Fatigue Strength Study of WAAM-Fabricated Shafts with Stacked Steel Ring Substrates Using Advanced Modeling

Abstract

1. Introduction

2. Materials and Methods

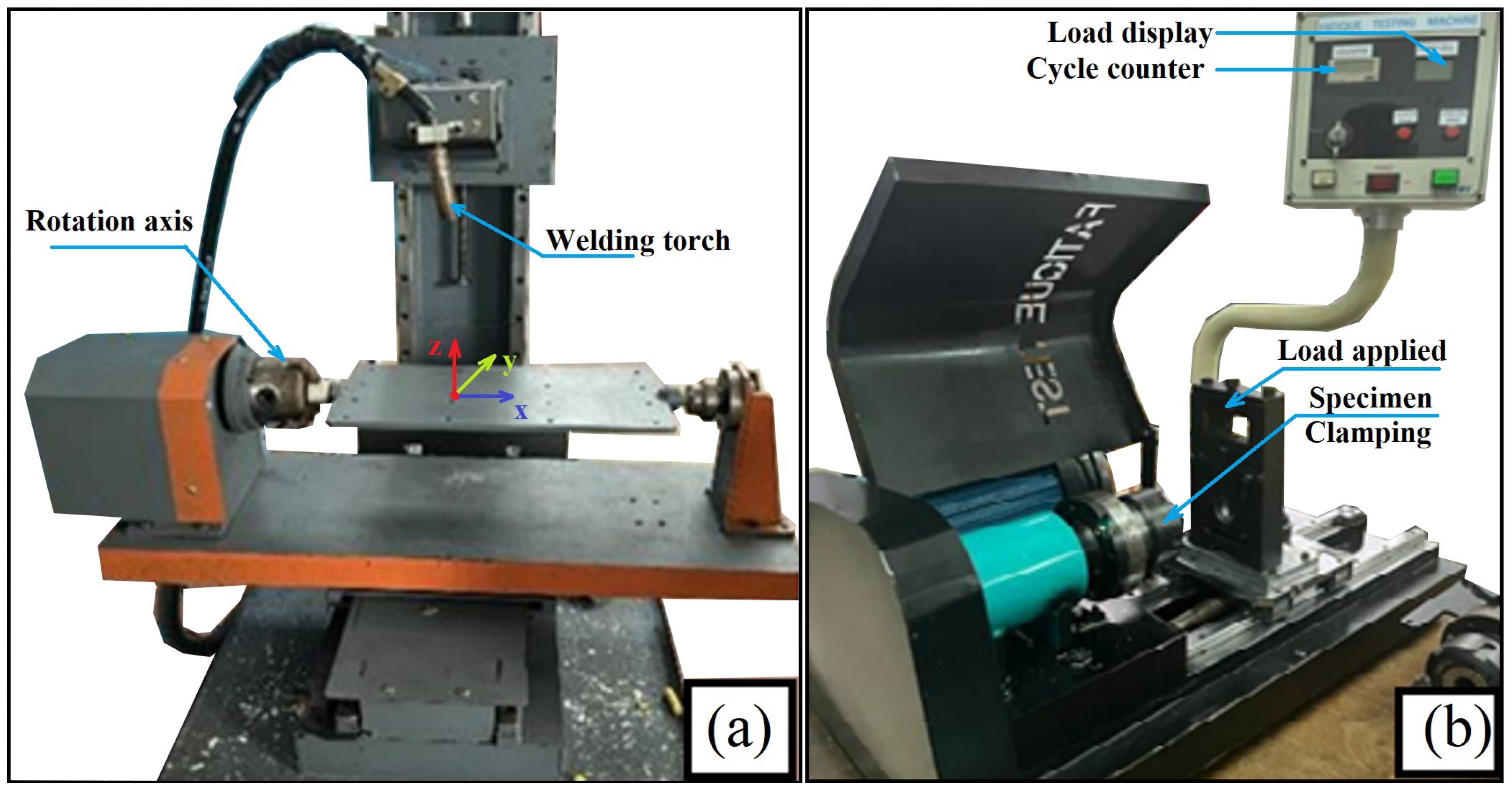

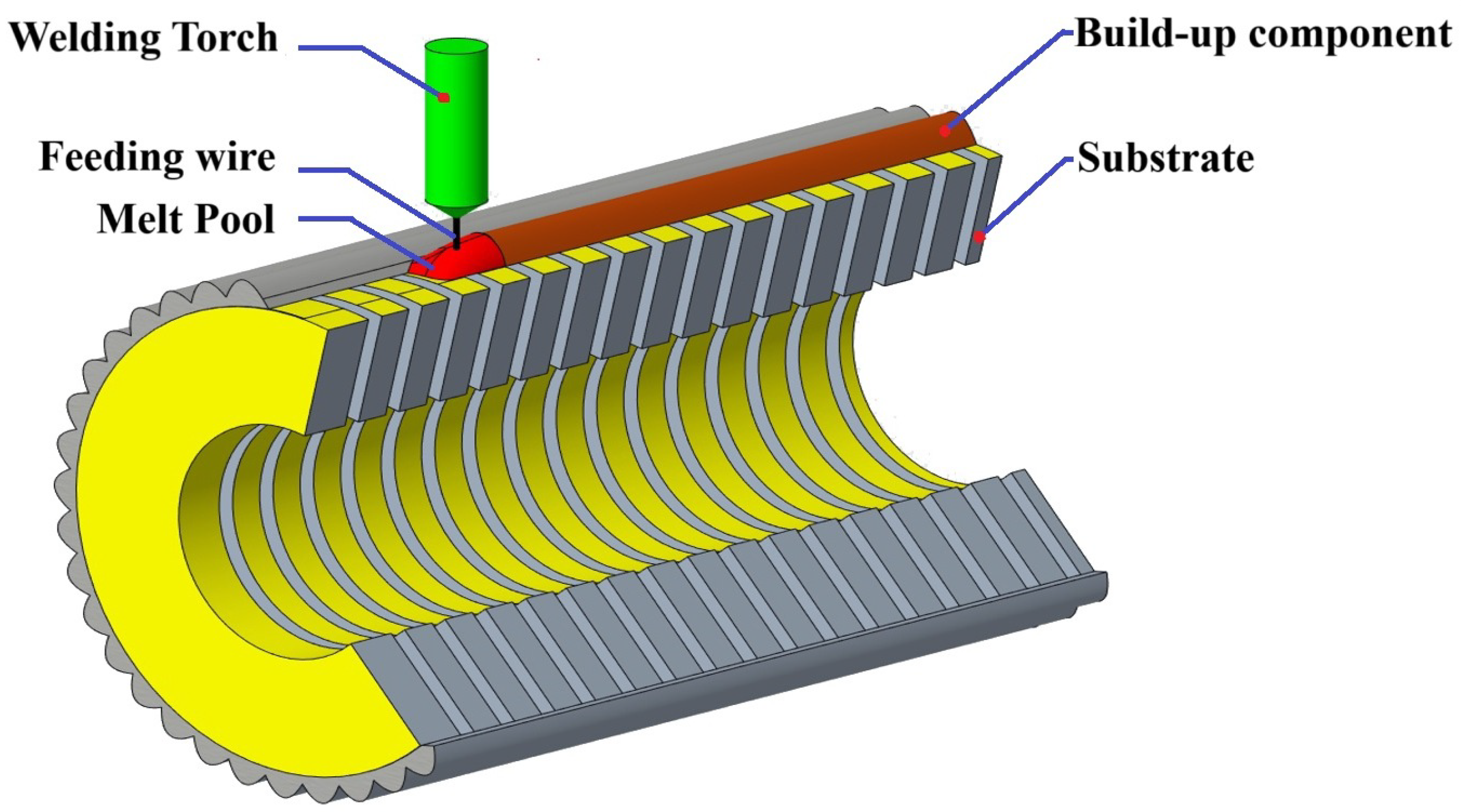

2.1. Experimental Setup

2.1.1. Equipment and Materials

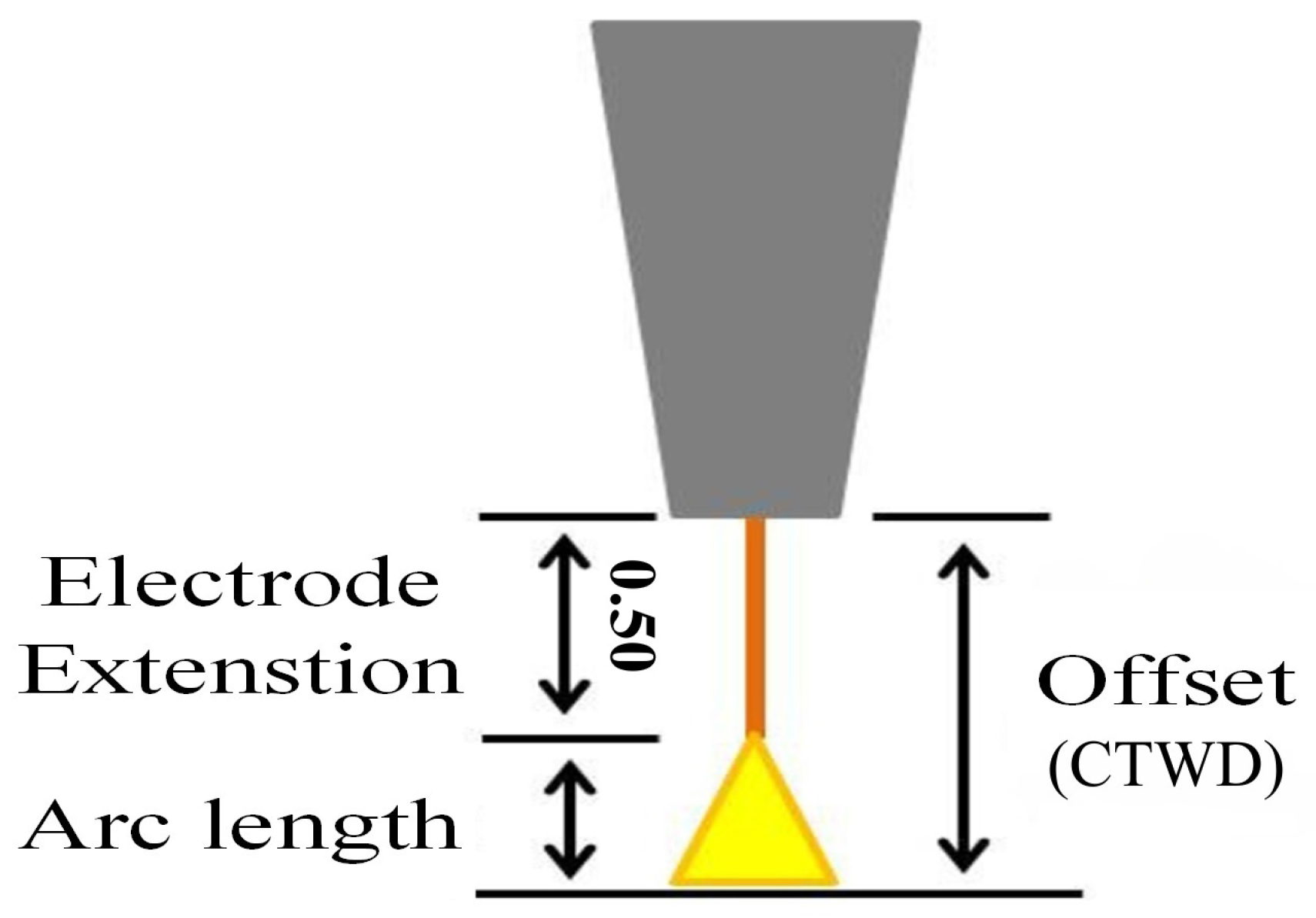

2.1.2. Process Parameters

- Q: heat input, in J/mm;

- V: arc voltage, in volts (V);

- I: welding current, in amperes (A);

- S: torch travel speed, in mm/min.

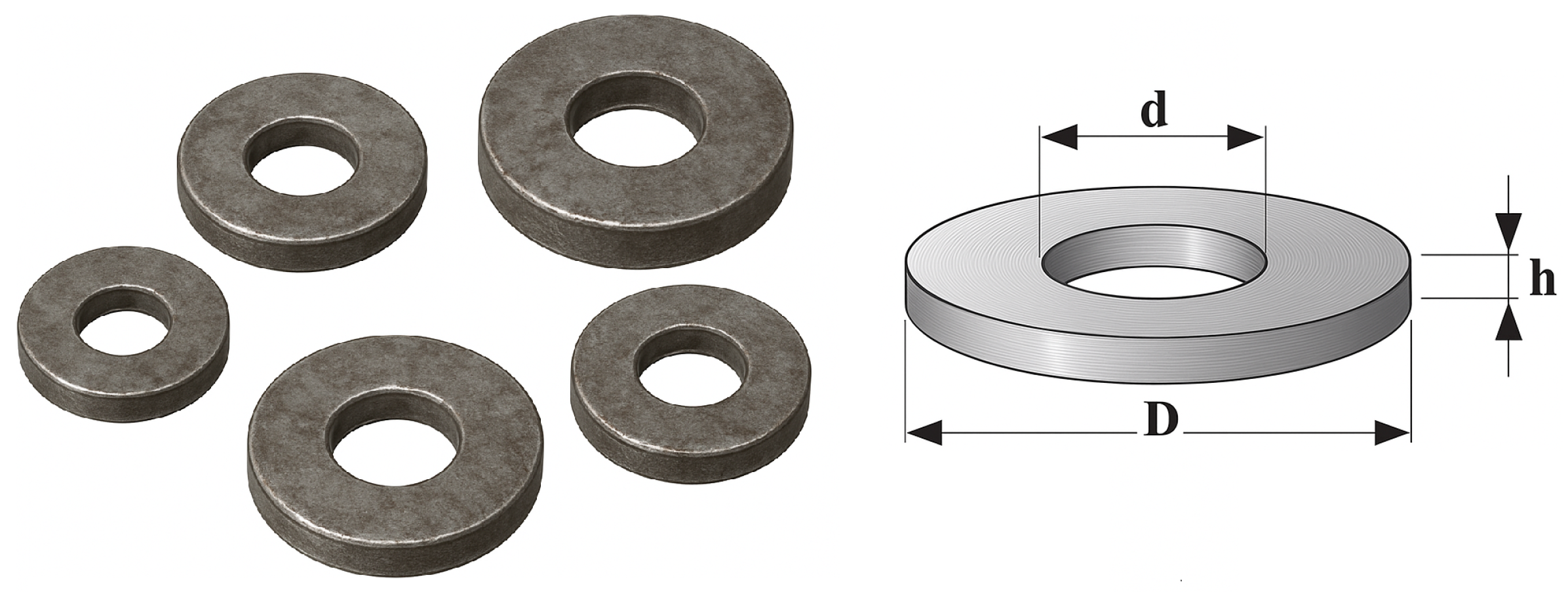

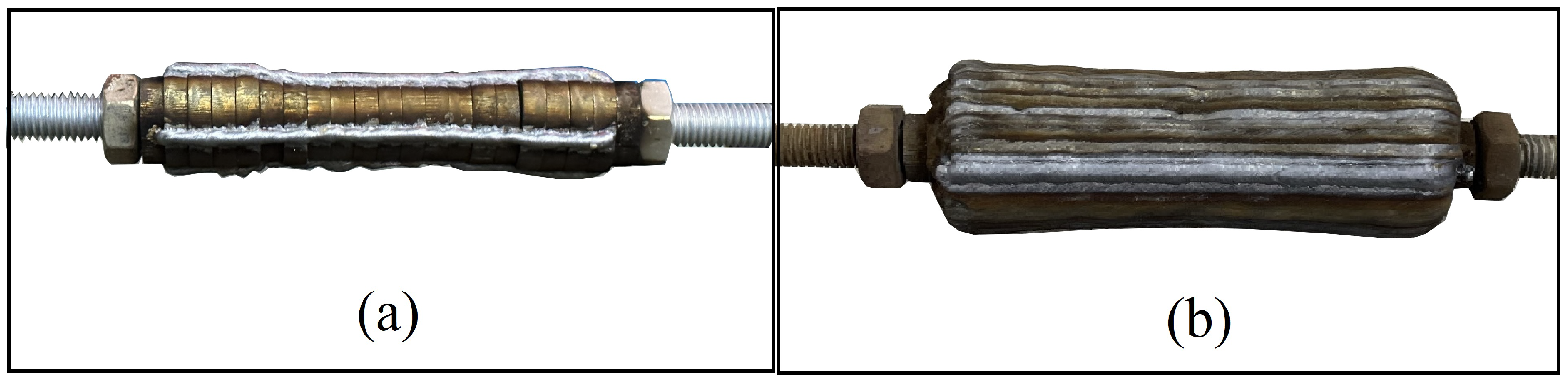

- Steel Ring Diameter and Thickness: The outer diameter (D) of the steel rings ranged from 14 mm to 16 mm with a consistent inner diameter (d) of 10 mm, and the ring thickness (h) ranged from 1 mm to 5 mm, as shown in Figure 3. A ring diameter of 14.0 mm was selected based on preliminary simulations showing reduced fatigue crack initiation compared to larger diameters, aligning with heat input considerations for uniform cooling in stacked configurations [5,8,22]. The ring thickness supports heat accumulation between layers, minimizing distortion under calculated heat input values.

2.1.3. Fatigue Testing Setup

2.2. Specimen Design and Fabrication

2.2.1. Specimen Design

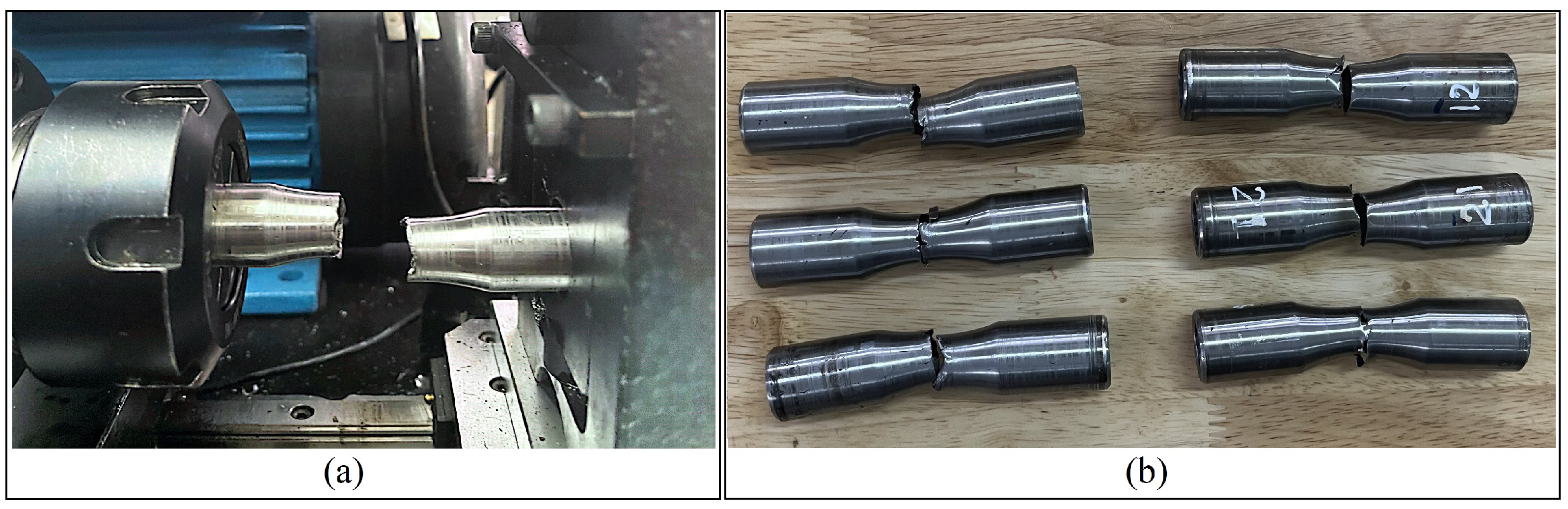

2.2.2. Specimen Fabrication Process

2.2.3. Post-Processing

2.3. Testing Procedure

2.4. Data Analysis and Method

3. Results

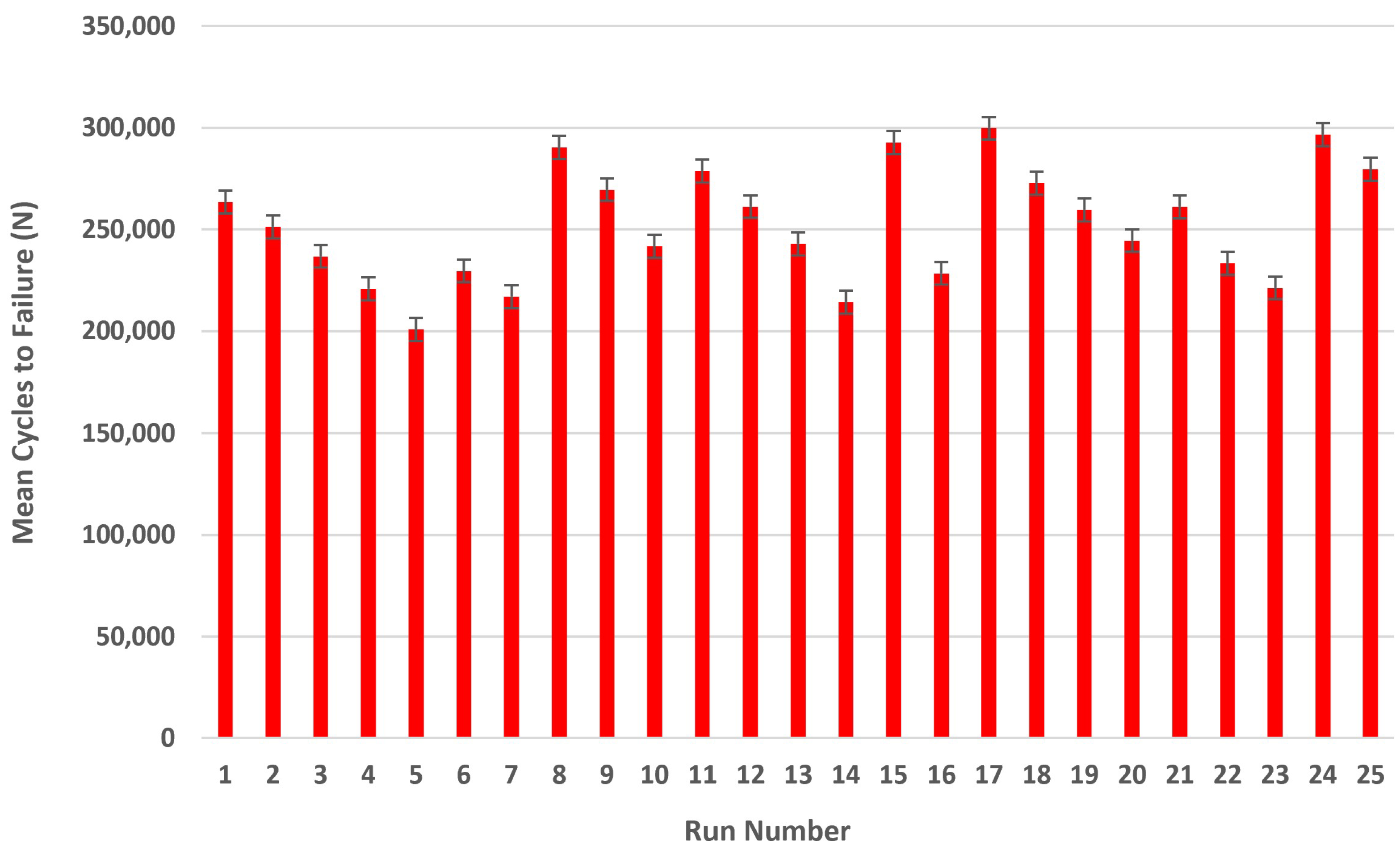

3.1. Fatigue Life Data

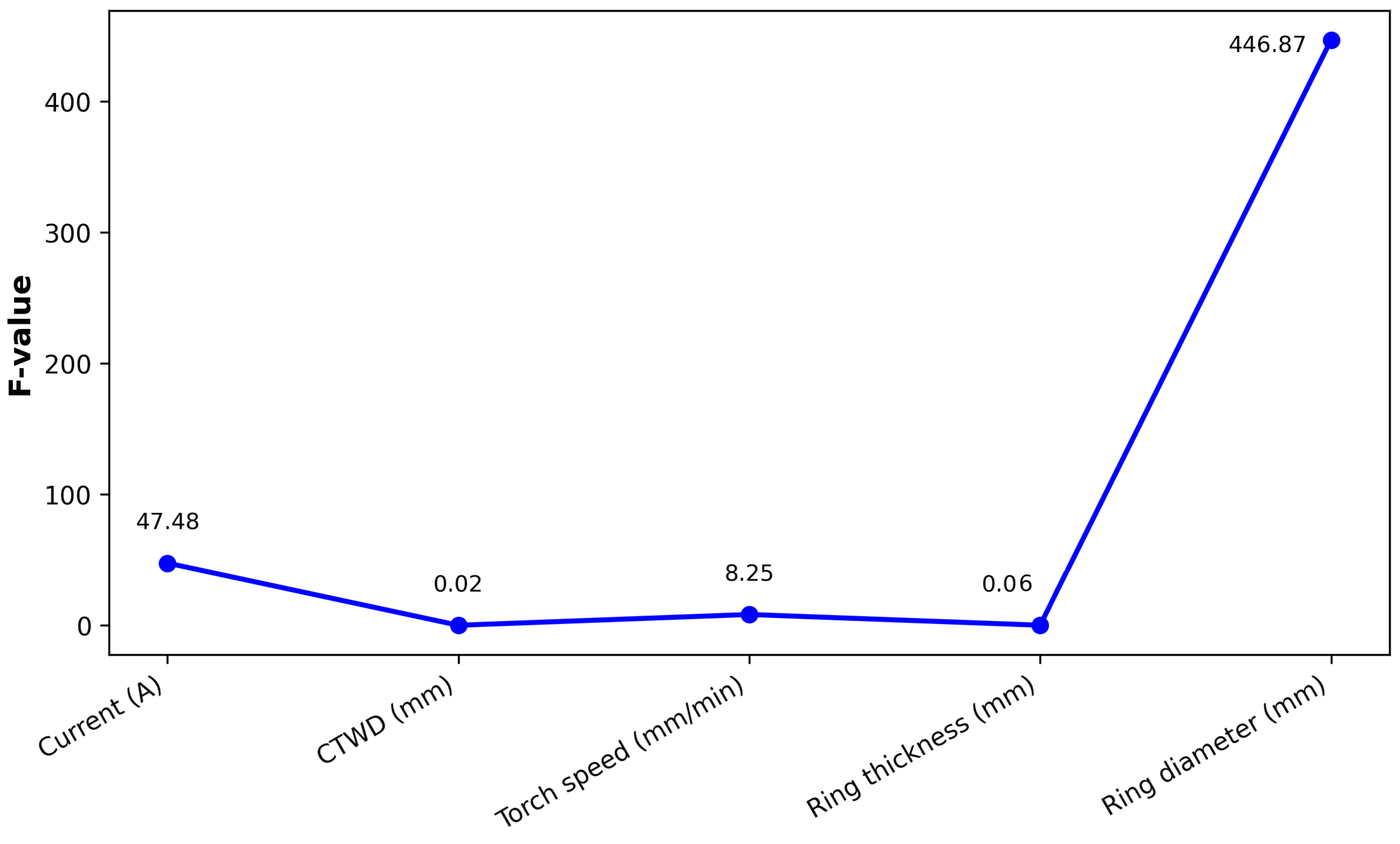

3.2. ANOVA Analysis and Parameter Influence

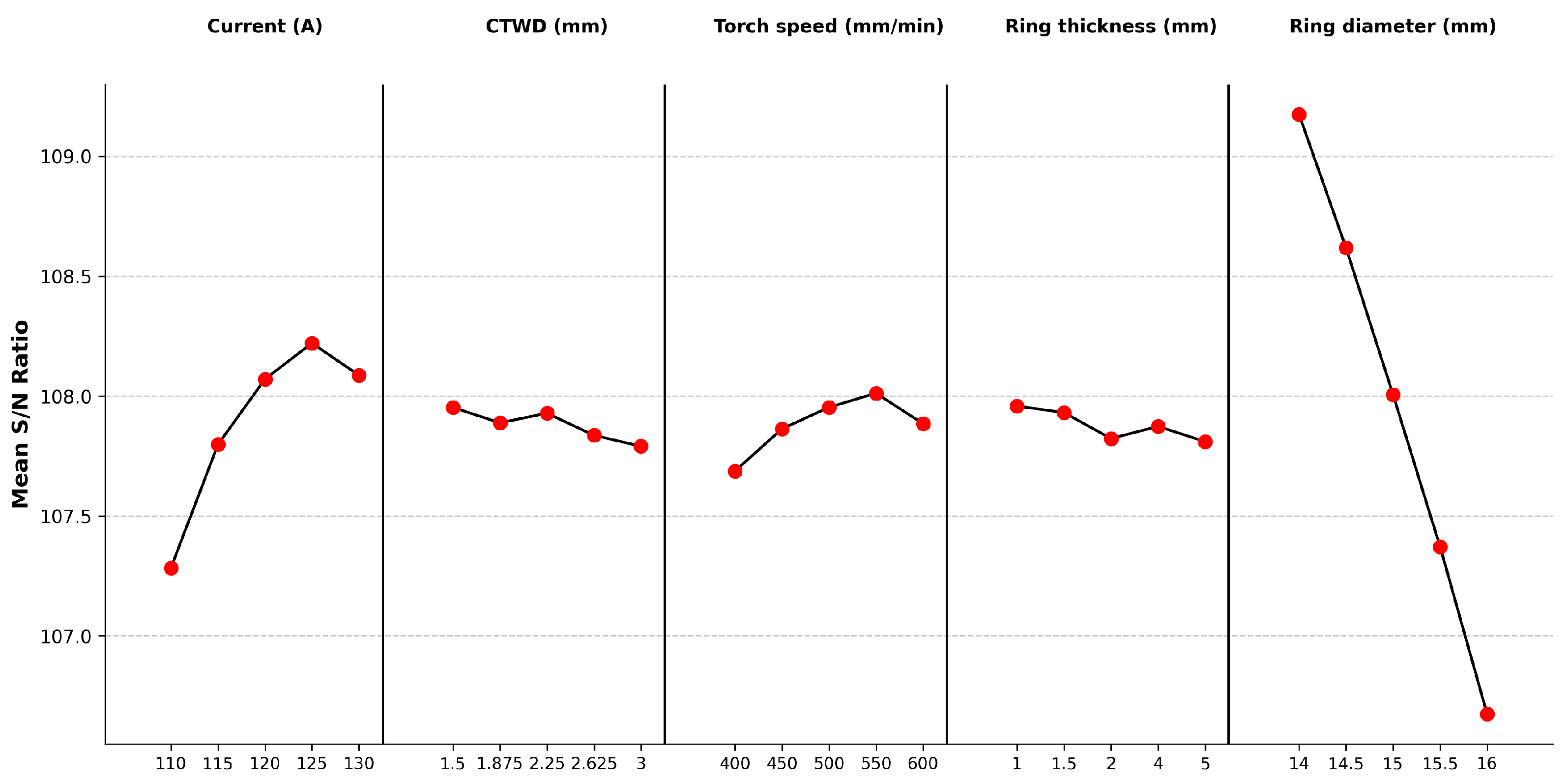

3.3. S/N Ratio for Process Robustness

3.4. Standardized Regression Results

3.5. R-Squared Model Fit Analysis

4. Discussion

4.1. Parameter Effects

4.1.1. Ring Diameter

4.1.2. Current Intensity

4.1.3. Torch Speed

4.1.4. Ring Thickness and CTWD

4.2. Optimal Parameter Settings and Process Implications

4.3. Comparison with Literature and Novelty

4.4. Limitations and Future Research Directions

5. Conclusions

- Enhanced fatigue performance of 3D-printed metal shafts, achieving 299,730 cycles under rotating bending (ISO 1143:2021) with optimal parameters: ring diameter 14.0 mm, current 125 A, torch speed 550 mm/min, ring thickness 1.0 mm, and CTWD 1.5 mm.

- ANOVA from the Taguchi L25 design identified ring diameter as the dominant factor (85.79% variance, F-value = 446.87, p < 0.001), optimizing fatigue life at 14.0 mm (S/N = 109.2). Current (9.11%, S/N = 108.3) and torch speed (1.58%, S/N = 108.1) at 125 A and 550 mm/min improved performance, while ring thickness and CTWD had minimal impact (0.014% and 0.032%, S/N = 108.0). The Ar-CO2 shielding gas (8–10 L/min) reduced oxide inclusions, with a regression model yielding R2 = 0.9603 and 3.5% unexplained variance.

- The stacked-ring WAAM configuration, optimized via Taguchi L25, ANOVA, and regression, enables high-fatigue-resistance components for aerospace and automotive applications. The four-point welding strategy mitigates delamination, and Response Surface Methodology (RSM) is recommended to address the 3.5% variance using non-linear modeling.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| WAAM | Wire Arc Additive Manufacturing |

| ANOVA | Analysis of Variance |

| CTWD | Contact Tip to Workpiece Distance |

| MIG | Metal Inert Gas |

| GMAW | Gas Metal Arc Welding |

| CT3 | Carbon Steel Type 3 |

| S/N | Signal-to-Noise Ratio |

References

- Li, Y.; Su, C.; Zhu, J. Comprehensive Review of Wire Arc Additive Manufacturing: Hardware System, Physical Process, Monitoring, Property Characterization, Application and Future Prospects. Results Eng. 2022, 13, 100330. [Google Scholar] [CrossRef]

- Williams, S.W. Wire + Arc Additive Manufacturing. Mater. Sci. Technol. 2016, 32, 641–647. [Google Scholar] [CrossRef]

- Cunningham, C.R.; Flynn, J.M.; Shokrani, A.; Dhokia, V.; Newman, S.T. Invited Review Article: Strategies and Processes for High Quality Wire Arc Additive Manufacturing. Addit. Manuf. 2018, 22, 672–686. [Google Scholar] [CrossRef]

- Wu, B. A Review of the Wire Arc Additive Manufacturing of Metals: Properties, Defects and Quality Improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- Shah, A. A Review of the Recent Developments and Challenges in Wire Arc Additive Manufacturing (WAAM) Process. J. Manuf. Mater. Process. 2023, 7, 97. [Google Scholar] [CrossRef]

- Jafari, D.; Vaneker, T.H.J.; Gibson, I. Wire and Arc Additive Manufacturing: Opportunities and Challenges to Control the Quality and Accuracy of Manufactured Parts. Mater. Des. 2021, 202, 109471. [Google Scholar] [CrossRef]

- Ding, D. Wire-Feed Additive Manufacturing of Metal Components: Technologies, Developments and Future Interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Pant, H. Applications of Wire Arc Additive Manufacturing (WAAM) for Aerospace Component Manufacturing. Int. J. Adv. Manuf. Technol. 2023, 127, 4995–5011. [Google Scholar] [CrossRef]

- Langelandsvik, G. Comparative Study of Eutectic Al-Si Alloys Manufactured by WAAM and Casting. Int. J. Adv. Manuf. Technol. 2020, 110, 4995–5011. [Google Scholar] [CrossRef]

- Omiyale, B.O.; Olugbade, T.O.; Abioye, T.E.; Farayibi, P.K. Wire Arc Additive Manufacturing of Aluminium Alloys for Aerospace and Automotive Applications: A Review. Mater. Sci. Technol. 2022, 38, 391–408. [Google Scholar] [CrossRef]

- Ryan, E.M.; Sabin, T.J.; Watts, J.F.; Whiting, M.J. The Influence of Build Parameters and Wire Batch on Porosity of Wire and Arc Additive Manufactured Aluminium Alloy 2319. J. Mater. Process. Technol. 2018, 262, 577–584. [Google Scholar] [CrossRef]

- Tomar, B.; Shiva, S.; Nath, T. A Review on Wire Arc Additive Manufacturing: Processing Parameters, Defects, Quality Improvement and Recent Advances. Mater. Today Commun. 2022, 31, 103739. [Google Scholar] [CrossRef]

- Dias, M. Economic and Environmental Potential of Wire-Arc Additive Manufacturing. Sustainability 2022, 14, 5197. [Google Scholar] [CrossRef]

- Ayan, Y.; Kahraman, N. Bending Fatigue Properties of Structural Steel Fabricated through Wire Arc Additive Manufacturing (WAAM). Eng. Sci. Technol. Int. J. 2022, 35, 101247. [Google Scholar] [CrossRef]

- Pandey, A.; Gaur, V. Effect of Dwell Time on Fatigue Properties of Wire-Arc Additively Manufactured IN718 Alloy. Int. J. Fatigue 2023, 176, 107863. [Google Scholar] [CrossRef]

- Albannai, A.I. A Brief Review on the Common Defects in Wire Arc Additive Manufacturing. Int. J. Curr. Sci. Res. Rev. 2022, 5, 4556–4576. [Google Scholar] [CrossRef]

- Baufeld, B.; Biest, O.; Gault, R. Additive Manufacturing of Ti-6Al-4V Components by Shaped Metal Deposition: Microstructure and Mechanical Properties. Mater. Des. 2010, 31, S106–S111. [Google Scholar] [CrossRef]

- Rao, Z.H.; Zhou, J.; Tsai, H.L. Determination of Equilibrium Wire-Feed-Speeds for Stable Gas Metal Arc Welding. Int. J. Heat Mass Transf. 2012, 55, 6651–6664. [Google Scholar] [CrossRef]

- Zong, L.; Fang, W.; Huang, C.; Wang, Z.; Gardner, L. Low Cycle Fatigue Behaviour of Wire Arc Additively Manufactured ER70S-6 Steel. Int. J. Fatigue 2023, 176, 107910. [Google Scholar] [CrossRef]

- Wang, F. Microstructure and Mechanical Properties of Wire and Arc Additive Manufactured Ti-6Al-4V. Metall. Mater. Trans. A 2012, 44, 968–977. [Google Scholar] [CrossRef]

- Dekis, M.; Tawfik, M.; Egiza, M.; Dewidar, M. Unveiling the Characteristics of ER70S-6 Low Carbon Steel Alloy Produced by Wire Arc Additive Manufacturing at Different Travel Speeds. Met. Mater. Int. 2025, 31, 325–338. [Google Scholar] [CrossRef]

- Anshari, M.A.A.; Mishra, R.; Imam, M.; Pandit, D.; Jha, K.K.; Kesharwani, R.; Kar, M.; Chinthapenta, V. Comparison of the Microstructures and Mechanical Properties in the Overlapping Region of Low Carbon Steel Additive Bead Fabricated by WAAM and FSP. Metall. Mater. Trans. A 2023, 54, 869–895. [Google Scholar] [CrossRef]

- Dinovitzer, M. Effect of Wire and Arc Additive Manufacturing (WAAM) Process Parameters on Bead Geometry and Microstructure. Addit. Manuf. 2019, 26, 138–146. [Google Scholar] [CrossRef]

- Mehrabi, O.; Seyedkashi, S.H.; Moradi, M. Experimental and response surface study on additive manufacturing of functionally graded steel-inconel wall using direct laser metal deposition. Opt. Laser Technol. 2023, 167, 109707. [Google Scholar] [CrossRef]

- Bhardwaj, S.; Sharma, S. Design and analysis of a response surface model to realize the mechanical properties of stainless steel in additive manufacturing. Int. J. Eng. Res. Technol. 2024, 13, 1234–1245. Available online: https://www.ijert.org/design-and-analysis-of-a-response-surface-model-to-realize-the-mechanical-properties-of-stainless-steel-in-additive-manufacturing (accessed on 16 August 2025).

- Jerold, S.; Kumar, R.P.; Thamizhmaran, K. Optimization of process parameters using response surface methodology: A review. Mater. Today Proc. 2021, 45, 6514–6518. [Google Scholar] [CrossRef]

- Chia, H.Y.; Wu, J.; Wang, X.; Yan, W. Process parameter optimization of metal additive manufacturing: A review and outlook. J. Mater. Inform. 2022, 2, 16. [Google Scholar] [CrossRef]

- Lewandowski, J.J.; Seifi, M. Metal additive manufacturing: A review of mechanical properties. Annu. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef]

- Yamaguchi, M. Influence of Metal Transfer Behavior under Ar and CO2 Shielding Gases on Geometry and Surface Roughness of Single and Multilayer Structures in GMAW-Based Wire Arc Additive Manufacturing of Mild Steel. Int. J. Adv. Manuf. Technol. 2021, 119, 911–926. [Google Scholar] [CrossRef]

- Jurić, I. Influence of Shielding Gas Composition on Structure and Mechanical Properties of Wire and Arc Additive Manufactured Inconel 625. JOM 2018, 71, 703–708. [Google Scholar] [CrossRef]

- Barath Kumar, M.D.; Arivazhagan, N.; Tofil, S.; Andersson, J.; Kozak, J.; Manikandan, M. Influence of Pulsed Current GTAW-WAAM Process Parameters on the Single Layer Bead Geometry and Multi Bead Multi-Layer Deposition of a Nickel-Based Superalloy. Mater. Today Commun. 2024, 39, 108824. [Google Scholar] [CrossRef]

- Ganesan, G. Effect of Varying Layer Thickness by Interlayer Machining on Microstructure and Mechanical Properties in Wire Arc Additive Manufacturing. J. Manuf. Mater. Process. 2025, 9, 135. [Google Scholar] [CrossRef]

- Qu, G.; Guo, W.; Shi, J.; He, D.; Zhang, Y.; Dong, Y.; Chi, J.; Shen, Z.; Li, Y.; Chen, Z.; et al. Improvement of gradient microstructure and properties of wire-arc directed energy deposition titanium alloy via laser shock peening. Mater. Sci. Eng. A 2024, 198, 147422. [Google Scholar] [CrossRef]

- Kumar, J.P.; Raman, R.J.; Festus, N.J.; Kanmani, M.; Nath, S.P. Optimization of Wire Arc Additive Manufacturing Parameters Using Taguchi Grey Relation Analysis. In Proceedings of the 2023 International Conference on Intelligent Systems for Communication, IoT and Security (ICISCoIS), Coimbatore, India, 9 February 2023; pp. 108–113. [Google Scholar]

- ISO 1143:2021; Metallic Materials — Rotating Bar Bending Fatigue Testing. International Organization for Standardization: Geneva, Switzerland, 2021.

- Treutler, K.; Wesling, V. The Current State of Research of Wire Arc Additive Manufacturing (WAAM): A Review. Appl. Sci. 2021, 18, 8619. [Google Scholar] [CrossRef]

- Vishwanatha, H.M.; Rao, R.N.; Maiya, M.; Kumar, P.; Gupta, N.; Saxena, K.K.; Vijayan, V. Effects of Arc Current and Travel Speed on the Processing of Stainless Steel via Wire Arc Additive Manufacturing (WAAM) Process. J. Adhes. Sci. Technol. 2024, 38, 2222–2239. [Google Scholar] [CrossRef]

- Chen, C. Effect of Equivalent Heat Input on WAAM Al-Si Alloy. Int. J. Mech. Sci. 2023, 238, 107831. [Google Scholar] [CrossRef]

- Albannai, A.I.; Ramirez, A.J. The Effect of Altering Heat Input & Torch Motion on the Grain Formation of SS316L Material in WAAM. Discov. Mech. Eng. 2024, 3, 49. [Google Scholar] [CrossRef]

- Ajay, V.; Nakrani, J.; Mishra, N.K.; Shrivastava, A. Anisotropic Fatigue Crack Propagation in Wire Arc Additively Manufactured 316L Stainless Steel. Int. J. Fatigue 2023, 177, 107976. [Google Scholar] [CrossRef]

- Aldalur, E.; Veiga, F.; Suárez, A.; Bilbao, J.; Lamikiz, A. High Deposition Wire Arc Additive Manufacturing of Mild Steel: Strategies and Heat Input Effect on Microstructure and Mechanical Properties. J. Manuf. Process. 2020, 58, 615–626. [Google Scholar] [CrossRef]

- Wani, Z.K.; Abdullah, A.B.; Jaafar, N.A.; Hussain, Z. Multi-Stages, Multi-Responses Optimisation of Wire Arc Additive Manufacturing Parameters Using Taguchi Method. Mater. Today Proc. 2022, 66, 2660–2664. [Google Scholar] [CrossRef]

- Ahsan, M.R.U. Effects of Process Parameters on Bead Shape, Microstructure, and Mechanical Properties in Wire + Arc Additive Manufacturing of Al0.1CoCrFeNi High-Entropy Alloy. J. Manuf. Process. 2021, 68, 1314–1327. [Google Scholar] [CrossRef]

- Zhang, H. State-of-Art Review on the Process-Structure-Properties-Performance Linkage in Wire Arc Additive Manufacturing. Virtual Phys. Prototyp. 2024, 19, e2390495. [Google Scholar] [CrossRef]

- Assunção, M.T.; Queiroz, A.; Bracarense, A.Q. A Novel Strategy to Improve Melting Efficiency and Arc Stability in Underwater FCAW via Contact Tip Air Chamber. J. Manuf. Process. 2023, 104, 1–16. [Google Scholar] [CrossRef]

- Liberini, M. Selection of Optimal Process Parameters for Wire Arc Additive Manufacturing. Procedia CIRP 2017, 62, 470–474. [Google Scholar] [CrossRef]

- Ali, M.H.; Han, Y.S. A Finite Element Analysis on the Effect of Scanning Pattern and Energy on Residual Stress and Deformation in Wire Arc Additive Manufacturing of EH36 Steel. Materials 2023, 16, 4698. [Google Scholar] [CrossRef]

| Parameter | Range |

|---|---|

| Welding Current (I) | 110–130 A |

| Contact Tip to Workpiece Distance (CTWD) | 1.5–3 mm |

| Torch Speed (V) | 400–600 mm/min |

| Steel Ring Diameter (D) | 14–16 mm |

| Steel Ring Thickness (h) | 1–5 mm |

| Parameter | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 |

|---|---|---|---|---|---|

| Welding Current (A) | 110 | 115 | 120 | 125 | 130 |

| CTWD (mm) | 1.5 | 1.875 | 2.25 | 2.625 | 3.0 |

| Torch Speed (mm/min) | 400 | 450 | 500 | 550 | 600 |

| Ring Thickness (mm) | 1.0 | 1.5 | 2.0 | 4.0 | 5.0 |

| Ring Diameter (mm) | 14.0 | 14.5 | 15.0 | 15.5 | 16.0 |

| Run | Welding Current (A) | CTWD (mm) | Torch Speed (mm/min) | Ring Thickness (mm) | Ring Diameter (mm) | Fatigue Life (Cycles) |

|---|---|---|---|---|---|---|

| 1 | 110 | 1.5 | 400 | 1.0 | 14.0 | 250,120 |

| 2 | 110 | 1.875 | 450 | 1.5 | 14.5 | 245,890 |

| 3 | 110 | 2.25 | 500 | 2.0 | 15.0 | 240,750 |

| 4 | 110 | 2.625 | 550 | 4.0 | 15.5 | 235,620 |

| 5 | 110 | 3.0 | 600 | 5.0 | 16.0 | 200,682 |

| 6 | 115 | 1.5 | 450 | 2.0 | 15.5 | 238,450 |

| 7 | 115 | 1.875 | 500 | 4.0 | 16.0 | 232,780 |

| 8 | 115 | 2.25 | 550 | 5.0 | 14.0 | 260,340 |

| 9 | 115 | 2.625 | 600 | 1.0 | 14.5 | 255,670 |

| 10 | 115 | 3.0 | 400 | 1.5 | 15.0 | 248,910 |

| 11 | 120 | 1.5 | 500 | 5.0 | 14.5 | 252,430 |

| 12 | 120 | 1.875 | 550 | 1.0 | 15.0 | 258,760 |

| 13 | 120 | 2.25 | 600 | 1.5 | 15.5 | 246,320 |

| 14 | 120 | 2.625 | 400 | 2.0 | 16.0 | 241,890 |

| 15 | 120 | 3.0 | 450 | 4.0 | 14.0 | 265,230 |

| 16 | 125 | 1.5 | 550 | 1.5 | 16.0 | 242,560 |

| 17 | 125 | 1.875 | 600 | 2.0 | 14.0 | 299,730 |

| 18 | 125 | 2.25 | 400 | 4.0 | 14.5 | 254,890 |

| 19 | 125 | 2.625 | 450 | 5.0 | 15.0 | 249,670 |

| 20 | 125 | 3.0 | 500 | 1.0 | 15.5 | 247,340 |

| 21 | 130 | 1.5 | 600 | 4.0 | 15.0 | 243,120 |

| 22 | 130 | 1.875 | 400 | 5.0 | 15.5 | 239,890 |

| 23 | 130 | 2.25 | 450 | 1.0 | 16.0 | 237,560 |

| 24 | 130 | 2.625 | 500 | 1.5 | 14.0 | 262,450 |

| 25 | 130 | 3.0 | 550 | 2.0 | 14.5 | 256,780 |

| Parameter | DoF | Sum of Squares (SS) | F-Value | p-Value | Contribution (%) |

|---|---|---|---|---|---|

| Welding Current (A) | 4 | 1.73 × 109 | 47.48 | 0.001 | 9.11 |

| CTWD (mm) | 4 | 6.14 × 105 | 0.02 | 0.896 | 0.032 |

| Torch Speed (mm/min) | 4 | 3.01 × 108 | 8.25 | 0.002 | 1.58 |

| Ring Thickness (mm) | 4 | 2.16 × 108 | 0.06 | 0.048 | 0.014 |

| Ring Diameter (mm) | 4 | 16.32 × 109 | 446.87 | <0.001 | 85.79 |

| Error | 4 | 6.68 × 108 | – | – | 3.514 |

| Total | 24 | 19.062 × 109 | – | – | 100.0 |

| Level | Current (A) | CTWD (mm) | Torch Speed (mm/min) | Ring Thickness (mm) | Ring Diameter (mm) |

|---|---|---|---|---|---|

| 1 | 107.4 | 108.0 | 107.8 | 108.0 | 109.2 |

| 2 | 107.9 | 108.0 | 107.9 | 108.0 | 108.6 |

| 3 | 108.2 | 108.0 | 108.1 | 108.0 | 108.0 |

| 4 | 108.3 | 108.0 | 108.1 | 108.0 | 107.4 |

| 5 | 108.2 | 107.9 | 108.0 | 108.0 | 106.7 |

| Delta | 0.9 | 0.1 | 0.4 | 0.0 | 2.5 |

| Rank | 2 | 4 | 3 | 5 | 1 |

| Parameter | Standardized Coefficient | Absolute Value |

|---|---|---|

| Ring diameter (mm) | −25,557.3 | 25,557.3 |

| Current (A) | 8330.821 | 8330.821 |

| Torch speed (mm/min) | 3472.234 | 3472.234 |

| Ring thickness (mm) | 294.5029 | 294.5029 |

| CTWD (mm) | −156.723 | 156.7231 |

| Training R2 | Validation R2 | Test R2 | Overall R2 |

|---|---|---|---|

| 0.9427 | 0.9734 | 0.775 | 0.9603 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Minh, P.S.; Truong, Q.T.; Nguyen, V.-M. Fatigue Strength Study of WAAM-Fabricated Shafts with Stacked Steel Ring Substrates Using Advanced Modeling. Metals 2025, 15, 1110. https://doi.org/10.3390/met15101110

Minh PS, Truong QT, Nguyen V-M. Fatigue Strength Study of WAAM-Fabricated Shafts with Stacked Steel Ring Substrates Using Advanced Modeling. Metals. 2025; 15(10):1110. https://doi.org/10.3390/met15101110

Chicago/Turabian StyleMinh, Pham Son, Quang Tri Truong, and Van-Minh Nguyen. 2025. "Fatigue Strength Study of WAAM-Fabricated Shafts with Stacked Steel Ring Substrates Using Advanced Modeling" Metals 15, no. 10: 1110. https://doi.org/10.3390/met15101110

APA StyleMinh, P. S., Truong, Q. T., & Nguyen, V.-M. (2025). Fatigue Strength Study of WAAM-Fabricated Shafts with Stacked Steel Ring Substrates Using Advanced Modeling. Metals, 15(10), 1110. https://doi.org/10.3390/met15101110