Abstract

This study investigates H13 steel through Q-P-T (quenching–partitioning–tempering) heat treatment experiments, focusing on the effects of quenching and tempering temperatures on its microstructure and mechanical properties. Experimental results demonstrate that elevated heat treatment temperatures induce grain coarsening and increased hardness. Under the optimized thermal processing parameters of 1020 °C quenching followed by 530 °C tempering, H13 steel achieves an optimal balance between strength and toughness. This balanced performance effectively addresses the issue of insufficient toughness and susceptibility to fracturing when H13 steel is utilized as shank material.

1. Introduction

H13 steel, a chromium-based hot-work die steel, is widely adopted for manufacturing various tool shanks due to its high hardenability, excellent toughness, superior thermal crack resistance, favorable thermal wear resistance, and machinability. Notably, it retains adequate strength and hardness under extreme operating conditions characterized by high temperatures, pressures, and abrasion [1]. For example, H13 steel high-speed milling cutter shanks exhibit sufficient rigidity and thermal stability to ensure operational reliability during high-speed cutting processes [2]. Similarly, H13 steel shanks employed in drills for machining high-hardness materials demonstrate enhanced strength and hardness to withstand demanding mechanical stresses [3].

Heat treatment serves as the ultimate processing stage in die steel manufacturing, critically determining its service performance. The heat treatment process governs the internal microstructure of die steel, thereby dictating its strength and toughness characteristics. While varying heat treatment techniques can achieve desired hardness levels in die steel, their microstructural properties may differ substantially. To fully exploit the strengthening and toughening effects of alloying elements, it is imperative to investigate the correlation between heat treatment processes, microstructural evolution, and mechanical performance. This research framework elucidates the phase transformation mechanisms of H13 steel, providing theoretical guidance for optimizing its strength–toughness balance [4].

Scholars have conducted systematic investigations into the heat treatment processes of H13 steel, focusing on optimizing quenching and tempering parameters, elucidating microstructural evolution, and clarifying their impacts on mechanical properties. Deng [5] categorized the heat treatment processes into two main stages: preparatory treatments (normalizing and spheroidizing annealing) and quenching–tempering cycles. The preparatory treatments refine carbide distribution and eliminate forging-induced banded structures, ensuring a homogeneous microstructure for subsequent quenching. For instance, isothermal spheroidizing annealing (845–900 °C holding followed by slow cooling to 710–740 °C) promotes globular pearlite formation and suppresses carbide network inheritance. Ma et al. [6] evaluated four quenching temperatures (1000–1100 °C) and identified 1000 °C as optimal, where fine lath martensite with high dislocation density enhances strength-toughness synergy. Zhan Shuangyuan further observed that increasing quenching temperature to 1030 °C facilitates complete carbide dissolution into austenite, increasing retained austenite content for improved hardness and crack resistance. However, temperatures exceeding 1080 °C induce austenite grain coarsening and mixed-grain structures, leading to hardness reduction. Fan Mingqiang proposed an optimized process combining 1080 °C × 1 h air-cooled quenching with 600 °C × 2 h air-cooled double tempering, which promotes fine MC/M2C carbide precipitation for enhanced strength (1534 MPa) and ductility (8.10%). Lu highlighted the risks of tempering above 620 °C, where heterogeneous carbide coarsening (e.g., M23C6) and matrix softening cause localized plasticity and thermal fatigue cracking. These findings collectively suggest that H13 steel achieves optimal performance within 1030 °C quenching + 530–600 °C tempering, balancing strength and toughness for demanding applications such as high-speed milling and machining of hardened materials.

Synthesizing the findings from the aforementioned studies, it is evident that quenching temperature critically governs the microstructure and hardness evolution of H13 steel. Within the quenching temperature range of 950–1100 °C, the hardness exhibits a triphasic trend: an initial increase (below 1040 °C), followed by a decline (1040–1060 °C), and a subsequent rise (above 1060 °C) [7]. Concurrently, tensile strength displays an initial enhancement followed by a reduction with increasing quenching temperature, while impact toughness progressively improves. Notably, elevated quenching temperatures shift the secondary hardening peak to lower tempering temperatures during subsequent tempering processes [8]. The tempering process fundamentally involves the desorption, precipitation, and coarsening of supersaturated elements in quenched martensite. Higher tempering temperatures generally reduce hardness under identical quenching conditions, yet all tempering curves exhibit characteristic secondary hardening peaks. To achieve optimal mechanical performance, tempering temperatures should be maintained within 550–600 °C after selecting an appropriate quenching temperature, with double tempering recommended to stabilize microstructure and mitigate residual stresses.

In 2003, Speer et al. [9,10] from the Colorado School of Mines proposed a novel heat treatment process termed Quenching & Partitioning (Q&P) based on the transformation-induced plasticity (TRIP) effect. This innovation opened new avenues for designing advanced high-strength steels for modern thermomechanical applications. Compared to conventional quenching-tempering (Q-T) processes, the Q&P process leverages alloying elements such as Si and Al to suppress carbide precipitation from martensite. Instead, supersaturated carbon atoms in martensite diffuse into retained austenite (RA), stabilizing it in a metastable state at elevated temperatures. This dual-phase synergy between RA and martensite (M) achieves an exceptional balance of strength and ductility [11]. Zheng [12] utilized finite element simulations to analyze the uniaxial tensile behavior and overall mechanical properties of Q&P steels, revealing that strain-induced martensite transformation in RA accommodates high stresses, while softer phases sustain large strains, thereby enhancing both strength and toughness. However, excessive Si content (>2%) may induce surface defects during hot rolling, necessitating precise compositional control. To address this limitation while capitalizing on the beneficial effects of secondary phase precipitation, Academician Xu Zuyao of Shanghai Jiao Tong University pioneered the Quenching-Partitioning-Tempering (Q-P-T) process by integrating precipitation hardening principles into the Q&P framework. The Q-P-T process introduces an additional tempering (precipitation) step during the carbon partitioning stage, followed by final quenching to room temperature. Specifically, austenitization is conducted at relatively low temperatures, followed by quenching to a temperature between the martensite start (Ms) and finish (Mf) points to achieve a tailored mixture of martensite and austenite [13]. During lath martensite formation, carbon atoms diffuse from martensite to adjacent austenite. Concurrently, ε-carbides and other precipitates may form within the martensitic matrix. To maximize the stabilization of carbon-enriched RA at room temperature, carbon partitioning is typically performed slightly above the Ms temperature. Consequently, the quenching termination temperature, partitioning temperature, and tempering temperature collectively govern the carbon distribution in martensite, ultimately dictating the comprehensive mechanical properties of the steel [14]. In this study, the quenching temperature and tempering temperature in the Q-P-T process are selected as critical variables to systematically investigate their effects on the hardness, strength, and microstructure of H13 steel.

1.1. Existing Problems

Quenching plays a pivotal role in heat treatment processes. For hot-work die steels such as H13, the requirement for thermal strength necessitates sufficient alloying elements and matrix strengthening (tempering resistance) through carbide dissolution and precipitation hardening (secondary hardening mechanisms during high-temperature tempering). This highlights the criticality of temperature control during quenching for achieving optimal carbide dissolution within grains [15]. In H13 steel, the high alloy content results in the formation of diverse carbide types. Some carbides have high hardness and are not easily melted at high temperatures, which has a significant impact on cutting performance and may even cause problems such as edge chipping. To ensure partial but sufficient carbide dissolution for alloy enrichment while avoiding complete dissolution, elevated quenching temperatures are required. However, excessively high temperatures risk grain coarsening (intrinsic grain growth initiates at ~930 °C), degrading mechanical properties. Additionally, the presence of silicon (Si)—a non-carbide-forming element with pronounced overheating susceptibility and decarburization tendency—exacerbates these adverse effects at high temperatures [16]. Conventionally, hypereutectoid steels are quenched between Ac1~Ac3 temperatures to preserve carbide-induced second-phase pinning effects. However, analogous to high-speed steel treatments, hot-work die steels demand quenching above Ac3 to achieve adequate alloy absorption for subsequent secondary hardening during high-temperature tempering. This process activates secondary quenching mechanisms, promoting the precipitation of hard carbide phases. To mitigate risks such as excessive grain growth, overheating, or grain boundary incipient melting—particularly considering manganese (Mn)-enhanced overheating susceptibility—strict upper temperature limits must be enforced [17].

Tempering represents another critical phase in heat treatment. Given the operational demands of hot-work die steels, which require sustained mechanical performance at elevated temperatures, high-temperature tempering is essential to activate the secondary hardening mechanism. This process facilitates precipitation strengthening via carbide formation while leveraging the transformation of retained austenite into martensite during secondary quenching for additional strengthening. However, excessive tempering cycles may excessively deplete austenite content, adversely affecting dimensional stability. Conversely, excessively high tempering temperatures risk significant hardness reduction (e.g., bypassing the secondary hardening peak), while slow cooling rates between 450 and 650 °C may induce second-type tempering brittleness. These factors necessitate a balanced integration of alloying effects and thermal parameters. For instance, alloying elements in H13 steel enhance tempering resistance. To mitigate tempering brittleness, rapid cooling is effective for small components, whereas large-scale parts require alloy additions such as Mo and W to suppress embrittlement tendencies [18].

Current heat treatment processes exhibit insufficient enhancement in balancing hardness and toughness, failing to simultaneously meet performance benchmarks. This limitation increases the risk of catastrophic fracture in tool shanks due to excessive hardness and brittleness. Furthermore, the mechanistic understanding of how heat treatment parameters influence material properties remains ambiguous. To address these challenges, systematic heat treatment experiments are imperative to elucidate the correlation between thermal processing conditions and the mechanical behavior of H13 steel, thereby clarifying the microstructural drivers of strength–toughness trade-offs. Such investigations will provide critical insights for optimizing process parameters and mitigating premature tool failure in high-stress applications.

1.2. Research Contents

To enhance the performance of H13 steel tool shanks, ensure adequate toughness, improve surface hardness, and address the brittleness issue associated with high hardness while enhancing wear resistance, this study systematically characterizes the microstructure and intrinsic properties of H13 steel. A series of heat treatment experiments were conducted, followed by comprehensive evaluations of post-treatment samples, including microstructural characterization and macromechanical property testing. These analyses aim to explore the influence of heat treatment parameters on the mechanical properties of H13 steel tool holders, in order to reveal the microstructural mechanisms that control the hardness toughness balance. This approach provides a scientific basis for optimizing process routes to achieve synergistic improvements in wear resistance and fracture resistance for demanding machining applications. Although the obtained heat treatment process parameters are difficult to provide both high hardness and toughness, and have certain limitations, they have guiding significance for optimizing the heat treatment process of H13 steel tool holder performance.

2. Experimental Materials and Methods

2.1. Existing Problems

The chemical composition of the H13 steel used in this study is detailed in Table 1. Prior to experimentation, the material underwent isothermal spheroidizing annealing as a preparatory treatment. The specific protocol involved: heating to 650 °C with a 0.5 h holding period, followed by further heating to 860 °C for 2 h isothermal treatment. Subsequent controlled cooling to 730 °C with a 4 h holding phase was implemented, after which the steel was furnace-cooled to 500 °C and finally air-cooled to ambient temperature. This pre-treatment aims to achieve microstructural homogenization, eliminate internal residual stresses, and establish a refined carbide distribution, thereby providing an optimal foundation for subsequent heat treatment processes.

Table 1.

Chemical composition of H13 steel (mass fraction/%).

2.2. Protocol

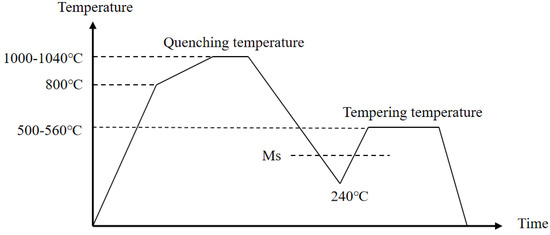

The Q-P-T heat treatment experiments were conducted using an FZK-05/16 vacuum chamber furnace (Hefei Feisheruo Thermal Equipment Co., Ltd., Hefei, China) To systematically investigate the influence of thermal processing parameters—specifically quenching temperature and tempering temperature—on material performance, the experimental design is schematically illustrated in Figure 1. Three quenching temperatures (1000 °C, 1020 °C, and 1050 °C) and three tempering temperatures (500 °C, 530 °C, and 560 °C) were selected as variable inputs. The quenching process involved a holding duration of 30 min at the target temperature, followed by rapid cooling. Subsequent tempering was performed with a 2 h holding period at designated temperatures to evaluate phase transformation kinetics and carbide precipitation behavior.

Figure 1.

Q-P-T heat treatment process route.

Microstructural characterization and mechanical property testing were performed on H13 steel samples subjected to various heat treatment processes. Scanning electron microscopy (SEM), Carl Zeiss AG, Oberkochen, Germany was employed for microstructural observation, following a standardized metallographic preparation protocol. First, heat-treated specimens were sectioned into 10 mm × 10 mm × 10 mm cubes using wire electrical discharge machining (WEDM), Suzhou Electric Processing Machine Tool Research Institute Co., Ltd., Suzhou, China. Subsequently, sequential wet grinding was conducted with 400-, 600#, 800#, 1200#, 1500#, and 2000# grit silicon carbide abrasive papers to progressively remove surface oxides and achieve planarization. The ground specimens were then mechanically polished using 3.5 μm and 0.5 μm diamond suspensions until a scratch-free mirror finish was attained. Following polishing, the samples underwent ultrasonic cleaning in ethanol and hot-air drying to eliminate residual polishing agents. Finally, microstructural features were revealed by chemical etching with a 4% nital solution (4% HNO3 in ethanol) for 10–15 s, enabling clear visualization of martensitic lath structures, carbide distributions, and retained austenite morphology under SEM.

Mechanical property evaluations encompassed hardness testing and tensile property analysis. Specimens for hardness measurements were prepared using grinding and polishing steps consistent with the microstructural preparation procedure (excluding the etching stage). Vickers hardness testing was performed with a diamond indenter under a 3 kg load applied for 15 s. To ensure statistical reliability, five distinct locations on each specimen were tested, with the average value calculated as the final hardness. This protocol minimizes measurement errors arising from local microstructural heterogeneity and surface imperfections.

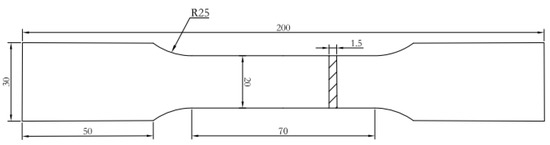

Tensile testing was conducted using specimens with geometry and dimensions illustrated in Figure 2. The experiments were performed on a WDW-50E electronic universal testing machine (Jinan, China) at speed of 1 mm/min to ensure quasi-static loading conditions.

Figure 2.

Tensile specimen size. (Unit: mm).

3. Results and Discussion

3.1. Microstructure Under Different Heat Treatment Processes

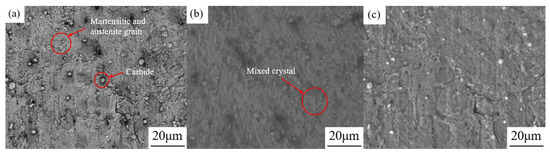

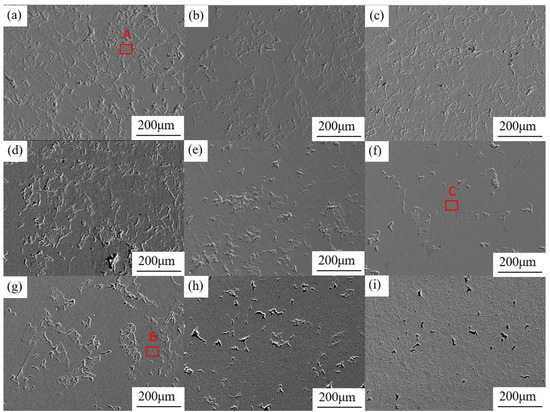

Figure 3 presents the SEM microstructures of H13 steel subjected to different heat treatment conditions, aiming to elucidate the influence of quenching temperature and tempering temperature on microstructural evolution during the Q-P-T process.

Figure 3.

SEM microstructure of H13 steel under different heat treatment processes. (a) 1000 °C quenching-500 °C tempering; (b) 1000 °C quenching-530 °C tempering; (c) 1000 °C quenching-560 °C tempering; (d) 1020 °C quenching-500 °C tempering; (e) 1020 °C quenching-530 °C tempering; (f) 1020 °C quenching-560 °C tempering; (g) 1040 °C quenching-500 °C tempering; (h) 1040 °C quenching-530 °C tempering; (i) 1040 °C quenching-560 °C tempering. The magnified local image at A, B and C will be shown in Figure 4.

Figure 3 reveals that the microstructure of H13 steel after heat treatment primarily consists of martensite and austenite. At a lower quenching temperature (1000 °C), the microstructure contains abundant carbides, with fine martensitic laths and austenitic grains observable in Figure 4a. As the quenching temperature increases, martensite gradually coarsens (Figure 4b), accompanied by partial dissolution of Cr-, Mn-, and V-rich carbides. This reduction in carbide content weakens their grain boundary pinning effect, leading to mixed-grain structures within the matrix when the quenching temperature reaches 1040 °C. With elevated tempering temperatures, Figure 4c demonstrates increased carbide precipitation at grain boundaries, along with coarsening of granular carbides. The tempering process governs carbide precipitation in H13 steel. At 500 °C tempering, a significant fraction of martensite persists, while metastable carbides such as Fe3C exhibit inhomogeneous distribution, resulting in limited precipitation strengthening. H13 steel grain refinement is caused by undissolved alloy carbides pinning austenite grain boundaries, strongly hindering their migration. As tempering temperature rises, grain boundary carbides aggregate and coarsen, accompanied by the decomposition of retained austenite into tempered martensite [19].

3.2. Performance Analysis Under Different Processes

The results of tensile test are shown in Table 2.

Table 2.

The results of tensile test.

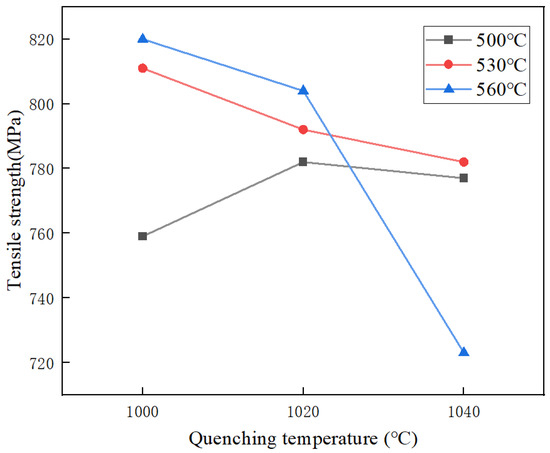

Figure 5 illustrates the influence of quenching temperature on the tensile strength of H13 steel under different tempering temperatures. As shown in Figure 3, at lower quenching temperatures (1000 °C), the tensile strength increases with rising tempering temperature, while this trend becomes less pronounced at higher quenching temperatures. At tempering temperatures of 530 °C and 560 °C, the tensile strength decreases progressively with increasing quenching temperature. Notably, a sharp decline in tensile strength is observed when the quenching temperature rises from 1020 °C to 1040 °C under 560 °C tempering. At 500 °C tempering, the tensile strength initially increases and then decreases with elevated quenching temperatures. These observations indicate that lower quenching temperatures combined with higher tempering temperatures enhance the tensile strength of H13 steel.

Figure 5.

Tensile strength of H13 steel at different quenching and tempering temperatures.

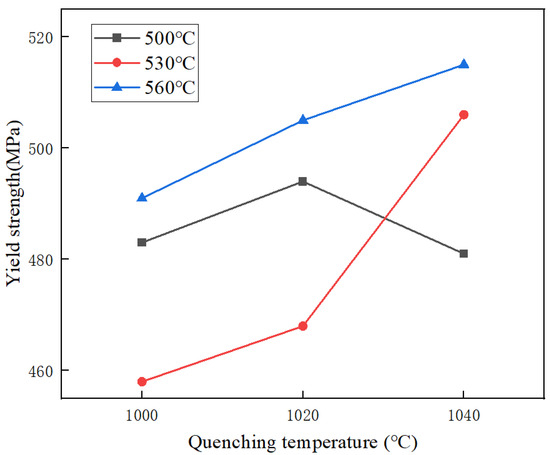

Figure 6 demonstrates the effect of quenching temperature on the yield strength of H13 steel across varying tempering temperatures. At lower quenching temperatures (1000 °C), the yield strength increases with higher tempering temperatures, reaching its maximum at 560 °C. However, this correlation diminishes at elevated quenching temperatures. For tempering at 530 °C and 560 °C, the yield strength exhibits an upward trend with increasing quenching temperatures. Conversely, at 500 °C tempering, the yield strength first rises and then declines with higher quenching temperatures. This suggests that higher quenching and tempering temperatures synergistically improve the yield strength of H13 steel.

Figure 6.

Yield strength of H13 steel at different quenching and tempering temperatures.

In summary, although the combination of 1040 °C quenching + 560 °C tempering achieves superior yield strength, its tensile strength remains suboptimal. Therefore, the optimal parameters of 1020 °C quenching + 560 °C tempering are recommended to achieve a balanced enhancement of both yield strength and tensile strength in H13 steel.

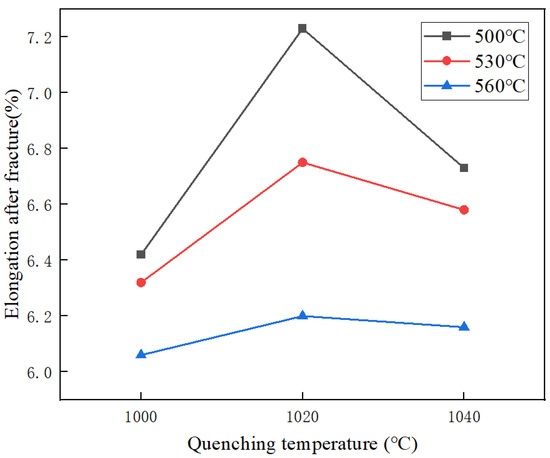

Figure 7 presents the variation in elongation after fracture of H13 steel under different quenching and tempering temperatures. As shown in Figure 5, the elongation after fracture initially increases and then decreases as the quenching temperature rises from 1000 °C to 1040 °C, reaching a maximum at 1020 °C under the experimental conditions. With increasing tempering temperatures (500 °C to 560 °C), the elongation after fracture exhibits a declining trend, and its sensitivity to quenching temperature variations diminishes. These results indicate that moderate quenching temperatures (1020 °C) combined with lower tempering temperatures (500 °C) yield superior ductility in H13 steel.

Figure 7.

Elongation after fracture of H13 steel at different quenching and tempering temperatures.

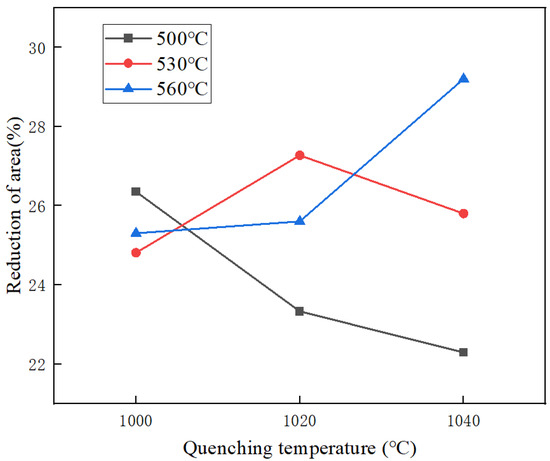

Figure 8 illustrates the reduction in area of H13 steel under varying thermal parameters. As depicted in Figure 6, the variation in tempering temperature has no obvious pattern of influence on the reduction in area. At lower tempering temperatures (500 °C), the reduction in area decreases with increasing quenching temperatures. For intermediate tempering temperatures (530 °C), it initially rises and then declines with higher quenching temperatures. Conversely, at elevated tempering temperatures (560 °C), the reduction in area shows a progressive increase with rising quenching temperatures. Collectively, moderate quenching (1020 °C) and high tempering (560 °C) parameters result in enhanced reduction in area, suggesting improved plastic deformation capacity under these conditions.

Figure 8.

Reduction in area of H13 steel at different quenching and tempering temperatures.

3.3. Hardness Analysis Under Different Processes

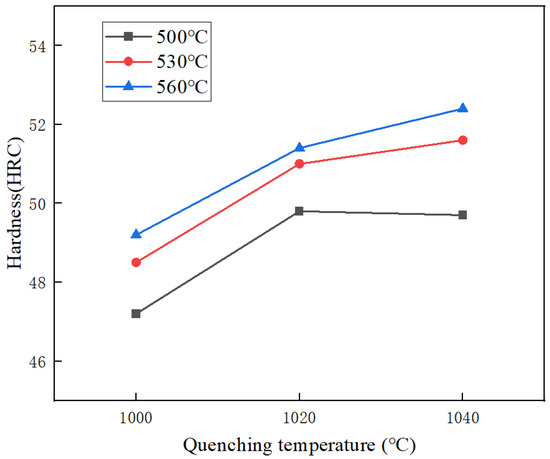

Figure 9 displays the hardness test results of H13 steel under varying quenching and tempering temperatures. The Vickers hardness values, averaged from five measurements per specimen, were converted to Rockwell hardness (HRC) using a standardized conversion table.

Figure 9.

Hardness of H13 steel at different quenching and tempering temperatures.

The results indicate that hardness increases with rising tempering temperatures at a fixed quenching temperature and elevates with higher quenching temperatures at a constant tempering temperature. The lowest hardness (47.2 HRC) is observed for the 1000 °C quenching + 500 °C tempering condition, while the highest hardness (52.4 HRC) is achieved with 1040 °C quenching + 560 °C tempering.

A pronounced hardness increase occurs when the quenching temperature rises from 1000 °C to 1020 °C, primarily attributed to enhanced dissolution of carbides, which enriches the matrix with carbon and alloying elements. Beyond 1020 °C, the hardness gain diminishes due to reduced carbide dissolution and the onset of mixed-grain structures. During tempering, the precipitation of dispersed carbides impedes dislocation motion within the matrix, further contributing to hardness improvement. These findings highlight the interplay between carbide dynamics and microstructural evolution in governing the hardening response of H13 steel.

Table 3 presents the results of the hardness analysis of variance (ANOVA). The sum of squares deviations indicates that quenching temperature exerts a more pronounced influence on the hardness of H13 steel compared to tempering temperature, with both statistical parameters (F-values) significantly exceeding 1. This demonstrates that the effects of quenching and tempering temperatures dominate over random experimental errors. Furthermore, the statistical significance is confirmed by P < 0.05 and F > Fcrit, validating that both quenching and tempering temperatures have statistically significant impacts on hardness. These findings quantitatively corroborate the critical role of thermal processing parameters in tailoring the mechanical properties of H13 steel.

Table 3.

The results of hardness variance analysis.

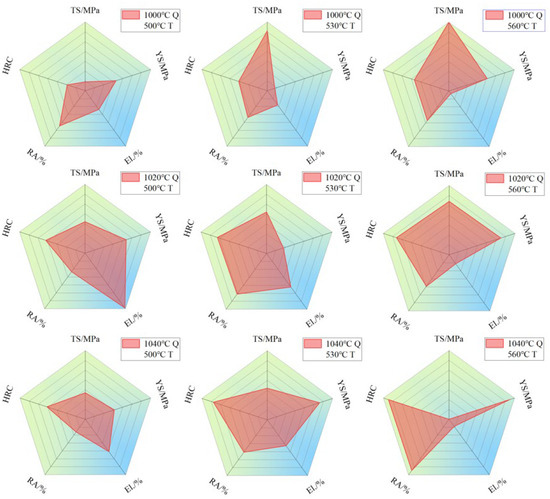

Figure 10 presents the hardness test results of H13 steel under varying quenching and tempering temperatures. At a tempering temperature of 500 °C, the steel exhibits lower hardness with reduced susceptibility to chipping but suffers from inadequate strength, leading to deformation risks. When quenched at 1000 °C, H13 steel demonstrates favorable tensile strength but poor plasticity, as evidenced by its low elongation after fracture. Conversely, quenching at 1040 °C results in high hardness but increases the likelihood of brittle fracture.

Figure 10.

Various indicators of H13 steel at different quenching (Q) and tempering temperatures (T). Tensile strength (TS); Yield strength (YS); Elongation after fracture (El.); Reduction in area (RA); Hardness (HRC).

The optimal heat treatment parameters are identified as 1020 °C quenching + 530 °C tempering and 1020 °C quenching + 560 °C tempering. Under these conditions, the material achieves a balanced combination of hardness and tensile properties while retaining acceptable plasticity and toughness. However, the 1020 °C + 530 °C process yields relatively lower yield strength, whereas the 1020 °C + 560 °C protocol compromises elongation after fracture. Practical applications should therefore prioritize parameter selection based on specific performance requirements, such as prioritizing strength-toughness balance for dynamic loading or favoring hardness-wear resistance for abrasive environments.

4. Strengthening and Toughening Mechanism of H13 Steel

The quenching process generates lath martensite with high dislocation density and fine-grained structures, where solid solution strengthening impedes dislocation motion, thereby enhancing the strength of H13 steel. During tempering, elements such as Mo and V form fine, dispersed carbides, significantly improving hardness and high-temperature strength through precipitation strengthening. Although dislocation density in tempered martensite decreases, partial strengthening effects are retained. Elevated quenching temperatures promote the dissolution of alloy carbides, intensifying secondary hardening, but concurrently induce grain coarsening. Higher tempering temperatures facilitate carbide homogenization, stress relief, and microstructural stabilization. Collectively, the synergistic effects of lath martensite, carbide precipitation, and solid solution strengthening enhance strength, while grain refinement and carbide homogenization improve toughness. Optimizing quenching and tempering temperatures to regulate carbide size and distribution achieves a balanced strength–toughness profile [20].

Excessively high yield and tensile strengths may compromise material ductility, as increased strength reduces deformation capacity. Higher elongation after fracture and reduction in area indicate superior energy absorption during deformation, correlating with enhanced ductility and toughness. Comprehensive analysis of heat treatment parameters and mechanical properties suggests that 1020 °C quenching + 530 °C tempering delivers optimal ductility.

5. Conclusions

This study systematically investigated the effects of Q-P-T (Quenching–Partitioning–Tempering) heat treatment on the microstructure, hardness, and tensile properties of H13 steel, elucidating its strengthening-toughening mechanisms. Key conclusions are summarized as follows:

- (1)

- Quenching temperature elevation induces martensite coarsening and carbide dissolution, while higher tempering temperatures promote carbide aggregation and retained austenite decomposition.

- (2)

- At 1020 °C quenching + 530 °C tempering, as well as at 1020 °C quenching + 560 °C tempering, H13 steel has good toughness and hardness matching and tensile properties. In actual processing, the choice between the two should be made according to the requirements.

- (3)

- Both quenching and tempering temperature increases enhance hardness, with tempering exhibiting a more pronounced effect. To mitigate tool shank embrittlement while maintaining mechanical performance, lower heat treatment temperatures are recommended.

Author Contributions

Conceptualization, Y.W.; Methodology, Y.W. and A.J.; Software, Y.W.; Validation, Z.H.; Formal analysis, Z.H. and J.Z.; Investigation, A.J.; Resources, X.R. and A.J.; Data curation, Z.H.; Writing—original draft, Y.W.; Writing—review & editing, X.R. and Z.L.; Visualization, Z.H.; Supervision, J.Z. and Z.L.; Project administration, J.Z. and Z.L.; Funding acquisition, X.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Major Scientific and Technological Special Project (Development and Verification of Diamond Cutting Tools for Ceramic Matrix Composite Processing 2025ZD0717601).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Authors Yuzhong Wang and Aisheng Jiang were employed by the Zhuzhou Cemented Carbide Cutting Tools Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Dhondapure, P.; Mha, P.T.; Nayak, S.; Ebacher, L.; Dourandish, S.; Champliaud, H.; Morin, J.-B.; Jahazi, M. Influence of deformation path on the stress state and damage evolution along the central axis of a large size forged ingot of AISI H13 steel. J. Mater. Res. Technol. 2023, 27, 8244–8257. [Google Scholar] [CrossRef]

- Wang, Y.; Song, K.; Zhang, Y.; Wang, G. Microstructure evolution and fracture mechanism of H13 steel during high temperature tensile deformation. Mater. Sci. Eng. A 2019, 746, 127–133. [Google Scholar] [CrossRef]

- Zhou, H.; Guo, Q.; Lin, P.; Zhang, W.; Zhang, X.-L.; Ren, L.-Q. Influence of H13 steel unit on wear behavior of vermicular cast iron. Appl. Surf. Sci. 2008, 255, 3394–3399. [Google Scholar] [CrossRef]

- Li, T.; Wang, F.; Li, C.; Zhang, G.-Q.; Meng, Q.-Y. Carbide evolution in high molybdenum Nb-microalloyed H13 steel during annealing process. J. Iron Steel Res. Int. 2015, 22, 330–336. [Google Scholar] [CrossRef]

- Madhankumar, S.; Narayanan, K.H.; Harini, V.; Gokulraj, K.; Selvakumar, S.; Dharshini, R.; Dharshini, K.; Harikrishnan, T. Study and selection of hot forging die materials and hardness. Mater. Today Proc. 2021, 45, 6563–6566. [Google Scholar] [CrossRef]

- Yuan, M.; Cao, Y.; Karamchedu, S.; Hosseini, S.; Yao, Y.; Berglund, J.; Liu, L.; Nyborg, L. Characteristics of a modified H13 hot-work tool steel fabricated by means of laser beam powder bed fusion. Mater. Sci. Eng. A 2022, 831, 142322. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, X.J.; Li, G.Q.; Liu, Y. Investigation on Band Segregate Formation during the Electroslag Remelting of H13 Die Steel. IOP Conf. Ser. Mater. Sci. Eng. 2019, 529, 012064. [Google Scholar] [CrossRef]

- Li, S.; Wu, X.; Chen, S.; Li, J. Wear Resistance of H13 and a New Hot-Work Die Steel at High temperature. J. Mater. Eng. Perform. 2016, 25, 2993–3006. [Google Scholar] [CrossRef]

- Matlock, D.K.; Bräutigam, V.E.; Speer, J.G. Application of the Quenching and Partitioning (Q&P) Process to a Medium-Carbon, High-Si Microalloyed Bar Steel. Mater. Sci. Forum 2003, 426, 1089–1094. [Google Scholar] [CrossRef]

- Speer, J.; Matlock, D.K.; De Cooman, B.C.; Schroth, J.G. Carbon partitioning into austenite after martensite transformation. Acta Mater. 2003, 51, 2611–2622. [Google Scholar] [CrossRef]

- Chen, R.; Wang, Z.; He, J.; Zhu, F.; Li, C. Effects of Rare Earth Elements on Microstructure and Mechanical Properties of H13 Die Steel. Metals 2020, 10, 918. [Google Scholar] [CrossRef]

- Zheng, H.; Li, W.; Gong, Y.; Wang, L.; Jin, X.-J. Microstructure-based finite element modeling of effect of metastable austenite on mechanical properties of quenching and partitioning (Q&P) 980 steel. J. Iron Steel Res. Int. 2018, 25, 1140–1148. [Google Scholar] [CrossRef]

- Eser, A.; Broeckmann, C.; Simsir, C. Multiscale modeling of tempering of AISI H13 hot-work tool steel—Part 1: Prediction of microstructure evolution and coupling with mechanical properties. Comput. Mater. Sci. 2016, 113, 280–291. [Google Scholar] [CrossRef]

- Zhao, L.; Qian, L.; Zhou, Q.; Li, D.; Wang, T.; Jia, Z.; Zhang, F.; Meng, J. The combining effects of ausforming and below-Ms or above-Ms austempering on the transformation kinetics, microstructure and mechanical properties of low-carbon bainitic steel. Mater. Des. 2019, 183, 108123. [Google Scholar] [CrossRef]

- Zhao, J.; Zhao, X.; Dong, C.; Zhao, X.; Kang, S. Effect of bainitic transformation combined with hot forming on the microstructure and mechanical properties of bainite-martensite multiphase steel. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2018, 731, 102–106. [Google Scholar] [CrossRef]

- Ning, A.; Gao, R.; Yue, S.; Guo, H.; Li, L. Effects of cooling rate on the mechanical properties and precipitation behavior of carbides in H13 steel during quenching process. Mater. Res. Express 2020, 8, 016503. [Google Scholar] [CrossRef]

- Mao, M.; Guo, H.; Wang, F.; Sun, X. Effect of Cooling Rate on the Solidification Microstructure and Characteristics of Primary Carbides in H13 Steel. ISIJ Int. 2019, 59, 848–857. [Google Scholar] [CrossRef]

- Lin, M.; Zhao, X.; Han, L.; Liu, Q.; Gu, J. Microstructural Evolution and Carbide Precipitation in a Heat-Treated H13 Hot Work Mold Steel. Metallogr. Microstruct. Anal. 2016, 5, 520–527. [Google Scholar] [CrossRef]

- Chen, R.; Wang, Z.; Qi, L.; Zhong, L.; Guan, R.; He, J.; Hu, X. The carbides, tensile properties, and work-hardening behavior of annealed H13 die steels with varied yttrium contents. Mater. Sci. Eng. A 2021, 806, 140856. [Google Scholar] [CrossRef]

- Fonseca, E.B.; Gabriel, A.H.; Ávila, J.A.; Vaz, R.F.; Valim, D.B.; Cano, I.G.; Lopes, É.S. Fracture toughness and wear resistance of heat-treated H13 tool steel processed by laser powder bed fusion. Addit. Manuf. 2023, 78, 103862. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).