Alternatives to Reduce Hot Cracking Susceptibility of IN718 Casting Alloy Laser Beam Welds with a Mushroom Shape

Abstract

1. Introduction

2. Materials and Methods

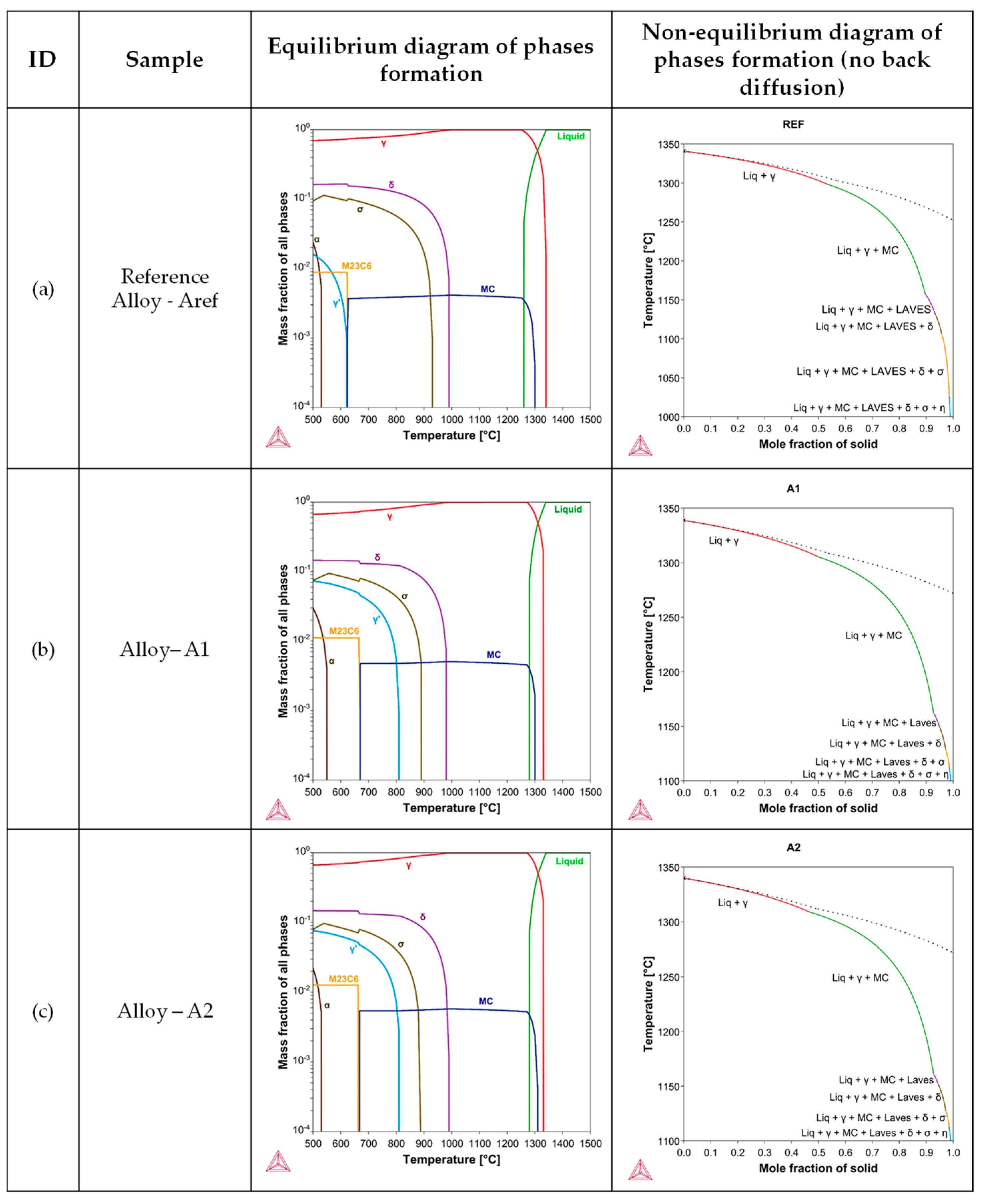

2.1. Materials

- Pre-HIP (homogenization): 1052 °C for 8 h, air cooling in open atmosphere (only to some samples of alloys under study) for comparison with standard ones.

- HIP (hot isostatic pressing): 1121 °C for 4 h, furnace cooling until room temperature in inert atmosphere.

- Post-HIP: 1052 °C for 1 h, furnace cooling.

- Solubilization: 954 °C for 1 h, air cooling.

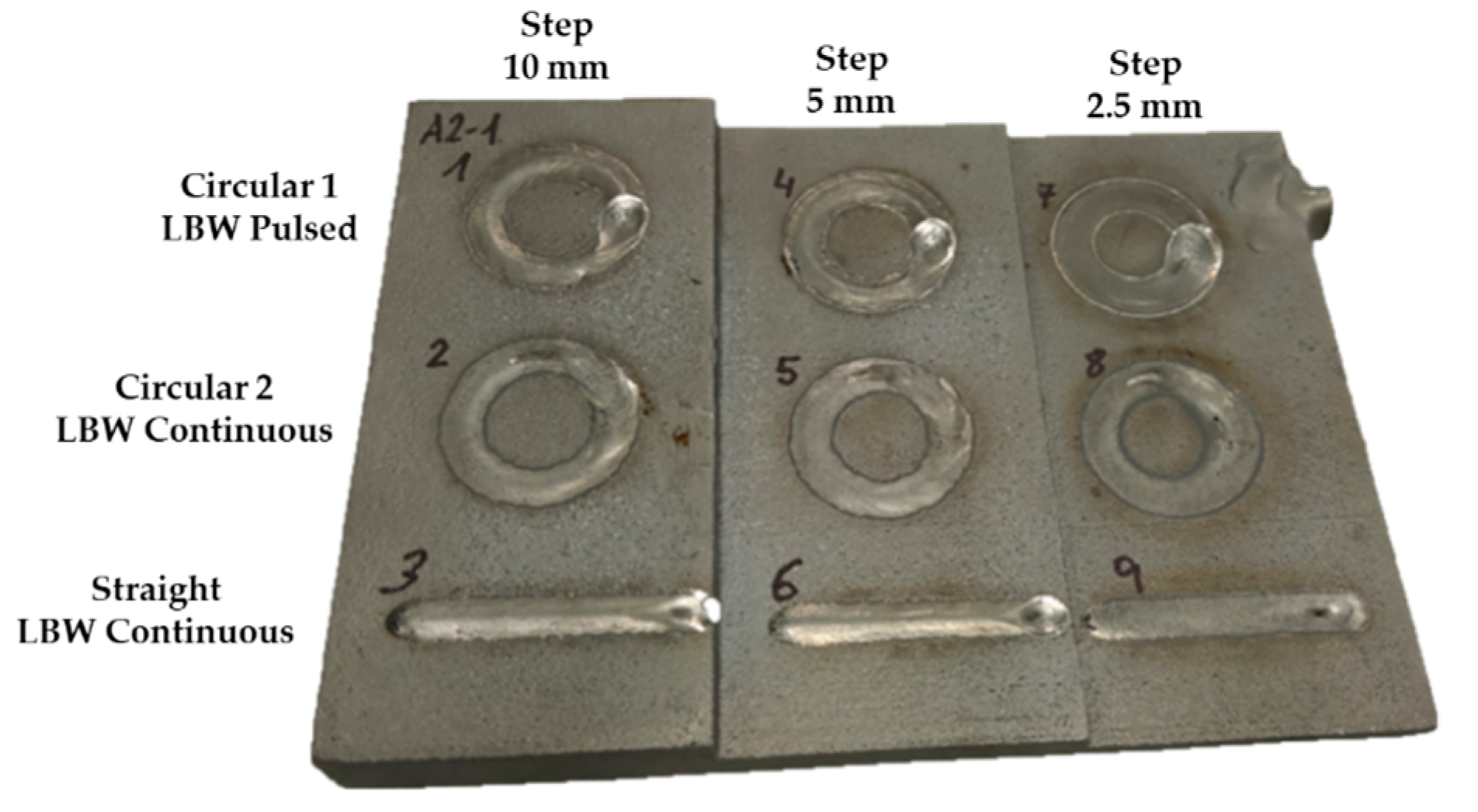

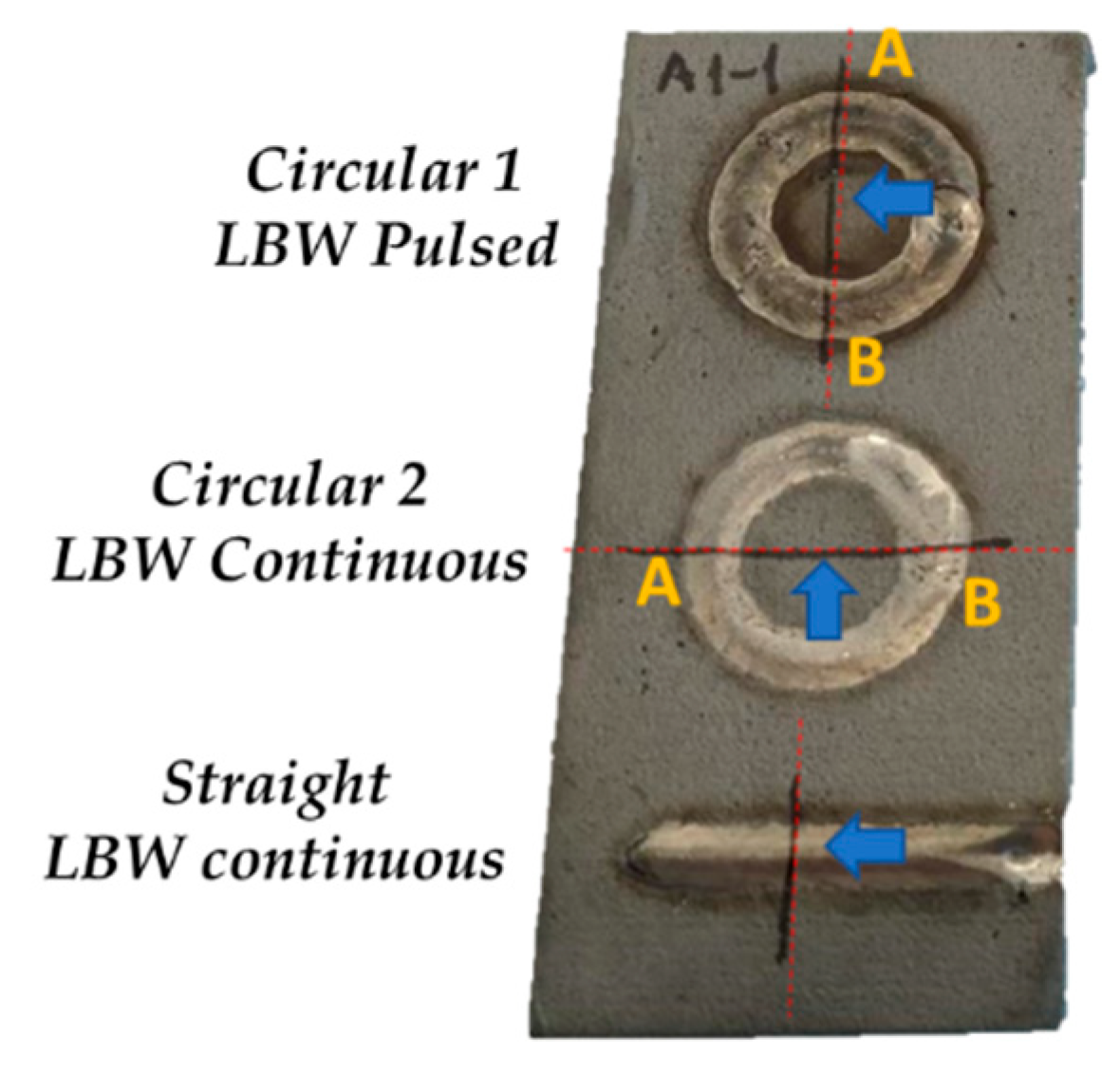

2.2. Laser Bead on Plate Welding Process

2.3. Non-Destructive Inspection Techniques and Microstructural Characterization

2.3.1. Fluorescent Penetrant Inspection Testing (FPI)

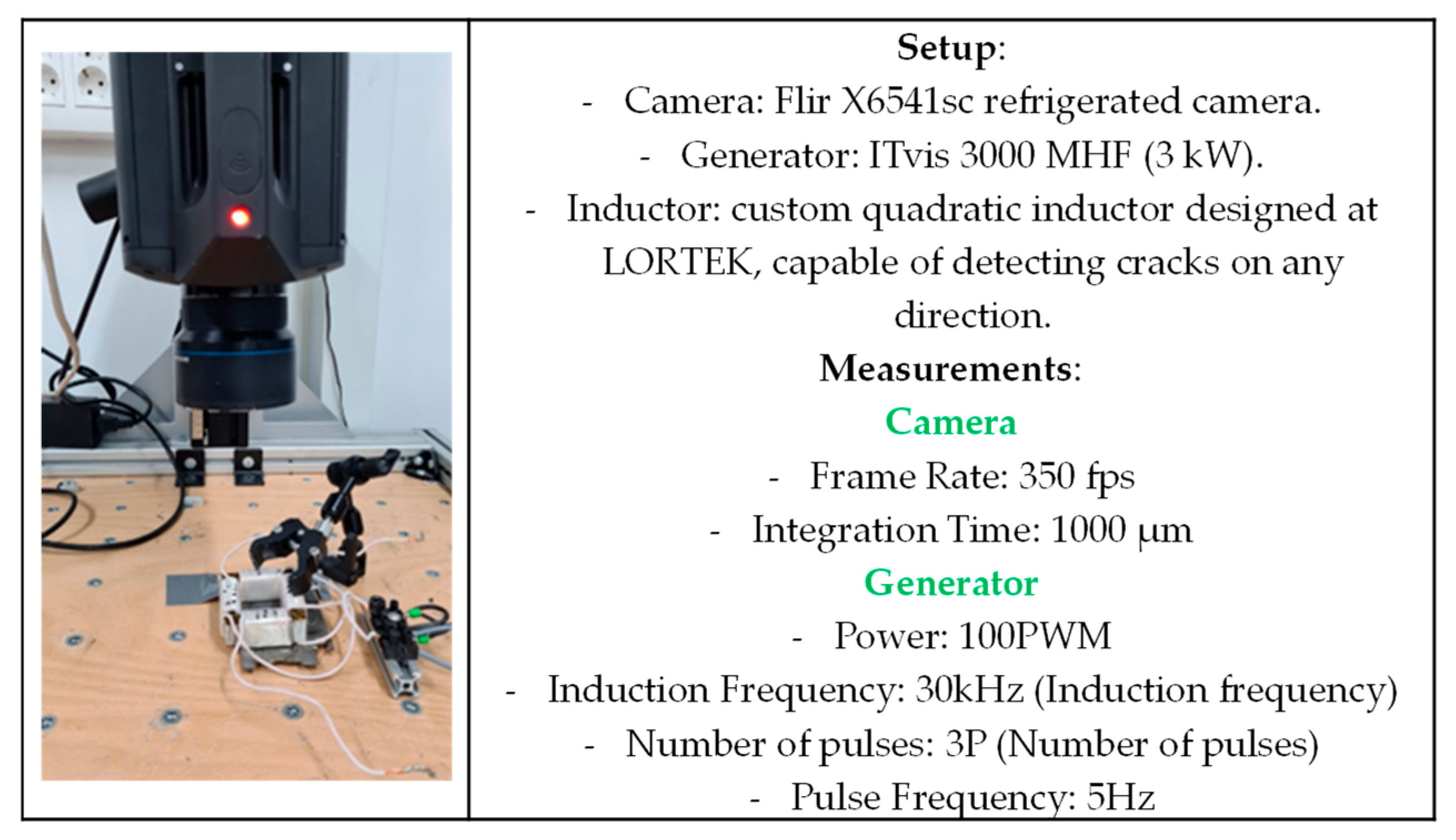

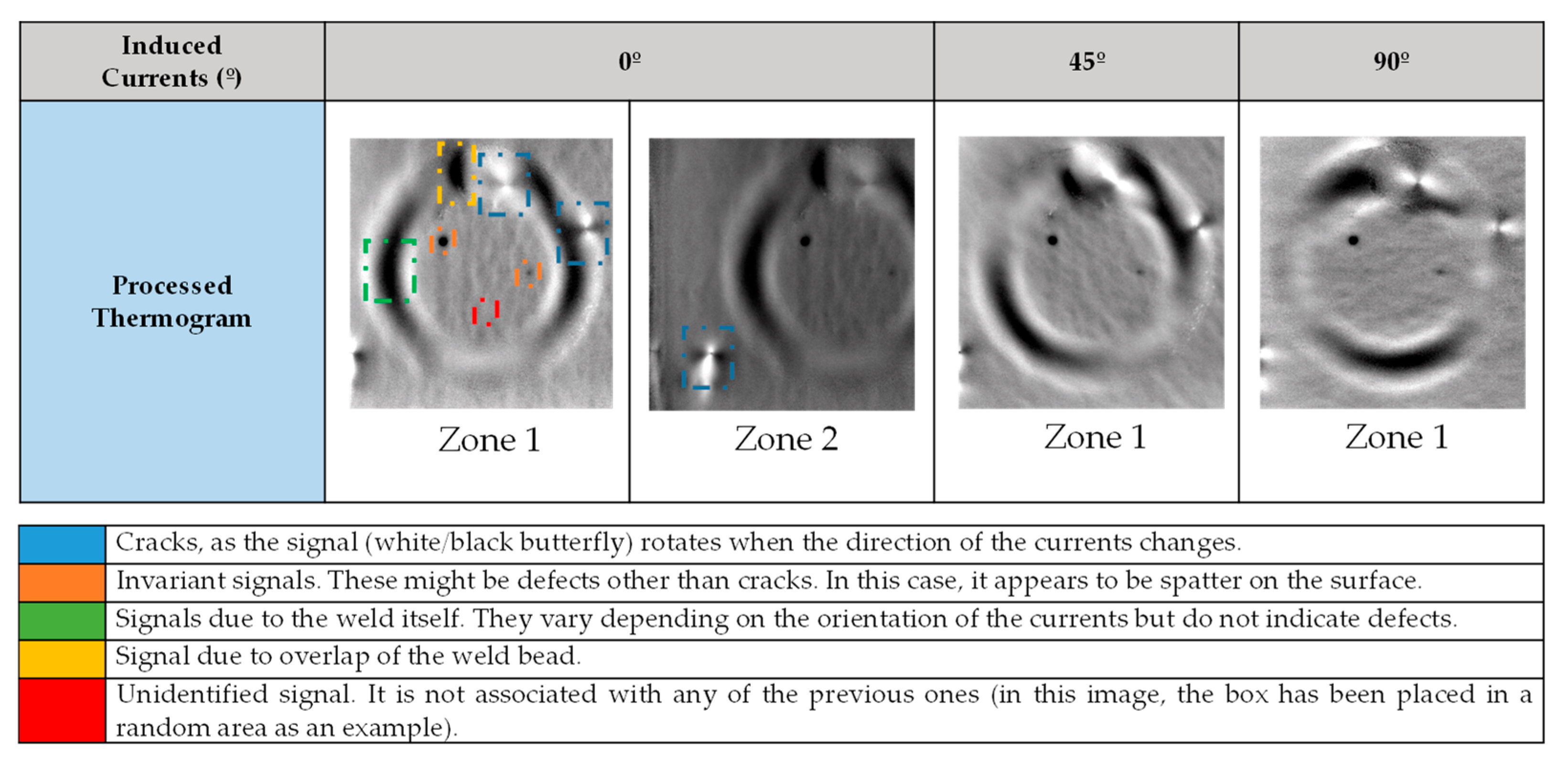

2.3.2. Inductive Thermography

2.3.3. X-ray Inspection

2.4. Metallographic Characterization

3. Results

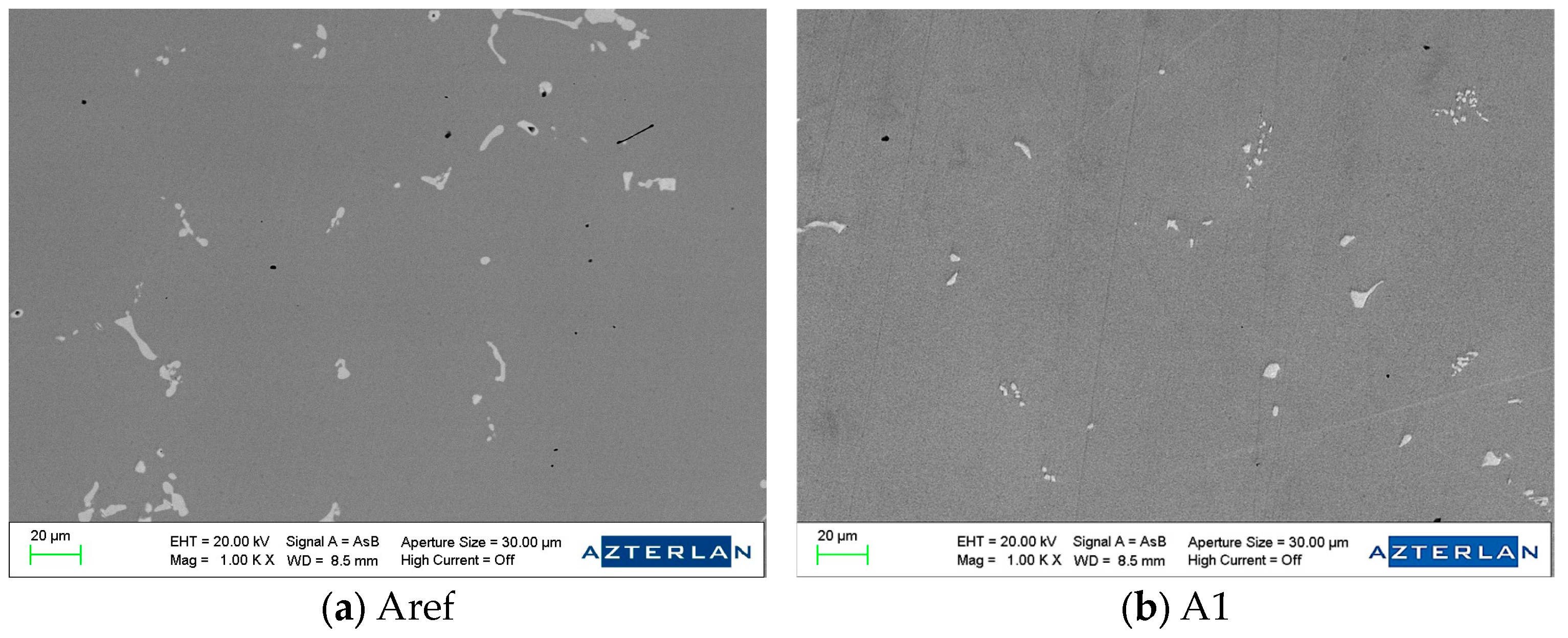

3.1. As-Cast Microstructure and Chemical Composition

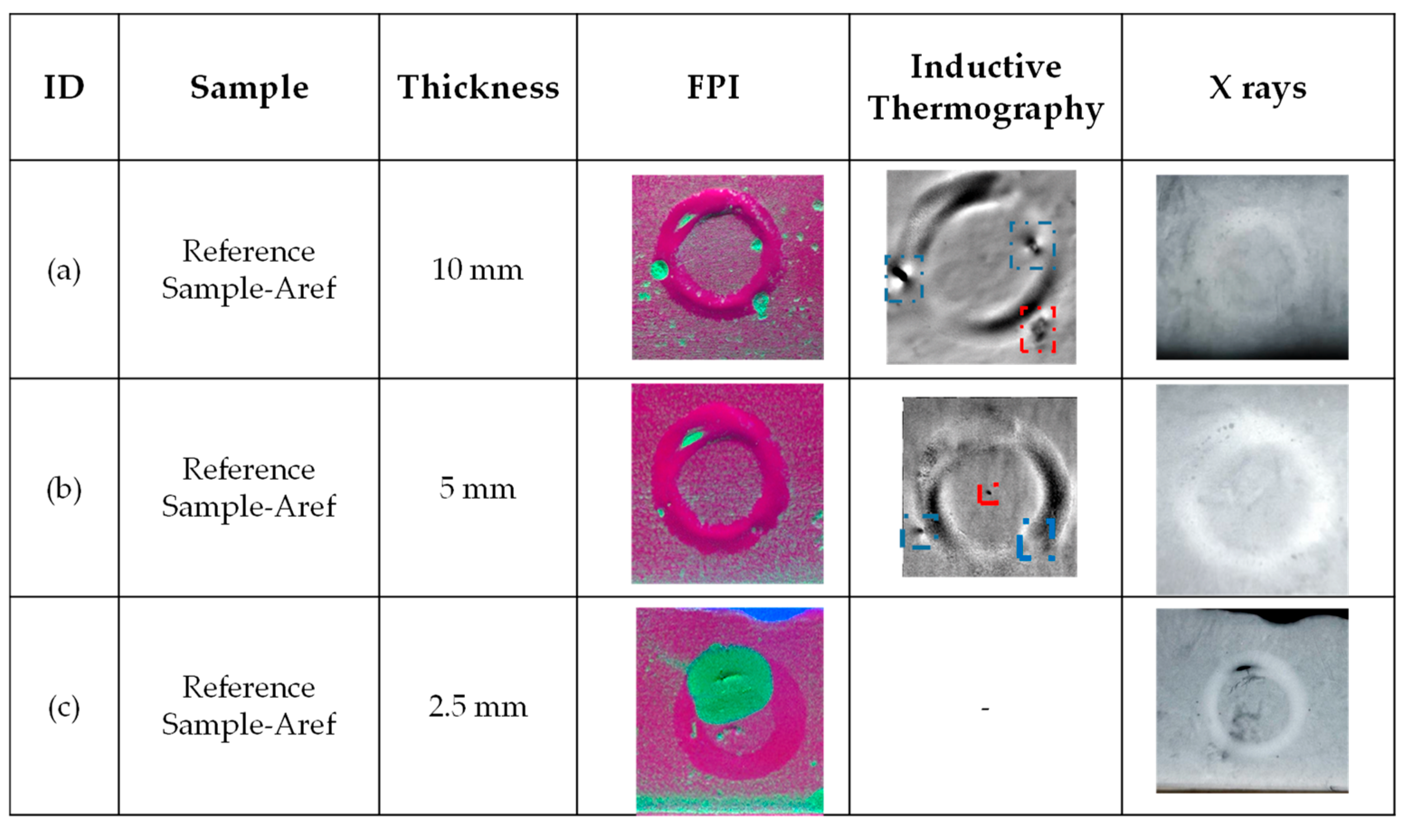

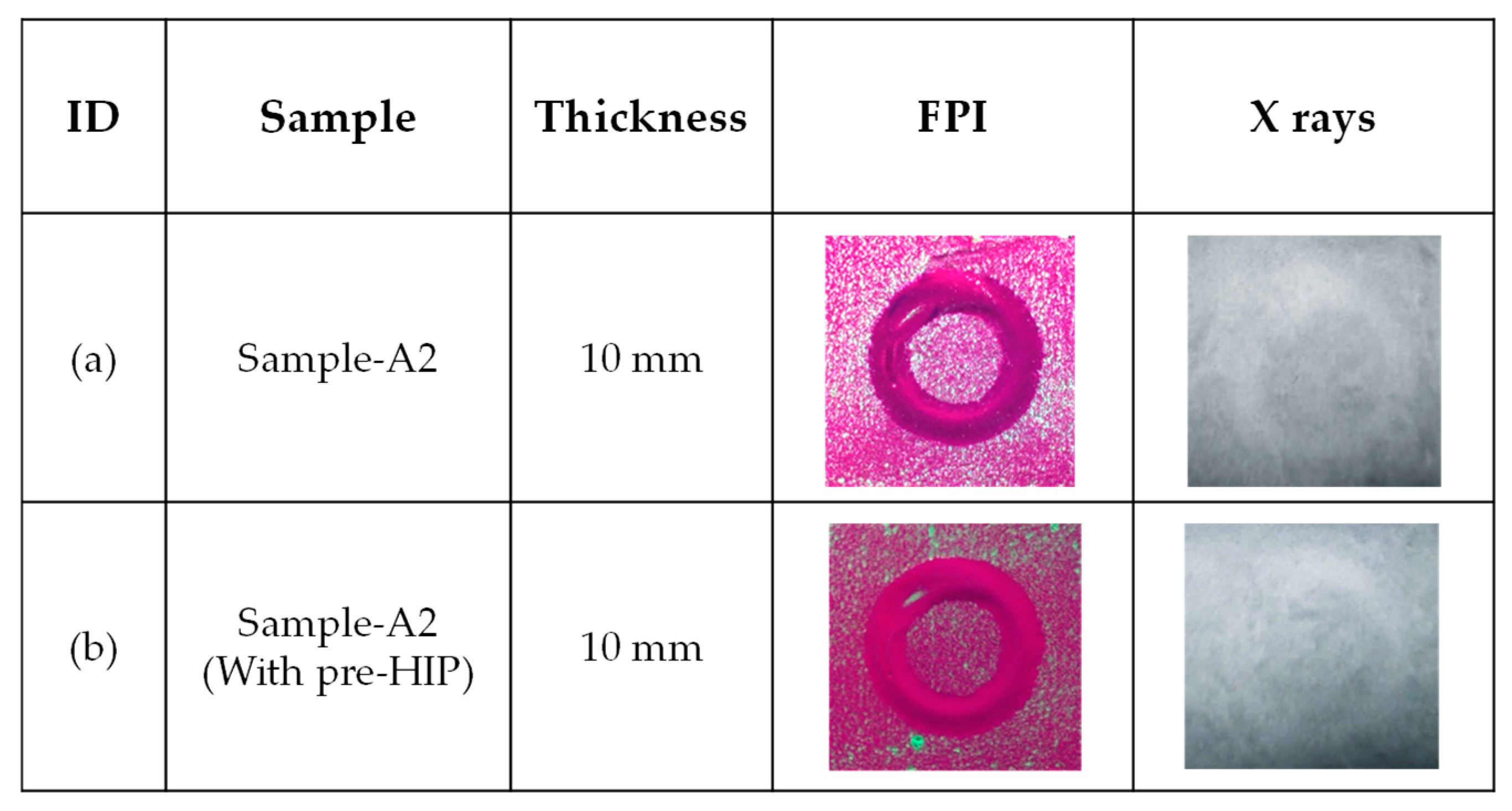

3.2. Non-Destructive Tests (NDT)

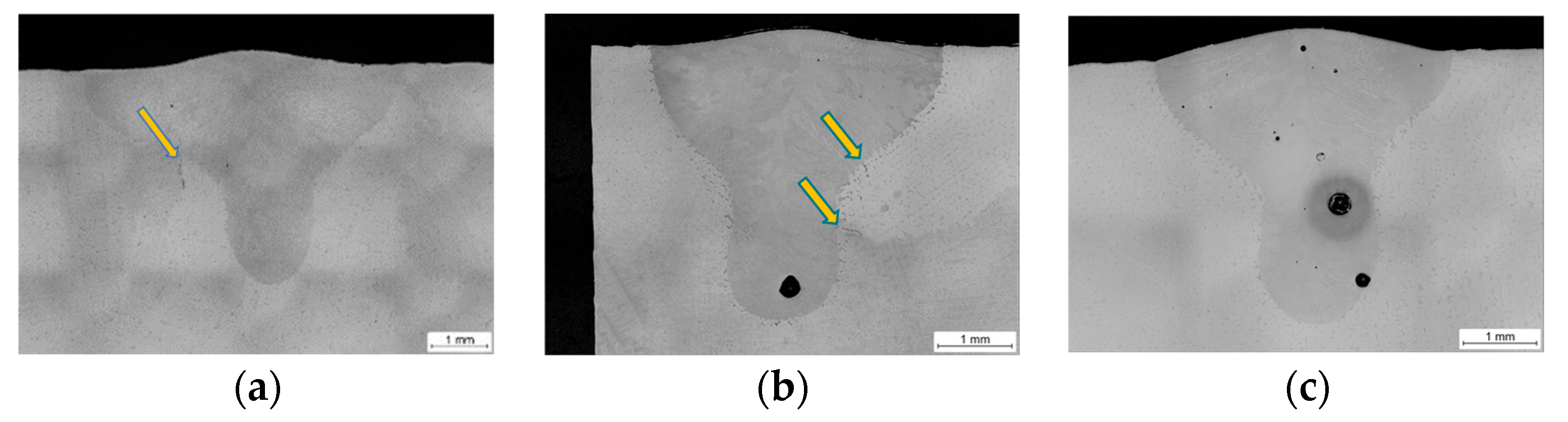

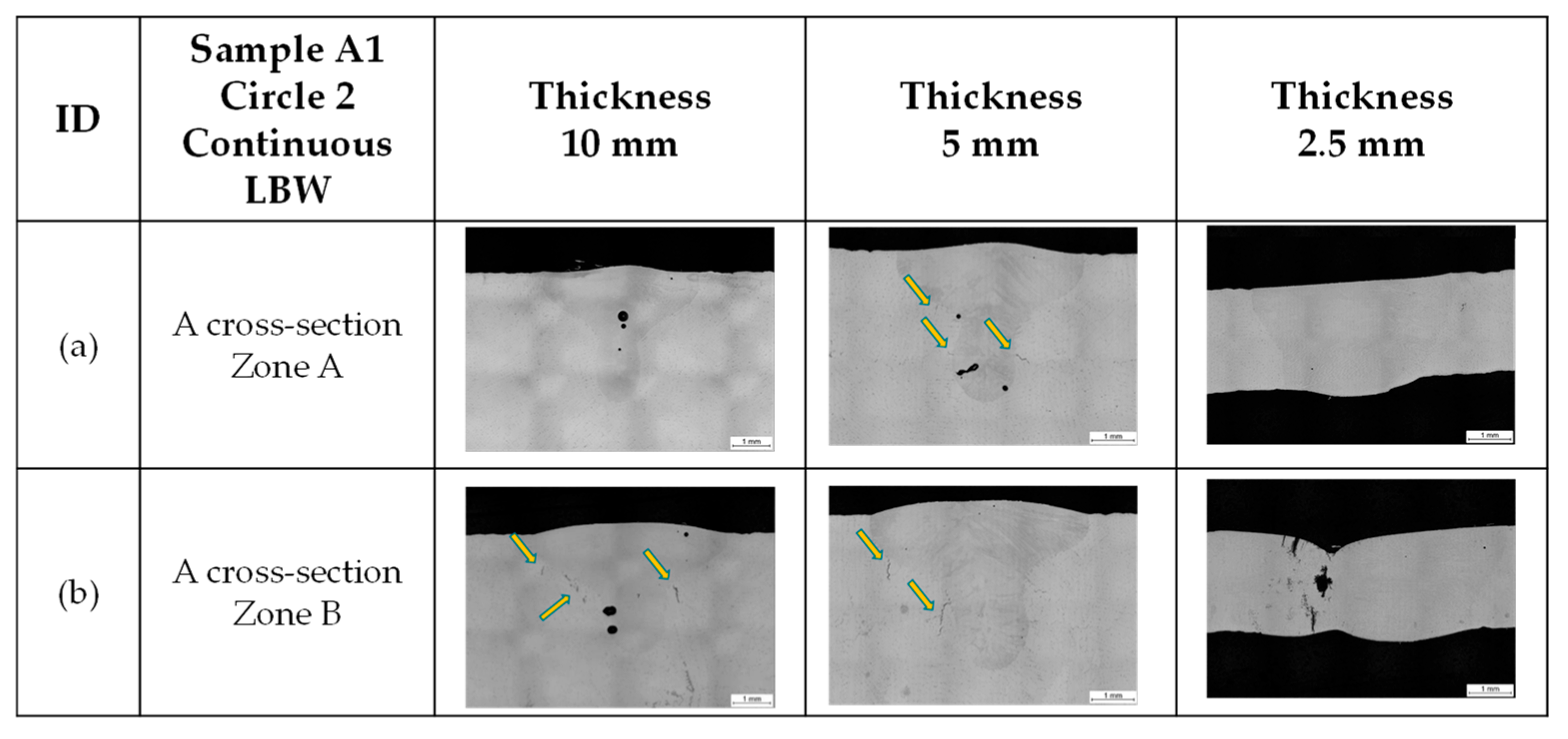

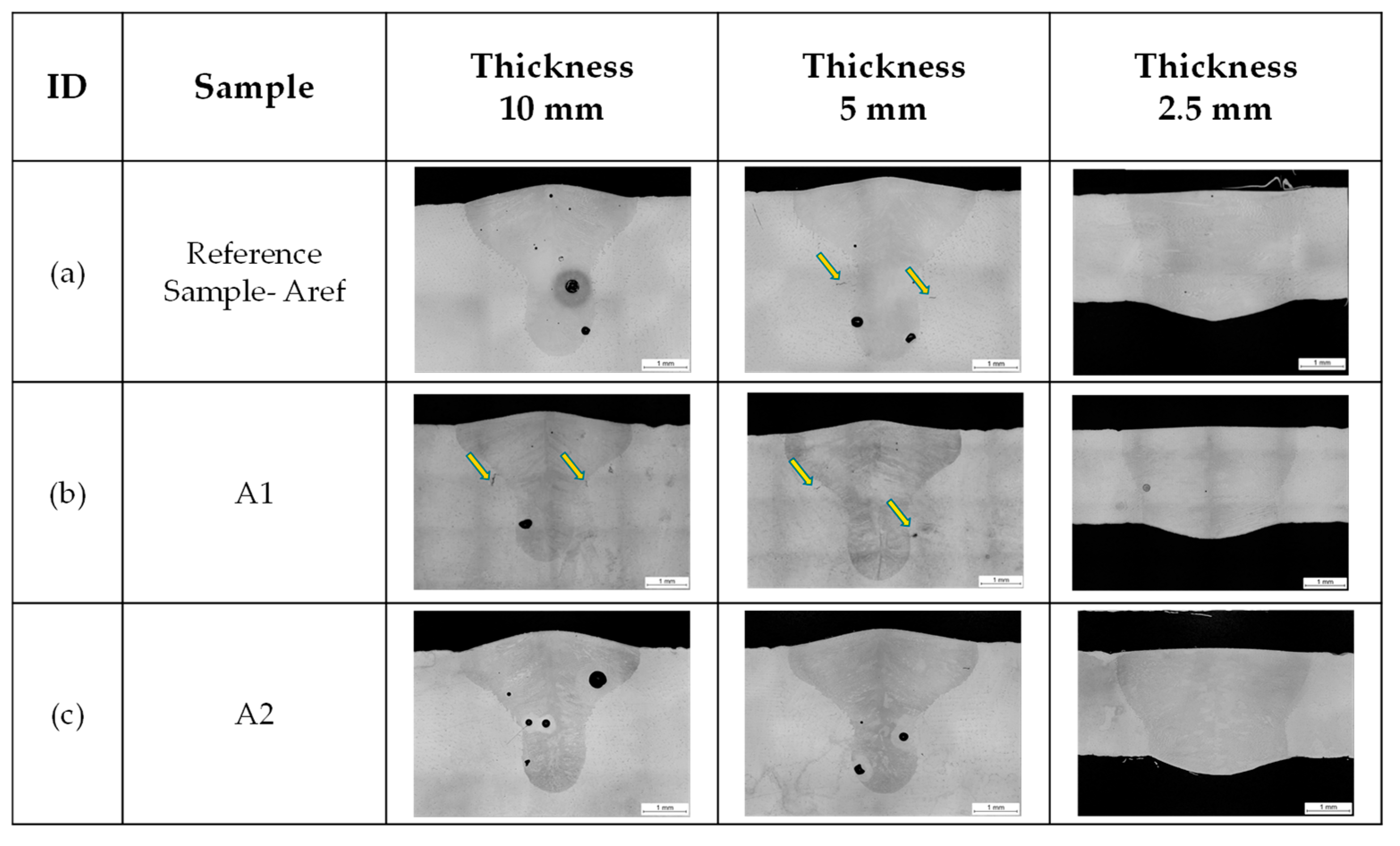

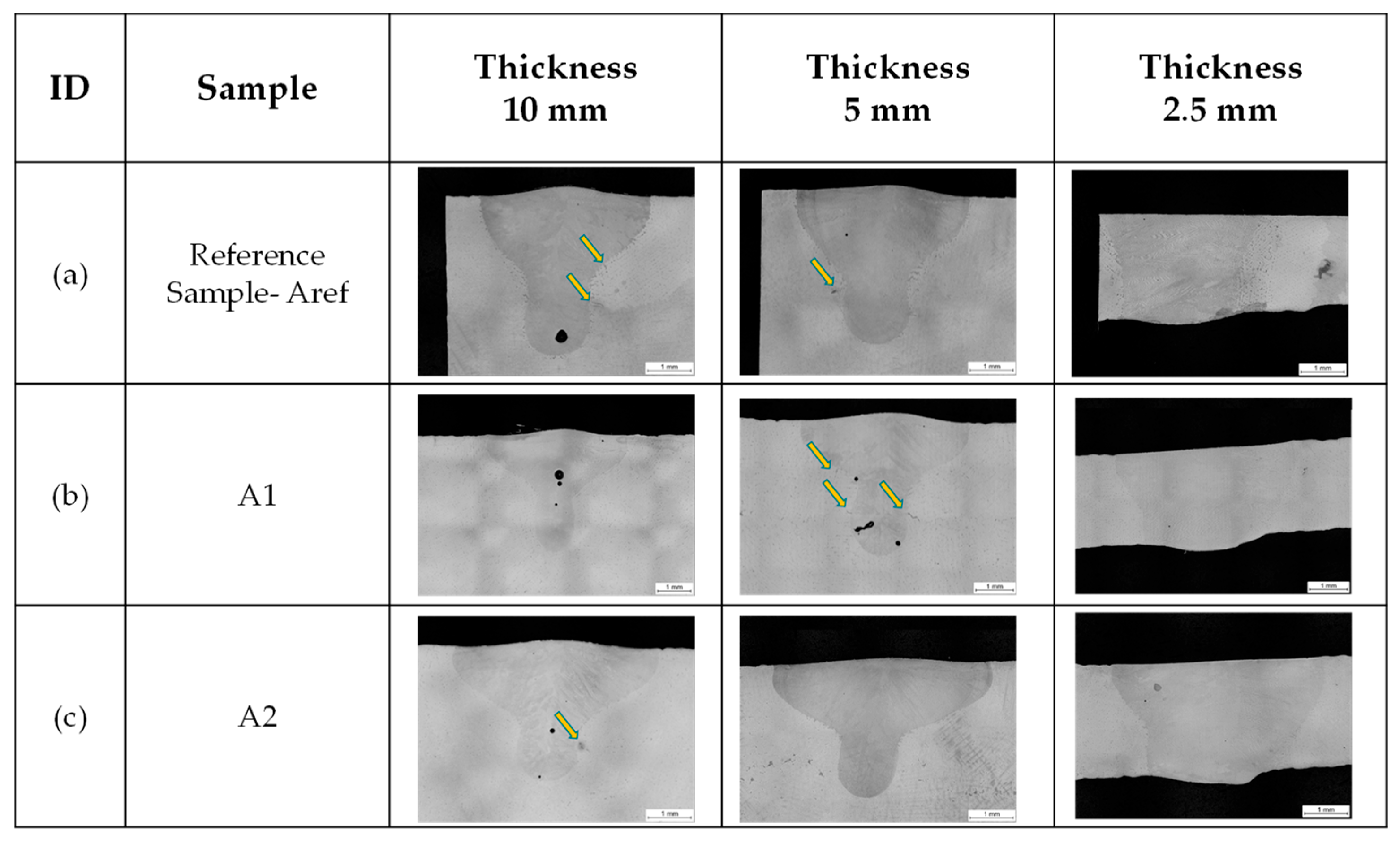

3.3. Metallographic Characterization Results

4. Discussion

Alternatives to Reduce Hot Cracking

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Andersson, J. Weldability of Precipitation Hardening Superalloys: Influence of Microstructure. Ph.D. Thesis, Chalmers Tekniska Hogskola, Göteborg, Sweden, 2011. [Google Scholar]

- Donachie, M.J.; Donachie, S.J. Superalloys: A Technical Guide, 2nd ed.; ASM International: Novelty, OH, USA, 2002. [Google Scholar]

- DuPont, J.N.; John, N.; Lippold, J.C.; John, C.; Kiser, S.D.; Samuel, D. Welding Metallurgy and Weldability of Nickel-Base Alloys; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Andersson, J.; Raza, S.; Eliasson, A.; Surreddi, K.B. Solidification of Alloy 718, ATI 718Plus and Waspaloy. In Proceedings of the 8th International Symposium on Superalloy, Pittsburgh, PA, USA, 28 September–1 October 2014; Volume 718, pp. 181–192. [Google Scholar] [CrossRef]

- Frank, R.B.; Roberts, C.G.; Zhang, J. Effect of Nickel Content on Delta Solvus Temperature and Mechanical Properties of Alloy 718. In Superalloy 718 and Derivatives; John Wiley & Sons: Hoboken, NJ, USA, 2010; pp. 724–736. [Google Scholar] [CrossRef]

- Chang, K.-M.; Nahm, A.H. Rene 220: 100 F Improvement Over Alloy 718. In Superalloy 718-Metallurgy and Applications; Loria, E.A., Ed.; The Minerals, Metals & Materials Society: Evendale, OH, USA, 1989; pp. 631–646. [Google Scholar] [CrossRef]

- DuPont, J.N.; Notis, M.R.; Marder, A.R.; Robino, C.V.; Michael, J.R. Solidification of Nb-Bearing Superalloys: Part I. Reaction Sequences. Metall. Mater. Trans. A 1998, 29, 2785–2796. [Google Scholar] [CrossRef]

- Guo, H.; Chaturvedi, M.C.; Richards, N.L. Effect of Boron Concentration and Grain Size on Weld Heat Affected Zone Microfissuring in Inconel 718 Base Superalloys. Sci. Technol. Weld. Join. 1999, 4, 257–264. [Google Scholar] [CrossRef]

- Richards, N.L.; Chaturvedi, M.C. Effect of Minor Elements on Weldability of Nickel Base Superalloys. Int. Mater. Rev. 2000, 45, 109–129. [Google Scholar] [CrossRef]

- Kelly, T.J. Elemental Effects on Cast 718 Weldability Boron, an Essential Element in Alloy 718, Appears to Cause the Most Detriment to Weldability, Creating a Dilemma for Improvement. Weld. Res. Suppl. 1989, 68, 44–51. [Google Scholar]

- Swalin, R.A.; Martin, A.; Olson, R. Diffusion of Magnesium, Silicon, and Molybdenum in Nickel. Jom 1957, 9, 936–939. [Google Scholar] [CrossRef]

- Dong, J.X.; Xie, X.S.; Thompson, R.G. The Influence of Sulfur on Stress-Rupture Fracture in Inconel 718 Superalloys. Metall. Mater. Trans. A 2000, 31, 2135–2144. [Google Scholar] [CrossRef]

- Singh, S.; Andersson, J. Hot Cracking in Cast Alloy 718. Sci. Technol. Weld. Join. 2018, 23, 568–574. [Google Scholar] [CrossRef]

- Ojo, O.A.; Richards, N.L. Heat-Affected Zone Cracking in Welded Nickel Superalloys. In Welding and Joining of Aerospace Materials; Elsevier: Amsterdam, The Netherlands, 2012; pp. 142–177. [Google Scholar]

- Oshobe, O.E. Fiber Laser Welding of Nickel-Based Superalloy Inconel 718; University of Manitoba: Winnipeg, MB, Canada, 2012. [Google Scholar]

- Khan, A.; Hilton, P.; Blackburn, J.; Allen, C. Meeting Weld Quality Criteria When Laser Welding Ni-Based Alloy 718. In Proceedings of the International Congress on Applications of Lasers & Electro-Optics, Anaheim, CA, USA, 23–27 September 2012; pp. 549–557. [Google Scholar]

- Huang, X. A Microstructural Study of Heat Affected Zone Microfissuring of Electron Beam Welds in Cast Alloy 718; Department of Mechanical and Industrial Engineering: Winnipeg, MA, Canada, 1994. [Google Scholar]

- Zhang, Y.; Li, J. Characterization of the Microstructure Evolution and Microsegregation in a Ni-Based Superalloy under Super-High Thermal Gradient Directional Solidification. Mater. Trans. 2012, 53, 1910–1914. [Google Scholar] [CrossRef]

- Nishimoto, K. The Factors Affecting HAZ Crack Susceptibility in the Laser Weld-Study on Weldability of Cast Alloy 718 (Report 4). Quar. J. JWS 2001, 19, 308–316. [Google Scholar]

- Woo, I.; Nishimoto, K.; Tanaka, K.; Shirai, M. Effect of Grain Size on Heat Affected Zone Cracking Susceptibility. Study of Weldability of Inconel 718 Cast Alloy (2nd Report). Weld. Int. 2000, 14, 514–522. [Google Scholar] [CrossRef]

- Schirra, J.J.; Caless, R.H.; Hatala, R.W. The Effect of Laves Phase on The Mechanical Properties of Wrought and Cast + HIP Inconel 718. Miner. Met. Mater. Soc. 1991, 375–388. [Google Scholar]

- Muralidharan, B.G.; Shankar, V.; Gill, T.P.S. Weldability of Inconel 718—A Review; Indira Gandhi Centre for Atomic Research: Kalpakkam, India, 1996. [Google Scholar]

- Tharappel, J.T.; Babu, J. Welding Processes for Inconel 718—A Brief Review. IOP Conf. Ser. Mater. Sci. Eng. 2018, 330, 012082. [Google Scholar] [CrossRef]

- Sonar, T.; Balasubramanian, V.; Malarvizhi, S.; Venkateswaran, T.; Sivakumar, D. An Overview on Welding of Inconel 718 Alloy—Effect of Welding Processes on Microstructural Evolution and Mechanical Properties of Joints. Mater. Charact. 2021, 174, 110997. [Google Scholar] [CrossRef]

- Bai, Y.; Lu, Q.; Ren, X.; Yan, H.; Zhang, P. Study of Inconel 718 Welded by Bead-on-Plate Laser Welding under High-Frequency Micro-Vibration Condition. Metals 2019, 9, 1335. [Google Scholar] [CrossRef]

- Odabaci, A.; Ünlü, N.I.; Göller, G.I.; Eruslu, M.N.I.I. A Study on Laser Beam Welding (LBW) Technique: Effect of Heat Input on the Microstructural Evolution of Superalloy Inconel 718. Metall. Mater. Trans. A 2010, 41, 2357–2365. [Google Scholar] [CrossRef]

- Alvarez, P.; Vázquez, L.; Ruiz, N.; Rodríguez, P.; Magaña, A.; Niklas, A.; Santos, F. Comparison of Hot Cracking Susceptibility of Tig and Laser Beam Welded Alloy 718 by Varestraint Testing. Metals 2019, 9, 958. [Google Scholar] [CrossRef]

- Kuo, T.-Y.; Jeng, S.-L. Porosity Reduction in Nd–YAG Laser Welding of Stainless Steel and Inconel Alloy by Using a Pulsed Wave. J. Phys. D Appl. Phys. 2005, 38, 722. [Google Scholar] [CrossRef]

- Álvarez, P.; Cobos, A.; Vázquez, L.; Ruiz, N.; Rodríguez, P.P.; Magaña, A.; Niklas, A.; Santos, F. Weldability Evaluation of Alloy 718 Investment Castings with Different Si Contents and Thermal Stories and Hot Cracking Mechanism in Their Laser Beam Welds. Metals 2021, 11, 402. [Google Scholar] [CrossRef]

- Raza, T.; Andersson, J.; Svensson, L.E. Varestraint Testing of Selective Laser Additive Manufactured Alloy 718—Influence of Grain Orientation. Metals 2019, 9, 1113. [Google Scholar] [CrossRef]

- Janaki Ram, G.D.; Venugopal Reddy, A.; Prasad Rao, K.; Madhusudhan Reddy, G. Control of Laves Phase in Inconel 718 GTA Welds with Current Pulsing. Sci. Technol. Weld. Join. 2013, 9, 390–398. [Google Scholar] [CrossRef]

- Alvarez, P.; Vázquez, L.; García-Riesco, P.M.; Rodríguez, P.P.; Magaña, A.; Santos, F. A Simplified Varestraint Test for Analyzing Weldability of Fe-Ni Based Superalloys. In Proceedings of the 9th International Symposium on Superalloy 718 & Derivatives: Energy, Aerospace, and Industrial Applications, Pittsburgh, PA, USA, 3–6 June 2018; pp. 849–865. [Google Scholar]

- Andersson, J.; Jacobsson, J.; Lundin, C. A Historical Perspective on Varestraint Testing and the Importance of Testing Parameters. In Cracking Phenomena in Welds IV; Springer: Berlin/Heidelberg, Germany, 2016; pp. 3–23. [Google Scholar]

- Rösler, J.; Hentrich, T.; Gehrmann, B. On the Development Concept for a New 718-Type Superalloy with Improved Temperature Capability. Metals 2019, 9, 1130. [Google Scholar] [CrossRef]

- Gorostegui Colinas, E.; Muniategui, A.; López de Uralde, P.; Gorosmendi, I.; Hériz, B.; Sabalza, X. A Novel Automatic Defect Detection Method for Electron Beam Welded Inconel 718 Components Using Inductive Thermography. In Proceedings of the 14th International Conference on Quantitative Infrared Thermography, Berlin, Germany, 18 July 2018. [Google Scholar]

- Urtasun, B.; Andonegui, I.; Gorostegui-Colinas, E. Phase-Shifted Imaging on Multi-Directional Induction Thermography. Sci. Rep. 2023, 13, 17540. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Hanning, F.; Andersson, J. Influence of Hot Isostatic Pressing on the Hot Ductility of Cast Alloy 718: The Effect of Niobium and Minor Elements on the Liquation Mechanism. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2020, 51, 6248–6257. [Google Scholar] [CrossRef]

- Niklas, A.; Santos, F.; Gonzalez-Martinez, R.; Rodríguez, P.P.; Bernal, D.; Cobos, A.; Vázquez, L.; Álvarez, P. Effects of Different Si Content and Thermal Stories on the Secondary Phase Formation, Hot Ductility, and Stress Rupture Properties of Alloy 718 Investment Castings. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2023, 54, 2670–2688. [Google Scholar] [CrossRef]

- Allen, C.; Shaw-Edwards, R.; Nijdam, T. Nickel-Containing Superalloy Laser Weld Qualities and Properties. J. Laser Appl. 2015, 27, S29001. [Google Scholar] [CrossRef]

- Thompson, R.; Genculu, S. Microstructural Evolution in the HAZ of Inconel 718 and Correlation with the Hot Ductility Test. Weld. J. 1983, 62, 337s–345s. [Google Scholar] [CrossRef]

| Ref. | C | Si | S | Co | Cr | Mo | Cu | Mn | P | Ti | Al | B | Ni 1 | Nb + Ta | Fe | Mg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Aref | 0.046 | 0.45 | <0.005 | 0.099 | 17.6 | 3.03 | 0.016 | <0.050 | <0.010 | 0.66 | 0.23 | 0.0025 | 52.8 | 4.93 | 20.0 | 0.0012 |

| A1 | 0.058 | 0.11 | <0.005 | <0.10 | 17.6 | 2.82 | 0.015 | <0.050 | <0.010 | 0.92 | 0.62 | 0.0019 | 55.8 | 5.00 | 17.0 | 0.0012 |

| A2 | 0.066 | 0.11 | <0.005 | 1.11 | 17.6 | 2.83 | 0.015 | <0.050 | 0.003 | 0.93 | 0.62 | 0.0021 | 55.6 | 5.08 | 16.1 | 0.0012 |

| UNE EN 10302:2010 Standard | ||||||||||||||||

| INCO 718 | 0.02–0.08 | 0.35 | 0.015 | 1.0 | 17.0–21.0 | 2.8–3.3 | 0.30 | 0.35 | 0.015 | 0.6–1.2 | 0.3–0.7 | 0.002–0.006 | 50.0–55.0 | 4.7–5.5 | Bal. | - |

| Alloy | Phases [%-Mass] | |||

|---|---|---|---|---|

| Laves | MC | Sigma | Delta | |

| Aref | 1.79 | 0.43 | 0.61 | 2.09 |

| A1 | 0.98 | 0.62 | 0.4 | 1.11 |

| A2 | 1.13 | 0.61 | 0.44 | 1.32 |

| General Parameters |

|---|

| TRUDISK 6002 |

| 400-micron fibre diameter |

| BEO D70 (200:200) |

| Vweld: 0.5 m/min (8.33 mm/s) |

| Spot size: 0.8 mm |

| Ar Camera (30 l/min) |

| Shot blasting followed by alcohol cleaning |

| LBW Curve | Ws (mm/s) | Ppeak 2 (W) | Pbase 2 (W) | Frequency (Hz) | Energy (J/mm) | Energy Density (J/mm3) |

|---|---|---|---|---|---|---|

| Circular 1 Pulsed | 8.33 | 3166 | 1582 | 78.7 | 285 | 567 |

| Circular 2 Continuous | 8.33 | 2300 | 2300 | - | 276 | 549 |

| Straight Continuous | 8.33 | 2300 | 2300 | - | 276 | 549 |

| Aref | A1 | A2 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Step | 10 mm | 5 mm | 2.5 mm | 10 mm | 5 mm | 3 mm | 10 mm | 5 mm | 2.5 mm |

| As-Cast | 3.8 | 3.7 | 3 | 1.5 | 1.3 | 1.1 | 1.6 | 1.4 | 1.1 |

| Pre-HIP | 2.6 | 2.4 | 1.7 | 0.98 | 0.88 | 0.77 | 1.1 | 1.0 | 0.8 |

| Pre-HIP + HIP + S | 1.8 | 1.9 | 1.2 | 0.3 | 0.3 | 0.4 | 0.4 | 0.4 | 0.4 |

| HIP + S | 1.7 | 1.8 | 1.0 | 0.3 | 0.4 | 0.2 | 0.5 | 0.4 | 0.4 |

| Circular 2 Continuous LBW | Step/Thickness | |||||

|---|---|---|---|---|---|---|

| 10 mm | 5 mm | 2.5 mm | ||||

| FPI | X-ray | FPI | X-ray | FPI | X-ray | |

| Aref | 3 | 3 | 4 | 6 | 1 | 5 |

| A2 | 0 | 0 | 0 | 2 | 0 | 2 |

| Step/ Thickness | Aref | A1 | A2 | PreHIP Aref |

|---|---|---|---|---|

| 10 mm | G: 0 | G: 0.74 | G: 0 | G: 1.14 |

| P: 0.20 | P: 0.32 | P: 0.19 | P: 0.39 | |

| 5 mm | G: 0.37 | G: 0.25 | G: 0 | G: 0.37 |

| P: 0.16 | P: 0 | P: 0.18 | P: 0.08 | |

| 2.5 mm | G: 0 | G: 0 | G: 0 | G: 0 |

| Step/ Thickness | Aref | A1 | A2 | PreHIP Aref |

|---|---|---|---|---|

| 10 mm | G: 0.31 | G: 0 | G: 0.26 | G: 1.14 |

| P: 0.31 | P: 0.17 | P: 0.08 | P: 0.39 | |

| 5 mm | G: 0.29 | G: 0.68 | G: 0 | G: 0 |

| P: 0 | P: 0.27 | P: 0 | P: 0 | |

| 2.5 mm | G: 0 | G: 0 | G: 0 | G: 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García-Sesma, L.; Álvarez, P.; Gorostegui-Colinas, E.; Huarte, I.; Santos, F. Alternatives to Reduce Hot Cracking Susceptibility of IN718 Casting Alloy Laser Beam Welds with a Mushroom Shape. Metals 2024, 14, 1067. https://doi.org/10.3390/met14091067

García-Sesma L, Álvarez P, Gorostegui-Colinas E, Huarte I, Santos F. Alternatives to Reduce Hot Cracking Susceptibility of IN718 Casting Alloy Laser Beam Welds with a Mushroom Shape. Metals. 2024; 14(9):1067. https://doi.org/10.3390/met14091067

Chicago/Turabian StyleGarcía-Sesma, Leire, Pedro Álvarez, Eider Gorostegui-Colinas, I. Huarte, and Fernando Santos. 2024. "Alternatives to Reduce Hot Cracking Susceptibility of IN718 Casting Alloy Laser Beam Welds with a Mushroom Shape" Metals 14, no. 9: 1067. https://doi.org/10.3390/met14091067

APA StyleGarcía-Sesma, L., Álvarez, P., Gorostegui-Colinas, E., Huarte, I., & Santos, F. (2024). Alternatives to Reduce Hot Cracking Susceptibility of IN718 Casting Alloy Laser Beam Welds with a Mushroom Shape. Metals, 14(9), 1067. https://doi.org/10.3390/met14091067