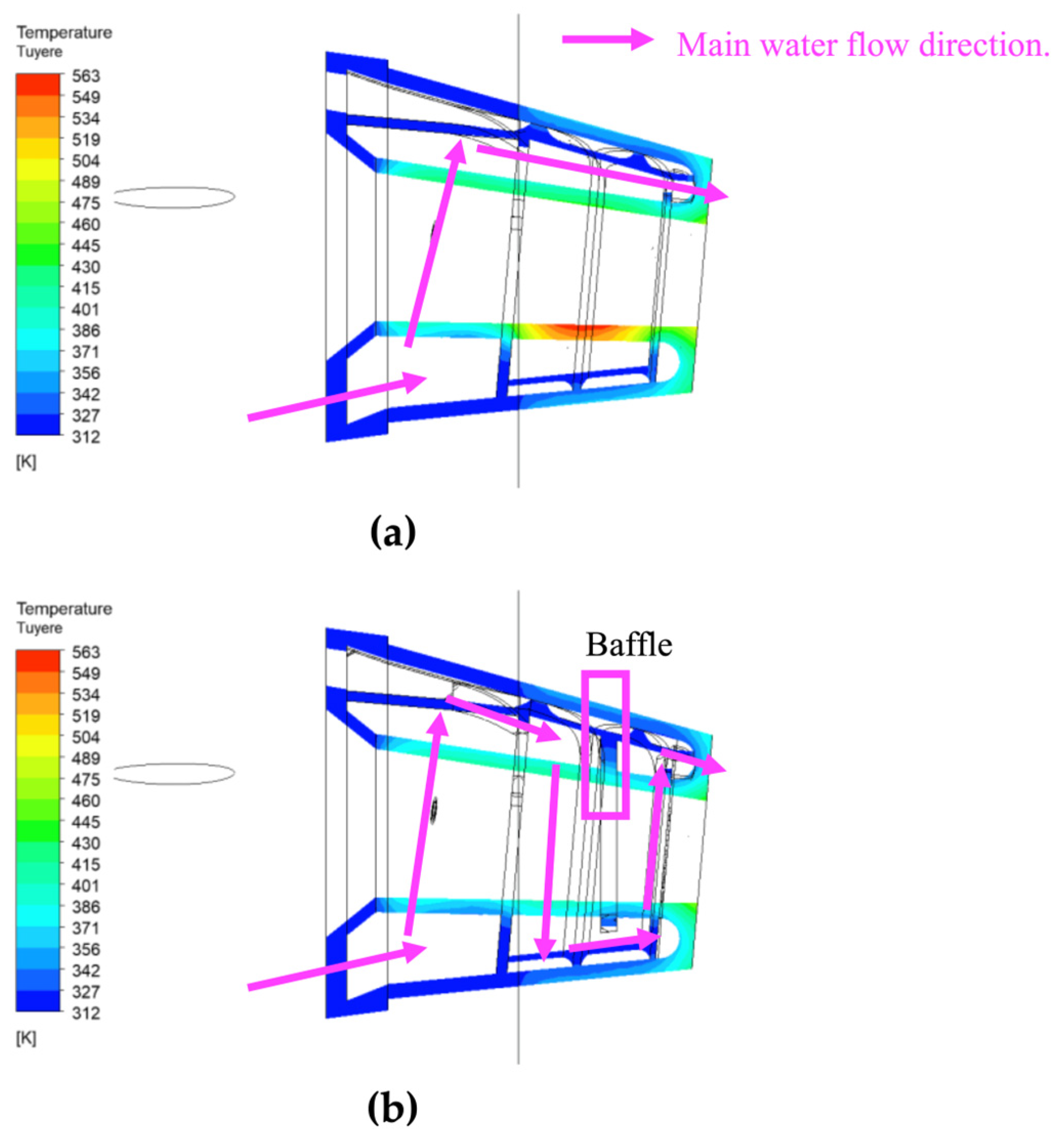

To evaluate the thermal load on blast furnace tuyeres, Borjoui Raky et al. [

8] investigated the effects of water cooling systems with different designs on heat transfer and cooling efficiency. They demonstrated that a helical cooling configuration was more effective than a conventional cooling system design in directing water toward high-temperature areas. The enhanced water transfer ability of the helical cooling system configuration decreased the tuyere body temperature and substantially reduced the risk of thermal damage. Chatterjee et al. [

9] examined the effects of the design and structural optimization of tuyere cooling systems on their service life. By using fiber Bragg grating sensing technology to monitor operating conditions, they detected local temperatures of up to 496 °C, which is considerably higher than the copper creep limit of 406 °C. Such local temperatures led to reduced mechanical strength and structural deformation. Their analysis indicated that conventional cooling channel designs can lead to local water stagnation, which reduces heat transfer efficiency. Through a numerical simulation, they confirmed that an improved design reduced localized temperatures by approximately 40 °C and helped prevent water boiling within the cooling circuit. Zhu et al. [

10] conducted a numerical simulation using Ansys to evaluate how the structural optimization of the wear-resistant layer of a tuyere influences its thermal and stress fields. Their results indicated that the use of an annular wear-resistant coating design reduced the average temperature of the coating by 24 K and decreased the heat loss by 16.7%, which resulted in lower fuel consumption in the furnace. Furthermore, the new design decreased the maximum thermal stress from 624.98 to 427.99 MPa, which represents a 31.5% reduction. This improvement extended the service life of the tuyere. Chen et al. [

11] explored the influence of the copper content of Ni60A wear-resistant coatings on the temperature distribution of a blast furnace tuyere. As the copper content increased, the thermal conductivity of the coating also increased, resulting in a gradual decrease in the surface temperature. However, when the copper content exceeded 40%, the internal temperature of the tuyere became higher than that in the uncoated case, suggesting that excessive copper can reduce the coating’s thermal insulation performance. They recommended maintaining a copper content of less than 40% for wear-resistant coating on the tuyere to balance thermal conductivity and durability, thereby improving the thermal stability and extending the service life of the tuyere.

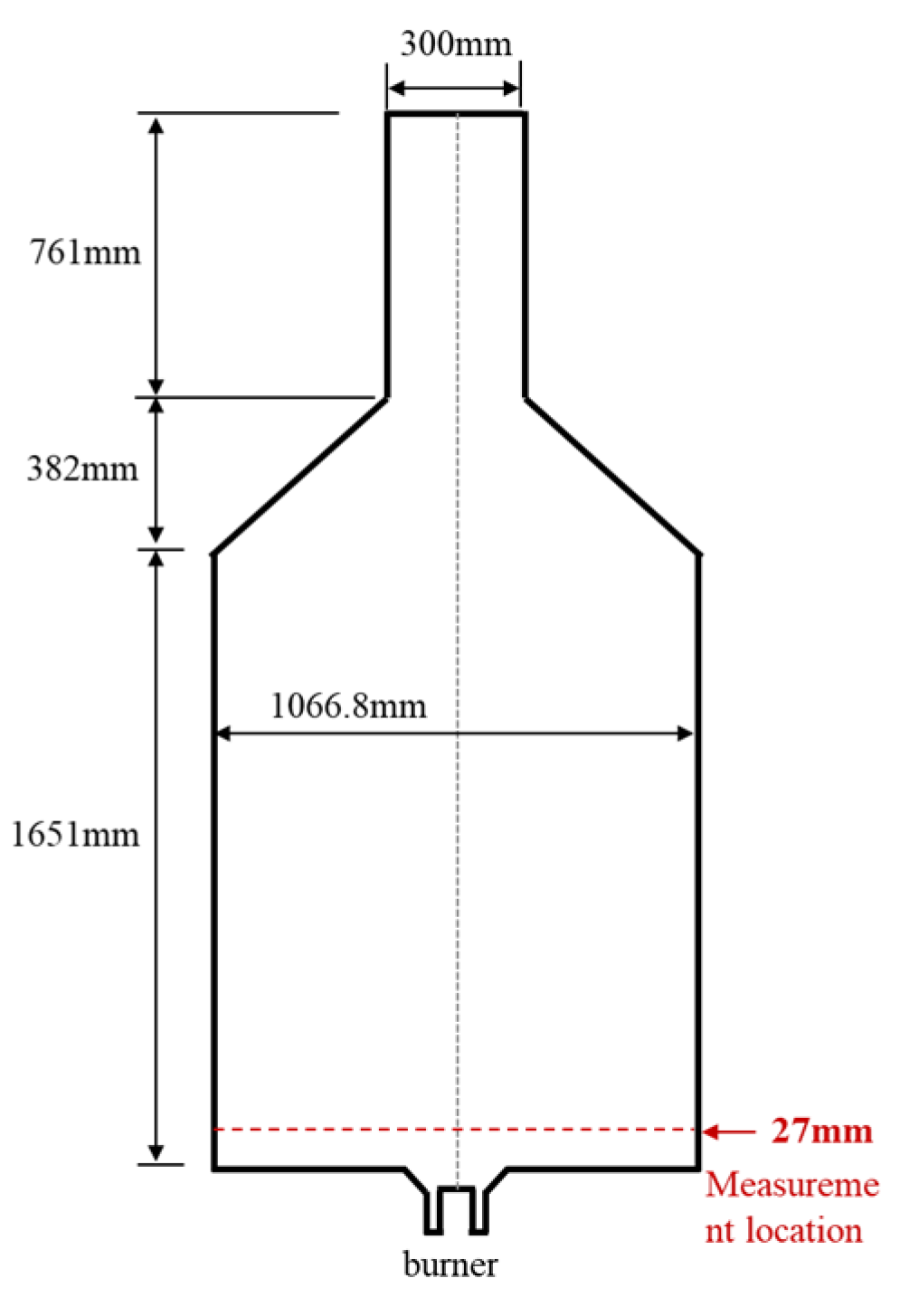

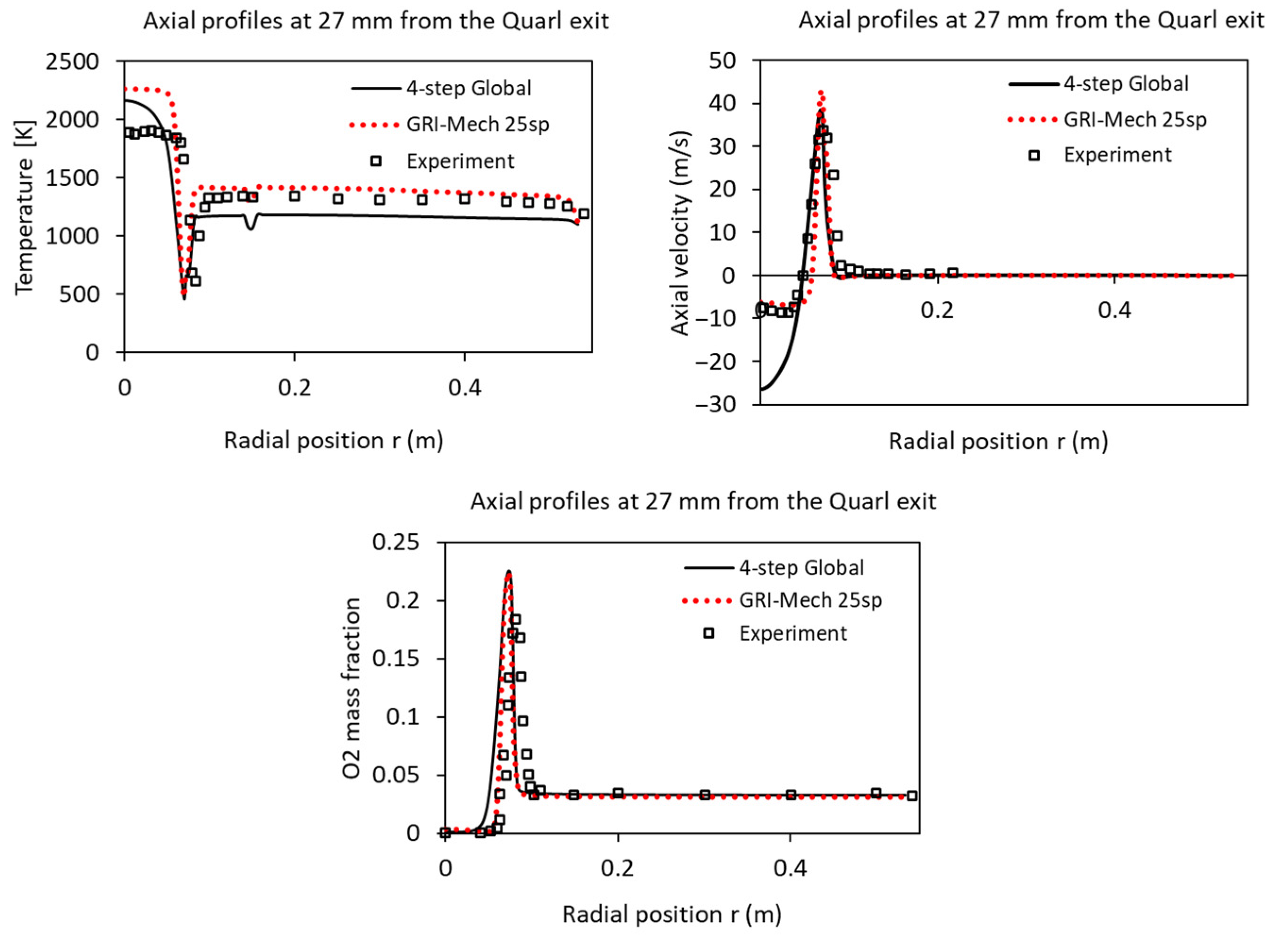

To comprehensively assess the effect of HRG combustion on the thermal load on a tuyere, this study developed a fully coupled fluid–thermal–solid CFD model of the lower part of a blast furnace. This model includes the lance, blowpipe, tuyere, and raceway, thus enabling a detailed numerical analysis of the combustion and heat transfer characteristics in the lower region of the blast furnace. The model was used to systematically examine the effects of different operating conditions on raceway combustion and tuyere temperature. The results of this study can serve as a valuable reference for optimizing blast furnace operations and promoting the use of low-carbon combustion technologies.