Aluminum and Inorganic Natural Pigment Colored Composites by Powder Metallurgy Forming

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

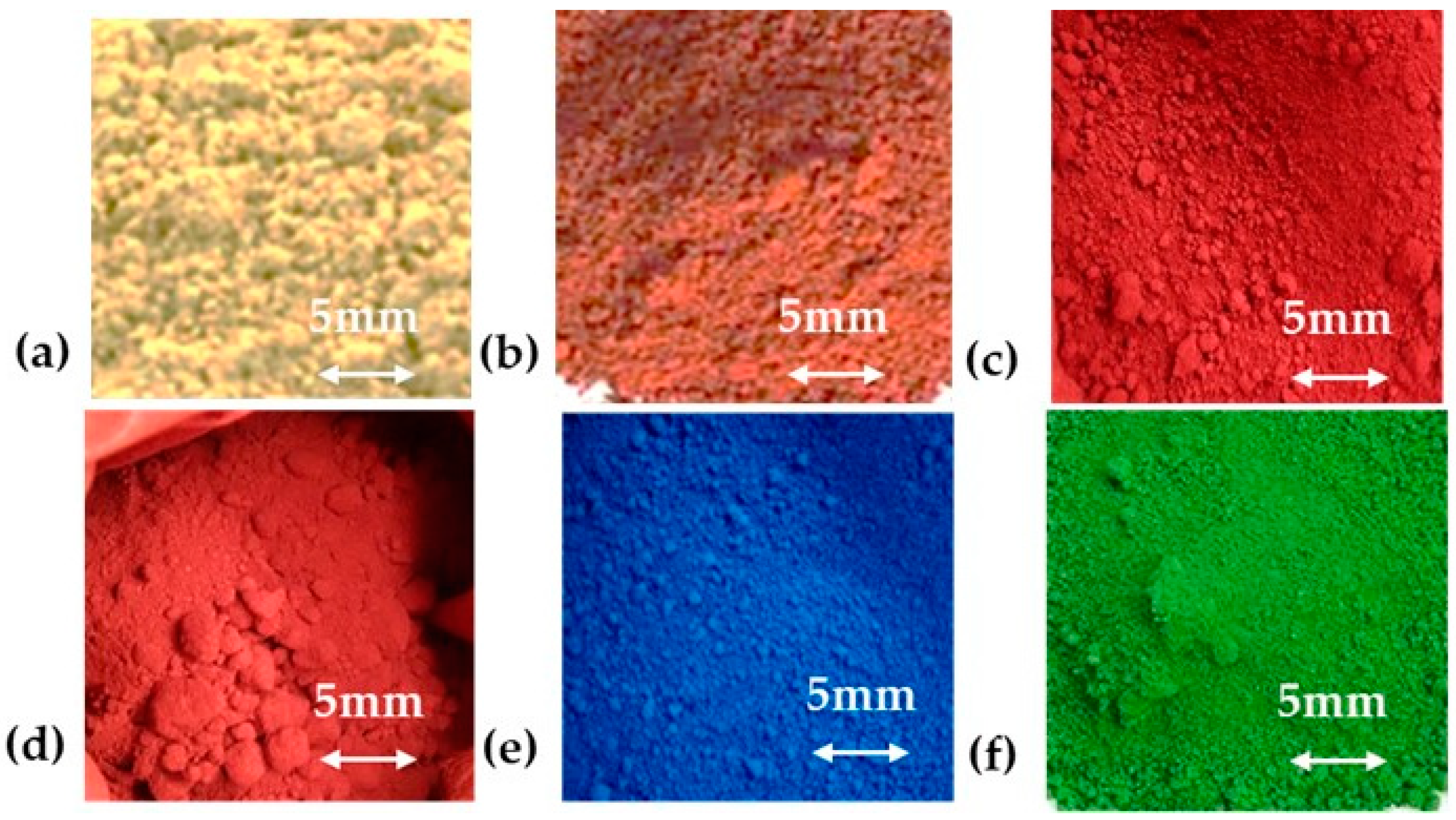

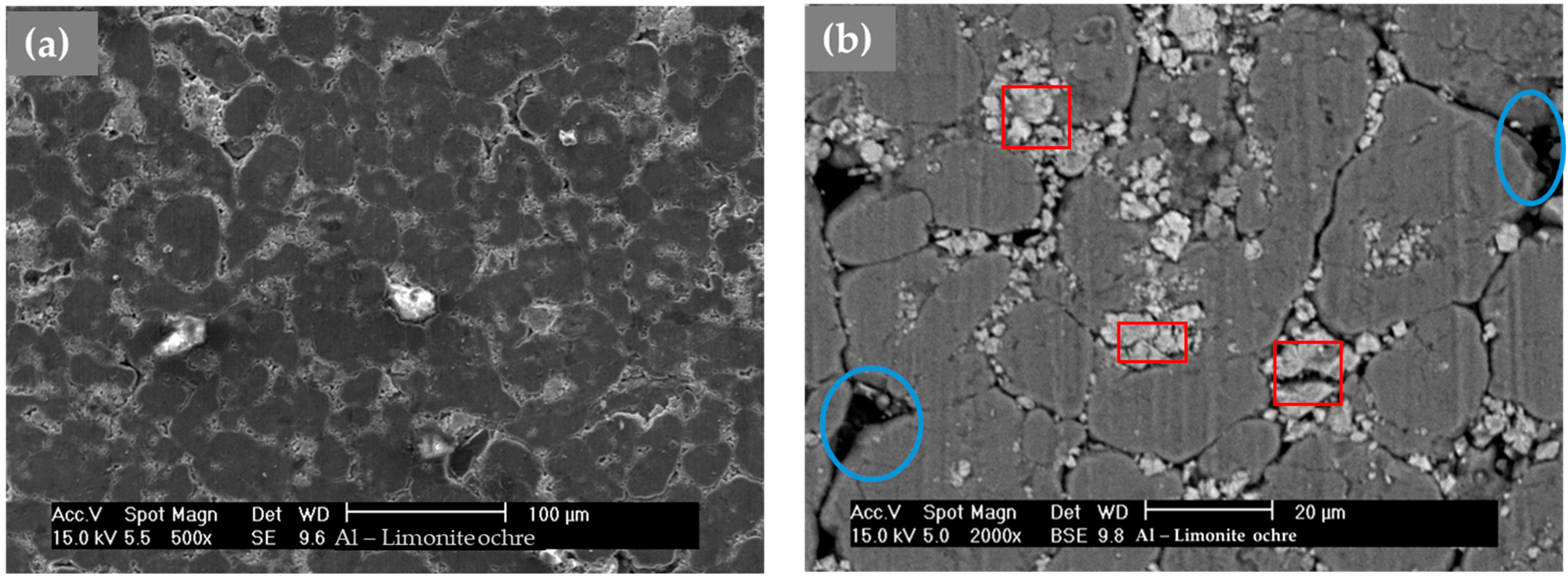

- Limonite ochre is a natural inorganic pigment with a yellowish earth color (Figure 2a). It consists of aluminum silicate (clay), silicon dioxide (quartz), and calcium salts, colored by ferric hydroxide (iron ore). This pigment offers good light resistance, is relatively harmless, and has a density of 0.99 g/cm3. Before mixing with aluminum, the pigment underwent a color modification process involving heating at 350 °C for 1 h. The loss of water produces a light brown color (Figure 2b).

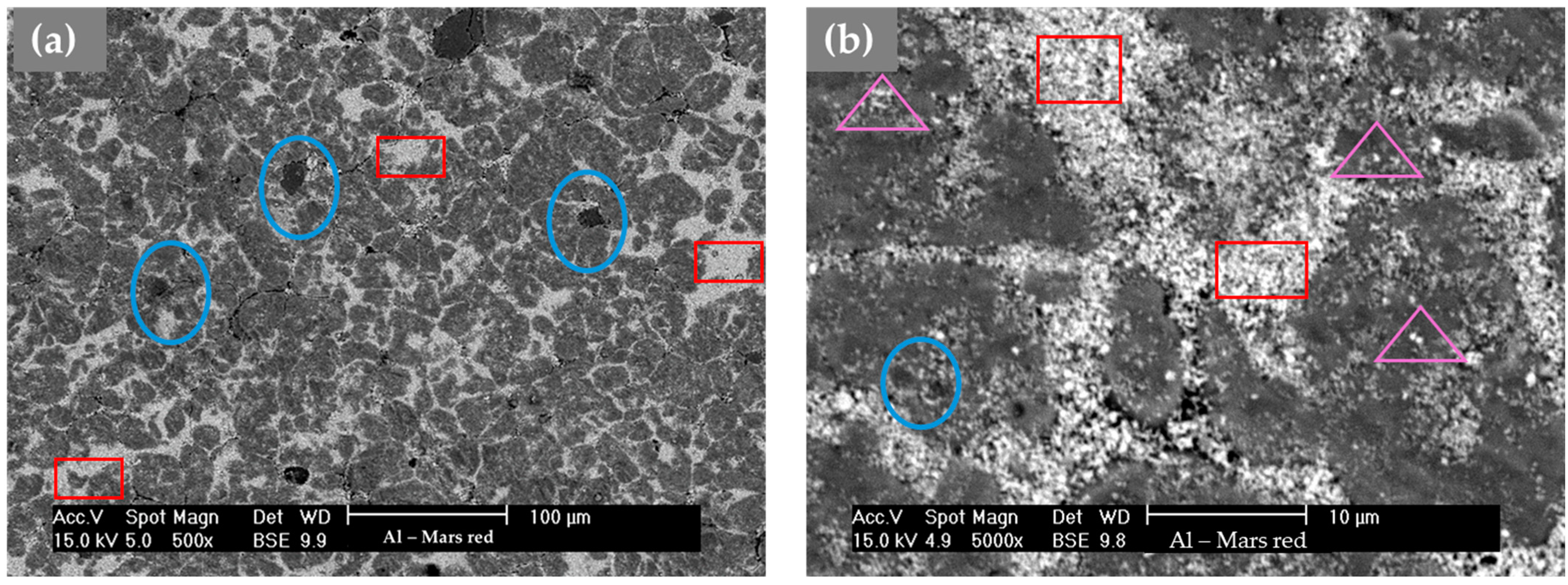

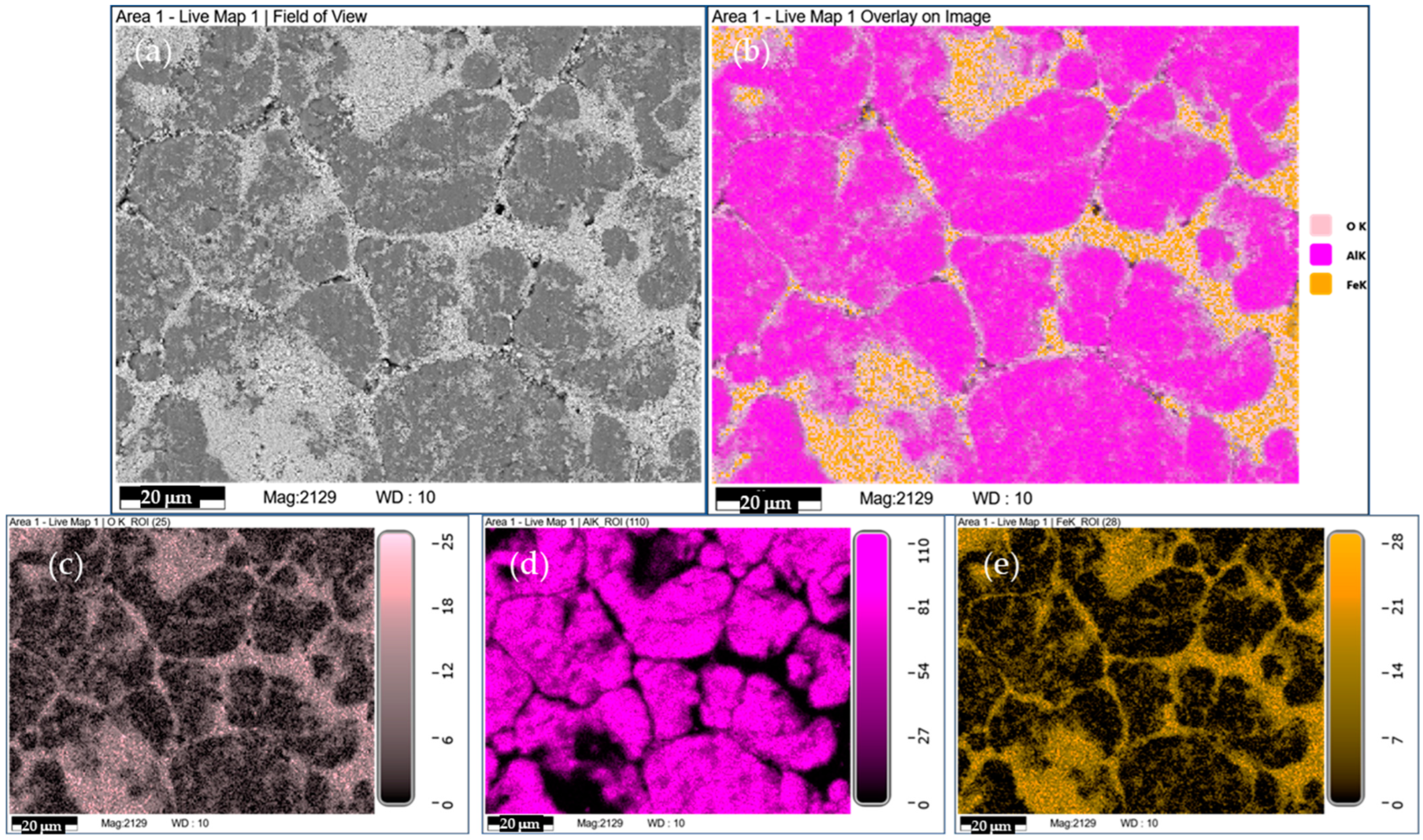

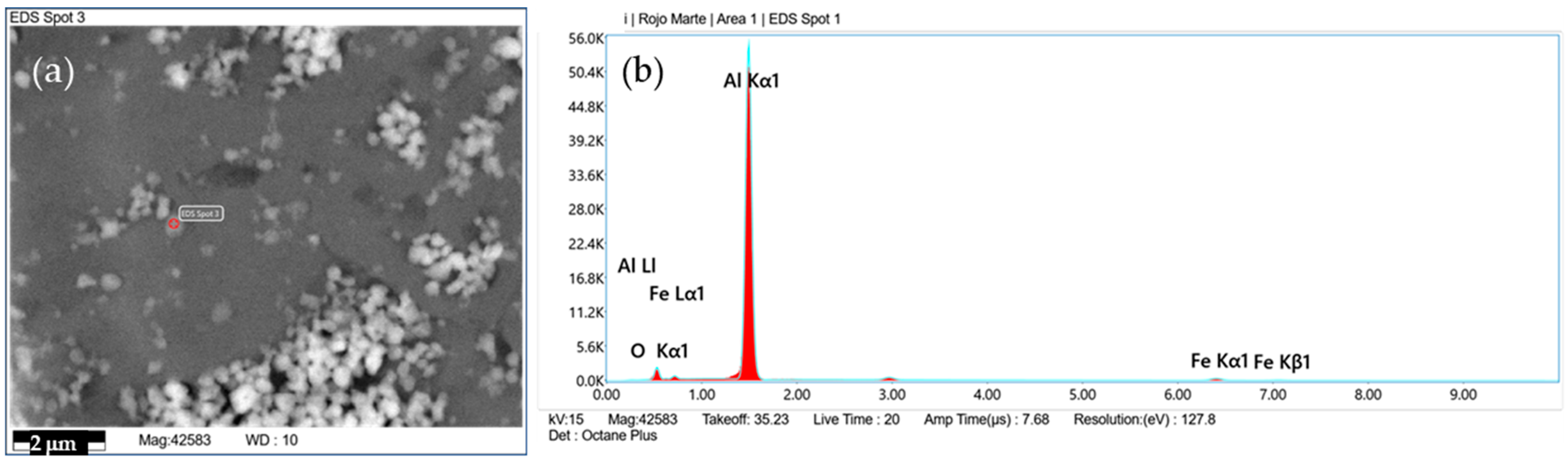

- Deep Mars red is a synthetic inorganic pigment made from iron oxide (Fe2O3). Its color varies from bluish to yellowish red (Figure 2c). The pigment is characterized by high opacity, excellent tinting strength, and outstanding lightfastness. It is also relatively non-toxic.

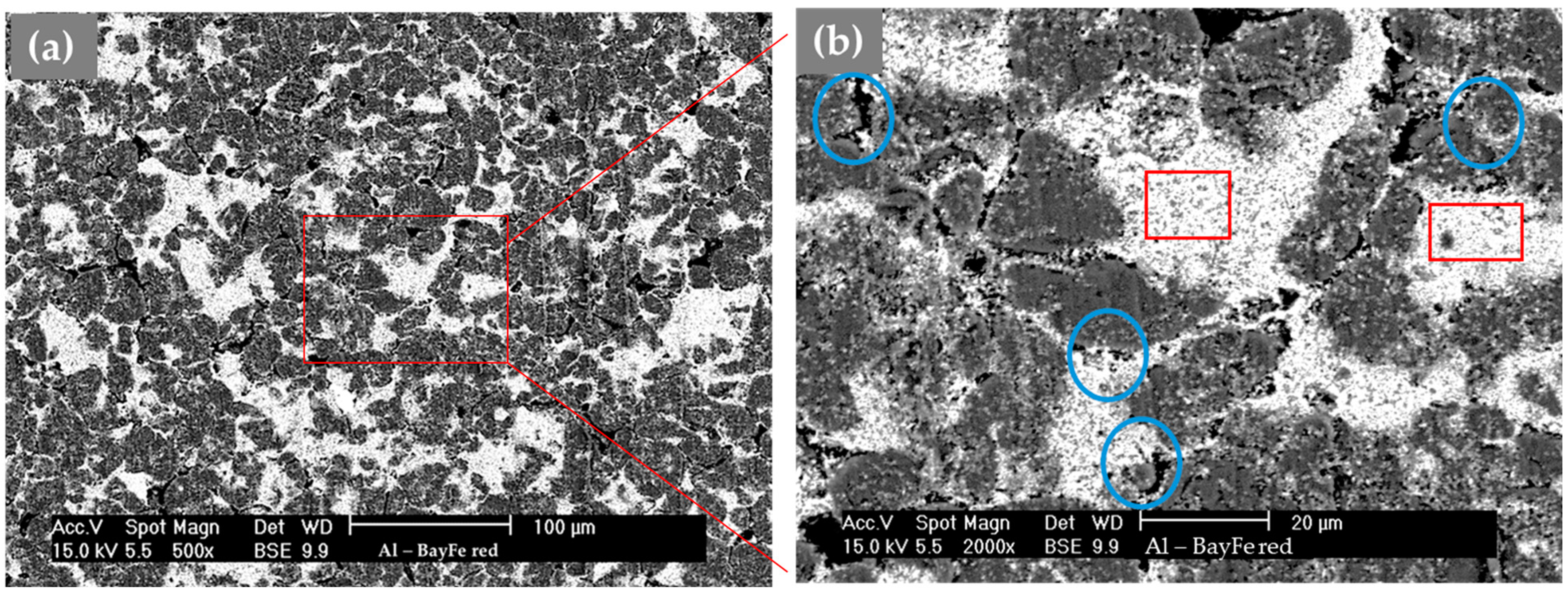

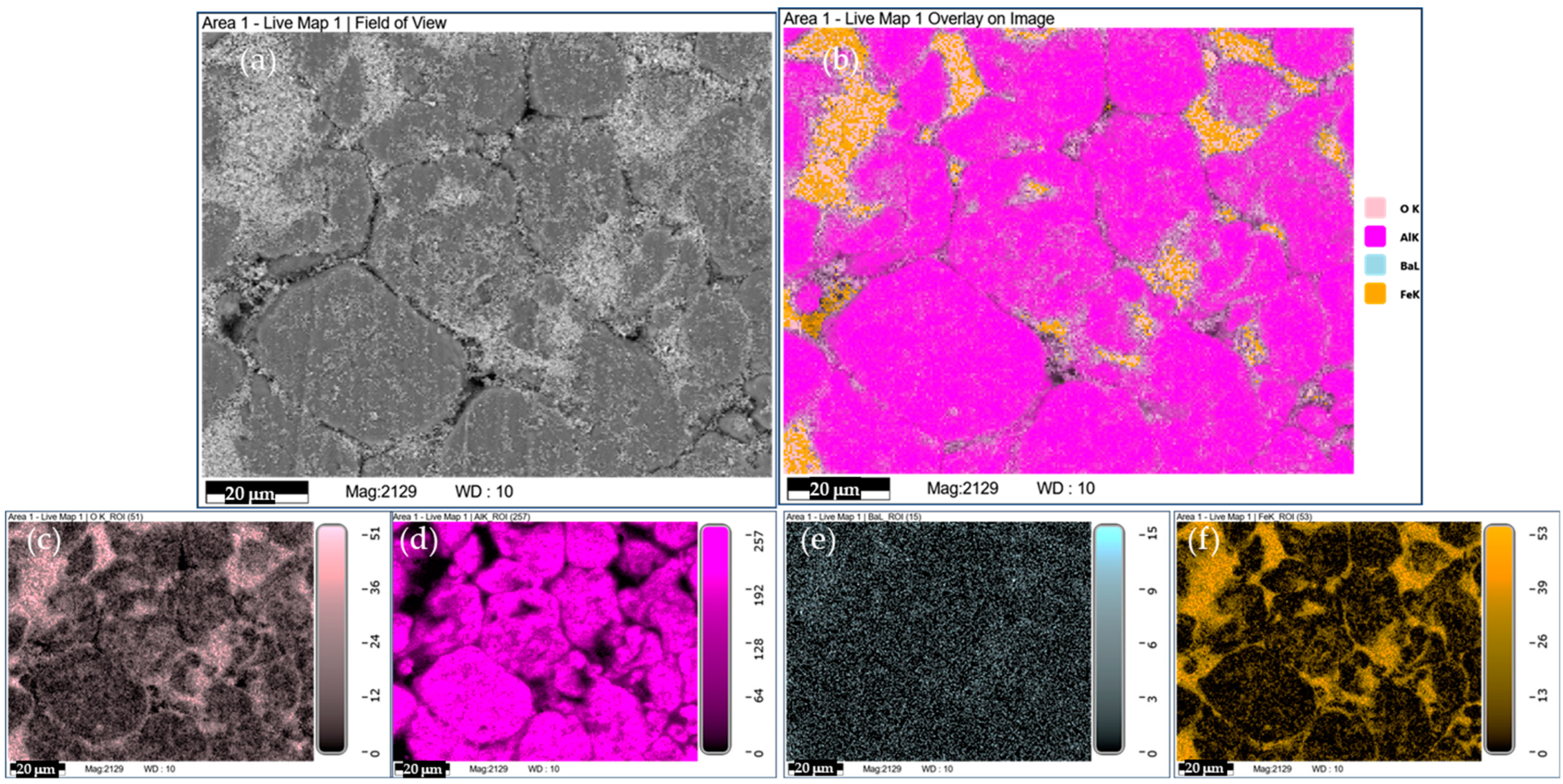

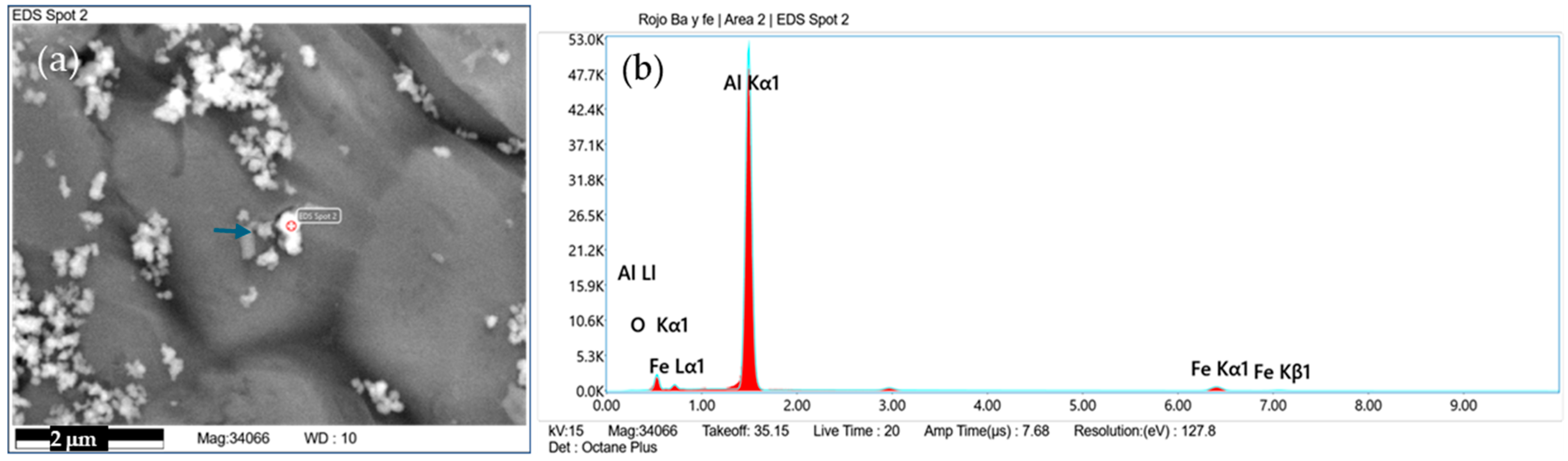

- BayFe red is another synthetic iron oxide pigment (Fe2O3) (Figure 2d).

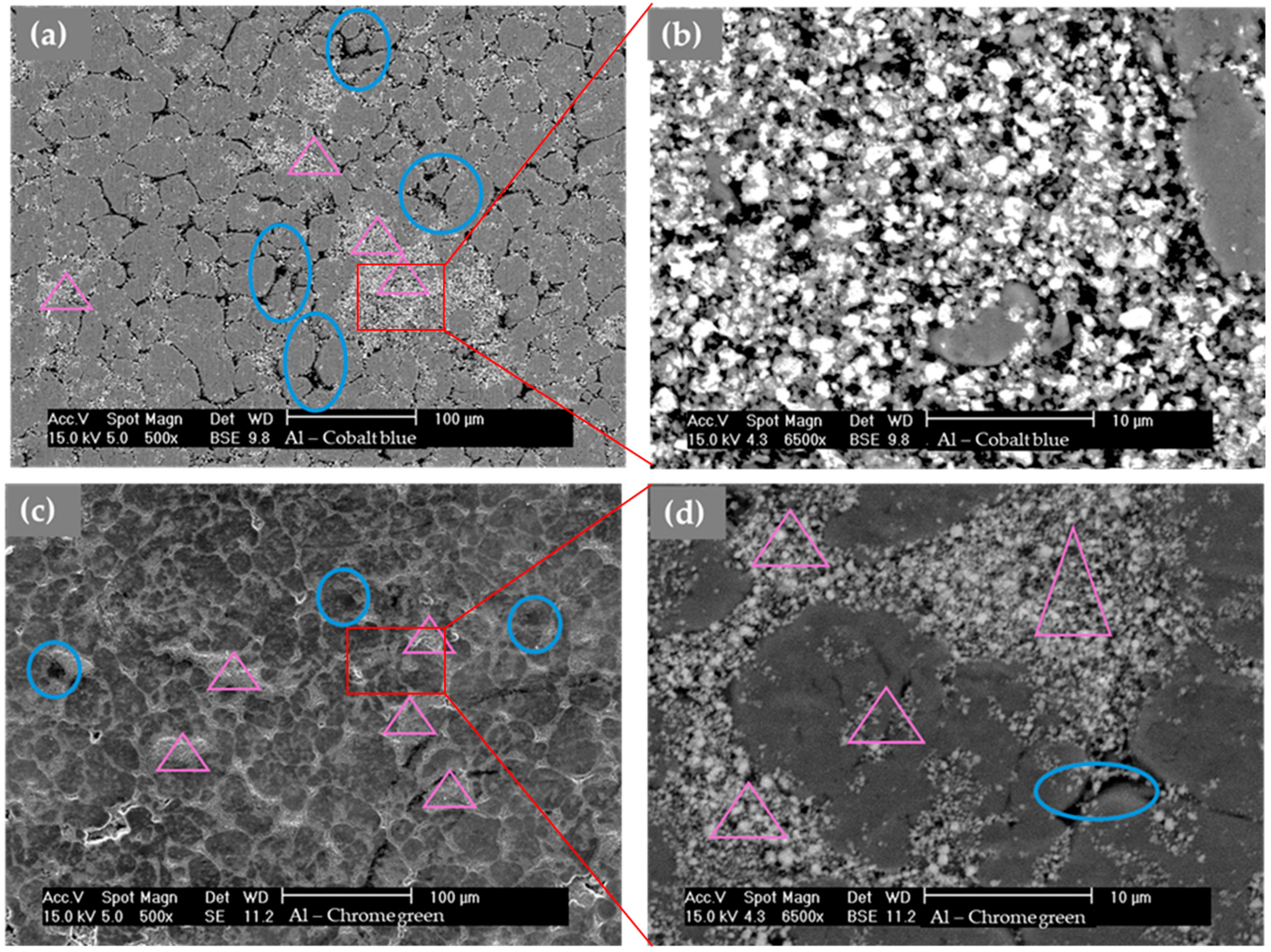

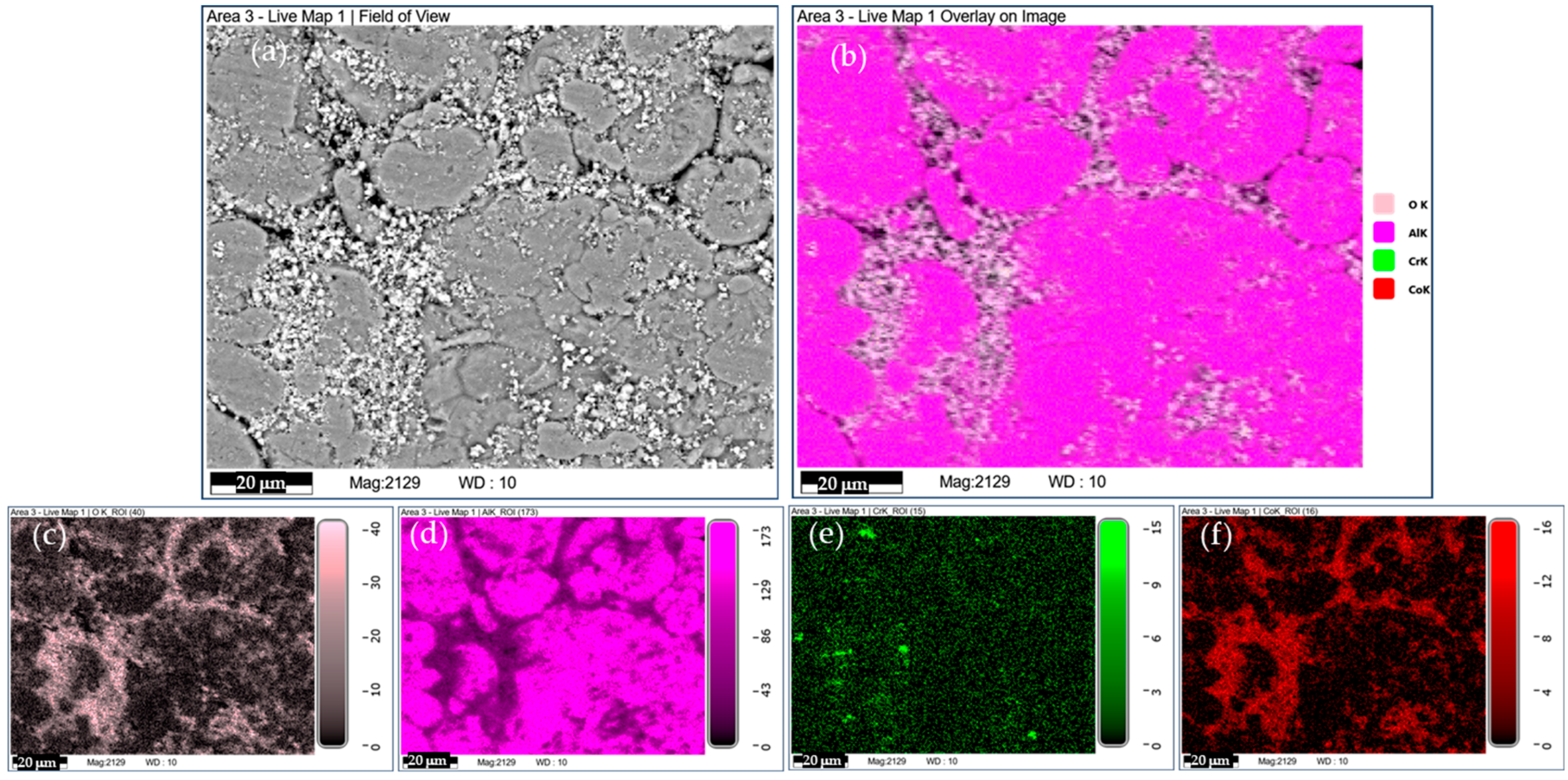

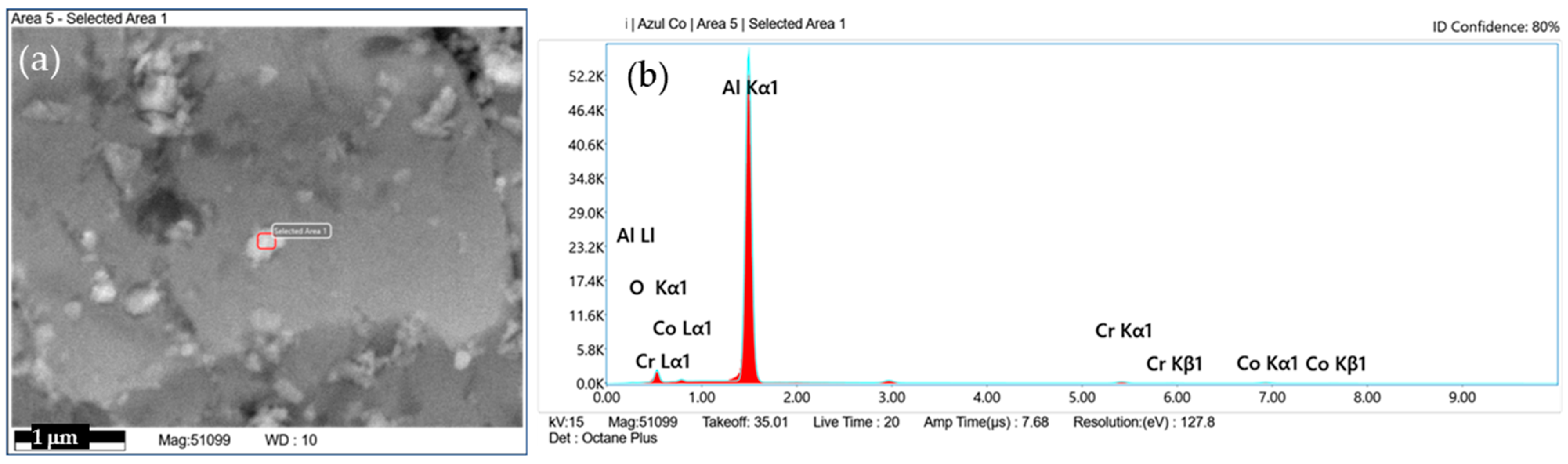

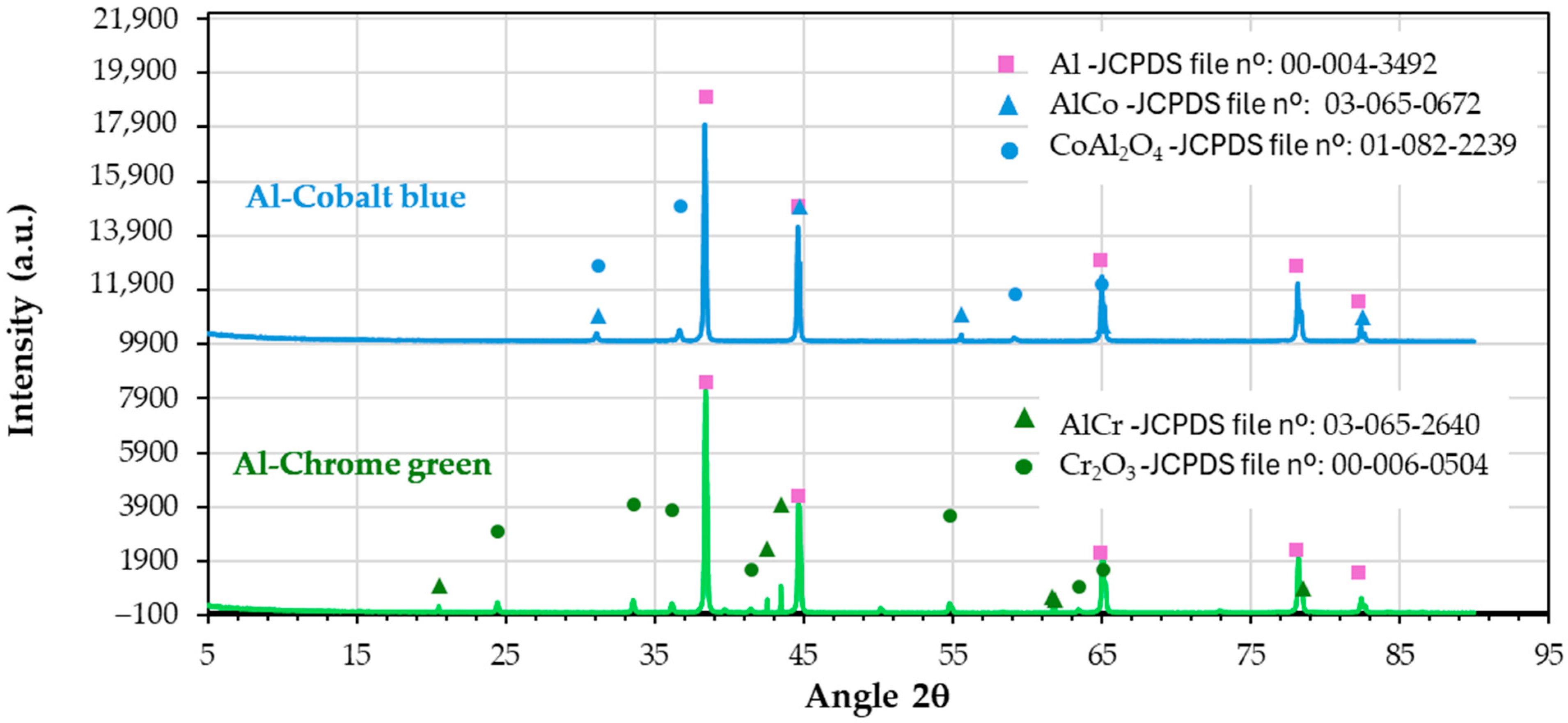

- Deep Cobalt blue, also known as Royal blue, is cobalt aluminate (CoAl2O4), an inorganic pigment with moderate tinting strength (Figure 2e). It offers good lightfastness and poses minimal toxicity risks.

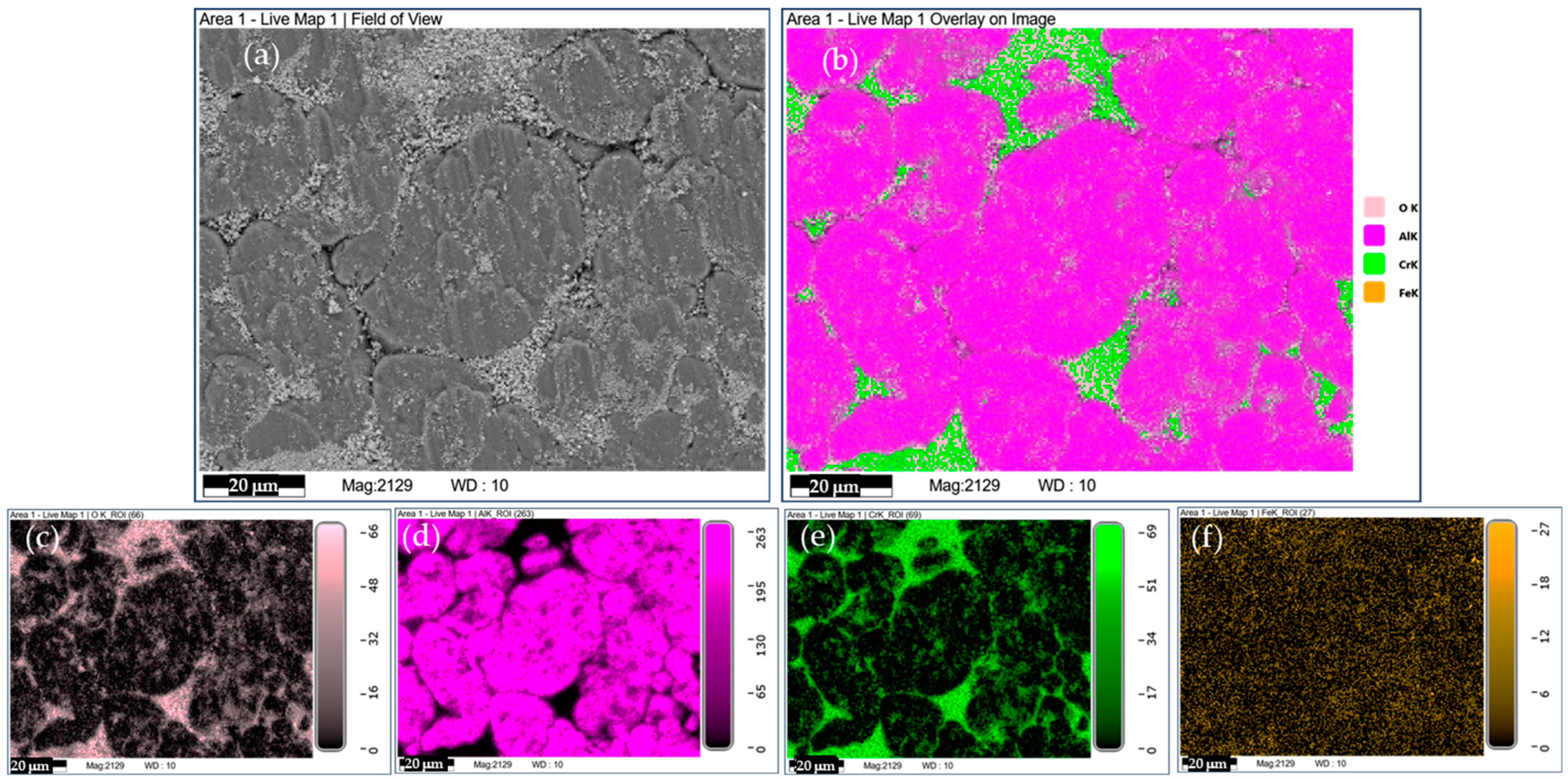

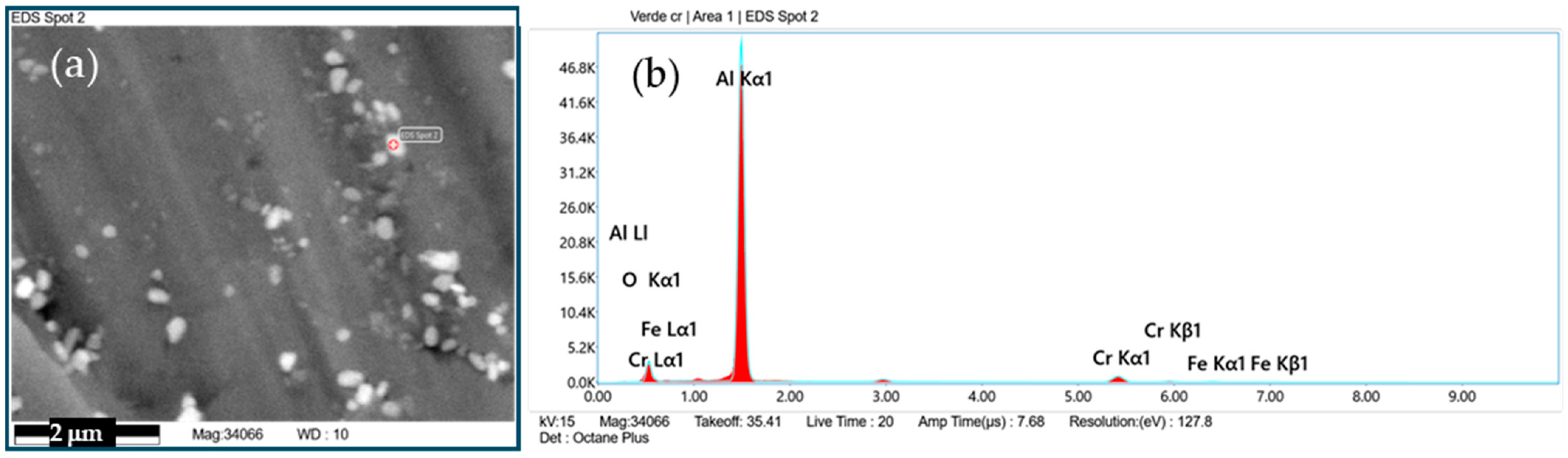

- Chrome green is chromium sesquioxide (Cr2O3), which appears as a pale yellowish-green color (Figure 2f). It is opaque with weak tinting power, but boasts good lightfastness and is relatively non-toxic.

2.2. Sample Preparation

2.3. Color Study

2.4. Physical Properties

2.4.1. Green Properties

2.4.2. Sintering Properties

2.5. Mechanical Properties

2.5.1. Bending Behavior

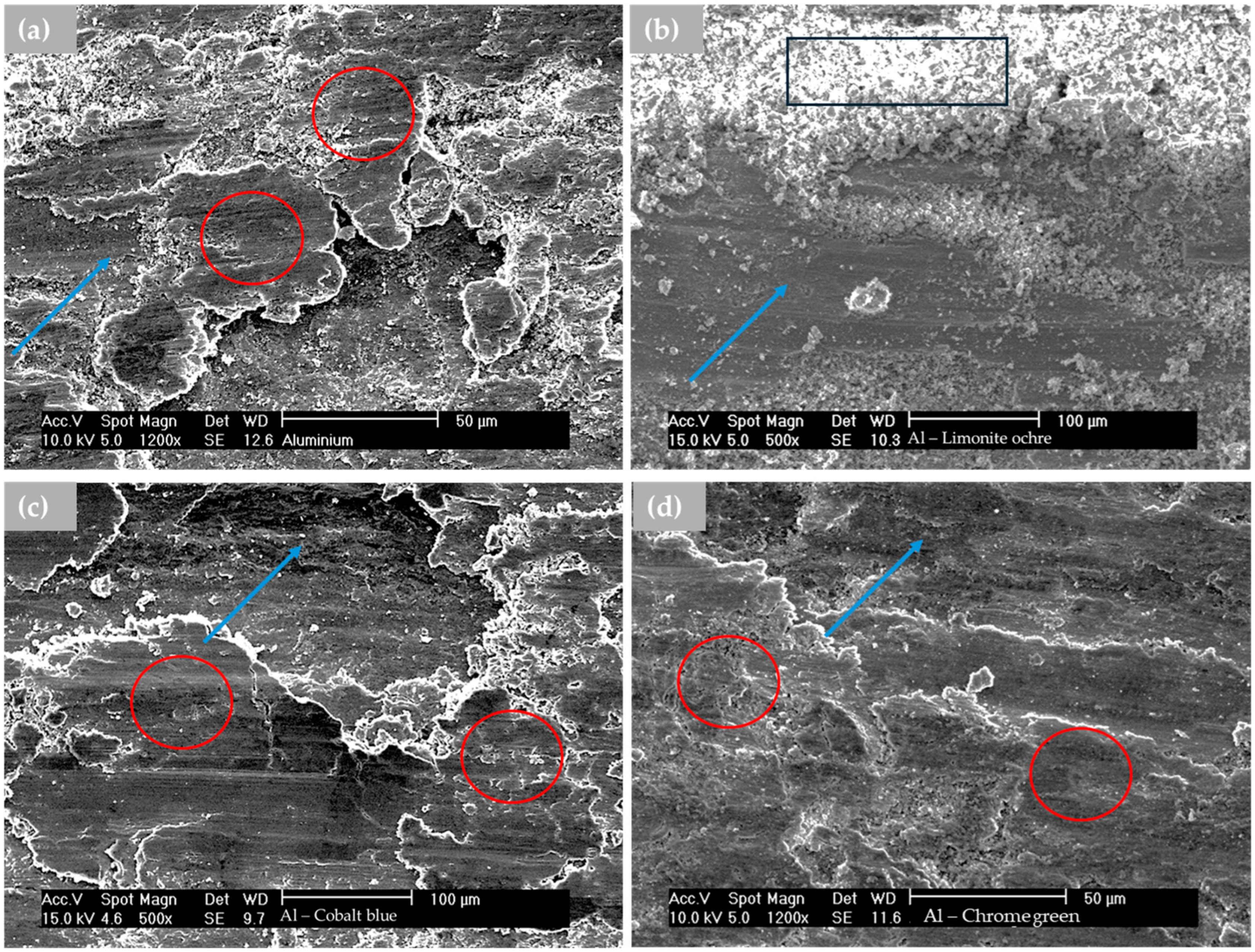

2.5.2. Wear Resistance

2.6. Microstructural Analysis and Thermal Performance

3. Results

3.1. Pigment Selection and Color Study

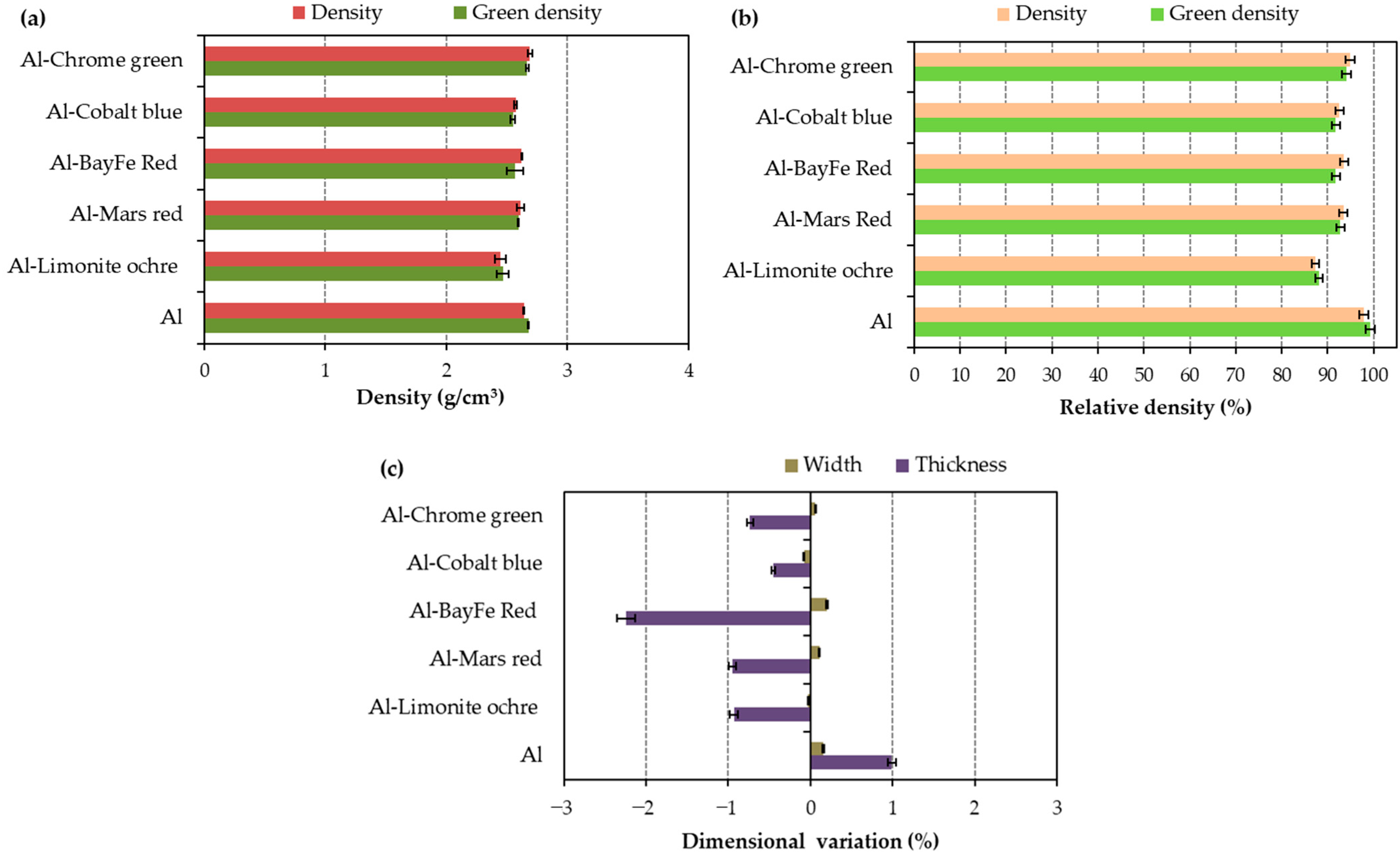

3.2. Physical Properties

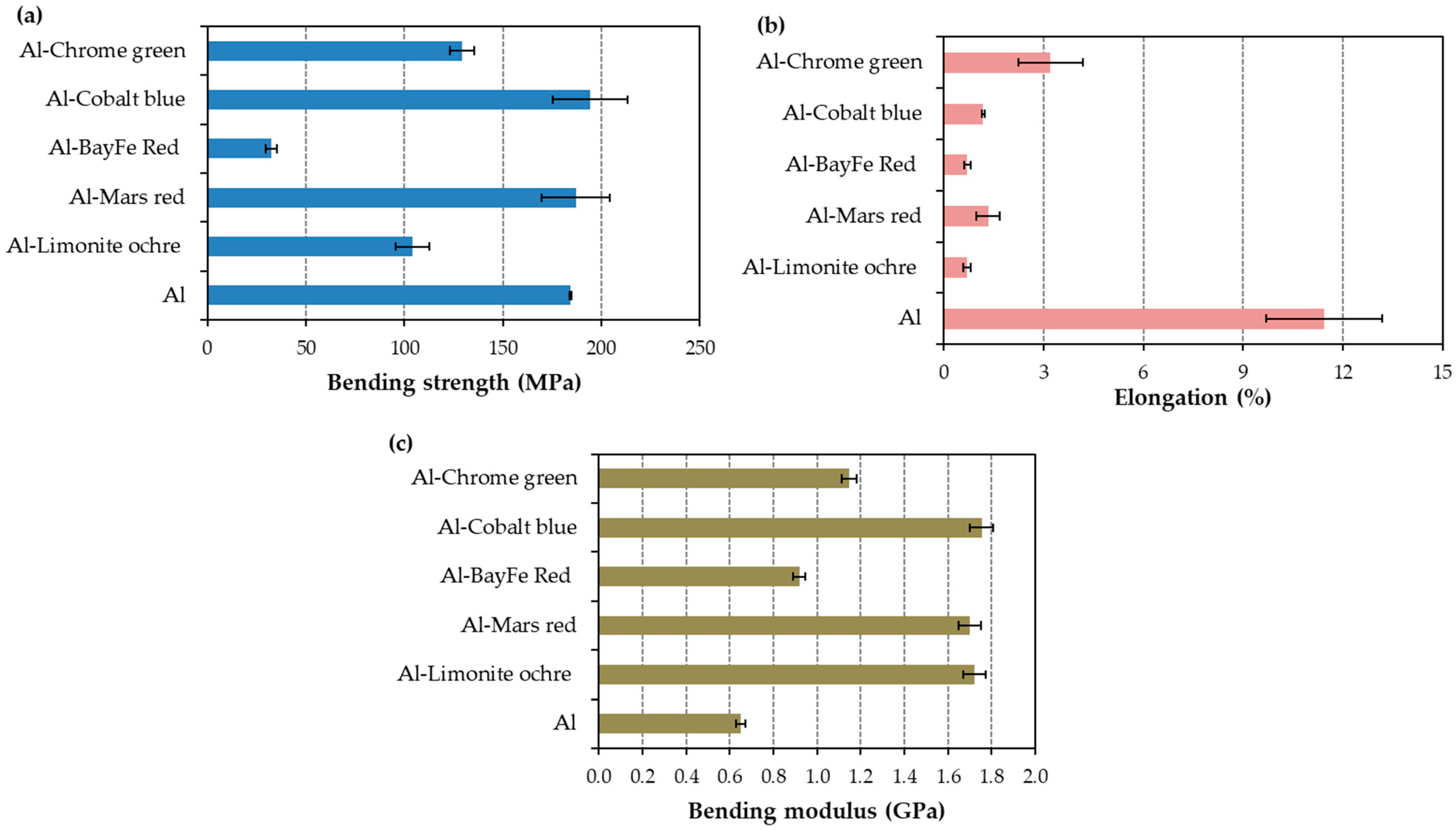

3.3. Bending Properties

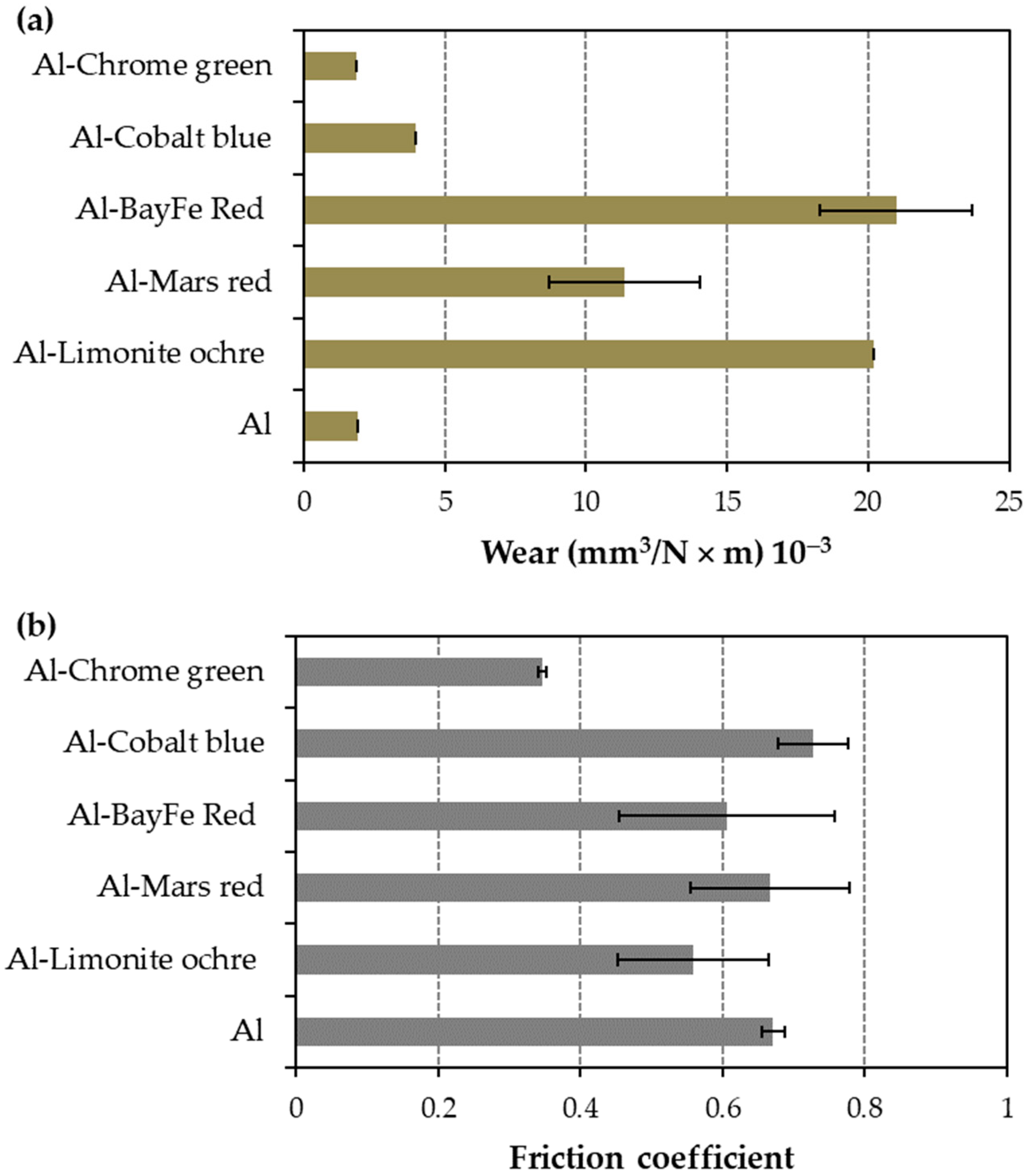

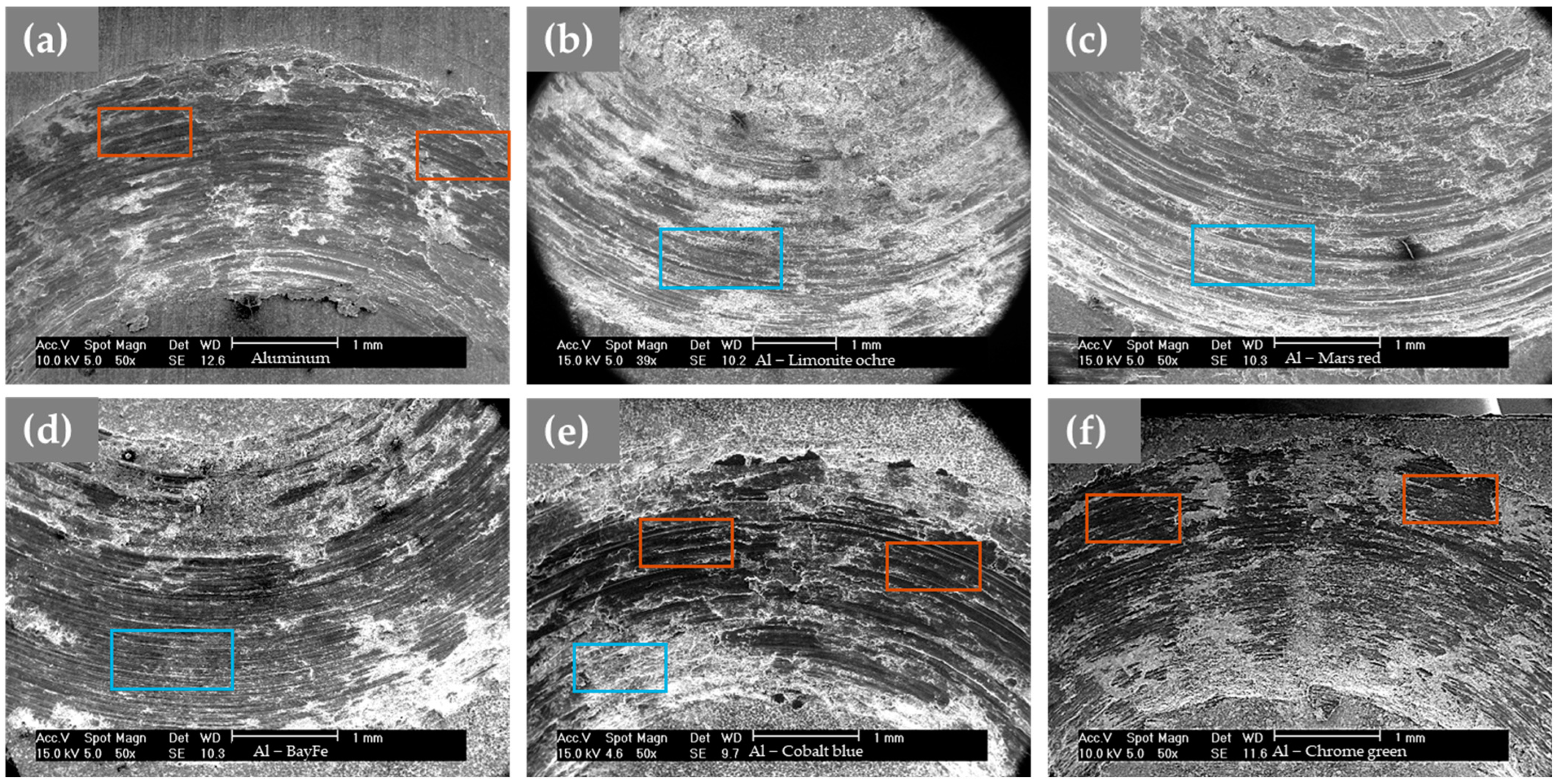

3.4. Wear Behavior

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Saevarsdottir, G.; Kvande, H.; Welch, B.J. Aluminum Production in the Times of Climate Change: The Global Challenge to Reduce the Carbon Footprint and Prevent Carbon Leakage. Jom 2020, 72, 296–308. [Google Scholar] [CrossRef]

- Dai, M.; Wang, P.; Chen, W.Q.; Liu, G. Scenario Analysis of China’s Aluminum Cycle Reveals the Coming Scrap Age and the End of Primary Aluminum Boom. J. Clean. Prod. 2019, 226, 793–804. [Google Scholar] [CrossRef]

- Jarfors, A.E.W.; Du, A.; Yu, G.; Zheng, J.; Wang, K. On the Sustainable Choice of Alloying Elements for Strength of Aluminum-Based Alloys. Sustainability 2020, 12, 1059. [Google Scholar] [CrossRef]

- Bathula, S.; Jayasimhadri, M.; Dhar, A. Mechanical Properties and Microstructure of Spark Plasma Sintered Nanostructured P-Type SiGe Thermoelectric Alloys. Mater. Des. 2015, 87, 414–420. [Google Scholar] [CrossRef]

- Avram, V.; Semenescu, A.; Ioana, A.; Unal, R.; Marcu, D. Evolution of Non-Ferrous Metals Production, Consumption and Prices in the World Market for the Third Millenium. In Proceedings of the International Conference on Management and Industrial Engineering, Bangkok Thailand, 24–26 April 2024; No. 10. Niculescu Publishing House: Bucharest, Romania, 2021; pp. 664–678. [Google Scholar]

- Kraner, J.; Medved, J.; Godec, M.; Paulin, I. Characterization of Non-Ferrous Metal Powders. Mater. Tehnol. 2020, 54, 149–153. [Google Scholar] [CrossRef]

- Huang, X.L.; El Badawy, A.M.; Arambewela, M.; Adkins, R.; Tolaymat, T. Mineral Phases and Metals in Baghouse Dust from Secondary Aluminum Production. Chemosphere 2015, 134, 25–30. [Google Scholar] [CrossRef] [PubMed]

- Palazzo, J.; Geyer, R. Consequential Life Cycle Assessment of Automotive Material Substitution: Replacing Steel with Aluminum in Production of North American Vehicles. Environ. Impact Assess. Rev. 2019, 75, 47–58. [Google Scholar] [CrossRef]

- Sun, X.; Meng, F.; Liu, J.; McKechnie, J.; Yang, J. Life Cycle Energy Use and Greenhouse Gas Emission of Lightweight Vehicle—A Body-in-White Design. J. Clean. Prod. 2019, 220, 1–8. [Google Scholar] [CrossRef]

- Sharma, A.K.; Bhandari, R.; Aherwar, A.; Rimašauskiene, R.; Pinca-Bretotean, C. A Study of Advancement in Application Opportunities of Aluminum Metal Matrix Composites. Mater. Today Proc. 2020, 26, 2419–2424. [Google Scholar] [CrossRef]

- Devezas, T.; Ruao, H. Aluminum Production and Aviation: An Interesting Case of an Interwoven Rebound Effect in a Digital Transforming World. In The Economics of Digital Transforming World; Devezas, T., Leitao, J., Sarygulov, A., Eds.; Springer: Cham, Switzerland, 2021; pp. 251–281. ISBN 978-3-030-59959-1. [Google Scholar]

- Bertram, M.; Martchek, K.J.; Rombach, G. Material Flow Analysis in the Aluminum Industry. J. Ind. Ecol. 2009, 13, 650–654. [Google Scholar] [CrossRef]

- Pahlevan, S.M.; Hosseini, S.M.S.; Goli, A. Sustainable Supply Chain Network Design Using Products’ Life Cycle in the Aluminum Industry. Environ. Sci. Pollut. Res. 2021, 1–25. [Google Scholar] [CrossRef]

- Sudha, G.T.; Stalin, B.; Ravichandran, M.; Balasubramanian, M. Mechanical Properties, Characterization and Wear Behavior of Powder Metallurgy Composites—A Review. Mater. Today Proc. 2019, 22, 2582–2596. [Google Scholar] [CrossRef]

- Abenojar, J.; Velasco, F.; Martínez, M.A. Optimization of Processing Parameters for the Al + 10% B4C System Obtained by Mechanical Alloying. J. Mater. Process. Technol. 2007, 184, 441–446. [Google Scholar] [CrossRef]

- Sharath, B.N.; Madhu, P.; Verma, A. Enhancing Tribological Performance: A Review of Ceramic Reinforced Aluminium Hybrid Composites for High-Temperature Engineering Applications. Hybrid Adv. 2023, 4, 100094. [Google Scholar] [CrossRef]

- Dinaharan, I.; Allwyn Kingsly Gladston, J.; David Raja Selvam, J.; Jen, T.C. Influence of Particle Content and Temperature on Dry Sliding Wear Behavior of Rice Husk Ash Reinforced AA6061 Slurry Cast Aluminum Matrix Composites. Tribol. Int. 2023, 183, 108406. [Google Scholar] [CrossRef]

- Yolcular Karaoglu, S.; Karaoglu, S.; Unal, I. Aerospace Industry and Aluminum Metal Matrix Composites. Int. J. Aviat. Sci. Technol. 2021, 2, 73–81. [Google Scholar] [CrossRef]

- Nturanabo, F.; Masu, L.; Kirabira, J.B. Novel Applications of Aluminium Metal Matrix Composites. In Aluminium Alloys and Composites; Cooke, K.O., Ed.; IntecOpen Limited: London, UK, 2020; pp. 71–94. ISBN 978-1-78984-515-0. [Google Scholar]

- Srinivasan, V.; Kunjiappan, S.; Palanisamy, P. A Brief Review of Carbon Nanotube Reinforced Metal Matrix Composites for Aerospace and Defense Applications. Int. Nano Lett. 2021, 11, 321–345. [Google Scholar] [CrossRef]

- Cavezza, F.; Boehm, M.; Terryn, H.; Hauffman, T. A Review on Adhesively Bonded Aluminium Joints in the Automotive Industry. Metals 2020, 10, 730. [Google Scholar] [CrossRef]

- Ramamoorthi, R.; Hillary, J.J.M.; Sundaramoorthy, R.; Joseph, J.D.J.; Kalidas, K.; Manickaraj, K. Influence of Stir Casting Route Process Parameters in Fabrication of Aluminium Matrix Composites—A Review. Mater. Today Proc. 2020, 45, 6660–6664. [Google Scholar] [CrossRef]

- Yadav, P.; Ranjan, A.; Kumar, H.; Mishra, A.; Yoon, J. A Contemporary Review of Aluminium Mmc Developed through Stir-Casting Route. Materials 2021, 14, 6386. [Google Scholar] [CrossRef] [PubMed]

- Upadhyay, G.; Saxena, K.K. Role of Stir Casting in Development of Aluminium Metal Matrix Composite (AMC): An Overview. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1116, 012022. [Google Scholar] [CrossRef]

- Vasanthakumar, P.; Sekar, K.; Venkatesh, K. Recent Developments in Powder Metallurgy Based Aluminium Alloy Composite for Aerospace Applications. Mater. Today Proc. 2019, 18, 5400–5409. [Google Scholar] [CrossRef]

- Aynalem, G.F. Processing Methods and Mechanical Properties of Aluminium Matrix Composites. Adv. Mater. Sci. Eng. 2020, 2020, 3765791. [Google Scholar] [CrossRef]

- Uzun, A. Production of Aluminium Foams Reinforced with Silicon Carbide and Carbon Nanotubes Prepared by Powder Metallurgy Method. Compos. Part B Eng. 2019, 172, 206–217. [Google Scholar] [CrossRef]

- De Angelo, P.C.; Subramanian, R.; Ravisankar, B. Powder Metallurg, Second Edition: Science, Techechnology and Application, 2nd ed.; De Angelo, P.C., Subramanian, R., Ravisankar, B., Eds.; PHI Leaming Private Limited: Delhi, India, 2023; ISBN 978-93-91818-49-4. [Google Scholar]

- Moghimian, P.; Poirié, T.; Habibnejad-Korayem, M.; Zavala, J.A.; Kroeger, J.; Marion, F.; Larouche, F. Metal Powders in Additive Manufacturing: A Review on Reusability and Recyclability of Common Titanium, Nickel and Aluminum Alloys. Addit. Manuf. 2021, 43, 102017. [Google Scholar] [CrossRef]

- Parsons, E.M.; Shaik, S.Z. Additive Manufacturing of Aluminum Metal Matrix Composites: Mechanical Alloying of Composite Powders and Single Track Consolidation with Laser Powder Bed Fusion. Addit. Manuf. 2022, 50, 102450. [Google Scholar] [CrossRef]

- Chelladurai, S.J.S.; Kumar, S.S.; Venugopal, N.; Ray, A.P.; Manjunath, T.C.; Gnanasekaran, S. A Review on Mechanical Properties and Wear Behaviour of Aluminium Based Metal Matrix Composites. Mater. Today Proc. 2020, 37, 908–916. [Google Scholar] [CrossRef]

- Edalati, K.; Ashida, M.; Horita, Z.; Matsui, T.; Kato, H. Wear Resistance and Tribological Features of Pure Aluminum and Al-Al2O3 Composites Consolidated by High-Pressure Torsion. Wear 2014, 310, 83–89. [Google Scholar] [CrossRef]

- Poria, S.; Sahoo, P.; Sutradhar, G. Tribological Characterization of Stir-Cast Aluminium-TiB2 Metal Matrix Composites. Silicon 2016, 8, 591–599. [Google Scholar] [CrossRef]

- Khan, M.M.; Nisar, M. Effect of in Situ TiC Reinforcement and Applied Load on the High-Stress Abrasive Wear Behaviour of Zinc–Aluminum Alloy. Wear 2022, 488–489, 204082. [Google Scholar] [CrossRef]

- Zamani, N.A.B.N.; Iqbal, A.A.; Nuruzzaman, D.M. Mechanical and Tribological Behavior of Powder Metallurgy Processed Aluminum–Graphite Composite. Russ. J. Non-Ferrous Met. 2019, 60, 274–281. [Google Scholar] [CrossRef]

- Yadav, R.; Meena, A.; Lee, S.Y.; Park, S.J. Experimental Tribological and Mechanical Behavior of Aluminium Alloy 6061 Composites Incorporated Ceramic Particulates Using Taguchi Analysis. Tribol. Int. 2024, 192, 109243. [Google Scholar] [CrossRef]

- Binti Nor Zamani, N.A.; Iqbal, A.A.; Nuruzzaman, D.M. Tribo-Mechanical Characterisation of Self-Lubricating Aluminium Based Hybrid Metal Matrix Composite Fabricated via Powder Metallurgy. Materialia 2020, 14, 100936. [Google Scholar] [CrossRef]

- Maranata, G.J.; Megantara, S.; Hasanah, A.N. An Update in Computational Methods for Environmental Monitoring: Theoretical Evaluation of the Molecular and Electronic Structures of Natural Pigment–Metal Complexes. Molecules 2024, 29, 1680. [Google Scholar] [CrossRef] [PubMed]

- Mulyaningsih, R.D.; Pratiwi, R.; Hasanah, A.N. An Update on the Use of Natural Pigments and Pigment Nanoparticle Adducts for Metal Detection Based on Colour Response. Biosensors 2023, 13, 554. [Google Scholar] [CrossRef] [PubMed]

- Sirimanne, P.M.; Senevirathna, M.K.I.; Premalal, E.V.A.; Pitigala, P.K.D.D.P.; Sivakumar, V.; Tennakone, K. Utilization of Natural Pigment Extracted from Pomegranate Fruits as Sensitizer in Solid-State Solar Cells. J. Photochem. Photobiol. A Chem. 2006, 177, 324–327. [Google Scholar] [CrossRef]

- Kumara, N.T.R.N.; Lim, A.; Lim, C.M.; Petra, M.I.; Ekanayake, P. Recent Progress and Utilization of Natural Pigments in Dye Sensitized Solar Cells: A Review. Renew. Sustain. Energy Rev. 2017, 78, 301–317. [Google Scholar] [CrossRef]

- Cortez, R.; Luna-Vital, D.A.; Margulis, D.; Gonzalez de Mejia, E. Natural Pigments: Stabilization Methods of Anthocyanins for Food Applications. Compr. Rev. Food Sci. Food Saf. 2017, 16, 180–198. [Google Scholar] [CrossRef] [PubMed]

- Di Salvo, E.; Lo Vecchio, G.; De Pasquale, R.; De Maria, L.; Tardugno, R.; Vadalà, R.; Cicero, N. Natural Pigments Production and Their Application in Food, Health and Other Industries. Nutrients 2023, 15, 1923. [Google Scholar] [CrossRef]

- Poli, T.; Piccirillo, A.; Nervo, M.; Chiantore, O. Interactions of Natural Resins and Pigments in Works of Art. J. Colloid Interface Sci. 2017, 503, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Monrós Tomás, G.; García, A.; Badenes, J.A.; Tena, M.A. The Color of Ceramics: New Mechanisms in Pigments for Modern Ceramic Processing (El Color de La Cerámica: Nuevos Mecanismos En Pigmentos Para Los Nuevos Procesados de La Industria Cerámica); Universitat Jaume I. Servei de Comunicació i Publicacions: Castellón de la Plana, Spain, 2013; ISBN 978-84-15443-22-3. [Google Scholar]

- Enríquez, E.; Reinosa, J.J.; Fuertes, V.; Fernández, J.F. Advances and Challenges of Ceramic Pigments for Inkjet Printing. Ceram. Int. 2022, 48, 31080–31101. [Google Scholar] [CrossRef]

- Vitek, V.; Yan, M.; Schulson, E. Physical Metallurgy and Processing of Intemetallic Compounds (Part 1—Chapters 2 and 3); Stoloff, N.S., Sikka, V.K., Eds.; Chapman & Hall: New York, NY, USA, 1996; ISBN 978-1-4612-8515-1. [Google Scholar]

- Abenojar, J.; Velasco, F.; Martinez, M.A. Differential Thermal Analysis of the Al + 20% (Fe-50%B) System. J. Solid State Chem. 2006, 179, 2787–2790. [Google Scholar] [CrossRef]

- Abenojar, J.; Velasco, F.; Martínez, M.A. Influence of Carbon and Aluminium Additions on the Fe-10% B (Wt.) System. J. Mater. Process. Technol. 2003, 143–144, 28–33. [Google Scholar] [CrossRef]

- Jamil, S.J.; Chadwick, G.A. Investigation and Analysis of Liquid Phase Sintering of Fe—Cu and Fe–Cu–C Compacts. Powder Metall. 1985, 28, 65–71. [Google Scholar] [CrossRef]

- Prasad, A.R.; Renuka Prasad, A.; Prakash, S. A Review on Anodizing Process of Aluminum and Non-Aluminium Alloys. In Proceedings of the National conference on Recent Advances in Mechanical, Robotics & Technology, Srinivas University: Mangalore, Kamataka, India, 28–29 June 2022. [Google Scholar]

- Mohitfar, S.H.; Mahdavi, S.; Etminanfar, M.; Khalil-Allafi, J. Characteristics and Tribological Behavior of the Hard Anodized 6061-T6 Al Alloy. J. Alloys Compd. 2020, 842, 155988. [Google Scholar] [CrossRef]

- Nam, J.; Kang, J. Effect of Anodized Coating on Friction Noise in Aluminum. J. Mech. Sci. Technol. 2019, 33, 1545–1554. [Google Scholar] [CrossRef]

- UNE-EN ISO/CIE 11664-2:2023; Colorimetry—Part 2:CIE Standard Illuminants. UNE: Madrid, Spain, 2023.

- UNE-ENISO/CIE 11664-4:2020; Colorimetry-Part 4:CIE1976 L*a*b* Colour Space. UNE: Madrid, Spain, 2020.

- UNE-EN ISO 4492:2018; Metallic Powders, Excluding Powders for Hardmetals—Determination of Dimensional Changes Associated with Compacting and Sintering. UNE: Madrid, Spain, 2018.

- UNE-EN ISO 3327:2010; Hardmetals—Determination of Transverse Rupture Strength. UNE: Madrid, Spain, 2010.

- ASTM G99-05:2010; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM: West Conshohocken, PA, USA, 2010.

- Dunstan, M.K.; Paramore, J.D.; Fang, Z.Z. The Effects of Microstructure and Porosity on the Competing Fatigue Failure Mechanisms in Powder Metallurgy Ti-6Al-4V. Int. J. Fatigue 2018, 116, 584–591. [Google Scholar] [CrossRef]

- Vicent, C.; Silvain, J.F.; Heintz, J.M.; Chandra, N. Effect of porosity on the hermal conductivity of copperprocessed by powder metallurgy. J. Phys. Chem. Sol. 2012, 73, 499–504. [Google Scholar] [CrossRef]

- Schicker, S.; Garcia, D.E.; Bruhn, J.; Janssen, R.; Claussen, N. Reaction Processing of Al2O3 Composites Containing Iron and Iron Aluminides. J. Am. Ceram. Soc. 1997, 80, 2294–2300. [Google Scholar] [CrossRef]

- Abenojar, J.; Velasco, F.; Martínez, M.A. Influencia de La Temperatura de Sinterización En Las Propiedades Mecánicas Del Sistema Al + 20 % Fe/B. Rev. Metal. 2006, 42, 114–120. [Google Scholar] [CrossRef]

- Wang, Y.; Cacciamani, G. Experimental Investigation and Thermodynamic Assessment of the Al-Co-Ni System. Calphad Comput. Coupling Phase Diagr. Thermochem. 2018, 61, 198–210. [Google Scholar] [CrossRef]

- Grushko, B.; Kowalska-Strzȩciwilk, E.; Przepiórzyński, B.; Surowiec, M. Investigation of the Al-Cr γ-Range. J. Alloys Compd. 2005, 402, 98–104. [Google Scholar] [CrossRef]

- Fivel, M.; Franc, J.-P. Volume 18, Fricition, Lubrication, and Wear Technology; Totten, G.E., Ed.; ASM International: Novelty, OH, USA, 2017; ISBN 978-1-62708-141-2. [Google Scholar]

- Abenojar, J.; López de Armentia, S.; Martínez, M.A. Enhancing the Fire Resistance of Ablative Materials: Role of the Polymeric Matrix and Silicon Carbide Reinforcement. Polymers 2024, 16, 2454. [Google Scholar] [CrossRef] [PubMed]

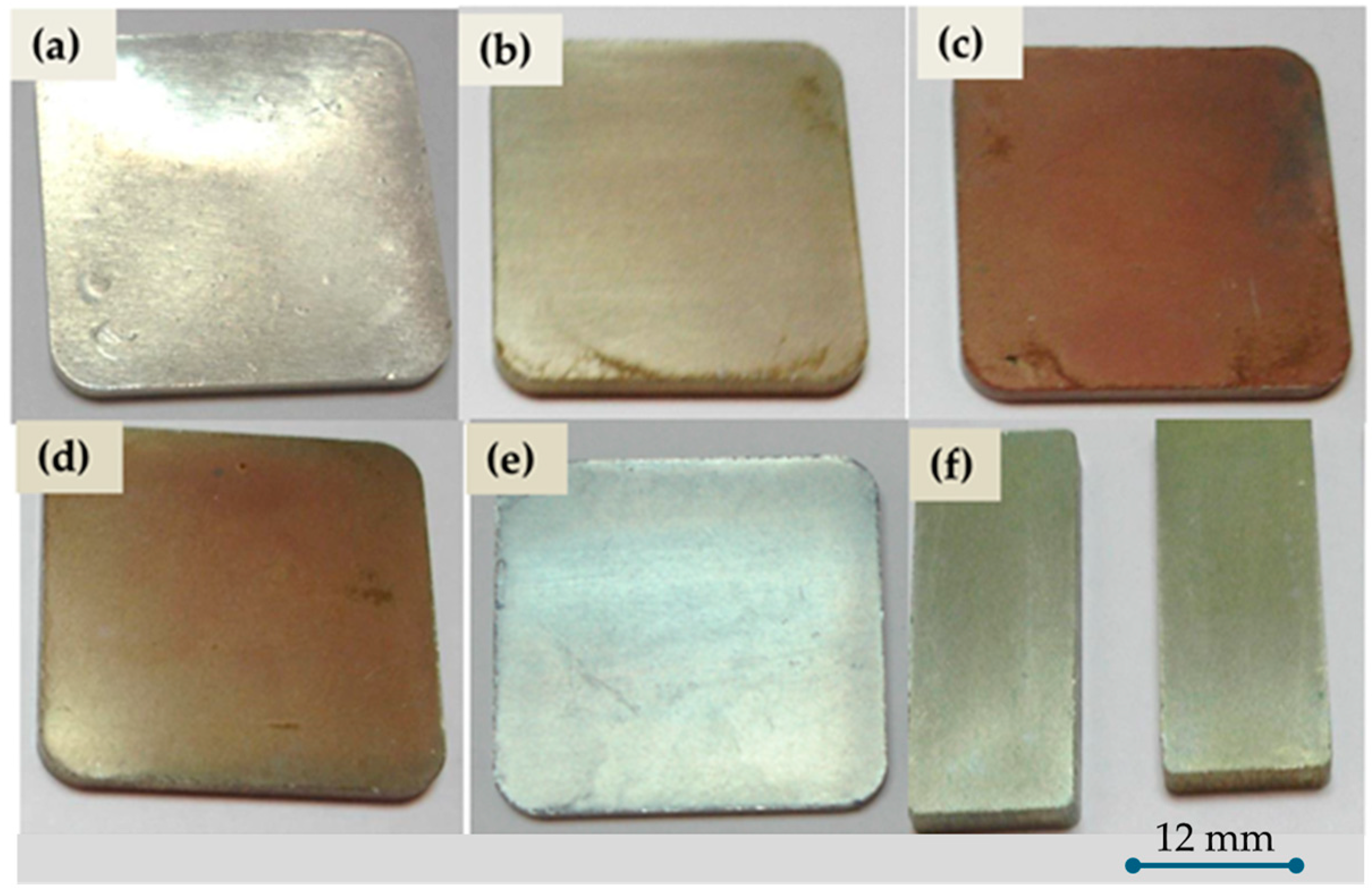

| Composite | L* | a* | b* | C* | h |

|---|---|---|---|---|---|

| Al | 79.86 | 0.23 | 8.20 | 1.91 | 1.54 |

| Al–Limonite ochre | 66.84 | 2.46 | 6.97 | 17.10 | 1.23 |

| Al–Mars red | 49.13 | 10.83 | 12.04 | 130.34 | 0.84 |

| Al–BayFe red | 69.81 | −3.62 | −6.96 | 25.20 | 1.09 |

| Al–Cobalt blue | 60.38 | −2.97 | 8.68 | 25.74 | −1.24 |

| Al–Chrome green | 72.96 | 1.07 | 2.55 | 2.73 | 1.17 |

| Composite | ΔL* | Δa* | Δb* | ΔE* | ΔC* | Δh |

| Al | ||||||

| Al–Limonite ochre | 13.01 | −2.22 | 1.23 | 13.26 | −15.19 | 0.31 |

| Al–Mars red | 30.73 | −10.60 | −3.84 | 32.73 | −128.43 | 0.70 |

| Al–BayFe red | 28.82 | −11.24 | −5.02 | 31.34 | −149.76 | 0.69 |

| Al–Cobalt blue | 10.05 | 3.86 | 15.16 | 18.59 | −23.30 | 0.45 |

| Al–Chrome green | 19.48 | 3.20 | −0.48 | 19.74 | −23.83 | 2.78 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martínez, M.A.; Abenojar, J. Aluminum and Inorganic Natural Pigment Colored Composites by Powder Metallurgy Forming. Metals 2025, 15, 58. https://doi.org/10.3390/met15010058

Martínez MA, Abenojar J. Aluminum and Inorganic Natural Pigment Colored Composites by Powder Metallurgy Forming. Metals. 2025; 15(1):58. https://doi.org/10.3390/met15010058

Chicago/Turabian StyleMartínez, Miguel Angel, and Juana Abenojar. 2025. "Aluminum and Inorganic Natural Pigment Colored Composites by Powder Metallurgy Forming" Metals 15, no. 1: 58. https://doi.org/10.3390/met15010058

APA StyleMartínez, M. A., & Abenojar, J. (2025). Aluminum and Inorganic Natural Pigment Colored Composites by Powder Metallurgy Forming. Metals, 15(1), 58. https://doi.org/10.3390/met15010058