Effects of Tool Rotational Speed on the Microstructure and Properties of Friction Stir Welded AZ61 Magnesium Alloy Joints

Abstract

1. Introduction

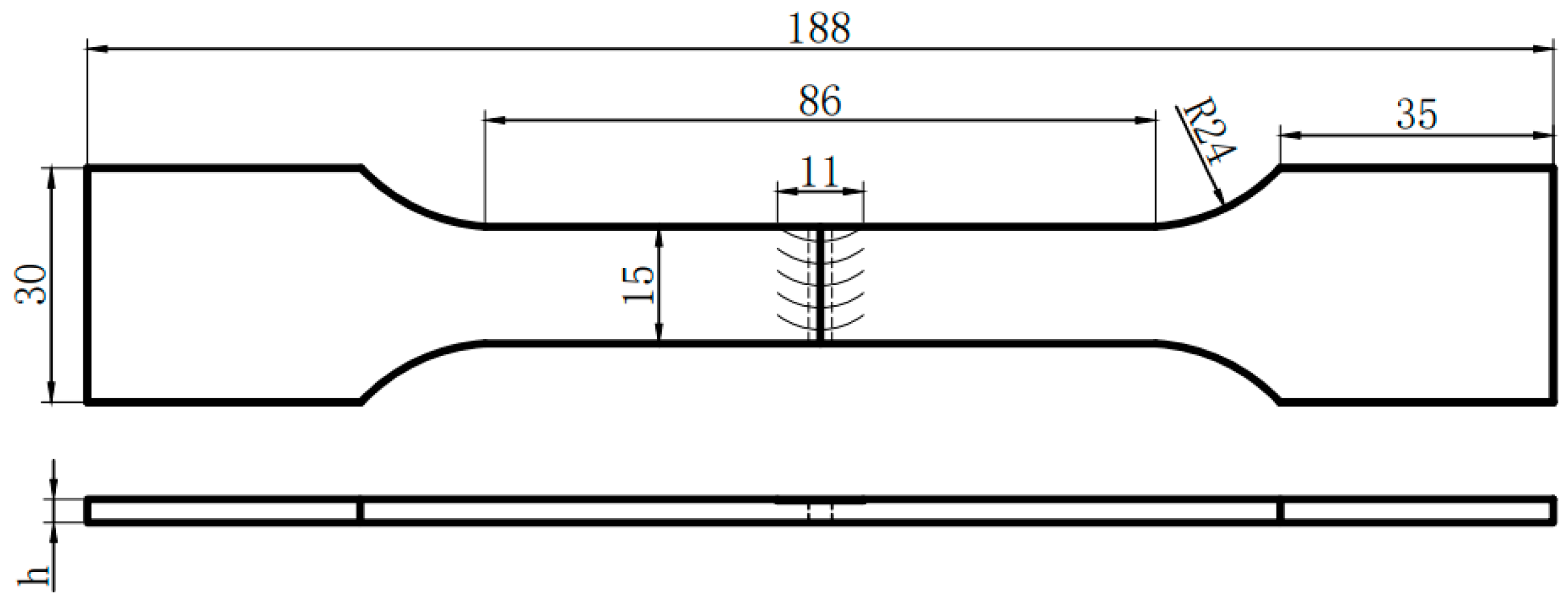

2. Experimental Materials and Methods

3. Results

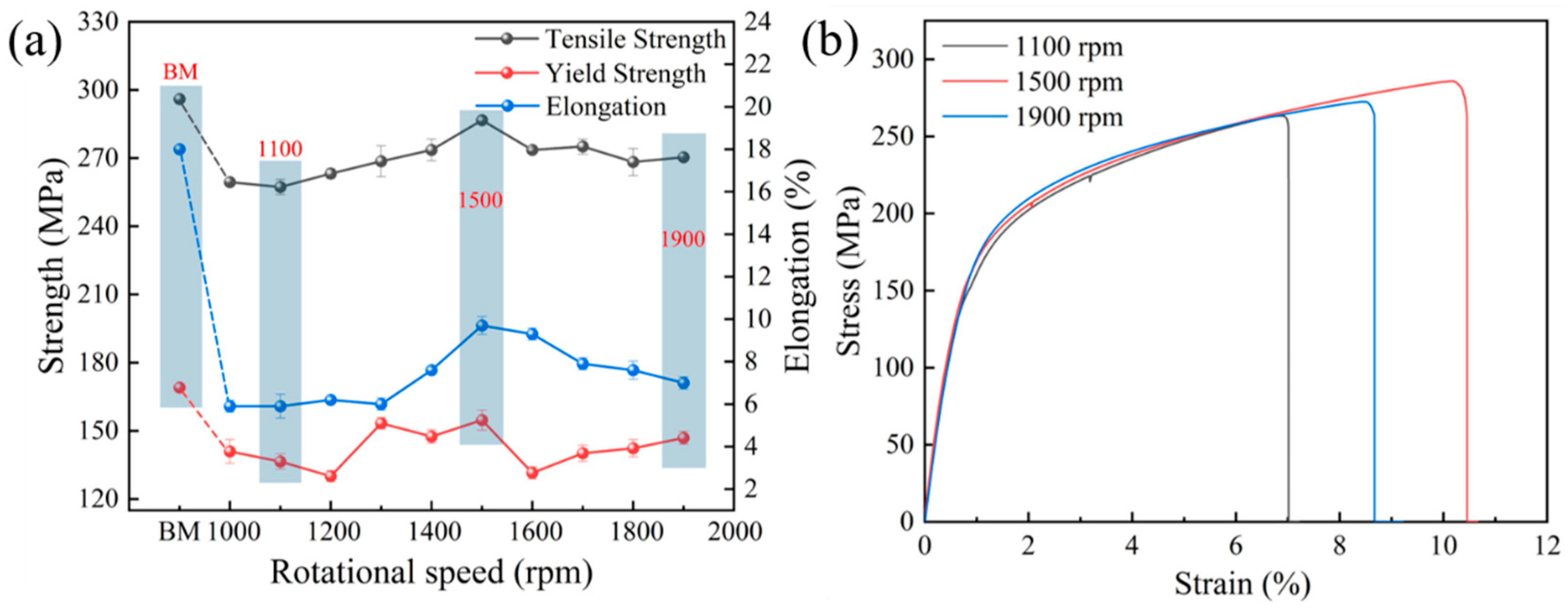

3.1. Mechanical Properties

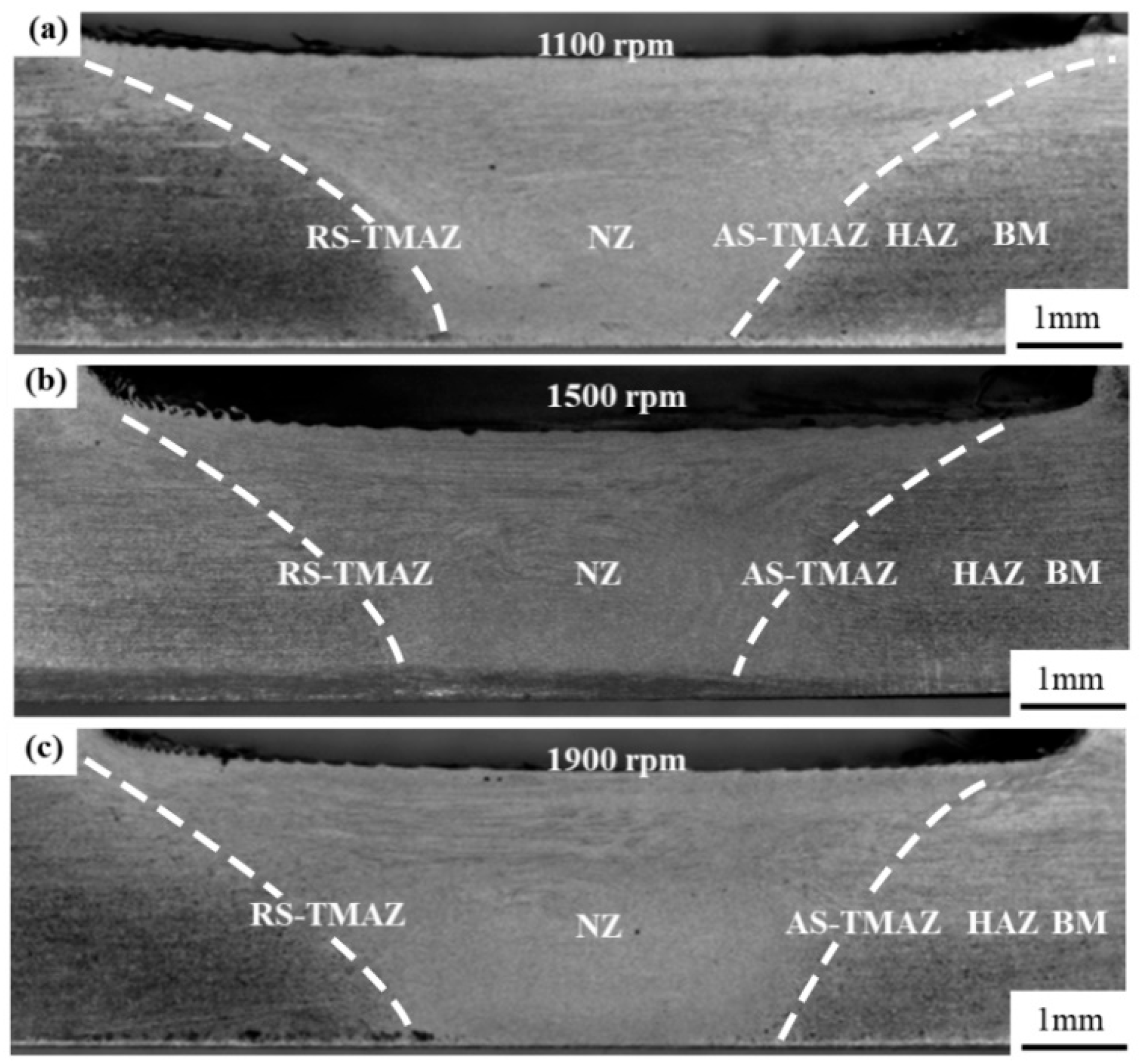

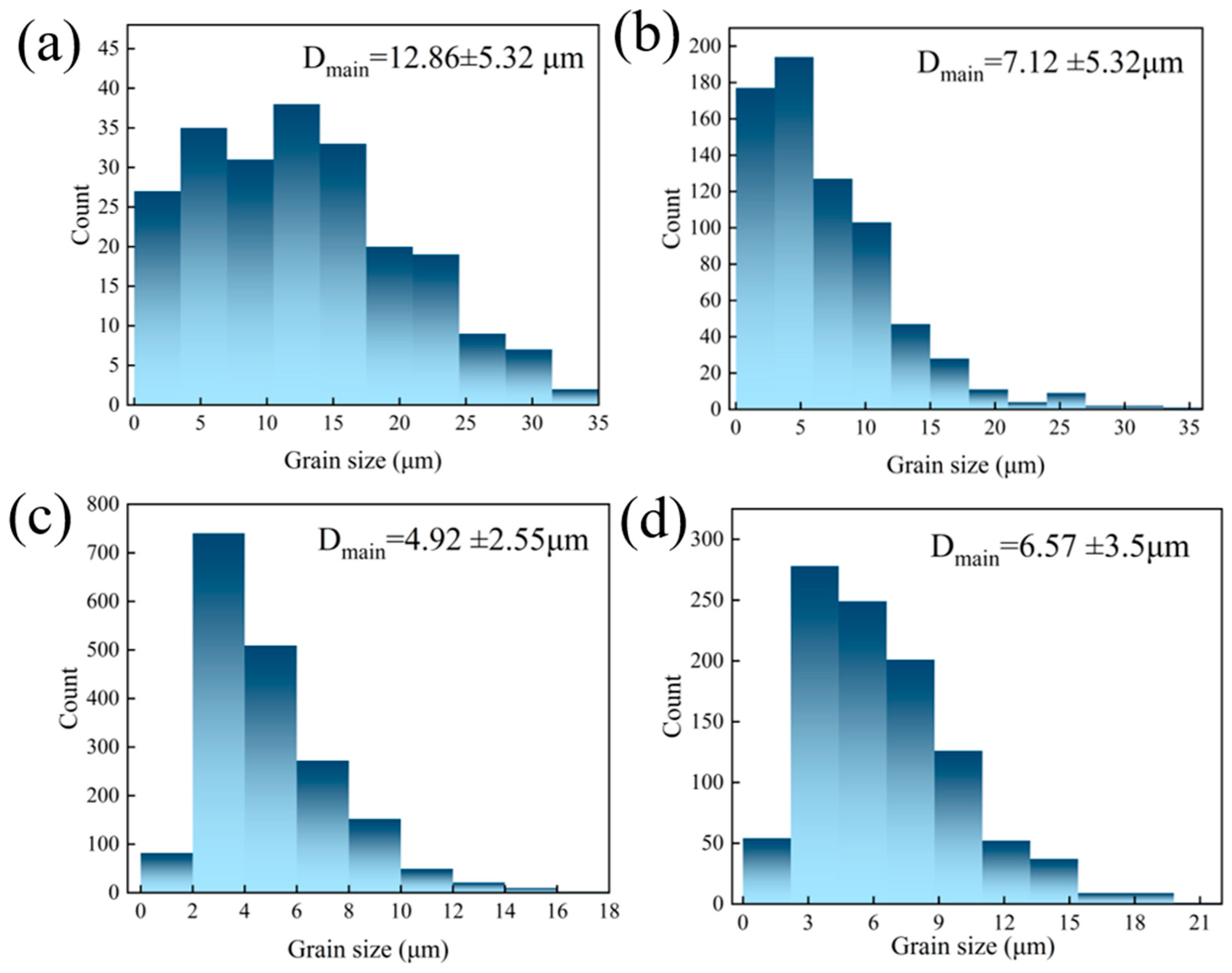

3.2. Microstructural Characterization of Welded Joints

4. Discussion

4.1. Effect of Rotational Speed on the Microstructure and Mechanical Properties of FSW Joints

4.2. Comparison of Mechanical and Microstructural Properties of AZ61 FSW Joints Under Different Processing Parameters

5. Conclusions

- (1)

- This study systematically investigates the influence of rotational speed on the microstructure and mechanical properties of friction stir welded joints in 3 mm thick AZ61 magnesium alloy thin-walled hollow profiles. The results demonstrate that the geometric characteristics of the thin-walled hollow profiles substantially constrain the optimal processing window, rendering it distinctly different from that of conventional solid thick plates. Within the investigated parameter range, 1500 rpm was identified as the optimum rotational speed, at which the heat input and mechanical stirring action reached an optimal balance, resulting in microstructural refinement and performance enhancement.

- (2)

- Based on the current findings, future work should expand the processing window and explore optimization strategies—such as variable-speed welding or specialized tool design—to address the challenges arising from the high thermal sensitivity of thin-walled structures. Furthermore, assessing the long-term service performance of the joints under fatigue, dynamic loading, and corrosive conditions, along with extending the process to other magnesium alloy systems, represents crucial directions for advancing the engineering application of this technology.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- She, J.; Chen, J.; Xiong, X.; Yang, Y.; Peng, X.; Chen, D.; Pan, F. Research advances of magnesium and magnesium alloys globally in 2023. J. Magnes. Alloys 2024, 12, 3441–3475. [Google Scholar] [CrossRef]

- Prasad, S.S.; Prasad, S.B.; Verma, K.; Mishra, R.K.; Kumar, V.; Singh, S. The role and significance of magnesium in modern day research-a review. J. Magnes. Alloys 2022, 10, 1–61. [Google Scholar] [CrossRef]

- Tuz, L.; Kolasa, A.; Pfeifer, T. Structure and mechanical properties of MIG welded butt-joints of magnesium alloys. Weld. Int. 2016, 30, 202–207. [Google Scholar] [CrossRef]

- Liu, K.; Wang, H.; Li, J.; Geng, S.; Chen, Z.; Okulov, A. A review on factors influencing solidification cracking of magnesium alloys during welding. Met. Mater. Int. 2024, 30, 1723–1742. [Google Scholar] [CrossRef]

- Mehdi, H.; Bhati, S.S.; Mouria, P.K.; Mishra, S. A comprehensive review of progressive developments and challenges in dissimilar welding of aluminum and magnesium alloy by friction stir welding. J. Adhes. Sci. Technol. 2025, 39, 1979–2026. [Google Scholar] [CrossRef]

- Unnikrishnan, M.; Dhas, J.E.R.; Lewise, K.A.S.; Varghese, J.C.; Ganesh, M. Challenges on friction stir welding of magnesium alloys in automotives. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Xu, Y.; Ke, L.; Mao, Y.; Yang, P.; Niu, P. Friction stir welding of aluminium to magnesium: A critical review. Mater. Sci. Technol. 2022, 38, 517–534. [Google Scholar] [CrossRef]

- Li, Y.; Qin, F.; Liu, C.; Wu, Z. A review: Effect of friction stir welding on microstructure and mechanical properties of magnesium alloys. Metals 2017, 7, 524. [Google Scholar] [CrossRef]

- Zhang, B.; Liu, J.; Sun, Y.; Liu, Q. On the fatigue resistance assessment of friction stir welded joints affected by heat input. Eng. Fail. Anal. 2024, 161, 108262. [Google Scholar] [CrossRef]

- Li, H.; Gao, J.; Li, Q. Fatigue of Friction Stir Welded Aluminum Alloy Joints: A Review. Appl. Sci. 2018, 8, 2626. [Google Scholar] [CrossRef]

- Ahmed, H.; Hafeez, M.A.; Asghar, M.B.; Sarwar, U.; Qureshi, M.H.; Afzal, M.; Farooq, A. Effect of tool rotational speed on the mechanical and electrochemical properties of friction stir welded 5083 Al-Mg alloy. Eng. Res. Express 2025, 7, 035435. [Google Scholar] [CrossRef]

- Laska, A.; Szkodo, M.; Koszelow, D.; Cavaliere, P. The Effect of Processing Parameters on the Strength and Corrosion Resistance of AA6082 Friction Stir Welding. Metals 2022, 12, 192. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, S. Quality and influencing factors of friction stir welded magnesium alloys. Hot Work. Technol. 2022, 51, 1–6. [Google Scholar]

- Kilic, S.; Ozturk, F.; Demirdogen, M.F. A comprehensive literature review on friction stir welding: Process parameters, joint integrity, and mechanical properties. J. Eng. Res. 2025, 13, 122–130. [Google Scholar] [CrossRef]

- Sachin, S.; Singh, J.C.; Singh, K.B. Evaluating the microstructural characteristics in friction stir welding of magnesium AZ61A alloy. Mater. Today Proc. 2022, 48, 1762–1768. [Google Scholar]

- Mohamed, M.F.; Yaknesh, S.; Kumar, C.A.; Rajadurai, J.G.; Janarthanan, S.; Vignes, A. Optimization of friction stir welding parameters for enhancing welded joints strength using Taguchi based grey relational analysis. Mater. Today Proc. 2020, 39, 676–681. [Google Scholar] [CrossRef]

- Ugender, S. Influence of tool pin profile and rotational speed on the formation of friction stir welding zone in AZ31 magnesium alloy. J. Magnes. Alloys 2018, 6, 205–213. [Google Scholar] [CrossRef]

- Hou, J.; Qin, D.; Mao, Y.; Ni, Y.; Xiao, X.; Fu, L. Research on high speed friction stir welding process of magnesium alloys. Precis. Form. Eng. 2019, 11, 127–134. [Google Scholar]

- Singh, K.; Singh, G.; Singh, H. Review on friction stir welding of magnesium alloys. J. Magnes. Alloys 2018, 6, 399–416. [Google Scholar] [CrossRef]

- Pu, J.; Grigorievicth, B.S.; Wang, H.; Liu, S.; Song, W.; Jiang, D.; Ge, X.; Shouzhen, C.; Dong, Q. Analysis of Microstructure and Mechanical Properties of AZ31B Thick Plate Magnesium Alloy Stir Friction Welded Joints. Integr. Ferroelectr. 2023, 236, 70–84. [Google Scholar] [CrossRef]

- Wang, Y. Study on the Influence of Process Parameters on the Microstructure and Properties of AZ31 Magnesium Alloy Friction Stir Processing. Master’s Thesis, Chongqing University, Chongqing, China, 2017. [Google Scholar]

- Yan, Z.; Liu, X.; Yang, S.; Zhang, W. Numerical simulation and experimental investigation on friction stir welding of AZ31 magnesium alloy. Mater. Res. Express 2024, 11, 076519. [Google Scholar] [CrossRef]

- Li, Y.-L.; Xia, W.-J.; Yan, H.-G.; Chen, J.-H.; Ding, T.; Sun, Y.-P.; Li, X.-Y. Microstructure and mechanical properties of friction-stir-welded high-Mg-alloyed Al–Mg alloy plates at different rotating rates. Rare Met. 2020, 40, 2167–2178. [Google Scholar] [CrossRef]

- Li, X. Study on the Microstructure and Mechanical Properties of AZ31B Magnesium Alloy Inclined Penetration Friction Stir Welding Joints. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2023. [Google Scholar]

- Li, G. Research on Forming Mechanism and Microstructure and Properties of Double-Axis Shoulder Friction Stir Welding Joint of ZK60 Magnesium Alloy. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2022. [Google Scholar]

- Luo, X.; Kang, L.; Liu, H.; Li, Z.; Liu, Y.; Zhang, D.; Chen, D. Enhancing mechanical properties of AZ61 magnesium alloy via friction stir processing: Effect of processing parameters. Mater. Sci. Eng. A 2020, 797, 139945–139953. [Google Scholar] [CrossRef]

| BM | Chemical Composition/wt.% | UTS | YS | EL | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Al | Zn | Mn | Fe | Si | Cu | Ni | /MPa | /MPa | /% | |

| AZ61 | 6.45 | 0.58 | 0.23 | 0.0023 | 0.012 | 0.0019 | 0.00030 | 296 | 169 | 18 |

| Rotational Speed/rpm | Welding Speed/(mm/min) | Plunge Depth/mm | Tool Tilt Angle/° |

|---|---|---|---|

| 1000–1900 | 300 | 0.15 | 2.5 |

| Second Phase in the Weld Nugget Zone | Rotational Speed/rpm | |||

|---|---|---|---|---|

| B M | 1100 | 1500 | 1900 | |

| Average Size/μm | 1.33 | 2.32 | 2.14 | 2.29 |

| Volume Fraction/% | 1.10 | 1.26 | 0.67 | 0.60 |

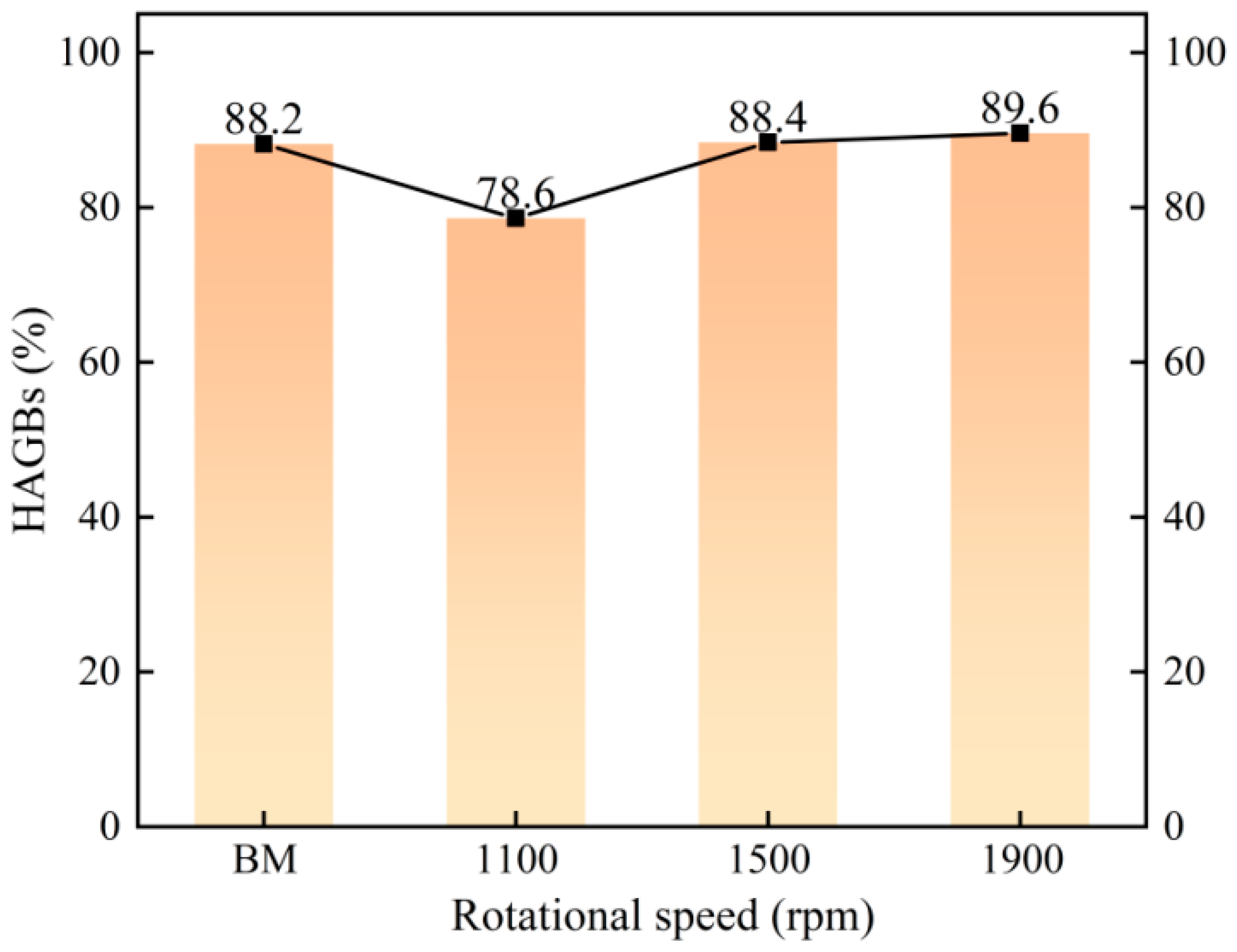

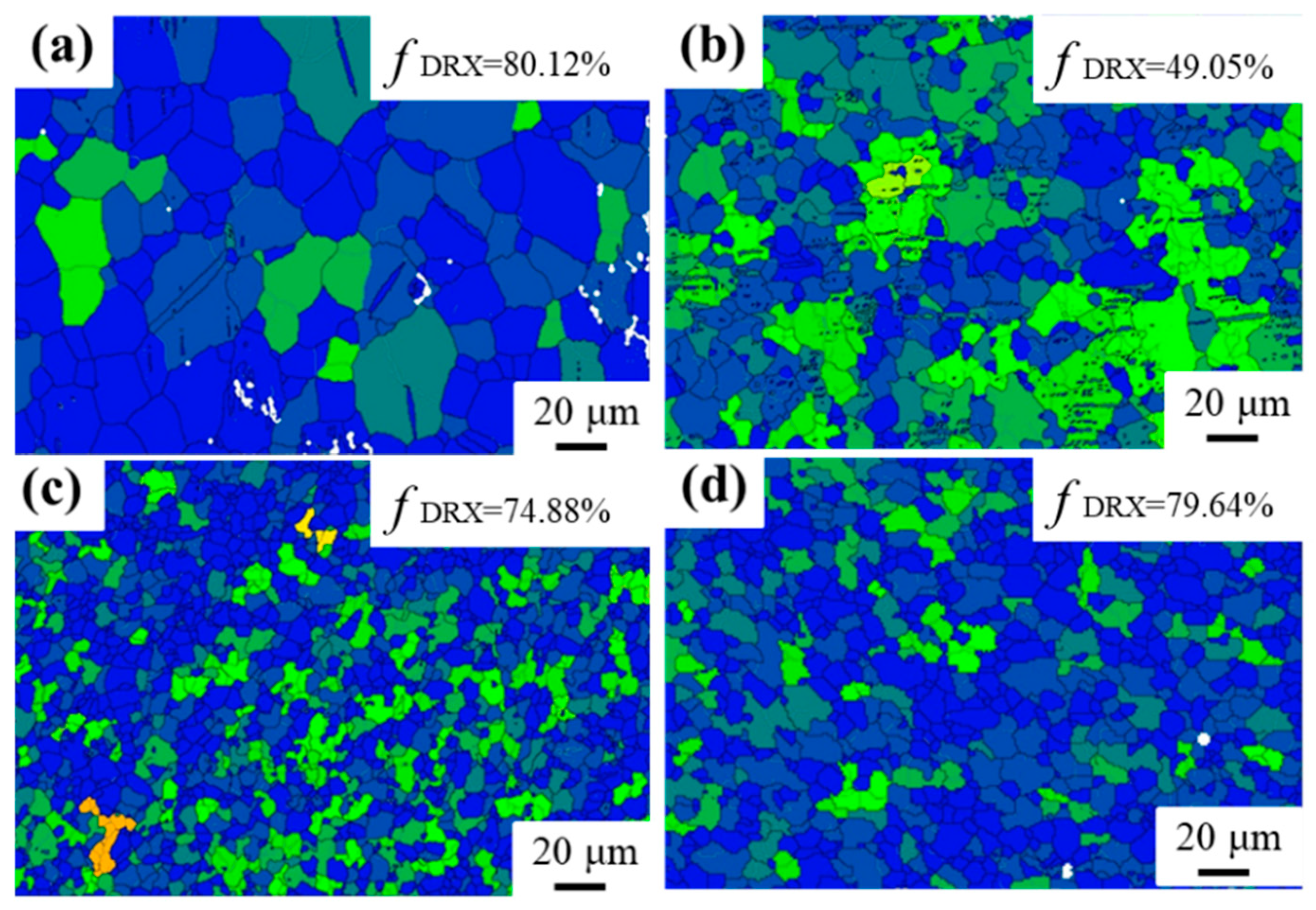

| BM | 1100 rpm | 1500 rpm | 1900 rpm | |

|---|---|---|---|---|

| Recrystallization Volume Fraction (%) | 80.12 | 49.05 | 74.88 | 79.64 |

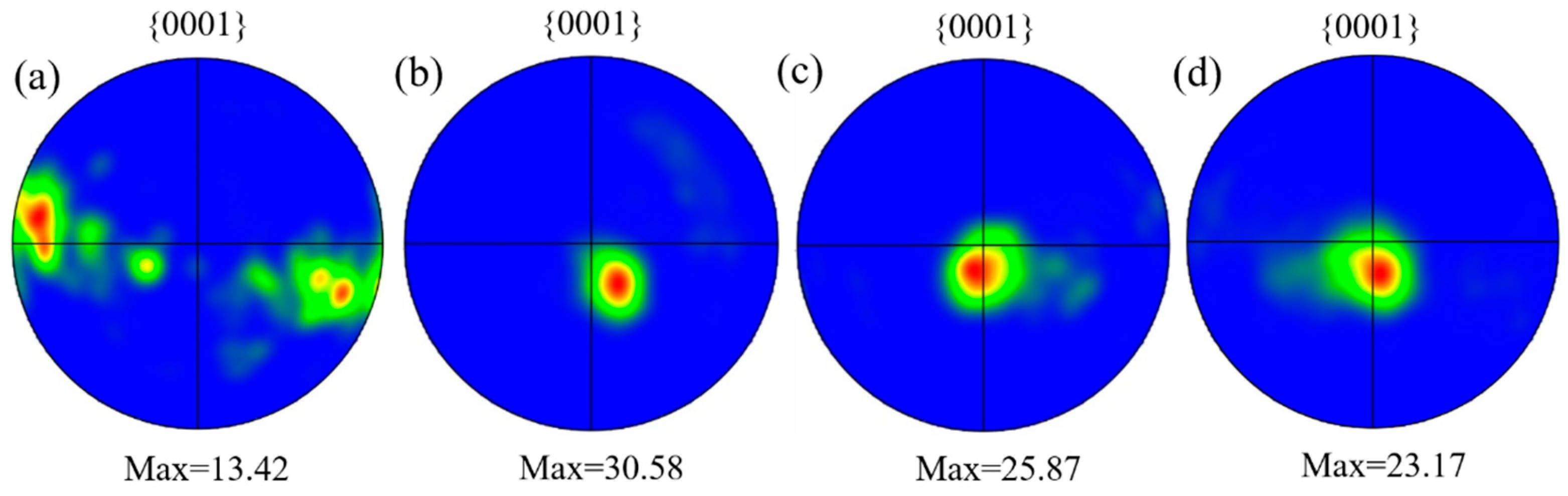

| BM | 1100 rpm | 1500 rpm | 1900 rpm | |

|---|---|---|---|---|

| Maximum Pole Density | 13.42 | 30.58 | 25.87 | 23.17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, X.; He, M.; Su, Y.; Li, H.; Feng, X.; Xie, N.; Huang, J.; Peng, J. Effects of Tool Rotational Speed on the Microstructure and Properties of Friction Stir Welded AZ61 Magnesium Alloy Joints. Metals 2025, 15, 1128. https://doi.org/10.3390/met15101128

Jin X, He M, Su Y, Li H, Feng X, Xie N, Huang J, Peng J. Effects of Tool Rotational Speed on the Microstructure and Properties of Friction Stir Welded AZ61 Magnesium Alloy Joints. Metals. 2025; 15(10):1128. https://doi.org/10.3390/met15101128

Chicago/Turabian StyleJin, Xihong, Minjie He, Yongzhang Su, Hongfei Li, Xuhui Feng, Na Xie, Jiaxin Huang, and Jian Peng. 2025. "Effects of Tool Rotational Speed on the Microstructure and Properties of Friction Stir Welded AZ61 Magnesium Alloy Joints" Metals 15, no. 10: 1128. https://doi.org/10.3390/met15101128

APA StyleJin, X., He, M., Su, Y., Li, H., Feng, X., Xie, N., Huang, J., & Peng, J. (2025). Effects of Tool Rotational Speed on the Microstructure and Properties of Friction Stir Welded AZ61 Magnesium Alloy Joints. Metals, 15(10), 1128. https://doi.org/10.3390/met15101128