Synergistic Effects of Sub-Micron WC Reinforcement and T6 Heat Treatment on the Evolution of Microstructure and Mechanical Behavior in Al–Cu–Mg Composites Fabricated Through Powder Metallurgy

Abstract

1. Introduction

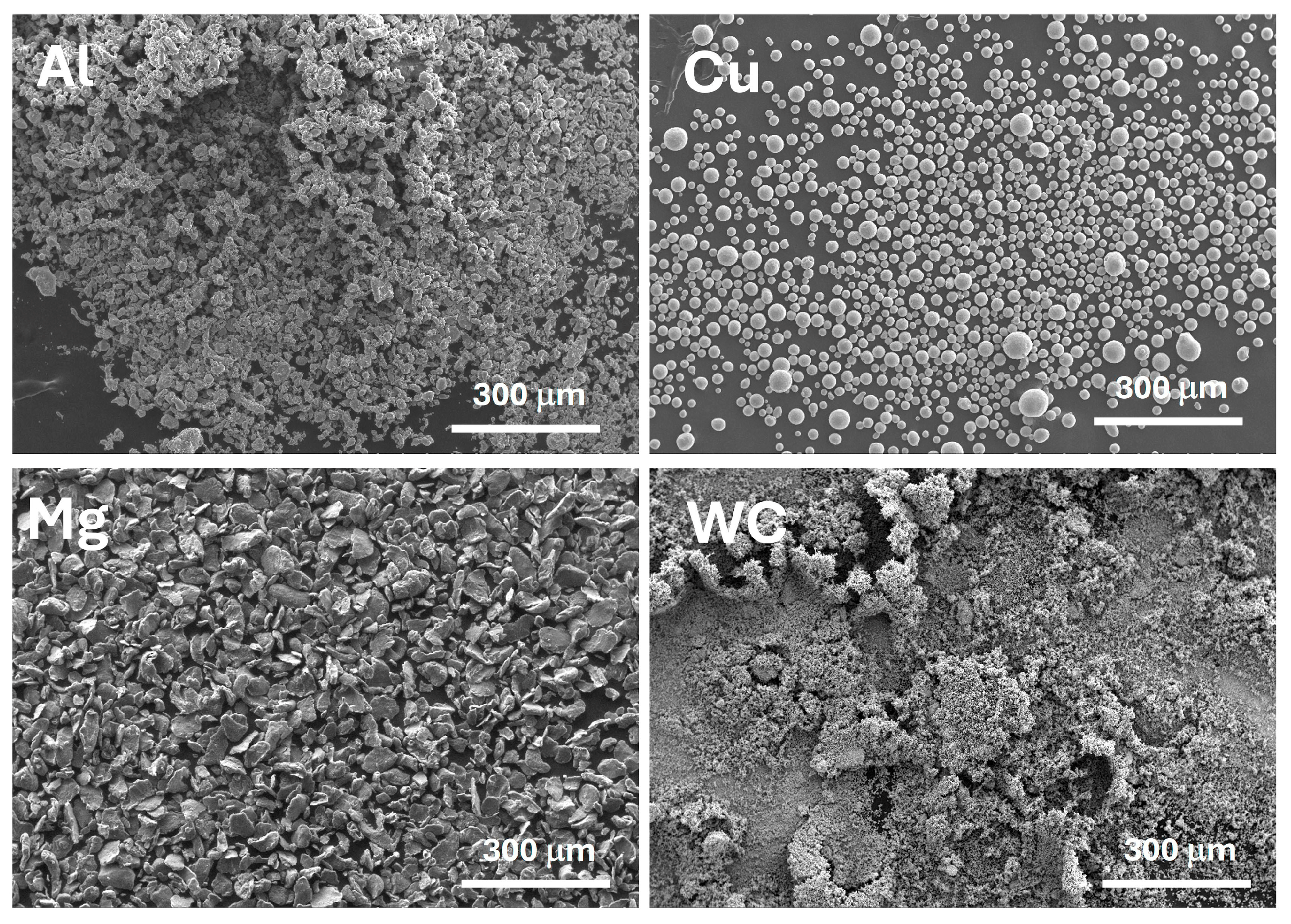

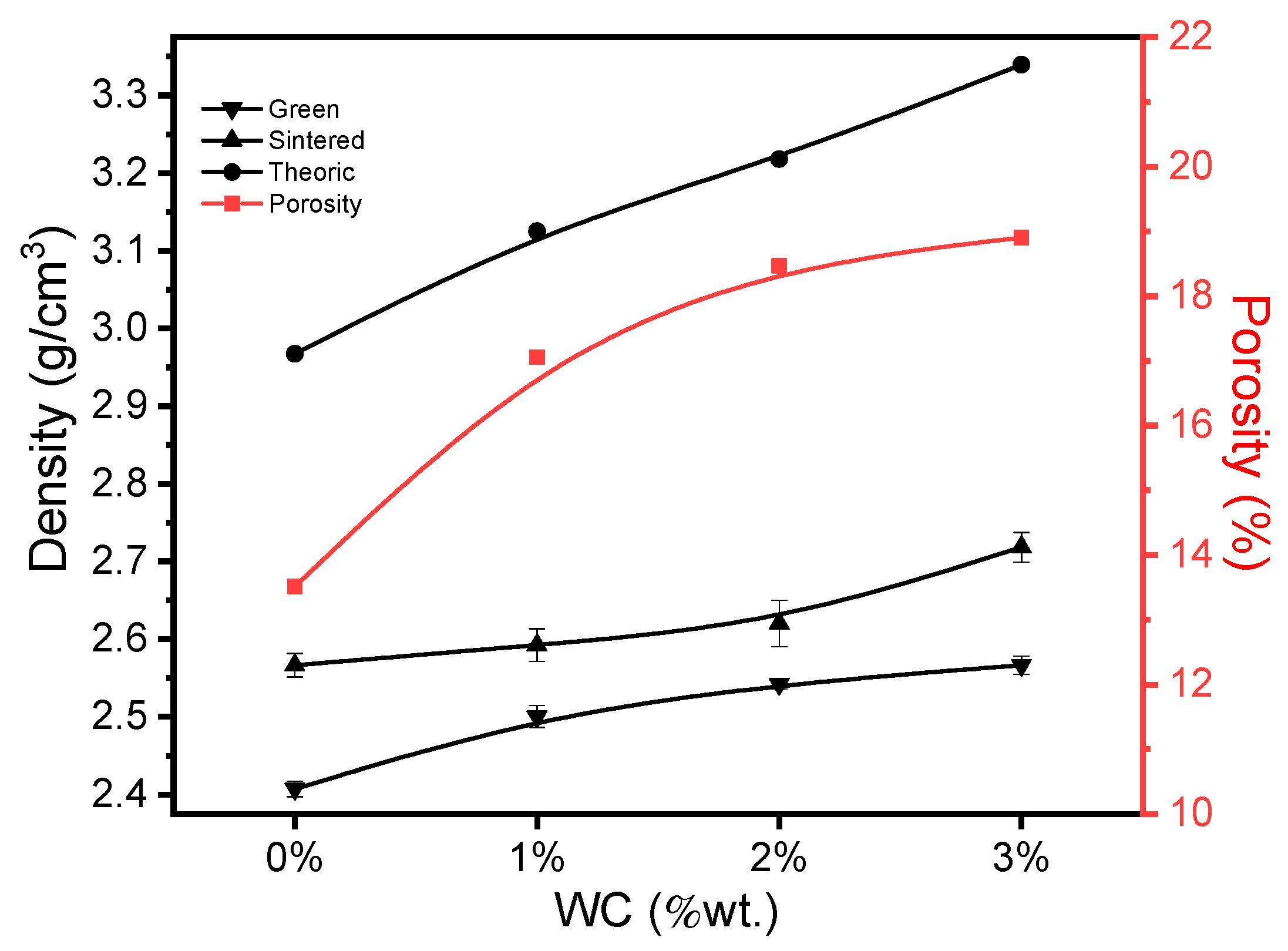

2. Materials and Methods

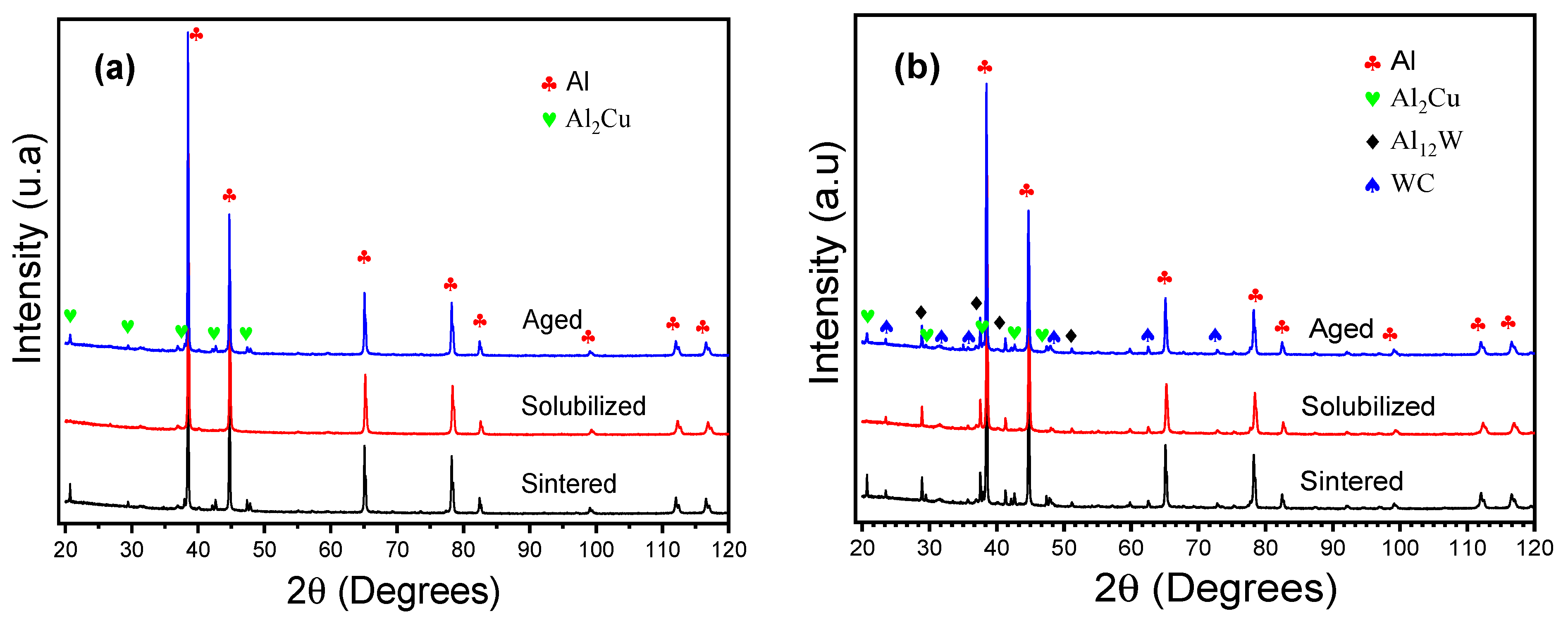

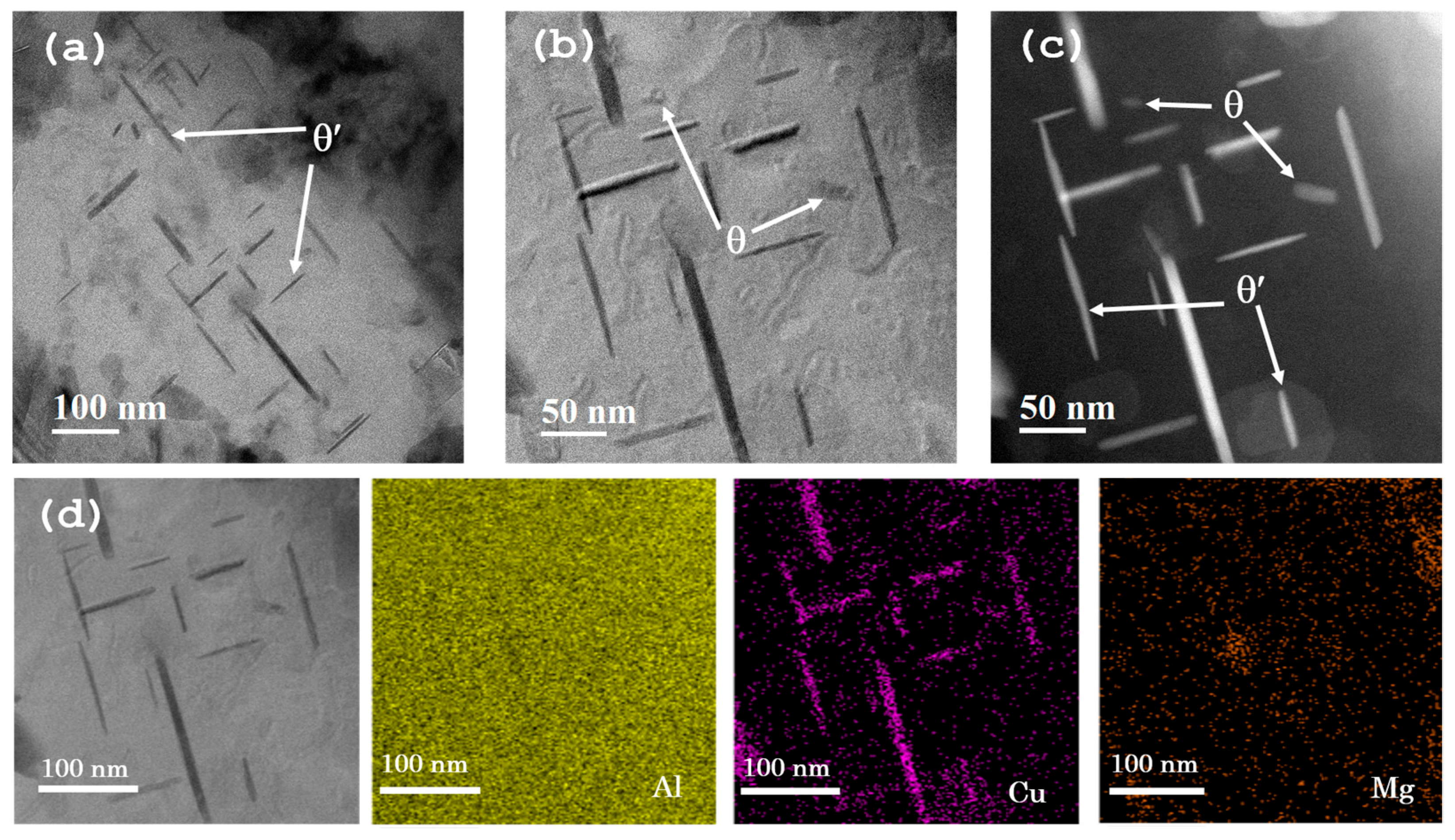

3. Results and Discussions

4. Conclusions

- Al-Cu-Mg/WC composites containing uniformly dispersed sub-micron WC particles (~0.8 μm) were successfully fabricated by PM, demonstrating good interfacial compatibility between the matrix and reinforcement.

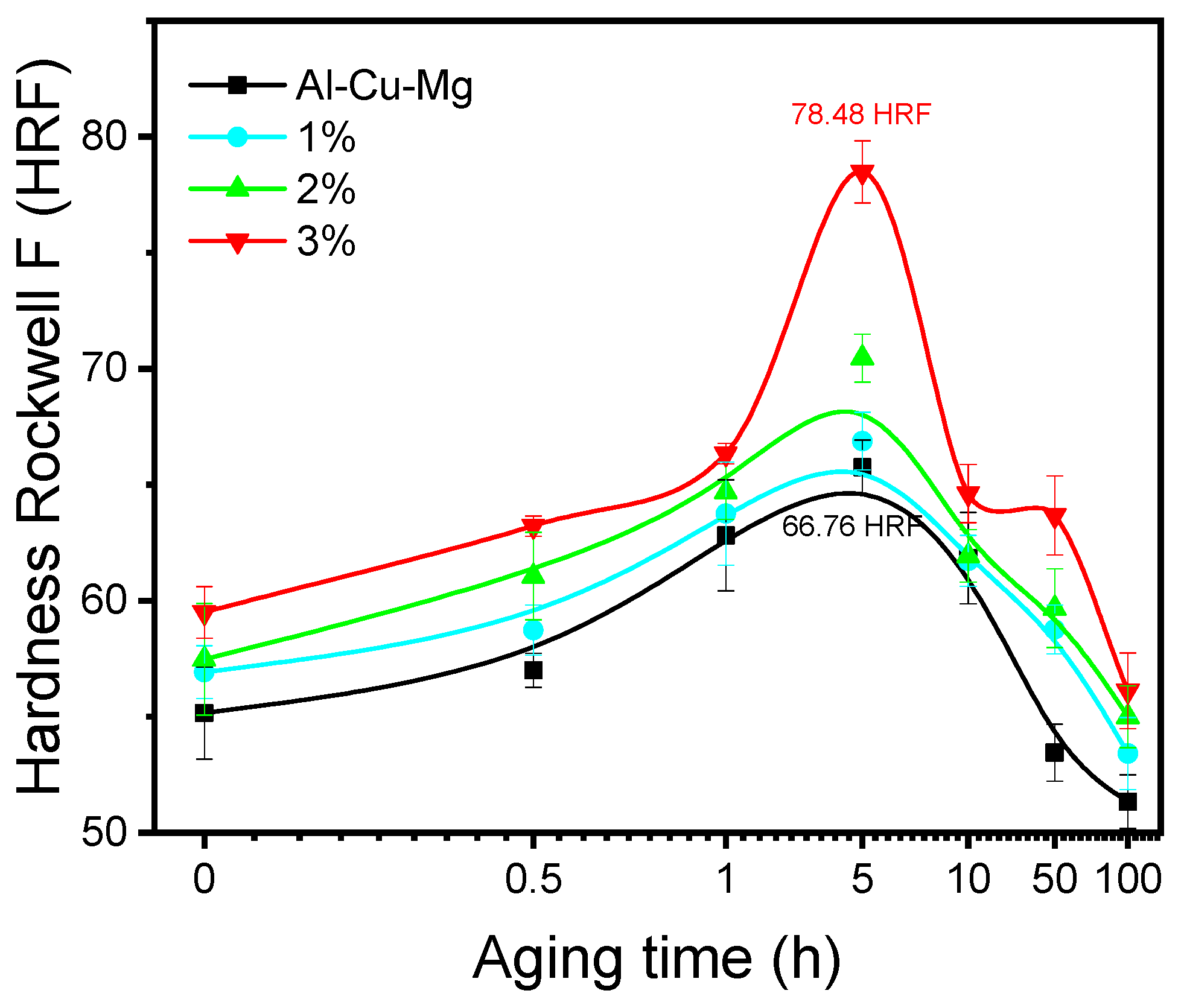

- The 3 wt.% WC composite exhibited superior hardness and compressive strength compared to the unreinforced alloy.

- The addition of WC particles did not disrupt the characteristic aging sequence of the Al-Cu-Mg system, maintaining a homogeneous distribution of the reinforcement.

- XRD and TEM revealed that the strengthening precipitates correspond exclusively to the metastable θ′ (Al2Cu) phase under the applied aging conditions.

- Compression tests evidenced a synergistic strengthening effect from the combined action of aged precipitation and WC particle dispersion.

- The incorporation of sub-micron WC particles did not delay the aging kinetics; all composites reached peak hardness at the same time as the unreinforced alloy, demonstrating that fine WC reinforcement enhances mechanical strength without compromising heat-treatment efficiency.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gao, Y.Y.; Liu, Y.; Li, Y.L.; Zhang, A.; Teng, H.; Dong, Z.H.; Li, T.; Jiang, B. Preparation and Characterization of In Situ (TiC-TiB2)/Al-Cu-Mg-Si Composites with High Strength and Wear Resistance. Materials 2022, 15, 8750. [Google Scholar] [CrossRef]

- Bhowmik, A.; Dey, D.; Biswas, A. Comparative Study of Microstructure, Physical and Mechanical Characterization of SiC/TiB2 Reinforced Aluminium Matrix Composite. Silicon 2021, 13, 2003–2010. [Google Scholar] [CrossRef]

- Chakrapani, P.; Suryakumari, T.S.A. Mechanical properties of aluminium metal matrix composites—A review. Mater. Today Proc. 2020, 45, 2214–7853. [Google Scholar] [CrossRef]

- Huang, G.; Hou, W.; Shen, Y. Evaluation of the microstructure and mechanical properties of WC particle reinforced aluminum matrix composites fabricated by friction stir processing. Mater. Charact. 2018, 138, 26–37. [Google Scholar] [CrossRef]

- Karthikeyan, N.; Krishnan, B.R.; Vembathu Rajesh, A.; Vijayan, V. Experimental analysis of Al-Cu-Si metal matrix composite by powder-metallurgy process. Mater. Today Proc. 2020, 37, 2770–2774. [Google Scholar] [CrossRef]

- Esin, V.A.; Briez, L.; Sennour, M.; Köster, A.; Gratiot, E.; Crépin, J. Precipitation-hardness map for Al-Cu-Mg alloy (AA2024-T3). J. Alloys Compd. 2021, 854, 157164. [Google Scholar] [CrossRef]

- Kumar, N.S.; Pramod, G.K.; Samrat, P.; Sadashiva, M. A Critical Review on Heat Treatment of Aluminium Alloys. Mater. Today Proc. 2022, 58, 71–79. [Google Scholar] [CrossRef]

- Li, L.; Han, Z.; Gao, M.; Li, S.; Wang, H.; Kang, H.; Guo, E.; Chen, Z.; Wang, T. Microstructures, mechanical properties, and aging behavior of hybrid-sized TiB2 particulate-reinforced 2219 aluminum matrix composites. Mater. Sci. Eng. A 2022, 829, 142180. [Google Scholar] [CrossRef]

- Wu, L.; Yu, Z.; Liu, C.; Ma, Y.; Huang, Y.; Wang, T.; Yang, L.; Yan, H.; Liu, W. Microstructure and tensile properties of aluminum powder metallurgy alloy prepared by a novel low-pressure sintering. J. Mater. Res. Technol. 2021, 14, 1419–1429. [Google Scholar] [CrossRef]

- Lu, H.; Kadolkar, P.; Nakazawa, K.; Ando, T.; Blue, C.A. Precipitation Behavior of AA2618. Metall. Mater. Trans. A 2007, 38A, 2379–2388. [Google Scholar] [CrossRef]

- Gao, Z.H.; Gao, H.J.; Zhang, Y.D.; Wu, Q. Experiment and mechanism investigation on the effect of heat treatment on residual stress and mechanical properties of SiCp/Al-Cu-Mg composites. Mater. Sci. Eng. A 2023, 884, 145555. [Google Scholar] [CrossRef]

- Wang, S.C.; Starink, M.J.; Gao, N. Precipitation hardening in Al-Cu-Mg alloys revisited. Scr. Mater. 2006, 54, 287–291. [Google Scholar] [CrossRef]

- Li, Y.; Li, J.; Jin, Q.; Li, Z.; Li, L.; Sun, Y. Study on the Mechanism of CNTs Regulating the Microstructures and Properties of Al-Cu-Mg Alloy. Crystals 2024, 14, 165. [Google Scholar] [CrossRef]

- Ma, S.; Wang, Y.; Wang, X. Microstructures and mechanical properties of an Al-Cu-Mg-Sc alloy reinforced with in-situ TiB2 particulates. Mater. Sci. Eng. A 2020, 788, 139603. [Google Scholar] [CrossRef]

- Chen, X.; Kim, D.; Marioara, C.D.; Andersen, S.J.; Lervik, A.; Holmestad, R.; Kobayashi, E. Effect of pre-deformation on age-hardening behaviors in an Al-Mg-Cu alloy. Mater. Sci. Eng. A 2021, 820, 141557. [Google Scholar] [CrossRef]

- Sharath, B.N.; Venkatesh, C.V.; Afzal, A.; Baig, M.A.A.; Kumar, A.P. Study on effect of ceramics on dry sliding wear behavior of Al-Cu-Mg based metal matrix composite at different temperature. Mater. Today Proc. 2021, 46, 8723–8733. [Google Scholar] [CrossRef]

- Adediran, A.A.; Akinwande, A.A.; Balogun, O.A.; Olorunfemi, B.J.; Kumar, M.S. Optimization studies of stir casting parameters and mechanical properties of TiO2 reinforced Al 7075 composite using response surface methodology. Sci. Rep. 2021, 11, 19860. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Fan, J.; Liu, Y.; Nie, J.; Yang, Z.; Kang, Y. Strengthening and Weakening Effects of Particles on Strength and Ductility of SiC Particle Reinforced Al-Cu-Mg Alloys Matrix Composites. Materials 2021, 14, 1219. [Google Scholar] [CrossRef]

- Chak, V.; Chattopadhyay, H.; Dora, T.L. A review on fabrication methods, reinforcements and mechanical properties of aluminum matrix composites. J. Manuf. Process. 2020, 56, 1059–1074. [Google Scholar] [CrossRef]

- Bedolla-Becerril, E.; Garcia-Guerra, J.; Lopez-Morelos, V.H.; Garcia-Renteria, M.A.; Falcon-Franco, L.A.; Martinez-Landeros, V.H.; García-Villarreal, S.; Flores-Villaseñor, S.E. Tribological Behaviour of Al-2024/TiC Metal Matrix Composites. Coatings 2023, 13, 77. [Google Scholar] [CrossRef]

- Schiopu, A.G.; Girish, B.M.; Satish, B.M.; Shubha, S. Wear and Hardness Characterization of Hot Forged Tungsten Carbide Reinforced Aluminium 6061 Composite Materials. Eng. Technol. Appl. Sci. Res. 2023, 14, 12688–12693. [Google Scholar] [CrossRef]

- Jayakanth, J.J.; Mamidi, V.K.; Pugazhenthi, R.; Anbuchezhiyan, G.; Ponshanmugakumar, A. An investigation on wear properties of SiC/WC strengthened aluminium alloy hybrid composites. Mater. Today Proc. 2020, 46, 3542–3545. [Google Scholar] [CrossRef]

- Anand, P.; Rajesh, D.; Lenin, N.; Balaji, V.; Raja, V.B.; Palanikumar, K. Enhancement of mechanical characterization of aluminum alloy with tungsten carbide metal matrix composite by particulate reinforcements. Mater. Today Proc. 2021, 46, 3690–3692. [Google Scholar] [CrossRef]

- Abood, A.S.; Jayanthi, M.; Thethi, H.P.; Singh, S.; Chahuan, N. Advancing Aluminum-Based Composite Manufacturing: Leveraging WC Reinforcement through Stir Casting Technique. In Proceedings of the E3S Web of Conferences, Nagpur, India, 23–24 February 2024; Volume 507. [Google Scholar]

- Cai, Y.; Su, Y.; Liu, K.; Hua, A.; Wang, X.; Cao, H.; Zhang, D.; Ouyang, Q. Effect of Sc microalloying on fabrication, microstructure and mechanical properties of SiCp/Al-Cu-Mg-Sc composites via powder metallurgy. Mater. Sci. Eng. A 2023, 877, 145152. [Google Scholar] [CrossRef]

- Wang, T.; Huang, Y.; Ma, Y.; Wu, L.; Yan, H.; Liu, C.; Liu, Y.; Liu, B.; Liu, W. Microstructure and mechanical properties of powder metallurgy 2024 aluminum alloy during cold rolling. J. Mater. Res. Technol. 2021, 15, 3337–3348. [Google Scholar] [CrossRef]

- Rodríguez-Cabriales, G.; Lometo-Sánchez, A.M.; Guía-Tello, J.C.; Medrano-Prieto, H.M.; Gutiérrez-Castañeda, E.J.; Estrada-Guel, I.; Garay-Reyes, C.G.; Hernández-Rivera, J.L.; Cruz-Rivera, J.J.; Maldonado-Orozco, M.C.; et al. Synthesis and characterization of Al-Cu-Mg system reinforced with tungsten carbide through powder metallurgy. Mater. Today Commun. 2020, 22, 100758. [Google Scholar] [CrossRef]

- Gowda, K.P.; Prakash, J.N.; Gowda, S.; Babu, B.S. Effect of Particulate Reinforcement on the Mechanical Properties of Al2024-WC MMCs. J. Miner. Mater. Charact. Eng. 2015, 3, 469–476. [Google Scholar] [CrossRef]

- Othman, A.R.; Sardarinejad, A.; Masrom, A.K. Effect of milling parameters on mechanical alloying of aluminum powders. Int. J. Adv. Manuf. Technol. 2014, 76, 1319–1332. [Google Scholar] [CrossRef]

- Rodríguez-Cabriales, G.; Garay-Reyes, C.G.; Guía-Tello, J.C.; Medrano-Prieto, H.M.; Estrada-Guel, I.; García-Hernández, L.J.; Ruiz-Esparza-Rodríguez, M.A.; Mendoza-Duarte, J.M.; García-Aguirre, K.A.; Gonzáles-Sánchez, S.; et al. Abrasive Wear Behavior of Al-4Cu-1.5Mg-WC Composites Synthesized through Powder Metallurgy. Lubricants 2023, 11, 103. [Google Scholar] [CrossRef]

- Bhowmik, A.; Sen, B.; Beemkumar, N.; Chohan, J.S.; Bains, P.S.; Singh, G.; Kumar, A.V. Development and wear resistivity performance of SiC and TiB2 particles reinforced novel aluminium matrix composites. Results Eng. 2024, 24, 102981. [Google Scholar] [CrossRef]

- Patela, A.; Patelb, A.; Parmarc, S.; Jadav, H. Review on Effect of Heat Treatment on Properties of AA 2024. In Special Edition ICRPMSME 2022; Gandhinagar University: Kalol, India, 2022; Volume 14, pp. 51–59. [Google Scholar]

- Kvackaj, T. Aluminium Alloys: Theory and Applications; BoD–Books on Demand: Hamburg, Germany, 2011. [Google Scholar]

- Elias Junior, P.J.O.; das Neves, E.B.; Biehl, L.V.; Baierle, I.C.; Martins, C.O.D.; Medeiros, J.L.B. Study of the Effect of Tin Addition in Aluminum–Copper Alloys Obtained from Elemental Powders. Metals 2025, 15, 559. [Google Scholar] [CrossRef]

- Sarker, S.; Haque, M.S.; Alvy, M.S.A.; Abir, M.M.H. The effects of solution heat treatment on the microstructure and hardness of an aluminum-4% copper alloy with added nickel and tin. J. Alloys Metall. Syst. 2023, 4, 100042. [Google Scholar] [CrossRef]

- Singh, G.; Sharma, N. Study on the influence of T4 and T6 heat treatment on the wear behavior of coarse and fine WC particulate reinforced LM28 Aluminium cast composites. Compos. Part C Open Access 2021, 4, 100106. [Google Scholar] [CrossRef]

- Simon, A.; Lipusz, D.; Baumli, P.; Balint, P.; Kaptay, G.; Gergely, G.; Sfikas, A.; Lekatou, A.; Karantzalis, A.; Gácsi, Z. Microstructure and Mechanical Properties of Al-WC Composites. Arch. Metall. Mater. 2015, 60, 1517–1521. [Google Scholar] [CrossRef]

- Wąsik, A.; Leszczyńska-Madej, B.; Madej, M.; Goły, M. Effect of Heat Treatment on Microstructure of Al4Cu-SiC Composites Consolidated by Powder Metallurgy Technique. J. Mater. Eng. Perform. 2020, 29, 1841–1848. [Google Scholar] [CrossRef]

- Wang, Z.; Li, C.; Wang, H.; Zhu, X.; Wu, M.; Li, J.; Jiang, Q. Aging Behavior of Nano-SiC/2014Al Composite Fabricated by Powder Metallurgy and Hot Extrusion Techniques. J. Mater. Sci. Technol. 2016, 32, 1008–1012. [Google Scholar] [CrossRef]

- Ghasali, E.; Pakseresht, A.H.; Agheli, M.; Marzbanpour, A.H.; Ebadzadeh, T. WC-Co Particles Reinforced Aluminum Matrix by Conventional and Microwave Sintering. Mater. Res. 2015, 18, 1197–1202. [Google Scholar] [CrossRef]

- Heugue, P.; Larouche, D.; Breton, F.; Martinez, R.; Chen, X.G. Evaluation of the Growth Kinetics of θ′ and θ″-Al2Cu Precipitates in a Binary Al-3.5 Wt Pct Cu Alloy. Metall. Mater. Trans. A 2019, 50, 3048–3060. [Google Scholar] [CrossRef]

- Wang, F.; Zeng, Y.; Xiong, B.; Zhang, Y.; Li, X.; Li, Z.; Liu, H. Effect of Si addition on the microstructure and mechanical properties of Al-Cu-Mg alloy. J. Alloys Compd. 2014, 585, 474–478. [Google Scholar] [CrossRef]

- Wang, S.C.; Starink, M.J. Precipitates and intermetallic phases in precipitation hardening Al-Cu-Mg–(Li) based alloys. Int. Mater. Rev. 2005, 50, 193–215. [Google Scholar] [CrossRef]

- Zhou, Y.; Chang, T.; Fang, X.; Chen, R.; Li, Y.; Huang, K. Tailoring the mechanical properties and thermal stability of additive manufactured micro-alloyed Al-Cu alloy via multi-stage heat treatment. Mater. Des. 2023, 233, 112287. [Google Scholar] [CrossRef]

- Lakshmikanthan, A.; Angadi, S.; Malik, V.; Saxena, K.K.; Prakash, C.; Dixit, S.; Mohammed, K.A. Mechanical and Tribological Properties of Aluminum-Based Metal-Matrix Composites. Materials 2022, 15, 6111. [Google Scholar] [CrossRef]

- Zeng, X.; Liu, W.; Xu, B.; Shu, G.; Li, Q. Microstructure and Mechanical Properties of Al-SiC Nanocomposites Synthesized by Surface-Modified Aluminium Powder. Metals 2018, 8, 253. [Google Scholar] [CrossRef]

- Hasan, L.K.; Jiaad, S.M.; Salman, K.D.; Al-Maliki, W.A.K.; Alobaid, F.; Epple, B. Wear Characteristics of (Al/B4C and Al/TiC) Nanocomposites Synthesized via Powder Metallurgy Method. Appl. Sci. 2023, 13, 12939. [Google Scholar] [CrossRef]

- Bilsland, C.; Barrow, A.; Ben Britton, T. Correlative statistical microstructural assessment of precipitates and their distribution, with simultaneous electron backscatter diffraction and energy dispersive X-ray spectroscopy. Mater. Charact. 2021, 176, 111071. [Google Scholar] [CrossRef]

- Zhang, L.; Luo, H. Precipitation Behavior during Aging Operations in an Ultrafine-Grained Al-Cu-Mg Alloy Produced by High-Strain-Rate Processing. Materials 2022, 15, 8687. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Papadimitriou, I.; Lin, F.X.; LLorca, J. Precipitation during high temperature aging of Al-Cu alloys: A multiscale analysis based on first principles calculations. Acta Mater. 2019, 167, 121–135. [Google Scholar] [CrossRef]

- Wu, C.; Ma, K.; Zhang, D.; Wu, J.; Xiong, S.; Luo, G.; Zhang, J.; Chen, F.; Shen, Q.; Zhang, L.; et al. Precipitation phenomena in AlZn-Mg alloy matrix composites reinforced with B4C particles. Sci. Rep. 2017, 7, 9589. [Google Scholar]

- Pal, S.; Mitra, R.; Bhanuprasad, V.V. Aging behaviour of Al-Cu-Mg alloy-SiC composites. Mater. Sci. Eng. A 2008, 480, 496–505. [Google Scholar] [CrossRef]

- Rajaram, S.; Subbiah, T.; Mahali, P.K.; Thangaraj, M. Effect of Age-Hardening Temperature on Mechanical and Wear Behavior of Furnace-Cooled Al7075-Tungsten Carbide Composite. Materials 2022, 15, 5344. [Google Scholar] [CrossRef]

- Casati, R.; Vedani, M. Metal Matrix Composites Reinforced by Nano-Particles—A Review. Metals 2014, 4, 65–83. [Google Scholar] [CrossRef]

- Bignon, M.; Bernacki, M. Particle pinning during grain growth—A new analytical model for predicting the mean limiting grain size but also grain size heterogeneity in a 2D polycrystalline context. Acta Mater. 2024, 227, 120174. [Google Scholar] [CrossRef]

- Alexopoulos, N.D.; Velonaki, Z.; Stergiou, C.I.; Kourkoulis, S.K. Effect of artificial ageing on the work hardening stages of precipitation hardened wrought Al-Cu-Mg alloy. Mater. Sci. Eng. A 2017, 700, 457–467. [Google Scholar] [CrossRef]

- Chen, Y.; Ma, G.; Zhu, S.; Wang, D.; Xiao, B.; Ma, Z. Two-stage aging treatment to accelerate aging kinetics without impairing strength in B4C/7A04Al composite. Sci. China Technol. Sci. 2024, 67, 2485–2492. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodríguez-Cabriales, G.; Flores-De los Ríos, J.P.; López de Lara-Herrera, J.F.; Sánchez-Carrillo, M.; Medrano Prieto, H.M.; Mendoza-Duarte, J.M.; Ruiz-Esparza-Rodríguez, M.A.; Garay-Reyes, C.G.; González, S.; Martínez-García, A.; et al. Synergistic Effects of Sub-Micron WC Reinforcement and T6 Heat Treatment on the Evolution of Microstructure and Mechanical Behavior in Al–Cu–Mg Composites Fabricated Through Powder Metallurgy. Metals 2025, 15, 1216. https://doi.org/10.3390/met15111216

Rodríguez-Cabriales G, Flores-De los Ríos JP, López de Lara-Herrera JF, Sánchez-Carrillo M, Medrano Prieto HM, Mendoza-Duarte JM, Ruiz-Esparza-Rodríguez MA, Garay-Reyes CG, González S, Martínez-García A, et al. Synergistic Effects of Sub-Micron WC Reinforcement and T6 Heat Treatment on the Evolution of Microstructure and Mechanical Behavior in Al–Cu–Mg Composites Fabricated Through Powder Metallurgy. Metals. 2025; 15(11):1216. https://doi.org/10.3390/met15111216

Chicago/Turabian StyleRodríguez-Cabriales, Gustavo, Juan Pablo Flores-De los Ríos, Juan Francisco López de Lara-Herrera, Mario Sánchez-Carrillo, Hansel Manuel Medrano Prieto, Jose Manuel Mendoza-Duarte, Marco Antonio Ruiz-Esparza-Rodríguez, Carlos Gamaliel Garay-Reyes, Sergio González, Alfredo Martínez-García, and et al. 2025. "Synergistic Effects of Sub-Micron WC Reinforcement and T6 Heat Treatment on the Evolution of Microstructure and Mechanical Behavior in Al–Cu–Mg Composites Fabricated Through Powder Metallurgy" Metals 15, no. 11: 1216. https://doi.org/10.3390/met15111216

APA StyleRodríguez-Cabriales, G., Flores-De los Ríos, J. P., López de Lara-Herrera, J. F., Sánchez-Carrillo, M., Medrano Prieto, H. M., Mendoza-Duarte, J. M., Ruiz-Esparza-Rodríguez, M. A., Garay-Reyes, C. G., González, S., Martínez-García, A., Estrada-Guel, I., & Martínez-Sánchez, R. (2025). Synergistic Effects of Sub-Micron WC Reinforcement and T6 Heat Treatment on the Evolution of Microstructure and Mechanical Behavior in Al–Cu–Mg Composites Fabricated Through Powder Metallurgy. Metals, 15(11), 1216. https://doi.org/10.3390/met15111216