A Test for Susceptibility to Solidification Cracking and Liquation Cracking in Additive Manufacturing

Abstract

1. Introduction

2. Materials and Methods

2.1. Identifying a Weldability Test for AM

- (1)

- Lengthy specimen mounting/removal: A weldability test such as the Sigmajig test [23] uses many (ten) screws to clamp down a specimen and pre-stretch it. This lengthy procedure can be difficult to perform with gloves from outside an Ar-filled chamber.

- (2)

- Welding along a joint: Since a single-pass, single-layer deposit is narrow and shallow, precise alignment with a joint and melting/wetting both sides of the joint can be difficult. For example, a butt joint exists in the circular-patch test [24] and the Murex hot cracking test [25]. An inverse-T joint exists in the VDR test [26] and the T-joint weldability test [27]. A lap joint exists in the Transverse-Tension Weldability test [28].

- (3)

- Transverse tension during welding: The workpiece is typically greater in length than width. So, transverse tension, e.g., in the Controlled-Tension Weldability test [29], requires a heavier horizontal tensile testing machine than longitudinal tension.

- (4)

- Instantaneous tension during welding: The widely used Varestraint test [30] and the transverse Varestraint test [31] are examples. Since the liquid pool in arc welding travels slowly, the tension applied instantaneously has risen to its full level before the pool travels significantly. However, since the liquid pool in AM travels fast, the pool has already moved significantly while the tension is still rising, i.e., the applied tension varies along the deposit.

- (5)

- Automatic crack initiation at specimen’s leading edge: A weld pool fully penetrating through the specimen at its leading edge may initiate cracks automatically when the pool travels inward, e.g., in the Houldcroft test [32]. In AM, the liquid pool can be too shallow to penetrate through the thickness of the specimen.

- (6)

- Automatic crack initiation in a pre-stressed specimen: When a rectangular specimen is pre-stressed in the longitudinal direction [33,34] before welding, cracks may be initiated near a weld pool that penetrates through the thickness of the specimen. Examples included a specimen thickness of 2.3 mm in arc welding [33] and 2.0 or 5.7 mm in laser welding (in the so-called U-Type Hot Cracking test [34]). Since the liquid pool is shallow in AM, cracks may not be initiated.

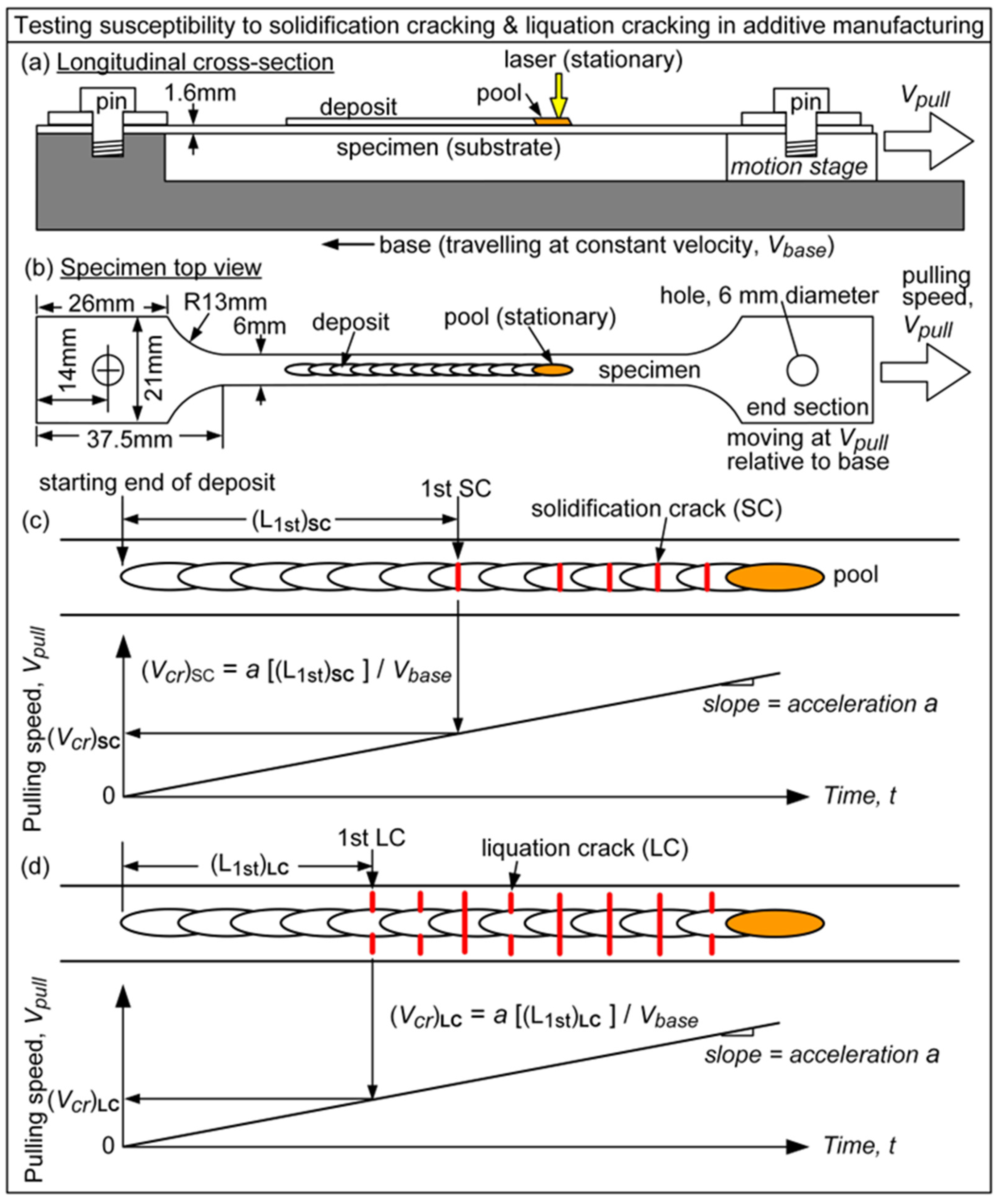

2.2. The AM-PVR Test for Hot Cracking Susceptibility in AM

3. Results

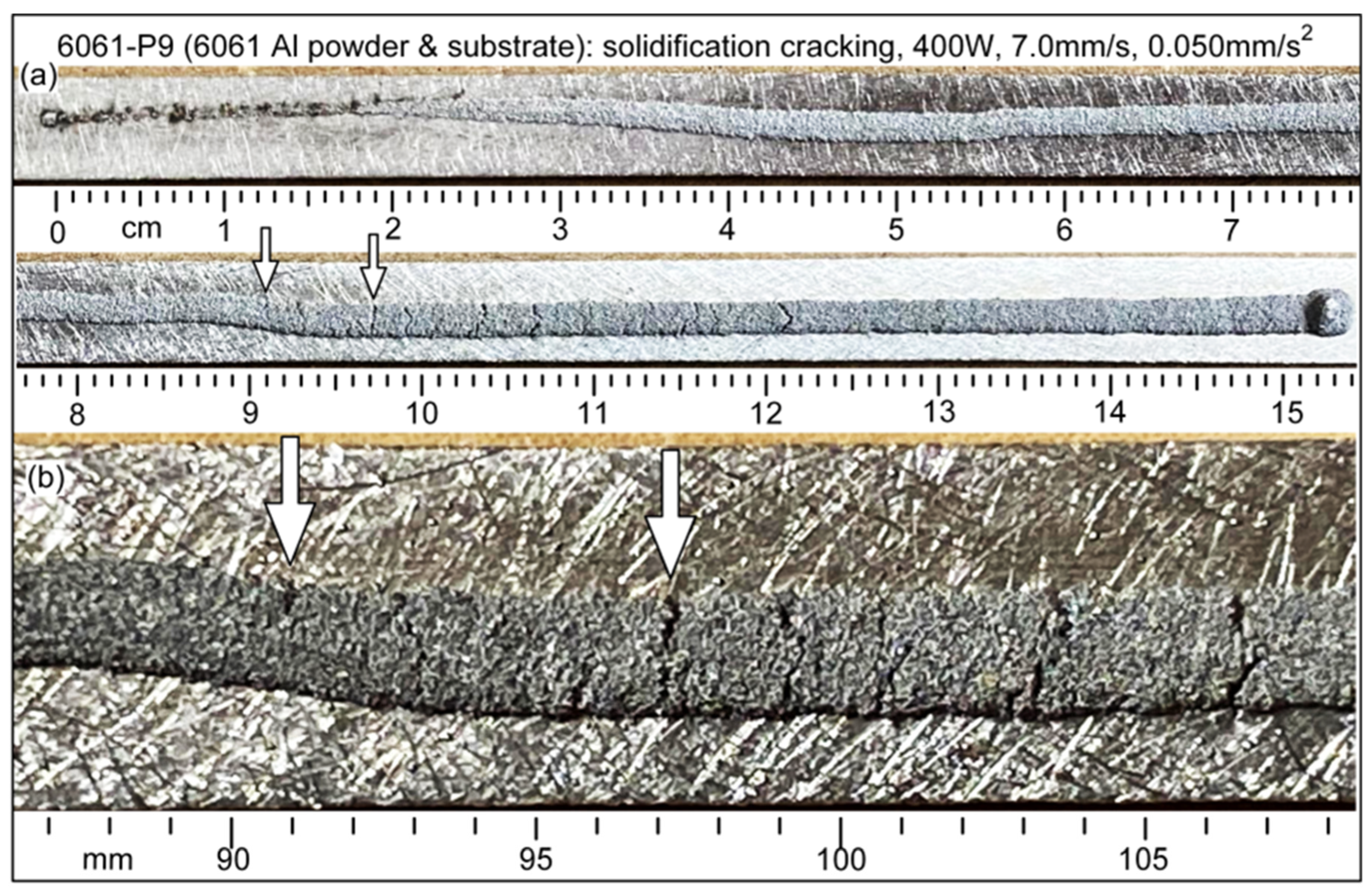

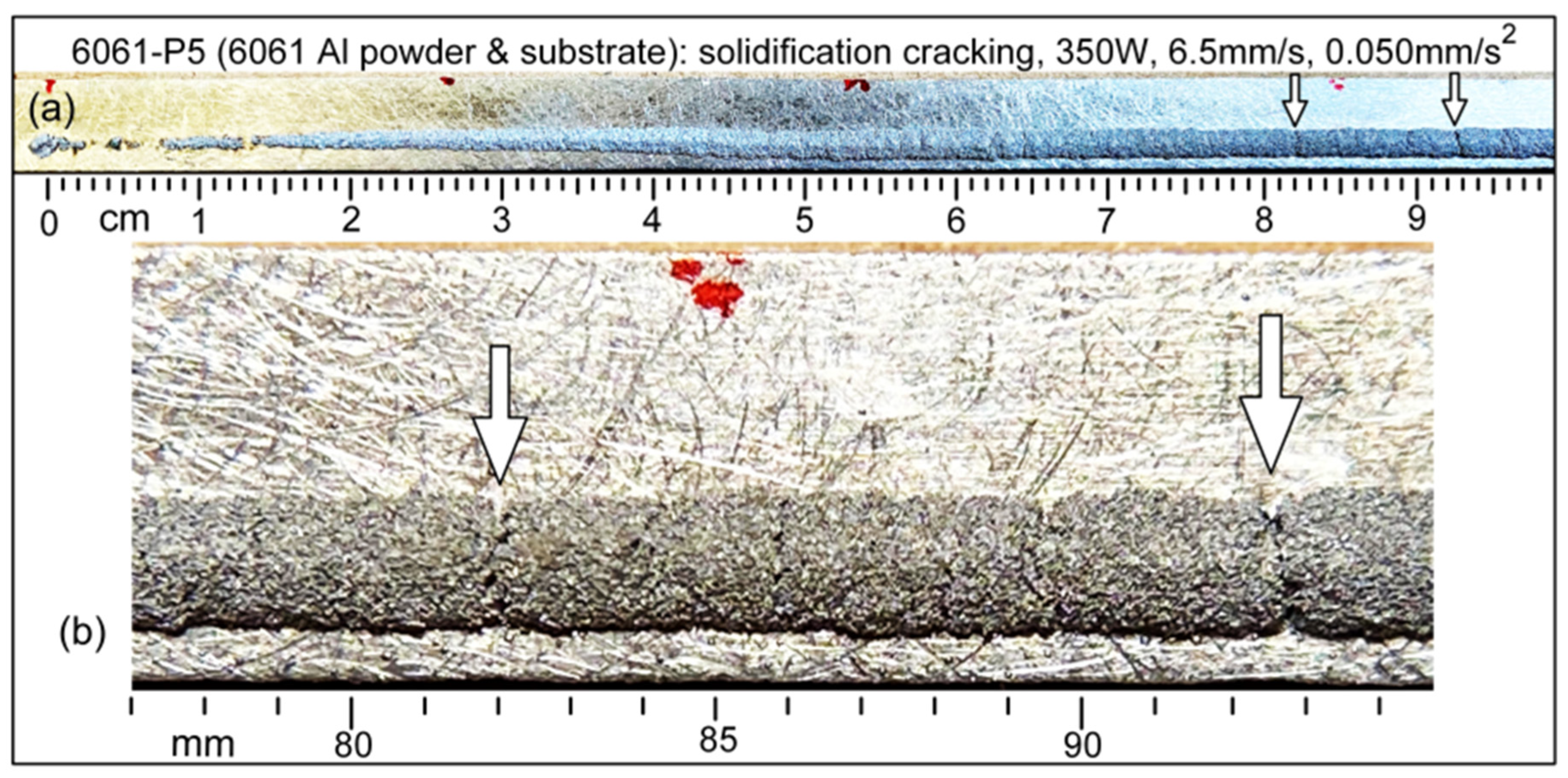

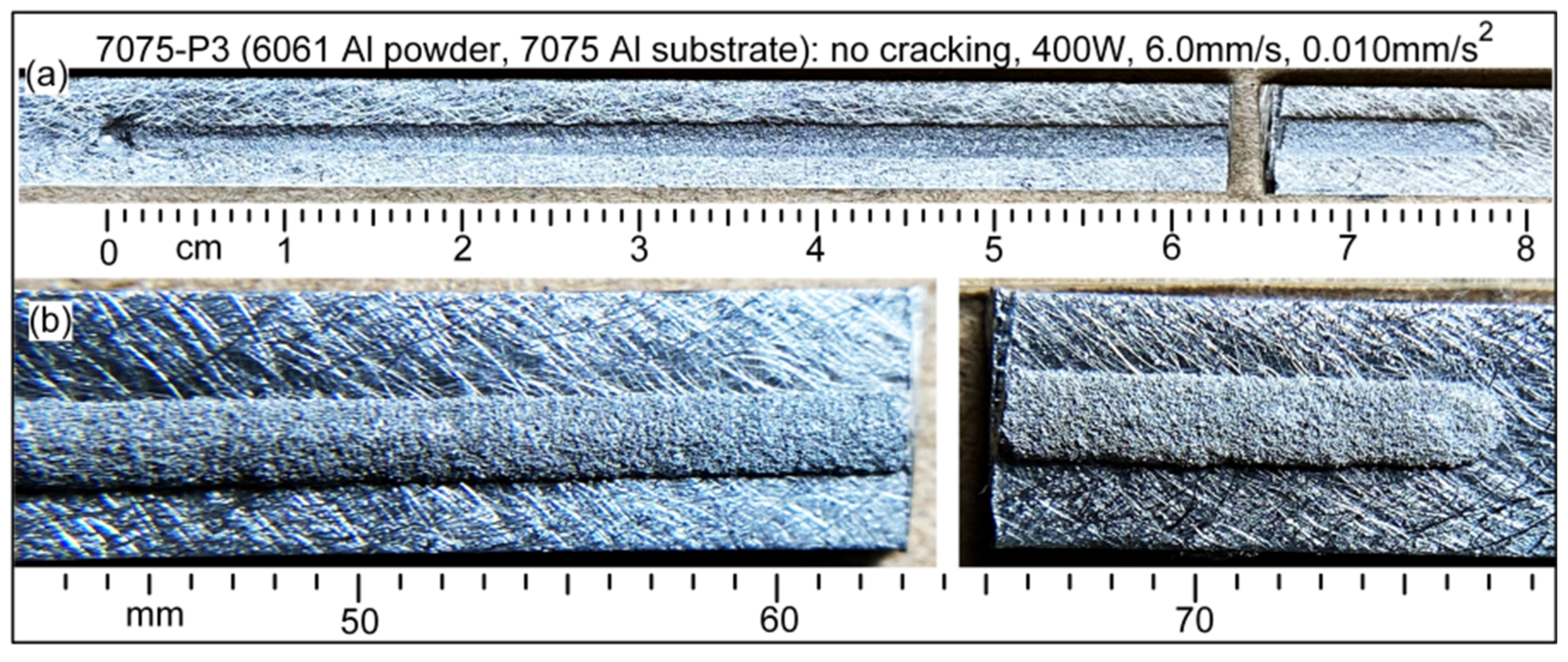

3.1. Solidification Cracking Susceptibility

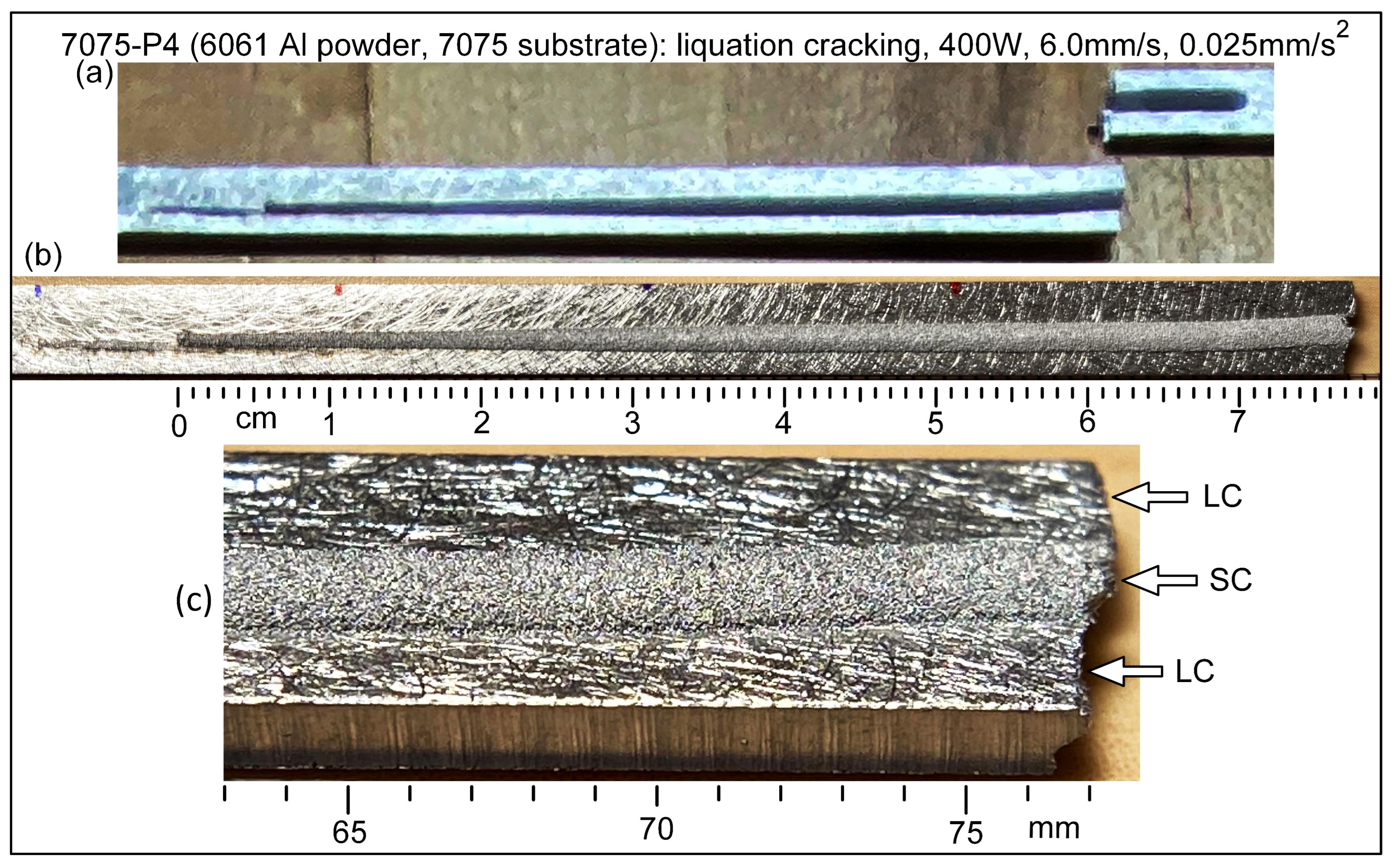

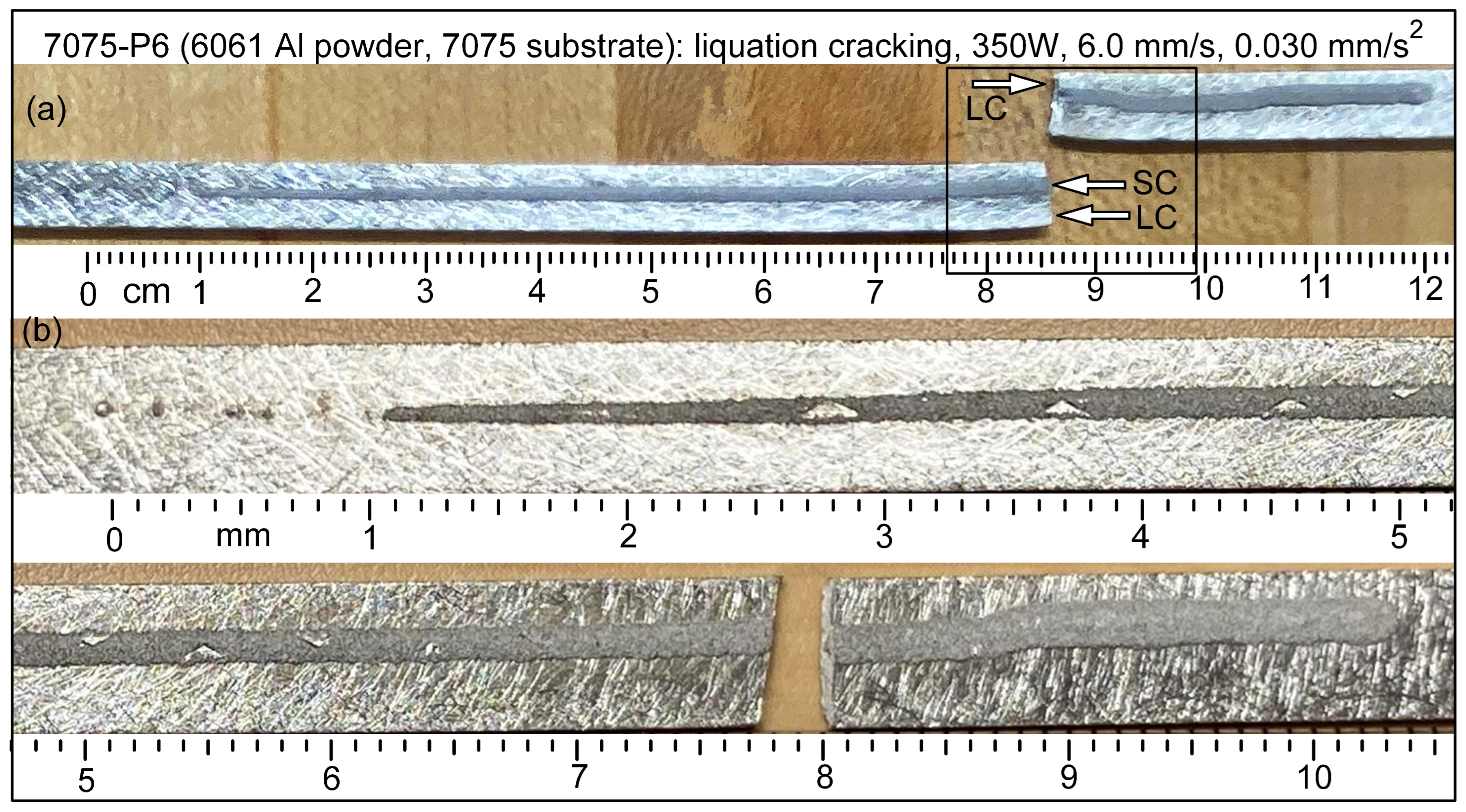

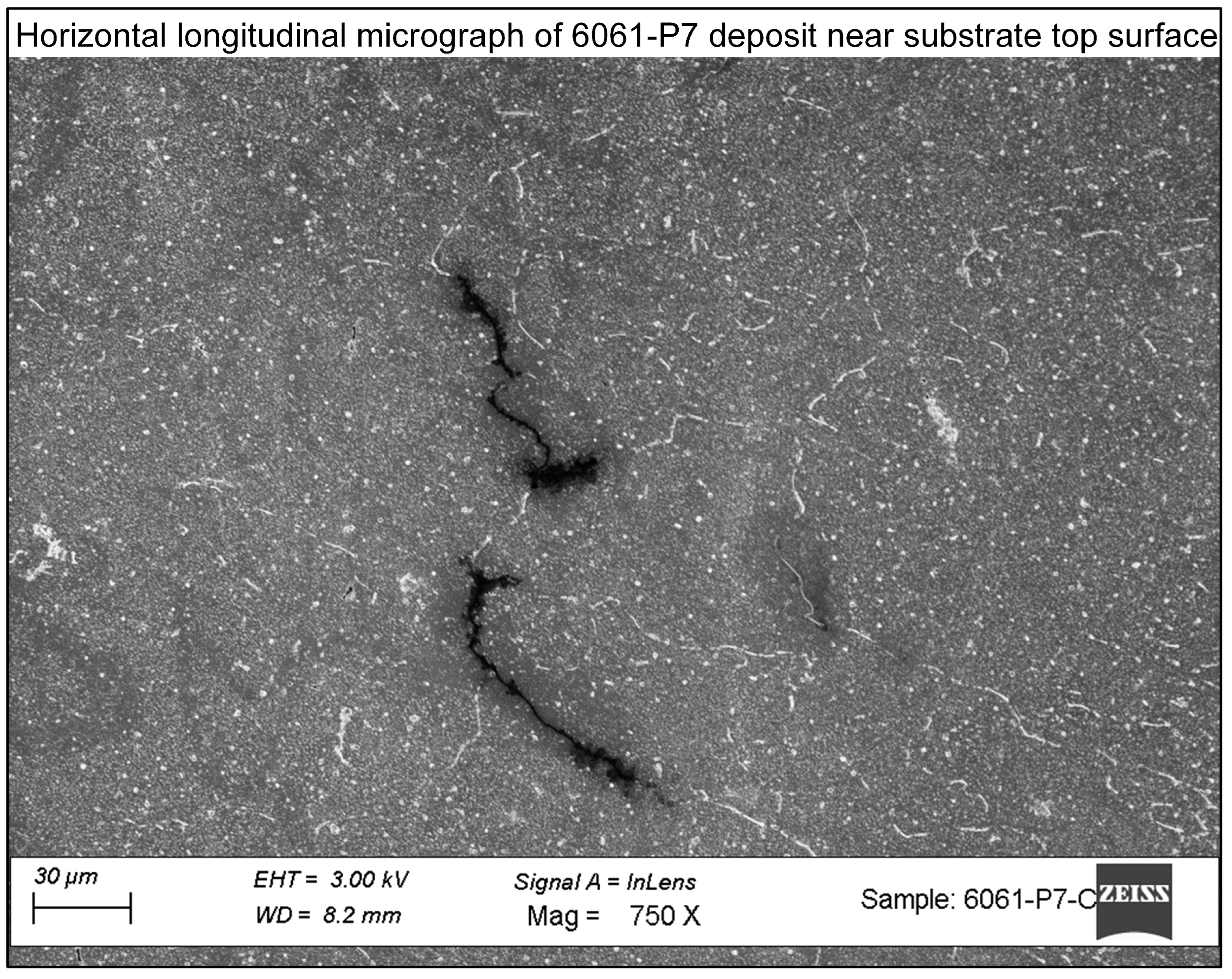

3.2. Liquation Cracking Susceptibility

4. Discussion

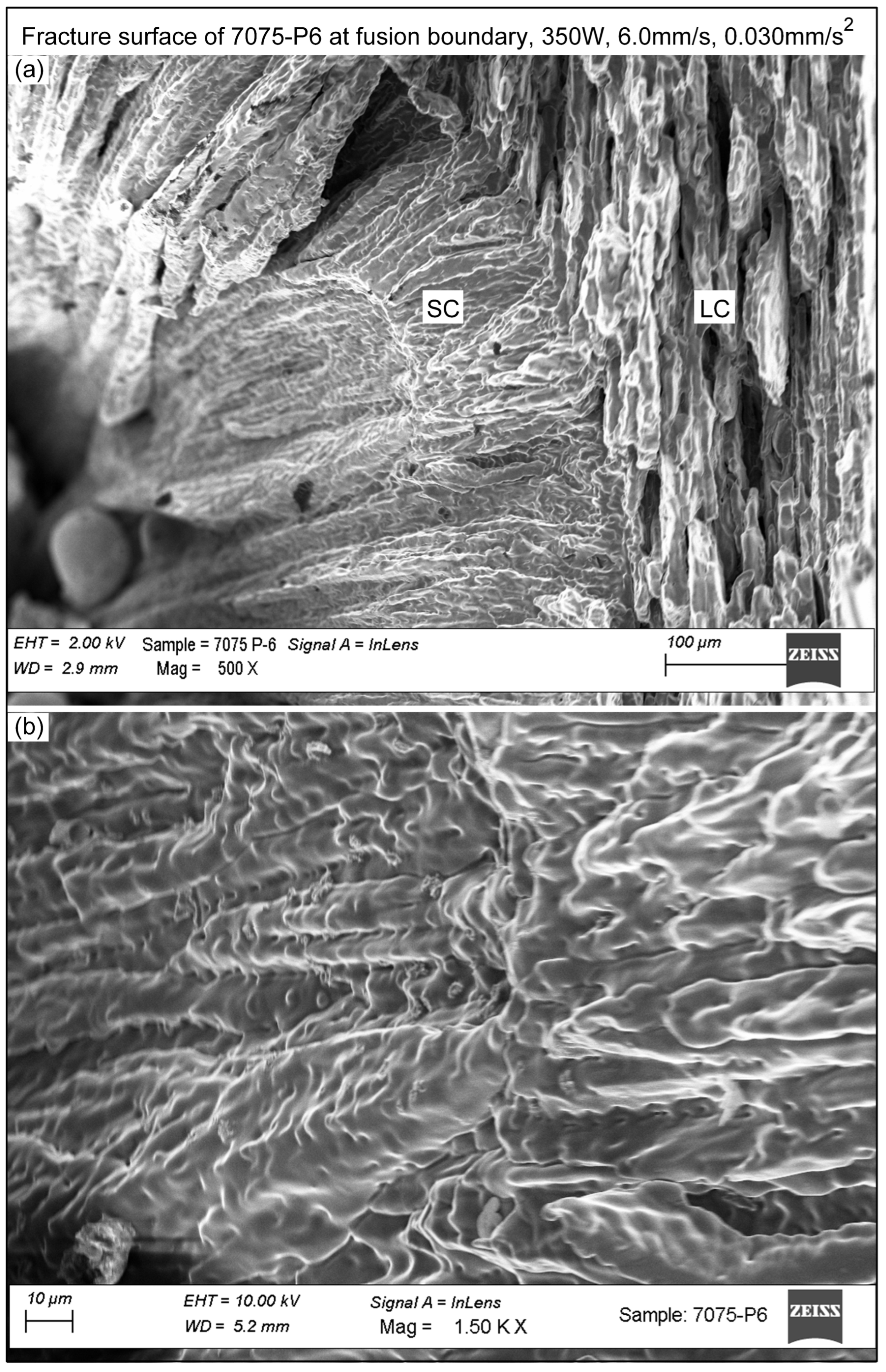

4.1. Fracture Surfaces

4.2. Solidification Cracking Susceptibility

4.3. Liquation Cracking Susceptibility

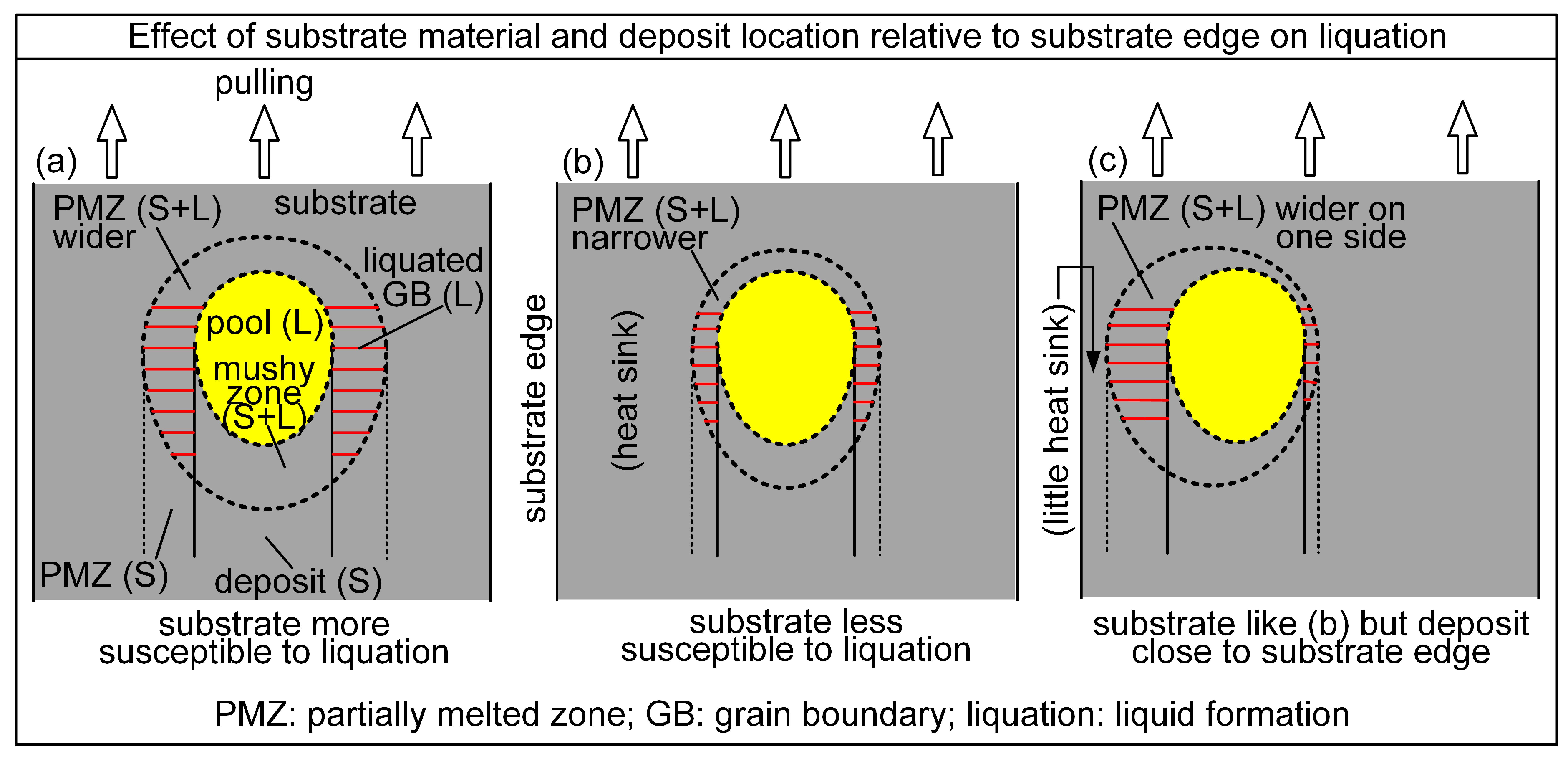

4.4. Effect of Substrate and Deposit Location

5. Conclusions

- (1)

- The PVR weldability test has been selected, modified and used as a test for evaluating the susceptibility to solidification cracking and liquation cracking in AM. In this AM-PVR test, a single-pass, single-layer deposit is made along a slender specimen that is pulled, like in tensile testing, but with acceleration.

- (2)

- Solidification cracks are visible on the surface of the deposit. Liquation cracks are visible in the substrate near the deposit, and they can propagate through the specimen. The fracture surfaces are readily accessible for examination by SEM. Dendritic fracture surfaces of the deposits have confirmed solidification cracking. Nondendritic fracture surfaces of the substrates showing intergranular cracking have confirmed liquation cracking.

- (3)

- The critical pulling speed for solidification cracking can be determined as an index for the cracking susceptibility under the conditions of deposition and testing used in the test, so can that for liquation cracking. In either type of cracking, the lower the critical pulling speed, the higher the cracking susceptibility.

- (4)

- The results of the present study can be considered as a proof of concept for this AM-PVR test.

6. Patents

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AM | Additive Manufacturing |

| PMZ | Partially Melted Zone |

| PVR | Programmierter (Programmable) Verformungs (Deformation) Riss (Crack) |

| SEM | Scanning Electron Microscopy |

References

- Flemings, M.C. Solidification Processing; McGraw-Hills: New York, NY, USA, 1974; pp. 252–258. [Google Scholar]

- Kou, S. Welding Metallurgy, 3rd ed.; John Wiley and Sons: Hoboken, NJ, USA, 2021; pp. 323–366, 419–439. [Google Scholar]

- Kou, S. Grain refining and cracking during solidification. Metall. Mater. Trans. A 2024, 55, 4663–4675. [Google Scholar] [CrossRef]

- Mousavi, M.; Cross, C.C.; Grong, Ø. Effect of scandium and titanium–boron on grain refinement and hot cracking of alumin-ium alloy 7108. Sci. Technol. Weld. Join. 1999, 4, 381–388. [Google Scholar] [CrossRef]

- Kimura, R.; Hatayama, H.; Shinozaki, K.; Murashima, I.; Asada, J.; Yoshida, M. Effect of grain refiner and grain size on the susceptibility of Al–Mg die casting alloy to cracking during solidification. J. Mater. Process. Technol. 2009, 209, 210–219. [Google Scholar] [CrossRef]

- Karunakar, B.D.; Rai, R.N.; Patra, S.; Datta, G.L. Effects of grain refinement and residual elements on hot tearing in aluminum castings. Int. J. Adv. Manuf. Technol. 2009, 45, 851–858. [Google Scholar] [CrossRef]

- Dasgupta, S.; Kou, S. Undercooling and cracking during solidification. Metall. Mater. Trans. A 2024, 55, 3450–3462. [Google Scholar] [CrossRef]

- Liu, J.; Duarte, H.P.; Kou, S. Evidence of back diffusion reducing cracking during solidification. Acta Mater. 2017, 122, 47–59. [Google Scholar] [CrossRef]

- Kou, S. A criterion for cracking during solidification. Acta Mater. 2015, 88, 366–374. [Google Scholar] [CrossRef]

- Kannengiesser, T.; Boellinghaus, T. Hot cracking tests—An overview of present technologies and applications. Weld. World 2014, 58, 397–421. [Google Scholar] [CrossRef]

- Yu, J.; Rombouts, M.; Maes, G. Cracking behavior and mechanical properties of austenitic stainless steel parts produced by laser metal deposition. Mater. Design 2013, 45, 228–235. [Google Scholar] [CrossRef]

- Yang, J.; Li, F.; Wang, Z.; Zeng, X. Cracking behavior and control of Rene 104 superalloy produced by direct laser fabrication. J. Mater. Process. Technol. 2015, 225, 229–239. [Google Scholar] [CrossRef]

- Hu, Z.; Nie, X.; Qi, Y.; Zhang, H.; Zhu, H. Cracking criterion for high strength Al–Cu alloys fabricated by selective laser melting. Addit. Manuf. 2021, 37, 101709. [Google Scholar] [CrossRef]

- Hyer, H.; Zhou, L.; Mehta, A.; Park, S.; Huynh, T.; Song, S.; Bai, Y.; Cho, K.; McWilliams, B.; Sohn, Y. Composition-dependent solidification cracking of aluminum-silicon alloys during laser powder bed fusion. Acta Mater. 2021, 208, 116698. [Google Scholar] [CrossRef]

- Qi, T.; Zhu, H.; Zhang, H.; Yin, J.; Ke, L.; Zeng, X. Selective laser melting of Al7050 powder: Melting mode transition and comparison of the characteristics between the keyhole and conduction mode. Mater. Des. 2017, 135, 257–266. [Google Scholar] [CrossRef]

- Mehta, A.; Zhou, L.; Huynh, T.; Park, S.; Hyer, H.; Song, S.; Bai, Y.; Imholte, D.D.; Woolstenhulme, N.E.; Wachs, D.M.; et al. Additive manufacturing and mechanical properties of the dense and crack free Zr-modified aluminum alloy 6061 fabricated by the laser-powder bed fusion. Addit. Manuf. 2021, 41, 101966. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef] [PubMed]

- Bermingham, M.J.; StJohn, D.H.; Krynen, J.; Tedman-Jones, S.; Dargusch, M.S. Promoting the columnar to equiaxed transition and grain refinement of titanium alloys during additive manufacturing. Acta Mater. 2019, 168, 261–274. [Google Scholar] [CrossRef]

- Zhang, D.; Prasad, A.; Bermingham, M.J.; Todaro, C.J.; Benoit, M.J.; Patel, M.N.; Qiu, D.; StJohn, D.H.; Qian, M.; Easton, M.A. Grain refinement of alloys in fusion-based additive manufacturing processes. Metall. Mater. Trans. A 2020, 51, 4341–4359. [Google Scholar] [CrossRef]

- Uddin, S.Z.; Murr, L.E.; Terrazas, C.A.; Morton, P.; Roberson, D.A.; Wicker, R.B. Processing and characterization of crack-free aluminum 6061 using high-temperature heating in laser powder bed fusion additive manufacturing. Addit. Manuf. 2018, 22, 405–415. [Google Scholar] [CrossRef]

- Seidel, A.; Finaske, T.; Straubel, A.; Wendrock, H.; Maiwald, T.; Riede, M.; Lopez, E.; Brueckner, F.; Leyens, C. Additive manufacturing of powdery Ni-based superalloys Mar-M-247 and CM 247 LC in hybrid laser metal deposition. Metall. Mater. Trans. A 2018, 49, 3812–3830. [Google Scholar] [CrossRef]

- Chen, Y.; Lu, F.; Zhang, K.; Nie, P.; Hosseini, S.R.E.; Feng, K.; Li, Z. Dendritic microstructure and hot cracking of laser additive manufactured Inconel 718 under improved base cooling. J. Alloys Compd. 2016, 670, 312–321. [Google Scholar] [CrossRef]

- Goodwin, G.M. Development of a new hot-cracking test—The Sigmajig. Weld. J. 1987, 66, 33–38. [Google Scholar]

- Borland, J.C.; Rogerson, J.H. Examination of the patch test for assessing hot cracking tendencies of weld metal. Br. Weld. J. 1963, 8, 494–499. [Google Scholar]

- Jones, P.W. A Summary of Recent Work on the Murex Hot Cracking Test. Br. Weld. J. 1957, 4, 189–197. [Google Scholar]

- Matsuda, F.; Nakagawa, H.; Nakata, K.; Okada, H. The VDR cracking test for solidification crack susceptibility on weld metals and its application to aluminum alloys. Trans JWRI 1979, 8, 85–95. [Google Scholar]

- Kolarik, L.; Kovanda, K.; Valova, M.; Vondrous, P.; Dunovsky, J. Hot cracking T-joint weldability test of precipitation harden-able Al alloys. Ann. DAAAM Proc. 2011, 22, 633–635. [Google Scholar]

- Soysal, T.; Kou, S. A simple test for assessing solidification cracking susceptibility and checking validity of susceptibility prediction. Acta Mater. 2018, 143, 181–197. [Google Scholar] [CrossRef]

- Coniglio, N.; Cross, C.E.; Michael, T.; Lammers, M. Defining a critical weld dilution to avoid solidification cracking in aluminum. Weld. J. 2008, 87, 237s–247s. [Google Scholar]

- Savage, W.F.; Lundin, C.D. The varestraint test. Weld. J. 1965, 44, 433s–442s. [Google Scholar]

- Senda, T.; Fukuhisa, T.A.; Genta, W.A.; Kiyoshi, K.O.; Tadaaki, M.A. Fundamental investigations on solidification crack sus-ceptibility for weld metals with Trans-Varestraint test. Trans. Jpn. Weld. Soc. 1971, 2, 141–162. [Google Scholar]

- Houldcroft, P.T. A simple cracking test for use with argon-arc welding. Br. Weld. J. 1955, 2, 471–475. [Google Scholar]

- Niel, A.; Deschaux-Beaume, F.; Bordreuil, C.; Fras, G.; Drezet, J.M. Hot tearing test for TIG welding of aluminum alloys: Application of a stress parallel to the fusion line. In Hot Cracking Phenomena in Welds III; Springer: Berlin/Heidelberg, Germany, 2011; pp. 43–58. [Google Scholar]

- Shinozaki, K.; Kuroki, H.; Luo, X.; Ariyoshi, H.; Shirai, M. Comparison of hot-cracking susceptibilities of various Ni-base, heat-resistant superalloys by U-type hot cracking test. Study of laser weldability of Ni-base, heat-resistant superalloys (2nd report). Weld. Int. 1999, 13, 952–959. [Google Scholar] [CrossRef]

- Herold, H.; Zinke, M. Entwicklungstendenzen bei korrosionsbeständigen hochwarmfesten Werkstoffen und ihre schweißtechnische Verarbeitung. Trends of development for highly corrosion and heat resistant alloys and their weldability. Mater. Und Werkst. 1999, 30, 678–681. (In German) [Google Scholar]

- Yushchenko, K.; Savchenko, V.; Chervyakov, N.; Zvyagintseva, A.; Guyot, E. Comparative hot cracking evaluation of welded joints of alloy 690 using filler metals Inconel Sr 52 and 52 Mss. Weld. World 2011, 55, 28–35. [Google Scholar] [CrossRef]

- Yushchenko, K.A.; Savchenko, V.S.; Chervyakov, N.O.; Zvyagintseva, A.V.; Monko, G.G.; Pestov, V.A. Comparative evaluation of sensitivity of welded joints on alloy Inconel 690 to hot cracking. Paton Weld. J. 2011, 11, 2–7. [Google Scholar] [CrossRef]

- Kou, S. Device and Method for Evaluating the Susceptibility of Hot Cracking in Additive Manufacturing. U.S. Patent 12,442,739 B2, 14 October 2025. [Google Scholar]

- Kotkunde, N.; Krishnamurthy, H.N.; Singh, S.K.; Jella, G. Experimental and numerical investigations on hot deformation behavior and processing maps for ASS 304 and ASS 316. High Temperature Mater. Process. 2018, 37, 73–888. [Google Scholar] [CrossRef]

- ASTM E8/E8M-11; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2011.

- Dowd, J.D. Weld cracking of aluminum alloys. Weld. J. 1952, 31, 448–456. [Google Scholar]

- Dudas, J.H.; Collins, F.R. Preventing weld cracks in high-strength aluminum alloys. Weld. J. 1966, 45, 241–249. [Google Scholar]

- Li, Z.; Zhang, Y.; Li, H.; Wang, Y.; Wang, L.; Zhang, Y. Liquation cracking susceptibility and mechanical properties of 7075 aluminum alloy GTAW joints. Materials 2022, 15, 3651. [Google Scholar] [CrossRef]

- Huang, C.; Cao, G.; Kou, S. Liquation cracking in partial-penetration aluminum welds. Sci. Technol. Weld. Join. 2004, 9, 149–157. [Google Scholar] [CrossRef]

- The LENS MR-7 System. Optomec Inc.: Albuquerque, NM, USA, 2016.

- Martin, A.C.; Oliveira, J.P.; Fink, C. Elemental effects on weld cracking susceptibility in AlxCoCrCuy FeNi high-entropy alloy. Metall. Mater. Trans. A 2020, 51, 778–787. [Google Scholar] [CrossRef]

- Santos, G.M.; Goulart, P.R.; Couto, A.A.; Garcia, A.M.A.U.R.I. Primary dendrite arm spacing effects upon mechanical properties of an Al–3wt% Cu–1wt% Li alloy. In Properties and Characterization of Modern Materials; Springer: Singapore, 2017; pp. 215–229. [Google Scholar]

- Slyvinsky, A.; Herold, H.; Streitenberger, M. Influence of welding speed on the hot cracking resistance of the nickel-base alloy NiCr25FeAlY during TIG-welding. In Hot Cracking Phenomena in Welds; Springer: Berlin/Heidelberg, Germany, 2005; pp. 42–58. [Google Scholar]

- Coniglio, N.; Cross, C.E. Effect of weld travel speed on solidification cracking behavior. Part 2: Testing conditions and metrics. Int. J. Adv. Manuf. Technol. 2020, 107, 5025–5038. [Google Scholar] [CrossRef]

- Senda, T.; Matsuda, T.; Takano, F.; Watanabe, G.; Kobayashi, K.; Matsuzaka, T. Fundamental investigations on solidification crack susceptibility for weld metals with trans-Varestraint test. Trans. Jpn. Weld. Soc. 1971, 2, 1–22. [Google Scholar]

- Goodwin, G.M. The Effects of Heat Input and Weld Process on Hot Cracking in Stainless Steel. Weld. J. 1988, 67, 88s–94s. [Google Scholar]

- Nelson, T.W.; Lippold, J.C.; Lin, W.; Baeslack, W.A., III. Evaluation of the Circular Patch Test for Assessing Weld Solidification Cracking, Part I Development of a Test Method. Weld. J. 1997, 76, 110–119. [Google Scholar]

- Cicalǎ, E.; Duffet, G.; Andrzejewski, H.; Grevey, D.; Ignat, S. Hot cracking in Al-Mg-Si alloy laser welding—Operating param-eters and their effects. Mater. Sci. Eng. A 2005, 395, 1–9. [Google Scholar] [CrossRef]

- Fabrègue, D.; Deschamps, A.; Suéry, M.; Proudhon, H. Hot tearing during laser buttwelding of 6xxx aluminium alloys: Process optimisation and 2D/3D characterisation of hot tears. In Hot Cracking Phenomena in Welds II; Springer: Berlin/Heidelberg, Germany, 2007; pp. 241–253. [Google Scholar]

- Chen, Y.; Zhang, K.; Huang, J.; Hosseini, S.R.E.; Li, Z. Characterization of heat affected zone liquation cracking in laser additive manufacturing of Inconel 718. Mater. Des. 2016, 90, 586–594. [Google Scholar] [CrossRef]

- Miyazaki, M.; Nishio, K.; Katoh, M.; Mukae, S.; Kerr, H.W. Quantitative investigation of heat-affected zone cracking in aluminum alloy 6061. Weld. J. 1990, 69, 263s–272s. [Google Scholar] [CrossRef]

- Pandat, Version 2020. Phase Diagram Calculation Software Package for Multicomponent Systems. CompuTherm LLC: Madison, WI, USA, 2020.

- PanAluminum, Version 2020. Thermodynamic Database for Aluminum Alloys. CompuTherm LLC: Madison, WI, USA, 2020.

| Wt% | Cr | Cu | Fe | Mg | Mn | Si | Ti | Zn | Al |

|---|---|---|---|---|---|---|---|---|---|

| 6061 | 0.20 | 0.33 | 0.6 | 1.0 | 0.08 | 0.72 | 0.02 | 0.1 | balance |

| 7075 | 0.19 | 1.5 | 0.17 | 2.4 | 0.03 | 0.07 | 0.03 | 5.7 | balance |

| Cracking | Specimen | Laser Power (W) | Travel Speed, Vbase (mm/s) | Energy per Unit Length (J/mm) | Acceleration, a (mm/s2) | Deposit Length at 1st SC, L1st (mm) | Critical Pulling Speed Vcr for SC (mm/s) | Deposit Length at 1st LC, L1st (mm) | Critical Pulling Speed Vcr for LC (mm/s) |

|---|---|---|---|---|---|---|---|---|---|

| No | 6061-P2 | 350 | 7.5 | 46.7 | 0.020 | ||||

| 6061-P3 | 400 | 7.5 | 53.3 | 0.020 | |||||

| SC | 6061-P5 | 350 | 6.5 | 53.8 | 0.050 | 82–93 | 0.67 ± 0.04 | ||

| 6061-P9 | 400 | 7.0 | 57.1 | 0.050 | 91–97 | 0.67 ± 0.02 | |||

| LC | 6061-P7 | 400 | 6.5 | 61.5 | 0.050 | 82 | 0.63 | ||

| No | 7075-P3 | 400 | 6.0 | 66.7 | 0.010 | ||||

| 7075-P5 | 350 | 6.0 | 58.3 | 0.010 | |||||

| LC | 7075-P4 | 400 | 6.0 | 66.7 | 0.025 | 77 | 0.32 | ||

| 7075-P6 | 350 | 6.0 | 58.3 | 0.030 | 86 | 0.43 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dasgupta, S.; Thoma, D.; Kou, S. A Test for Susceptibility to Solidification Cracking and Liquation Cracking in Additive Manufacturing. Metals 2025, 15, 1147. https://doi.org/10.3390/met15101147

Dasgupta S, Thoma D, Kou S. A Test for Susceptibility to Solidification Cracking and Liquation Cracking in Additive Manufacturing. Metals. 2025; 15(10):1147. https://doi.org/10.3390/met15101147

Chicago/Turabian StyleDasgupta, Soumyadeep, Dan Thoma, and Sindo Kou. 2025. "A Test for Susceptibility to Solidification Cracking and Liquation Cracking in Additive Manufacturing" Metals 15, no. 10: 1147. https://doi.org/10.3390/met15101147

APA StyleDasgupta, S., Thoma, D., & Kou, S. (2025). A Test for Susceptibility to Solidification Cracking and Liquation Cracking in Additive Manufacturing. Metals, 15(10), 1147. https://doi.org/10.3390/met15101147