Performance of Gears Manufactured Through Additive Manufacturing

Abstract

1. Introduction

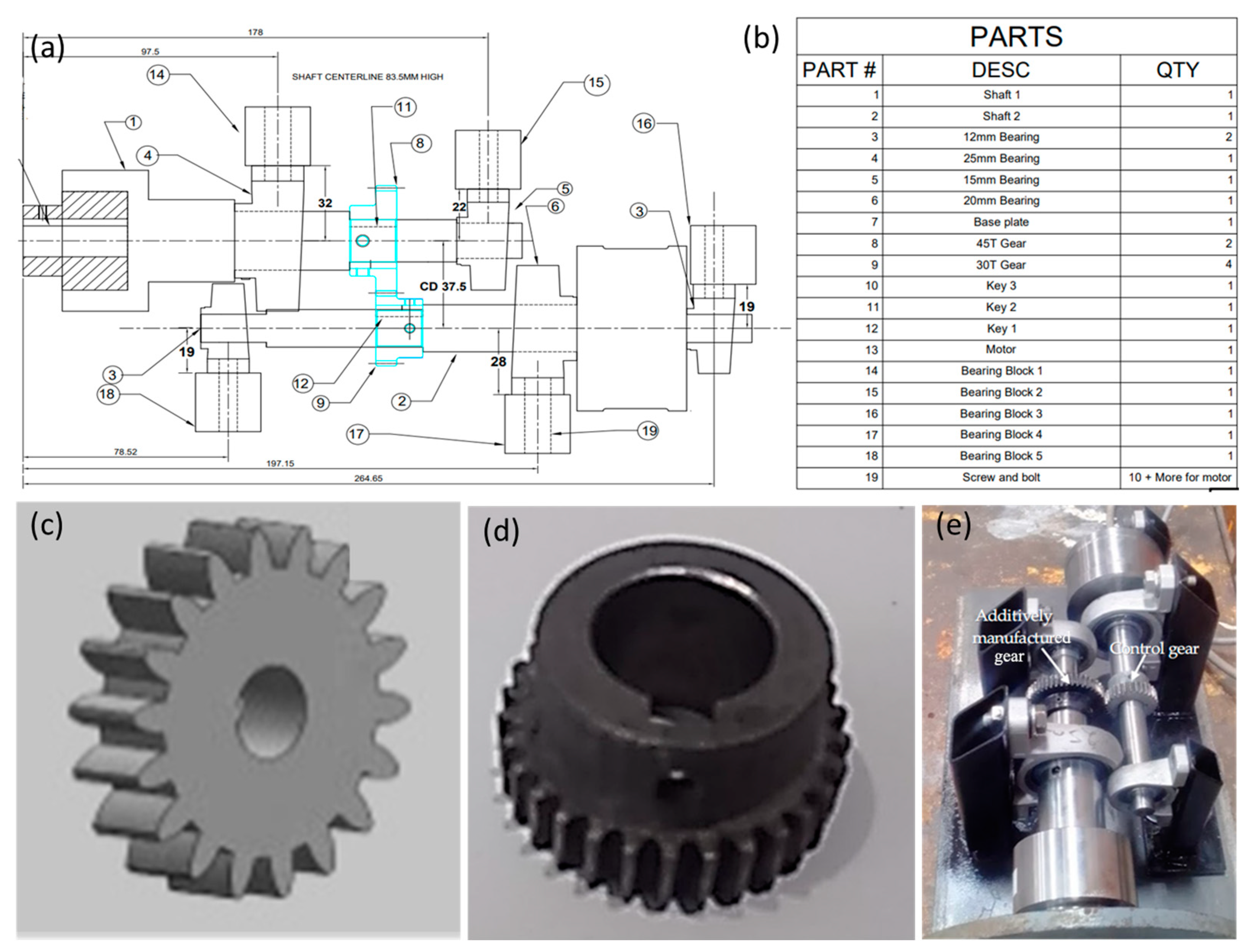

2. Materials and Methods

2.1. Feed Stock Materials

2.2. Additive Manufacturing Process

- Holding the specimens at 350 °C for the polymer binder to burn out; and

- slow ramping the temperature up to 450 °C.

2.3. Experimental Details

3. Results and Discussion

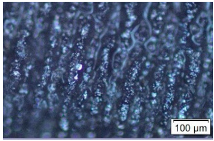

3.1. Surface Appearance

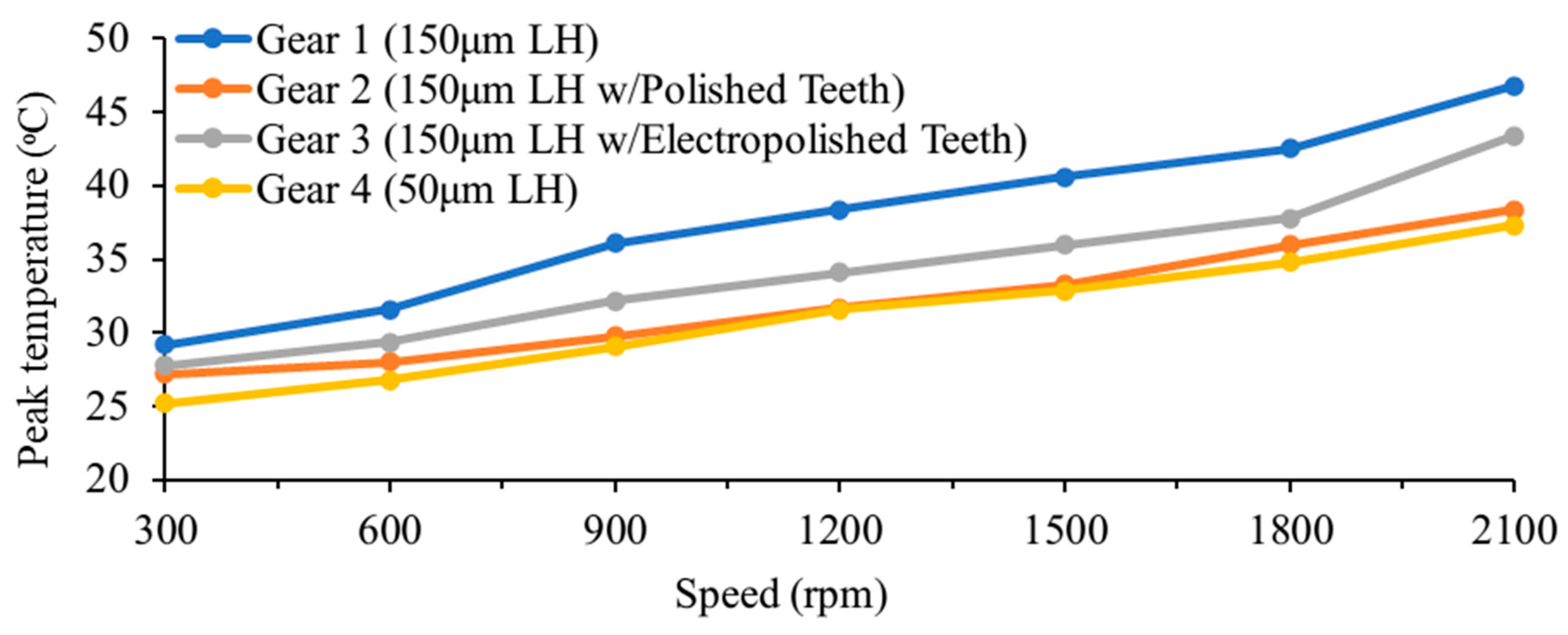

3.2. Temperature Evolution

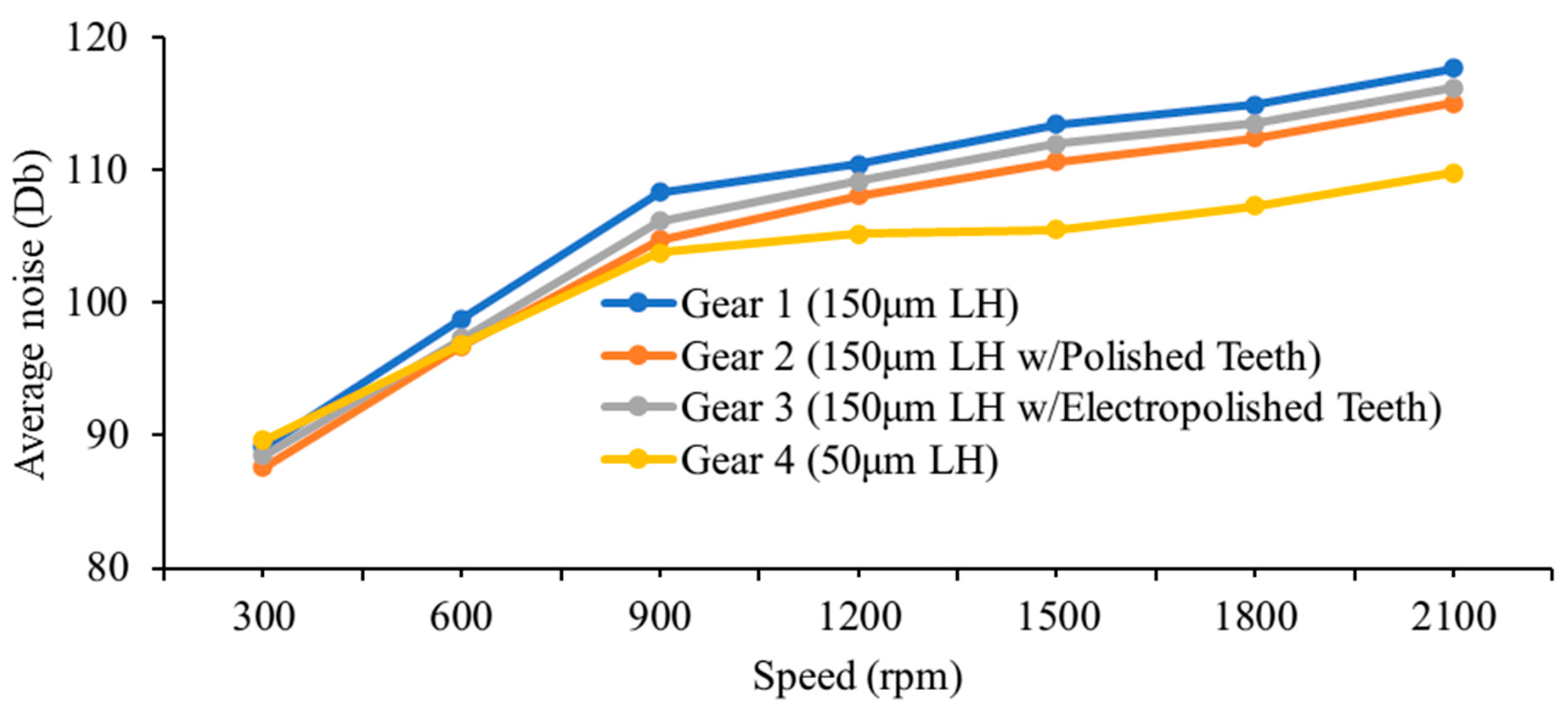

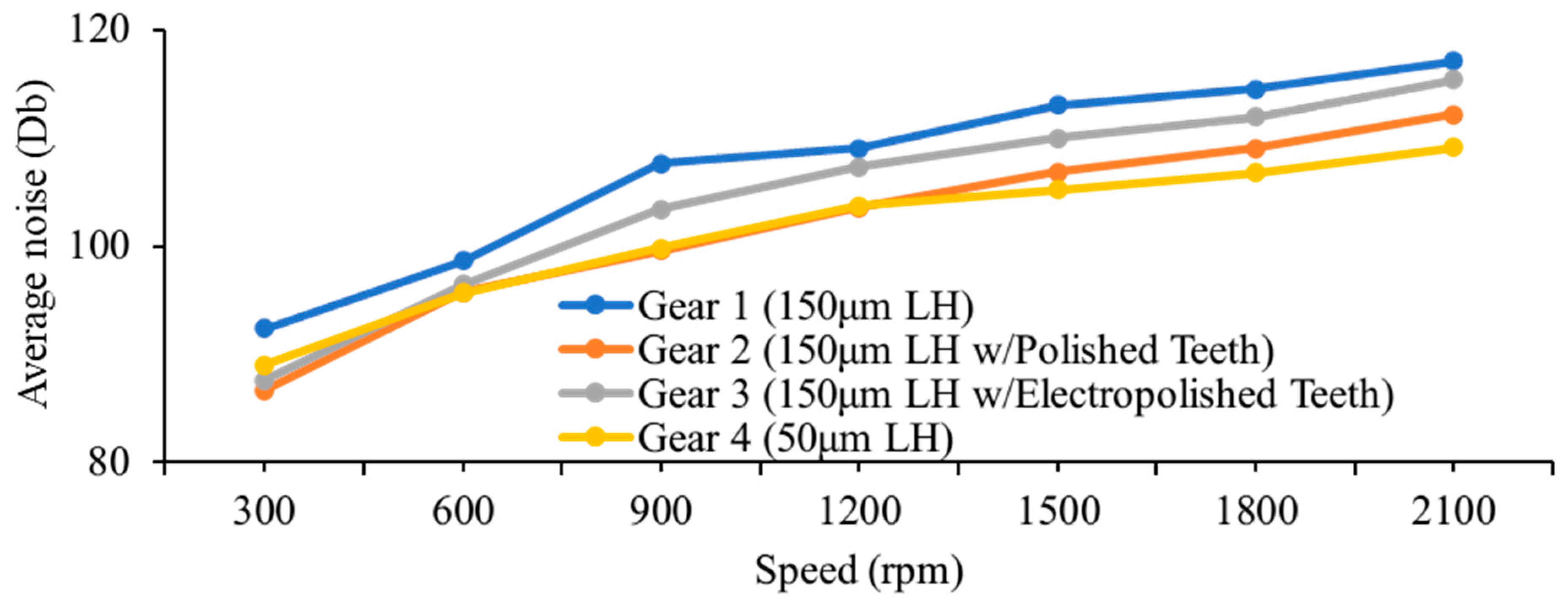

3.3. Noise Generation

3.4. Material Loss Due to Wear

3.5. Cost and Performance

4. Conclusions

- The surface modification through mechanical and chemical processes affects the surface wear and wear morphology of gear produced at different conditions.

- The gear temperatures are linearly proportional to the gear speed. The lower layer thickness generates less temperature in the gears. However, mechanical polishing and chemical polishing reduces the temperature in gears.

- The trends of noise were like that of temperature, where the noise level was linearly proportional to the gear speed. The lower layer thickness generates less noise in the gears. However, mechanical polishing and chemical polishing reduces the noise level in gears.

- The minimum wear was noted for the gear with lowest layer height, but the surface modification through polishing reduced the wear.

- The post-fabrication polishing of the gear increased its overall performance-incorporated cost, surface appearance, and performance, which makes it 33% cheaper compared to others. On the other hand, if only performance was considered, then the lowest layer height (50 μm) gear was the best. Irrespective of the 3D-printed gears, the commercially sourced gear had the lowest wear loss (19 mg), as it possesses higher hardness due to induction heat treatment of its teeth.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Concli, F.; Bonaiti, L.; Gerosa, R.; Cortese, L.; Nalli, F.; Rosa, F.; Gorla, C. Bending fatigue behavior of 17-4 ph gears produced by additive manufacturing. Appl. Sci. 2021, 11, 3019. [Google Scholar] [CrossRef]

- Bulduk, M.E.; Çalışkan, C.İ.; Çoşkun, M.; Özer, G.; Koç, E. Comparison of the effect of different topological designs and process parameters on mechanical strength in gears. Int. J. Adv. Manuf. Technol. 2022, 119, 6707–6716. [Google Scholar] [CrossRef]

- Singh, S.; Singh, G.; Prakash, C.; Ramakrishna, S. Current status and future directions of fused filament fabrication. J. Manuf. Process. 2020, 55, 288–306. [Google Scholar] [CrossRef]

- Li, X.; Wang, C.; Tian, C.; Fu, S.; Rong, Y.; Wang, L. Digital design and performance evaluation of porous metal-bonded grinding wheels based on minimal surface and 3D printing. Mater. Des. 2021, 203, 109556. [Google Scholar] [CrossRef]

- Nugroho, W.T.; Dong, Y.; Pramanik, A. 3D printing composite materials: A comprehensive review. In Composite Materials; Elsevier: Amsterdam, The Netherlands, 2021; pp. 65–115. [Google Scholar]

- Hasan, M.R.; Davies, I.J.; Pramanik, A.; John, M.; Biswas, W.K. Technical assessment of 3D-printed spur gears produced from recycled PLA. Int. J. Adv. Manuf. Technol. 2024. [Google Scholar] [CrossRef]

- Gupta, K. Recent developments in additive manufacturing of gears: A review. In Advances in Manufacturing Technology XXXII; IOS Press: Amsterdam, The Netherlands, 2018; pp. 131–136. [Google Scholar]

- Basak, A.; Lee, A.; Pramanik, A.; Neubauer, K.; Prakash, C.; Shankar, S. Material extrusion additive manufacturing of 17–4 PH stainless steel: Effect of process parameters on mechanical properties. Rapid Prototyp. J. 2023, 29, 1097–1106. [Google Scholar] [CrossRef]

- Stojković, J.R.; Turudija, R.; Vitković, N.; Górski, F.; Păcurar, A.; Pleşa, A. An experimental study on the impact of layer height and annealing parameters on the tensile strength and dimensional accuracy of FDM 3D printed parts. Materials 2023, 16, 4574. [Google Scholar] [CrossRef]

- Farashi, S.; Vafaee, F. Effect of printing parameters on the tensile strength of FDM 3D samples: A meta-analysis focusing on layer thickness and sample orientation. Prog. Addit. Manuf. 2022, 7, 565–582. [Google Scholar] [CrossRef]

- Tontowi, A.E.; Ramdani, L.; Erdizon, R.V.; Baroroh, D.K. Optimization of 3D-printer process parameters for improving quality of polylactic acid printed part. Int. J. Eng. Technol. 2017, 9, 589–600. [Google Scholar]

- Dief, A. Desktop Metal Aims to Increase Accessibility of Metal-Making Capabilities [1]; Harvard Business School: Boston, MA, USA, 2022. [Google Scholar]

- Watson, A.; Belding, J.; Ellis, B.D. Characterization of 17-4 PH processed via bound metal deposition (BMD). In TMS 2020 149th Annual Meeting & Exhibition Supplemental Proceedings; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Zhang, Y.; Mao, K.; Leigh, S.; Shah, A.; Chao, Z.; Ma, G. A parametric study of 3D printed polymer gears. Int. J. Adv. Manuf. Technol. 2020, 107, 4481–4492. [Google Scholar] [CrossRef]

- Basak, A.K.; Pramanik, A.; Chen, Y.X.; Prakash, C.; Radhika, N.; Shankar, S. Bound metal deposition of stainless steel 316L: Effect of process variables on microstructural and mechanical behaviors. Materialia 2024, 36, 102196. [Google Scholar] [CrossRef]

- Tran, N.H.; Nguyen, V.N.; Ngo, A.V.; Nguyen, V.C. Study on the effect of fused deposition modeling (FDM) process parameters on the printed part quality. Int. J. Eng. Res. Appl. 2017, 7, 71–77. [Google Scholar]

- Dimić, A.; Mišković, Ž.; Mitrović, R.; Ristivojević, M.; Stamenić, Z.; Danko, J.; Bucha, J.; Milesich, T. The influence of material on the operational characteristics of spur gears manufactured by the 3D printing technology. Stroj. Čas.-J. Mech. Eng. 2018, 68, 261–270. [Google Scholar] [CrossRef]

- Chemezov, D.; Zubatov, D.; Vakhromeev, E.; Shchetnikov, V.; Goremykin, V.; Kuznetsov, A.; Zavrazhnov, D. Surfaces quality of plastic gears made by 3D printing. Theor. Appl. Sci. 2019, 10, 522–529. [Google Scholar] [CrossRef]

- Dennig, H.-J.; Zumofen, L.; Kirchheim, A. Feasibility investigation of gears manufactured by fused filament fabrication. In Industrializing Additive Manufacturing, Proceedings of the AMPA2020, Zurich, Switzerland, 1–3 September 2020; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Basak, A.K.; Celis, J.P. Coefficient of friction measured from nano-to macro-normal loads on plasma sprayed nanostructured cermet coatings. Metall. Mater. Trans. A 2014, 45, 1049–1056. [Google Scholar] [CrossRef]

- Apparao, D.; Raju, M.J. Design and analysis of spur gear manufactured by DMLS process. Mater. Today Proc. 2021, 46, 149–153. [Google Scholar] [CrossRef]

- Rokicki, P.; Kozik, B.; Budzik, G.; Dziubek, T.; Bernaczek, J.; Przeszlowski, L.; Markowska, O.; Sobolewski, B.; Rzucidlo, A. Manufacturing of aircraft engine transmission gear with SLS (DMLS) method. Aircr. Eng. Aerosp. Technol. Int. J. 2016, 88, 397–403. [Google Scholar] [CrossRef]

- Karmase, P.; Chaudhary, Y. An Experimental Investigation & Analysis of Gear Component Manufactured By 3D Printing & Conventional Process—A Review. Int. Eng. Res. J. 2016, 3, 9. [Google Scholar]

- Tezel, T.; Topal, E.S.; Kovan, V. Failure analysis of 3D-printed steel gears. Eng. Fail. Anal. 2020, 110, 104411. [Google Scholar] [CrossRef]

- Brecher, C.; Brumm, M.; Krömer, M. Design of gear hobbing processes using simulations and empirical data. Procedia CIRP 2015, 33, 484–489. [Google Scholar] [CrossRef]

- Basak, A.K.; Matteazzi, P.; Vardavoulias, M.; Celis, J.P. Corrosion–wear behaviour of thermal sprayed nanostructured FeCu/WC–Co coatings. Wear 2006, 261, 1042–1050. [Google Scholar] [CrossRef]

- Basak, A.K.; Celis, J.P.; Vardavoulias, M.; Matteazzi, P. Effect of nanostructuring and Al alloying on friction and wear behaviour of thermal sprayed WC–Co coatings. Surf. Coat. Technol. 2012, 206, 3508–3516. [Google Scholar] [CrossRef]

- Buj-Corral, I.; Zayas-Figueras, E.E. Comparative study about dimensional accuracy and form errors of FFF printed spur gears using PLA and Nylon. Polym. Test. 2023, 117, 107862. [Google Scholar] [CrossRef]

- Kramer, P.C. Investigation of Rolling-Sliding Contact Fatigue Damage of Carburized Gear Steels. Master’s Thesis, Colorado School of Mines, Golden, CO, USA, 2014. [Google Scholar]

- Sachidananda, H.; Raghunandana, K.; Shivamurthy, B. Power loss analysis in altered tooth-sum spur gearing. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2018. [Google Scholar]

- Ramadani, R.; Pal, S.; Kegl, M.; Predan, J.; Drstvenšek, I.; Pehan, S.; Belšak, A. Topology optimization and additive manufacturing in producing lightweight and low vibration gear body. Int. J. Adv. Manuf. Technol. 2021, 113, 3389–3399. [Google Scholar] [CrossRef]

- Łuszczek, J. Review of methods of designing and additive manufacturing of gears. Biul. Wojsk. Akad. Tech. 2021, 70, 15–34. [Google Scholar]

- Brummer, M.; Raddatz, K.J.; Schmitt, M.M.; Schlick, G.; Tobie, T.; Daub, R.; Stahl, K. Static load-carrying behavior and material properties of additively manufactured gears (PBF-LB/M, 16MnCr5). Rapid Prototyp. J. 2023, 29, 117–130. [Google Scholar] [CrossRef]

| Layer Height | 150 μm (gears 1–3), 50 μm (gear 4) |

| Shell Wall Thickness | 1.44 mm |

| Infill Density | 100% |

| Print Head | Standard 400 μm (gears 1–3), High resolution 250 μm (gear 4) |

| Characteristics | Gear 1 | Gear 2 | Gear 3 | Gear 4 | Control Gear |

|---|---|---|---|---|---|

| Layer height | 150 μm | 150 μm | 150 μm | 50 μm | - |

| Post-fabrication conditions | None | Teeth mechanically grinded followed by polishing | Teeth electropolished in phosphoric solution | None | Tooth surface induction hardened (by manufacturer) |

| Cost (Including debinding and sintering) | AUD 62.93 | AUD 62.93 | AUD 62.93 | AUD 92.66 | AUD 162.00 |

| Printing time | 3 h 43 m | 3 h 43 m | 3 h 43 m | 11 h 9 m | - |

| Material | 17-4 PH | S45C | |||

| Density (g/cm3) | 7.644 | 7.85 | |||

| Hardness | 37 HRC | 50–60 HRC | |||

| Gear | Before Test | After Test |

|---|---|---|

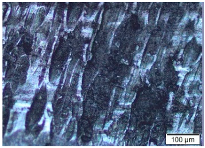

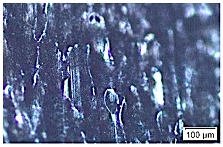

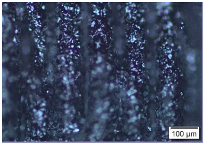

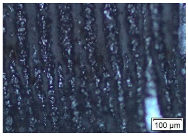

| Gear 1: 150 μm layer height |  |  |

| Gear 2: 150 μm layer height and mechanical polished |  |  |

| Gear 3: 150 μm layer height and electropolished |  |  |

| Gear 4: 50 μm layer height |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Basak, A.K.; Ghasseb, J.; Pramanik, A. Performance of Gears Manufactured Through Additive Manufacturing. Metals 2025, 15, 63. https://doi.org/10.3390/met15010063

Basak AK, Ghasseb J, Pramanik A. Performance of Gears Manufactured Through Additive Manufacturing. Metals. 2025; 15(1):63. https://doi.org/10.3390/met15010063

Chicago/Turabian StyleBasak, Animesh Kumar, Jack Ghasseb, and Alokesh Pramanik. 2025. "Performance of Gears Manufactured Through Additive Manufacturing" Metals 15, no. 1: 63. https://doi.org/10.3390/met15010063

APA StyleBasak, A. K., Ghasseb, J., & Pramanik, A. (2025). Performance of Gears Manufactured Through Additive Manufacturing. Metals, 15(1), 63. https://doi.org/10.3390/met15010063