Extraction of Titanium from Blast Furnace Slag: Research on the Crushing Process of TiC-Bearing Slag

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Material

2.2. Experimental Method

2.3. Characterization and Analysis

3. Result Analysis and Discussion

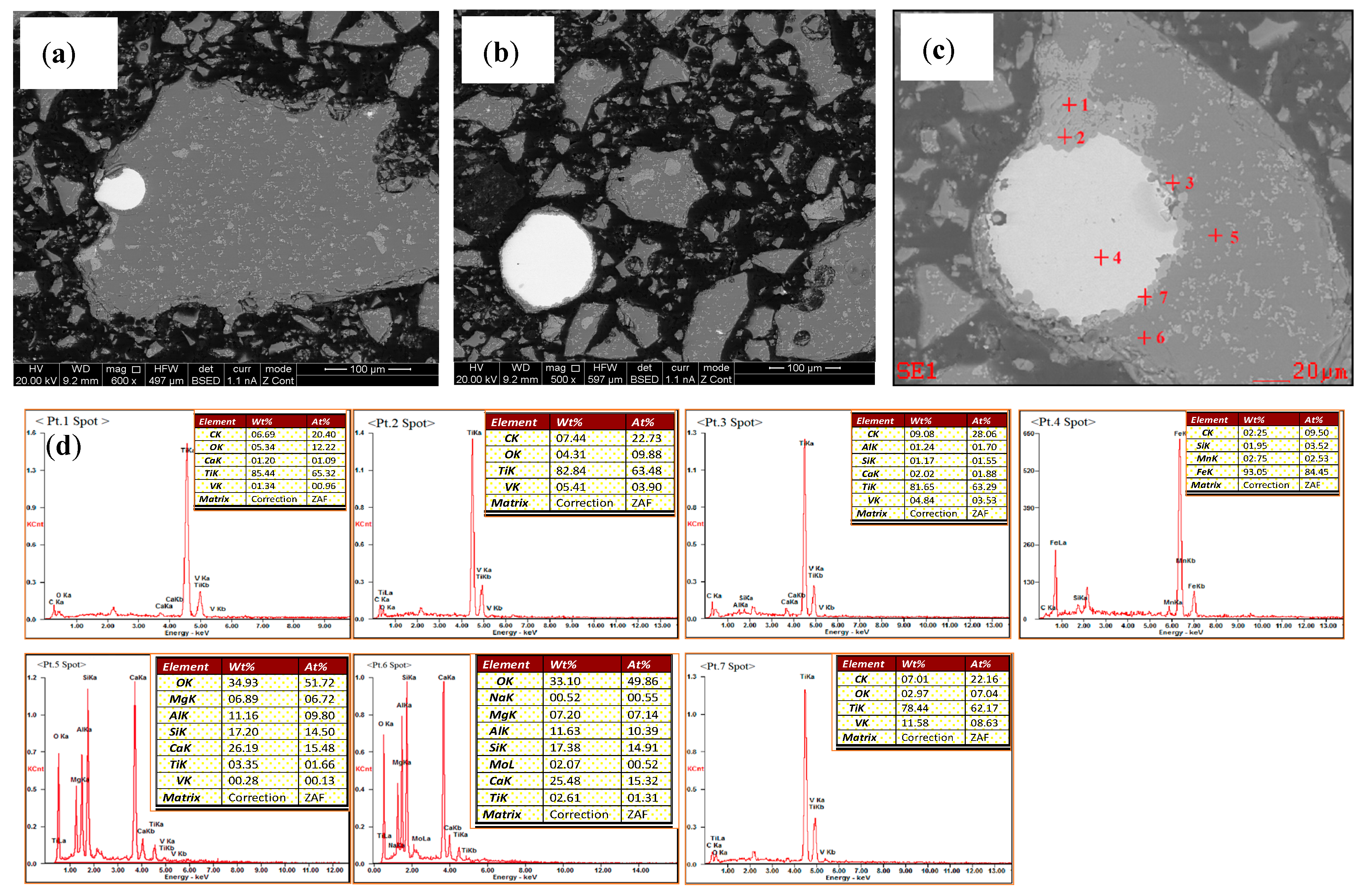

3.1. SEM Analysis

3.2. Bond Milling Power Index and Abrasion Index

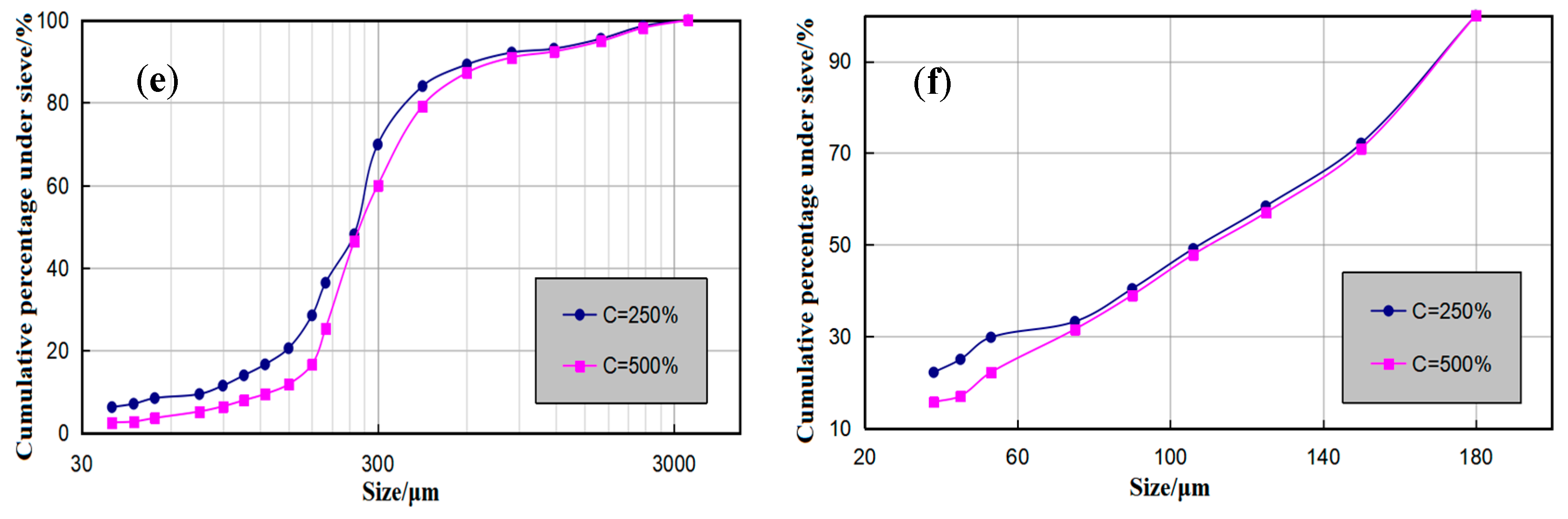

3.3. Ball Milling

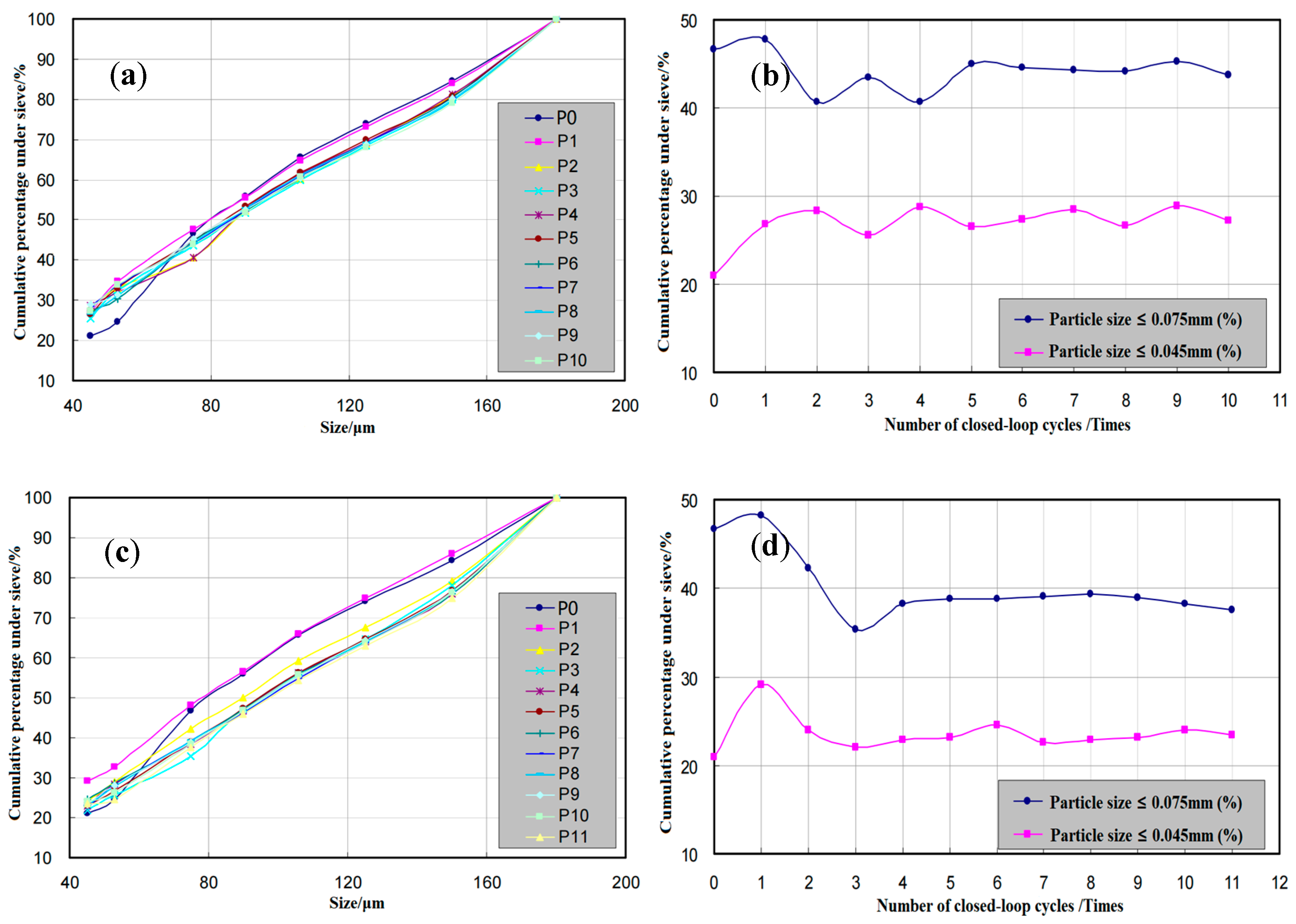

3.4. Rod Milling

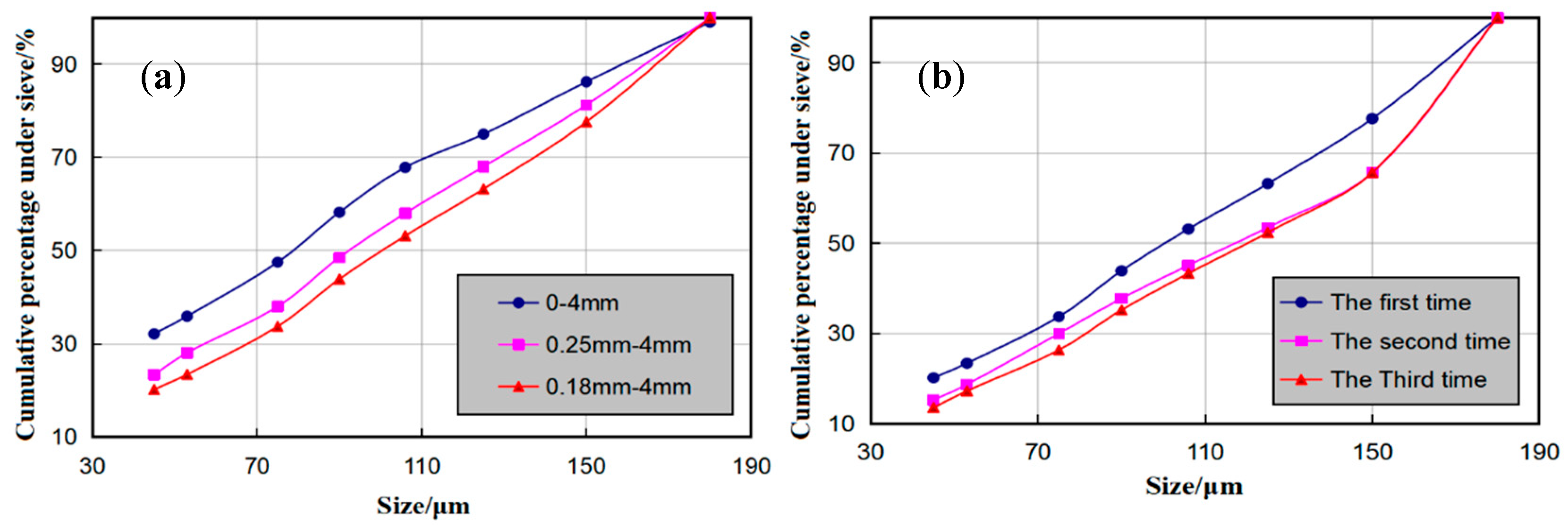

3.5. High-Pressure Roller Milling

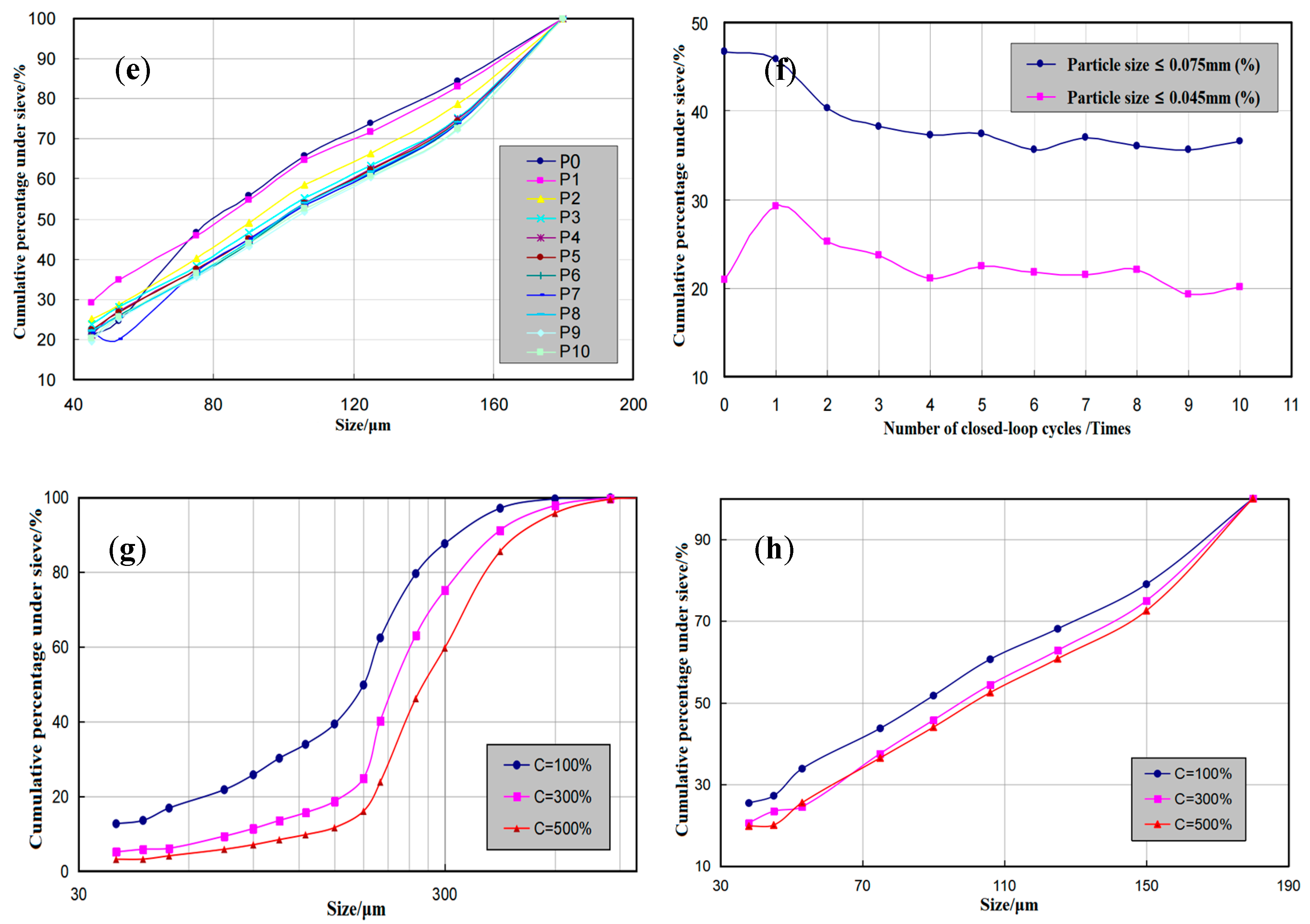

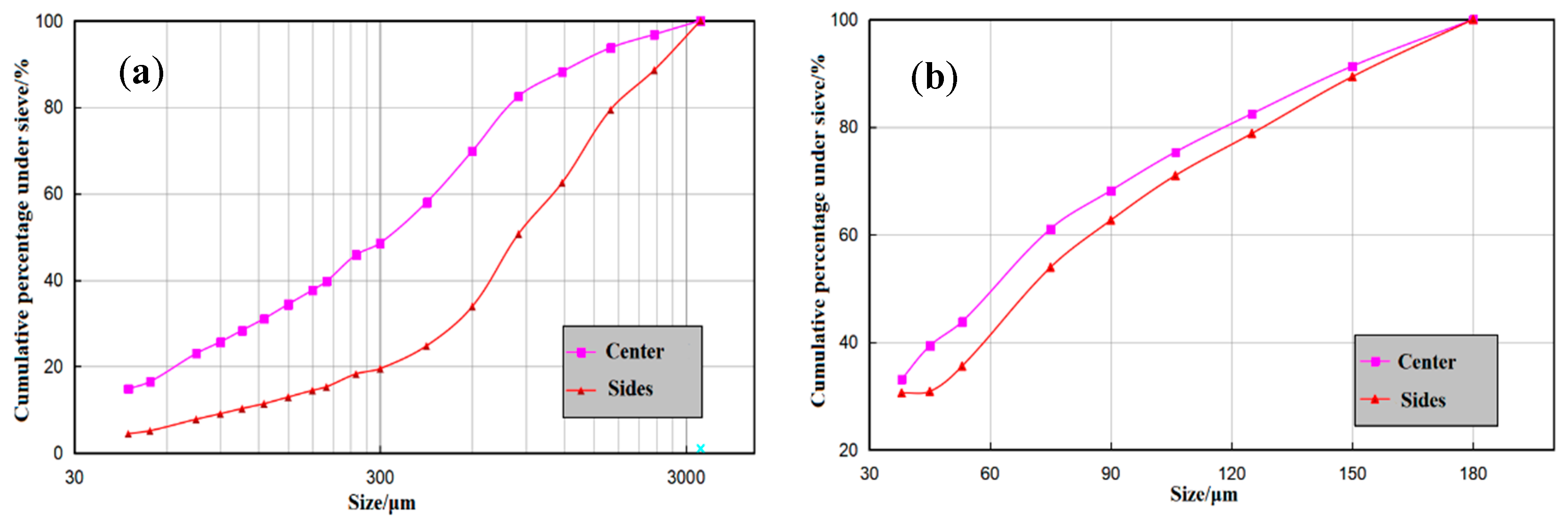

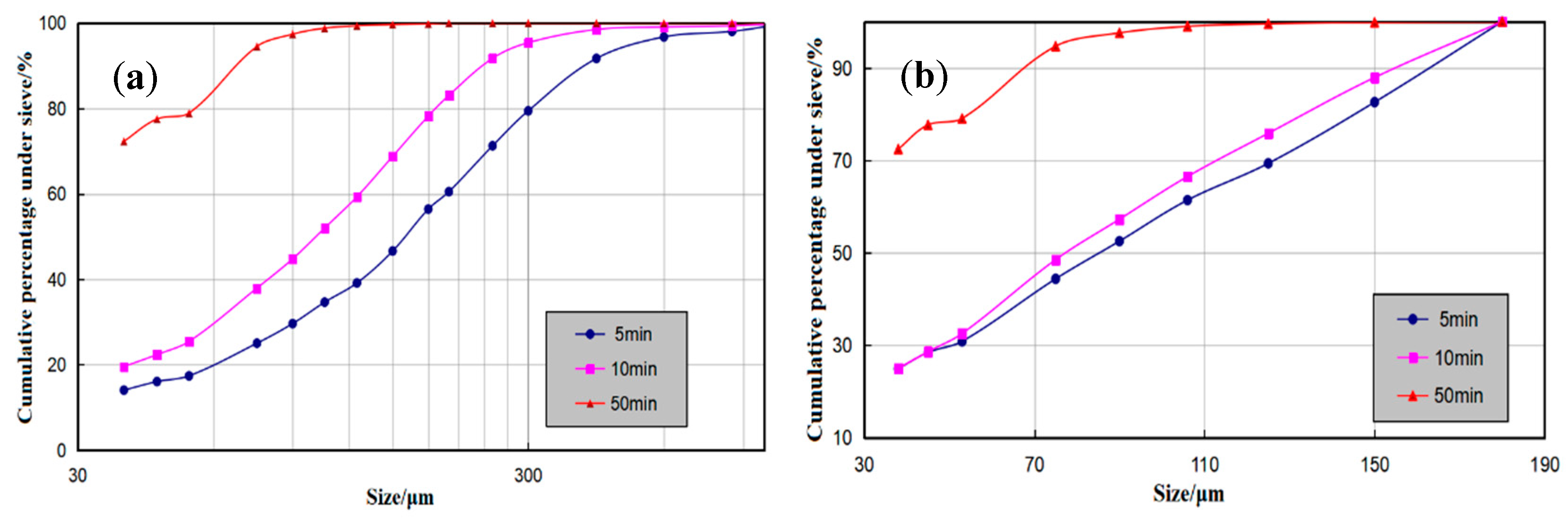

3.6. Wet Ball Milling

3.7. High-Speed Impact Crushing

3.8. Comprehensive Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, S.; Yang, S. Present State and Perspectives of Complex Utilization on Panzhihua BF Slag. Light Met. 2007, 7, 48–50. (In Chinese) [Google Scholar]

- Qu, Y.; Xing, L.; Gao, M.; Zhao, S.; Ren, Q.; Li, L.; Long, Y. Progress and Prospects for Titanium Extraction from Titanium-Bearing Blast Furnace Slag. Materials 2024, 17, 6291. [Google Scholar] [CrossRef]

- Shi, J.; Qiu, Y.; Yu, B.; Xie, X.; Dong, J.; Hou, C.; Li, J.; Liu, C. Titanium Extraction from Titania-Bearing Blast Furnace Slag: A Review. JOM 2022, 74, 654–667. [Google Scholar] [CrossRef]

- Li, Z.; Liu, T.; Li, Z. The Study on Smelting Ti-Si Ferroalloy by DC Elecrothermalprocess Using PISC Blast Furnace Titaniferous Slag. J. Chongqing Univ. 1996, 19, 82–86. [Google Scholar]

- Gu, H.; Cao, J.; Wu, J.; Wei, K.; Ma, W. A Novel Method for Preparing Si-Ti Alloy by Co-Reduction of Silicon Slag and Ti-Bearing Blast Furnace Slag. Metall. Mater. Trans. B 2023, 54, 2815–2823. [Google Scholar] [CrossRef]

- Sui, Z.; Guo, Z.; Zhang, L.; Zhang, L.; Wang, M.; Lou, T.; Li, G. Green Separation Technique of Ti Component from Ti-Bearing Blast Furnace Slag. J. Mater. Metall. 2006, 5, 93–97. (In Chinese) [Google Scholar]

- He, C. Panzhihua Blast Furnace Slag Beneficiation Pilot Study of Perovskite. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2002. [Google Scholar]

- Feng, C.; Zhang, J. Preparation of TiC from Panzhihua Blast-Furnace Slags Containing TiO2. Miner. Util. 1997, 6, 34–40. (In Chinese) [Google Scholar]

- Zhu, F.; Ma, S.; Ma, Z.; Qi, L.; Peng, W.; Li, K.; Qiu, K. Preparation of TiCl4 from Panzhihua Ilmenite Concentrate by Boiling Chlorination. J. Mater. Res. Technol. 2023, 23, 2703–2718. [Google Scholar] [CrossRef]

- Liu, X.; Sui, Z. Leaching ofTi-bearing blast furnace slag by pressuring. J. Chin. Nonferrous Met. 2002, 12, 1281–1284. [Google Scholar]

- Wang, Y.; Gao, X.; He, S.; Guo, J. Kinetics of Extracting Valuable Components from Ti-Bearing Blast Furnace Slag by Acidolysis with Sulphuric Acid. Front. Chem. 2024, 12, 1369937. [Google Scholar] [CrossRef]

- He, S.; Peng, T.; Sun, H. Titanium Recovery from Ti-Bearing Blast Furnace Slag by Alkali Calcination and Acidolysis. JOM 2019, 71, 3196–3201. [Google Scholar] [CrossRef]

- Zai, H.; Zhang, C.; Li, Z.; Wang, R.; Ma, E.; Zhang, X. Extraction of Titanium from Ti-Bearing Blast Furnace Slag Using Ammonium Sulfate Roasting-Water Leaching Enhanced by Mechanical Activation. J. Sustain. Metall. 2025, 11, 1937–1951. [Google Scholar] [CrossRef]

- Huang, S.; Pan, J.; Zhang, R. Pilot Test of Carbonization of the Molten Blast Furnace TiO2 Slag at panzhihuaIronand Steel Company. Iron Steel Vanadium Titan. 1994, 15, 17–21. (In Chinese) [Google Scholar]

- Zhen, Y.-L.; Zhang, G.-H.; Chou, K.-C. Carbothermic Reduction of Titanium-Bearing Blast Furnace Slag. High Temp. Mater. Process. 2016, 35, 309–319. [Google Scholar] [CrossRef]

- Wang, J.; Yue, D.; Wen, L.; Hu, L.; Lv, X. Experimental Characterization of Chemical Mineral Composition and Morphology of Titanium in Carbonized Slag Particles. J. Mater. Res. Technol. 2025, 34, 1571–1581. [Google Scholar] [CrossRef]

- Hu, M.; Wei, R.; Hu, M.; Wen, L.; Ying, F. Nonisothermal Carbothermal Reduction Kinetics of Titanium-Bearing Blast Furnace Slag. JOM 2018, 70, 1443–1448. [Google Scholar] [CrossRef]

- Ye, Q.; Zou, L.; Lu, M.; Zhang, Z.; An, Y.; Wang, Q.; Qian, G. Pyrometallurgical Extraction of Titanium from Titanium-Bearing Blast Furnace Slag: Recently Development and Prospect. Miner. Eng. 2025, 234, 109734. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, Y.; Lu, P.; Liu, S.; Wang, Y. Study on Preparation of TiCl4 Using Titanium-Containing Carbonized Blast Furnace Slag as Rawmaterial. Iron Steel Vanadium Titan. 2016, 37, 24–28. [Google Scholar]

- Wang, D.; Zhang, J.; Zhao, Q.; Huang, J. Simulation and Experimental Study on the Air Jet Pulverization of TiC-Containing Slag. MATEC Web Conf. 2019, 277, 03001. [Google Scholar] [CrossRef]

- Zou, P.; Zhang, M.; Zeng, C.; Li, P.; Chen, J.; Chen, H. The Crushing Control of 20-100 Mesh Expanded Black Rice Flour. J. Chin. Cereals Oils Assoc. 2017, 32, 34–38. [Google Scholar]

- Li, Z.; Fu, Y.; Zhou, A.; Yang, C.; Liu, L. Effects of Different Pulverizing Modes on Particle Size Distribution of Shenfu Coal. Coal Technol. 2017, 36, 269–271. [Google Scholar]

- Zhou, X. Research on Key Technologies and Applications of Controlled Crushing. Master’s Thesis, Southwest University of Science and Technology, Mianyang, China, 2007. [Google Scholar]

- Xu, Z.; Gai, G. Influencing factors of classification for fine-grained powder products with narrow particlesize distribution. China Powder Sci. Technol. 1999, 5, 41–42. [Google Scholar]

- JC/T 734-2005; Test Method for Grindability of Cement Raw Materials-Bond Method. National Cement Standardization Technical Committee (SAC/TC 184); China Standards Press: Beijing, China, 2011.

- GB/T 1345-2005; The Test Sieving Method for Fineness of Cement(S). China Standards Press: Beijing, China, 2011.

- Riedel, R. Handbook of Ceramic Hard Materials; Wiley-VCH: Weinheim, Germany, 2000; Volume 1, p. 210. [Google Scholar]

- Luo, F. Conversion Verification and Evaluation of Hardness Index and Bond Work Index. Cement 2007, 10, 34–36. [Google Scholar]

| Compositions | CaO | SiO2 | Al2O3 | TiC | MgO | Ti2O3 | Cf | Fe | Other |

|---|---|---|---|---|---|---|---|---|---|

| Mass fraction | 27.4 | 24.69 | 13.25 | 14.14 | 8.16 | 4.46 | 2.98 | 1.41 | 3.51 |

| Particle Size/mm | <0.038 | 0.038~0.15 | 0.15~0.25 | 0.25~0.83 | 0.83~1.4 | >1.4 |

|---|---|---|---|---|---|---|

| Mass fraction | 1.35 | 6.79 | 3.77 | 32.64 | 33.32 | 22.13 |

| No. | Crushing Method | Experimental Equipment Parameters | Experimental Process Parameters |

|---|---|---|---|

| 1 | Ball milling | The dimensions of the ball mill cylinder are φ305 × 305 mm. The ball size distribution is as follows: 43 balls of φ36.5 mm, 67 balls of φ30.2 mm, 10 balls of φ25.4 mm, 71 balls of φ19.1 mm, and 94 balls of φ15.9 mm, totaling 285 balls with a combined mass of 20.13 kg. | Closed-circuit grinding experiments were conducted under the conditions of a 250% and 500% circulating load, with a charging quantity of 15 kg, a mill rotation speed of 70 rpm, and a control sieve of 80 mesh. |

| 2 | Rod milling | The rod mill has barrel dimensions of φ305 × 610 mm. It is loaded with six steel rods of φ31.75 mm and two steel rods of φ44.45 mm, each measuring 533.4 mm in length, resulting in a total steel rod mass of 33.38 kg. | The experimental setup consisted of a feed quantity of 20 kg, with the mill operating at 46 rpm and an 80-mesh screen. Closed-circuit grinding tests were carried out under circulating load conditions of 100%, 300%, and 500%. The specific experimental methods are similar to the closed-loop cycle experiment of ball milling. |

| 3 | High-pressure roller milling | The high-pressure roller mill testing machine is equipped with rollers having a diameter of φ420 mm and a width of 100 mm. The rotational speed of the compression rollers is 15 r/min, while the hydraulic station operates at a pressure of 0.5 MPa. | The material loading capacity is 15 kg per batch, with a moisture content of 6.4%. The experiment was conducted using a high-pressure roller mill operating in an open-circuit configuration. After the slag is crushed once, a particle size analysis is conducted on the entire sample. |

| 4 | Wet ball milling | The wet ball mill cylinder has dimensions of φ420 × 450 mm and is loaded with a grinding media mass of 55 kg. Among the steel balls, 60% of them have a diameter of 10 mm, while the rest have a diameter of 20 mm. | The batch loading capacity is 7 kg, with a pulp concentration of 50%. The mill operates at a rotational speed of 59 r/min, and the grinding durations for the open-circuit experiments are set at 5 min, 10 min, and 50 min, respectively. |

| 5 | High-speed impact crushing | Rated power: 2.2 kW; cutter head diameter: φ150 mm; no-load speed: 6000 rpm. | The raw material was subjected to sieving pretreatment and classified into three particle size ranges: 0–4 mm, 0.25–4 mm, and 0.18–4 mm, each with a mass of 1 kg, for an initial open-circuit crushing experiment. Subsequently, the powder obtained from the first crushing of the 0.18–4 mm fraction was sieved, and particles with a size of ≥0.18 mm underwent secondary crushing, followed by tertiary crushing using the same procedure. |

| Point | Ti | V | Fe | Mn | Si | C | O | Ca | Al | Mg | Na | Possible Phase |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 85.44 | 1.34 | — | — | — | 6.68 | 5.34 | 1.20 | — | — | — | TiC |

| 2 | 82.84 | 5.41 | — | — | — | 7.44 | 4.31 | — | — | — | — | TiC |

| 3 | 81.65 | 4.84 | — | — | 1.17 | 9.08 | — | 2.02 | 1.24 | — | — | TiC |

| 4 | — | — | 81.06 | 4.11 | 3.32 | 11.51 | — | — | — | — | — | Fe |

| 5 | 3.35 | 0.28 | — | — | 17.2 | — | 34.93 | 26.19 | 11.16 | 6.89 | — | Augite |

| 6 | 2.62 | — | — | 2.07 | 17.38 | — | 33.1 | 25.48 | 11.63 | 7.2 | 0.52 | Augite |

| 7 | 78.44 | 11.58 | — | — | — | 7.01 | 2.97 | — | — | — | — | TiC (with Fe) |

| Mineral | Wt% | Area% | Area (Micron) | Particle Count | Grain Count |

|---|---|---|---|---|---|

| Augite (Ca(Ti,Mg,Al)(Si,Al)2O6) | 62.07 | 61.11 | 4,826,893.72 | 9539 | 12,852 |

| Carbon (C) | 0.85 | 0.84 | 66,203.7 | 1235 | 1477 |

| Magnesium aluminate spinel | 2.03 | 2 | 157,669.3 | 691 | 1232 |

| (MgO-Al2O3) | |||||

| Magnesium-titanium spinel (MgO-TiO2) | 0.75 | 0.73 | 58,014.28 | 1522 | 4699 |

| Titanium carbide (TiCxOy) | 6.72 | 6.61 | 522,427.83 | 4222 | 17,750 |

| Iron (Fe) | 0.13 | 0.13 | 10,129.17 | 212 | 260 |

| Vitric (SiO2) | 2.68 | 2.64 | 208,220.71 | 4118 | 23,938 |

| Titanaugite ((Ca(Ti,Mg,Al)(Si,Al)2O6), high Ti) | 23.92 | 23.55 | 1,859,934.68 | 15,752 | 40,836 |

| Fe-Si alloy (Fe-Si) | 0.14 | 0.14 | 11,106.22 | 30 | 37 |

| Forsterite (Ca2Mg(Si2O7)) | 0.35 | 0.34 | 26,960.18 | 149 | 251 |

| Calcium aluminate (CaO-6Al2O3) | 0.06 | 0.06 | 4733.95 | 68 | 83 |

| Perovskite (CaO-TiO2) | 0.19 | 0.18 | 14,408.84 | 204 | 336 |

| Other | 0.11 | 1.67 | 132,306.04 | 2098 | 5437 |

| Total | 100 | 100 | 7,899,008.62 | 39,840 | 109,188 |

| Sample | Particle Size (mm) | Ball Milling Power Index Wib (250% Cycle Load) kWh/t | Rod Mill Work Index Wib (100% Cycle Load) kWh/t | The Hardgrove Grindability Index Hg |

|---|---|---|---|---|

| S-1# | 13~19 | 34.61 | 24.17 | 17.94 |

| S-2# | 0~6 | 23.84 | 18.96 | 27.01 |

| Cement clinker | - | 13.4~14.87 | - | 38~50 |

| Sample | Particle Size (mm) | The Mass of the Blade Before Testing (g) | The Mass of the Blade After the Test (g) | Abrasion Index |

|---|---|---|---|---|

| S-1# | 13~19 | 92.7158 | 92.5116 | 0.2042 |

| S-2# | 0~6 | 92.8674 | 92.7931 | 0.0743 |

| No. | Grinding Method | Experimental Conditions | Acting Force | Particle Size ≤ 0.075 mm in the Product (%) | Particle Size ≤ 0.045 mm in the Product (%) | Strengths | Weaknesses |

|---|---|---|---|---|---|---|---|

| 1 | Ball milling | C = 250% | Compression, shearing, and impact | 33.29 | 25.05 | The equipment is mature and has a large processing capacity. | Requires a very high grinding circulation load; high energy consumption. |

| C = 500% | 31.62 | 17.09 | |||||

| 2 | Rod milling | C = 100% | Compression and impact | 44.54 | 28.1 | ||

| C = 300% | 37.6 | 23.48 | |||||

| C = 500% | 36.53 | 20.1 | |||||

| 3 | High-pressure roller milling | / | Compression | 61.08 | 39.31 | High grinding efficiency. | The product is severely overgrounded; the quality of the product fails to meet the process requirements. |

| 4 | Wet ball milling | 5 min | Compression, shearing, and impact | 44.38 | 28.47 | The equipment is mature. | The work environment is noisy and dirty; the product is severely overgrounded. |

| 10 min | 48.52 | 28.62 | |||||

| 50 min | 94.69 | 77.67 | |||||

| 5 | High-speed impact crushing | The first time | Crushing | 33.75 | 20.2 | High quality of products. | Low equipment processing capacity and low efficiency. |

| The second time | 30 | 15.24 | |||||

| The third time | 26.37 | 13.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Hou, Y.; Guo, W. Extraction of Titanium from Blast Furnace Slag: Research on the Crushing Process of TiC-Bearing Slag. Metals 2025, 15, 1063. https://doi.org/10.3390/met15101063

Wang D, Hou Y, Guo W. Extraction of Titanium from Blast Furnace Slag: Research on the Crushing Process of TiC-Bearing Slag. Metals. 2025; 15(10):1063. https://doi.org/10.3390/met15101063

Chicago/Turabian StyleWang, Dongsheng, Yanqing Hou, and Wenming Guo. 2025. "Extraction of Titanium from Blast Furnace Slag: Research on the Crushing Process of TiC-Bearing Slag" Metals 15, no. 10: 1063. https://doi.org/10.3390/met15101063

APA StyleWang, D., Hou, Y., & Guo, W. (2025). Extraction of Titanium from Blast Furnace Slag: Research on the Crushing Process of TiC-Bearing Slag. Metals, 15(10), 1063. https://doi.org/10.3390/met15101063