The Vanadium Micro-Alloying Effect on the Microstructure of HSLA Steel Welded Joints by GMAW

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

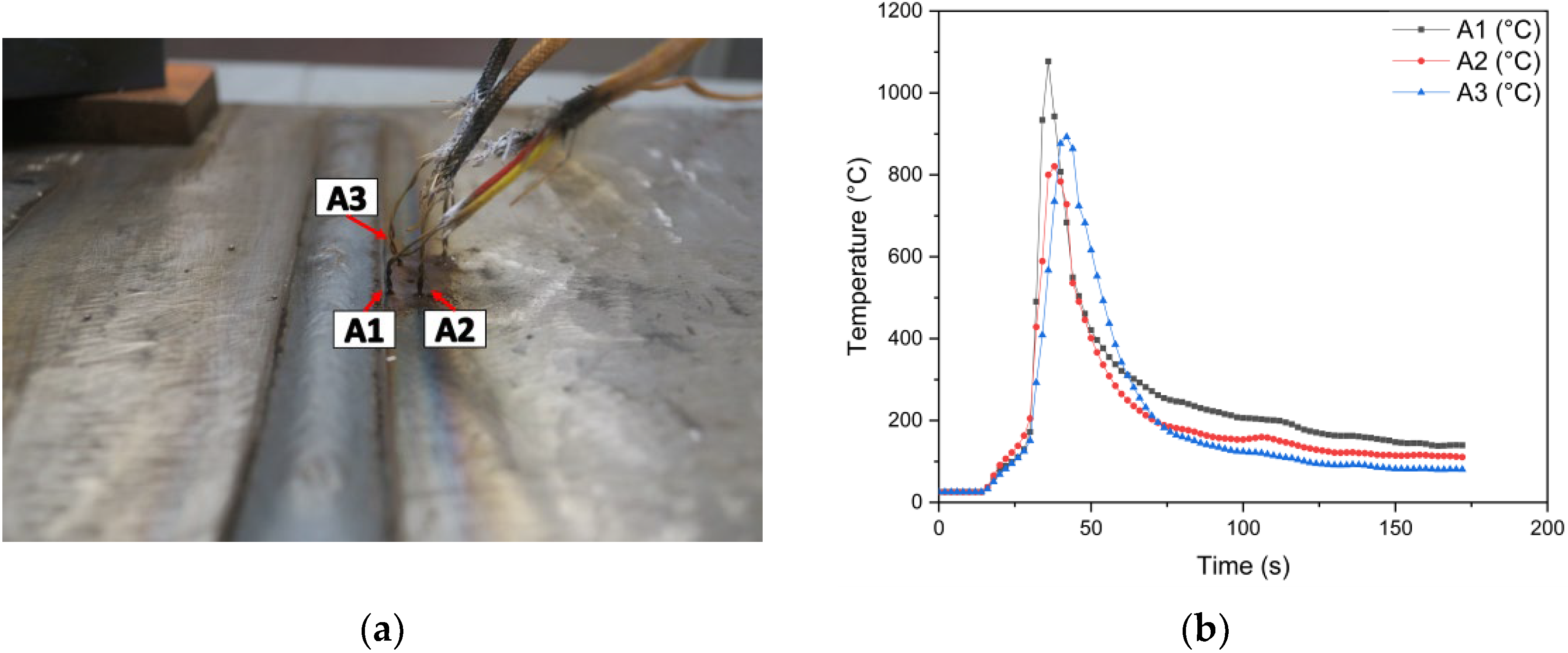

2.2. Welding Procedure

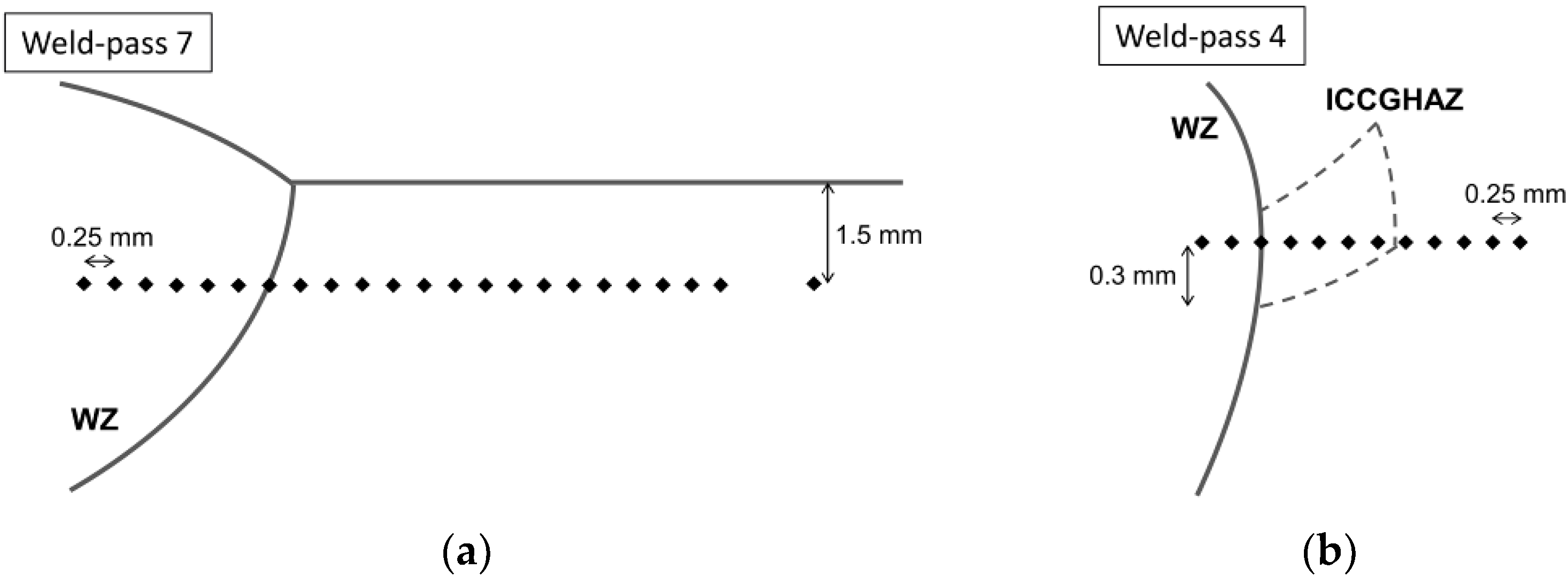

2.3. Macro/Microstructural Characterization

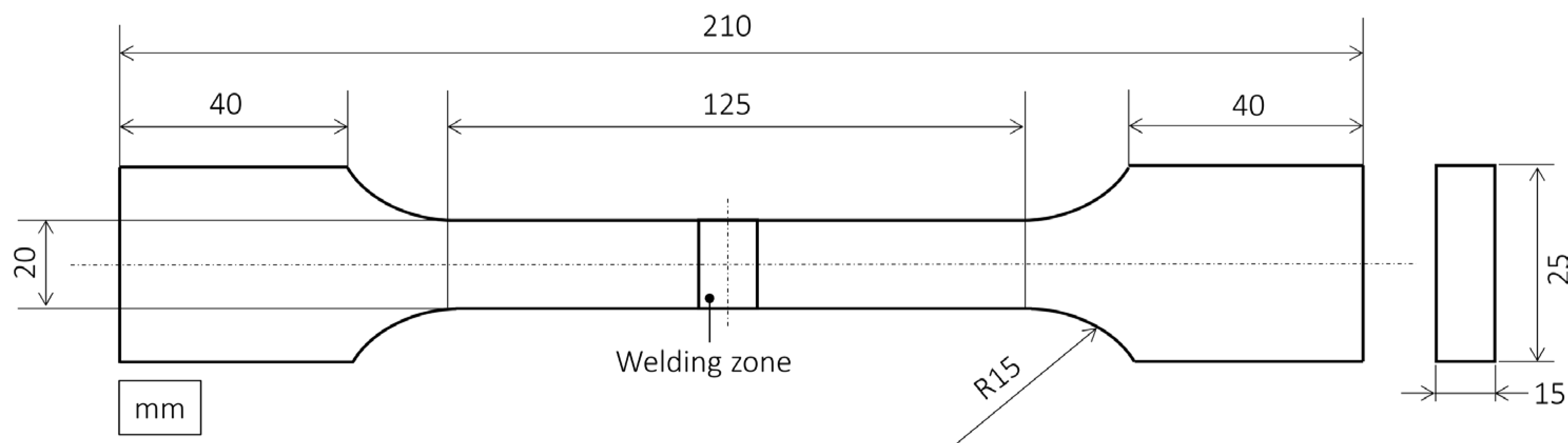

2.4. Evaluation of Mechanical Properties

3. Results

3.1. Macrostructure of Welds

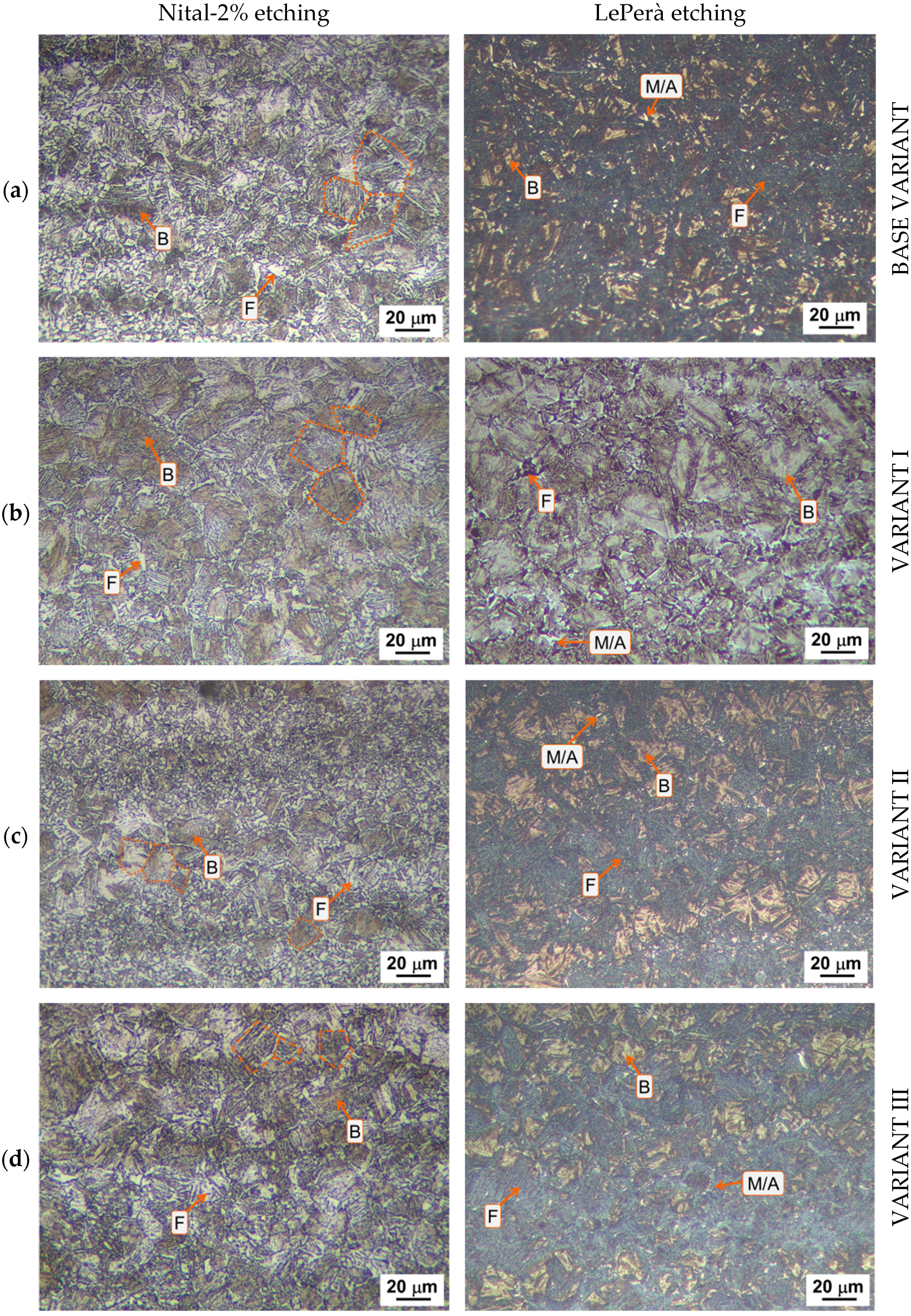

3.2. Microstructure Characterization

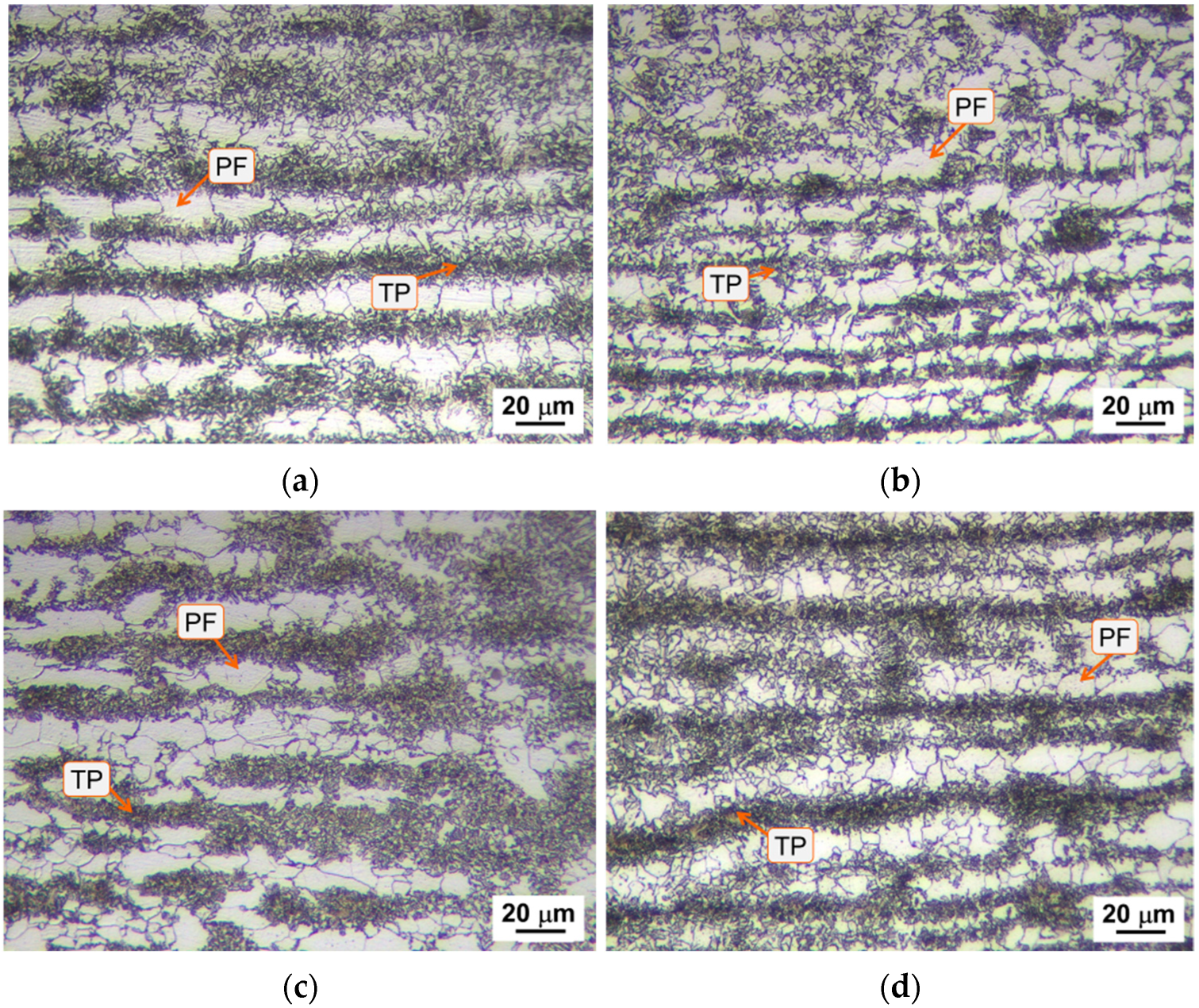

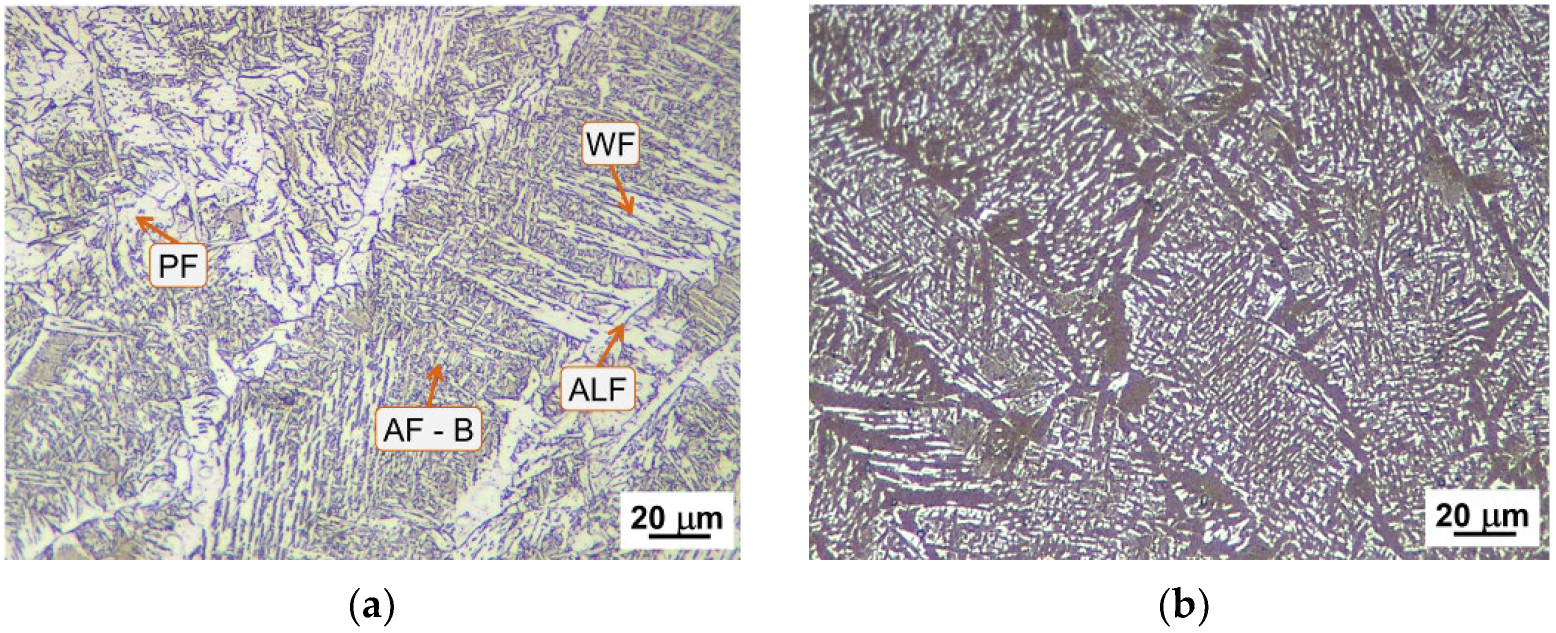

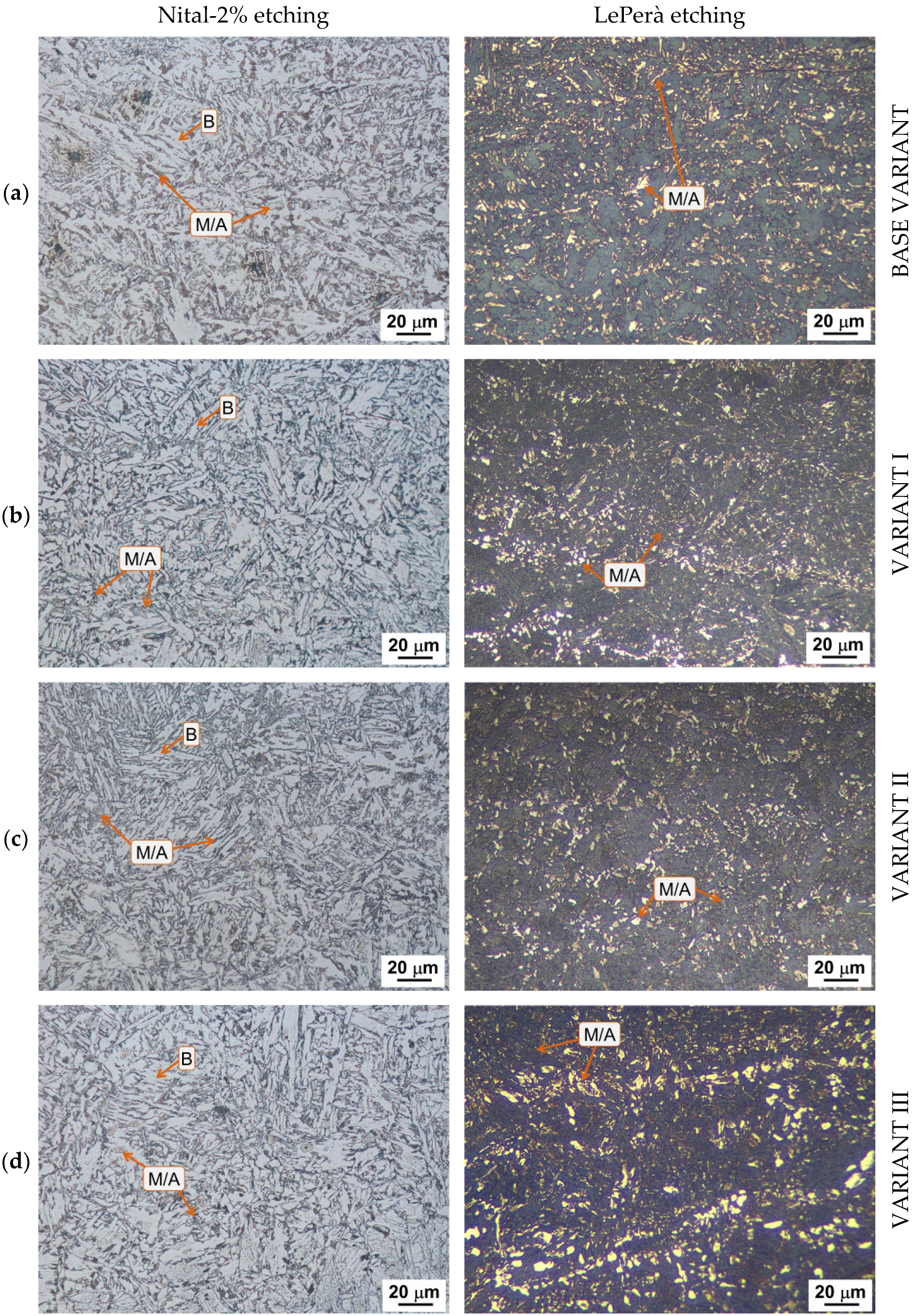

3.2.1. The Welding Zone

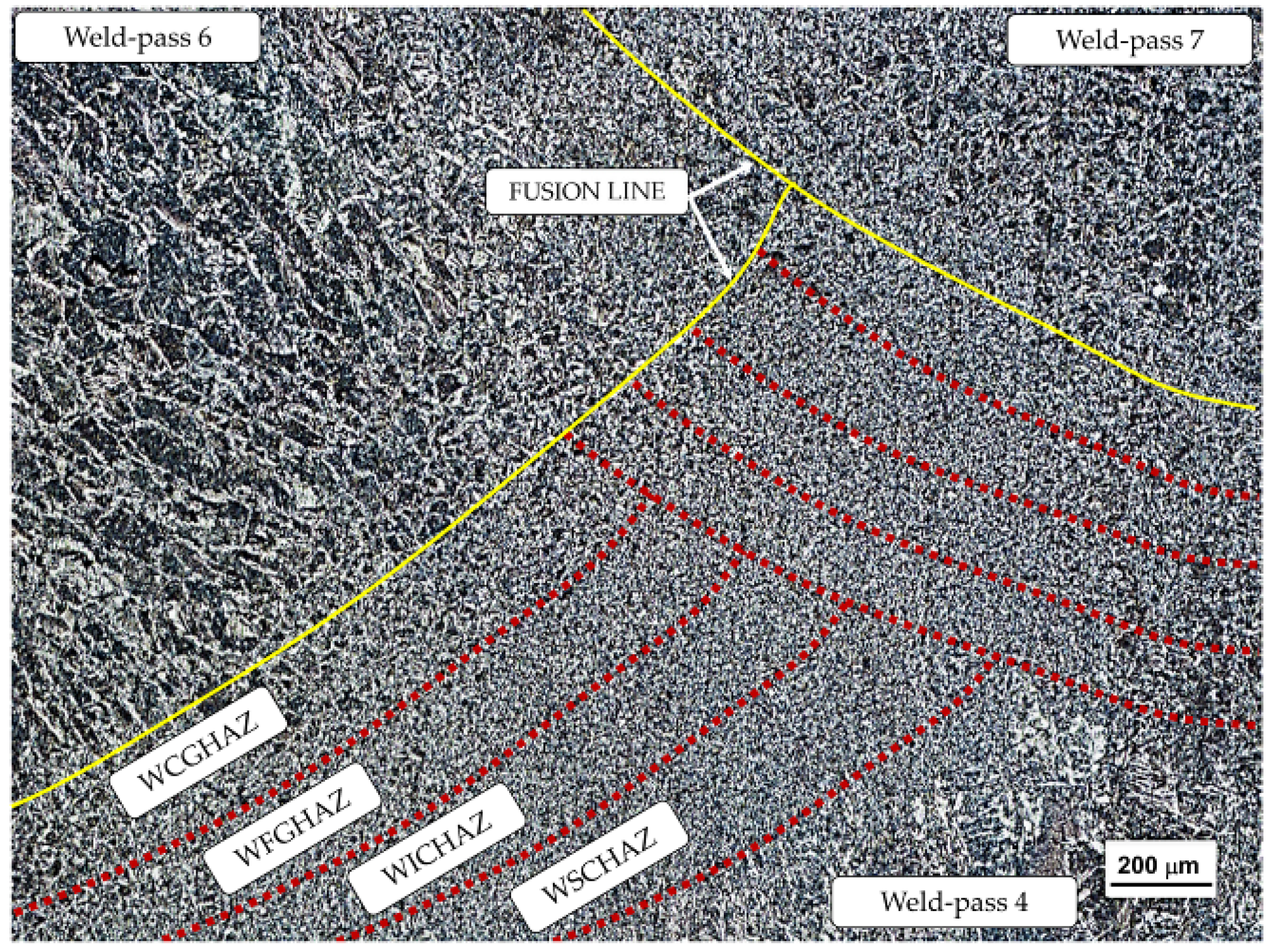

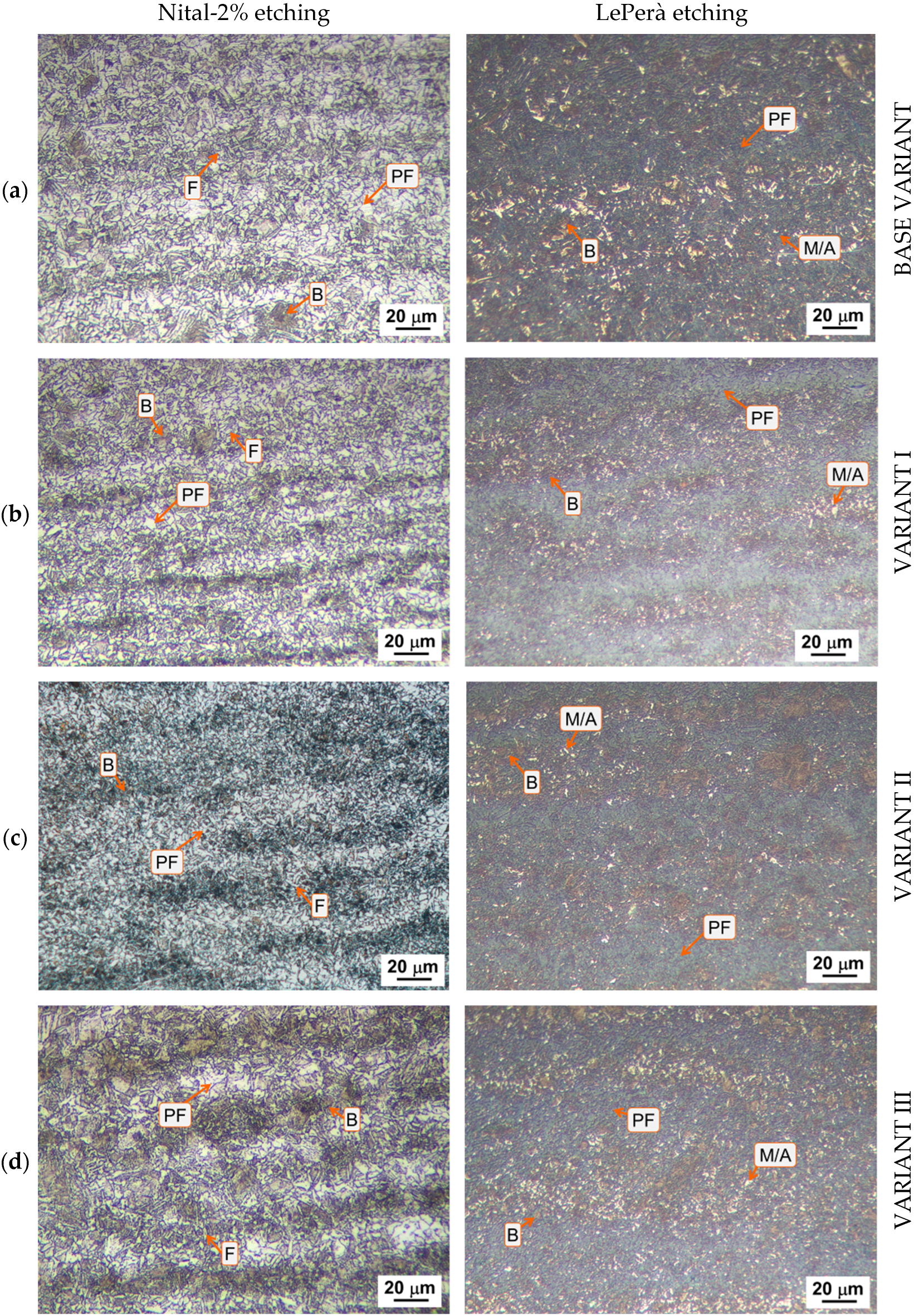

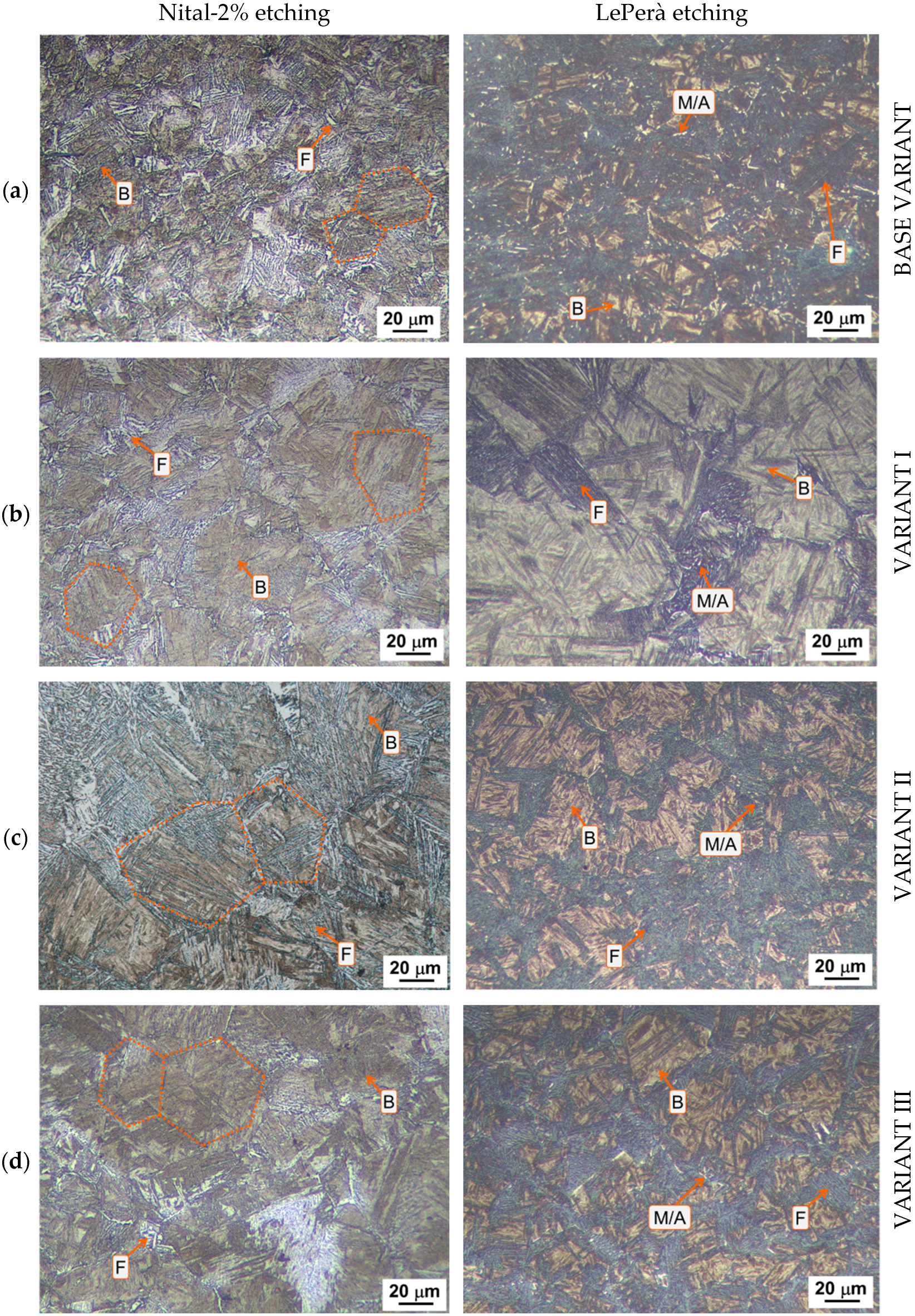

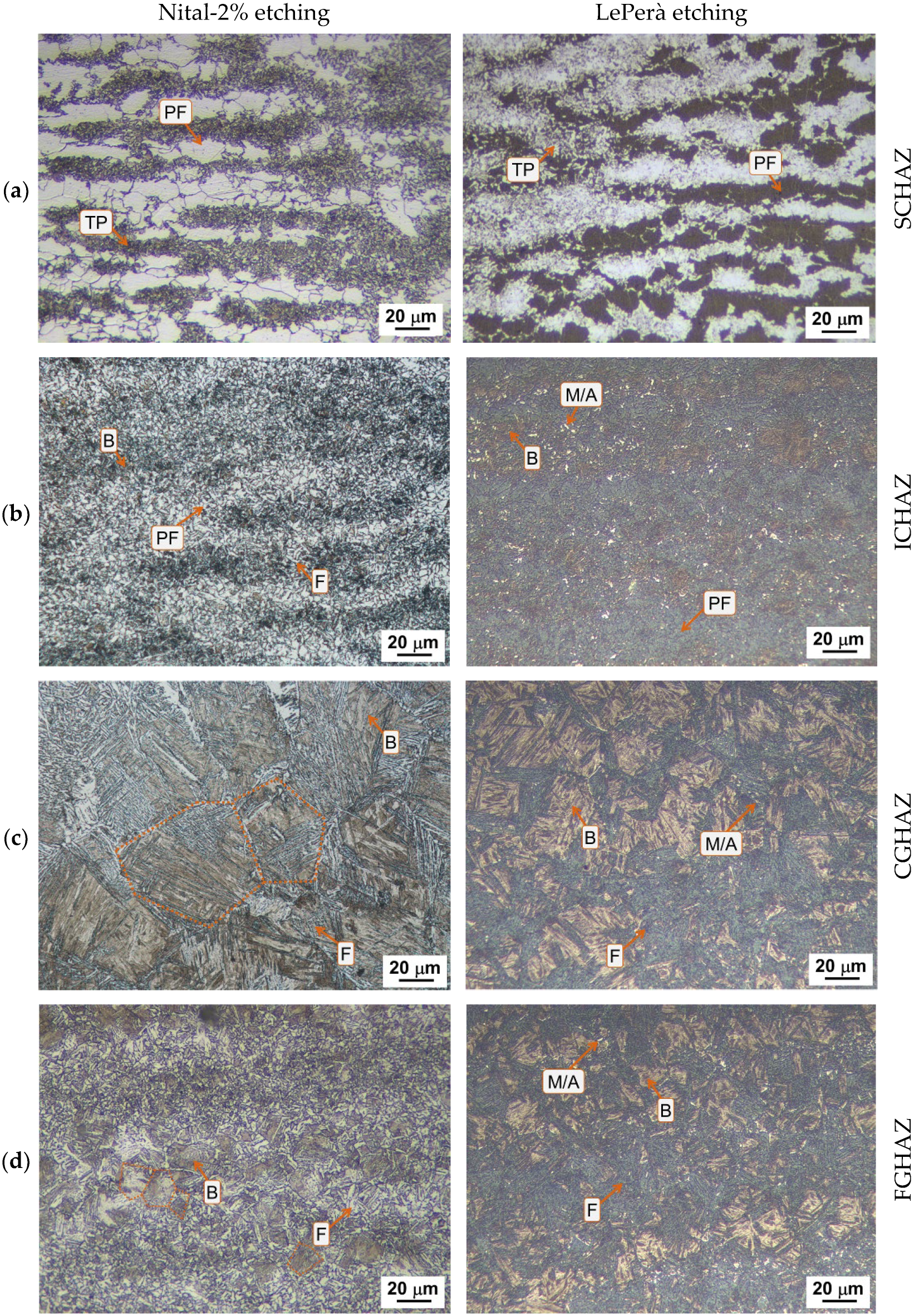

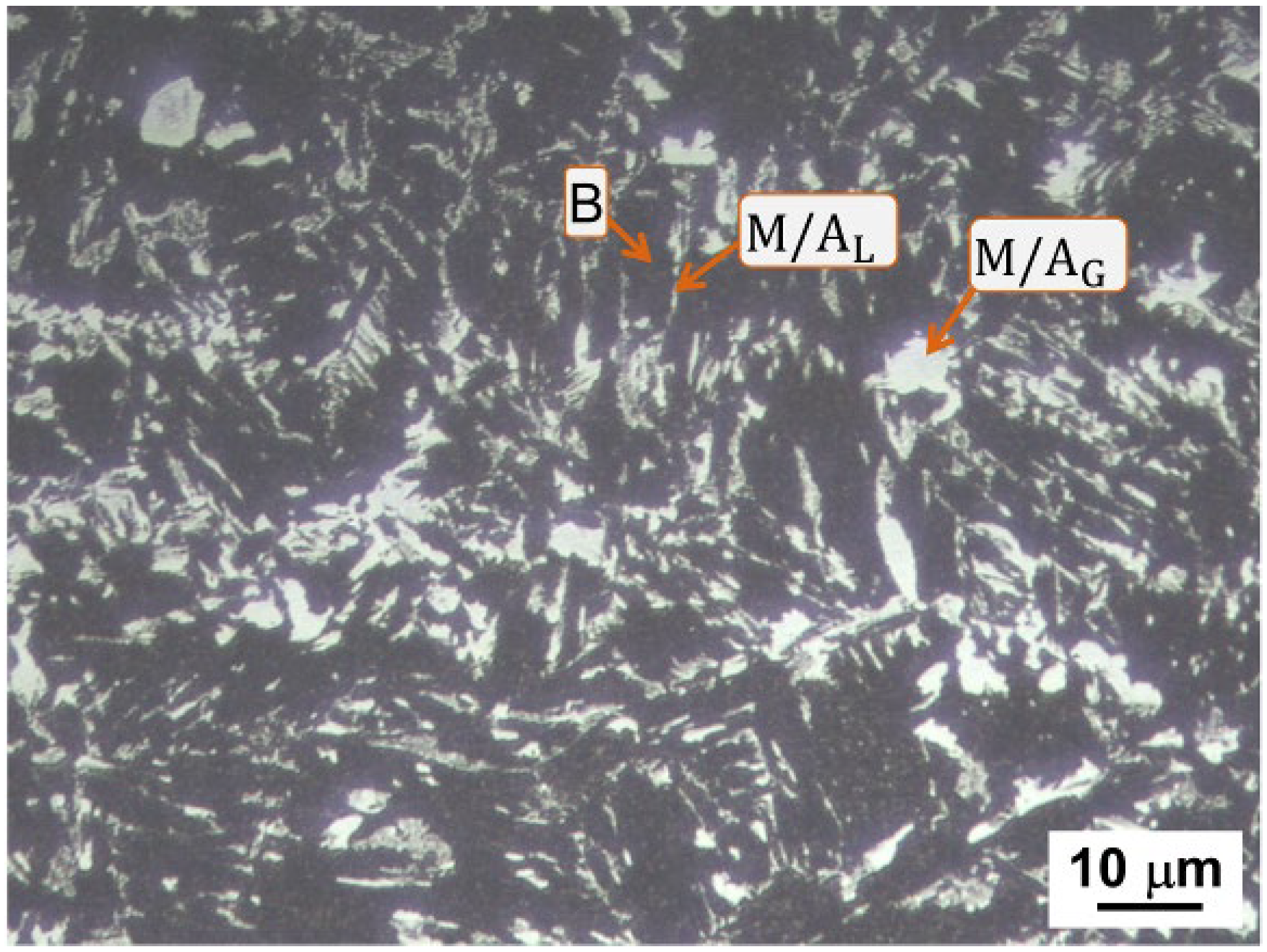

3.2.2. The Heat-Affected Zone

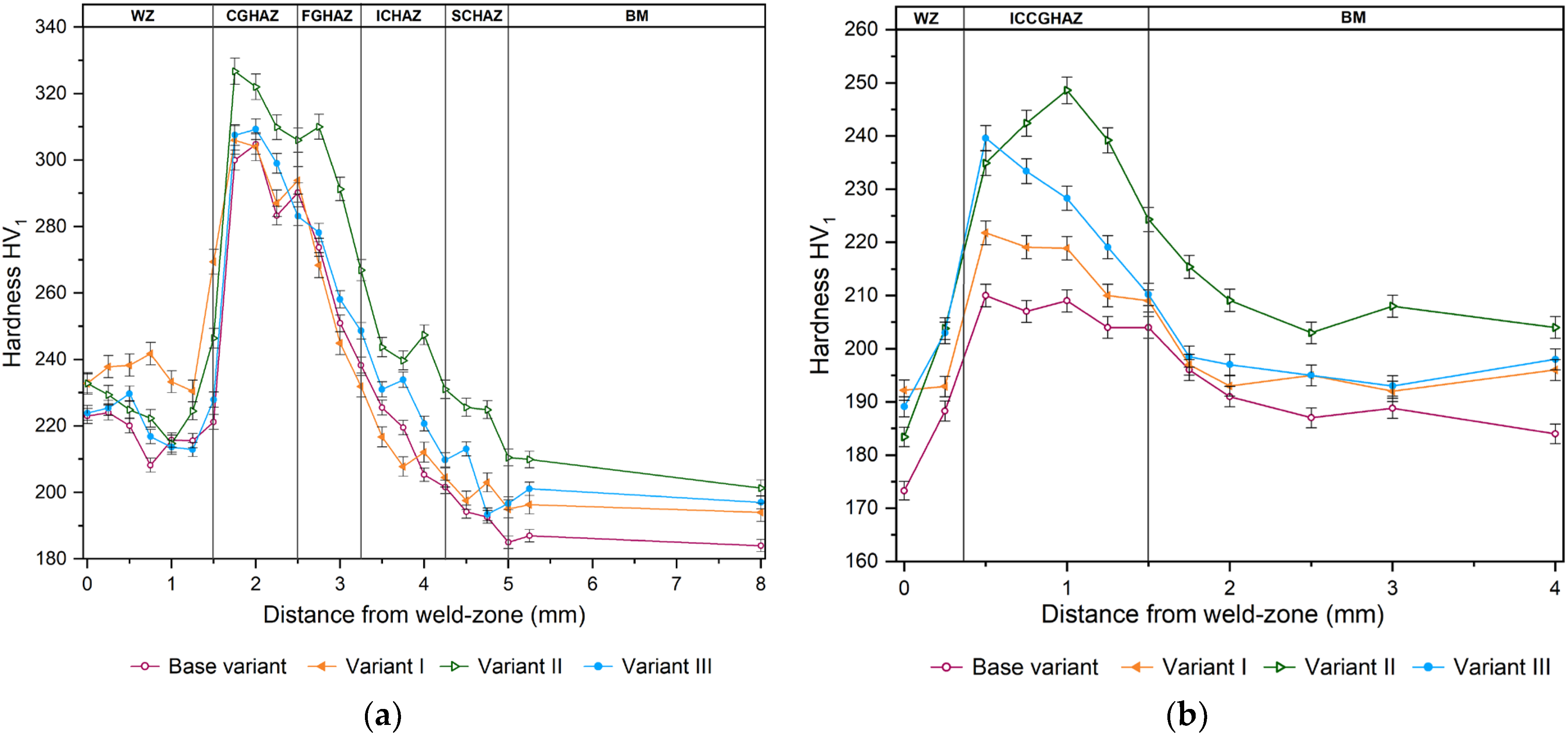

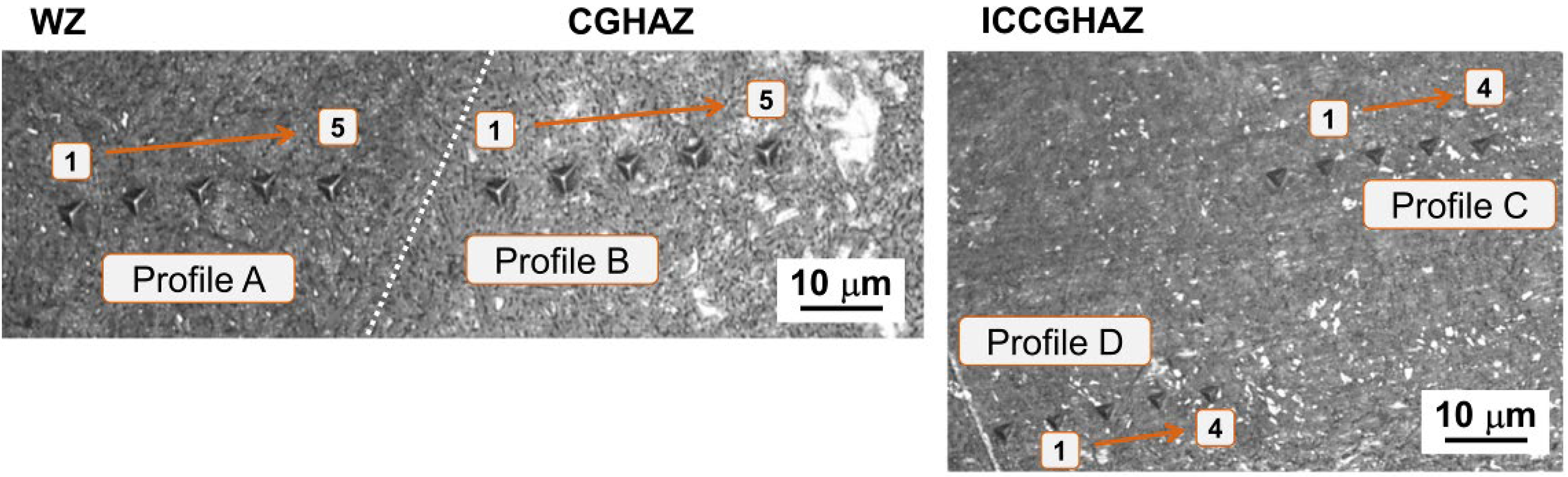

3.2.3. Mechanical Behavior of Welded Joints

4. Discussion

- (i)

- The elastic recovery coefficient () describes the proportion of elastic deformation undergone by the material, compared to the total deformation during indentation. Therefore, the parameter reflects the elastic recovery of the material during the unloading process and is evaluated according to Equation (2):where indicates complete elastic recovery; thus all deformations were elastic, and there is no residual plastic deformation. indicates no elastic recovery, with all deformations being plastic. indicates a combination of elastic and plastic deformations.

- (ii)

- The plasticity index () is the ratio between the plastic work () and total work () performed during indentation:with being close to one indicating the work mainly dissipated through plastic deformation (characteristic of ductile materials); on the contrary, for , a value close to zero suggests that the work has been stored as elastic energy (typical of brittle materials).

- (iii)

- H/E is the correlation used to evaluate the dissipation of elastic energy.

- (iv)

- H/E2 is the correlation used to evaluate the dissipation of plastic energy.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| A | Total elongation |

| AF | Acicular ferrite |

| ALF | Allotriomorphic ferrite |

| Au | Uniform elongation |

| B | Bainite |

| BM | Base metal |

| BV | Base variant |

| CGHAZ | Coarse-grain heat-affected zone |

| E | Elastic modulus |

| F | Ferrite |

| FGHAZ | Fine-grain heat-affected zone |

| GMAW | Gas metal arc welding |

| H | Nano-hardness |

| H/E | Correlation used to evaluate the dissipation of elastic energy |

| H/E^2 | Correlation used to evaluate the dissipation of plastic energy |

| HAZ | Heat-affected zone |

| hf | Residual depth after unloading |

| hmax | Maximum indentation depth |

| HSLA | High-strength low-alloy |

| HV | Hardness Vickers |

| ICCGHAZ | Inter-critical coarse-grain heat-affected zone |

| ICHAZ | Inter-critical heat-affected zone |

| IP | Plasticity index |

| Ke | Elastic recovery coefficient |

| M/A | Martensite/austenite |

| M/AG | M/A with granular morphology |

| M/AL | M/A with lamellar morphology |

| Nb | Niobium |

| P | Pearlite |

| PAG | Prior austenite grain |

| PF | Polygonal ferrite |

| SCHAZ | Sub-critical heat-affected zone |

| TEM | Transmission electron microscopy |

| UTS | Ultimate tensile stress |

| V | Vanadium |

| V-I | Variant I |

| V-II | Variant II |

| V-III | Variant III |

| We | Elastic work |

| WF | Widmanstätten ferrite |

| Wp | Plastic work |

| WZ | Weld zone |

| YS | Yield stress |

Appendix A

Microstructural Characterization of the Welding Zone

Appendix B

Microstructural Characterization of the Heat-Affected Zone

Appendix C

Comparison of Punctual Results from Nanoindentation Tests

| hmax * (µm) | E * (GPa) | H * (GPa) | Wp * (nJ) | We * (nJ) | hf * (µm) | |

|---|---|---|---|---|---|---|

| 1 | 1.33 | 186.4 | 1.7 | 46.5 | 4.3 | 1.10 |

| 2 | 1.18 | 170.3 | 2.1 | 40.3 | 5.3 | 1.01 |

| 3 | 1.22 | 164.0 | 2.0 | 40.1 | 4.8 | 1.03 |

| 4 | 1.22 | 166.9 | 2.0 | 40.5 | 4.3 | 1.06 |

| 5 | 1.25 | 168.1 | 1.9 | 40.3 | 5.0 | 1.09 |

| hmax * (µm) | E * (GPa) | H * (GPa) | Wp * (nJ) | We * (nJ) | hf * (µm) | |

|---|---|---|---|---|---|---|

| 1 | 1.19 | 175.0 | 2.1 | 37.1 | 4.8 | 1.06 |

| 2 | 1.23 | 138.1 | 2.0 | 39.3 | 5.0 | 1.03 |

| 3 | 1.18 | 192.2 | 2.1 | 36.7 | 5.0 | 1.00 |

| 4 | 1.22 | 143.1 | 2.0 | 39.8 | 4.7 | 1.09 |

| 5 | 1.20 | 183.0 | 2.1 | 37.7 | 5.2 | 1.04 |

| hmax * (µm) | E * (GPa) | H * (GPa) | Wp * (nJ) | We * (nJ) | hf * (µm) | |

|---|---|---|---|---|---|---|

| 1 | 1.23 | 141.5 | 2.0 | 37.9 | 5.1 | 1.00 |

| 2 | 1.18 | 141.6 | 2.2 | 37.2 | 5.4 | 0.95 |

| 3 | 1.14 | 167.1 | 2.3 | 36.6 | 5.3 | 0.91 |

| 4 | 1.19 | 166.1 | 2.1 | 36.9 | 5.7 | 0.90 |

| hmax * (µm) | E * (GPa) | H * (GPa) | Wp * (nJ) | We * (nJ) | hf * (µm) | |

|---|---|---|---|---|---|---|

| 1 | 1.14 | 135.6 | 2.3 | 33.9 | 5.2 | 887.0 |

| 2 | 1.08 | 184.7 | 2.5 | 34.5 | 5.1 | 857.0 |

| 3 | 1.06 | 140.1 | 2.7 | 34.5 | 6.2 | 729.0 |

| 4 | 1.09 | 210.9 | 2.5 | 37.1 | 5.5 | 821.0 |

References

- Roy, S.; Romualdi, N.; Yamada, K.; Poole, W.; Militzer, M.; Collins, L. The Relationship Between Microstructure and Hardness in the Heat-Affected Zone of Line Pipe Steels. JOM 2022, 74, 2395–2401. [Google Scholar] [CrossRef]

- Jindal, S.; Chhibber, R.; Mehta, N.P. Issues in Welding of HSLA Steels. Adv. Mat. Res. 2011, 365, 44–49. [Google Scholar] [CrossRef]

- Ceschini, L.; Marconi, A.; Martini, C.; Morri, A.; Di Schino, A. Tensile and Impact Behaviour of a Microalloyed Medium Carbon Steel: Effect of the Cooling Condition and Corresponding Microstructure. Mater. Des. 2013, 45, 171–178. [Google Scholar] [CrossRef]

- Di Schino, A.; Di Nunzio, P.E. Effect of Nb Microalloying on the Heat Affected Zone Microstructure of Girth Welded Joints. Mater. Lett. 2017, 186, 86–89. [Google Scholar] [CrossRef]

- Di Schino, A. Analysis of Phase Transformation in High Strength Low Alloyed Steels. Metalurgija 2017, 56, 349–352. [Google Scholar]

- Di Schino, A.; Guarnaschelli, C. Microstructure and Cleavage Resistance of High Strength Steels. Mater. Sci. Forum 2010, 638–642, 3188–3193. [Google Scholar] [CrossRef]

- Liao, W.; Mazánová, V.; Heczko, M.; Hou, W.; Procario, J.; Mills, M.J.; Liu, X. Underlying mechanisms for the effect of Nb micro-alloying on the elemental distribution and precipitation behavior in the X70 weld metal. Materialia 2024, 38, 102264. [Google Scholar] [CrossRef]

- Di Schino, A.; Gaggiotti, M.; Testani, C. Heat Treatment Effect on Microstructure Evolution in a 7% Cr Steel for Forging. Metals 2020, 10, 808. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, Y. Research Progress on Titanium–Niobium Micro-Alloyed High-Strength Steel. Materials 2025, 18, 325. [Google Scholar] [CrossRef]

- Tian, Y.; Zhao, M.C.; Zeng, Y.P.; Shi, X.B.; Yan, W.; Yang, K.; Zeng, T.Y. Elimination of Primary NbC Carbides in HSLA Steels for Oil Industry Tubular Goods. JOM 2022, 74, 2409–2419. [Google Scholar] [CrossRef]

- Ye, Z.; Chen, G.; Wang, W.; Wang, S.; Yang, J.; Huang, J. High-Strength and High-Toughness Weld of S690QL HSLA Steel via a High-Speed High Frequency Electric Cooperated Arc Welding without Additional Heating Measures. Mater. Sci. Eng. A 2023, 880, 145328. [Google Scholar] [CrossRef]

- Chen, J.; Shi, Z.; Luo, X.; Chai, F.; Pan, T.; Feng, G.; Yang, C. Micro-Alloying Effects on Microstructure and Weldability of High-Strength Low-Alloy Steel: A Review. Materials 2025, 18, 1036. [Google Scholar] [CrossRef]

- Narimani, M.; Hajjari, E.; Eskandari, M.; Szpunar, J.A. Electron Backscattered Diffraction Characterization of S900 HSLA Steel Welded Joints and Evolution of Mechanical Properties. J. Mater. Eng. Perform. 2022, 31, 3985–3997. [Google Scholar] [CrossRef]

- Shi, S.C.; Wang, W.C.; Ko, D.K. Influence of Inclusions on Mechanical Properties in Flash Butt Welding Joint of High-Strength Low-Alloy Steel. Metals 2022, 12, 242. [Google Scholar] [CrossRef]

- Geng, R.; Li, J.; Shi, C.; Zhi, J.; Lu, B. Effect of Ce on Microstructures, Carbides and Mechanical Properties in Simulated Coarse-Grained Heat-Affected Zone of 800-MPa High-Strength Low-Alloy Steel. Mater. Sci. Eng. A 2022, 840, 142919. [Google Scholar] [CrossRef]

- Kumar, V.; Ranjan Sahu, D.; Mandal, A. Parametric Study and Optimization of GMAW Based AM Process for Multi-Layer Bead Deposition. Mater. Today Proc. 2022, 62, 255–261. [Google Scholar] [CrossRef]

- Rodriguez-Vargas, B.R.; Stornelli, G.; Hdz-García, H.M.; Miranda Pérez, A.F.; Di Schino, A. Microstructural assessment of ferrite-austenite ratio and its influence on corrosion and mechanical performance of DSS 2205 welds under H2S-rich real environment. Mater. Today Commun. 2025, 47, 113144. [Google Scholar] [CrossRef]

- Shukla, P.; Chitral, S.; Kumar, T.; Venkata Kiran, D. The influence of GMAW correction parameters on stabilizing the deposition characteristics for wire arc additive manufacturing. J. Manuf. Process. 2023, 90, 54–68. [Google Scholar] [CrossRef]

- Ferreira Filho, D.; Souza, D.; Gonçalves Júnior, J.L.; Reis, R.P.; Da Silva Junior, W.M.; Tavares, A.F. Influence of Substrate on the Tribological Behavior of Inconel 625 GMAW Overlays. Coatings 2023, 13, 1454. [Google Scholar] [CrossRef]

- Bettahar, K.; Bouabdallah, M.; Badji, R.; Gaceb, M.; Kahloun, C.; Bacroix, B. Microstructure and Mechanical Behavior in Dissimilar 13Cr/2205 Stainless Steel Welded Pipes. Mater. Des. 2015, 85, 221–229. [Google Scholar] [CrossRef]

- Kim, B.C.; Lee, S.; Kim, N.J.; Lee, D.Y. Microstructure and Local Brittle Zone Phenomena in High-Strength Low-Alloy Steel Welds. Metall. Trans. A 1991, 22, 139–149. [Google Scholar] [CrossRef]

- Kvackaj, T.; Bidulská, J.; Bidulský, R. Overview of Hss Steel Grades Development and Study of Reheating Condition Effects on Austenite Grain Size Changes. Materials 2021, 14, 1988. [Google Scholar] [CrossRef] [PubMed]

- Prasad, K.; Dwivedi, D.K. Some Investigations on Microstructure and Mechanical Properties of Submerged Arc Welded HSLA Steel Joints. Int. J. Adv. Manuf. Technol. 2008, 36, 475–483. [Google Scholar] [CrossRef]

- Davis, C.L.; King, J.E. Cleavage Initiation in the Intercritically Reheated Coarse-Grained Heat-Affected Zone: Part I. Fractographic Evidence. Metall. Mater. Trans. A 1994, 25, 563–573. [Google Scholar] [CrossRef]

- Akselsen, O.M.; Grong, Ø.; Solberg, J.K. Structure–Property Relationships in Intercritical Heat Affected Zone of Low-Carbon Microalloyed Steels. Mater. Sci. Technol. 1987, 3, 649–655. [Google Scholar] [CrossRef]

- Qiu, H.; Mori, H.; Enoki, M.; Kishi, T. Fracture Mechanism and Toughness of the Welding Heat-Affected Zone in Structural Steel under Static and Dynamic Loading. Metall. Mater. Trans. A 2000, 31, 2785–2791. [Google Scholar] [CrossRef]

- Boniszewski, T.; Keeler, T. HAZ Hardness Control in C-Mn Microalloyed Structural Steels. Met. Constr. 1984, 16, 608–617. [Google Scholar]

- Schofield, R.; Weiner, R.T. Simulating HAZ Toughness in Pipeline Steels. Met. Constr. Br. Weld. J. 1974, 6, 45–47. [Google Scholar]

- Ouchi, C. Advances in Physical Metallurgy and Processing of Steels. Development of Steel Plates by Intensive Use of TMCP and Direct Quenching Processes. ISIJ Int. 2001, 41, 542–553. [Google Scholar] [CrossRef]

- Zhang, H.; Deng, Y.; Chen, F.; Luo, Y.; Xiao, X.; Lu, N.; Liu, Y.; Deng, Y. Fatigue life prediction for orthotropic steel bridge decks welds using a Gaussian variational bayes network and small sample experimental data. Reliab. Eng. Syst. Saf. 2025, 264, 111406. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, L.; Yang, S.; Deng, Y.; Ouyang, Z. Fatigue evaluation of Orthotropic steel deck welds based on WIM data and UD-BP neural network. Structures 2025, 78, 109198. [Google Scholar] [CrossRef]

- Zhang, H.; Deng, Y.; Cao, Y.; Chen, F.; Luo, Y.; Xiao, X.; Deng, Y.; Liu, Y. Field testing, analytical, and numerical assessments on the fatigue reliability on bridge suspender by considering the coupling effect of multiple pits. Struct. Infrastruct. Eng. 2025, 1–16. [Google Scholar] [CrossRef]

- Bonnevie, E.; Ferrière, G.; Ikhlef, A.; Kaplan, D.; Orain, J.M. Morphological Aspects of Martensite–Austenite Constituents in Intercritical and Coarse Grain Heat Affected Zones of Structural Steels. Mater. Sci. Eng. A 2004, 385, 352–358. [Google Scholar] [CrossRef]

- Stornelli, G.; Tselikova, A.; Mirabile Gattia, D.; Mortello, M.; Schmidt, R.; Sgambetterra, M.; Testani, C.; Zucca, G.; Di Schino, A. Influence of Vanadium Micro-Alloying on the Microstructure of Structural High Strength Steels Welded Joints. Materials 2023, 16, 2897. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Crowther, D.N.; Green, M.J.W.; Mitchell, P.S.; Baker, T.N. The Effect of Vanadium and Niobium on the Properties and Microstructure of the Intercritically Reheated Coarse Grained Heat Affected Zone in Low Carbon Microalloyed Steels. ISIJ Int. 2001, 41, 46–55. [Google Scholar] [CrossRef]

- Taillard, R.; Verrier, P.; Maurickx, T.; Foct, J. Effect of Silicon on CGHAZ Toughness and Microstructure of Microalloyed Steels. Metall. Mater. Trans. A 1995, 26, 447–457. [Google Scholar] [CrossRef]

- Jang, J.; Lee, J.-S.; Ju, J.-B.; Lee, B.-W.; Kwon, D.; Kim, W.-S. Determination of Microstructural Criterion for Cryogenic Toughness Variation in Actual HAZs Using Microstructure-Distribution Maps. Mater. Sci. Eng. A 2003, 351, 183–189. [Google Scholar] [CrossRef]

- Jang, J.-I.; Lee, B.-W.; Ju, J.-B.; Kwon, D.; Kim, W.-S. Crack-Initiation Toughness and Crack-Arrest Toughness in Advanced 9 Pct Ni Steel Welds Containing Local Brittle Zones. Metall. Mater. Trans. A 2002, 33, 2615–2622. [Google Scholar] [CrossRef]

- Li, C.; Wang, Y.; Chen, Y. Influence of Peak Temperature during In-Service Welding of API X70 Pipeline Steels on Microstructure and Fracture Energy of the Reheated Coarse Grain Heat-Affected Zones. J. Mater. Sci. 2011, 46, 6424–6431. [Google Scholar] [CrossRef]

- Ju, J.-B.; Kim, W.; Jang, J. Variations in DBTT and CTOD within Weld Heat-Affected Zone of API X65 Pipeline Steel. Mater. Sci. Eng. A 2012, 546, 258–262. [Google Scholar] [CrossRef]

- Bertolo, V.; Jiang, Q.; Terol Sanchez, M.; Riemslag, T.; Walters, C.L.; Sietsma, J.; Popovich, V. Cleavage Fracture Micromechanisms in Simulated Heat Affected Zones of S690 High Strength Steels. Mater. Sci. Eng. A 2023, 868, 144762. [Google Scholar] [CrossRef]

- Mohseni, P.; Solberg, J.K.; Karlsen, M.; Akselsen, O.M.; Østby, E. Investigation of Mechanism of Cleavage Fracture Initiation in Intercritically Coarse Grained Heat Affected Zone of HSLA Steel. Mater. Sci. Technol. 2012, 28, 1261–1268. [Google Scholar] [CrossRef]

- Lee, S.G.; Kim, B.; Sohn, S.S.; Kim, W.G.; Um, K.-K.; Lee, S. Effects of Local-Brittle-Zone (LBZ) Microstructures on Crack Initiation and Propagation in Three Mo-Added High-Strength Low-Alloy (HSLA) Steels. Mater. Sci. Eng. A 2019, 760, 125–133. [Google Scholar] [CrossRef]

- Li, Y.; Baker, T.N. Effect of Morphology of Martensite–Austenite Phase on Fracture of Weld Heat Affected Zone in Vanadium and Niobium Microalloyed Steels. Mater. Sci. Technol. 2010, 26, 1029–1040. [Google Scholar] [CrossRef]

- Bayraktar, E.; Kaplan, D. Mechanical and Metallurgical Investigation of Martensite–Austenite Constituents in Simulated Welding Conditions. J. Mater. Process. Technol. 2004, 153–154, 87–92. [Google Scholar] [CrossRef]

- Kumar, S.; Nath, S.K. Effect of Weld Thermal Cycles on Microstructures and Mechanical Properties in Simulated Heat Affected Zone of a HY 85 Steel. Trans. Indian Inst. Met. 2017, 70, 239–250. [Google Scholar] [CrossRef]

- Zhang, P.; Laleh, M.; Hughes, A.E.; Marceau, R.K.W.; Hilditch, T.; Tan, M.Y. Effect of Microstructure on Hydrogen Embrittlement and Hydrogen-Induced Cracking Behaviour of a High-Strength Pipeline Steel Weldment. Corros. Sci. 2024, 227, 111764. [Google Scholar] [CrossRef]

- Hausmann, K.; Krizan, D.; Spiradek-Hahn, K.; Pichler, A.; Werner, E. The Influence of Nb on Transformation Behavior and Mechanical Properties of TRIP-Assisted Bainitic–Ferritic Sheet Steels. Mater. Sci. Eng. A 2013, 588, 142–150. [Google Scholar] [CrossRef]

- Yu, H.; Wu, K.; Dong, B.; Yu, L.; Liu, J.; Liu, Z.; Xiao, D.; Jing, X.; Liu, H. Effect of Niobium Content on the Microstructure and Mechanical Properties of Simulated Coarse-Grained Heat-Affected Zone (CGHAZ) of High-Strength Low-Alloy (HSLA) Steels. Materials 2022, 15, 3318. [Google Scholar] [CrossRef]

- Mitchell, P.S.; Hart, P.H.M.; Morrison, W.B. The Effect of Microalloying on HAZ Toughness. In Proceedings of the International Conference Microalloying, Pittsburgh, PA, USA, 10–12 September 1995; pp. 149–162. [Google Scholar]

- Cui, J.; Zhu, W.; Chen, Z.; Chen, L. Microstructural Characteristics and Impact Fracture Behaviors of a Novel High-Strength Low-Carbon Bainitic Steel with Different Reheated Coarse-Grained Heat-Affected Zones. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2020, 51, 6258–6268. [Google Scholar] [CrossRef]

- Benz, J. The Effect of Vanadium and Other Microalloying Elements on the Microstructure and Properties of Bainitic HSLA Steels. Mater. Sci. Technol. Conf. Exhib. 2017, 1, 490. [Google Scholar]

- Fazeli, F.; Amirkhiz, B.S.; Scott, C.; Arafin, M.; Collins, L. Kinetics and Microstructural Change of Low-Carbon Bainite Due to Vanadium Microalloying. Mater. Sci. Eng. A 2018, 720, 248–256. [Google Scholar] [CrossRef]

- Baker, T.N. Microalloyed Steels. Ironmak. Steelmak. 2016, 43, 264–307. [Google Scholar] [CrossRef]

- Sun, W.; Wang, G.; Zhang, J.; Xia, D. Microstructure Transformation Behaviour of 610 MPa HSLA Steel Plate for 150000 M3 Oil Storage Tank Construction. J. Iron Steel Res. Int. 2010, 17, 48–52. [Google Scholar] [CrossRef]

- Baker, T.N. Processes, Microstructure and Properties of Vanadium Microalloyed Steels. Mater. Sci. Technol. 2009, 25, 1083–1107. [Google Scholar] [CrossRef]

- Wu, H.; Xia, D.; Ma, H.; Du, Y.; Gao, C.; Gao, X.; Du, L. Study on Microstructure Characterization and Impact Toughness in the Reheated Coarse-Grained Heat Affected Zone of V-N Microalloyed Steel. J. Mater. Eng. Perform. 2022, 31, 376–382. [Google Scholar] [CrossRef]

- Kalantar, M.; Najafi, H.; Afshar, M.R. Comparison Between Vanadium and Niobium Effects on the Mechanical Properties of Intercritically Heat Treated Microalloyed Cast Steels. Met. Mater. Int. 2019, 25, 229–237. [Google Scholar] [CrossRef]

- Chen, Y. Microstructure and mechanical property development in the simulated heat affected zone of v treated HSLA steels. Acta Metall. Sin. 2006, 19, 57–67. [Google Scholar] [CrossRef]

- Miletić, I.; Ilić, A.; Nikolić, R.R.; Ulewicz, R.; Ivanović, L.; Sczygiol, N. Analysis of Selected Properties of Welded Joints of the HSLA Steels. Materials 2020, 13, 1301. [Google Scholar] [CrossRef]

- Cho, L.; Tselikova, A.; Holtgrewe, K.; De Moor, E.; Schmidt, R.; Findley, K.O. Critical Assessment 42: Acicular Ferrite Formation and Its Influence on Weld Metal and Heat-Affected Zone Properties of Steels. Mater. Sci. Technol. 2022, 38, 1425–1433. [Google Scholar] [CrossRef]

- Hernandez-Flores, J.E.; Rodriguez-Vargas, B.R.; Stornelli, G.; Pérez, A.F.M.; de García-Vázquez, F.J.; Gómez-Casas, J.; Di Schino, A. Evaluation of Austenitic Stainless Steel ER308 Coating on H13 Tool Steel by Robotic GMAW Process. Metals 2023, 14, 43. [Google Scholar] [CrossRef]

- Hunkel, M. Segregations in Steels during Heat Treatment—A Consideration along the Process Chain. HTM J. Heat Treat. Mater. 2021, 76, 79–104. [Google Scholar] [CrossRef]

- ASTM E3-11; Standard Guide for Preparation of Metallographic Specimens. ASTM International: West Conshohocken, PA, USA, 2011.

- LePera, F.S. Improved Etching Technique for the Determination of Percent Martensite in High-Strength Dual-Phase Steels. Metallography 1979, 12, 263–268. [Google Scholar] [CrossRef]

- ISO 6892-1:2019; Metallic Materials—Tensile Testing Part 1: Method of Test at Room Temperature. ISO: Geneva, Switzerland, 2019.

- DuPont, J.N.; Babu, S.; Liu, S. Welding of Materials for Energy Applications. Metall. Mater. Trans. A 2013, 44, 3385–3410. [Google Scholar] [CrossRef]

- Yang, Y.-P. Recent Advances in the Prediction of Weld Residual Stress and Distortion—Part 2. Weld. J. 2021, 100, 193–205. [Google Scholar] [CrossRef]

- Sindo, K. Welding Metallurgy, 3rd ed.; Wiley: Hoboken, NJ, USA, 2021; ISBN 978-1-119-52481-6. [Google Scholar]

- Lancaster, J.F. Metallurgy of Welding, 6th ed.; Paperback; Woodhead: Cambridge, UK, 1999; ISBN 9781855734289. [Google Scholar]

- Amin, S.A.; Marhoon, I.I.; Kattab, D.A.A.N.; Eleiwi, M.A.; Majdi, H.S.; Habeeb, L.J. Experimental and numerical investigating of heat input effects in gas metal arc welding and shielded metal arc welding: A detailed comparison of welded alloy steel properties. Math. Model. Eng. Probl. 2025, 12, 2351–2361. [Google Scholar] [CrossRef]

- Anandavijayan, S.; Mehmanparast, A.; Braithwaite, J.; Brennan, F.; Chahardehi, A. Material pre-straining effects on fatigue behaviour of S355 structural steel. J. Constr. Steel Res. 2021, 183, 106707. [Google Scholar] [CrossRef]

- Tomków, J.; Rogalski, G.; Fydrych, D.; Łabanowski, J. Improvement of S355G10+N Steel Weldability in Water Environment by Temper Bead Welding. J. Mater. Process. Technol. 2018, 262, 372–381. [Google Scholar] [CrossRef]

- Tomków, J.; Rogalski, G.; Fydrych, D.; Łabanowski, J. Advantages of the Application of the Temper Bead Welding Technique During Wet Welding. Materials 2019, 12, 915. [Google Scholar] [CrossRef]

- Serrano, R.; Ambriz, R.R.; Ayoub, G.; Jaramillo, D. Mechanical Behavior of Armor Steel Gas Metal Arc Welding Joints Performed by Nickel-Chromium and Low-Alloy Steel Filler Metals. J. Mater. Eng. Perform. 2022, 31, 3930–3942. [Google Scholar] [CrossRef]

- Ghosh, P.K. Introduction to Gas Metal Arc Welding Process; Springer: Singapore, 2017. [Google Scholar]

- Mičian, M.; Winczek, J.; Gucwa, M.; Koňár, R.; Málek, M.; Postawa, P. Investigation of Welds and Heat Affected Zones in Weld Surfacing Steel Plates Taking into Account the Bead Sequence. Materials 2020, 13, 5666. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Wang, D.; Cheng, F.; Di, X.; Deng, C.; Xu, W. Microstructural and Mechanical Performance of Underwater Wet Welded S355 Steel. J. Mater. Process. Technol. 2016, 238, 333–340. [Google Scholar] [CrossRef]

- Thewlis, G. Weldability of X100 Linepipe. Sci. Technol. Weld. Join. 2000, 5, 365–377. [Google Scholar] [CrossRef]

- Thewlis, G.; Whiteman, J.A.; Senogles, D.J. Dynamics of Austenite to Ferrite Phase Transformation in Ferrous Weld Metals. Mater. Sci. Technol. 1997, 13, 257–274. [Google Scholar] [CrossRef]

- Thewlis, G. Classification and Quantification of Microstructures in Steels. Mater. Sci. Technol. 2004, 20, 143–160. [Google Scholar] [CrossRef]

- Sinha, M.; Yadav, S.; Ghosh, S. A novel observation of Widmanstätten ferrite and pearlite by thermo-mechanical processing of interstitial-free steel. Mater. Manuf. Process. 2022, 37, 1766–1771. [Google Scholar] [CrossRef]

- Leont’ev, B.A.; Buzovskii, Y.N. Mechanical properties of steel with a Widmanstatten structure. Met. Sci. Heat Treat. 1968, 10, 930–932. [Google Scholar] [CrossRef]

- Otterberg, R.; Sandström, R.; Sandberg, A. Influence of Widmanstätten ferrite on mechanical properties of microalloyed steels. Met. Technol. 1980, 7, 397–408. [Google Scholar] [CrossRef]

- Zhu, Z.; Kuzmikova, L.; Li, H.; Barbaro, F. Effect of Inter-Critically Reheating Temperature on Microstructure and Properties of Simulated Inter-Critically Reheated Coarse Grained Heat Affected Zone in X70 Steel. Mater. Sci. Eng. A 2014, 605, 8–13. [Google Scholar] [CrossRef]

- Vishnu, P.R. Solid-State Transformations in Weldments. In Welding, Brazing, and Soldering; ASM International: Materials Park, OH, USA, 1993; pp. 70–87. [Google Scholar]

- Babu, S.S.; Bhadeshia, H.K.D.H. A Direct Study of Grain Boundary Allotriomorphic Ferrite Crystallography. Mater. Sci. Eng. A 1991, 142, 209–219. [Google Scholar] [CrossRef]

- Babu, S.S. The Mechanism of Acicular Ferrite in Weld Deposits. Curr. Opin. Solid State Mater. Sci. 2004, 8, 267–278. [Google Scholar] [CrossRef]

- Sarma, D.S.; Karasev, A.V.; Jönsson, P.G. On the Role of Non-Metallic Inclusions in the Nucleation of Acicular Ferrite in Steels. ISIJ Int. 2009, 49, 1063–1074. [Google Scholar] [CrossRef]

- Guo, H.; Bai, Y.; Yang, S.W.; He, X.L. Nucleation of Bainite on Allotriomorphic Ferrite/Austenite Interface in a Low Carbon Steel. Mater. Sci. Forum 2010, 654–656, 2326–2329. [Google Scholar] [CrossRef]

- Lee, T.-K.; Kim, H.J.; Kang, B.Y.; Hwang, S.K. Effect of Inclusion Size on the Nucleation of Acicular Ferrite in Welds. ISIJ Int. 2000, 40, 1260–1268. [Google Scholar] [CrossRef]

- Furuhara, T.; Yamaguchi, J.; Sugita, N.; Miyamoto, G.; Maki, T. Nucleation of Proeutectoid Ferrite on Complex Precipitates in Austenite. ISIJ Int. 2003, 43, 1630–1639. [Google Scholar] [CrossRef]

- Jones, S.J.; Bhadeshia, H.K.D.H. Competitive Formation of Inter- and Intragranularly Nucleated Ferrite. Metall. Mater. Trans. A 1997, 28, 2005–2013. [Google Scholar] [CrossRef]

- Garcia, C.; Cornide, J.; Capdevila, C.; Caballero, F.G.; de Andrés, C.G. Influence of V Precipitates on Acicular Ferrite Transformation Part 2: Transformation Kinetics. ISIJ Int. 2008, 48, 1276–1279. [Google Scholar] [CrossRef]

- Babu, S.S.; David, S.A. Inclusion Formation and Microstructure Evolution in Low Alloy Steel Welds. ISIJ Int. 2002, 42, 1344–1353. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Capdevila, C.; Caballero, F.G.; de Andrés, C.G. Influence of V Precipitates on Acicular Ferrite Transformation Part 1: The Role of Nitrogen. ISIJ Int. 2008, 48, 1270–1275. [Google Scholar] [CrossRef]

- Barbaro, F.J.; Krauklis, P.; Easterling, K.E. Formation of Acicular Ferrite at Oxide Particles in Steels. Mater. Sci. Technol. 1989, 5, 1057–1068. [Google Scholar] [CrossRef]

- Zhang, J.; Xin, W.; Luo, G.; Wang, R.; Meng, Q.; Xian, S. Effect of Welding Heat Input on Microstructural Evolution, Precipitation Behavior and Resultant Properties of the Simulated CGHAZ in High-N V-Alloyed Steel. Mater. Charact. 2020, 162, 110201. [Google Scholar] [CrossRef]

- Hu, J.; Du, L.-X.; Wang, J.-J.; Gao, C.-R. Effect of Welding Heat Input on Microstructures and Toughness in Simulated CGHAZ of V–N High Strength Steel. Mater. Sci. Eng. A 2013, 577, 161–168. [Google Scholar] [CrossRef]

- Loder, D.; Michelic, S.K.; Bernhard, C. Acicular Ferrite Formation and Its Influencing Factors-A Review. J. Mater. Sci. Res. 2016, 6, 24. [Google Scholar] [CrossRef]

- Capdevila, C.; García-Mateo, C.; Chao, J.; Caballero, F.G. Effect of V and N Precipitation on Acicular Ferrite Formation in Sulfur-Lean Vanadium Steels. Metall. Mater. Trans. A 2009, 40, 522–538. [Google Scholar] [CrossRef]

- He, K.; Edmonds, D.V. Formation of Acicular Ferrite and Influence of Vanadium Alloying. Mater. Sci. Technol. 2002, 18, 289–296. [Google Scholar] [CrossRef]

- Ishikawa, F.; Takahashi, T.; Ochi, T. Intragranular Ferrite Nucleation in Medium-Carbon Vanadium Steels. Metall. Mater. Trans. A 1994, 25, 929–936. [Google Scholar] [CrossRef]

| C | Mn | V | Si | Nb | |

|---|---|---|---|---|---|

| Base Variant-(S355) (BV) | 0.16 | 1.45 | - | 0.03 | - |

| Variant I (V-I) | 0.16 | 1.45 | 0.05 | 0.03 | - |

| Variant II (V-II) | 0.16 | 1.45 | 0.10 | 0.03 | - |

| Variant III (V-III) | 0.16 | 1.45 | 0.03 | 0.03 | 0.02 |

| ER70S-6 | 0.08 | 1.45 | - | 0.90 | - |

| Weld-Pass | Current (A) | Voltage (V) | Welding Speed (mm/min) | Wire Feed Speed (mm/s) | Heat Input (kJ/mm) |

|---|---|---|---|---|---|

| 1 | 125–135 | 16–17 | 170–190 | 400 | 0.51–0.65 |

| 2 | 165–175 | 210–230 | 380 | 0.59–0.72 | |

| 3 | 175–185 | 17–18 | 230–250 | 450 | 0.57–0.67 |

| 4 | 175–185 | 220–240 | 450 | 0.60–0.73 | |

| 5 | 180–190 | 310–330 | 480 | 0.45–0.53 | |

| 6 | 180–190 | 390–410 | 500 | 0.36–0.42 | |

| 7 | 180–190 | 390–410 | 500 | 0.36–0.42 |

| Base Variant | Variant I | Variant II | Variant III | |

|---|---|---|---|---|

| M/A fraction (%) | 8.9 | 6.4 | 5.4 | 5.8 |

| V | Nb | Fe | Mn | Si | |

|---|---|---|---|---|---|

| Variant I (low V) | 89.9 ± 0.2 | - | 8.0 ± 0.2 | 0.3 ± 0.1 | 1.8 ± 0.1 |

| Variant II (high V) | 80.4 ± 0.2 | - | 16.9 ± 0.2 | 0.9 ± 0.1 | 1.8 ± 0.1 |

| Variant III (V and Nb) | 33.5 ± 0.2 | 46.2 ± 0.2 | 18.7 ± 0.2 | 0.2 ± 0.1 | 1.4 ± 0.1 |

| hmax * (µm) | E * (GPa) | H * (GPa) | Wp * (nJ) | We * (nJ) | hf * (µm) | |

|---|---|---|---|---|---|---|

| Profile A (WZ) | 1.24 ± 0.05 | 171.1 ± 8.8 | 1.9 ± 0.2 | 41.5 ± 2.8 | 4.7 ± 0.4 | 1.06 ± 0.04 |

| Profile B (CGHAZ) | 1.20 ± 0.02 | 166.3 ± 24.3 | 2.1 ± 0.1 | 38.1 ± 1.4 | 4.9 ± 0.2 | 1.04 ± 0.03 |

| Profile C (ICCGHAZ—low M/A) | 1.19 ± 0.04 | 154.1 ± 14.5 | 2.1 ± 0.1 | 37.1 ± 0.6 | 5.4 ± 0.3 | 0.94 ± 0.05 |

| Profile D (ICCGHAZ—high M/A) | 1.09 ± 0.03 | 167.8 ± 36.3 | 2.5 ± 0.1 | 35.0 ± 1.4 | 5.5 ± 0.5 | 0.82 ± 0.07 |

| YS * (MPa) | UTS * (MPa) | YS/UTS | AU * (%) | A * (%) | Breaking Zone | |

|---|---|---|---|---|---|---|

| Base Variant | 360 ± 14 | 567 ± 21 | 0.6 | 29.2 ± 1.7 | 48.3 ± 1.9 | Base metal |

| Variant I | 428 ± 20 | 579 ± 28 | 0.7 | 27.4 ± 1.3 | 46.7 ± 0.6 | Base metal |

| Variant II | 410 ± 24 | 575 ± 28 | 0.7 | 31.0 ± 0.8 | 50.3 ± 1.5 | Base metal |

| Variant III | 415 ± 19 | 578 ± 23 | 0.7 | 30.0 ± 1.1 | 46.1 ± 1.2 | Base metal |

| Element | Solubilization Temperature (°C) |

|---|---|

| V in V-I | 770 °C |

| V in V-II | 820 °C |

| V in V-III | 1150 °C |

| Nb in V-III | 1150 °C |

| * | H/E * | H/E2 * | * | |

|---|---|---|---|---|

| WZ | 0.89 | 0.011 | 6·10−5 | 0.15 |

| CGHAZ | 0.88 | 0.013 | 8·10−5 | 0.14 |

| ICCGHAZ—low M/A | 0.87 | 0.014 | 8·10−5 | 0.21 |

| ICCGHAZ—high M/A | 0.86 | 0.015 | 9·10−5 | 0.24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stornelli, G.; Rodríguez-Vargas, B.R.; Tselikova, A.; Schimdt, R.; Mortello, M.; Di Schino, A. The Vanadium Micro-Alloying Effect on the Microstructure of HSLA Steel Welded Joints by GMAW. Metals 2025, 15, 1127. https://doi.org/10.3390/met15101127

Stornelli G, Rodríguez-Vargas BR, Tselikova A, Schimdt R, Mortello M, Di Schino A. The Vanadium Micro-Alloying Effect on the Microstructure of HSLA Steel Welded Joints by GMAW. Metals. 2025; 15(10):1127. https://doi.org/10.3390/met15101127

Chicago/Turabian StyleStornelli, Giulia, Bryan Ramiro Rodríguez-Vargas, Anastasiya Tselikova, Rolf Schimdt, Michelangelo Mortello, and Andrea Di Schino. 2025. "The Vanadium Micro-Alloying Effect on the Microstructure of HSLA Steel Welded Joints by GMAW" Metals 15, no. 10: 1127. https://doi.org/10.3390/met15101127

APA StyleStornelli, G., Rodríguez-Vargas, B. R., Tselikova, A., Schimdt, R., Mortello, M., & Di Schino, A. (2025). The Vanadium Micro-Alloying Effect on the Microstructure of HSLA Steel Welded Joints by GMAW. Metals, 15(10), 1127. https://doi.org/10.3390/met15101127