1. Introduction

Additive Manufacturing (AM) is a production process that creates three-dimensional objects by adding material layer by layer, unlike subtractive manufacturing, where material is removed from a solid block to achieve the desired shape. It is commonly used for prototyping, given its flexibility in creating a wide variety of geometries, but also for standard parts production. Parts made using AM are particularly recognizable because the production method is clearly reflected on the ‘as-built’ surface, which usually shows the construction layers used. The roughness of surfaces produced by metal AM is influenced by many parameters, among which [

1]:

Technology.

Raw materials: type, shape (wire, sheets, or powders), and dimensions or particle size.

Process-related parameters such as energy density, layer thickness, and building speed.

Parts-related parameters, such as the presence of inclined surfaces, supports, etc.

The ones listed above are the ones with the greater impact, but many more have a smaller role, such as building strategies within each layer, orientation in the building plate, inert gas flow, etc.

Surface roughness plays a critical role in determining the functional performance, reliability, and quality of components across a wide range of industrial sectors. In mechanical engineering, rough surfaces can lead to increased friction, wear, and premature fatigue failure of moving parts. This is particularly problematic in precision assemblies, where tight tolerances and smooth interactions are essential for optimal operation [

2,

3,

4].

In the aerospace industry, surface roughness directly influences aerodynamic performance. Components such as turbine blades, airframes, and nozzles require extremely smooth surfaces to minimize drag and improve fuel efficiency. Even minor deviations in surface texture can lead to turbulent airflow, increased energy consumption, and reduced operational lifespan [

5,

6,

7].

The food industry also faces challenges related to surface roughness, especially in equipment used for processing, packaging, and handling. Rough surfaces can harbor contaminants and microorganisms, making cleaning and sterilization more difficult. This not only compromises hygiene standards but also increases the risk of product contamination and regulatory non-compliance. A direct example is the requirement for a specific surface roughness value when food products come into direct contact with metallic components [

8,

9,

10].

In the medical field, implants and surgical tools must exhibit controlled surface roughness to ensure biocompatibility and proper integration with biological tissues. Excessive roughness can lead to inflammation, poor healing, or rejection, while insufficient roughness may hinder cell adhesion and osseointegration [

11,

12,

13].

Surface roughness also affects coating adhesion, corrosion resistance, and fatigue strength in automotive and marine applications. For instance, rough substrates may lead to uneven coating thickness, resulting in weak spots and accelerated degradation under environmental stress [

14,

15,

16].

Moreover, in additive manufacturing, surface roughness is a key parameter influencing post-processing requirements, dimensional accuracy, and mechanical properties. Various technologies exhibit different degrees of surface roughness depending on process parameters, material properties, layer resolution, etc.

Despite its importance, surface roughness is often under-characterized in industrial studies. More comprehensive investigations are needed to understand its behavior under different processing conditions and its long-term impact on component performance.

In conclusion, surface roughness is a multifaceted issue that affects product quality, safety, and efficiency across diverse industries. Addressing it through improved design, material selection, and process control is essential for advancing manufacturing technologies and meeting increasingly stringent performance standards.

Concerning technologies, the most widely used for metal parts are Powder Bed Fusion (PBF), Direct Energy Deposition (DED), Binder Jetting (BJ) and Material Extrusion (ME).

PBF technologies are a group of additive manufacturing techniques that produce 3D parts from powder materials. The laser source is fixed, and the beam is directed across the printing bed using a system of lenses [

17]. Among the PBF technologies, the most relevant are:

Selective Laser Melting (SLM). This technology uses one or more lasers to melt layers of metal powder. The laser focuses on a single spot, melting the powder with an average layer thickness between 30 and 60 µm or larger [

18]. The laser spot is circular and can vary in diameter from 20 to 200 µm.

Area Wise Laser Powder Bed Fusion (AWLPBF)/Diode-based Additive Manufacturing (DiAM). Also called area printing LPBF, this technology uses a wide pulsed beam composed of multiple lasers to create an image of approximately 1 cm

2 that melts the powder. The layer thickness ranges between 50 and 100 µm [

19].

Electron Beam Melting (EBM) uses an electron beam as a heat source instead of a laser. The beam focuses on a single point, similarly to SLM. Unlike the typical argon-shielded chamber, EBM operates in a vacuum. Common layer thickness ranges between 50 and 100 µm [

20].

Selective Laser Sintering (SLS) technologies, while architecturally similar to SLM, and thus typically listed among the PBF methods, SLS does not fully melt the metal powders. There are many ways to realize metal components by sintering. In Solid State Sintering, the part is formed at the sintering temperature of the printing metal, and the raw material is just made of the metal powder in which the components are printed. In Chemically Induced Binding, chemical reactions occurring between the material powders or between the powders and the atmosphere of the printing chamber are used to impart form to the powders. The products of these reactions act as binders for the primary powders. In Liquid Phase Sintering/Partial Melting, there are three further subclasses according to the type of powder grains used: separate grains, composite grains, and coated. These three categories explain how the binder and powder material are mixed or prepared before printing. In this case, the binder can be polymeric or metallic [

21].

Direct Energy Deposition (DED) technologies are a group of additive manufacturing techniques that build 3D objects using either powders or wire as raw materials, usually assisted by a laser as a heat source. Unlike PBF, in DED the material is deposited and melted simultaneously, and the heat source is mobile, moving across the printing area. The layer thickness in DED processes is typically in the millimeter or sub-millimeter range, which is significantly higher than in PBF. These technologies are particularly efficient for adding material only where needed, making them well-suited for repair applications or for building large, near-net-shape components [

17,

22]. Among the DED techniques, the most widely used are:

Binder technologies utilize metal powders combined with a binder, which imparts sufficient mechanical strength to the green parts prior to sintering. On average, the layer thickness used in these processes ranges between 50 and 100 µm. In most cases, a debinding step is required either before or during the sintering phase to remove the binder and ensure proper densification of the final component, or impregnation with a lower melting point metal is performed alternatively to sintering. Among these technologies, the most relevant are:

Metal Binder Jetting (MBJ): This process spreads a layer of metal powder and selectively deposits binder only where the part is to be formed. The binder is then activated using a heat source, typically a lamp. MBJ does not require support structures [

29].

Mold Slurry Deposition (MSD)/MoldJet (MJ)/Layerwise Slurry Deposition (LSD): In this method, metal powder and binder are pre-mixed into a slurry. A wax mold is first created additively using a drop-on-demand technique and then filled with slurry. The wax mold provides integrated support during printing [

30].

Lithography-based Metal Manufacturing (LMM)/Area Wise Vat Polymerization (AWVP)/Digital Light Processing (DLP)/Vat Photo Polymerization (VPP): Even if not commonly listed among the BJ technologies, it combines metal powders and binders, and it is here included for this reason. This technology uses a photopolymerization process similar to Stereolithography (SLA). Metal powder is suspended in a photopolymer binder, which is selectively cured by light exposure. LMM is the only technology among these that requires support structures [

31].

Material Jetting (MJ)/Metal Material Jetting (MMJ). This technique is very similar to Metal Binder Jetting (MBJ). Instead of using a recoater that deposits only metallic powder, which is subsequently impregnated with a binder, MMJ employs a slurry in which the binder and metallic powder are pre-mixed. This mixture is deposited through a series of nozzles, like MBJ. Additionally, a second set of nozzles is used to deposit support material. The powders used in this technology are typically very fine, often in the nanometric range, as they must be able to pass through the narrow nozzles required by jetting systems [

32,

33].

Material Extrusion (ME) technologies are polymer additive manufacturing processes, such as extrusion and jetting-based methods, which have been adapted for metal printing. These technologies share the need for post-processing steps such as debinding and sintering to remove the binder and densify the final part or, alternatively, impregnation. Among them:

Fused Deposition Modeling (FDM)/Filament Material Extrusion (FME), also known as Fused Filament Fabrication (FFF): It is one of the most widely used 3D printing technologies. It operates by extruding a thermoplastic filament through a heated nozzle, depositing material layer by layer onto a build platform. When applied to metal printing, the filament is loaded with metal powder [

34].

Pellet Material Extrusion (PME): follows the same principle as FDM, but the feedstock is in the form of pellets rather than filament, offering potential advantages in terms of material cost and feed flexibility.

Dispersion Material Extrusion (DME): Follows the same architecture of the previous two technologies; instead of using a polymer as a binder during extrusion, a liquid binder is employed, resulting in a metallic powder dispersed in the form of a slurry. This slurry is then deposited onto the build platform via an extruder, similarly to a conventional FME process [

35].

Layer Laminate Manufacturing (LLM), also referred to as Sheet Lamination (SL), is an additive manufacturing process used to fabricate three-dimensional objects by stacking and bonding successive layers of material. The process begins with sheets of material-typically paper, plastic, or metal foil-which are layered and bonded using techniques such as adhesive application, ultrasonic welding, heat, or pressure. Each sheet is precisely cut to the desired geometry either before or after the bonding step. This method is considered a hybrid additive-subtractive technique, as it involves both the addition of material through layering and the removal of excess material during the cutting phase [

17], and it will be excluded from this review.

Friction Energy Deposition (FED), Friction Stir Additive Manufacturing (FSAM), Friction Stir Powder Additive Manufacturing (FSPAM), or Additive Friction Stir Deposition (AFSD): This technology utilizes the energy generated by friction resulting from the rotation of the deposition head against the build platform initially, and subsequently against the underlying layers [

36]. It operates either with a feedstock in the form of rods or powder, or in combination with LLM as a method for welding metallic sheets [

37,

38].

Liquid Metal Printing (LMP), Direct Metal Writing (DMW), Drop-On-Demand Liquid Metal Jetting (DOD-LMJ) or Molten Metal Jetting (MMJ): This technology resembles Drop-on-Demand (DoD) printing where the feedstock was replaced by molten metal [

39]. This makes it challenging to work with metals that have high melting points. As a result, one of the most commonly used materials is aluminum and its alloys [

40,

41].

Localized Electrodeposition in Liquid (LEL), Localized Electrochemical Deposition (LECD): It utilizes a conductive substrate immersed in a liquid electrolyte. The extrusion head injects a metal solution that is electrochemically deposited onto the substrate, which acts as the cathode, while the anode is positioned around the perimeter of the build area, separated by an insulating layer. This submicrometric technique is patented by Exaddon [

42]. Although its industrial application is currently limited due to the small build volume and low production speed, this technology has been included in the overview of metal additive manufacturing methods for completeness. Nevertheless, it finds application in the medical field [

43,

44].

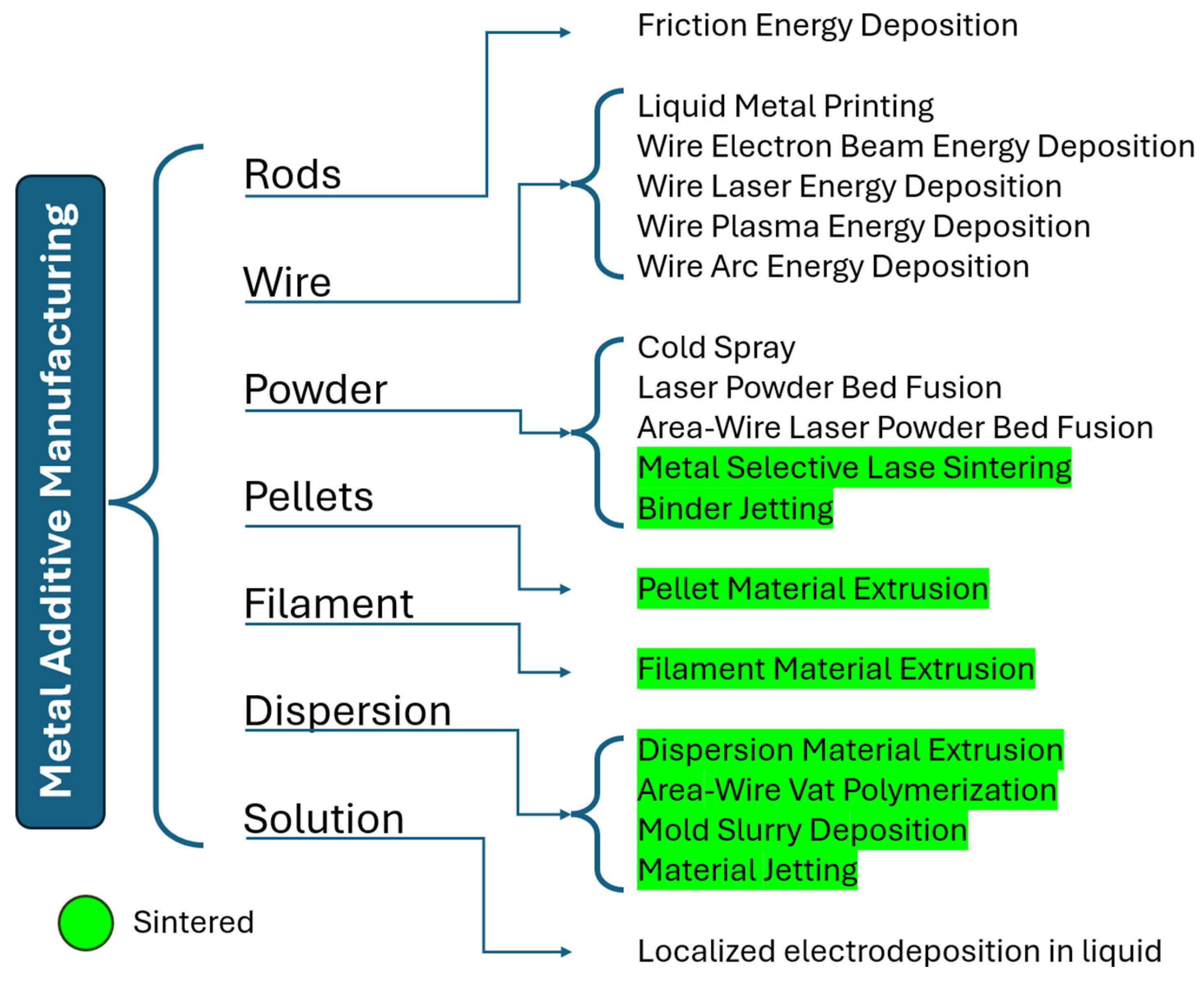

Figure 1 presents all the technologies mentioned above.

2. As-Built Surface Roughness

2.1. Selective Laser Melting

Starting with SLM technologies, the effect of processing parameters on surface roughness has been widely investigated. Hatching spacing, scan speed, and laser power effects were recently studied by Mansoura et al. by analyzing the effect of two parameters at a time, while keeping the layer thickness constant at 40 µm [

18]. Measurements were taken on the 0° up-skin surface. The reported values by Mansoura et al. for 316L stainless steel powder show an average roughness (Ra) ranging from 4.30 to 6.47 µm. The analysis of the three contour plots reported in that study highlights the influence of process parameters on surface roughness, showing that increasing both hatching spacing and scan speed is responsible for an increase in the as-built surface roughness. The same study explores the relationship between laser power and hatch spacing, and it demonstrates that roughness decreases with increasing laser power but increases with increasing hatch spacing. In the case of the combined effects of laser power and scan speed, as expected, roughness increases when laser power increases and scan speed increases.

The combination of the three plots provides useful information for the combined optimization of these parameters, providing a more detailed insight into the process with respect to the energy density parameter alone. Overall, the interaction plots of this study serve as a fundamental tool for identifying optimal operating conditions aimed at minimizing surface roughness, thereby contributing to the improvement of additive manufacturing or laser processing surface quality [

45]. However, these studies contrast with the findings of Correa-Gómez et al. and Yildiz et al., which report opposite effects in response to changes in energy density, despite similar trends in scan speed, hatch spacing, and laser power. In this case, a reduction in surface roughness was observed with decreasing laser power and increasing scan speed [

46,

47].

This shift in the effect of process variables at different energy densities can be attributed to changes in melt pool behavior, as demonstrated in Jiang et al. studies. It is shown that, at both high and low energy densities, fusion defects can occur—ranging from unmelted powder to open surface porosity—which contribute to the final surface roughness of the as-built component [

48].

This encourages the search for an optimal intermediate energy density that can yield the best possible as-built surface roughness.

As previously mentioned, another variable that influences surface roughness is the geometry of the component and, specifically, the inclination of the surface relative to the printing plate.

This correlation was studied by Wang et al. [

19], who demonstrated that surface roughness can increase by up to a factor of 10 when comparing the best and worst surface orientations. For up-skin surfaces, the average roughness (Ra) measured for processing 316L stainless steel powders ranges from 5.03 µm to 24.2 µm, while the Rz values range from 12.7 µm to 55.90 µm. Similar trends were observed for down-skin surfaces, where Ra values range from 6.25 µm to 65.10 µm, and Rz values range from 15.80 µm to 230.00 µm [

49].

The last variable considered is the metal powder particle size, which also plays a significant role in surface roughness, not only because it practically sets a lower limit to PBF layer thickness.

For SLM, the commonly used particle size distribution has a D10 of 15 µm and a D90 of 45 µm, often referred to as 15–45. In their study, Sinico et al. [

20] analyzed three different Maraging 300 powder size distributions: 15–45 µm, 10–30 µm, and 5–15 µm. The finest distribution, 5–15 µm, was excluded from further analysis due to its poor flowability, which negatively affects the powder spreading process during printing [

50]. Considering all tested combinations of energy density and laser power, specimens fabricated with smaller particles consistently exhibited higher surface quality, with a reduction in Ra ranging from approximately 20% to over 50% with respect to the coarser particles.

The following table (

Table 1) summarizes the main findings of the aforementioned studies:

2.4. Selective Laser Sintering

Due to the specific sub-category of binding methods that do not fully melt the metal powder—or only melt the binder component—Selective Laser Sintering (SLS) is considered separately from other Laser Powder Bed Fusion (L-PBF) techniques in this study.

Among the various bonding systems, this work focuses on those most commonly used for the manufacturing of metal components, starting with metal powders, either coated with a binder or not [

21].

Like L-PBF, the main parameters influencing surface roughness in SLS are energy density and its related variables, such as laser power, layer thickness, scan speed, hatch spacing, and spot size. Additional factors include part bed temperature and scan strategy.

Wang et al. investigated an iron-based powder blend containing 29% Nickel, 8.3% Copper, and 1.35% Phosphorus. Their study reported surface roughness values for 0° up-skin surfaces and those perpendicular to the build direction. The average roughness was 18.2 µm for the top view and 12.6 µm for the side view. These values were primarily attributed to thermal stresses that caused surface cracking. Pores formed during sintering were correlated with the build direction, with areas ranging from approximately 120 ± 280 µm

2 on the top surface and 57 ± 114 µm

2 on the side surface. Pore formation was most prevalent between layers [

56].

A comprehensive study by Sachdeva et al. [

57] focused on the roughness of 0° up-skin surfaces in SLS, analyzing additional parameters such as bed temperature, hatch length, and scan count. Their reference energy density was 28 J/mm

2, significantly higher than that used in Song and Koenig’s work [

58]. Sachdeva’s findings illustrate the trends of Ra and Rz roughness values as functions of laser power, hatch spacing, bed temperature, and hatch length. The variation of the aforementioned process parameters affected both Ra and Rz similarly. The reference values were 28 W laser power (ranging from 24 to 32 W), 0.2 mm hatch spacing (ranging from 0.1 to 0.3 mm), 175 °C bed temperature (ranging from 172 to 178 °C), and 100 mm hatch length (ranging from 40 to 120 mm). Ra and Rz both showed a maximum at the reference laser power and a minimum with lower scan speed and bed temperature. Hatch length exhibited a progressive reduction in roughness with increasing values. The only notable difference was that the Rz maximum was slightly shifted to a higher laser power compared to Ra [

57].

The roughness values reported in both studies ranged from 5.46 to 18.2 µm for Ra and from 30.87 to approximately 160 µm for Rz [

57,

58].

From the work of Attarzadeh et al., it is possible to derive the trends in surface roughness for surfaces parallel to the build plate, under even higher energy densities—effectively continuing the investigation initiated by Song and Koenig. Across this entire energy range, a reduction in surface roughness is observed, attributed to the removal of defects [

59].

Zhu et al. conducted extensive research on the sintering of coated metal powders. Their findings indicate that varying binder contents have a direct impact on the maximum sintering temperature, along with the particle size distribution of the powders used. Powders with an average size of 14.2 µm do not exhibit lower thermal stability compared to those of 22 µm, yet they produce components with higher density at lower temperatures and offer a superior surface finish, 1.72 µm [

60]. This technique does not directly modify the metal powders through laser interaction; therefore, the printing parameters are of secondary importance.

The following table (

Table 3) summarizes the main trends that emerged from the literature search:

2.6. Wire Laser Energy Deposition

As with LMD technology, surface roughness in WLED varies depending on multiple factors and can be categorized into two types:

Overall roughness, which accounts for the valleys between layers and the scan pattern tracks.

Single-track roughness, which refers to the roughness measured only on the top surface of an individual track, is shaped by the melt pool after solidification.

Overall roughness is primarily influenced by geometric variables such as surface angle, layer thickness, and wire diameter [

67].

The key process parameters affecting roughness include spot diameter, laser pulse rate and duration, wire feed angle, wire feed direction [

68], wire feed rate, average laser power, and stage speed.

Shaikh et al. [

67] conducted their analysis on 304 and 316L steel wire by keeping all other parameters constant while varying three key factors for single track: average laser power, pulse duration, and stage speed, and just two for multilayer deposition, fixing stage speed. The influence of average power, pulse duration, and stage speed on the width and height of the deposition track is illustrated in the work of Shaikh et al., where the relevant variables are, respectively, the overlap of adjacent tracks and the geometry of the deposition of different surface angles. An increase in width and a decrease in height is recorded with an increase in laser power and pulse duration, while an increase in stage speed reduces the height of the welding bead but almost does not affect the width.

Concerning overlap, ranging from 30% to 80% in 10% increments, it affects the continuity and uniformity of the surface, thereby influencing the final roughness. Results show that overlapping multiple tracks shows an improvement of surface finishing, reaching a maximum for 70% overlap, but then a drastic increase in roughness at 80% is observed. The effect of the deposition angles is also analyzed, with a maximum in roughness at 30° and lower values for 0° and 90° [

24,

67].

The feeding direction has a significant impact on surface roughness. Findings by Syed and Li indicate that when the wire approaches the melt pool from the front (front feeding), the resulting roughness is considerably lower compared to rear feeding. Furthermore, the angle at which the wire enters the melt pool also plays a role: in front feeding, roughness increases with the angle, whereas in rear feeding, the effect is reversed. These phenomena are primarily governed by the behavior of the melt pool and its cooling dynamics [

68].

By comparing the studies conducted by Shaiki et al., Li et al., and Syed and Li, it becomes evident that the wire diameter directly affects the height of the weld bead and, consequently, the final surface roughness of the part. Specifically, an increase in wire diameter leads to a corresponding increase in roughness.

In the best cases, average surface roughness (Ra) values of approximately one micron were measured.

A study on the effect of auxiliary heating conducted by Sang et al. on stainless steel 304. The study analyzes the influence of both print bed and wire preheating on surface roughness. The roughness measured under auxiliary heating conditions was lower than that observed without heating. The investigated effect appears to contribute significantly to the reduction in defects and control of the melt pool cooling. The results obtained in this study were based on a lower laser power compared to other works, which may lead to defects that are subsequently mitigated by substrate and wire heating, providing additional energy to the material through alternative mechanisms [

69].

The following table (

Table 5) summarizes the main trends that emerged from the literature search: